- 1School of Instructional Technology and Innovation, Bagwell College of Education, Kennesaw State University, Kennesaw, GA, United States

- 2KSU 3D Center, Mechanical Engineering Technology, Kennesaw State University, Marietta, GA, United States

- 3Modular Agile Deployment Laboratory, Information Systems and Security, Coles College of Business, Kennesaw State University, Kennesaw, GA, United States

- 43D Tech Lab, Art and Design, Kennesaw State University, Kennesaw, GA, United States

This perspective article outlines the design and development of a 3D Printing Ecosystem (3DPE) that aims to lay the groundwork for STEAM education. The 3DPE is a coordinated system of hardware, software, and people that has been intentionally designed to scale computer-aided design (CAD) and 3D printing (3DP) at an institutional level. CAD and 3DP are two prime examples of technologies that support STEAM by blending engineering with the arts. These technologies, however, are typically only taught in select university courses that focus on engineering, product development, and industrial design. In recent years, the availability of affordable, reliable, and highly maintainable 3D printers has created an opportunity to infuse CAD and 3DP as a shared set of literacies that can cross disciplinary boundaries. The 3DPE consists of a decentralized series of 3DP labs, a centralized 3DP server, and faculty training. Using a train-the-trainer model, the 3DPE supports STEAM education by training faculty in CAD and 3DP while also providing ongoing curricular support to infuse these skills into their courses through project-based learning. This article provides preliminary examples of how the 3DPE is supporting STEAM education and offers advice for others seeking to replicate the model.

Introduction

In undergraduate education, there is currently a gap in the widespread adoption of computer-aided design (CAD) and additive manufacturing technologies, such as 3D printing (3DP), that is limiting the interdisciplinary integration of these innovations into science, technology, arts, engineering, and mathematics (STEAM) education. The teaching of CAD and 3DP conventionally occurs in select university courses that focus on computer graphics (Payne, 2015), general engineering (Chong et al., 2018; Taheri, 2018), product development (Yang et al., 2019; Savolainen and Collan, 2020), and industrial design (Junk and Matt, 2015; Ford and Minshall, 2019). Recently, however, the availability of affordable, reliable, and highly maintainable consumer-grade 3D printers has created an opportunity to infuse CAD and 3DP as shared literacies that can cross disciplinary boundaries in a meaningful way.

There have been numerous calls from both inside and outside of higher education to address how society can benefit from the integration and synthesis of knowledge across the disciplines (Pfirman et al., 2011; Frodeman, 2017). STEAM education has the potential to bridge the disciplines by piquing student interest through creative thinking and artistic expression while simultaneously exploring science, technology, engineering, and mathematics (STEM) concepts. CAD and 3DP are two prime examples of technologies that support STEAM education by blending engineering with the arts. The integration of these technologies in STEAM education is not simply about designing and manufacturing products, rather CAD and 3DP allow users to bring their imagination to life through the creation of personally meaningful objects that can be made tangible.

While these 3D technologies show promise in supporting STEAM education, there are several barriers that need to be addressed before CAD and 3DP can be widely adopted across the disciplines. These barriers include a lack of faculty and student training (Ford and Minshall, 2019), limited access to equipment (Berman et al., 2020), slow print speeds (Renda and Kuys, 2015), and few curricular examples (Pikkarainen and Piili, 2020; Novak et al., 2021). To address these barriers, this perspective article outlines the design and development of a vibrant and inclusive 3D Printing Ecosystem (3DPE) which aims to lay the groundwork for STEAM education.

3D Printing Ecosystem

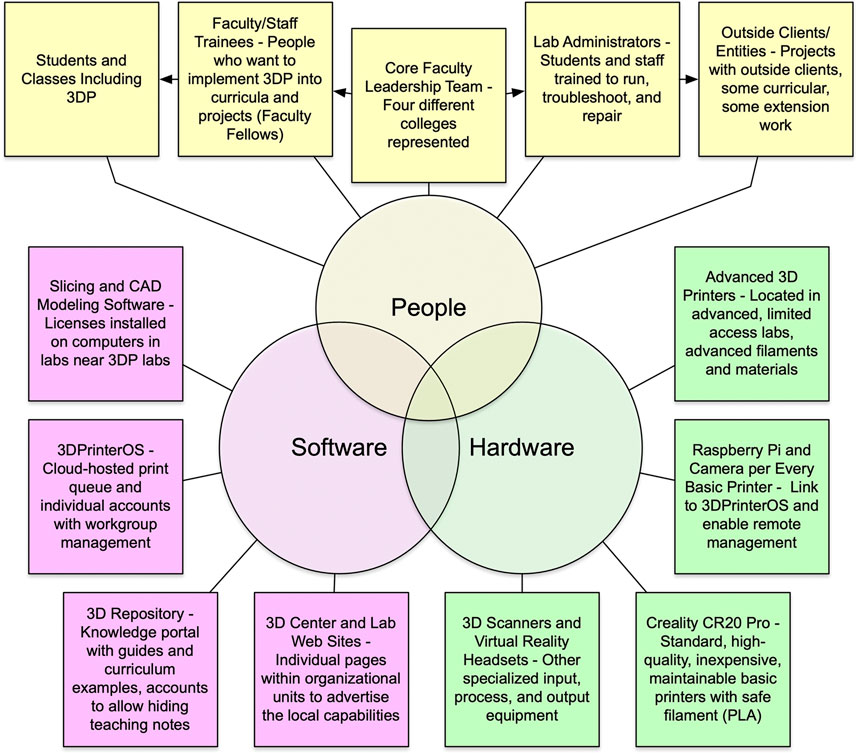

The 3DPE is a coordinated system of hardware, software, and people that has been intentionally designed to scale CAD and 3DP at an institutional level. Drawing from over a decade of experience with these technologies, the authors have found that this combination of resources cannot be casual or unmanaged when scaling to meet institutional demands. Our university founded its first 3D Center in 2010, but discovered the facilities were only used by faculty and students who were in close proximity. In recent years, there have been several uncoordinated efforts to add 3DP to the campus through departmental purchases of one-off 3D printers. These printers, however, are frequently underutilized due to a lack of access, training, and maintenance. To overcome these issues, the 3DPE has been designed with baked-in intentional processes to ensure these technologies are accessible to all students and faculty both in-person and online (see Figure 1).

FIGURE 1. Visualization of the 3D Printing Ecosystem (3DPE) as a coordinated system of hardware, software, and people.

Hardware and Software

The hardware that supports the 3DPE consists of consumer-grade 3D printers that are standardized, user-friendly, reliable, and highly maintainable. The use of affordable consumer printers align with the university mission of providing a high-quality, low-cost education to all students. Each printer is equipped with a Raspberry Pi three and webcam for remote print monitoring. To use space wisely, the 3D printers are placed on sturdy shelving racks that can hold about 10 printers each. This provides space for twice as many printers in each lab. Additionally, the 3DP labs are furnished with comfortable furniture and placed in highly visible locations to encourage faculty and students to explore the facilities. The 3DPE supports STEAM education by providing multiple redundancies across two campuses, with 3DP labs established in the engineering, business, and art buildings. The use of multiple 3DP labs creates a resilient system that accounts for equipment breakdowns and other technical issues while reducing barriers to access.

The 3DP labs are connected to a centralized print server running 3DPrinterOS. This software allows users to wirelessly upload files and monitor their print jobs remotely via webcam. Remote monitoring allows the 3DPE to support classes that are entirely online, hybrid, or face-to-face. The centralized print server handles all work processes including slicing, wirelessly sending print files, collecting money for filament usage, and managing the print queue. The distributive capability of the 3DPE allows for dynamic scaling that can support surge capacity from large-scale classes that may exceed the demands of a single 3DP lab. Furthermore, the 3DPE is supported by a knowledge portal website, which includes written and video guides. The knowledge portal is also designed as a repository for faculty developed 3DP curricula.

These hardware and software decisions follow the design principles of low threshold, high ceiling, and wide walls (Resnick et al., 2005). The affordable, easy to use, consumer-grade 3D printers and print server are designed to provide novices with the confidence that they can be successful (i.e., low threshold). These simple tools provide users with room for growth as they advance towards increasingly sophisticated projects (i.e., high ceilings). Along this growth trajectory, users have opportunities to apply these tools creatively across a wide range of personal interests and expressions (i.e., wide walls). Even when they outgrow the consumer-grade tools, the 3DPE includes more advanced printers that support larger print sizes, flexible filaments, and exotic materials (e.g., sand and metal). Thus, rather than fixating on the needs of one discipline, the 3DPE is designed to support creative STEAM endeavors across all teaching and learning.

Supporting Faculty and Students

Hardware and software by itself are not enough to support STEAM education. Instead, the majority of the 3DPE consists of the effort to transform how faculty and students engage with 3D technologies. Central to this project is a core faculty leadership team with representatives from four different disciplines (i.e., art, business, education, and engineering.) Members of this leadership team met through a shared interest in 3DP technologies and a desire to expand interdisciplinary learning at the undergraduate level. This leadership team has taken a two-pronged approach to expanding access and training to 3DP.

First, members of the leadership team serve as lab administrators who train the student employees and staff to run, troubleshoot, and repair the 3D printers. These employees can control the print queue, provide in-person monitoring services, and replace filament as needed. As the 3D printers complete their jobs, these employees remove objects from the print bed and store them for retrieval. These employees also interact with outside clients and entities, which provide a revenue stream that helps to sustain the project.

Second, the lab administrators are training faculty on how to incorporate CAD and 3DP into their existing courses. This project recognizes that although these faculty members are experts in their subject area, there is often a pedagogical gap when integrating new tools and technologies. One popular method of integrating technology into curriculum is through project-based learning (PBL). University faculty, however, need additional support since implementing PBL requires that they make simultaneous changes to curriculum, instruction, and assessment practices (Barron et al., 1998). Rather than having faculty simply describing how 3DP works, the 3DPE provides faculty members with the curricular scaffolding and support needed to implement PBL in their courses. By doing so, the 3DPE respects the autonomy and uniqueness of faculty and students, while also building confidence in both CAD and 3DP through authentic PBL experiences.

Research has found that using 3DP to facilitate teaching has a positive effect on learning while also creating opportunities for cross-disciplinary research through the development of innovative curriculum (Novak et al., 2021). To support the development of STEAM curriculum, the 3DPE applies train-the-trainer (TTT) as a professional development model. In this model, a subject-matter expert trains other employees in a new skill while simultaneously teaching them how to train others. This is a common approach used in the health-related disciplines (Marks et al., 2013) and has also been successfully used to teach K-12 STEM educators to teach CAD and 3DP (Hung et al., 2020).

The TTT approach is centered around the development of a Faculty Fellows Program (FFP). The aim of this program is to train and support at least 20 new faculty members over 3 years. The FFP supports faculty members by providing workshops where they receive curriculum support, develop an activity that is authentic to their subject area, network with faculty from other disciplines, and are encouraged to form STEAM collaborations. As part of the workshop, fellows receive a 3D printer that they build and take home to allow for further experimentation. Additional compensation includes $100 for completing the initial training, $200 after course implementation, and another $200 for sustained participation in the learning community. All the 3DP curriculum developed by the fellows are captured and shared as part of the knowledge portal website. This curriculum repository serves as a searchable archive of discipline specific examples that can be replicated by others. By doing so, this project aims to scale STEAM education to undergraduate students throughout engineering, business, and the visual arts—with plans to expand into other disciplines such as education, health care, humanities, and the social sciences.

Laying the Groundwork for STEAM

To lay the groundwork for STEAM, the 3DPE leverages CAD and 3DP as a shared set of literacies that go beyond the disciplinary boundaries. These technologies give faculty and students new ways of conceptualizing their ideas. Designing, repairing, and modifying CAD models allow users to engage in new ways of thinking through the spatial exploration of the Z-axis. CAD and 3DP further lay the groundwork for STEAM by making it possible to engage in rapid prototyping in 3D space. These virtual capabilities along with the shared language of CAD and 3DP can support collaborations from across the STEAM spectrum. By doing so, diverse perspectives can imagine together, identify shared problems, and work towards designing and actualizing tangible solutions.

The multiple 3DP labs also serve as innovation commons, or shared spaces where people can come together to exchange information and knowledge while discovering the new opportunities and capabilities that these technologies can afford them (Allen and Potts, 2016). Since these labs are open to multiple disciplines, the space can also serve to inspire projects and ideas that support STEAM collaborations through cross-pollination. Furthermore, these spaces are equipped with video conference portals that connect all the 3DP labs together, making it possible for lab patrons and technicians to engage in synchronous communication from across the entire 3DPE.

Rather than relying entirely on departmental funds, the 3DPE has actively sought institutional level funding to create a shared network of resources across the university’s two campuses. These additional funds have allowed for the purchase of five iMacs for the visual art lab, 74 new 3D printers distributed across three 3DP labs (i.e., business, engineering, and visual arts), upgraded print beds, extra parts for maintenance and repair (e.g., nozzles, filament tubes, belts), wireless hardware (e.g., Raspberry Pi 3, webcams, and USB cables), over 100 kg of PLA filament, funding for three student assistants, and a 1-year extension of the print server license. These shared resources support faculty and students by ensuring the 3DPE is resilient enough to meet demands of scaling these 3D technologies across dozens of undergraduate courses.

Preliminary Examples of STEAM Collaborations Supported by the 3DPE

The development of the 3DPE has already led to several examples of successful STEAM collaborations. First, business students helped prototype the printer rack system, designed the 3D printed webcam arms, and created the knowledge portal. Additionally, student assistants from art, business, and engineering have been working together to assemble, calibrate, and test all of the equipment in each of the 3DP labs to ensure the 3DPE is ready to support faculty and students for the upcoming academic year.

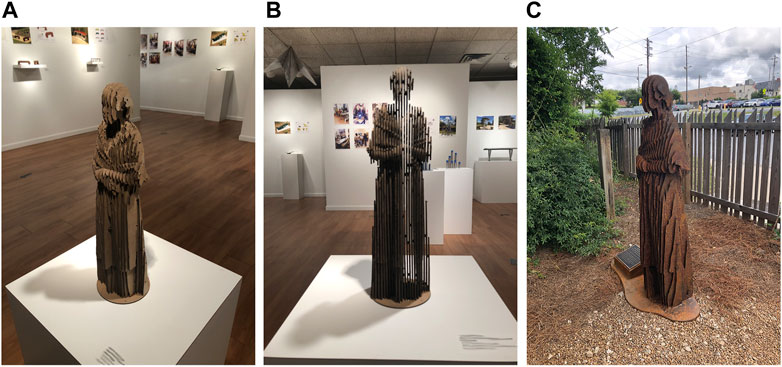

As part of a STEAM collaboration, art students utilized elements of the 3DPE to make a life-sized sculpture that pays homage to local enslaved ancestors. Using handheld 3D scanning technology, art students scanned a person to capture their likeness as a 3D model. After scanning was complete, these students worked in CAD to clean-up the model and eliminate any unwanted artifacts. 3DP was then used to create prototypes of the monument prior to cutting a full-sized sculpture with a water-jet cutter. The final sculpture was installed as a permanent public artwork in the courtyard of a local historical museum (see Figure 2). This sculpture was recently revealed as part of a Juneteenth ceremony to celebrate the emancipation of the last freed slaves.

FIGURE 2. 3D sculpture created by art students as part of a visual arts course. Photos include: (A) 3D printed model of sculpture (side view), (B) 3D printed model of sculpture (front view), and (C) full-sized monument cut with a water-jet cutter.

Additionally, students from art, engineering, and architecture have been collaborating to create interactive exhibits for a local art museum. As part of this initiative, engineering students scanned large sculptures from the museum’s permanent collection. The scans were then brought into Fusion 360 by art students and sliced to create pieces of a 3D puzzle. These puzzle pieces were laser cut by the architecture department and given to the museum as hands-on activities for visitors.

Empirical Development of Core Curriculum Learning Activity Using 3DPE

The authors have taken an iterative approach towards testing and improving an introductory learning activity that can be scaled to support broader curricular integration. This process involved the development of an initial course activity followed by five sequential test and improvement cycles. In total, the introductory activity has been completed by about 125 undergraduate business students in their sophomore year, with plans to expand to a core course taken by over 1,000 undergraduates this upcoming year. These students were evenly divided by gender and included some demographic diversity aligned with the average at the university.

The first test cycle uncovered the importance of short video demonstrations. Since CAD and 3DP have many options and somewhat complex interfaces, replay ability and demonstrating a working solution were achieved in this manner. The second test included one longer video and provided capabilities for instructors to remotely monitor and review student models. These additional features did not disrupt the work process, but the ability to remotely monitor student work was not viewed as important to the faculty. For the third iteration, the instructions were simplified from paragraphs to a numbered list. The longer video was split into two videos that focused on the design work in CAD and the slicing and printing process. Neither video exceeded 20 min. In the fourth test, written instructions were made available without requiring the videos. This was a problem since students created shapes that were not feasible to print. Subsequently, the fifth test included a stricter protocol for the facilitator plus all of the preceding insights.

While exact participation numbers are unclear due absent students being allowed to make-up the activity, in all the print failure rate among 268 prints during the development process was 3.5%. Among the 63 prints subsequent to the finalization of the activity, this failure rate fell to 2.1%. Additionally, we observed widespread satisfaction and excitement among the participating students and received positive feedback from faculty. As an example, one told us: “I had not used the 3D printer before the experience. It was fun  . I am going to do it in my two F2F in the Fall.”

. I am going to do it in my two F2F in the Fall.”

Additional examples of subject areas where faculty members are interested in implementing tools include business majors creating entrepreneurial prototypes to help students develop an understanding of emerging business opportunities, education majors creating elementary mathematic manipulatives, biology faculty printing experimental cellular structures and apparatuses, and art collaborating with chemistry and the nursing program to investigate alternative materials to create complex structures out of clay, monomers, and polymers to be used orthotics and other medical applications.

Discussion

The 3DPE is designed to be replicated at other institutions. From the authors’ experience, it is difficult to make these types of initiatives happen at scale if you are the only champion in your department. Thus, in order to replicate this model, there needs to be a consorted effort that seeks to build momentum around the various 3D technology enthusiasts at the institution. Those seeking other STEAM collaborators may consider strategies such as word-of-mouth, internal press releases, or taking on a leadership role to attract others with shared interests, such as forming a STEAM education committee.

Finding room for facilities can be a challenge. The 3DPE is highly adaptable and does not need a dedicated lab space. Instead, the decentralized structure allows printers to be put in multiple spaces with far less overhead. Often it is easy to find space for four-to-five printers, but challenges start to emerge when labs begin to have 20 or more printers. The authors recommend that those considering adding larger 3DP labs should use shelving systems to stack printers vertically, install outlets and breakers that can handle the electrical demands, and ensure there is good ventilation.

While the design of the 3DPE is scalable, there are three challenges with making the initiative sustainable. First, 3DP uses consumable materials such as PLA filament. Currently, we have a system where student lab fees pay for filament for class related assignments and students are only billed for personal projects (e.g., printing a Pokémon figure). Second, while many of our student employees are paid through work-study grant money, we currently have three student employees funded through one-time institutional funds. Third, there is currently no funding mechanism in place for the renewal of the 3DPrinterOS license, thus the authors are investigating open-source alternatives, such as Octoprint, to ensure the project is sustainable.

Currently there is no evidence whether the fellows program and curriculum repository will be enough to support an ongoing STEAM learning community. It is the aspirations of the authors, however, that the 3DPE will fuel STEAM research and enable interdisciplinary collaborations through the development of cross-listed courses. For example, engineers and theatre majors could collaborate to create innovative props and costumes, or mathematicians could work alongside educators to create innovative mathematical manipulatives.

Ultimately, the 3DPE is one step towards unlocking new ways of thinking that transform how we teach and learn. CAD and 3DP are just two technologies that support the mission of STEAM education. However, for these technologies to make a lasting impact there must be a robust and reliable hardware and software infrastructure, opportunities for faculty to be trained with curricular support, and the fostering of a STEAM culture at the institutional level that values and supports interdisciplinary collaborations.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Author Contributions

JH, RE, JC, and DT contributed to conception and design of the project. RE, JC, and DT serve as the administrators of the 3D printing labs outlined in the article. JH wrote the first draft of the manuscript. DT contributed Figure 1. JC contributed the photos and JH edited them for Figure 2. RE, JS, and DT wrote sections of the manuscript. All authors contributed to manuscript revision, read, and approved the submitted version.

Funding

The authors declare that this project received funding from Kennesaw State University Information Technology Services (UITS). UITS was not involved in the writing of this article or the decision to submit it for publication. Funding for publication was provided from the KSU 3D Center.

Conflict of Interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s Note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Acknowledgments

In addition, the authors would also like to thank KSU faculty Page Burch for leading the visual arts course that created the 3D sculpture.

References

Allen, D. W. E., and Potts, J. (2016). How Innovation Commons Contribute to Discovering and Developing New Technologies. Int. J. Commons 10 (2), 1035–1054. doi:10.18352/ijc.644

Barron, B. J. S., Schwartz, D. L., Vye, N. J., Moore, A., Petrosino, A., Zech, L., et al. (1998). Doing with Understanding: Lessons from Research on Problem- and Project-Based Learning. J. Learn. Sci. 7 (3-4), 271–311. doi:10.1080/10508406.1998.9672056

Berman, A., Quek, F., Woodward, R., Okundaye, O., and Kim, J. (2020, October). "Anyone Can Print": Supporting Collaborations with 3D Printing Services to Empower Broader Participation in Personal Fabrication. In Proceedings of the 11th Nordic Conference on Human-Computer Interaction: Shaping Experiences, 2020, October, (Tallinn, Estonia: Shaping Society), 1–13. doi:10.1145/3419249.3420068

Chong, S., Pan, G.-T., Chin, J., Show, P., Yang, T., and Huang, C.-M. (2018). Integration of 3D Printing and Industry 4.0 into Engineering Teaching. Sustainability 10 (11), 3960. doi:10.3390/su10113960

Ford, S., and Minshall, T. (2019). Invited Review Article: Where and How 3D Printing Is Used in Teaching and Education. Additive Manufacturing 25, 131–150. doi:10.1016/j.addma.2018.10.028

Frodeman, R. (2017). “The Future of Interdisciplinarity: An Introduction to the 2nd Edition,” in The Oxford Handbook of Interdisciplinarity. 2 ed. (New York: Oxford University Press).

Hung, W., Kuttolamadom, M., and Tornquist, S. (2020, June). Manufacturing Impact: Training the Trainers. In 2020 ASEE Virtual Annual Conference, 2020, June. Available at: https://par.nsf.gov/servlets/purl/10225465 [Accessed August 18, 2021].

Junk, S., and Matt, R. (2015). New Approach to Introduction of 3D Digital Technologies in Design Education. Proced. Cirp 36, 35–40. doi:10.1016/j.procir.2015.01.045

Marks, B., Sisirak, J., and Chang, Y. C. (2013). Efficacy of the HealthMatters Program Train-The-Trainer Model. J. Appl. Res. Intellect. Disabil. 26 (4), 319–334. doi:10.1111/jar.12045

Novak, E., Brannon, M., Librea-Carden, M. R., and Haas, A. L. (2021). A Systematic Review of Empirical Research on Learning with 3D Printing Technology. J. Comput. Assist. Learn. 37, 1455–1478. doi:10.1111/jcal.12585

Payne, B. R. (2015). Using 3D Printers in a Computer Graphics Survey Course. J. Comput. Sci. Colleges 31 (2), 244–251. doi:10.5555/2831432.2831473

Pfirman, S., Martin, P., Danielson, A., Goodman, R. M., Steen-Adams, M., Waggett, C., et al. (2011). Interdisciplinary Hiring and Career Development: Guidance for Individuals and Institutions. Washington, DC: National Council for Science and the Environment.

Pikkarainen, A., and Piili, H. (2020). Implementing 3D Printing Education through Technical Pedagogy and Curriculum Development. Int. J. Eng. Ped. 10 (6), 95–119. doi:10.3991/ijep.v10i6.14859

Renda, G., and Kuys, B. (2015). Connectivism as a Pedagogical Model within Industrial Design Education. Proced. Technol. 20, 15–19. doi:10.1016/j.protcy.2015.07.004

Resnick, M., Myers, B., Nakakoji, K., Shneiderman, B., Pausch, R., Selker, T., et al. (2005). Design Principles for Tools to Support Creative Thinking. Journal contribution. Pittsburgh, PA: Carnegie Mellon University. doi:10.1184/R1/6621917.v1

Savolainen, J., and Collan, M. (2020). How Additive Manufacturing Technology Changes Business Models? - Review of Literature. Additive manufacturing 32, 101070. doi:10.1016/j.addma.2020.101070

Taheri, P. (2018). Project-Based Approach in a First-Year Engineering Course to Promote Project Management and Sustainability. Int. J. Eng. Ped. 8 (3), 104–119. Available at: https://www.learntechlib.org/p/207434/, (Accessed August 18, 2021). doi:10.3991/ijep.v8i3.8573

Keywords: digital fabrication, emerging technologies, interdisciplinary, scalability, STEM/STEAM education, train-the-trainer

Citation: Harron JR, Emert R, Thomas DM and Campana J (2022) Laying the Groundwork for STEAM: Scaling and Supporting 3D Design and Printing in Higher Education. Front. Educ. 6:763362. doi: 10.3389/feduc.2021.763362

Received: 23 August 2021; Accepted: 20 December 2021;

Published: 31 January 2022.

Edited by:

Maria Meletiou-Mavrotheris, European University Cyprus, CyprusReviewed by:

Eva Ropero-Moriones, European University of Madrid, SpainDaniel Frischemeier, University of Münster, Germany

Copyright © 2022 Harron, Emert, Thomas and Campana. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Jason R. Harron, amhhcnJvbkBrZW5uZXNhdy5lZHU=

Jason R. Harron

Jason R. Harron Randy Emert

Randy Emert Dominic M. Thomas

Dominic M. Thomas Jeff Campana

Jeff Campana