- 1Department of Food Science, University of Guelph, Guelph, ON, Canada

- 2Arrell Food Institute, University of Guelph, Guelph, ON, Canada

Food production cannot be decoupled from human and planetary wellbeing. Meeting safety, nutritional, sensorial, and even price requirements entails applying an integral view of food products and their manufacturing and distribution processes. Virtualization of food commodities and products, i.e., their digital representation, offers opportunities to study, simulate, and predict the contributions of internal (e.g., composition and structure) and external factors (e.g., processing conditions) to food quality, safety, stability, and sustainability. Building virtual versions of foods requires a holistic supporting framework composed of instrumental and computational techniques. The development of virtual foods has been bolstered by advanced tools for collecting data, informing and validating modelling, e.g., micro-computed tomography, to accurately assess native food structures, multi-omics approaches, to acquire vast information on composition and biochemical processes, and nondestructive and real-time sensing, to facilitate mapping and tracking changes in food quality and safety in real-world situations. Comprehensive modeling techniques (including heat and mass transfer, thermodynamics, kinetics) built upon physic laws provide the base for realistic simulations and predictions of food processes that a virtual food might undergo. Despite the potential gaps in knowledge, increasing the adoption of food virtualization (data-based, physics-based or hybrid) in manufacturing and food systems evaluation can facilitate the optimal use of resources, the rational design of functional characteristics, and even inform the customization of composition and structural components for better product development. This mini-review focuses on critical steps for developing and applying virtual foods, their future trends, and needs.

Introduction

Efficient use and transformation of resources along the food supply chain are critical to achieving sustainability goals such as food security and waste reduction. To this end, food systems must be integrally conceptualized to acknowledge their dynamic nature, complex interactions, and transformations, and the effects of external factors on their safety, quality, stability, and even consumer acceptance (Erdogdu et al., 2017; Vitrac et al., 2021; Marra, 2022). Adopting advanced modeling, high-resolution, and real-time data acquisition techniques plays an important role in virtualizing, simulating, and predicting phenomena in foods so that such milestones can be achieved (Saguy, 2016; Datta et al., 2022).

Although the role of virtualization of the food supply chain as an improvement tool has been introduced for over 10 years, its applications are still limited (Marra, 2016). ‘Virtual foods’ or ‘in silico foods’ can be defined as digital representations with the same characteristics (e.g., physical properties, chemical composition) as their real-life counterparts (Verdouw et al., 2016). They are digital twins constrained to the food product itself (Verboven et al., 2020). To be effective and useful, these digital twins of specific commodities or products should be built so that all physical principles, transport phenomena, and food reactions are applicable to them. As such, virtual foods should respond to simulated stimuli in ‘virtual environments’ in ways that accurately mimic the behavior of their real-world versions. The ‘virtual environments’ can be tuned to reflect relevant scenarios throughout the food supply chain to i) evaluate external effects on food structure, quality, and safety, ii) develop and optimize processes to attain high efficiency and sustainability (Marra, 2023), iii) predict the occurrence and impact of failure events during distribution and storage (Peleg et al., 2011); and iv) reduce the time-to-market of new products (Saguy, 2016; Mengucci et al., 2022). Building virtual foods is intricate since it relies on the availability of extensive databases of physical, structural, chemical, and biological attributes and a holistic supporting framework of advanced characterization, modeling, data processing, and management approaches (Datta et al., 2022). This mini-review aims to identify the critical components, summarize the available approaches, and discuss the challenges, needs, and future trends in developing and applying food product virtualization.

Building a virtual food

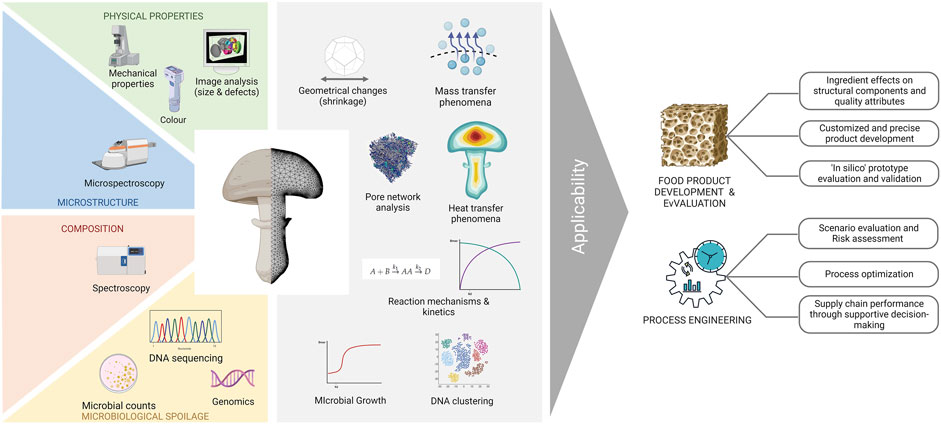

Food undergoes transformations from harvest to consumption (Singh and Corradini, 2023); some are intentional and rapid such as those imposed by processing, and others progressive and cumulative, such as the ones that ensue from a food’s inherent deterioration processes. Regardless of their triggers, these transformations highly depend on a food’s intrinsic properties, such as physical attributes, chemical composition, hierarchical organization of its structural components, and natural microbiota. External factors, such as temperature, humidity, atmosphere composition, and airflow (Duan et al., 2020), also influence the rate and extent of the transformations a food undergoes along the supply chain. Linking these factors coherently provides the foundation to build a virtual version of an actual product. Even if a physics-based digital twin is being built, it requires knowledge of actual food properties to assist in its development and validation (Datta, 2016; Erdogdu et al., 2017; Erdogdu, 2023). Thus, accurate and careful spatial and temporal mapping of food properties, components, structures, and surrounding factors is required to create a reliable avatar of a product. This thorough assessment will allow accounting for the effects of intrinsic and extrinsic factors and their dynamic nature on transport phenomena and reactions kinetics modeling. The following sections will briefly present techniques valuable to build upon information on intrinsic factors and modeling approaches, as seen in Figure 1, and to incorporate this information into data-based, physics-based, or hybrid food models.

Physical properties and structural features

Knowing the physical properties of food materials (e.g., density, size, shape, thermal properties) is one of the cornerstones of effectively simulating natural and manufacturing processes. Measuring techniques for these properties have been extensively documented (e.g., Figura and Teixeira, 2007). Although important progress has been achieved on every front, advances in size, shape, and structural determinations have probably benefited the most due to the advent of high-resolution image acquisition, analysis, and reconstruction. Hence, they will be primarily discussed in the following section.

Data acquisition

Food (micro)structure is complex and heterogeneous. The irregular arrangement of different structural units, e.g., lignocellulosic backbones and protein networks, and component compartmentalization result in materials with irregular shapes and composition (Piovesan et al., 2021). Regarding size and shape, 3D laser scanning has been identified as an improved tool for collecting information to develop geometric models of foods with irregular shapes at high morphological resolution (Zhang et al., 2020). Similarly, over the past 20 years, high-resolution techniques have improved the scouting of food microstructure (Gruyters et al., 2020). Microstructural features percolate into macroscopic properties, transport phenomena, and biochemical processes at different stages of a product’s life (Mahiuddin et al., 2018). Therefore, accurate visualization and realistic representation of microstructural constituents are useful in developing or validating an in silico food. Several techniques traditionally used for medical applications, such as magnetic resonance imaging (MRI) and X-ray micro-computed tomography (X-ray μCT), have been consistently gaining popularity for the nondestructive and noninvasive assessment of food structure (Kirtil et al., 2017; Van Dael et al., 2019).

Based on the differences in components’ molecular mobility within a food matrix, MRI has been employed to characterize food structure and track moisture distribution and loss during processing (Schork et al., 2020). X-ray μCT has been applied to capture the 3D microstructure of various foods and track the deformation of, for example, porous networks’ specific surface area, size, and fragmentation during processing, including drying, cold storage, and ripening (Cantre et al., 2014; Gruber et al., 2021). Despite the efficacy of these techniques in characterizing microstructural features in solid foods, their application to liquid/semi-solid, soft materials (e.g., multiphase products such as weak gels, emulsions, froth, or frozen foams) still encounters several hurdles due to these materials’ optical opacity, low shear strength, and susceptibility to beam effects due to high energy synchrotronic radiation that can induce melting, deformation, and damages (Metilli et al., 2021). These limitations can be overcome by clever sample preparation (e.g., inclusion within sheltering structures), pre-tempering samples at freezing conditions (e.g., −15°C), or rapid data acquisition (Guo et al., 2017). However, alternative techniques should be applied to soft materials for proper characterization. It should also be noted that in-situ and real-time characterization of food structures during processing is still rare.

Data use

Food properties and quality attributes have been linked to features revealed from X-ray μCT images by complementing them with other measuring techniques and multivariate analysis. For example, internal defects, disorders, and injuries were detected in vegetables and fruits using this approach. Even the position- and porosity-dependent effective O2 diffusivity have been accurately determined in this kind of product based on high-resolution images (Chigwaya et al., 2021; Nugraha et al., 2021).

Extensive research has been conducted on reconstructing food structures and modeling deformation using empirical and mechanistic-based approaches from high-resolution data. X-ray CT images have been used to rebuild food geometry at different levels of granularity, from a single corn kernel microstructure to bulk packing of pears in a box (Suresh and Neethirajan, 2015; Verdouw et al., 2016; Gruyters et al., 2020). The reconstructed geometric models can be implemented into computational fluid dynamics (CFD) and transport models to simulate, for example, the performance of cooling systems on a food’s temperature during storage (Yin et al., 2022). Machine learning approaches (e.g., artificial–ANN- and convolutional neural networks - CNN) have also been applied to rebuild structures from images (Wu et al., 2019; Röding et al., 2020).

Regarding modeling structural deformation during processing, Mahiuddin et al. (2018) provided a comparative analysis of mechanistic-based approaches to account for these changes. Proper material characterization allows the informed selection of a model for different foods (e.g., elastoplastic, linear-elastic, viscoelastic, or hyper-elastic), resulting in more realistic simulations. Novel hybrid models, as proposed by Pacheco-Aguirre et al. (2015), who introduced a shrinkage-deformation algorithm to simulate size reduction, shape change, and microstructure deformation more realistically during drying and evaluate the effect of these changes on moisture diffusivity, will increasingly play a more important role in reproducing food structure more realistically and accurately simulating deformations in virtual foods.

Food composition and microbiota

Foods have complex compositions, with specific compounds contributing to their nutritional, organoleptic, and quality attributes. Not only does chemical composition varies among food items, but it also changes throughout a food’s production and shelf-life. A series of chemical and biochemical reactions, whose rates are dependent on external factors, progressively modify food composition (van Boekel, 2008). Additionally, foods are natural hosts of various microorganisms and are susceptible to spoilage by bacteria, yeasts, and fungi. The comprehensive study of food composition, reaction mechanisms, microbial-host interactions, and kinetics, thus, is essential for accurately simulating food quality changes and predicting the remaining shelf life in digital renderings of a food.

Data acquisition

Similar to physical properties, there is no lack of methods to report on food composition accurately (Nielsen, 2017). However, the comprehensive assessment of major and minor food components requires innovative and multidisciplinary approaches to address the interconnected reactions occurring alongside food-related phenomena.

Nondestructive and real-time sensing based on spectroscopic techniques, e.g., machine vision and hyperspectral imaging (HSI) in several modes, allows the simultaneous and continuous acquisition of composition and spatial information. These spatially resolved spectra are fast and easy to acquire noninvasively and in-line, being capable of monitoring from compositional changes to the effectiveness of processing operations (Colaruotolo et al., 2021).

Foodomics refers to applying high-throughput omics techniques (e.g., genomics, proteomics, lipidomics, interactomics) to monitor biomolecules in foods (Cifuentes, 2012; Pollo et al., 2021). Currently, it is impossible to think about food safety without genomics. However, its applications have expanded beyond surveillance to allow characterizing the complex microbial communities in foods involved in potential spoilage and safety risks (Beck et al., 2021; Palevich et al., 2021). A foodomics-based approach has also been used to gain insights into underlying mechanisms involved in food quality losses (Hu et al., 2022) and bioactivity (Ding et al., 2023), as well as mapping changes in composition and microbial loads during processing (Sinanoglou et al., 2014; Lerma-García et al., 2016; Topcam et al., 2023). It has also been proposed as a potential replacement for costly and subjective methods, such as sensory analysis. By implementing a foodomics approach, arrays from electronic noses and tongues coupled with chemometrics can result in accurate sensory prediction models (Tan and Xu, 2020). These models could be integrated with transport and reaction kinetics models to predict the ‘virtual smell and taste’ of the virtual foods. Hence, foodomics will progressively play a more prominent role in holistically mapping the relationships between composition and food phenomena, contributing to developing representative and accurate virtual foods.

Data use

Chemical formation and degradation kinetics, as well as microbial growth, and inactivation models are critical to developing representative virtual foods. Although novel analytical techniques progressively allow better elucidation and monitoring of these processes, this progress has not permeated to data analysis or characterization. Microbial inactivation and chemical reactions (e.g., Maillard reaction, lipid oxidation, vitamin degradation) kinetics in foods have been historically described using fixed-order kinetic models, particularly first-order (van Boekel, 2008; Corradini, 2018). Microbial growth is routinely modeled using several empirical models, e.g., Verhulst’s model variants (Peleg et al., 2011). The parameters of these primary models have been primarily estimated on model systems or liquid foods, and their dependence on state variables has been primordially established using models with limited physical meaning, for example, the Arrhenius equation (Peleg et al., 2012; Saguy, 2016). Hence, to adequately mimic changes in composition and microbial load in a virtual food, some advances need to be implemented. Since most kinetic models are valid only under the assumption that the involved reactions are elementary, which is not always the case, a comprehensive study of complex reaction networks and mechanisms is needed. Also, coupling food reaction kinetics with multidimensional and multiscale transport models should become the norm rather than the exception (Ranjbaran et al., 2021). Such efforts would help provide a more realistic view of chemical and microbiological changes in the entirety of a food matrix (Peleg, 2023). Finally, recent advances in deep learning techniques have enabled the extraction of kinetic parameters from limited data, which could potentially accelerate the accurate modeling of these reactions in real and virtual foods.

Transport models for the utilization of virtual foods

Food exposure to different and fluctuating environmental factors, e.g., temperature and relative humidity, throughout the supply chain lead to thermal and water content gradients within food matrices, significantly influencing reaction rates and non-homogenous changes in quality and safety attributes (Sun et al., 2021). Therefore, transport models are important building blocks to ensure the development and utilization of a virtual food.

Food materials are multiscalar matrices with unique shapes, porosity, and cellular microstructures (Janssen et al., 2020). To realistically and accurately represent a food matrix, transport models should be multiscalar too. They should be composed of a hierarchy of interconnected sub-models, each of them defining the food’s behavior and properties at a specific scale (Rahman et al., 2018). At a macroscopic scale, transport phenomena are governed by heat and mass balance principles, grounded in classic theory such as Fourier’s law of thermal conduction, Fick’s law of diffusion, and Darcy’s law of pressure-driven flows (Turner and Mujumdar, 1996; Erdogdu et al., 2017). Applying these principles allows for characterizing and simulating the spatial-temporal distribution of state variables (e.g., temperature, pressure). The integrated application of these principles within a multiphase transport approach allows for modeling water evaporation/condensation within solid porous media as driven by local dynamically and under nonequilibrium gradients of water vapor pressure, for example,. Hence, heat and moisture exchange between a food and its environment can be estimated more accurately and realistically than ever before (Chen and Pan, 2021).

By using finite element (FE) or finite volume (FV) methods, modeling transport phenomena in bodies with irregular geometries, material discontinuity, and heterogeneous composition, such as foods, can be effectively achieved (Curcio et al., 2016; Chen et al., 2022). Mesh-free methods (MFM), including pore network, dissipative particle dynamics, and smooth particle hydrodynamics, can be applied to overcome some of the limitations imposed by FE or FV methods due to the rigidity of the mesh itself. MFM allows diving into an assumed ‘homogenized region’ and studying microscopic deformations and transport phenomena at the microscale (Karunasena et al., 2015). This results in accurate descriptions of pore geometry, dynamic tracking of the gas-liquid interfaces and gas distribution within porous media, and determining moisture diffusivities at a cellular level (Metzger, 2019; Welsh et al., 2021; Panda et al., 2022).

Building interconnected multiscale transport models could provide valuable insights into composition-property-structure-environment relationships in foods and food processes. However, applications of such models are still few, and several challenges remain to be surmounted to expand their use. They will require i) increased accessibility to rapid, high resolution, nondestructive data acquisition of structural attributes and components in real time, ii) obtaining accurate food properties and state variables data at multiple scales for model validation; ii) expanding the modeling of metabolic gases (e.g., O2, CO2) transport in porous food matrices, and iv) increased use of deep learning approaches to determine governing equations and critical parameters for processes such as diffusion in a heterogeneous media (Im et al., 2023). It is envisaged that these advances and hybrid approaches will contribute significantly to the development of virtual foods (Sun and Shi, 2022).

Applications of a virtual food

The value of developing virtual foods is profound for scientific research and practical applications. Conceived as comprehensive in silico models of real foods, they will allow us to better study and understand composition-structure-property-performance relationships. From a practical perspective, and as a crucial component of more extensive digital twins comprising a process, sets of thereof or even the whole supply chain, these avatars can be paraded through different virtualized environments to acquire realistic responses of a commodity or product to different scenarios as discussed below.

Novel product design and development

Accurate in silico foods could facilitate the development of novel food products, including packaging (Marra, 2022). Desirable geometries, microstructural features, and nutrient stability can be pinpointed, designed, and tested through modeling and simulation to meet sensorial attributes, nutritional requirements (e.g., personalized needs), and sustainability goals (Nikitina and Chernukha, 2020; Marra, 2023). Additive manufacturing could be applied to build actual prototypes for validation. Packaging allows preserving quality and freshness, in silico food models can be used to scout and predict the performance of packaging materials virtually.

Process development, improvement, and optimization

Food processing is critical for producing safe, nutritious, and sustainable products. However, thermal and nonthermal processing result in lower food quality, functionality, or nutrition. Additionally, several conventional treatments, such as hot air drying, pose sustainability challenges, e.g., excessive energy consumption. Thus, as a food avatar embedded within a process digital twin can help develop efficient food processes and optimize operating conditions (Verboven et al., 2020; Erdogdu, 2023; Topcam et al., 2023). A virtual food could serve as a new ‘pre-check’ approach to test whether a novel processing approach works. Using a multiphysics approach, optimal operating conditions could be matched to specific commodity varieties or products with different composition. This will allow the simultaneous optimization of food and process.

Supply chain mapping and smart logistics

Food virtualization provides a feasible, rapid, and efficient way to assess potential sources of concern throughout the supply chain that might shorten a product’s shelf-life or present a higher risk of exposure to potential contamination (Tagliavini et al., 2019; Defraeye et al., 2021). By simulating these situations and retrieving valuable information from the food avatar, a smarter distribution/storage system with integrated measures to minimize risks can be enacted and customized for different types of foods to prevent food waste and outbreaks, as recently reported by Shrivastava et al. (2022).

Conclusions and recommendations

Several elements that contribute to the virtualization of a food product, from databases to modeling approaches, are already available. Advances in computational power, characterization techniques, and data integration strategies are completing the jigsaw puzzle. Despite their potential value, the implementation this powerful tool has been demonstrated on limited occasions. Numerous challenges remain for their full implementation as a routine tools to optimize the performance of the food supply chain.

Full virtualization of a food product requires interdisciplinary contributions. Expanding collaborations beyond strictly food disciplines at the academic and industrial level can facilitate this process. The data needed to inform each component of a virtual food are substantial and require contributions that reflect spatial and temporal variability. Thus, cloud-based storage with the capability to integrate categorized information should be established and shared among stakeholders.

Additionally, development and operation of virtual food models will require specific knowledge and skills, which may limit their applicability. Translation and dissemination of the outcomes (Kansou et al., 2022), user-friendly graphical user interfaces (GUI), and proper training in relevant skills are critical to expanding their future use and building more sustainable and secure global food systems.

Author contributions

CC, AH-J, and MC contributed to the conceptualization of the manuscript. CC and MC compiled the literature review, and all authors organized the sources. AH-J developed the illustration. CC wrote the first draft of the manuscript; subsequent versions reflect the contributions of all authors. All authors contributed to the article and approved the submitted version.

Funding

Natural Sciences and Engineering Research Council of Canada (NSERC) Discovery Program RGPIN-2019-04995; SMART Training Platform at the University of Guelph.

Acknowledgments

AH-J would also like to express her gratitude to the SMART Training Platform for the financial support to conduct her Ph.D. studies at the University of Guelph.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

The author MC declared that they were an editorial board member of Frontiers, at the time of submission. This had no impact on the peer review process and the final decision.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Beck, K. L., Haiminen, N., Chambliss, D., Edlund, S., Kunitomi, M., Huang, B. C., et al. (2021). Monitoring the microbiome for food safety and quality using deep shotgun sequencing. Npj Sci. Food 5, 3. doi:10.1038/s41538-020-00083-y

Cantre, D., Herremans, E., Verboven, P., Ampofo-Asiama, J., and Nicolaï, B. (2014). Characterization of the 3-D microstructure of mango (Mangifera indica L. cv. Carabao) during ripening using X-ray computed microtomography. Innov. Food Sci. Emerg. Technol. 24, 28–39. doi:10.1016/j.ifset.2013.12.008

Chen, C., and Pan, Z. (2021). Heat and moisture transfer studies on walnuts during hot air drying in a fixed-bed column dryer. Appl. Therm. Eng. 199, 117554. doi:10.1016/j.applthermaleng.2021.117554

Chen, C., Upadhyaya, S., Khir, R., and Pan, Z. (2022). Simulation of walnut drying under hot air heating using a nonequilibrium multiphase transfer model. Dry. Technol. 40, 987–1001. doi:10.1080/07373937.2020.1846552

Chigwaya, K., du Plessis, A., Viljoen, D. W., Crouch, I. J., and Crouch, E. M. (2021). Use of X-ray computed tomography and 3D image analysis to characterize internal browning in ‘Fuji’apples after exposure to CO2 stress. Sci. Hortic. 277, 109840. doi:10.1016/j.scienta.2020.109840

Cifuentes, A. (2012). Food analysis: Present, future and foodomics. ISRN Anal. Chem. 2012, 1–16. doi:10.5402/2012/801607

Colaruotolo, L. A., Peters, E., and Corradini, M. G. (2021). Novel luminescent techniques in aid of food quality, product development, and food processing. Curr. Opin. Food Sci. 42, 148–156. doi:10.1016/j.cofs.2021.06.005

Corradini, M. G. (2018). Shelf life of food products: From open labeling to real-time measurements. Ann. Rev. Food Sci. Technol. 9, 251–269. doi:10.1146/annurev-food-030117-012433

Curcio, S., Aversa, M., Chakraborty, S., Calabrò, V., and Iorio, G. (2016). Formulation of a 3D conjugated multiphase transport model to predict drying process behavior of irregular-shaped vegetables. J. Food Eng. 176, 36–55. doi:10.1016/j.jfoodeng.2015.11.020

Datta, A. K., Nicolaï, B., Vitrac, O., Verboven, P., Erdogdu, F., Marra, F., et al. (2022). Computer-aided food engineering. Nat. Food 3, 894–904. doi:10.1038/s43016-022-00617-5

Datta, A. K. (2016). Toward computer-aided food engineering: Mechanistic frameworks for evolution of product, quality and safety during processing. J. Food Eng. 176, 9–27. doi:10.1016/j.jfoodeng.2015.10.010

Defraeye, T., Shrivastava, C., Berry, T., Verboven, P., Onwude, D., Schudel, S., et al. (2021). Digital twins are coming: Will we need them in supply chains of fresh horticultural produce? Trends Food Sci. Technol. 109, 245–258. doi:10.1016/j.tifs.2021.01.025

Ding, Z., Jiang, F., Shi, J., Wang, Y., He, M., Tan, C. P., et al. (2023). Foodomics reveals anti-obesity properties of cannabinoids from hemp oil. Mol. Nutr. Food Res. 67, 2200508. doi:10.1002/mnfr.202200508

Duan, Y., Wang, G. B., Fawole, O. A., Verboven, P., Zhang, X. R., Wu, D., et al. (2020). Postharvest precooling of fruit and vegetables: A review. Trends Food Sci. Tech. 100, 278–291. doi:10.1016/j.tifs.2020.04.027

Erdogdu, F., Sarghini, F., and Marra, F. (2017). Mathematical modeling for virtualization in food processing. Food Eng. Rev. 9, 295–313. doi:10.1007/s12393-017-9161-y

Erdogdu, F. (2023). Mathematical modeling of food thermal processing: Current and future challenges. Curr. Opin. Food Sci. 51, 101042. doi:10.1016/j.cofs.2023.101042

Figura, L. O., and Teixeira, A. A. (2007). Food physics: Physical properties – measurements and applications. Heidelberg: Springer Berlin.

Gruber, S., Vorhauer-Huget, N., and Foerst, P. (2021). In situ micro-computed tomography to study microstructure and sublimation front during freeze-drying. Food Struct. 29, 100213. doi:10.1016/j.foostr.2021.100213

Gruyters, W., Van De Looverbosch, T., Wang, Z., Janssen, S., Verboven, P., Defraeye, T., et al. (2020). Revealing shape variability and cultivar effects on cooling of packaged fruit by combining CT-imaging with explicit CFD modelling. Postharv. Biol. Technol. 162, 111098. doi:10.1016/j.postharvbio.2019.111098

Guo, E., Zeng, G., Kazantsev, D., Rockett, P., Bent, J., Kirkland, M., et al. (2017). Synchrotron X-ray tomographic quantification of microstructural evolution in ice cream–a multiphase soft solid. RSC Adv. 7, 15561–15573. doi:10.1039/C7RA00642J

Hu, Y., Cai, Y., Wang, H., Xiong, Y., Zhang, X., Wei, L., et al. (2022). Systematic study of the sensory quality, metabolomics, and microbial community of fresh-cut watermelon provides new clues for its quality control and preservation. Foods 11, 3423. doi:10.3390/foods11213423

Im, J., de Barros, F. P., Masri, S., Sahimi, M., and Ziff, R. M. (2023). Data-driven discovery of the governing equations for transport in heterogeneous media by symbolic regression and stochastic optimization. Phys. Rev. E 107, L013301. doi:10.1103/PhysRevE.107.L013301

Janssen, S., Verboven, P., Nugraha, B., Wang, Z., Boone, M., Josipovic, I., et al. (2020). 3D pore structure analysis of intact ‘Braeburn’apples using X-ray micro-CT. Postharvest Biol. Technol. 159, 111014. doi:10.1016/j.postharvbio.2019.111014

Kansou, K., Laurier, W., Charalambides, M., Della-Valle, G., Djekic, I., Hailu Feyissa, H., et al. (2022). Food modelling strategies and approaches for knowledge transfer. Trends Food Sci. Technol. 120, 363–373. doi:10.1016/j.tifs.2022.01.021

Karunasena, H. C. P., Brown, R. J., Gu, Y., and Senadeera, W. (2015). Application of meshfree methods to numerically simulate microscale deformations of different plant food materials during drying. J. Food Eng. 146, 209–226. doi:10.1016/j.jfoodeng.2014.09.011

Kirtil, E., Cikrikci, S., McCarthy, M. J., and Oztop, M. H. (2017). Recent advances in time domain NMR and MRI sensors and their food applications. Curr. Opin. Food Sci. 17, 9–15. doi:10.1016/j.cofs.2017.07.005

Lerma-García, M. J., D'Amato, A., Simó-Alfonso, E. F., Righetti, P. G., and Fasoli, E. (2016). Orange proteomic fingerprinting: From fruit to commercial juices. Food Chem. 196, 739–749. doi:10.1016/j.foodchem.2015.10.009

Mahiuddin, M., Khan, M. I. H., Kumar, C., Rahman, M. M., and Karim, M. A. (2018). Shrinkage of food materials during drying: Current status and challenges. Compr. Rev. Food Sci. Food Saf. 17, 1113–1126. doi:10.1111/1541-4337.12375

Marra, F. (2016). Virtualization of processes in food engineering. J. Food. Eng. 176, 1. doi:10.1016/j.jfoodeng.2016.01.021

Marra, F. (2022). Food products and digital tools: The unexpected interconnections. Front. Nutr. 9, 847038. doi:10.3389/fnut.2022.847038

Marra, F. (2023). Combining computer-aided food engineering and electro-heating applications as contribution to food processing sustainability. Front. Sustain. 4, 1170467. doi:10.3389/frsus.2023.1170467

Mengucci, C., Ferranti, P., Romano, A., Masi, P., Picone, G., and Capozzi, F. (2022). Food structure, function and artificial intelligence. Trends Food Sci. Tech. 123, 251–263. doi:10.1016/j.tifs.2022.03.015

Metilli, L., Storm, M., Bodey, A. J., Wanelik, K., Tyler, A. I., Lazidis, A., et al. (2021). Investigating the microstructure of soft, microporous matter with synchrotron X-ray tomography. Mater. Charact. 180, 111408. doi:10.1016/j.matchar.2021.111408

Metzger, T. (2019). A personal view on pore network models in drying technology. Dry. Technol. 37, 497–512. doi:10.1080/07373937.2018.1512502

Nielsen, S. S. (2017). “Food analysis,” in Food science text series (New York, NY: Springer Press). doi:10.1007/978-3-319-45776-5_1

Nikitina, M., and Chernukha, I. (2020). Personalized nutrition and “digital twins” of food. Potravin. Slovak J. Food Sci. 14, 264–270. doi:10.5219/1312

Nugraha, B., Verboven, P., Janssen, S., Hertog, M. L., Boone, M., Josipovic, I., et al. (2021). Oxygen diffusivity mapping of fruit and vegetables based on X-ray CT. J. Food Eng. 306, 110640. doi:10.1016/j.jfoodeng.2021.110640

Pacheco-Aguirre, F. M., García-Alvarado, M. A., Corona-Jiménez, E., Ruiz-Espinosa, H., Cortés-Zavaleta, O., and Ruiz-López, I. I. (2015). Drying modeling in products undergoing simultaneous size reduction and shape change: Appraisal of deformation effect on water diffusivity. J. Food Eng. 164, 30–39. doi:10.1016/j.jfoodeng.2015.04.031

Palevich, N., Palevich, F. P., Maclean, P. H., Altermann, E., Gardner, A., Burgess, S., et al. (2021). Comparative genomics of Clostridium species associated with vacuum-packed meat spoilage. Food Microbiol. 95, 103687. doi:10.1016/j.fm.2020.103687

Panda, D., Bhaskaran, S., Paliwal, S., Kharaghani, A., Tsotsas, E., and Surasani, V. K. (2022). Pore-scale physics of drying porous media revealed by Lattice Boltzmann simulations. Dry. Technol. 40, 1114–1129. doi:10.1080/07373937.2020.1850469

Peleg, M., and Corradini, M. G. (2011). Microbial growth curves: What the models tell us and what they cannot. Crit. Rev. Food Sci. Nutr. 51, 917–945. doi:10.1080/10408398.2011.570463

Peleg, M., Normand, M. D., and Corradini, M. G. (2011). Expanded ‘Fermi solution’ for estimating the relationship between product spoilage or deterioration and the number of consumer complaints. Trends Food Sci. Tech. 22, 341–349. doi:10.1016/j.tifs.2011.03.007

Peleg, M., Normand, M., and Corradini, M. G. (2012). The Arrhenius equation revisited. Crit. Rev. Food Sci. 54, 830–851. doi:10.1080/10408398.2012.667460

Peleg, M. (2023). Selected challenges to modeling the kinetics of microbial inactivation and chemical reactions during food preservation. Curr. Opin. Food Sci. 101029, 101029. doi:10.1016/j.cofs.2023.101029

Piovesan, A., Vancauwenberghe, V., Van De Looverbosch, T., Verboven, P., and Nicolaï, B. (2021). X-ray computed tomography for 3D plant imaging. Trends Plant Sci. 26, 1171–1185. doi:10.1016/j.tplants.2021.07.010

Pollo, B. J., Teixeira, C. A., Belinato, J. R., Furlan, M. F., de Matos Cunha, I. C., Vaz, C. R., et al. (2021). Chemometrics, comprehensive two-dimensional gas chromatography and “omics” sciences: Basic tools and recent applications. Trends Anal. Chem. 134, 116111. doi:10.1016/j.trac.2020.116111

Rahman, M. M., Joardder, M. U., Khan, M. I. H., Pham, N. D., and Karim, M. A. (2018). Multiscale model of food drying: Current status and challenges. Crit. Rev. Food Sci. Nutr. 58, 858–876. doi:10.1080/10408398.2016.1227299

Ranjbaran, M., Carciofi, B. A. M., and Datta, A. K. (2021). Engineering modeling frameworks for microbial food safety at various scales. Compr. Rev. Food Sci. Food Saf. 20, 4213–4249. doi:10.1111/1541-4337.12818

Röding, M., Ma, Z., and Torquato, S. (2020). Predicting permeability via statistical learning on higher-order microstructural information. Sci. Rep. 10, 15239. doi:10.1038/s41598-020-72085-5

Saguy, I. S. (2016). Challenges and opportunities in food engineering: Modeling,virtualization, open innovation and social responsibility. J. Food Eng. 176, 2–8. doi:10.1016/j.jfoodeng.2015.07.012

Schork, N., Schuhmann, S., Gruschke, O., Gross, D., Zick, K., Nirschl, H., et al. (2020). Recent MRI and diffusion studies of food structures. Annu. Rep. NMR Spectrosc. 100, 145–197. doi:10.1016/bs.arnmr.2016.09.001

Shrivastava, C., Berry, T., Cronje, P., Schudel, S., and Defraeye, T. (2022). Digital twins enable the quantification of the trade-offs in maintaining citrus quality and marketability in the refrigerated supply chain. Nat. Food 3, 413–427. doi:10.1038/s43016-022-00497-9

Sinanoglou, V. J., Kokkotou, K., Fotakis, C., Strati, I., Proestos, C., and Zoumpoulakis, P. (2014). Monitoring the quality of γ-irradiated macadamia nuts based on lipid profile analysis and chemometrics. Traceability models of irradiated samples. Food Res. Int. 60, 38–47. doi:10.1016/j.foodres.2014.01.015

Singh, M., and Corradini, M. G. (2023). “Big data and its role in mitigating food spoilage and quality deterioration along the supply chain,” in Harnessing big data in food safety. Editors J. Farber, R. Dara, and J. Ronholm (New York, NY: Springer Press), 93–112.

Su, Y., Zhang, M., and Mujumdar, A. S. (2015). Recent developments in smart drying technology. Dry. Technol. 33, 260–276. doi:10.1080/07373937.2014.985382

Sun, C., and Shi, V. G. (2022). PhysiNet: A combination of physics-based model and neural network model for digital twins. Int. Syst. 37, 5443–5456. doi:10.1002/int.22798

Sun, Y., Zhang, M., Ju, R., and Mujumdar, A. (2021). Novel nondestructive NMR method aided by artificial neural network for monitoring the flavor changes of garlic by drying. Dry. Technol. 39, 1184–1195. doi:10.1080/07373937.2020.1821211

Suresh, A., and Neethirajan, S. (2015). Real-time 3D visualization and quantitative analysis of internal structure of wheat kernels. J. Cereal Sci. 63, 81–87. doi:10.1016/j.jcs.2015.03.006

Tagliavini, G., Defraeye, T., and Carmeliet, J. (2019). Multiphysics modeling of convective cooling of non-spherical, multi-material fruit to unveil its quality evolution throughout the cold chain. Food Bioprod. process. 117, 310–320. doi:10.1016/j.fbp.2019.07.013

Tan, J., and Xu, J. (2020). Applications of electronic nose (e-nose) and electronic tongue (e-tongue) in food quality-related properties determination: A review. Artif. Intell. Agric. 4, 104–115. doi:10.1016/j.aiia.2020.06.003

Topcam, H., Coskun, E., Son, E., Kutuk, D., Aytac, S. A., Mert, B., et al. (2023). Microwave decontamination processing of tahini and process design considerations using a computational approach. Innov. Food Sci. Emerg. Technol. 86, 103377. doi:10.1016/j.ifset.2023.103377

Turner, I, and Mujumdar, A. S. (Editors) (1996). Mathematical modeling and numerical techniques in drying technology. CRC Press.

van Boekel, M. A. J. S. (2008). Kinetic modeling of food quality: A critical review. Compr. Rev. Food Sci. Food Saf. 7, 144–158. doi:10.1111/J.1541-4337.2007.00036.x

Van Dael, M., Verboven, P., Zanella, A., Sijbers, J., and Nicolaï, B. (2019). Combination of shape and X-ray inspection for apple internal quality control: In silico analysis of the methodology based on X-ray computed tomography. Postharv. Biol. Technol. 148, 218–227. doi:10.1016/j.postharvbio.2018.05.020

Verboven, P., Defraeye, T., Datta, A. K., and Nicolaï, B. (2020). Digital twins of food process operations: The next step for food process models? Curr. Opin. Food Sci. 35, 79–87. doi:10.1016/j.cofs.2020.03.002

Verdouw, C. N., Wolfert, J., Beulens, A. M. F., and Rialland, A. (2016). Virtualization of food supply chains with the internet of things. J. Food Eng. 176, 128–136. doi:10.1016/j.jfoodeng.2015.11.009

Vitrac, O., Nguyen, P. M., and Hayert, M. (2021). In silico prediction of food properties: A multiscale perspective. Front. Chem. Eng. 3, 786879. doi:10.3389/fceng.2021.786879

Welsh, Z. G., Simpson, M. J., Khan, M. I. H., and Karim, A. (2021). A multiscale approach to estimate the cellular diffusivity during food drying. Biosyst. Eng. 212, 273–289. doi:10.1016/j.biosystemseng.2021.10.017

Wu, H., Fang, W. Z., Kang, Q., Tao, W. Q., and Qiao, R. (2019). Predicting effective diffusivity of porous media from images by deep learning. Sci. Rep. 9, 20387. doi:10.1038/s41598-019-56309-x

Yin, J., Guo, M., Liu, G., Ma, Y., Chen, S., Jia, L., et al. (2022). Research progress in simultaneous heat and mass transfer of fruits and vegetables during precooling. Food Eng. Rev. 14, 307–327. doi:10.1007/s12393-022-09309-z

Keywords: virtualization, multiscale modeling, optimization, food quality, food processing, shelf-life, food supply chain

Citation: Chen C, Homez-Jara A and Corradini MG (2023) Virtualization of foods: applications and perspectives toward optimizing food systems. Front. Food. Sci. Technol. 3:1203544. doi: 10.3389/frfst.2023.1203544

Received: 10 April 2023; Accepted: 06 July 2023;

Published: 13 July 2023.

Edited by:

Fanbin Kong, University of Georgia, United StatesReviewed by:

Francesco Marra, University of Salerno, ItalyCopyright © 2023 Chen, Homez-Jara and Corradini. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Maria G. Corradini, bWNvcnJhZGlAdW9ndWVscGguY2E=

Chang Chen

Chang Chen Angie Homez-Jara

Angie Homez-Jara Maria G. Corradini

Maria G. Corradini