- 1Faculty of Drilling Oil and Gas, AGH University of Krakow, Krakow, Poland

- 2Strata Mechanics Research Institute, Polish Academy of Sciences, Krakow, Poland

Threshold pressure is a critical parameter in evaluating the capillary sealing capacity of rocks, especially in reservoir and caprock studies related to CO2 storage and hydrocarbon recovery. In this research, we conducted a comparative analysis of two methods for measuring threshold pressure: the traditional mercury intrusion porosimetry (MIP), which operates under different fluid dynamics, and a new gas-water/brine system (e.g., CO2-water) using novel equipment. The new apparatus employs techniques to directly measure the threshold pressure by monitoring the displacement of water by gas, such as CO2, in core samples. This system is designed to more accurately replicate in-situ subsurface reservoir conditions by accounting for key parameters such as CO2-brine interfacial tension, and pressure. By directly measuring the point at which gas begins to displace water from rock pores, it provides a more realistic assessment of the threshold pressure for CO2 sequestration projects. For example, in the case of Sample 1, the direct measurement under a confining pressure of 15 MPa resulted in a threshold pressure of 0.4 MPa. In contrast, mercury intrusion data converted for CO2 drainage estimated the threshold pressure at only 0.1 MPa. Similarly, for Sample 2, the direct measurement yielded a threshold pressure of 0.24 MPa, while the MIP method indicated a significantly lower threshold of 0.05 MPa. These discrepancies underscore the limitations of mercury intrusion when applied to CO2-water/brine systems. Underestimation of threshold pressure can have significant consequences for the design and safety of CO2 storage projects, as this parameter is essential to assess the sealing efficiency of the caprocks and determine the storage capacity.

1 Introduction

The rise in global warming is related to increased CO2 emissions in the atmosphere (IPCC, 2007). The urgency to mitigate climate change has forced advancements in Carbon Capture and Storage (CCS) technologies, focusing on the geological sequestration of carbon dioxide (CO2) (War and Arnepalli, 2021). This involves injecting CO2 into underground geological formations such as saline aquifers, depleted oil and gas fields, and deep coal seams (Callas et al., 2022). A fundamental aspect of ensuring the effectiveness and safety of these storage methods is understanding the dynamics of capillary pressure, which significantly influences CO2 containment within these geological formations (Hu et al., 2017). Capillary pressure affects the movement of fluids within porous media, determining how CO2 interacts with brine and other fluids present in the formations (Al-Menhali and Krevor, 2016). Understanding these interactions is crucial for predicting the long-term stability of stored CO2 and assessing potential leakage risks, which can undermine the effectiveness of CCS as a climate mitigation strategy (Shojai Kaveh et al., 2016). The importance of capillary threshold pressure in the context of CO2 storage cannot be overstated, as it fundamentally influences the containment and structural integrity of geological storage sites (Song and Zhang, 2013). Capillary threshold pressure is the minimum pressure required to allow the non-wetting phase (CO2 in the case of sequestration) to enter the pore spaces of a caprock, overcoming the capillary forces that favor the wetting phase (typically brine) (Krevor et al., 2015). This parameter is critical in determining the effectiveness of caprock as a seal to prevent the upward migration of stored CO2, thereby ensuring the long-term security of the storage site (Naylor et al., 2011). Understanding and accurately measuring capillary threshold pressure are essential for predicting CO2 storage capacity and containment security (Iglauer, 2017). If the threshold pressure is too low, there is a risk that CO2 could leak through the caprock, compromising the integrity of the storage system and potentially leading to environmental concerns (Ostrowski and Uelker, 2007). Therefore, extensive research is necessary to assess the properties of caprocks and their ability to maintain effective seals under varying geological conditions. On the contrary, a high threshold pressure indicates a robust caprock that can effectively trap CO2 (Tan et al., 2024). There are several methods on how to measure this parameter, most commonly for fast estimation of the capillary threshold pressure mercury intrusion porosimetry (MIP) is used (Lohr and Hackley, 2018) but that does not correspond to the actual valve due to many reservoir paraments most significant being the confining pressure (Boulin et al., 2013), and MIP may not actually represent the core sample in case there are small scale heterogeneities (Brandimarte et al., 2017). Unlike mercury, which is a non-reactive and non-wetting fluid that does not chemically interact with rock surfaces, CO2 exhibits distinctive IFT and wettability traits when it encounters water/brine and rock minerals. While some methodologies include the standard or residual approach which record the brine/water production at the outlet, although some studies use combination of these methods that highlight innovative practices for measuring this pressure and its implications for storage capacity and safety as they introduce a fast and accurate method to measure threshold capillary pressure under representative conditions, which is crucial for realistic assessments of caprock performance (Egermann et al., 2006) but still there is a margin of error that can be the delay in recording the pressure right at the movement when the fluid starts to be displaced. Furthermore, some studies explore how capillary threshold pressure affects the estimation of CO2 column heights in depleted gas fields, which is vital for maximizing storage capacity (Naylor et al., 2011). Moreover, the wettability of the caprock, which can vary significantly under different conditions of pressure, temperature, and salinity, also affects the capillary threshold pressure (Al-Yaseri et al., 2016). Studies also show that changes in wettability can lead to variations in storage capacity and containment security, emphasizing the need for thorough characterization of caprock properties in CO2 sequestration projects (Alkan et al., 2010; Arif et al., 2016). In summary, capillary threshold pressure is a key parameter in ensuring the effectiveness and safety of CO2 geological storage. Accurate measurement and understanding of this pressure, along with caprock wettability, are crucial for designing and operating secure CO2 storage facilities. Thus in this study a similar approach (Zuta et al., 2022) has been adopted but a completely new system is designed and instead of predicting the threshold pressure by the flow at the outlet (offset of water/brine) the pressure is directly recorded which indicates the threshold of the particular sample. We have also performed a comparative analysis of these two methods for determining threshold pressure; the conventional mercury intrusion porosimetry (MIP) using Autopore V 9600 porosimeter, and a newly developed gas-water/brine system using novel instrumentation which directly measures threshold pressure in core samples. The actual intrusion of CO2 displacing water/brine is more realistic than mercury intruding the core sample for storage conditions. By measuring the exact point at which gas starts to displace water from the rock pores, offers a more practical evaluation of threshold pressure, particularly relevant for CO2 sequestration projects. Although mercury intrusion can provide a rough estimation of the threshold pressure, a more accurate assessment requires using techniques that simulate real subsurface conditions, such as the gas-water/brine system.

2 Experimental methodology

2.1 Sample preparation

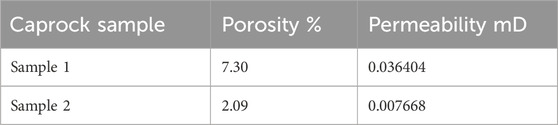

Two core cuttings were procured from a proposed CO2 storage well site in Poland, each measuring 31 mm in length and 22.3 mm in diameter as shown in Figure 1. These dimensions were chosen to ensure compatibility with the high-pressure vessel utilized for capillary threshold measurements. Additionally, reserve samples were extracted from the same core cuts for subsequent analysis using mercury intrusion porosimetry (MIP). The permeability and porosity of the core samples were also measured which is given in Table 1.

2.2 Experimental procedure

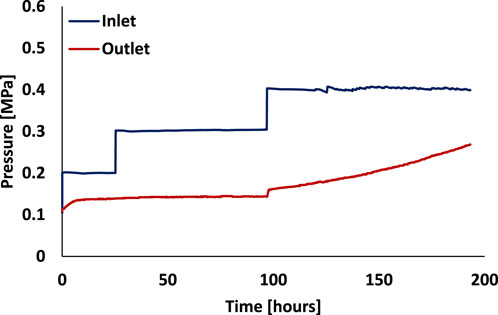

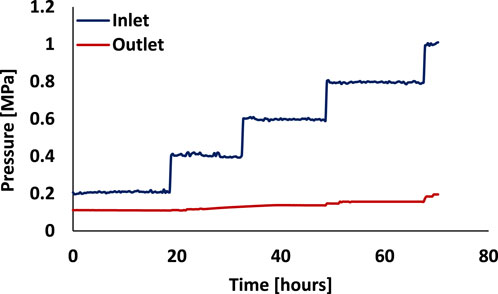

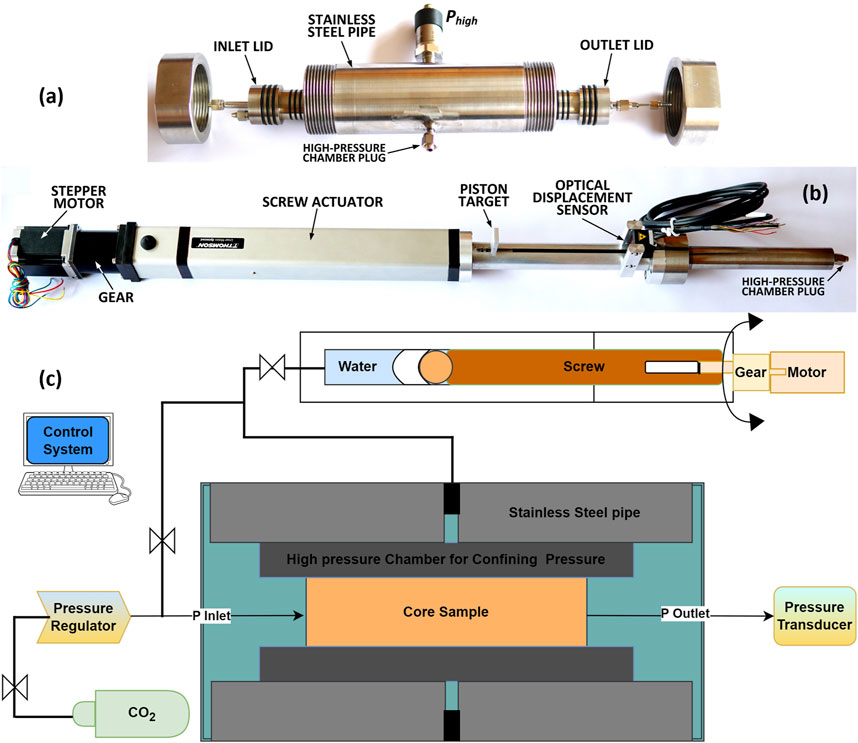

The initial experiments were conducted using the designed apparatus shown in the Figure 2, which consist of high pressure vessel made up of stainless steel pipe where the core is placed and is subjected to a confining pressure using an injection system consist of a piston that is responsible for maintaining the confining pressure using water and also injecting CO2 in the core sample. The inlet and outlet is connected to pressure transducers. The pressure at the inlet and outlet of the sample is measured using pressure transducers S-10 (WIKA) with a measuring range of 1.6 MPa and a measuring error of 0.25% of the full scale. At first the core is saturated with water and a confining pressure is applied that represent in situ conditions, here the pressure was set to 15 MPa. As Threshold pressure can be defined as the minimum pressure required to instigate fluid displacement in the caprock, a low pressure is applied at the inlet and is left for a period of time and the pressure is increased until any change at the outlet is observed signifying its corresponding threshold pressure. The capillary threshold pressure was determined for these core samples. Later the same rock samples were used to evaluate the capillary threshold pressure using a mercury intrusion porosimeter where the mercury intrusion data was scaled to obtain CO2 drainage curves using the equation. The threshold pressure was extracted by drawing a tangent through the drainage curve when the saturation is 100% (Vespo et al., 2024). The values from both these methods have been reported.

Figure 2. Original Capillary threshold pressure measuring equipment; (A) high-pressure chamber; (B) actuator for water/brine, CO2 injection and confining pressure; (C) schematics of the original apparatus.

3 Results

3.1 Original equipment measurements

The graphs in the Figures 3, 4 show the capillary threshold pressure values which are marked in red (the outlet) while the blue line indicates the pressure increments over time (the inlet), until the threshold pressure is reached. For Sample 1 the threshold pressure is recorded between 0.3 MPa and 0.4 MPa, while for Sample 2 it can be seen that there is a slight rise at the outlet pressure at 0.2 MPa even the porosity and permeability of this sample is lower than Sample 1, so we continue to analyze it for more pressure points over time to avoid uncertainty until there was a significant rise at the outlet. As there was a continuous rise at the outlet, so the initial pressure value between 0.2 MPa and 0.3 MPa was regarded as the capillary threshold pressure of this sample.

3.2 Mercury intrusion porosimetry measurements

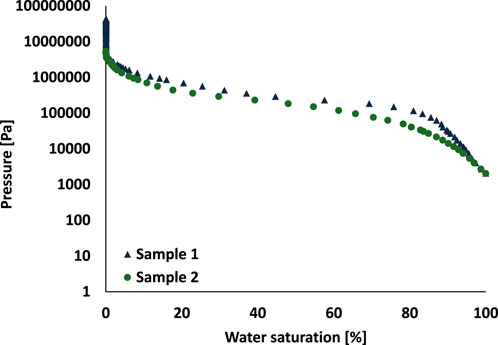

The same rock cuttings of the Sample 1 and Sample 2 were subjected to Mercury intrusion porosimeter as it the quickest way to determine the threshold pressure. Autopore V 9600 which is a mercury intrusion porosimeter was used to measure the cumulative intrusion vs. pressure. This mercury intrusion data was scaled to obtain CO2 drainage curves which represent how water/brine displaces CO2 from the caprock using Equation 1, Where P(CO2) is the CO2 capillary pressure, P(Hg) is the mercury intrusion pressure,

Figure 5 shows the CO2 drainage curves for Sample 1 and 2, the threshold pressure was extracted from these curves using tangent method where a tangent through the drainage curve plateau is extrapolated to pressure axis when the saturation is 100% (Vespo et al., 2024). The tangent method shows the threshold pressure for Sample 1 to be 0.1 MPa, however the direct measured value using the original equipment for this sample was 0.4 MPa under confining pressure of 15 MPa which is 4 times higher than the mercury intrusion value. For Sample 2 the threshold pressure was estimated to be 0.05 MPa while the direct measured value using the original equipment was 0.24 MPa which is 5 times higher than the mercury intrusion value.

4 Conclusion and implications

This study highlights the critical role of capillary threshold pressure in evaluating the sealing capacity of caprocks for CO2 geological storage. Through a comparative analysis of two measurement techniques, traditional mercury intrusion porosimetry (MIP) and a new gas-water system. we demonstrated significant discrepancies in threshold pressure values. The direct measurements obtained using our new apparatus revealed threshold pressures that were substantially higher than those estimated by MIP, indicating that reliance on mercury intrusion data may underestimate the sealing efficiency of caprocks. The results from Sample 1 showed a threshold pressure of 0.4 MPa compared to 0.1 MPa from MIP, while Sample 2 exhibited values of 0.24 MPa versus 0.05 MPa. These findings underscore the limitations of MIP in accurately representing CO2-brine interactions and emphasize the necessity for more reliable measurement methods in CO2 sequestration projects.

The implications of these findings extend beyond mere measurement accuracy; they directly impact the CO2 height column in geological storage scenarios. A higher capillary threshold pressure indicates a more effective seal, which is crucial for preventing the upward migration of CO2. If the threshold pressure is underestimated, there is a risk that CO2 could leak through caprocks, thereby compromising storage integrity and safety. Conversely, accurate assessments suggest that a robust caprock can support a taller CO2 column, thereby maximizing storage capacity. Furthermore, understanding the wettability characteristics of caprocks is essential, as variations can significantly impact capillary threshold pressure and, consequently, the safety and effectiveness of CO2 storage sites. This research not only contributes to the field by providing a more accurate assessment technique but also highlights the need for ongoing studies to refine methodologies for evaluating caprock integrity under realistic subsurface conditions. In conclusion, ensuring robust caprock performance is vital for the long-term security of CO2 storage, and our findings advocate for adopting advanced measurement techniques to enhance the reliability of threshold pressure assessments in future geological storage projects.

Data availability statement

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

Author contributions

AS: Conceptualization, Formal Analysis, Investigation, Writing–original draft, Writing–review and editing. ŁA: Conceptualization, Supervision, Writing–review and editing. MK: Writing–review and editing. KD: Supervision, Writing–review and editing. SN: Supervision, Writing–review and editing.

Funding

The author(s) declare that no financial support was received for the research, authorship, and/or publication of this article.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The author(s) declare that no Generative AI was used in the creation of this manuscript.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Alkan, H., Cinar, Y., and Ülker, E. B. (2010). Impact of capillary pressure, salinity and in situ conditions on CO2 injection into saline aquifers. Transp. Porous Media 84 (3), 799–819. doi:10.1007/s11242-010-9541-8

Al-Menhali, A. S., and Krevor, S. (2016). Capillary trapping of CO2 in oil reservoirs: observations in a mixed-wet carbonate rock. Environ. Sci. Technol. 50 (5), 2727–2734. doi:10.1021/ACS.EST.5B05925

Al-Yaseri, A. Z., Lebedev, M., Barifcani, A., and Iglauer, S. (2016). Receding and advancing (CO 2 + brine + quartz) contact angles as a function of pressure, temperature, surface roughness, salt type and salinity. J. Chem. Thermodyn. 93, 416–423. doi:10.1016/j.jct.2015.07.031

Arif, M., Barifcani, A., Lebedev, M., and Iglauer, S. (2016). Structural trapping capacity of oil-wet caprock as a function of pressure, temperature and salinity. Int. J. Greenh. Gas Control 50, 112–120. doi:10.1016/j.ijggc.2016.04.024

Boulin, P. F., Bretonnier, P., Vassil, V., Samouillet, A., Fleury, M., and Lombard, J. M. (2013). Sealing efficiency of caprocks: experimental investigation of entry pressure measurement methods. Mar. Petroleum Geol. 48, 20–30. doi:10.1016/j.marpetgeo.2013.07.010

Brandimarte, F., Eriksson, M., Moss, A., and Geoconsulting, A. (2017). How to obtain primary drainage capillary pressure curves using NMR T2 distributions in a heterogeneous carbonate reservoir.

Callas, C., Saltzer, S. D., Steve Davis, J., Hashemi, S. S., Kovscek, A. R., Okoroafor, E. R., et al. (2022). Criteria and workflow for selecting depleted hydrocarbon reservoirs for carbon storage. Appl. Energy 324, 119668. doi:10.1016/j.apenergy.2022.119668

Egermann, P., Lombard, J.-M., and Bretonnier, P. (2006). A fast and accurate method to measure threshold capillary pressure of caprocks under representative conditions.

Hu, R., Wan, J., Kim, Y., and Tokunaga, T. K. (2017). Wettability impact on supercritical CO2 capillary trapping: pore-scale visualization and quantification. Water Resour. Res. 53 (8), 6377–6394. doi:10.1002/2017WR020721

Iglauer, S. (2017). CO2-Water-Rock wettability: variability, influencing factors, and implications for CO2 geostorage. Accounts Chem. Res. 50 (5), 1134–1142. doi:10.1021/acs.accounts.6b00602

Krevor, S., Blunt, M. J., Benson, S. M., Pentland, C. H., Reynolds, C., Al-Menhali, A., et al. (2015). Capillary trapping for geologic carbon dioxide storage - from pore scale physics to field scale implications. Int. J. Greenh. Gas Control 40, 221–237. doi:10.1016/j.ijggc.2015.04.006

Lohr, C. D., and Hackley, P. C. (2018). Using mercury injection pressure analyses to estimate sealing capacity of the Tuscaloosa marine shale in Mississippi, USA: implications for carbon dioxide sequestration. Int. J. Greenh. Gas Control 78, 375–387. doi:10.1016/j.ijggc.2018.09.006

Naylor, M., Wilkinson, M., and Haszeldine, R. S. (2011). Calculation of CO2 column heights in depleted gas fields from known pre-production gas column heights. Mar. Petroleum Geol. 28 (5), 1083–1093. doi:10.1016/j.marpetgeo.2010.10.005

Ostrowski, Ł., and Uelker, B. (2007). In-situ determination of gas threshold pressure helps forecasting gas migration through caprock in underground gas storage and CO2 sequestration. Archives Min. Sci. 52 (4), 535–551. doi:10.2118/113509-MS

Shojai Kaveh, N., Barnhoorn, A., and Wolf, K. H. (2016). Wettability evaluation of silty shale caprocks for CO2 storage. Int. J. Greenh. Gas Control 49, 425–435. doi:10.1016/j.ijggc.2016.04.003

Song, J., and Zhang, D. (2013). Comprehensive review of caprock-sealing mechanisms for geologic carbon sequestration. Environ. Sci. Technol. 47 (1), 9–22. doi:10.1021/es301610p

Tan, Y., Li, Q., Xu, L., Onyekwena, C. C., Yu, T., and Xu, L. (2024). Effects of SiO2 nanoparticles on wettability and CO2-brine-rock interactions in carbonate reservoirs: implications for CO2 storage. Energy Fuels 38 (2), 1258–1270. doi:10.1021/acs.energyfuels.3c03356

Vespo, V. S., Messori, A., and Musso, G. (2024). Threshold capillary pressure of caprocks for CO2 storage: numerical insight on the dynamic and residual method. Int. J. Greenh. Gas Control 135, 104135. doi:10.1016/j.ijggc.2024.104135

War, K., and Arnepalli, D. N. (2021). “A review on coupled phenomena in aquifers from the perspective of geological storage of carbon dioxide with ecological significance,” in Building materials for sustainable and ecological environment, 135–149. doi:10.1007/978-981-16-1706-5_8

Zuta, J., Vatne, K. O., Askarhinade, R., Iversen, J. E., Lohne, A., Al-Noth, M. M., et al. (2022). “CO2 caprock threshold pressure measurements for the northern lights reservoir,” in Society of Petroleum Engineers - SPE Norway Subsurface Conference, BERG 2022, Bergen, Norway, April 27, 2022. doi:10.2118/209527-MS

Keywords: capillary threshold pressure, CO2 sequestration, mercury intrusion porosimetry (MIP), caprock integrity, CO2 injection

Citation: Soomro AN, Anioł Ł, Kudasik M, Dąbrowski K and Nagy S (2025) Comparative analysis of capillary threshold pressure measurement techniques: mercury intrusion porosimetry vs. innovative measuring tool for carbon storage. Front. Energy Res. 13:1518424. doi: 10.3389/fenrg.2025.1518424

Received: 29 October 2024; Accepted: 31 January 2025;

Published: 13 February 2025.

Edited by:

Abbas ZeiniJahromi, University of Adelaide, AustraliaReviewed by:

Hu Guo, Sinopec Research Institute of Petroleum Engineering (SRIPE), ChinaBilal Shams, Dawood University of Engineering and Technology, Pakistan

Copyright © 2025 Soomro, Anioł, Kudasik, Dąbrowski and Nagy. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Ahsan Nabi Soomro, c29vbXJvQGFnaC5lZHUucGw=

Ahsan Nabi Soomro

Ahsan Nabi Soomro Łukasz Anioł

Łukasz Anioł Mateusz Kudasik

Mateusz Kudasik Karol Dąbrowski

Karol Dąbrowski Stanisław Nagy

Stanisław Nagy