- SINOPEC Qilu Petrochemical Company, Zibo, China

The petrochemical industry is an important guarantee for the development of people’s lives, and the operational risk assessment method of personnel in the operation of petrochemical enterprises is the most important. Based on a deep learning algorithm, a new method based on the micro-Doppler effect and fuzzy analytic hierarchy process is proposed to evaluate the operational risk of personnel in petrochemical enterprises. The original monitoring image of petrochemical equipment is invoked, and micro-Doppler analysis is performed based on the original image to identify the activity target of the personnel on the job site and generate the activity map of the petrochemical plant operators. Based on the analysis data of the micro-Doppler effect, the fuzzy function and hierarchical analysis method are combined. The fuzzy theory is introduced into the analytic hierarchy process, and the inherent expert evaluation scores are transformed into fuzzy numbers. It makes the expert evaluation of petrochemical plants more accurate in the subsequent coupling and improves the objectivity of the traditional analytic hierarchy process. The scheme proposed in this paper can monitor real-time operation safety and provide a guarantee for the personal safety of field operators. This method plays an important role in improving the safety of petrochemical plants.

1 Introduction

Petrochemical plants mainly produce gasoline, aviation coal, diesel oil, asphalt, polyethylene, polypropylene, polyvinyl chloride, acrylonitrile, butanol, caustic soda, benzene, etc., which are important enterprises for people’s livelihood. The pain point of chemical enterprises’ safety control is that the safety control of direct operations is not in place, especially the control of special operations. Focus on the safety of personnel in high-altitude work, hot work, and restricted space work, and no one should be under the lifting arm during the lifting operation, there are warning fences, guardians are not in place, and pipeline equipment is leaking. With the development of computer technology, “artificial intelligence” technology has become more and more mature. Through the installation and deployment of intelligent security monitoring algorithm models in mobile individual soldier equipment and edge computing equipment, real-time analysis and early warning are realized on the job site, and cloud-edge collaborative management platforms with visual perception, intelligent identification, and hierarchical alarm are established. Intelligent visual analysis is integrated into the job scene industry. To “monitor violations, identify risks, eliminate hidden dangers, and eliminate accidents” as the main line, give full play to the role of the existing security video surveillance system to achieve the goal of improving the level of enterprise security control (Yang et al., 2024).

The importance of the operation safety of petrochemical workers can not be ignored, it is directly related to the production safety of enterprises, the life and health of employees environmental protection, and other aspects. There are high temperature, high pressure, inflammable and explosive, toxic and harmful risk factors in the petrochemical industry, and the operation safety of employees in the production process directly determines whether they are in a safe environment. Strict compliance with operating procedures and the proper use of protective equipment can significantly reduce the probability of accidents, thereby protecting employees from injury. Employee operation safety is the basis of the stable operation of enterprises. Once a safety accident occurs, it will not only lead to equipment damage, and production interruption but also may trigger a chain reaction, affecting the entire production process. Safety accidents bring huge economic losses, including equipment maintenance, production loss, compensation costs, etc. To ensure the safety of employees is to reduce these unnecessary economic losses. It is particularly important to strengthen the monitoring and evaluation of the operation safety behavior of employees in petrochemical plants.

Through artificial intelligence technology, supervision covers construction scenes such as hot operation, lifting operation, restricted space operation, high altitude operation, general operation, high-risk equipment, etc., to prevent safety accidents caused by unsafe behavior of personnel and unsafe state of objects. Improve the compliance and controllability of on-site construction personnel’s operations, strengthen the internal and external linkage warning mechanism, reduce the risk of accidents, and improve the efficiency of safety supervision business management; Standardize the assessment management process and improve the management ability. The critical temperature of human injury in the leakage fire of a petrochemical plant is 115°C. 10 s and after the high-temperature smoke rises and expands, it will cause serious life safety to employees. The need for corresponding personnel operations is to be technical.

Human posture recognition is essentially an object detection and recognition technology. The common human posture recognition methods are based on Fourier transform (FFT), time-frequency analysis (TDBA), and other methods, but these methods have their limitations in practical applications, such as noise interference, large data, and recognition accuracy is not high. A new method of human posture recognition based on the micro-Doppler effect is proposed. By analyzing the distribution characteristics of the micro-Doppler effect on time series, the eigenvector of the micro-Doppler effect is extracted, and the human posture recognition model is established based on the eigenvector. The experimental results show that this method can improve the accuracy of human posture recognition to a certain extent. “Micro-doppler effect” generally refers to the micro-doppler effect caused by the micro-motion of the target, that is, the unique Doppler spectrum form displayed by the micro-motion target in the echo. If the target’s non-uniform motion makes its Doppler frequency shows time-varying, fuzzy hierarchical analysis (FAHP) and computational process analytic Hierarchy Process (AHP) is a qualitative and quantitative combination of systematic analysis methods proposed by T.L. Saaty, an American operations research professor in 1970s. In this paper, “eigenvector” refers to the eigenvalue of the target displayed by micro-Doppler analysis in data acquisition (Nguyen et al., 2024; Lu et al., 2023).

Referring to the method mentioned above, The status identification of workers in petrochemical plants is very important for the overall safety status of petrochemical plants. The existing system risk status assessment methods are mainly analytic hierarchy process (AHP), which has different application methods for different system assessment, Article 4 is the radar signal micro-Doppler effect pedestrian recognition based on machine learning and multi-objective optimization (Severino et al., 2019); Article 5 is the micro-ultra-Doppler feature extraction based on continuous wave radar (Rani et al., 2021). Article 6 analyzes hierarchical network decisions based on fuzzy integral (Jung-Hsien, 1999), Article 7 analyzes and designs the hierarchical fuzzy system (Wang, 1999), article 8 analyzes the hierarchical clustering problem and fuzzy proximity relationship in particle space (Tang and Zhu, 2013), and Article 9 analyzes groundwater hydrogeochemical analysis based on fuzzy C-means clustering method (Rahbar et al., 2020). Article 10 Fingerprint identification of propolis ecosystem based on hierarchical fuzzy clustering and TLC pattern analysis (Sarbu and Mot, 2011); Article 11 Analysis of hierarchical control scheme of microgrid signal stability based on complementary loop and fuzzy controller (Baghaee et al., 2017); Article 12 Construction and analysis of performance evaluation index system of Chinese small and medium-sized enterprises based on fuzzy hierarchical analysis model (Mengning and Perez Estebanez, 2022); Article 13: Balanced supply chain Scorecard hierarchical evaluation model based on fuzzy principal component analysis (Xian et al., 2013); Article 14 is the Product quality evaluation based on fuzzy analytic Hierarchy process (Buckley et al., 2001); Article 15 is the Improved analytic Hierarchy process based on fuzzy and clear items (Yin, 1997); Article 16 is the Investment decision analysis of solar power plants based on analytic Hierarchy Process and fuzzy Analytic Hierarchy Process (Rida et al., 2022). Article 17 conducted hierarchical network decision analysis based on fuzzy integral (Hocaoglu et al., 1999), Article 18 carried out portfolio fuzzy hierarchical analysis under high moment constraint (Nguyen and Gordon-Brown, 2012), article 19 carried out hierarchical fuzzy system secondary stability analysis (PARK et al., 2001), and Article 20 carried out cluster analysis of hepatitis C virus DNA based on fuzzy C-means (Kindhi et al., 2019). However, the above fuzzy analysis methods and hierarchical analysis methods fail to analyze petrochemical plants, and the analysis of human safety production in petrochemical plants is rarely considered. The fuzzy theory is introduced to the analytic hierarchy process, and the inherent expert review is transformed into a fuzzy margin, which makes the expert review more accurate in the subsequent coupling, and improves the objectivity of the traditional analytic hierarchy process compared with the traditional analytic hierarchy process. In addition, multi-time spectral data is collected online and combined with the deep learning method of neural networks. In the future research field, the refinement of the fuzzy analytic hierarchy process in petrochemical plant evaluation will be more studied, and the digital-analog integration platform will be researched and developed to realize the real-time evaluation and analysis of the safety state of petrochemical plants.

The innovations of this paper are as follows.

A human motion simulation and analysis method based on the micro-Doppler effect is proposed, which can identify the posture of workers in the working area, focusing on the static and dynamic states. If the workers in the working area move quickly or stay still for a long time, the human motion simulation based on the micro-Doppler effect can effectively identify them. Improved worker safety in the work area. The innovation point is that in the previous factory, due to unclear monitoring images and subtle operations, there was no effective attention to operational safety issues in the factory.

At the same time, the analytic hierarchy process considering fuzzy function is established to evaluate the operational risk of petrochemical plants, and the operational safety risk of petrochemical plants is evaluated through the combination of fuzzy function and analytic hierarchy method, rapid status evaluation after identification, and timely measures are taken when the assessment is dangerous or possibly dangerous.

2 Establishment of an operational risk assessment method for petrochemical plants considering micro-Doppler effect

2.1 Human motion simulation based on the micro-Doppler effect

Human posture can be regarded as a three-dimensional human model, which includes three parts: the torso, pelvis, and upper and lower limbs. The main features of the human body are the torso, pelvis, and upper and lower limbs. In practice, the human torso is mainly composed of the spine, and its structure is relatively simple. Therefore, the torso of the human body can be considered as a whole.

The eigenvectors of the four human poses represent the torso, pelvis, upper and lower limbs, and the distance from the upper and lower limbs to the torso, respectively. Human posture recognition needs to analyze the micro-Doppler effect caused by human movement. The micro-doppler effect refers to the echo signal caused by the difference between the Doppler frequency generated by the target and the transmitting frequency in the radar echo caused by the target movement. In radar detection, the micro-Doppler effect means that the echo signal from the target contains the same or different target speed information than the frequency of the transmitted signal.

The micro-Doppler effect generated by human motion is a time-varying signal, so it needs to be tracked in real-time when human posture recognition is carried out, which puts forward higher requirements for radar systems. To obtain the motion state information of the target, it is necessary to process the echo signal in real-time, which requires the radar system to have high real-time performance. Because the time of acquiring human motion information is relatively short, the micro-Doppler effect generated by human motion should be processed together with the radar signal in human posture recognition. Since the micro-Doppler effect is mainly related to the speed of target motion, human posture can be recognized according to the time-frequency characteristics of the micro-Doppler effect. In this paper, three groups of human bodies with different postures were selected as research objects, namely standing, kneeling, and supine. To reduce noise interference as much as possible, the background noise used in the experiment was white noise. To further verify the effectiveness of the proposed method, three groups of experimental subjects were repeated several times in the experiment, and other human posture recognition methods based on the Doppler effect were compared. To better reflect the performance of human posture recognition, three kinds of human posture were selected for repeated experiments under the same experimental scene. Different experimental scenarios include the acquisition of target echo signal under different attitudes, extraction of micro-Doppler effect feature vector under different attitudes, and classification and recognition performance of support vector machine under different attitudes. The experimental results show that the proposed method has a good recognition performance for human posture recognition, and can realize the accurate recognition of different human postures.

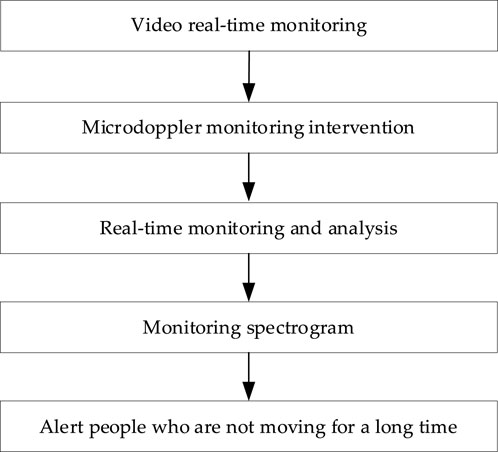

The specific process is shown in Figure 1. Real-time video monitoring of operations in petrochemical plants is carried out, micro-Doppler monitoring is carried out in the monitoring system, real-time monitoring analysis is carried out, spectral graphs are monitored, and dangerous state alerts are given to long-term immobile personnel.

2.2 Safety risk assessment of petrochemical plants based on fuzzy analytic hierarchy process

In the hierarchy analysis of general problems, the ambiguity of human judgment is usually not considered in the construction of the pinion comparison judgment matrix (Mehrjerdi, 2013; Xiufang et al., 2013; Habib et al., 2022), but only two possible extremes of human judgment are considered: selecting an index with membership 1 and negating (or selecting) other scale values with membership 1. When consulting experts on some problems (Pandey and Singh, 2022; Zhang, 2016), experts often give some fuzzy quantities (such as three-value judgment: lowest possible value, most likely value, highest possible value; Binary interval judgment), and any fuzzy set corresponds to a membership function. However, how to determine the membership function of a fuzzy set is an unsolved problem.

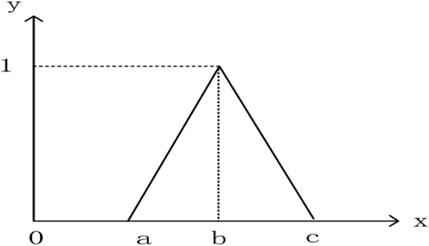

Usually, the distribution function in probability theory is imitated as a membership function, which is called fuzzy distribution function: normal distribution type, triangular number distribution is shown in Figure 2; Things that are not easy to be divided in real life are quantified by membership functions, where membership functions are between 0 and 1. These function domains are real numbers with parameters and ranges [0, 1].

The characteristics of the triangular fuzzy number the mathematical Equation 1 is as follows:

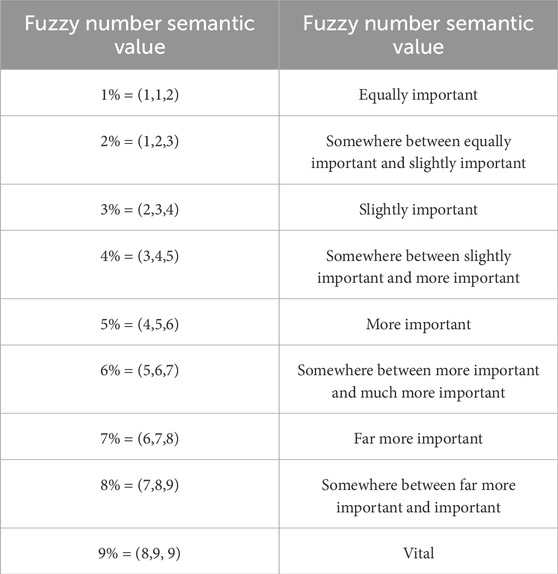

For complex or difficult-to-define cases, it is difficult to express them reasonably in traditional quantitative ways, and it is necessary to apply the view of semantic variables to deal with such cases. The so-called semantic variables are to convert human natural language into numerical values and divide the semantic variables into multiple appropriate and effective semantic scales. Fuzzy semantics in this paper is divided into five levels: equally important, slightly important, more important, much more important, and much more important, for the comparison of importance between the two factors, and their semantic values are shown in Table 1.

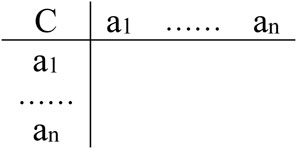

The fuzzy consistent matrix is established., Fuzzy consistent judgment matrix R represents the comparison of the relative importance between this level and its related elements for an element in the upper level. It is assumed that the element C in the upper level is the same as the element a1, a2, … , and is connected, then the fuzzy consistent judgment matrix can be expressed as Figure 3.

3 Security risk assessment practice

3.1 Operation identification of personnel petrochemical equipment based on the micro-Doppler effect

To ensure the accuracy of the proposed method, this paper selected a group of typical workers’ actual monitoring diagrams for petrochemical plant operation for analysis. Figure 4 is the actual monitoring diagram for workers’ crouching operation in the petrochemical plant, Figure 5 is the actual monitoring diagram for workers’ standing operation in the petrochemical plant, and Figure 6 is the actual monitoring diagram for workers’ standing and moving forward in the petrochemical plant.

Figure 6. Actual monitoring diagram of workers standing and moving forward in the petrochemical plant.

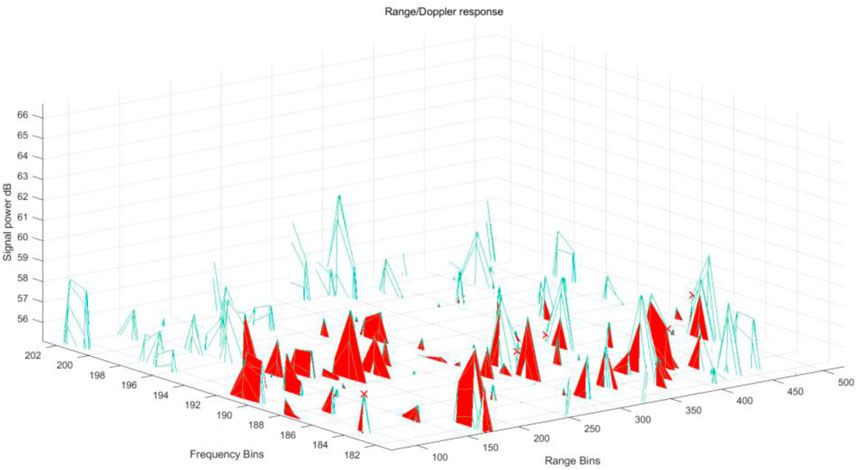

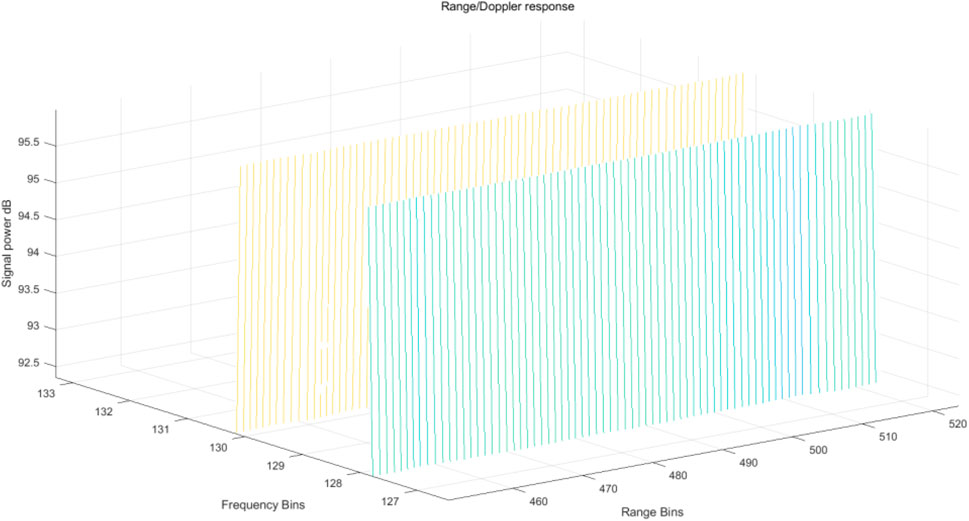

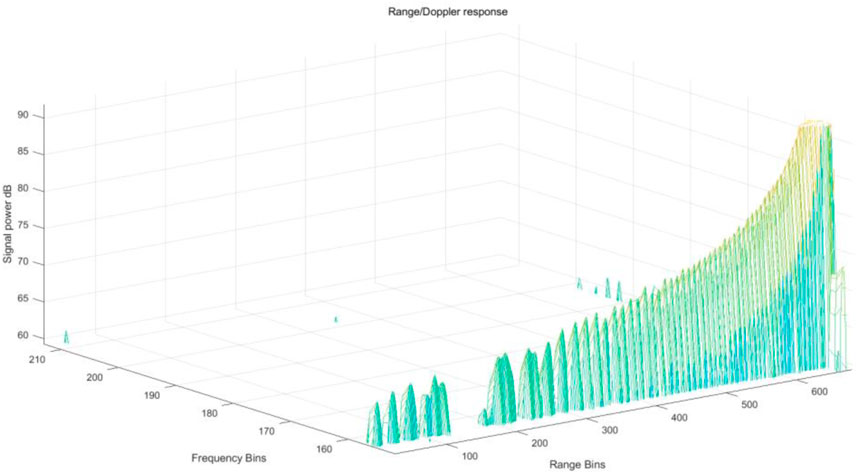

Micro-doppler analysis was carried out on the actual monitoring diagram of workers’ operation in the petrochemical plant, and the analysis results were shown as follows: Figure 7 is the micro-Doppler frequency time spectrum of operators in a static state, Figure 8 is the micro-Doppler frequency time spectrum of operators from a moving state to a static state, and Figure 9 is the micro-Doppler frequency time spectrum of operators in a large motion state. In this paper, Range/Doppler response analysis is carried out from the perspectives of Signal power dB, Frequency Bins, and Range Bins respectively.

Figure 8. MicroDoppler frequency time spectrum of an operator from stationary state to working state.

It can be seen from the micro-Doppler frequency time spectrum of the operator in the static state in Figure 7 that the Signal power dB is below 60, while the frequency of the micro-Doppler frequency time spectrum of the operator in the light motion state only slightly oscillates. The amplitude of frequency oscillation of the micro-Doppler frequency time spectrum becomes larger. From the micro-Doppler frequency time spectrum of the operator from the static state to the working state in Figure 8, multiple amplitudes begin to appear in the frequency of the micro-Doppler frequency time spectrum as time changes. The Signal power dB value gradually increases from 60 to more than 85. As can be seen from the micro-Doppler frequency time spectrum of the operator in the state of large movement in Figure 9, the Signal power dB value is above 90, indicating that the petrochemical plant is operating and is in the operating state. Table 3 shows the weight table of Layer 2 indicators, and Table 4 shows the weight table of Layer 3 indicators.

3.2 Evaluation of petrochemical plant operation methods based on fuzzy analytic hierarchy process d

The multi-moment spectral data is collected online, the fuzzy theory is introduced by combining the multi-data method with the deep learning method of the neural network, and the inherent expert review is transformed into a fuzzy margin, so that the expert review becomes more accurate in the subsequent mutual coupling.

A fuzzy consistent matrix is consistent with human decision thinking. Therefore, fuzzy hierarchical analysis (AHP) based on the fuzzy consistent matrix is widely used in the evaluation of fuzzy scheme selection with many evaluation indexes. The general steps of fuzzy AHP are as follows:

1) Establish a priority relationship matrix. The factors at each level establish a matrix against the relative importance of the factors above. This kind of matrix is a fuzzy complementary matrix. The values in the matrix are represented by the 0.1 to 0.9 scale. To accurately describe the relative importance of any two factors to a criterion, the 0.1 ∼ 0.9 scale is used to give a quantitative scale when constructing the priority relation matrix.

2) Transform the priority matrix into a fuzzy consistent matrix. The method in definition 1 is applied to transform each priority relation matrix into the fuzzy consistent matrix.

3) Hierarchical single sort. According to the fuzzy consistent matrix, the important order of the factors at the lower level of a target in the upper level is calculated. The ranking method given according to the relationship between elements and weights of the fuzzy consistent judgment matrix has a high resolution, which is conducive to improving scientific decision-making. For example, the calculation formula of the weight of factor Ai under the target is as follows:

Change is (i = 1, 2, … n) The order from largest to smallest shows the importance of the factors relative to the goal.

4) Hierarchical synthesis. When the middle layer is the criterion layer and the sub-criterion layer, the comprehensive hierarchical relationship is needed to convert the local importance weight between levels into the comprehensive weight relative to the overall goal.

5) Hierarchy total sort. Based on single hierarchical ranking and hierarchical synthesis, the overall goodness of Ti of each scheme relative to the total objective is calculated, the scheme is sorted according to the size of Ti, and the scheme is obtained from the best to the worst order.

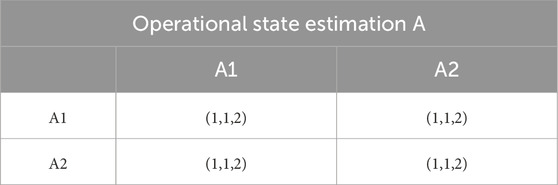

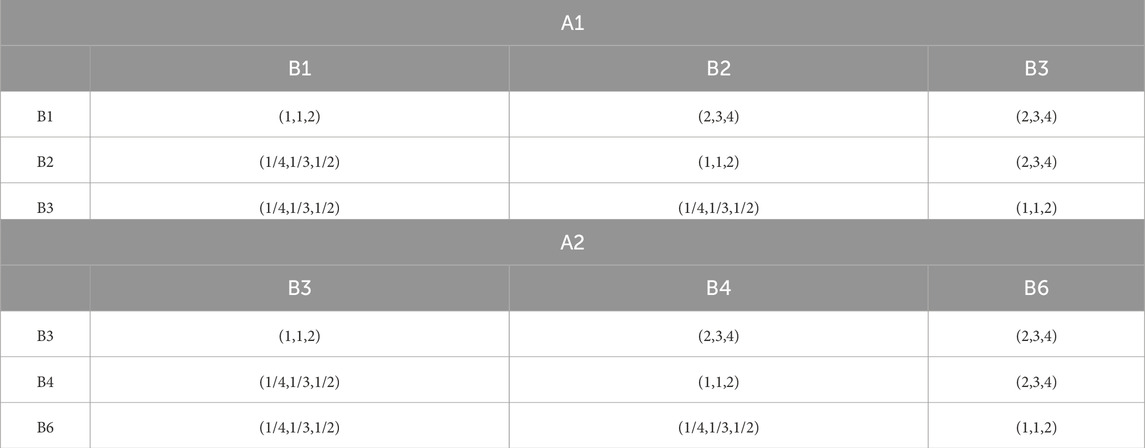

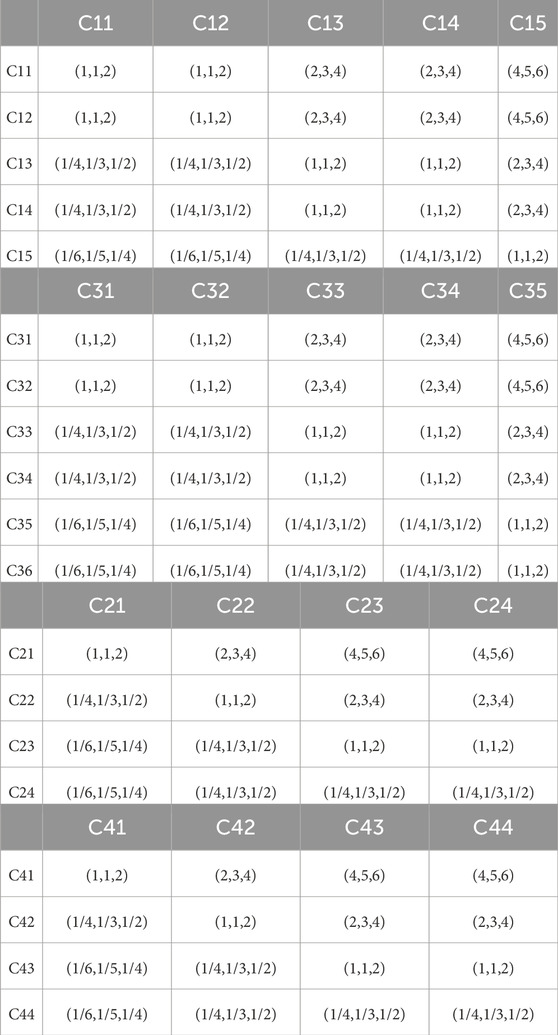

Establish a risk assessment model, The petrochemical plant operation is divided into static operation state (A1), dynamic operation state (A2), and then divided into two-person operation (B1), multi-person operation (B2), and hot work (C11), lifting work (C12), confined space work (C13), high work (C14), general work (C15), high-risk device construction (C 16).

According to the above analysis content, based on the analysis results of the importance degree among the process indicators calculated by improved hierarchical analysis and fuzzy theory combined with analytic hierarchy process, the fuzzy judgment matrix and weight calculation results of power regulation capability under power generation and electric driving conditions are shown in Table 2. (The original index is not fuzzy, which is equivalent to just AHP, without the concept of fuzzy degree), and fuzzy processing is carried out according to the original expert importance.

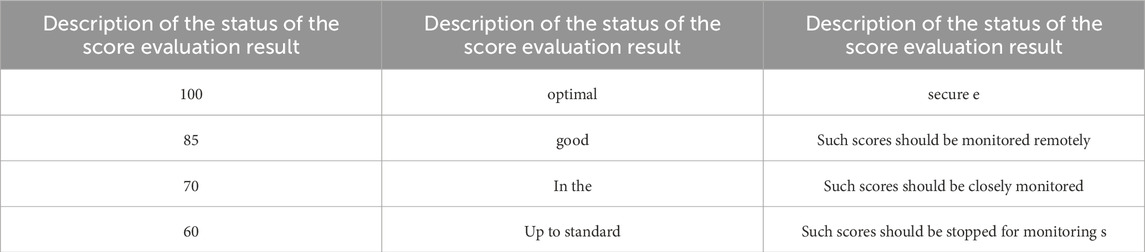

4 Calculation results of assessment items

Health status is divided into four levels: normal, attention, abnormal, and serious, as shown in Table 5. According to the comprehensive score of the calculated performance state, the level of the system is determined, and relevant operation suggestions are given.

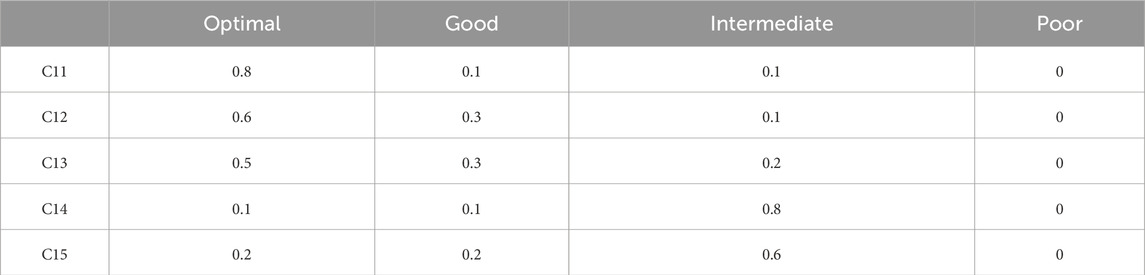

The fuzzy membership matrix is calculated for the bottom index according to the evaluation index and judgment matrix, and then the fuzzy membership degree of the upper index is calculated according to the index weight, as shown in Table 6:

5 Conclusion

A human motion simulation and analysis method based on the micro-Doppler effect is proposed, and fuzzy hierarchical analysis is constructed for state evaluation. Based on micro-Doppler analysis, the posture of workers in the work area can be identified, focusing on static and dynamic states. If workers are moving fast or standing still for a long time in the work area, the human movement simulation based on the micro-Doppler effect can be effectively identified. Improved worker safety in the work area. In the previous research methods, it was difficult to identify and evaluate the operation details, and attention was not paid to the safety problems existing in the production of this plant.

At the same time, the risk evaluation of the operation and operation of the staff in the plant is established considering fuzzy function, and the operation safety risk of the petrochemical plant is evaluated by combining fuzzy function and hierarchical analysis, and timely measures are taken when there is danger or possible danger in the evaluation. The critical temperature for human injury in a petrochemical plant leakage fire is 115°C. When the high-temperature smoke rises and expands, it will cause serious harm to the life safety of employees. The method proposed in this paper will warn the system before the danger occurs, so that the temperature will not rise to 115°C, and alert the system within 2–3 s to alert the dangerous state of the system, greatly improving the overall safety warning time of the system.

In the future, we will pay more attention to the refinement of the fuzzy analytic hierarchy process (AHP) in the safety evaluation of petrochemical installations, and research and develop a digital-analog integrated platform to realize real-time evaluation and analysis of the safety status of petrochemical installations. The algorithm is extended to more petroleum and petrochemical plants with different evaluation structures, which improves the universality of the evaluation strategy proposed in this paper.

Data availability statement

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

Author contributions

ZL: Conceptualization, Data curation, Formal Analysis, Funding acquisition, Investigation, Methodology, Project administration, Resources, Software, Supervision, Validation, Visualization, Writing–original draft, Writing–review and editing.

Funding

The author(s) declare that financial support was received for the research, authorship, and/or publication of this article. Supported by SINOPEC Qilu Petrochemical Company, Zibo 255400, China. The funder was not involved in the study design, collection, analysis, interpretation of data, the writing of this article, or the decision to submit it for publication.

Conflict of interest

Author ZL was employed by SINOPEC Qilu Petrochemical Company.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Baghaee, H. R., Mirsalim, M., Gharehpetian, G. B., and Talebi, H. A. (2017). Eigenvalue, robustness, and time delay analysis of hierarchical control scheme in multi-DER microgrid to enhance small/large-signal stability using complementary loop and fuzzy logic controller. J. circuits, Syst. Comput. 26 (6), 1750099. doi:10.1142/S0218126617500992

Buckley, J. J., Feuring, T., and Hayashi, Y. (2001). Fuzzy hierarchical analysis revisited. Eur. J. Operational Res. 129 (1), 48–64. doi:10.1016/s0377-2217(99)00405-1

Habib, A., Akram, M., and Kahraman, C. (2022). Minimum spanning tree hierarchical clustering algorithm: a new Pythagorean fuzzy similarity measure for the analysis of functional brain networks. Expert Syst. Appl. 201, 117016.1–117016.19. doi:10.1016/j.eswa.2022.117016

Hocaoglu, A. K., Gader, P., and Jung-Hsien Chiang, (1999). Comments on Choquet fuzzy integral-based hierarchical networks for decision analysis [with reply]. IEEE Trans. Fuzzy Syst. 7 (6), 767–768. doi:10.1109/91.811248

Jung-Hsien, C. (1999). Choquet fuzzy integral-based hierarchical networks for decision analysis. IEEE Trans. Fuzzy Syst. 7 (1), 63–71. doi:10.1109/91.746311

Kindhi, B. A., Sardjono, T. A., Purnomo, M. H., and Verkerke, G. J. (2019). Hybrid K-means, fuzzy C-means, and hierarchical clustering for DNA hepatitis C virus trend mutation analysis. Expert Syst. Appl. 121, 373–381. doi:10.1016/j.eswa.2018.12.019

Lu, Y., Kou, S., and Wang, X. (2023). Micro-Doppler effect and sparse representation analysis of underwater targets. Sensors 23 (19), 8066. doi:10.3390/s23198066

Mehrjerdi, Y. Z. (2013). Hierarchical multi-criteria risk-benefit analysis in fuzzy environment. Appl. Soft Comput. 13 (1), 590–599. doi:10.1016/j.asoc.2012.08.018

Mengning, H. E., and Perez Estebanez, R. (2022). Construction and analysis of performance evaluation index system for Chinese small and medium-sized enterprises based on fuzzy hierarchical analysis model. Comput. Intell. Neurosci. 2022 (Pt.40), 1230786. doi:10.1155/2022/1230786

Nguyen, N., Pham, M., Doan, S. V., and Le, V. (2024). Improving human activity classification based on micro-Doppler signatures of FMCW radar with the effect of noise. PloS one 19 (8), e0308045. doi:10.1371/journal.pone.0308045

Nguyen, T. T., and Gordon-Brown, L. (2012). Constrained fuzzy hierarchical analysis for portfolio selection under higher moments. IEEE Trans. Fuzzy Syst. 20 (4), 666–682. doi:10.1109/tfuzz.2011.2181520

Pandey, U., and Singh, S. (2022). Data envelopment analysis in hierarchical category structure with fuzzy boundaries. Ann. operations Res. 315 (2), 1517–1549. doi:10.1007/s10479-020-03854-8

Park, C.-W., Kim, J. H., and Kim, S. (2001). LMI-based quadratic stability analysis for hierarchical fuzzy systems. IEE proceedings.Control theory Appl. 148 (5), 340–349. doi:10.1049/ip-cta:20010679

Rahbar, A., Vadiati, M., Talkhabi, M., Nadiri, A. A., Nakhaei, M., and Rahimian, M. (2020). A hydrogeochemical analysis of groundwater using hierarchical clustering analysis and fuzzy C-mean clustering methods in Arak plain, Iran. Environ. Earth Sci. 79 (13), 342–342.17. doi:10.1007/s12665-020-09064-6

Rani, S., Chowdhury, A., Chakravarty, T., and Pal, A. (2021). Exploiting unique state transitions to capture micro-Doppler signatures of human actions using CW radar. IEEE Sensors J. 21 (24), 27878–27886. doi:10.1109/JSEN.2021.3126436

Rida, AZMI, Hicham, A., Jérôme, C., Diop, E. B., and Tekouabou Koumetio, C. S. (2022). Decision analysis related to solar farm investments based on analysis hierarchical process and fuzzyAHPfor sustainable energy production. Int. J. energy Res. 46 (9), 11730–11755. doi:10.1002/er.7943

Sarbu, C., and Mot, A. C. (2011). Ecosystem discrimination and fingerprinting of Romanian propolis by hierarchical fuzzy clustering and image analysis of TLC patterns. Talanta Int. J. Pure Appl. Anal. Chem. 85 (2), 1112–1117. doi:10.1016/j.talanta.2011.05.030

Severino, J. V., Zimmer, A., Brandmeier, T., and Freire, R. Z. (2019). Pedestrian recognition using micro-Doppler effects of radar signals based on machine learning and multi-objective optimization. Expert Syst. Appl. 136, 304–315. doi:10.1016/j.eswa.2019.06.048

Tang, X.-Q., and Zhu, P. (2013). Hierarchical clustering problems and analysis of fuzzy proximity relation on granular space. IEEE Trans. Fuzzy Syst. 21 (5), 814–824. doi:10.1109/tfuzz.2012.2230176

Wang, L. I.-X. I. N. (1999). Analysis and design of hierarchical fuzzy systems. IEEE Trans. Fuzzy Syst. 7 (5), 617–624. doi:10.1109/91.797984

Xian, S., Qiu, D., and Zhang, S. (2013). A fuzzy principal component analysis approach to hierarchical evaluation model for balanced supply chain scorecard grading. J. Optim. Theory Appl. 159 (2), 518–535. doi:10.1007/s10957-013-0337-1

Xiufang, J., Liangtu, S., Wei, L., and Hu, H. (2013). The hierarchical structure analysis of intuitionistic fuzzy tolerance relations. Int. J. Granul. Comput. rough sets, intelligent Syst. 3 (2), 117–129. doi:10.1504/ijgcrsis.2013.057240

Yang, Z., Jiao, D., Dai, X., Zhang, Y., and Zhang, J. (2024). Simulation and parameter extraction of flying-bird motion echo based on laser micro-Doppler effect. Microw. Opt. Technol. Lett. 66 (1). doi:10.1002/mop.34000

Yin, P. A. N. (1997). Revised hierarchical analysis method based on crisp and fuzzy entries. Int. J. General Syst. 26 (1-2), 115–131. doi:10.1080/03081079708945173

Keywords: petrochemicals, fuzzy evaluation, safety, evaluation, risk

Citation: Liu Z (2024) An operational risk assessment method for petrochemical plants based on deep learning. Front. Energy Res. 12:1455276. doi: 10.3389/fenrg.2024.1455276

Received: 26 June 2024; Accepted: 11 October 2024;

Published: 28 October 2024.

Edited by:

Xiaohu Yang, Xi’an Jiaotong University, ChinaReviewed by:

Abderraouf Bouafia, University of Skikda, AlgeriaMingxin Dong, Shandong Police College, China

Copyright © 2024 Liu. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Zhipeng Liu, bHpwemdzaEAxMjYuY29t

Zhipeng Liu

Zhipeng Liu