94% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

ORIGINAL RESEARCH article

Front. Food. Sci. Technol., 12 April 2023

Sec. Food Characterization

Volume 3 - 2023 | https://doi.org/10.3389/frfst.2023.1143371

This article is part of the Research TopicAdvances in Sensory Evaluation of FoodsView all 6 articles

Aquafaba and liluva are names used to define the processing water of food legumes. Large volumes of liluva are generated by frozen pea manufacturers (blanching water) and tofu producers (tofu whey). Studies have shown the potential of aquafaba and liluva in food applications as texture improvers and sources of bioactive substances and prebiotics. Nonetheless, no information on consumer perception of these new food ingredients is available. Therefore, this study investigated consumer expectations of steam blanching pea water (SBPW) and tofu whey (TW), correlating it with their actual sensory qualities and functional properties. Specifically, liluva was used as a source of prebiotics and hydrocolloids in 3D-printed mashed potatoes to enhance their rheology and printability. A preliminary survey showed a limited understanding of SBPW and TW as food ingredients, with only 43% and 38% of subjects willing to try TW and SBPW, respectively, with most subjects unsure on whether they wanted to or not (34% tofu whey and 49% liluva). Once the actual sensory test was conducted, TW-added mashed potato received favorable scores for all sensory attributes (appearance, aroma, taste, and texture). In contrast, SBPW-added mashed potato had a negative score on the color, as all nine focus group subjects described the color as gray. Overall, TW enhanced the printability of mashed potatoes due to its emulsifying ability and possibly coagulants derived from tofu making, and it was more appreciated sensory-wise, resulting in being the most preferred out of three samples (SBPW, TW, and control). Therefore, emphasizing consumer education may be key when expanding these innovative food ingredients to other food areas.

Food waste occurs at every stage of food preparation: production, handling, storage, processing, packaging, and distribution, and continues through to the consumers’ households (Thorsen et al., 2022). Food waste has gained the attention of organizations such as WRAP (the Waste and Resources Action Program) for action toward economic and environmental changes, including halving food waste in Europe by 2030 (WRAP, 2021). Upcycling food ingredients is a solution to minimize food waste. According to the Upcycled Food Association, upcycled foods use ingredients that otherwise would not have gone to human consumption, are procured and produced using verifiable supply chains, and have a positive impact on the environment (Upcycledfood.org, 2022). Legume water is a by-product that would usually be considered waste, but using it as an additive in other foods would limit wastage, positively impacting the environment and, thus, being an upcycled ingredient.

Two names have been used to describe legume water: aquafaba and liluva. The term aquafaba is specific to the cooking water of chickpeas. The term liluva is a comprehensive term including water from all food legumes (such as beans, chickpeas, peas, and lentils) and different processing types (soaking, cooking, sprouting, blanching, and tofu coagulation). Liluva, or the processing water of food legumes, is a functional ingredient emerging within the industry, known for being environmentally sustainable and having potential applications in emulsifiers, foaming agents, gelling agents, and anti-staling ingredients. Liluva is also known as and is closely related to aquafaba, which is the brine of chickpeas. Aquafaba is considered an emerging rheological additive expressing foaming, emulsification, and gelling properties. It consists of mostly water (92%–95%), protein, carbohydrates, and fiber (5%–8%) (He et al., 2021). Aquafaba has recently become a popular food additive or ingredient and is often used as a vegan or vegetarian alternative to eggs. Aquafaba’s functionality within the food industry is still yet to be thoroughly understood. However, there is growing interest in its commercial production and inclusion. Its prebiotic properties have also been investigated in a previous study, and thus, it demonstrates potential as a functional ingredient (Sun et al., 2022). However, to the best of the author’s knowledge, no studies have been performed on consumer expectations of aquafaba and liluva yet.

Potatoes are historically known to be a staple vegetable in the human diet. Potatoes provide a variety of micronutrients, including vitamin C, vitamin B6, thiamine, potassium, folate, and fiber (Robertson et al., 2018). Serving potatoes in the form of mashed potatoes is very common and can be found at grocery stores worldwide. Mashed potatoes often have a short shelf life, withstanding no longer than 3 to 5 days in refrigeration due to heat-resistant spore-forming bacteria such as Bacillus and Clostridium. Therefore, additives such as natural food preservatives nisin and salt are often added to enhance the shelf life and overall quality of the product (Thomas et al., 2002). Mashed potatoes are usually easily palatable, and common flavors are described by sensory panels as a food with high smoothness and mealiness, with mouthfeel and appearance being frequent sensory methods (Ooraikul, 1974; Ciccone et al., 2020).

Digitalizing food using 3-dimensional (3D) printing is an application used by many researchers within sectors such as architecture, education, textiles, industrial, and packaging and is slowly becoming more developed within the food technology sector. This is because 3D printing allows customized textures, tailored nutritional content, and food sustainability (Baiano, 2022). The process of 3D printing is rapid prototyping that produces pre-designed 3D objects using adhesive materials (Dankar et al., 2018; He et al., 2020). A previous study (Sun et al., 2022) showed prebiotic properties of this ingredient and determined its composition.

The liluva powder may enhance the quality and stability (taste and texture) of mashed potatoes. Thus, this study aimed to produce mashed potatoes incorporated with liluva using the 3D printing technique; investigate the functional, instrumental, and sensory qualities of liluva in mashed potatoes; and compare these internal properties to those of regular mashed potatoes. In addition, the foaming ability (FA), emulsifying ability (EA), emulsifying ability index (EAI), and water activity (WA) of liluva were also examined.

Steam blanching pea water (SBPW) and tofu whey (TW) were obtained from Talley’s Group Limited (Ashburton, New Zealand) and Poseidon Organics Limited (Christchurch, New Zealand), respectively. The SBPW and TW were frozen at −18°C until use. Canola oil and potatoes were purchased at local supermarkets, Countdown (Christchurch, New Zealand), and New World (Lincoln, New Zealand), respectively.

Upon collection from the manufacturers, samples were frozen at −18°C and then thawed in a refrigerator overnight prior to use. The samples were also heated in the microwave to return to room temperature and reach homogeneity. Freeze-drying of the samples was performed prior to the physicochemical analyses. A previous study investigated the microbial load of these samples. The SBPW and TW contained 4.8 x 103 and 8.12 × 106 CFU of Lactobacilli, respectively. No growth of yeast, mold, or Gram-negative bacteria was detected (Sun et al., 2022). Phytochemical analysis revealed low concentrations of saponins; 1.66 and 1.26 mg/mL for SBPW and TF, respectively (Sun et al., 2022).

The original SBPW and TW liquid samples were characterized for foaming ability. Freeze-dried powders were used to quantify water absorption capacity (WAC), EAI, and EA. To measure the FA of SBPW and TW, a volumetric method (Stantiall et al., 2018) was used. Briefly, a 100 mL aliquot of SBPW and TW was whipped for 7 min in a Brabantia BBEK109 electric mixer (Brabantia, Holland) at speed five. After whipping, the foams were transferred into a graduated cylinder and measured for volume. The FA was then calculated and expressed as a percentage (%) using the following equation, where Vf was the volume of the final foam after whipping, and Vi was the volume of the initial liquid in mL:

SBPW and TW samples were freeze-dried to test their physiochemical properties of WAC, EAI, and EA. WAC was tested through a modified version of a previous method (Damian et al., 2018). Aliquots of 2.5 g of freeze-dried SBPW and TW samples were put into a 50-mL test tube with 20 mL of distilled water. This was vortexed for 1 min. The solutions were then centrifuged using the Heraeus Multifuge X1R (Thermo Scientific, MA, United States) for 10 min at 1,260 g. After the completion of the centrifuge, the supernatant was removed and discarded, and the pellet was weighted. WAC was calculated as a ratio of pellet weight over sample weight and expressed in g water/g sample.

EAI was determined using a one-to-one ratio of the sample and oil; 20 mL of the sample and 20 mL of canola oil were put into a 50-mL centrifuge tube and homogenized using an Omni Mixer Variable-Speed Homogenizer, model no. 17106 (Omni International, Kennesaw GA, United States), for 1 minute at speed four. Then, 20 μL aliquot of the emulsion was diluted in 5 mL of 0.1% aqueous solution and vortexed. The absorbance at 500 nm was recorded with the V-1200 spectrophotometer (VWR, Pennsylvania, United States). Calculations of EAI were performed using the following equation and expressed as m2/g:

DM is the dry matter content of tested samples, VF is the volume fraction of water, and DF is the dilution factor.

EA of the freeze-dried SBPW and TW was tested as described previously (Damian et al., 2018): 2.5 g of freeze-dried sample was weighed into a centrifuge tube with 20 mL of RO water and 20 mL of canola oil. The mixtures were homogenized using the Omni Mixer Variable-Speed Homogenizer, model no. 17106 (Omni International, Kennesaw, GA, United States), at speed four for 1 minute. The centrifuge was set at 1,000 g for 5 minutes to separate the emulsion from the rest of the mixed solution. The EA was calculated with the following equation expressed as a %:

The mineral profile of SBPW and TW were determined following the method described elsewhere (Bhat et al., 2018) using an inductively coupled plasma optical emission spectrophotometer (Varian 720 ICP-OES, Melbourne, Australia). Parameters of mineral detection were set with plasma gas flow (15.0 L/min), Aux (1.5 L/min), nebulizer (0.9 L/min) with the SeaSpray nebulizer, and cyclonic spray chamber. Calibration and internal standards were diluted from Merck ICP standard solutions using MilliQ water in series. Calibration curves were created using four standards and a blank.

The formulation for making each batch of mashed potatoes consisted of 10 g of sample (SBPW, TW, or water), 4 g of salt, 8.42 g of canola oil, and 100 g of potatoes. The potatoes (approximately five) were peeled, diced, and cooked for 15 min in boiling water. They were then mashed with a hand potato masher, and the other ingredients were added. The mixture was then put into a NutriBullet 900W Blender (NutriBullet, New Zealand) and blended for approximately 5 s to reach homogeneity. The mixture was split into three different bowls, and the 10 g of one of the following: SBPW, TW, or water were weighed and mixed in manually with a spoon for 10 s. The samples have been treated as hydrocolloids, given their physicochemical properties. Therefore, a dosage of 0.3% (solids from these solutions in relation to the total weight of the recipe) was deemed in line with previous literature and industry standards.

The mashed potato mixture was placed into the Foodini 3D printer (Natural Machines, Barcelona, Spain) via the food syringes. The effect on viscosity and food structure has been investigated. Therefore, 3D printing settings were chosen to evaluate the printability of the ink (mashed potatoes) and structural stability of the food product (3D-printed mashed potatoes). Printability was assessed via a medium-sized syringe with a diameter of 40 mm, which allows for a large flow rate and requires stable flow (not runny, not thick). Structural stability was assessed via a multilayer flower shape. The printer was washed and dried before and after each sample to minimize contamination. Each batch was used to build one flower print on top of a sheet of baking paper. The samples were then labeled and stored in the kitchen refrigerator for 24 h before the sensory analysis.

The mashed potato samples (control, SBPW, and TW) were used to test and compare the viscosity of the mixtures. A digital rotational viscometer (1–100,000 mPa*s) (ATO, United States) was set with system 33, and a strain of 51.6 s-1 was used for 30 s. Each sample was tested in triplicates. The spindle and viscometer were washed after each use to limit contamination.

The color of the mashed potato samples was analyzed using a CR400 Chromameter (Konica Minolta, Japan). CIE L*, a*, and b* values representing lightness/darkness, redness/greenness, and yellowness/blueness, respectively, were measured, and a total color difference (∆E) compared to the control sample was also calculated using the following equation, using the rule ∆E > 3 is different from control.

where S is the sample, and C stands for the control.

A survey was distributed and completed by 53 participants of mixed demographic to gauge how people generally feel about upcycled ingredients, liluva, and how people tend to make decisions about food and food sustainability. The survey was distributed online via a Qualtrics link and in-person to the focus group contributors. The survey consisted of 14 required questions.

The sensory analysis of mashed potato samples was conducted directly to gain information on consumer acceptance of the SBPW and TW within the mashed potatoes. The 14 question-survey was distributed to the panelists prior to the sensory test. Nine semi-trained panelists were recruited, consisting of two Bachelor students, six Master students, and one Ph.D. student. To prepare for the sensory analysis, the mashed potatoes were heated in a microwave for 40 s. Each 3D-printed sample, control, SBPW, and TW, were used and tested in a focus group setting in which the panelists were required to come up with describing words for the appearance, smell, taste, and texture of each sample. The words which retained more than four votes of agreement were highlighted. After this process, a preference was determined out of the three samples. Focus groups typically request that at least half of the participants agree on a descriptor to state statistical significance. Ethical approval to perform the tests on human subjects was reviewed and approved by the ethics committee at Lincoln University, application number 2020-35.

All measurements were conducted in triplicates for the instrumental analysis. The results presented in the tables express the means and standard deviation. Data were processed via Microsoft© Excel© 2012 and one-way ANOVA tests, which assumed equal variances for the data analysis and a significance of p < 0.05. ANOVA was also conducted with Tukey’s post-hoc test in Minitab©17.

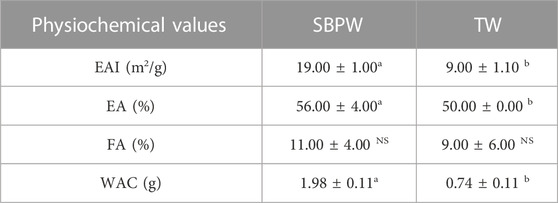

The results for the physiochemical properties of SBPW and TW liquid samples are shown in Table 1. EAI, EA, and WAC of SBPW were significantly higher than TW, while no difference was found in FA between these two samples.

TABLE 1. Physiochemical properties of the foaming agents (SBPW and TW). Properties analyzed were EAI (emulsifying activity index), EA (emulsifying ability), FA (foaming ability), and WAC (water absorption capacity). Data in the same row that do not share the same letter are significantly different (α 0.05). NS means non-significant.

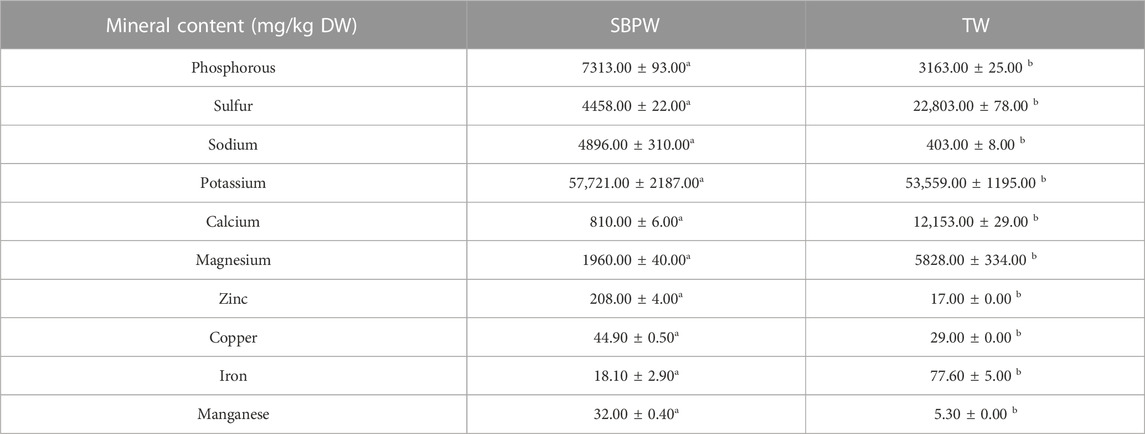

The SBPW and TW were analyzed for mineral composition. Table 2 indicates that macro minerals, especially potassium (K), predominantly constitute the mineral profiles of SBPW and TW samples used in this study. Phosphorus (P) was the second-most abundant macro mineral in SBPW, followed by sodium (Na), sulfur (S), magnesium (Mg), and calcium (Ca). On the other hand, the contents of S, Ca, and Mg in the TW sample were much higher than those in SBPW, while Na in TW was low. The contents of trace minerals, including zinc (Zn), copper (Cu), iron (Fe), and manganese (Mn), were relatively lower than macro minerals in both samples. SBPW contained more Zn, Cu, and Mn but less Fe than TW.

TABLE 2. Mineral content (mg/kg dry weight) of SBPW and TW. Data in the same row that do not share the same letter are significantly different (α 0.05).

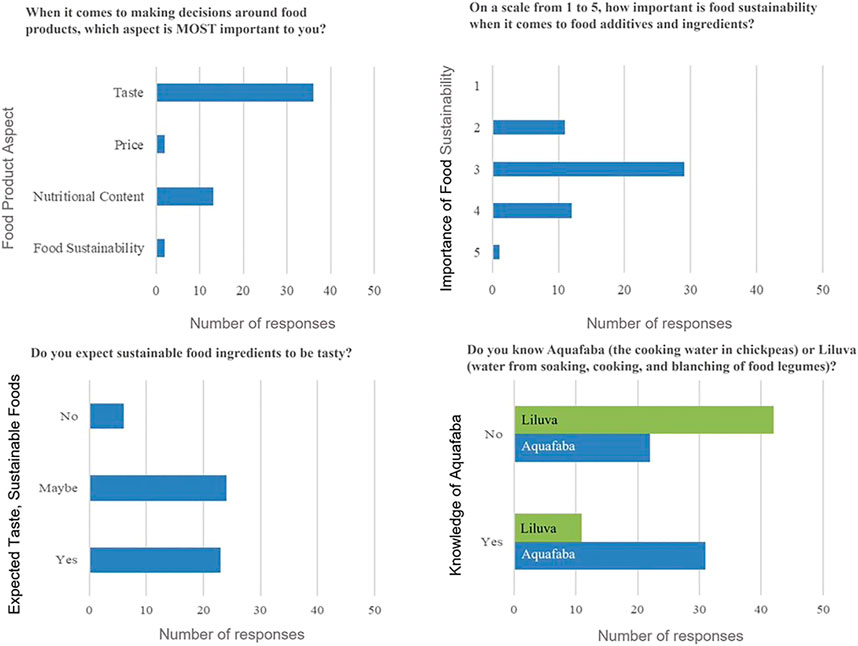

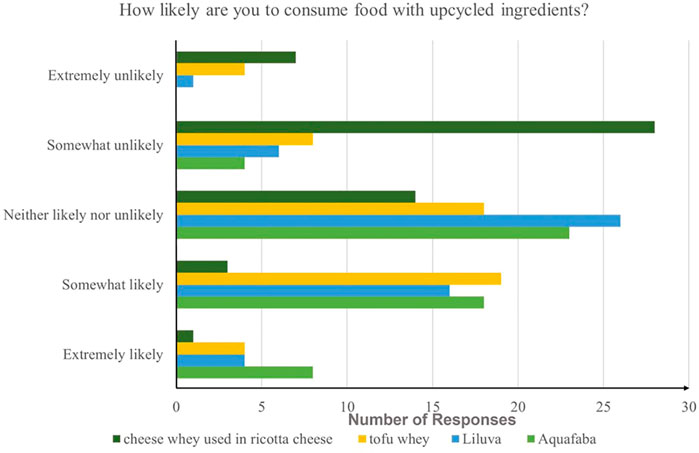

To understand what matters most to consumers when choosing food products, survey participants were asked, “When it comes to making decisions around food products, what aspect matters MOST?” Among 53 participants, 68% regarded “taste” as being most important over other factors such as nutritional content (25%), food sustainability (3.7%), and price (3.8%) (Figure 1). With taste being most important, sustainability was of medium importance, with over 50% of people rating sustainability a three out of five on a scale from one to five (Figure 1). In addition to these results, people were not sure if sustainable food ingredients were to be tasty, with most respondents selecting “maybe” (45%) when asked if they expect sustainable food ingredients to be tasty (Figure 1). In terms of the current understanding of legume waste ingredients, more people were familiar with aquafaba (59% selecting “yes”) than liluva (79% selecting “no”) (Figure 1). When participants were asked if they would consume upcycled ingredients such as tofu whey, 43% were somewhat or extremely likely, and 34% were neither likely nor unlikely. However, when they were answering the question if they would consume food with upcycled ingredients such as cheese whey used in ricotta cheese, 66% of people were somewhat or extremely likely to consume it (Figure 2). When it comes to aquafaba and liluva, most people took a neutral attitude that they were neither likely nor unlikely to consume them. The other participants were likely to try food with aquafaba and liluva, and only a few participants (7.5% toward aquafaba and 11.3% toward liluva) tended to be unlikely to consume these food products (Figure 2).

FIGURE 1. Response from focus group panelists to questions related to food sustainability: “When it comes to making decisions around food products, which aspect is MOST important to you?”, “On a scale from 1 to 5, how important is food sustainability when it comes to food additives and ingredients?”, “Do you expect sustainable food ingredients to be tasty?”, and “Do you know aquafaba (the cooking water in chickpeas) or liluva (water from soaking, cooking, and blanching of food legumes)?”

FIGURE 2. Response from focus group panelists to an intention question: “How likely are you to consume food with upcycled ingredients (such as cheese whey used in ricotta cheese, tofu whey, liluva, and aquafaba)?”

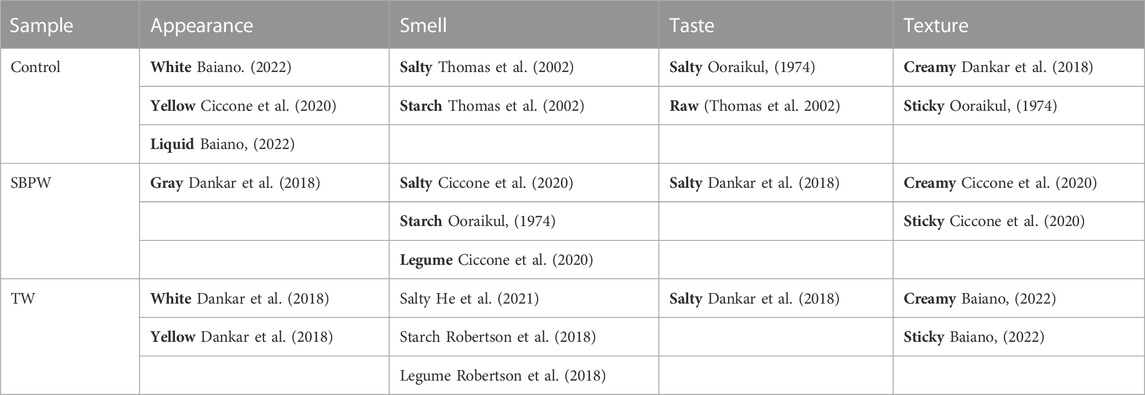

The focus group consisting of nine trained panelists tasted and analyzed the 3D-printed mashed potato samples (control, SBPW, and TW) and found a common vocabulary within the group for appearance, smell, taste, and texture for all three samples. Attributes that received four or more votes within the group were visually recorded on a whiteboard. Table 3 demonstrates the sensory results. The panelists noticed that the control appeared more like a liquid than the other samples, whilst the mashed potato with SBPW seemed gray in color. With regard to smell and taste, “salty” and “starch” were used for all three samples. It is noticeable that the control sample tasted raw to most panelists. A legume smell dominated the SBPW sample compared to the TW one. All three mashed potato samples were accepted in terms of texture, with words such as “creamy” and “sticky.” The preference scores of the mashed potato samples are shown in Table 4. The panel preferred the TW sample the most (eight), then the control (five), and finally, the SBPW (zero).

TABLE 3. Sensory descriptive word results from focus group panelists regarding 3D-printed products. Numbers in the brackets are the vote values each word received. Descriptors agreed by at least 5 panelists are bold.

Table 5 presents the results of viscosity values and color measurements of mashed potatoes made of control, SBPW, and TW. Figure 3 visually shows the 3D print of mashed potatoes. There was no significant difference in viscosity among the three samples. In terms of color, all three samples exhibited greenish and greyish colors visually. Control had the highest lightness (L*) value, whereas SBPW had the lowest. This was in accordance with Figure 3, where the control demonstrated higher lightness while SBPW was the darkest. The a* values for all samples were negative, representing the greenness in these three samples, where the control and TW mashed potato samples were greener than SBPW mashed potato. The b* values were all positive, indicating all the mashed potatoes had a shade of yellow. The highest yellow color was observed for the TW mashed potato, followed by the control with less yellowness, and SBPW had the least yellowness. Delta E, the total color difference based on the control sample, was larger in SBPW than in TW, demonstrating a bigger color difference between SBPW and control than that between TW and control, which was also visually proven, as shown in Figure 3.

FIGURE 3. 3D-printed mashed potato samples. (A) depicts the control, (B) depicts SBPW, and (C) depicts TW.

Understanding consumers’ initial reaction to making a purchasing decision is crucial in food product development as it provides an indicator of whether it will succeed within the food market. Therefore, consumer acceptability is vital to upcycled ingredients such as Liluva to ensure it will be considered amongst other food options. To understand consumer expectations of product choice, surveys were conducted prior to sensory evaluation. “Taste” was considered the leading element of panelists when it came to food product selection. A published study (Liem and Russell, 2019) has stated that liking the food is one of the most important drivers of food consumption, and the taste preferences and subsequent food preferences that are built early play a major role in the food choices of people. Sustainability, however, was not the main concern of the panel. Likewise, research (Tuorila and Hartmann, 2020) has clarified that when it comes to a novel food product, disgust toward new foods (neophobia) could affect the mental disposition of customers. Disgust can be elicited by several aspects, including texture, appearance, and unappealing materials. If people perceive disgust toward a novel food product, consumers tend to reject the novel product.

On a scale from one to five in terms of the importance of food sustainability when facing food additives and ingredients, over 50% of participants rated it three out of five. The low rating is mostly due to the lack of individual awareness and knowledge about creating positive environmental impacts (Haghighian Roudsari et al., 2021). The concept of upcycling and sustainability is relatively less recognized and foreign in New Zealand despite the damages to ecosystems, depleted fish stocks, soil degradation, and loss of biodiversity are very evident (Jones et al., 2019). The literature has specified that many people tend to hold positive attitudes and actual purchase and consumption of more sustainable food products (Vermeir et al., 2020), which explains why taste is considered to be a high priority when choosing food products and why people find sustainability important, but not the primary factor. In addition, when asked if they expect sustainable food ingredients to be tasty, most participants selected “maybe.” People may think that sustainability implies less taste than a less sustainable option or perhaps not associate sustainability with taste satisfaction.

Furthermore, the result of the current understanding of legume waste ingredients shows that more people were familiar with aquafaba than liluva. This reflects people’s likelihood of trying or consuming aquafaba, but a minority of people are likely to consume upcycled ingredients such as liluva. Other upcycled ingredients, such as cheese whey used in ricotta cheese, have been shown to gain relatively more willingness from participants rather than tofu whey, although both proportions were not large. These data show that the knowledge of upcycled food is still foreign and that people may associate upcycling with waste or perhaps do not see its application in food sustainability. In a study conducted by researchers from Otago University, participants in a focus group were asked a series of questions regarding the upcycling of old supermarket shelf food and reincorporating it back for later consumption. The participants were asked what they like least about the concept of upcycled food, and they reported back with terms including “cheap” and “afraid.” The thought of old food turned into new was declared “fit for only poor people” partially due to its cheaper price (Goodman-Smith et al., 2021). Upcycled ingredients, such as liluva, are inclined to be associated with waste foods from the perspectives of consumers and also tend to be unsuccessful in preference over other ingredients due to the lack of knowledge about food sustainability (Thorsen et al., 2022). Thus, the expectations for upcycled ingredients such as liluva were that they were not to be tasty and that people are not expected to try them. Moreover, according to existing literature (Tuorila and Hartmann, 2020), familiarity with a type of food makes people feel certain about a food product and decreases the anxiety and suspicion of having that food. This was also shown previously in a study (Grahl et al., 2018) that examined the consumer expectations of novel food products incorporated with microalgae spirulina. It was found that spirulina-filled pasta was the most preferable product compared to sushi and jerky, suggesting that the more familiarity customers have with a type of food, the more preference they possess.

The survey revealed consumers’ initial expectations of liluva, but the sensory analysis disclosed the reality. The instrumental parameters not only corresponded with the visual images (Figure 3), but also strengthened the sensory evaluation of 3D mashed potatoes. For instance, based on the color measurements of L*, a*, and b* values (Table 5), SBPW was shown to be darker and less yellow than TW and control, whereas TW and control had similar values. Soybean and pea contain isoflavones (yellow) and chlorophyll (green), which explains the negative values of a* and the positive values of b*. However, during the steam blanching process, peas are heated by steam, and, therefore, the chlorophyll and isoflavones are hydrolyzed and oxidized. This process can cause color degradation and changes (Turkmen et al., 2006; Palermo et al., 2014). On the other hand, the tofu-making process involves soaking and grinding soybeans and heating and coagulating soymilk, in addition to thermal treatment (Kao et al., 2003). Researchers have reported that the soaking process does not cause a relevant loss of isoflavones from soybeans (de Lima et al., 2014). When calculating the delta E values, representing the total color difference compared to the control sample, there was a noticeable difference between these two samples (SBPW and TW), and the delta E of SBPW was greater than that of TW, indicating the more notable dissimilarity of SBPW compared with the control.

No significant difference was detected regarding the viscosity among the three samples. This was shown indirectly within the sensory test as all three samples were accepted regarding the texture, with words such as “creamy” and “sticky” for all. Based on the results shown in Table 1, SBPW and TW were strong emulsifiers, but SBPW had greater emulsifying capacity. Previous research has examined the greater emulsifying ability of TW than soy whey due to the presence of soy proteins (around 15%–20% on the dry weight basis) (Sobral et al., 2018; Sun et al., 2022). Apart from that, legumes like soybeans are a good source of lecithin, a type of lipid compound that is known for its ability to interact with both water and oil (Gan et al., 2014). Both SBPW and TW could also have lecithin leached in, and this could have impacted the mashed potato samples, making them more stable and homogenizing their appearance.

Moreover, the panelist noticed that the control appeared to be more like a liquid than the other samples. The addition of legumes to bread could increase hardness, cohesiveness, springiness, chewiness, and resilience when Ca concentration was increased (Alpos et al., 2021). In a study on lentil-based tofu, calcium sulfate (CaSO4) and chitosan affected the gel properties, such as hardness and cohesiveness, modifying the textural profile of tofu products (Jao et al., 2022). In terms of smell and taste, “salty” was used for all three mashed potato samples. The mineral Na was present in the TW and SBPW, but SBPW had a far greater amount, which is why the SBPW might have smelt saltier than TW, with more participants agreeing on the saltiness exhibited in SBPW. SBPW and TW also contained certain levels of magnesium (Mg), with TW showing higher amounts of Ca. The significantly higher levels of Mg and Ca found in TW suggest that the possible coagulating agent used in making tofu might be Mg or Ca salts which leached into the processing water and largely enhanced the Mg and Ca amounts in TW. The addition of Mg and Ca in mashed potatoes led to decreased starch swelling, increased water binding, viscosity, and solubilization due to the interactions between these two minerals and cell wall phosphorus groups (Haydar et al., 1980). Likewise, a study on Ca- and Mg-fortified potato starches also showed that Mg altered the pasting ability of starch, resulting in a decrease in viscosity and a slower starch breakdown (Noda et al., 2014). This mechanism might be responsible for the different taste results of SBPW and TW compared to the control (raw taste). The highest preference score of TW mashed potatoes may be related to a combined result of the highest viscosity value, lightest color measurement, and moderate creaminess and stickiness perceived by the panelists. Creaminess is associated with a pleasant sensation while consuming food products (Fernández et al., 2009). Creaminess was the most important element of mashed potatoes regarding the overall acceptance when tasted by participants (Alvarez et al., 2009).

In conclusion, this study provides a specific view of consumers’ current perception and knowledge regarding food products incorporated with upcycled legume wastewater associated with the physiochemical properties and sensory evaluation of mashed potatoes made of upcycled SBPW or TW. Upcycling food ingredients needs to be better understood to enter the food industry as a source of food ingredients. Sustainable food consumption and upcycling are currently still understudied. Gaining further awareness and concern is crucial so that people can see the positive impact of upcycling and, therefore, be more conscious and considerate.

The raw data supporting the conclusion of this article will be made available by the authors, without undue reservation.

The studies involving human participants were reviewed and approved by the Lincoln University Human Ethics Committee. The patients/participants provided their written informed consent to participate in this study.

LH conducted the experiments and drafted the manuscript. ZF contributed to conceptualization, formatted the manuscript, and significantly implemented text, tables, and figures in all sections, including enhanced scientific discussion. YZ contributed to conceptualization. SL contributed to conceptualization and editing. LS led the conceptualization, supervised the experiments, and contributed to editing. All authors contributed to the article and approved the submitted version.

This study was funded by the Massey–Lincoln and Agricultural Industry Trust (MLAIT), grant number 46467.

The authors thank Rosy Tung (Lincoln University) for the sample freeze drying and Emily Huang (Lincoln University) for the mineral profiling.

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors, and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Alpos, M., Leong, S. Y., and Oey, I. (2021). Combined effects of calcium addition and thermal processing on the texture and in vitro digestibility of starch and protein of black beans (Phaseolus vulgaris). Foods 10 (6), 1368. doi:10.3390/foods10061368

Alvarez, M. D., Fernández, C., and Canet, W. (2009). Enhancement of freezing stability in mashed potatoes by the incorporation of kappa-carrageenan and xanthan gum blends. J. Sci. Food Agric. 89 (12), 2115–2127. doi:10.1002/jsfa.3702

Baiano, A. (2022). 3D printed foods: A comprehensive review on technologies, nutritional value, safety, consumer attitude, regulatory framework, and economic and sustainability issues. Food Rev. Int. 38 (5), 986–1016. doi:10.1080/87559129.2020.1762091

Bhat, Z. F., Morton, J. D., Mason, S. L., and Bekhit, A. E-D. A. (2018). Pulsed electric field: Role in protein digestion of beef Biceps femoris. Innovative Food Sci. Emerg. Technol. 50, 132–138. doi:10.1016/j.ifset.2018.09.006

Ciccone, M., Chambers, D., Chambers, I. V. E., and Talavera, M. (2020). Determining which cooking method provides the best sensory differentiation of potatoes. Foods 9 (4), 451. doi:10.3390/foods9040451

Damian, J. J., Huo, S., and Serventi, L. (2018). Phytochemical content and emulsifying ability of pulses cooking water. Eur. Food Res. Technol. 244 (9), 1647–1655. doi:10.1007/s00217-018-3077-5

Dankar, I., Haddarah, A., Omar, F. E., Sepulcre, F., and Pujolà, M. (2018). 3D printing technology: The new era for food customization and elaboration. Trends food Sci. Technol. 75, 231–242. doi:10.1016/j.tifs.2018.03.018

de Lima, F. S., Kurozawa, L. E., and Ida, E. I. (2014). The effects of soybean soaking on grain properties and isoflavones loss. LWT-Food Sci. Technol. 59 (2), 1274–1282. doi:10.1016/j.lwt.2014.04.032

Fernández, C., Canet, W., and Dolores Alvarez, M. (2009). The effect of long-term frozen storage on the quality of frozen and thawed mashed potatoes with added cryoprotectant mixtures. Int. J. food Sci. Technol. 44 (7), 1373–1387. doi:10.1111/j.1365-2621.2009.01967.x

Gan, L. J., Wang, X. Y., Yang, D., Zhang, H., Shin, J. A., Hong, S. T., et al. (2014). Emulsifying properties of lecithin containing different fatty acids obtained by immobilized lecitase ultra-catalyzed reaction. J. Am. Oil Chemists' Soc. 91 (4), 579–590. doi:10.1007/s11746-013-2396-8

Goodman-Smith, F., Bhatt, S., Moore, R., Mirosa, M., Ye, H., Deutsch, J., et al. (2021). Retail potential for upcycled foods: Evidence from New Zealand. Sustainability 13 (5), 2624. doi:10.3390/su13052624

Grahl, S., Strack, M., Weinrich, R., and Mörlein, D. (2018). Consumer-oriented product development: The conceptualization of novel food products based on spirulina (arthrospira platensis) and resulting consumer expectations. J. Food Qual. 2018, 1–11. doi:10.1155/2018/1919482

Haghighian Roudsari, A., Vedadhir, A., Pourmoradian, S., Rahimi-Ardabili, H., Shokouhi, M., and Milani-Bonab, A. (2021). Exploring adults’ motives for food choice of sustainable diet components: A qualitative study in tehran metropolis. BMC Nutr. 7 (1), 55–10. doi:10.1186/s40795-021-00459-7

Haydar, M., Moledina, K., Ooraikul, B., and Hadziyev, D. (1980). Effect of calcium and magnesium on cell wall and starch of dehydrated potato granules. J. Agric. Food Chem. 28 (2), 383–391. doi:10.1021/jf60228a048

He, C., Zhang, M., and Fang, Z. (2020). 3D printing of food: Pretreatment and post-treatment of materials. Crit. Rev. Food Sci. Nutr. 60 (14), 2379–2392. doi:10.1080/10408398.2019.1641065

He, Y., Meda, V., Reaney, M. J., and Mustafa, R. (2021). Aquafaba, a new plant-based rheological additive for food applications. Trends Food Sci. Technol. 111, 27–42. doi:10.1016/j.tifs.2021.02.035

Jao, C-H., Lin, C-Y., Chen, C-J., and Hsieh, J-F. (2022). Effects of calcium sulfate and chitosan on textural modification and microstructure of tofu made from lentils (lens culinaris). Processes 10 (10), 2000. doi:10.3390/pr10102000

Jones, R., Wham, C., and Burlingame, B. (2019). New Zealand's food system is unsustainable: A survey of the divergent attitudes of agriculture, environment, and health sector professionals towards eating guidelines. Front. Nutr. 99, 99. doi:10.3389/fnut.2019.00099

Kao, F-J., Su, N-W., and Lee, M-H. (2003). Effect of calcium sulfate concentration in soymilk on the microstructure of firm tofu and the protein constitutions in tofu whey. J. Agric. food Chem. 51 (21), 6211–6216. doi:10.1021/jf0342021

Liem, D. G., and Russell, C. G. (2019). The influence of taste liking on the consumption of nutrient rich and nutrient poor foods. Front. Nutr. 6, 174. doi:10.3389/fnut.2019.00174

Noda, T., Takigawa, S., Matsuura-Endo, C., Ishiguro, K., Nagasawa, K., and Jinno, M. (2014). Preparation of calcium-and magnesium-fortified potato starches with altered pasting properties. Molecules 19 (9), 14556–14566. doi:10.3390/molecules190914556

Ooraikul, B. (1974). Objective method for evaluation of texture of dehydrated mashed potatoes using sensory evaluation as a guideline. Am. Potato J. 51 (4), 105–114. doi:10.1007/bf02851342

Palermo, M., Pellegrini, N., and Fogliano, V. (2014). The effect of cooking on the phytochemical content of vegetables. J. Sci. Food Agric. 94 (6), 1057–1070. doi:10.1002/jsfa.6478

Robertson, T. M., Alzaabi, A. Z., Robertson, M. D., and Fielding, B. A. (2018). Starchy carbohydrates in a healthy diet: The role of the humble potato. Nutrients 10 (11), 1764. doi:10.3390/nu10111764

Sobral, P. A., Ossa, J. S. H., Palazolo, G. G., and Wagner, J. R. (2018). Emulsifying properties of dried soy-whey, dried tofu-whey, and their isolated proteins. Pol. J. Food Nutr. Sci. 68 (4), 347–358. doi:10.1515/pjfns-2018-0008

Stantiall, S. E., Dale, K. J., Calizo, F. S., and Serventi, L. (2018). Application of pulses cooking water as functional ingredients: The foaming and gelling abilities. Eur. Food Res. Technol. 244 (1), 97–104. doi:10.1007/s00217-017-2943-x

Sun, P., Zhang, Y., Zhang, Y., Feng, Z., Lee, S. J., and Serventi, L. (2022). Antimicrobial activity of tofu whey and steam blanching pea water for enhancement of shelf-life of 3D printed mashed potatoes. Food Biosci. 50, 102049. doi:10.1016/j.fbio.2022.102049

Thomas, L. V., Ingram, R. E., Bevis, H. E., Davies, E. A., Milne, C. F., and Delves-Broughton, J. (2002). Effective use of nisin to control Bacillus and Clostridium spoilage of a pasteurized mashed potato product. J. food Prot. 65 (10), 1580–1585. doi:10.4315/0362-028x-65.10.1580

Thorsen, M., Skeaff, S., Goodman-Smith, F., Thong, B., Bremer, P., and Mirosa, M. (2022). Upcycled foods: A nudge toward nutrition. Front. Nutr. 9, 2881. doi:10.3389/fnut.2022.1071829

Tuorila, H., and Hartmann, C. (2020). Consumer responses to novel and unfamiliar foods. Curr. Opin. Food Sci. 33, 1–8. doi:10.1016/j.cofs.2019.09.004

Turkmen, N., Poyrazoglu, E. S., Sari, F., and Sedat Velioglu, Y. (2006). Effects of cooking methods on chlorophylls, pheophytins and colour of selected green vegetables. Int. J. food Sci. Technol. 41 (3), 281–288. doi:10.1111/j.1365-2621.2005.01061.x

Keywords: sensory, upcycling, legume, functional ingredient, instrumental analysis

Citation: Hippolite LR, Feng Z, Zhang Y, Lee SJ and Serventi L (2023) Sensory quality of upcycled legume water: Expectation vs. reality. Front. Food. Sci. Technol. 3:1143371. doi: 10.3389/frfst.2023.1143371

Received: 12 January 2023; Accepted: 27 March 2023;

Published: 12 April 2023.

Edited by:

Sigfredo Fuentes, The University of Melbourne, AustraliaReviewed by:

Diego Luna-Vital, Monterrey Institute of Technology and Higher Education (ITESM), MexicoCopyright © 2023 Hippolite, Feng, Zhang, Lee and Serventi. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Ziqian Feng, dHlyYW5kZS5mZW5nQGxpbmNvbG51bmkuYWMubno=

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.