- Department of Management and Engineering, Environmental Technology and Management, Linköping University, Linköping, Östergötland, Sweden

Side-stream management in food processing companies has the potential to improve sustainability performance by upcycling or managing bio-residuals into high-value products. This article investigates how food processing companies manage their side-streams by studying their sustainability reports, interviewing the companies, identifying external or internal side-stream management alternatives, and qualitatively analyzing the data. By learning more about how food processing companies prefer to manage their side-streams, it becomes easier to develop ideas for further refining of bio-residuals. One of the main results is that most of the companies prefer to use external actors for side-stream management and for processing them into high-value products, rather than developing and investing in the technology themselves. The few actors investing in side-stream management themselves have long-term strategies on how to become more sustainable and circular. This study also identifies biogas solutions through anaerobic digestion to have a special role in side-stream management due to its versatile and multifunctional nature.

1 Introduction

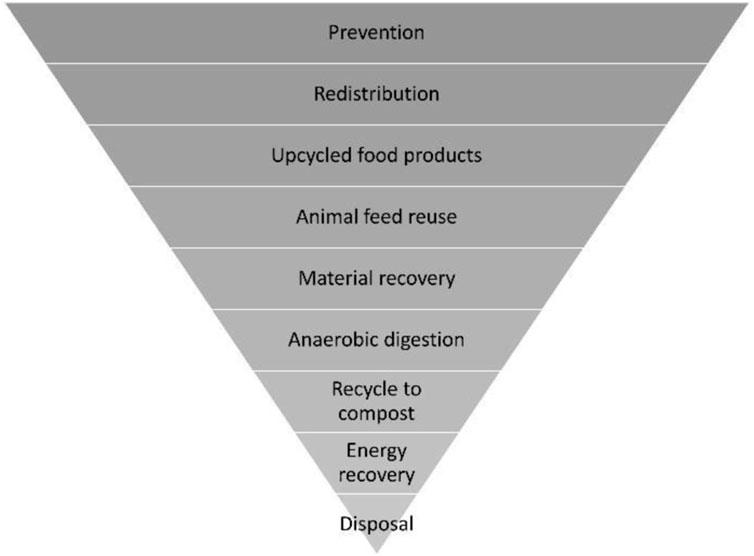

The circular bio-economy is important as fossil products, to a larger extent, need to be replaced by bio-based ones, which means energy, nutrients, plastics, chemicals, and more need to be sourced from bio-based resources. Food production is one of the major contributors to environmental change and has a significant role in transitioning towards a more sustainable society. Recirculation of nutrients is becoming more prominent as the production of mineral fertilizers today is energy intensive and we approach phosphorus depletion (Sherwood, 2020). A focus on side-stream management within food industries can improve nutrient recovery and reduce environmental impact from the food processing company value chain. A large impact derives from agriculture and animal husbandry activities, but there is still environmental work to be done by food processing companies regarding side-streams. Sustainability strategies are important for food processing companies since customers and other stakeholders have high demands (Lozano, 2015). Commonly, packaging, transport, reducing waste, and technology improvements in industrial plants are common measures taken when food processing companies try to reduce their environmental impact. Side-streams always arise in food processing companies, and they can be managed in several ways. In this article, side-streams are defined as all flows/streams not considered main products, thus including by-products, solid waste, and wastewater. The term side-stream is used as it gives the organic flow more value compared to calling it waste flow and is also used by practitioners (Adven, 2022; Metsä Group, n.d.2022). Value is used in this article and means benefits related to economic, environmental, societal, or business-related impacts of the side-stream management of the companies. When food processing companies manage their side-streams, they can be guided by the food waste hierarchy, following the steps of prevention, re-use, recycle, recovery, and disposal (Papargyropoulou et al., 2014), with the recent addition of upcycled food products and specific recirculation alternatives (Figure 1).

FIGURE 1. Food waste hierarchy (based on the study by Moshtaghian et al., 2021).

Valorization of food processing side-streams as animal feed is one of the most common practices in many settings (Otles et al., 2015). There is often potential for more high-value solutions, and side-stream management could provide an economic or environmental advantage (Garcia-Garcia et al., 2019). Legalization regarding food waste is improving, but there are still issues; for example, processed waste can be non-classified for human consumption, and thus, further development is impossible (Garske et al., 2020). The scientific literature regarding side-stream management in food industries focuses, to a large extent, on high-value products to be extracted from different food waste streams (c.f. Pfaltzgraff et al., 2013; Ravelli and Samorì, 2021), or a waste biorefinery approach (c.f. Alibardi et al., 2020; Chen et al., 2018; Dahiya et al., 2018), or the life-cycle impact of different treatment methods (c.f. Fei et al., 2022; Kobayashi et al., 2023; Xu et al., 2015). Yet, more research is needed regarding the role side-streams have in food processing companies’ sustainability strategy, business models, and if side-streams should acquire more attention than before. There are identified research gaps by Klitkou et al. (2019) and Salvador et al. (2021) regarding lack of business models for valorization of side-streams and the circular bio-economy in general. Therefore, this paper investigates if, and how, side-stream management is integrated into sustainability strategies among food processing companies and how they organize their management and use of side-streams. Sustainability strategies reflect long-term ideas for how the food processing company can reduce its environmental impact. The institutions and the food processing companies can work together to develop commercially viable processes for side-stream management according to Khedkar and Singh (2018). When it comes to the management literature, Magnusson et al. (2019) developed a framework for recovery of side-streams in manufacturing firms, and they identified four main alternatives for recovery and use of side-streams based on internal or external activities. Their article is like a bridge between this one and the field of industrial ecology and business strategy. There is more to learn from food processing industries regarding their perspective on side-streams and circularity and, especially, the side-streams seen as lower valued. Using side-streams as animal feed or for biogas solutions can mitigate global warming and recover energy and fertilizer (Hagman et al., 2020), which contributes to the development of more environmentally sustainable handling of different food side-streams and keeps valuable resources in a circular system (Scherhaufer et al., 2020).

Biogas solutions include anaerobic digestion of organic streams, where biogas is produced and can be used as energy either directly, through a generator, or upgraded to fuel; in addition, a nutrient and fiber-rich digestate is produced in biogas plants, which can be used as biofertilizer (Wellinger et al., 2013), as biochar, or dried as an incineration fuel. Their other advantage is that they involve the return of nutrients to food-producing fields. There is an important role for biogas solutions to play in the transition into more bio-based synergies between industries (Medkova et al., 2019; Vanhamäki et al., 2020), not only as a bio-refining concept but also as a hub for surrounding industries (Lybæk and Kjær, 2021) and for improved nutrient recovery from digested streams (Vaneeckhaute et al., 2017). Biogas solutions are multifunctional (Lindfors et al., 2020) and versatile (Mountraki et al., 2016). This means they can have several roles in a bio-based cluster, such as waste management, wastewater management, energy provision, or fertilizer production. Biogas solutions can handle a range of diverse types of substrates and are useful even when the quality of the residuals is not high enough for feed or when materials are bulky and expensive to transport (Pereira et al., 2013). To use biogas solutions at the end of a cascading sequence, a company may improve the value of its raw material while generating products useful for its suppliers and energy for its production facility (Fagerström et al., 2018).

This article aims to investigate how food processing companies manage and consider their side-streams with a special focus on biogas solutions as a management alternative. This topic will be studied in the light of sustainable strategies of the companies.

The structure of the article is as follows: Section 2 provides a description of methods used; Section 3 provides the results and analysis of how the side-stream management is organized, connected to strategy, and motivated; and Section 4 provides a discussion including circularity of side-stream management and the role of biogas solutions.

2 Methods

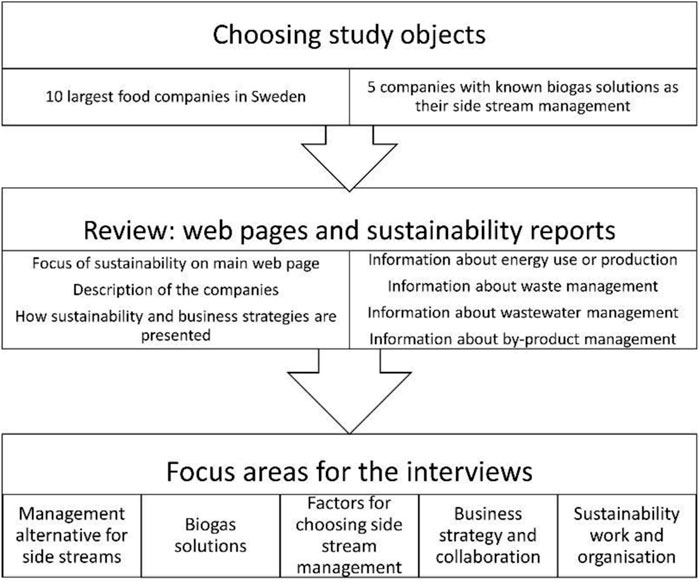

This article is based on a qualitative research approach (Bryman, 2016, chap. 17). Fifteen identified study objects from the Swedish food processing industry were asked to participate in this study, and ten of these were identified as the largest (based on turnover), according to largestcompanies.se January 2021 and, thus, covering a large part of the Swedish food market. In Sweden, the presence of large and centralized private or cooperative food processing actors is common. The remaining five were chosen as they had established biogas solutions as a side-stream management; three of these were identified by Google search using the keywords (“food processing company” +biogas + Sweden), and two were known from previous studies by the author. The study objects are chosen to assure that biogas solutions could be focused upon in the cases.

2.1 Data collection

A desktop study was performed, focusing on the study objects’ websites and sustainability reports. In Figure 2, the method is illustrated.

FIGURE 2. Method description regarding study objects chosen, desktop review performed, and focus areas for interviews.

Following the desktop study, interviews were conducted during 2021. Within the companies, the aim was to contact sustainability managers who would have a good perspective of the company’s organization and sustainability ambition together with the business strategies, while still having some knowledge of what happens to the side-streams. In some cases, if the sustainability manager could not be reached, then perspectives of employees working with side-streams were then used together with the information from the sustainability reports. Among the 15 contacted companies, 12 chose to respond to an interview, and the results are based on these 12 companies’ responses and background information. The three non-participating companies belonged to sectors included among the other companies. The interviews were semi-structured, and after the respondents (Table 1) had introduced themselves with background and work descriptions, attention was on five focus areas: management alternatives for side-streams, biogas solutions, factors for choosing side-stream management, business strategy and collaboration, and sustainability work and organization.

TABLE 1. Side-streams and side-stream management for all interviewed cases are presented. In addition, information about the respondents is also included.

The first results show the type of side-streams (defined by the companies themselves) and what they are used for. These results are followed by how the actors consider their side-stream management.

2.2 Data analysis

The first part of the analysis, reported in Section 3.2, uses the informant’s description of their business and collaboration strategies and the sustainability reports to analyze the company’s sustainability ambitions. It looks at the company’s long-term visions, plans for circularity, and role of the environmental issues.

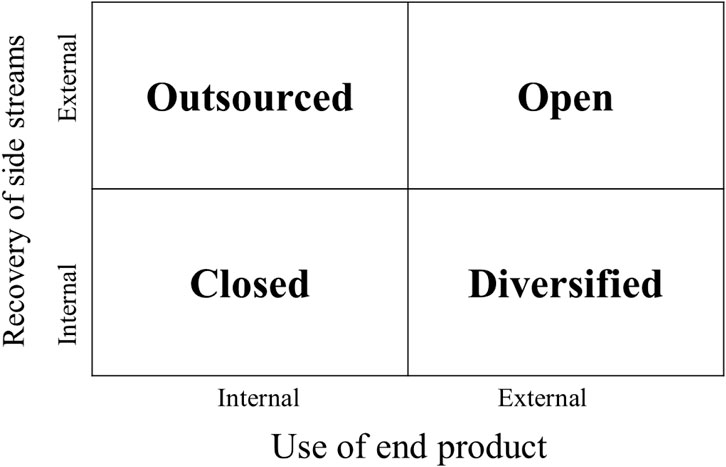

The second part of the analysis is based on the side-stream options found at the companies, and a framework given by Magnusson et al. (2019) is applied. The framework originates from manufacturing firms and how they manage their recovered resources. They perform recovery either internally or by external actors, and the product can then be used internally or sold externally. In this paper, it is reorganized according to Figure 3. The side-stream management mapped through the interviews is categorized into this framework, and the result shows the connection between a company’s side-stream management and way of including external actors.

FIGURE 3. Analysis method restructured from the work of Magnusson et al. (2019).

Another analysis of the data identifies a hierarchy among the side-stream management alternatives based on responses from several actors who ranked side-stream management options in the interviews. Because of biogas solutions’ nutrient recovery and potential for circularity within the value chain, there are specific discussions regarding this as a side-stream management option and the connections to a company’s sustainability strategy.

3 Results and analysis

3.1 Descriptions of the side-stream management among the studied cases

The companies participating in this study represent several types of food processing companies. In Table 1, the specific side-streams and types of management alternatives are listed. There is a range of various kinds of side-streams connected to dairies, slaughterhouses, vegetable processing, and fats, which are often used as food components, feed, or biogas solutions. Focus has been on the flows, which the companies themselves see as side-streams; for example, slaughterhouses have several products that could be considered side-streams but are commonly used as products and are, therefore, not included.

The results are based on activities in Sweden. Actors with activities in other countries mention that the circularity has not been prioritized, partly because landfilling is a cheap alternative, but food donations are also more common in these countries.

3.2 Results and analysis of sustainability and business strategies within the companies

The business strategy is to produce food and generate returns for shareholders. Side-streams are not prioritized among most food processing companies. Their sustainability strategies focus on reducing CO2 emissions by using fossil-free fuels and energy sources, energy efficiency measures, and smarter packaging. The main driver for this is the increased pressure from consumers and stakeholders. The studied companies have worked for a few years on improving their own climate emissions, and, recently, several of them have set up science-based targets, which are in line with the Paris 2015 agreement (Science Based Targets, 2022). They address the full value chain’s sustainability impact, and the results show that approximately 90% of the value chain’s impact is in the food-producing stage according to several respondents. The studied companies identify that collaboration with upstream partners or reducing food losses are other keys to improve the value chain’s sustainability. Other aspects discussed in company groups with activities outside Sweden are water quality and security. Upcycling side-streams into food products is also becoming more interesting; because some of the actors in this category have a wider range of products, the development potential for new food from side-streams is easier. Secondary products, which earlier could be sold at the local industrial plant, can now be sold as specific products, marketed to improve resource efficiency, on the regular market.

The author can identify two ambition levels regarding the companies’ sustainability strategies, based on information from interviews and sustainability reports. Some actors work with sustainability because customer demand has increased, but their main aim is to generate more money for their shareholders. Others invest large amounts of money in improving circularity and product development, as they see a need to work with this question for the environment’s sake, although economic results are still important.

When the companies in the first category discuss sustainability strategies for side-streams, economical, climate-related, high-value, and organizational aspects are in focus. The economical aspect is prioritized for these companies, and sustainable action is becoming more justified with more economic reasoning than a decade ago. Most actors are reactive to the stakeholders and changes in society demanding sustainable products and improved animal welfare. One company has not had high stakeholder and customer demands and noticed that its sustainability work lagged behind. Most of the companies find sustainability important and high on their agenda, yet they connect reduced climate impact with the possibility to reduce costs or market themselves. Circularity is not always an integrated strategy for these companies, but they are moving in that direction. The organization for sustainability in these companies differs; some have a group of people, others have sustainability managers who are putting the responsibility on plant managers, and others try to integrate sustainability in everyday work.

When the companies in the second category talk about strategies for side-streams, they work proactively to ensure sustainable operation in the future. Sustainable investments can be more expensive, as it becomes a competitive advantage. One company uses two investment budgets, one for long-term projects with a sustainability focus allowing a pay-off of 10–15 years and a regular one. Another company, family-owned, allows longer pay-off times compared to regular projects with only 3–5 years pay-off. Several actors in this category point out that customers and partners need to accept sustainable products cost more because they require higher investments and work intensity. The companies are working with this aim to integrate sustainability into the whole company and educate their employees on how to think and act. They monitor their side-streams to be able to identify further valorization alternatives for the streams. They mention that stubbornness is important to see change, as sustainability actions can be slow to get through. Most of these companies market their solutions very little; they are mentioned on websites and in sustainability reports, but some just see it as a natural way to work and have not considered it a unique selling point.

3.3 Analysis of side-stream management among food processing companies

The prioritization among interviewed actors is to reduce side-streams and ensure that fewer side-streams are generated. After that, it is preferred to either partner with external companies or invest in technology themselves regarding high-value components, like xylitol, or new food products. New food products could include sales of secondary products or side-streams refined into new products. The will to invest in innovative technology for side-streams is low, and most actors prefer if external actors want to buy the side-streams for further valorization; this is often true for lower-valued solutions. An example was a company with beetroot juice, which could be further refined to coloring additives, but the food processing company did not want the investment and no external actor was found. The choice of management for their side-streams can depend on the communication value of the solution. High-value components or new food products can be good to communicate or as feed, and biogas solutions can be communicated as local and circular options. There are other reasons why an option is chosen; one company mentioned that a side-stream they wanted to use as feed required quality analysis to be approved, and as soon as it was approved, they were not eager to change management alternatives as they had paid for the tests to use it as feed. The most important factor for the food processing companies is that side-streams do not end up in incinerators or landfills.

The management alternative can come with a risk as well. The demand for slaughter wastes as feed for the fur industry disappeared overnight when Denmark killed all their ferrets during the COVID-19 pandemic. It was a side-stream market in decline, so options like salmon feed and biogas production had been identified, but it was problematic to change with such short notice. It is common for food processing companies to be aware of and follow the food waste hierarchy. Figure 4 shows how food processing companies in general have chosen to recover their side-streams and how they use the recovered product. A company can appear in several squares, as they may have several side-streams and management alternatives.

FIGURE 4. This figure illustrates how the studied companies manage their side-streams in relation to external or internal actors for the recovery of side-streams and use of recovered products.

Open solutions are applied in all case companies on one or several side-streams. This option is driven by economic benefits, focusing on core business and a smooth solution. The food processing companies claim that those best suited to valorization should ensure it. Sustainability strategies have a role in open cases where higher valorization by an external actor is preferred. Business-related advantages with open solutions are that uncertainties are put to the external actors, as they make the necessary investments and manage the sales and marketing, and the food processing company can focus on ensuring that the operation runs smoothly with their external partners and that they stay in business (Magnusson et al., 2019). For food processing companies with large (often liquid) flows, alternatives which can manage the full volume are preferred to have long-term contracts with, such as biogas solutions. The open strategy depends on potential products produced from the side-stream, how much additional processing is needed, and how long transportation is required to valorize the side-stream. In open systems, biogas solutions are useful in local settings with short transportation or distribution through pipes. Depending on the distance, the income from biogas solutions is low for the food processing company; instead, values from regional development, reduced transportation, nutrient recirculation, and sustainability strategies are arguments for biogas solutions in open systems. The food processing company can sign long-term contracts with one side-stream actor who manages the side-streams in different parts of the country, and they can then get invoices and data directly from that company, which facilitates the side-stream management that can require significant paperwork for the food processing company due to reporting demands. The side-streams are monitored monthly and followed up on to see where further improvements are possible.

Outsourcing among all the studied cases includes a biogas component. There is an internal energy demand in the production plant which can be replaced by biogas, but they do not have the capacity to produce the biogas themselves, so they deliver side-streams for biogas production and buy the produced gas. This seems common when there is a local biogas plant, and the food processing company has goals to replace fossil fuels and reduce CO2 emissions. It requires long-term agreements to reduce uncertainty regarding deliveries in these setups as the food processing company is extending its value chain (Magnusson et al., 2019). The food processing industry’s side-stream volumes may be too small to invest in a biogas production facility itself, and so prefer to buy gas from a co-digestion plant. The business value lies in improving sustainability performance by using biogas instead of fossil fuels.

Diversification is chosen by actors who have side-streams through which they recover or upgrade to food products in four cases and oleochemical products in the fifth. In those cases, the upgraded product lies within their business strategy: “to produce high-value food products or fatty products.” They are not moving outside their business idea by refining these products. These companies see a value in their side-streams and integrate them into the business strategy because they become products that are easy to incorporate into the overall business strategy. The sustainability aspect of this alternative is important, as food is a prioritized product for a food processing company, and it reduces the need for other food products. Drivers for these solutions are either economical or part of the sustainability strategy. One company invested in technology to extract a high-value sweetener component, as the economic performance would improve and because the circular economy discourse in society inspired them to develop new products. By diversifying and creating new products from side-streams, new markets may open to the food processing company, but it comes with additional costs for technology, marketing, and potentially sales (Magnusson et al., 2019).

Closed arrangements are applied by companies recovering their own side-streams and are often used for internal energy purposes. These solutions are common in wastewater streams or when flows of by-products are large, and the produced gas has enough value to replace external energy. In four cases, biogas solutions are used as a closed system, and the final alternative is bio-oil for energy. These companies have made the investment to become more self-sufficient in energy. The companies could save money by producing energy from internal waste or wastewater flows and cost reduction is a motive for change (c.f. Van Beers et al., 2007). It was important for some of the actors to produce their own energy and reduce their climate impact. Two of the companies find the circularity of nutrients important, as they either have their own farm to fertilize or collaborate with farmers. Closed systems are useful if the company has internal needs for the recovered products and is willing to invest in technology for recovery (Magnusson et al., 2019).

3.4 Hierarchy of side-stream management

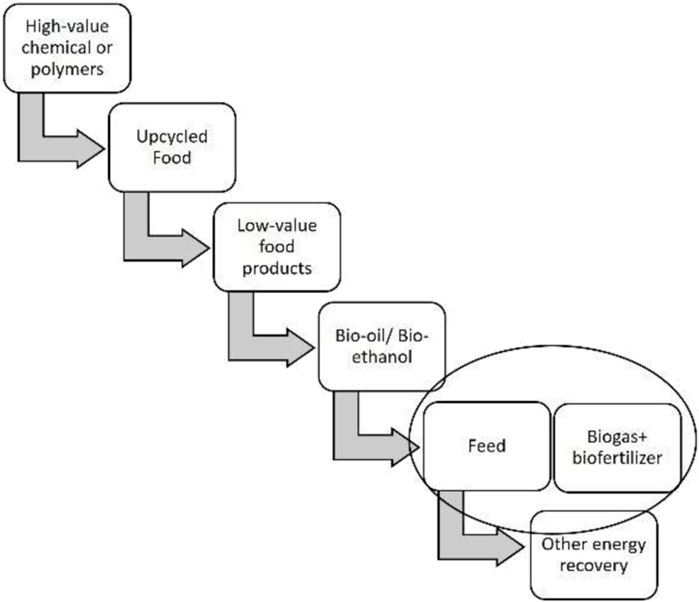

Improving resource efficiency implies that the food industries need to prioritize how to manage their side-streams. Based on the responses from the case studies, a hierarchy within food side-streams can be constructed (Figure 5), which is more specific in the re-use, recycle, and recovery steps in the food waste hierarchy compared to earlier examples (Papargyropoulou et al., 2014; Moshtaghian et al., 2021). It is illustrated as a staircase rather than a pyramid since volumes going into different treatments can vary, and large volumes of low-quality side-streams can be diverted to steps further down the hierarchy. Another difference is that anaerobic digestion is equal to feed, which in other hierarchies is often ranked lower (Papargyropoulou et al., 2014; Moshtaghian et al., 2021). Still, higher-value products should be prioritized, and biogas solutions can often manage side-streams originating from these upcycled products.

FIGURE 5. Hierarchy among side-stream management alternatives ranging from high-value chemicals to food, bioenergy, and feed.

To a large degree, the staircase hierarchy focuses on economic factors; higher-ranked options, for example, pay better. The options that are the hardest to separate among the respondents in this stair-based hierarchy are the feed and biogas alternatives (circled in Figure 3), which are often the main competitors for lower-quality residuals that are not fit for human consumption. Which one of these is chosen is related to the availability of the local actors. Biogas solutions have the advantage of handling larger volumes than most feed customers do. Biogas solutions are chosen instead of feed if the company desires to produce its own energy or when agricultural actors are already collaborating with the food processing company, and the biofertilizer is valuable to them; otherwise, feed is the chosen option.

4 Discussion

4.1 Implementation of sustainable side-stream management

According to the interviews, side-streams did not have a prominent role in business or sustainability strategies among the food companies a decade ago, but with the growing discourse about circular economy, the interest increased, which was also put forward by Kähkönen and Lintukangas (2022). The companies find it attractive to be a part of a circular system instead of a linear one, both from a financial and market perspective. The side-stream management can be inspired by other actors in the same sector, and the Swedish Food Federation is working more actively with improving sustainability among their members (Swedish Food Federation, 2019). One case study, which has been in action for generations, has ambitious sustainability plans to assure the company will survive for many more generations. Ferreira et al. (2021) also suggested that family businesses have more long-term perspectives compared to competitors in their area, indicating higher sustainability ambitions than others. Klein et al. (2022) studied agri-food companies handling potatoes and concluded that the industry needs to reform their business model to become more sustainable and see side-streams as a value rather than a waste, but this transformation is affected by both internal and external factors, and they also identified external partnerships as important in the development. Klein et al. (2022) put the finger on what this article will show: business models need to be thought through to improve sustainability in these value chains and external partners are important to assure a sustainable use of side-streams. Research focusing on business models regarding side-streams in the agri-food sector is not common, but this article can strengthen the results of Klein et al. (2022), as multiple cases show comparable results.

Actors preferring internal recovery of their side-stream often do so when new food products can be produced out of a side-stream. Magnusson et al. (2019) showed that valorizing side-streams internally can be tempting but hard, as it requires investments and comes with a risk. Deciding what kind of products should be produced from the side-stream can be hard; in scientific literature, there are a large number of articles focusing on bioenergy recovery rather than higher-valued physical products according to Jones et al. (2022). The organization around the side-stream management, therefore, needs to be assessed, and Lybæk and Kjær (2021) identified biogas solutions to be an attractive hub for circularity in a region rather than a component at biorefineries to improve circularity. Lybæk and Kjær (2021) demonstrated that agricultural residuals can be managed in a more circular way by extracting high-value products like wax and furfural substrates and that a biogas plant would function as a hub among the refining actors. These actors are typically small but can contribute with simple biorefinery modules in a region. The idea is to combine product development from side-streams but also recovery energy. Business models for circular economy may inspire food processing companies on how to manage their side-streams. Similar to the work of Lybæk and Kjær (2021), an article by Tsvetkova and Gustafsson (2012) points out the modular approach, where actors surrounding biofuel production plants, in their case, support the main actor with distinct functions, creating a bio-based local system that is reliable and persistent. The circular approach is driven by the close collaboration within the value chain, and biogas solutions are useful when the side-streams’ quality is low, and nutrients can be recovered locally according to the work of Feiz et al. (2021). Biomass production, nutrient flows, and energy use are interlinked, and biogas solutions could provide options for improving nutrient recycling as well as allowing for bioenergy production, which does not compete with food production (Koppelmäki et al., 2021).

Partnerships, value creation, and circularity play important roles when choosing internal recovery of side-streams among the studied cases. Partners that manage side-streams are often found locally, and several actors highlight the local circularity as important for their choice. This is in line with the work of Feiz et al. (2021) who identified local development to have a role in bio-based clusters with biogas solutions. While some see their side-stream partners as part of the business strategy, others focus on the economic value where the partners help in valorizing side-streams and food industry companies can focus on their core business. High-value components are investigated to improve circularity and income, and several actors in this study have started to look at biochar from their carbon-rich side-stream. Biochar is a way of improving carbon storage in soils (Lehmann et al., 2011).

The implications of these results show how a more resource efficient management of side-streams will be developed and what arguments are brought forward for different alternatives among practitioners. It can impact what strategies food processing companies will have when they need to find higher-valued uses of their side-streams. The results are useful in places where large food processing companies are common, where similar business strategies are applied, and where the management of bio-based waste is regulated in some way.

4.2 Role of biogas solutions

Food processing companies need to work with the full value chain to ensure sustainable practices; this includes cascading and upcycling between products and energy solutions. Biogas can be a suitable finish in a resource-efficient bio-economy (Hagman et al., 2018). Lyng et al. (2018) observed that biogas solutions are well integrated in a value chain and improve the sustainability performance of the system. In one of the cases studied in this article, a food processing company has close collaboration with the delivering farms; it sees value in delivering biofertilizer back to these farmers, which will reduce the overall environmental impact when replacing mineral fertilizers or reduce costs compared to other organic approved fertilizers. Even if side-streams should be avoided and high-value products prioritized according to Lybæk and Kjær (2021), the role of biogas solutions is to connect the farmers producing the food with the processing companies refining the products, creating a truly circular system thanks to the nutrient recovery (Carey et al., 2016; Vaneeckhaute et al., 2017).

This study shows that a beneficial solution can be used to combine manure-based biogas plants at farms with input from low-value side-streams from the food processing companies, as short transportation distances were preferred among the respondents. The results from Feiz et al. (2021) showed that nutrient recovery improved and transportation was reduced when applying biogas solutions compared to other alternatives, which may be of importance when food industries choose the management option. Other options for biogas solutions are when no higher-valued solutions can be identified, or the high-value extraction results in low-value side-streams, or if alternatives are too costly to perform due to transportation, or if circularity is important and the nutrient recovery is prioritized. Fagerström et al. (2018) suggested that a company may improve the value of its raw material while generating products useful for its suppliers and energy for its production facility through biogas solutions. That is in line with the results from the respondents in this article as well but the diversity of solutions that can potentially be realized from a biogas solution is not considered among most of the companies. Instead, few companies bring up the nutrient and fiber aspect when recovering side-streams. The nutrient question may not be so high on their agenda as climate impact and CO2 emissions are the priority among most companies and perhaps the nutrient issue is not well known. It is worth noting that composting, a nutrient recovery option, was not mentioned as an alternative among any food processing company in the study. The nutrient issue has become more pressing lately and will most likely be considered more in the future. The nutrient aspect of sustainable side-stream management in food processing companies should be further explored.

Biogas solutions have long been viewed as an energy recovery step that is often far down in the food waste hierarchies by Moshtaghian et al. (2021) and Papargyropoulou et al. (2014). This article shows that biogas solutions have a natural role in the food processing company’s side-stream management because of the additional possibility to recover nutrients and its versatile nature. When food waste cannot be avoided, Stone et al. (2019) identified further valorization to increase a company’s resilience.

With these results, the biogas sector can better understand what customers are looking for when comparing, for example, feed options and biogas options. Transportation distance, payment, and connection to farmers in need of digestate are reasons to choose biogas solutions over feed options. This can help them in choosing market strategies and their customer relations.

5 Conclusion

This article focuses on the strategic role of side-stream management in food processing industries. The interviewed Swedish companies are good at valorizing their side-streams, but there is potential to create more value. If external actors are available, food processing companies prefer external management rather than investing in innovative technology themselves, developing into a biorefinery. With this knowledge, local networks to valorize food processing side-streams can be developed.

The results from this article add to the existing literature an insight that side-stream management can be organized in several ways and that food processing companies often prefer external actors to manage their side-streams, which is in line with earlier research. However, more information on the characteristics of partnerships and interactions is needed to make more conclusive statements.

Companies with a circular approach in their sustainability strategy regarding their side-stream management seem to be more active in identifying new alternatives and accepting long-term investments. Embracing the side-stream management has the potential to improve sustainability, resource efficiency, and the value for the company.

When high-value products and new food products are extracted from the side-streams, the remaining fraction is often suited for a biogas solution to recover its energy and nutrients. If food processing companies work more within their own value chain, biogas solutions can improve sustainability performance for the agricultural actors in the value chain by using digestate as fertilizer to a higher degree.

In future studies, there can be a focus on how these systems will become more resource efficient either through developing an internal biorefinery processer or using external actors to continue processing the materials, how different alternatives can be facilitated, and what factors are relevant for either method to develop (Budzianowski, 2017; Venkata Mohan et al., 2019).

Data availability statement

The original contributions presented in the study are included in the article/Supplementary Material; further inquiries can be directed to the corresponding author.

Author contributions

The author confirms being the sole contributor of this work and has approved it for publication.

Acknowledgments

The author wants to thank her supervisors Mats Eklund and Niclas Svensson for the support in the work of this article. She is grateful for the funding received for this research through the Biogas Research Center by the Swedish Energy Agency, companies, and municipalities involved. She also wants to thank the reviewers who helped to improve this article.

Conflict of interest

The author declares that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors, and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Adven, (2022). Material and side stream recovery and processing. Available at: https://adven.com/solutions-industries/material-and-side-stream-recovery-and-processing/([WWW Document]. Adven. URL accessed 15 2, 22).

Alibardi, L., Astrup, T. F., Asunis, F., Clarke, W. P., De Gioannis, G., Dessì, P., et al. (2020). Organic waste biorefineries: Looking towards implementation. Waste Manag. 114, 274–286. doi:10.1016/j.wasman.2020.07.010

Budzianowski, W. M. (2017). High-value low-volume bioproducts coupled to bioenergies with potential to enhance business development of sustainable biorefineries. Renew. Sustain. Energy Rev. 70, 793–804. doi:10.1016/j.rser.2016.11.260

Carey, D. E., Yang, Y., McNamara, P. J., and Mayer, B. K. (2016). Recovery of agricultural nutrients from biorefineries. Bioresour. Technol. 215, 186–198. doi:10.1016/j.biortech.2016.02.093

Chen, Y., Ho, S.-H., Nagarajan, D., Ren, N., and Chang, J.-S. (2018). Waste biorefineries — Integrating anaerobic digestion and microalgae cultivation for bioenergy production. Curr. Opin. Biotechnol. Energy Biotechnol. • Environ. Biotechnol. 50, 101–110. doi:10.1016/j.copbio.2017.11.017

Dahiya, S., Kumar, A. N., Shanthi Sravan, J., Chatterjee, S., Sarkar, O., and Mohan, S. V. (2018). Food waste biorefinery: Sustainable strategy for circular bioeconomy. Bioconversion Food Wastes 248, 2–12. doi:10.1016/j.biortech.2017.07.176

Fagerström, A., and Murphy, J. D. (2018). “IEA bioenergy task 37,” in The role of anaerobic digestion and biogas in the circular economy (Paris, France: IEA Bioenergy Programme).

Fei, X., Jia, W., Chen, T., and Ling, Y. (2022). Life cycle assessment of food waste anaerobic digestion with hydrothermal and ionizing radiation pretreatment. J. Clean. Prod. 338, 130611. doi:10.1016/j.jclepro.2022.130611

Feiz, R., Larsson, M., Ekstrand, E.-M., Hagman, L., Ometto, F., and Tonderski, K. (2021). The role of biogas solutions for enhanced nutrient recovery in biobased industries—Three case studies from different industrial sectors. Resour. Conservation Recycl. 175, 105897. doi:10.1016/j.resconrec.2021.105897

Ferreira, J. J., Fernandes, C. I., Schiavone, F., and Mahto, R. V. (2021). Sustainability in family business – a bibliometric study and a research agenda. Technol. Forecast. Soc. Change 173, 121077. doi:10.1016/j.techfore.2021.121077

Garcia-Garcia, G., Stone, J., and Rahimifard, S. (2019). Opportunities for waste valorisation in the food industry – a case study with four UK food manufacturers. J. Clean. Prod. 211, 1339–1356. doi:10.1016/j.jclepro.2018.11.269

Garske, B., Heyl, K., Ekardt, F., Weber, L. M., and Gradzka, W. (2020). Challenges of food waste governance: An assessment of European legislation on food waste and recommendations for improvement by economic instruments. Land 9, 231. doi:10.3390/land9070231

Hagman, L., Blumenthal, A., Eklund, M., and Svensson, N. (2018). The role of biogas solutions in sustainable biorefineries. J. Clean. Prod. 172, 3982–3989. doi:10.1016/j.jclepro.2017.03.180

Hagman, L., Eklund, M., and Svensson, N. (2020). Assessment of by-product valorisation in a Swedish wheat-based biorefinery. Waste Biomass Valor 11, 3567–3577. doi:10.1007/s12649-019-00667-0

Jones, R. E., Speight, R. E., Blinco, J. L., and O’Hara, I. M. (2022). Biorefining within food loss and waste frameworks: A review. Renew. Sustain. Energy Rev. 154, 111781. doi:10.1016/j.rser.2021.111781

Kähkönen, A.-K., and Lintukangas, K. (2022). Towards sustainable supply strategy in the food industry: The case of Finland. Br. Food J. 124, 143–164. doi:10.1108/BFJ-03-2021-0257

Khedkar, R., and Singh, K. (2018). “Food industry waste: A panacea or pollution hazard?,” in Paradigms in pollution prevention, SpringerBriefs in environmental science. Editor T. Jindal (Berlin, Germany: Springer International Publishing), 35–47.

Klein, O., Nier, S., and Tamásy, C. (2022). Circular agri-food economies: Business models and practices in the potato industry. Sustain Sci. 17, 2237–2252. doi:10.1007/s11625-022-01106-1

A. Klitkou, A. M. Fevolden, and M. Capasso (Editors) (2019). From waste to ValueValorisation pathways for organic waste streams in circular bioeconomies (London, United Kingdom: Routledge).

Kobayashi, Y., El-Wali, M., Guðmundsson, H., Guðmundsdóttir, E. E., Friðjónsson, Ó. H., Karlsson, E. N., et al. (2023). Life-cycle assessment of yeast-based single-cell protein production with oat processing side-stream. Sci. Total Environ. 873, 162318. doi:10.1016/j.scitotenv.2023.162318

Koppelmäki, K., Helenius, J., and Schulte, R. P. O. (2021). Nested circularity in food systems: A nordic case study on connecting biomass, nutrient and energy flows from field scale to continent. Resour. Conservation Recycl. 164, 105218. doi:10.1016/j.resconrec.2020.105218

Lehmann, J., Rillig, M. C., Thies, J., Masiello, C. A., Hockaday, W. C., and Crowley, D. (2011). Biochar effects on soil biota - a review. Soil Biol. Biochem. 43, 1812–1836. doi:10.1016/j.soilbio.2011.04.022

Lindfors, A., Gustafsson, M., Anderberg, S., Eklund, M., and Mirata, M. (2020). Developing biogas systems in Norrköping, Sweden: An industrial symbiosis intervention. J. Clean. Prod. 277, 122822. doi:10.1016/j.jclepro.2020.122822

Lozano, R. (2015). A holistic perspective on corporate sustainability drivers. Corp. Soc. Responsib. Environ. Manag. 22, 32–44. doi:10.1002/csr.1325

Lybæk, R., and Kjær, T. (2021). Biogas technology as an “engine” for facilitating circular bio-economy in Denmark—the case of lolland & falster municipalities within region zealand. Front. Energy Res. 9. doi:10.3389/fenrg.2021.695685

Lyng, K.-A., Stensgård, A. E., Hanssen, O. J., and Modahl, I. S. (2018). Relation between greenhouse gas emissions and economic profit for different configurations of biogas value chains: A case study on different levels of sector integration. J. Clean. Prod. 182, 737–745. doi:10.1016/j.jclepro.2018.02.126

Magnusson, T., Andersson, H., and Ottosson, M. (2019). Industrial ecology and the boundaries of the manufacturing firm. J. Industrial Ecol. 23, 1211–1225. doi:10.1111/jiec.12864

Medkova, K., Vanhamäki, S., and Snell, J. (2019). Bio-based circular economy action plan sets the future steps in päijät-häme. Lille, France: BIOREGIO project,Interreg Europe.

Metsä Group, n. d. (2022). From side streams to new products. Available at: https://www.metsagroup.com/en/media/Pages/Case-From-side-streams-to-new-products.aspx ([WWW Document] URL accessed 10 2, 22).

Moshtaghian, H., Bolton, K., and Rousta, K. (2021). Challenges for upcycled foods: Definition, inclusion in the food waste management hierarchy and public acceptability. Foods 10, 2874. doi:10.3390/foods10112874

Mountraki, A., Tsakalova, M., Panteli, A., Papoutsi, A. I., and Kokossis, A. C. (2016). Integrated waste management in multiproduct biorefineries: Systems optimization and analysis of a real-life industrial plant. Industrial Eng. Chem. Res. 55, 3478–3492. doi:10.1021/acs.iecr.5b03431

Otles, S., Despoudi, S., Bucatariu, C., and Kartal, C. (2015). “Chapter 1 - food waste management, valorization, and sustainability in the food industry,” in Food waste recovery. Editor C. M. Galanakis (San Diego, United States: Academic Press), 3–23.

Papargyropoulou, E., Lozano, R., Steinberger, K. J., Wright, N., and Ujang, Z. B. (2014). The food waste hierarchy as a framework for the management of food surplus and food waste. J. Clean. Prod. 76, 106–115. doi:10.1016/j.jclepro.2014.04.020

Pereira, C. P. P., Slingerland, M. A., Lier, J. B., and Rabbinge, R. (2013). “Anaerobic digestion as a key technology for biomass valorization: Contribution to the energy balance of biofuel chains,” in The biogas handbook: Science, production and applications (Sawston, United Kingdom: Woodhead Publishing), 166–188.

Pfaltzgraff, L. A., Bruyn, M. D., Cooper, E. C., Budarin, V., and Clark, J. H. (2013). Food waste biomass: A resource for high-value chemicals. Green Chem. 15, 307–314. doi:10.1039/C2GC36978H

D. Ravelli, and C. Samorì (Editors) (2021). Biomass valorization: Sustainable methods for the production of chemicals (Weinheim, Germany: Wiley VCH).

Salvador, R., Puglieri, F. N., Halog, A., Andrade, F. G. D., Piekarski, C. M., and De Francisco, A. C. (2021). Key aspects for designing business models for a circular bioeconomy. J. Clean. Prod. 278, 124341. doi:10.1016/j.jclepro.2020.124341

Scherhaufer, S., Davis, J., Metcalfe, P., Gollnow, S., Colin, F., De Menna, F., et al. (2020). Environmental assessment of the valorisation and recycling of selected food production side flows. Resour. Conservation Recycl. 161, 104921. doi:10.1016/j.resconrec.2020.104921

Science Based Targets, (2022). Ambitious corporate climate action. Available at: https://sciencebasedtargets.org/([WWW Document]. Science Based Targets URL accessed 30 6, 22).

Sherwood, J. (2020). The significance of biomass in a circular economy. Bioresour. Technol. 300, 122755. doi:10.1016/j.biortech.2020.122755

Stone, J., Garcia-Garcia, G., and Rahimifard, S. (2019). Development of a pragmatic framework to help food and drink manufacturers select the most sustainable food waste valorisation strategy. J. Environ. Manag. 247, 425–438. doi:10.1016/j.jenvman.2019.06.037

Tsvetkova, A., and Gustafsson, M. (2012). Business models for industrial ecosystems: A modular approach. J. Clean. Prod. 29 (30), 246–254. doi:10.1016/j.jclepro.2012.01.017

Van Beers, D., Corder, G., Bossilkov, A., and Van Berkel, R. (2007). Industrial symbiosis in the Australian minerals industry: The cases of Kwinana and Gladstone. J. Industrial Ecol. 11, 55–72. doi:10.1162/jiec.2007.1161

Vaneeckhaute, C., Lebuf, V., Michels, E., Belia, E., Vanrolleghem, P. A., Tack, F. M. G., et al. (2017). Nutrient recovery from digestate: Systematic technology review and product classification. Waste Biomass Valor 8, 21–40. doi:10.1007/s12649-016-9642-x

Vanhamäki, S., Virtanen, M., Luste, S., and Manskinen, K. (2020). Transition towards a circular economy at a regional level: A case study on closing biological loops. Resour. Conservation Recycl. 156, 104716. doi:10.1016/j.resconrec.2020.104716

Venkata Mohan, S., Dahiya, S., Amulya, K., Katakojwala, R., and Vanitha, T. K. (2019). Can circular bioeconomy be fueled by waste biorefineries — a closer look. Bioresour. Technol. Rep. 7, 100277. doi:10.1016/j.biteb.2019.100277

A. Wellinger, J. Murphy, and D. Baxter (Editors) (2013). The biogas handbook: Science, production and applications (Sawston, United Kingdom: Woodhead).

Keywords: nutrients, food industry, side-stream, biogas, management, circularity

Citation: Hagman L (2023) Sustainable side-stream management in Swedish food processing companies using external actors and biogas solutions. Front. Food. Sci. Technol. 3:1073663. doi: 10.3389/frfst.2023.1073663

Received: 18 October 2022; Accepted: 16 May 2023;

Published: 25 May 2023.

Edited by:

Ana Ribeiro, University of Lisbon, PortugalReviewed by:

Manoj Paras, National Institute of Fashion Technology, IndiaLudo Diels, Flemish Institute for Technological Research (VITO), Belgium

Copyright © 2023 Hagman. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Linda Hagman, bGluZGFoYWdtYW4yMDE2QGdtYWlsLmNvbQ==

Linda Hagman

Linda Hagman