95% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

ORIGINAL RESEARCH article

Front. Earth Sci. , 09 January 2023

Sec. Structural Geology and Tectonics

Volume 10 - 2022 | https://doi.org/10.3389/feart.2022.1021436

This article is part of the Research Topic Multiple Field/Scale Rock Mechanics in Coordinated Exploitation of Coal and its Associated Resources View all 11 articles

Cheng Peng1,2,3*

Cheng Peng1,2,3*The gateway of the thick coal seam working face in the Datong mining area was excavated along a small coal pillar, resulting in serious bolt (cable) breaking failure, strong surrounding rock deformation, serious ground pressure appearance, and difficulties surrounding rock control. So, the bolt (cable) breaking characteristics and corresponding causes of the 5106 return air gateway with a small coal pillar in Dongzhouyao coal mine (a mine in the Datong mining area) were analyzed through an on-site investigation, surrounding rock geotechnical parameters test, theoretical analysis, laboratory experiment, on-site engineering test, and other research means. The study carried out laboratory testing and analysis on the stress distribution characteristics and laws of the bolts, put forward the bolt (cable) breaking mechanism and prevention countermeasures, and completed the field industrial test of the surrounding rock pressure relief and support joint control technology in the gateway. The on-site tracking and data showed that the breaking conditions of the bolts (cables) were significantly reduced by improving the initial force of the bolts (cables), optimizing the supporting materials and components, canceling the pressure ring, and implementing the hydraulic fracturing top cutting and pressure relief + high prestressed full cable support technology. The displacement of the top and bottom plates was reduced by 51%, the displacement of the two sides was reduced by 46%, and the influence distance of the working face advance stress was reduced from 85 m to 30 m. The successful implementation of the study results in the small pillar gateway of the Dongzhouyao coal mine provided a reference for the promotion and application of similar gateway conditions in the Datong mining area.

For China, coal has always been the main energy supply, accounting for more than half of the total energy. However, with the increase in mining intensity and depth year by year, the deep mining of underground coal mines has brought many problems (Kang et al., 2021a; Kang et al., 2021b), such as high stress (Xie et al., 2017; Xie et al., 2018), strong dynamic pressure (Li et al., 2022), rock burst (Zhang et al., 2019; Zhang et al., 2020), coal and gas outburst (Liu et al., 2020), roof fall (Lu et al., 2013; Lu et al., 2015), and high temperature (Ranjith et al., 2017). Among these disasters, the problems caused by the strong dynamic pressure and rock burst are more serious (Kang et al., 2019; Gao et al., 2021). Deep mining has also caused the length of affected roadways to increase year by year (Zhang et al., 2021), and the proportion of complex and difficult supporting roadways is increasing (Yang et al., 2018), especially the dynamic pressure gateways with small coal pillars. The deformation of roadways is generally strong, resulting in a larger range of plastic zones (Guo et al., 2019; Ma et al., 2019) and more diversified forms (Shan et al., 2021; Ren et al., 2022). Due to the larger scope of mining (Zhao, 2014), violent movement of overlying strata (Wang et al., 2017), and the generation of void fraction (Wang et al., 2016; Wang and Li, 2017), some bolts and cables are broken, causing serious damage, which makes it difficult to maintain the gateway and poses a higher challenge to safety production (Xie et al., 2019). In deep mining, if thick coal seam mining is simultaneously encountered, it will cause more severe ground bolts supporting (Wu et al., 2019) and cables supporting (Shichang et al., 2021), which is mainly due to the increase in mining intensity and mined out area. Therefore, the deep thick coal seam has a greater impact on safe tunneling and maintenance of the gateway.

In solving the problem of gateway support caused by strong dynamic pressure, scholars have adopted the method of leaving small coal pillars, which makes the gateway arranged before the lateral peak pressure, and reduces the impact of dynamic pressure on the chute. There are usually two methods to retain small coal pillars. One is to retain the gateway of the previous working face as the gateway of the next working face (Wang et al., 2020) and the other is to excavate a new gateway at a small distance on the side of the last gateway after the mining of the previous working face (Jia and Hu, 2020). These two methods can achieve the purpose of mining only by retaining small coal pillars, which are relatively mature for working faces with relatively low mining height, but they are not very mature for thick coal seams (Zhu et al., 2019). These measures have solved the problem of pressure to some extent, but they have not been further studied from the perspective of gateway support.

Dynamic pressure and high-intensity mining have a severe impact on support technology and production safety (Kang et al., 2018; Kang et al., 2020); however, it may be more affected by the support effect of the serving gateway (Lian et al., 2021). For complex and difficult supporting gateways, on the one hand, the method of reducing the influence of dynamic pressure on the working face can be adopted (Mondal and Roy, 2019). On the other hand, most coal mines generally adopt the method of reducing the row spacing between bolts and cables (Nierobisz, 2017), improving the structure (Kang et al., 2016), and capacity (Gao et al., 2014) of bolts, or add an auxiliary shed to strengthen the support. Although the bolts and cables density is very high, the support effect is still not ideal in many cases, and the deformation is still large. Some gateways need to be lifted and bottomed during the tunneling period. According to statistics, the total amount of gateway bottoming works from the excavation to the installation of the working face has reached 2–3 m. Under such conditions, the traditional gateway support method is not effective, and cannot fundamentally solve this kind of gateway support problem.

At present, the coal mine mainly adopted two treatment methods for the first caving of the working face and control of rock burst: blasting and water injection softening (Yongzheng, 2018). Domestic and foreign experts and scholars mainly focused on hydraulic fracturing pressure relief mechanism (Yuanjie et al., 2022), hydraulic fracturing fracture simulation (Gao, 2021), expansion law research (Zhao et al., 2021), and fracturing monitoring technology (Ziyi et al., 2022). Wu and Kang, (2017) pointed out that the directional hydraulic fracturing technology could eliminate the overhang effect of a hard roof and improve the surrounding rock stress environment of the second retaining gateway. Feng and Kang, (2013) analyzed the direction and conditions of crack propagation under the action of in-situ stress. Feng, (2013) established a set of physical simulation and characterization methods for shale hydraulic fracturing. Guo et al, (2014) studied the fracturing expansion law under triaxial conditions and discussed the formation mechanism of a fracture network. Hou et al, (2016) described a method of monitoring hydraulic fracturing fractures using seismic technology. In recent years, directional hydraulic fracturing technology had been developed rapidly. Compared with blasting technology, hydraulic fracturing had some prominent safety and cost advantages. At present, it has been popularized and applied on a large scale in coal mines, mainly focus on the first caving of the working face and the prevention and control of rock bursts (Jiang et al., 2017a; Jiang et al., 2017b). There were few relevant research results on the strength and scope of fracturing roof control technology, pressure relief technology, and anchor cable support technology (Chen et al., 2022a; Chen et al., 2022b), especially on solving the influence of concentrated stress in advance of working face and dynamic pressure gateway in the extra thick coal seam.

Based on the abovementioned background, this study carries out hydraulic fracturing roof cutting, pressure relief, and roof control tests for the typical hard roof in the Datong mining area. The pressure relief effect of gateways with different fracturing parameters is studied, the pressure in the process of hydraulic fracturing and the water output of boreholes are analyzed, and the variation laws of gateway deformation and support pressure are monitored. The obtained results provide a reference for hydraulic fracturing and roof cutting pressure relief of gateways with dynamic pressure in similar extra-thick coal seams.

In recent years, the geological conditions gradually extend from simple Jurassic to complex Carboniferous with the expansion of mining scale and production capacity of the Datong mining area. The mining intensity and depth of coal seams have increased year by year, resulting in the gradual deterioration of the geological conditions of the gateway surrounding rock. The proportion of complex and difficult supporting gateways has increased year by year, especially for the dynamic pressure gateways with small coal pillars. The gateway deformation is strong, and the breaking of bolts and cables is serious, as shown in Figure 1. Dongzhouyao coal mine (a coal mine in the Datong mining area) began to use snake-shaped bolts and bird’s nest cables in 5103 and 5203 gateways, and then popularized and applied them in the tunneling of the whole mine. In the process of popularization and application of the Dongzhouyao coal mine, the bolts and cables were broken and invalid in the gob side gateway along a small coal pillar or someplace nearby an abnormal geological structure, which seriously affected the safety of the supporting system. In view of the above situation, a large number of underground bolts and cables with broken ends and fractures were collected, the breaking characteristics and morphology of bolts and cables were studied, the breaking characteristics and laws of bolts and cables were analyzed, and the prevention and control measures of bolt and cable were put forward.

The broken forms of underground bolts were collected and analyzed, as shown in Figure 2. The fracture positions of bolts were mainly concentrated in the range of 0.5–1.5 m above the orifice, and the forms of fractures were mainly tensile, with obvious necking phenomena like ① and ② in Figure 2, while some were shear fractures without obvious necking phenomenon like ③ in Figure 2.

The broken forms of underground cables were also collected and analyzed, as shown in Figure 3. The facts showed that the cable fractures were mainly bending form, and the fracture locations were mostly concentrated near the orifice location. In addition, the compression rings were deformed, and the damaged ports were neat without necking.

In order to analyze the reasons for the breaking, the underground borehole structure peeping and the surrounding rock in-situ strength measuring device are used to test the structure and in-situ strength in the area where a large number of underground bolts and cables are broken. Analyze the surrounding rock structure, strength data, and characteristics to master the geological conditions of the underground surrounding rock, and then put forward corresponding measures and prevention countermeasures.

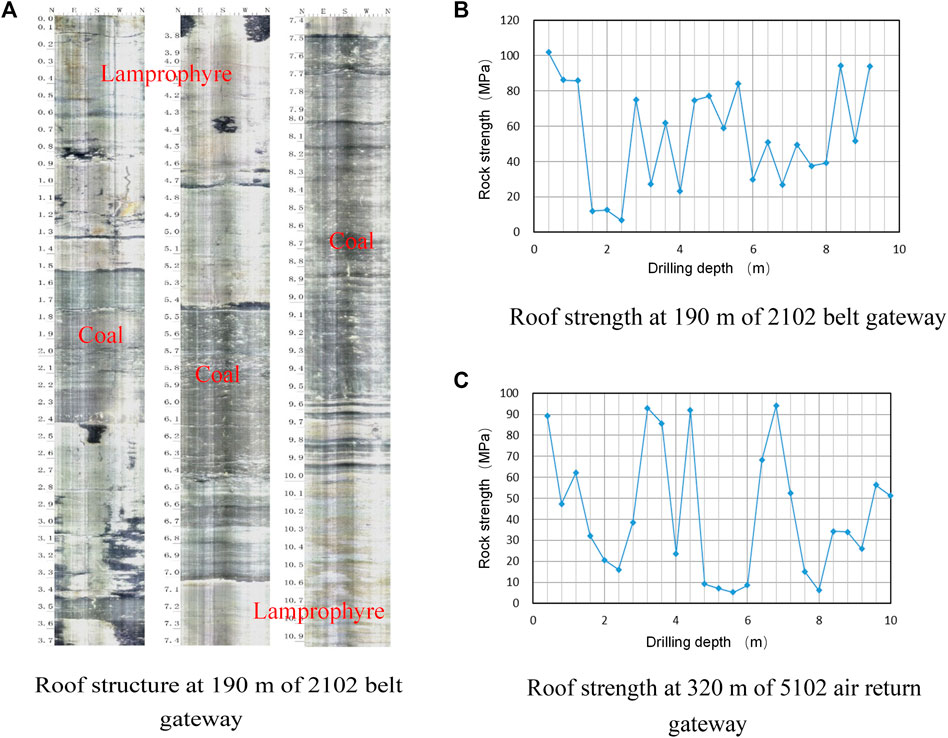

The thickness of 3–5 coal seams in the Datong area is mostly large, and the gateway is generally driven along the coal seam floor, so most of the roofs are the coal seams. Due to the complex geological conditions of the Dongzhouyao coal mine, it is greatly affected by the geological structure, especially in the local area invaded by lamprophyre, which results in great fluctuations in the strength of the gateway roof. The underground surrounding rock structure and strength test results of the Dongzhouyao coal mine are shown in Figure 4. Because lamprophyre is an igneous rock, the underground test strengths are very high, generally reaching 90–100 MPa. While the strengths of 3–5# coal are reduced from 10 to 25 MPa to 5–10 MPa due to the influence of lamprophyre, which leads to the result that the strengths of surrounding rock in the shallow part of the gateway roof fluctuate greatly. At the same time, the horizontal joints of the roof are developed, and the roofs are prone to the horizontal dislocation between lamprophyre and coal joint fissures, which is one of the important reasons for the serious shear failures of bolts and cables.

FIGURE 4. Structure and strength test of underground surrounding rock in Dongzhouyao coal mine. Roof structure at 190 m of 2102 belt gateway. Roof strength at 190 m of 2102 belt gateway. Roof strength at 320 m of 5102 air return gateway.

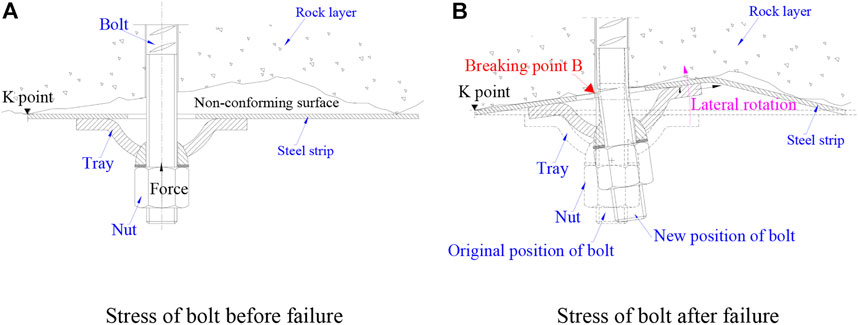

Due to the installation angle of the underground bolt and the actual conditions of the gateway surrounding rock, the bolt may inevitably have a certain installation angle with the surface of the gateway surrounding rock, resulting in the complex stress state of the bolt tail, and from the pure tensile stress state to the tension torsion bending stress state. At the same time, there is a tension bending torsion shear composite stress state due to the influence of geological structure and horizontal displacement of surrounding rock, which results in extremely complex stress, uneven load, breaking, and failure of support bodies and support members. There is usually a non-conforming surface between the steel strip and the rock layer interface, resulting in the load mostly concentrated at point K and the formation of uneven stress, as shown in Figure 5A. Affected by the uneven force, the bolt will rotate laterally, forming a new stress point B and breaking, as shown in Figure 5B.

FIGURE 5. Force analysis of breaking bolts. (A) Stress of bolt before failure. (B) Stress of bolt after failure.

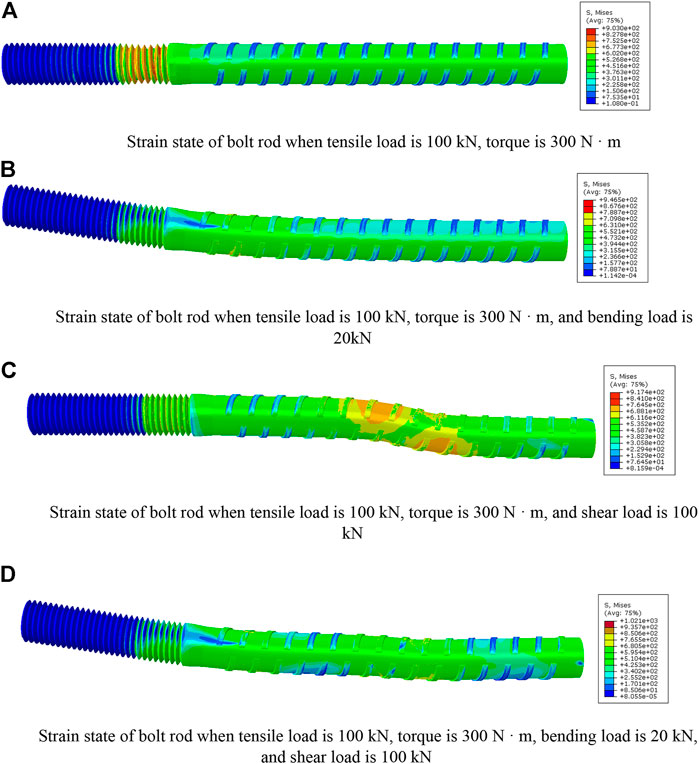

In this study, ABAQUS numerical simulation software is used to establish different simulation schemes, the stress and deformation characteristics of the bolt body and threaded section under the action of single and composite stresses of tension, torsion, bending, and shear are analyzed.

The ABAQUS software is used for simulation calculation, and the model is shown in Figure 6. The total length of the bolt model is 305 mm, the length of the ribbed bolt body is 205 mm, the horizontal rib is left-handed, the top width of the rib is 3 mm, the height of the rib is 0.8 mm, the spacing of the horizontal ribs is 11 mm, the horizontal ribs on both sides are asymmetric, and the diameter of the rod body is 22 mm. Thread parameters: thread M 24, pitch 3 mm, the actual total length of thread 93 mm, thread section plus transition section 100 mm in total.

The specific numerical simulation schemes are as follows:

1) Tension: different tensile loads 30 kN, 100 kN, 160 kN, and 210 kN

2) Tension + torsion: initially apply 100 N m, 300 N m, and 500 N m, and then increase the axial load to 210 kN

3) Tension + torsion + bending: on the basis of (2), apply different levels of bending loads 20 kN, 50 kN, and 80 Kn, respectively

4) Tension + torsion + bending + shear: on the basis of (3), apply different levels of shear loads 1 kN/mm, 2.5 kN/mm, 5 kN/mm at a certain position in the middle of the rod (in the middle of the non-threaded section), simulating the shear force caused by rock dislocation

Through the simulation and analysis of the actual working conditions in the process of underground bolt support, it is found that the underground bolt has the effects of tension, bending, torsion, shear, and other loads in the process of use, and is in a composite stress state, especially for the threaded section from the bolt installation orifice to the bolt tail. The stress of the rod is extremely complex, with high stress and a large variation gradient, as shown in Figure 7. Under the action of bending load and shear load, the stress concentration effect is significant (Figure 8). The load borne by the bolt obviously exceeds the strong performance of the bolt itself, resulting in the breakage and failure of the support body and support components. Therefore, it can be seen that it is very important to match the mechanical properties of underground bolts with the mechanics of supporting components, which can optimize the stress state of bolts and reduce the impact of harmful loads on the bearing performance of bolts.

FIGURE 7. Stress-strain state of the bolt under composite stress state. (A) Strain state of bolt rod when a tensile load is 100 kN, torque is 300 N m. (B) Strain state of bolt rod when a tensile load is 100 kN, torque is 300 N m, and bending load is 20 kN. (C) Strain state of bolt rod when a tensile load is 100 kN, torque is 300 N m, and shear load is 100 kN. (D) Strain state of bolt rod when tensile load is 100 kN, torque is 300 N m, bending load is 20 kN, and shear load is 100 kN.

Through the analysis of the breaking shape and characteristics of the bolts and cables, the test results of the geological conditions of the surrounding rock of the underground gateway, and the theoretical analysis and numerical calculation results, it is considered that the followings are the main reasons for the breaking failure of the bolts and cables in Dongzhouyao coal mine:

1) Geological conditions: the geological factors of the Dongzhouyao coal mine are complex, the geological conditions change greatly affected by lamprophyre intrusion, resulting in great changes in the lithology and strength of lamprophyre and coal body in the roof, which leads to horizontal dislocation deformation of the roof, and shear fracture under horizontal shear load.

2) Gateway stress environment: the surrounding rock stress environment of the gateway along a small coal pillar in the Dongzhouyao coal mine is poor. The gateway is strongly affected by the dynamic pressure of the working face, and the strength requirements of the bolts and cables are high, which are required to have high bearing capacity and elongation. Ordinary 1×7–17.8 mm cable and 20 mm - 335# bolt are difficult to resist the impact of small coal pillar dynamic pressure.

3) Gateway support parameters: through the investigation and sampling inspection of the initial preload of the underground bolts and cables, it is found that the initial prestress of the bolts and cables are low. The control abilities of the roof are poor, which are prone to harmful deformation such as delamination and expansion, and the bolts are prone to tensile failure, resulting in shrinkage fracture failure.

4) Gateway support materials: through the mechanical properties and matching analysis of the original support materials, it is found that the matching between the original support cable and the corresponding tray is poor. There is no self-aligning ball pad, and the stress state at the hole of the cable cannot be adjusted. The pressure ring is easy to deform, and the poor stress state at the hole of the rod and cable is formed when bearing the bending load, and furthermore causes shear failure.

Based on the analysis of the abovementioned reasons for the breaking of bolts and cables, the following prevention countermeasures are put forward:

1) Gateway pressure relief: blasting, hydraulic fracturing, and other means are used to relieve the pressure of the gateway, change the structure and thickness of the surrounding rock of the goaf roof, reduce the stress of the surrounding rock, improve the stress environment, and thus reduce the deformation degree.

2) Increase the initial preload of the bolts and cables: the pre-tightening torque of the bolt rod is increased from 200 N m to 400 N m, and the initial pretension of the cable is increased from 100 kN to 300 kN. Improve the control of the support on the surrounding rock of the roof, fully improve the mechanical properties of the surrounding rock of the support and enhance the bearing capacity.

3) Improve the strengths, mechanical properties, and toughness of support materials: the diameter of the bolts rod is adjusted from 20 mm to 22 mm, and the specification of the cable is changed from 1×7–17.8 mm to 1×19–21.8 mm.

4) The structure of the bolt and cable supporting plate is systematically optimized. The pressure ring is canceled, and the self-aligning ball pad is adopted to improve the stress state. Enhance the bearing capacity of the bolt and cable supporting plate, and optimize the mutual matching of supporting materials and components.

Dongzhouyao coal mine is located in Zuoyun County, Datong City, Shanxi Province, with a design production capacity of 10 million tons per year. Working face 8106 is located in panel 1 of 5 layer of Carboniferous Taiyuan formation. The main mining area is mountain five coal. The average thickness of the coal seam is 6.9 m, the dip angle of the coal seam is 5°, and the burial depth is 470–540 m. The northwest side of 8106 working face is the mined 8102 working face (which has been mined for 4–5 years), the coal pillar size between 5106 air return gateway and the goaf of 8102 working face is 6 m. Due to the large thickness of the coal seam and the small size of the coal pillar, the 5106 air return gateway may be affected by the double mining of the 8102 and 8106 working face during the service period. The stressed environment is complex, the peak stress of the coal pillar is high, and the gateway deformation or damage is serious, which poses a great challenge to mine safety production.

The hydraulic fracturing pressure relief test length of 5106 return air gateway is 300 m, the number of pressure relief holes is 31, and the depth and diameter of the hole are 50 m (including 35 m in the fracturing section and 15 m in the non-fracturing section) and 60 mm, respectively. The hole spacing is 8–10 m and the elevation of the hole is 50°, see Figure 9 for details. Considering that the hard roof rock formation in the deep part of the working face forms a fracture line at the edge of the coal pillar, the included angle range between the horizontal direction of the borehole and the strike of the gateway is designed to be between 5°–10°. The mining high-pressure pump with a large flow is used for water injection. The drilling fracturing range is 15–50 m, and the fracturing is carried out every 2–3 m, with a water injection volume of 2.4 m3 each time.

After a comprehensive analysis, it is determined to adopt high-prestressed full cable strong support technology. Five cables, with a diameter of 21.8 mm, length of 5.2 m, and 1 × 19 high-strength prestressed steel strands, are used in the gateway roof, as shown in Figure 10. The ultimate bearing capacity is 582 kN, the elongation is 5%, the preload is 300 kN, and the spacing between rows is 1.1 m × 0.9 m. The top plate cable adopts a W-shaped steel guard plate and a special-shaped cable support plate to protect the top. At the same time, two single cables with a diameter of 21.8 mm and a length of 7.2 m are constructed for every two rows of steel belts. The upper adopts four cables, with a diameter of 17.8 mm and 1 × 7 strands of prestressed steel strands, and the row spacing is 0.9 m × 0.95 m, the preload is 200 kN.

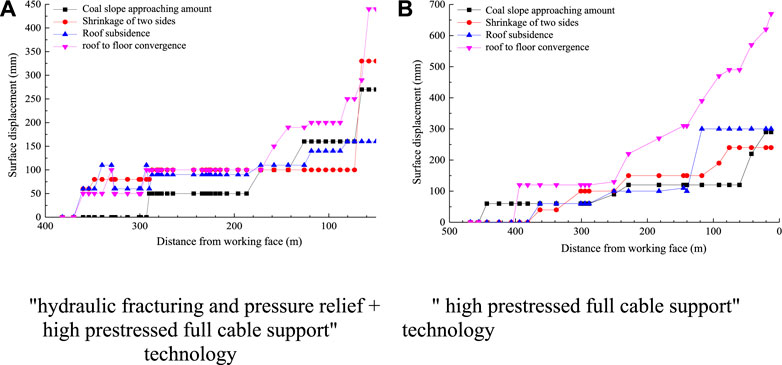

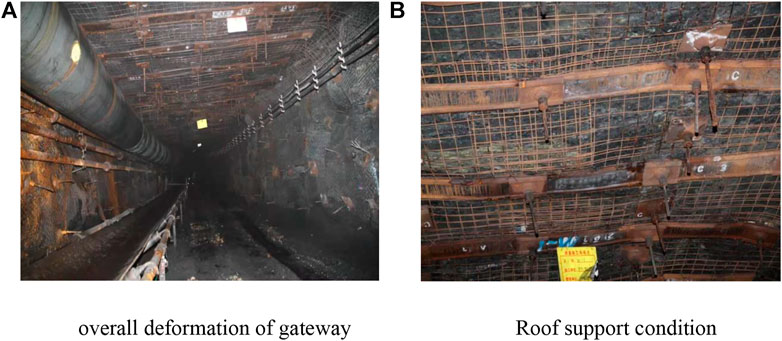

The field test shows that hydraulic fracturing and pressure relief drilling in the deep part of the roof of the small coal pillar gateway can change the basic roof structure and strength and reduce the influence of the advanced abutment pressure during mining. At the same time, the strength and matching of support materials are optimized combined with the gateway high prestressed full cable support technology, and the effective anchoring of the shallow surrounding rock of the gateway is realized. The support breaking situation is effectively alleviated and improved, and there is no large-scale breaking failure. The ground pressure monitoring data shows that the combined control technology of hydraulic fracturing and pressure relief + high prestressed full cable support has a very significant effect on the surrounding rock control of a small coal pillar dynamic pressure gateway. The overall deformation of the gateway has been significantly reduced, of which the maximum displacement of the two sides is 330 mm, and the maximum displacement of the roof and floor is 440 m, as shown in Figure 11. Compared with other gateways with similar conditions in the mine, the roof and floor displacements are reduced by 51% after the application of the “support unloading coupling” joint control technology. The displacements of two sides are reduced by 46%, and the influence distance of the advance stress of the working face is reduced from 85 m to within 30 m, the final deformation of the gateway is shown in Figure 12.

FIGURE 11. Deformation monitoring curve of underground gateway after hydraulic fracturing and pressure relief + high prestressed full cable support” technology. (A) “Hydraulic fracturing and pressure relief + high prestressed full cable support” technology. (B) " High prestressed full cable support” technology.

FIGURE 12. Underground gateway condition after “hydraulic fracturing and pressure relief + high prestressed full cable support” technology. (A) Overall deformation of the gateway. (B) Roof support condition.

1) This study makes a comprehensive analysis of the breaking shape of the bolts and cables in the Dongzhouyao coal mine, gets the stress characteristics of underground bolts (cables), and measurement of the geomechanical parameters of the gateway surrounding rock. It is considered that the changes in the geological conditions of gateway surrounding rock, stress environment, unreasonable support parameters, and mismatching of support materials are the important reasons for the failure of dynamic pressure gateway along small coal pillar.

2) In view of the difficult problem of surrounding rock control of dynamic pressure gateway along small coal pillar, the measures including the hydraulic fracturing technology, pressure relief technology, optimizing strength and matching of support materials, and improving the initial support prestress are proposed, which effectively solves the fracture failure and support of dynamic pressure gateway along small coal pillar.

3) Compared with other similar dynamic pressure gateways along small coal pillars in the mine, the combined control technology of “hydraulic fracturing and pressure relief + high prestressed full cable support” is adopted. Results show that the roof and floor displacement of the gateway is reduced by 51%, the displacement of the two sides is reduced by 46%, and the influence distance of the advance stress of the working face is reduced from 85 m to 30 m.

The original contributions presented in the study are included in the article/Supplementary Material; further inquiries can be directed to the corresponding author.

The author completed all the contents by himself.

The author gratefully acknowledges the financial support by the Natural Science Foundation of China (Grant no. 52004126) and the special project of science and technology innovation and entrepreneurship fund of Tiandi Science and Technology Co., Ltd. (Grant no. 2022-2-TD-MS013).

Author CP was employed by Tiandi Science and Technology Co., Ltd.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors, and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Chen, J., Liu, P., Liu, L., Zeng, B., Zhao, H., Zhang, C., et al. (2022). Anchorage performance of a modified cable anchor subjected to different joint opening conditions. Constr. Build. Mater. 27 (03), 607–614. doi:10.1016/j.conbuildmat.2022.127558

Chen, J., Zeng, B., Liu, L., Tao, K., Zhao, H., Zhang, C., et al. (2022). Investigating the anchorage performance of full-grouted anchor bolts with a modified numerical simulation method. Eng. Fail. Anal. 106640. doi:10.1016/j.engfailanal.2022.106640

Feng, Y., and Kang, H. (2013). The initiation of Ⅰ-Ⅱ mixed mode crack subjected to hydraulic pressure in brittle rock under compression. J. China Coal Soc. 38 (02), 226–232.

Feng, Y. (2013). Research and application of fracture propagation mechanism of hydraulic fracturing in hard and difficult roof of coal mine. Beijing: Graduate School of China Coal Research Institute.

Gao, F. (2021). Influence of hydraulic fracturing of strong roof on mining-induced stress-insight from numerical simulation. J. Min. Strata Control Eng. 3.

Gao, F., Kang, H., and Li, J. (2021). Numerical simulation of fault-slip rockbursts using the distinct element method. Tunn. Undergr. Space Technol. 110, 103805. doi:10.1016/j.tust.2020.103805

Gao, F., Stead, D., and Coggan, J. (2014). Evaluation of coal longwall caving characteristics using an innovative UDEC Trigon approach. Comput. Geotechnics 55, 448–460. doi:10.1016/j.compgeo.2013.09.020

Guo, X., Zhao, Z., Gao, X., Wu, X., and Ma, N. (2019). Analytical solutions for characteristic radii of circular roadway surrounding rock plastic zone and their application. Int. J. Min. Sci. Technol. 29, 263–272. doi:10.1016/j.ijmst.2018.10.002

Guo, Y., Yang, C., Jia, C., Xu, J., Wang, L., and Li, D. (2014). Research on hydraulic fracturing physical simulation of shale and fracture characterization methods. Chin. J. Rock Mech. Eng. 33 (01), 52–59.

Hou, Z., Yang, C., Wang, L., and Lei, P. (2016). Hydraulic fracture propagation of shale horizontal well by large-scale true triaxial physical simulation test, 37. Chongqing: Rock and Soil Mechanics.

Jia, C., and Hu, C. (2020). Instability mechanism and control technology of longwall entries driving along the gob in a thick coal seam. J. Min. Strata Control Eng. 2 (4), 38–45.

Jiang, L., Wang, P., Zhang, P., Zheng, P., and Xu, B. (2017). Numerical analysis of the effects induced by normal faults and dip angles on rock bursts. Comptes Rendus Mécanique 345, 690–705. doi:10.1016/j.crme.2017.06.009

Jiang, L., Zhang, P., Chen, L., Hao, Z., Sainoki, A., Mitri, H. S., et al. (2017). Numerical approach for goaf-side entry layout and yield pillar design in fractured ground conditions. Rock Mech. Rock Eng. 50, 3049–3071. doi:10.1007/s00603-017-1277-0

Kang, H., Jiang, P., Wu, Y., and Gao, F. (2021). A combined “ground support-rock modification-destressing” strategy for 1000-m deep roadways in extreme squeezing ground condition. Int. J. Rock Mech. Min. Sci. 142, 104746. doi:10.1016/j.ijrmms.2021.104746

Kang, H., Lou, J., Gao, F., Yang, J., and Li, J. (2018). A physical and numerical investigation of sudden massive roof collapse during longwall coal retreat mining. Int. J. Coal Geol. 188, 25–36. doi:10.1016/j.coal.2018.01.013

Kang, H., Wu, L., Gao, F., Lv, H., and Li, J. (2019). Field study on the load transfer mechanics associated with longwall coal retreat mining. Int. J. Rock Mech. Min. Sci. 124, 104141. doi:10.1016/j.ijrmms.2019.104141

Kang, H., Wu, Y., Gao, F., Jiang, P., Cheng, P., Meng, X., et al. (2016). Mechanical performances and stress states of rock bolts under varying loading conditions. Tunn. Undergr. Space Technol. 52, 138–146. doi:10.1016/j.tust.2015.12.005

Kang, H., Yang, J., Gao, F., and Li, J. (2020). Experimental study on the mechanical behavior of rock bolts subjected to complex static and dynamic loads. Rock Mech. Rock Eng. 53, 4993–5004. doi:10.1007/s00603-020-02205-0

Kang, H., Yuan, G., Gao, F., and Lou, J. (2021). Experimental study on the performance of different meshes under quasi-static loading. Rock Mech. Rock Eng. 55, 249–258. doi:10.1007/s00603-021-02651-4

Li, C., Zuo, J., Xing, S., Du, W., and Chuai, X. (2022). Failure behavior and dynamic monitoring of floor crack structures under high confined water pressure in deep coal mining: A case study of Hebei, 139. China: Engineering Failure Analysis.

Lian, X., Zhang, W., Li, C., and Guo, X. (2021). Application of discrete data extreme value distribution in the analysis of mine pressure rule. Arab. J. Geosci. 14, 2011. doi:10.1007/s12517-021-08352-0

Liu, H., Guo, L., and Zhao, X. (2020). Expansionary evolution characteristics of plastic zone in rock and coal mass ahead of excavation face and the mechanism of coal and gas outburst. Energies 13, 984. doi:10.3390/en13040984

Lu, C.-P., Dou, L.-M., Zhang, N., Xue, J.-H., Wang, X.-N., Liu, H., et al. (2013). Microseismic frequency-spectrum evolutionary rule of rockburst triggered by roof fall. Int. J. Rock Mech. Min. Sci. 64, 6–16. doi:10.1016/j.ijrmms.2013.08.022

Lu, C.-P., Liu, G.-J., Liu, Y., Zhang, N., Xue, J.-H., and Zhang, L. (2015). Microseismic multi-parameter characteristics of rockburst hazard induced by hard roof fall and high stress concentration. Int. J. Rock Mech. Min. Sci. 76, 18–32. doi:10.1016/j.ijrmms.2015.02.005

Ma, N., Ji, M., Zhiqiang, Z., and Xiaofei, G. (2019). Mechanical mechanism and evolution of X-shaped conjugate shear fractures-seism. J. China Coal Soc. 44 (6), 1647–1653.

Mondal, D., and Roy, P. N. S. (2019). Fractal and seismic b-value study during dynamic roof displacements (roof fall and surface blasting) for enhancing safety in the longwall coal mines. Eng. Geol. 253, 184–204. doi:10.1016/j.enggeo.2019.03.018

Nierobisz, A. (2017). Identification of load to dog heading support during a rockburst. J. Min. Sci. 52, 1129–1142. doi:10.1134/s1062739116061662

Ranjith, P. G., Zhao, J., Ju, M., De Silva, R. V. S., Rathnaweera, T. D., and Bandara, A. K. M. S. (2017). Opportunities and challenges in deep mining: A brief review. Engineering 3, 546–551. doi:10.1016/j.eng.2017.04.024

Ren, J., Zhang, W., and Ma, J. (2022). Experimental study on butterfly shape of failure zone and fractal characteristics of rock burst. Eng. Fail. Anal. 140, 106636. doi:10.1016/j.engfailanal.2022.106636

Shan, R., Li, Z., Wang, C., Wei, Y., Bai, Y., Zhao, Y., et al. (2021). Research on the mechanism of asymmetric deformation and stability control of near-fault roadway under the influence of mining. Eng. Fail. Anal. 127, 105492. doi:10.1016/j.engfailanal.2021.105492

Shichang, S., Yongzheng, W., Yukai, F., and Penghao, Z. (2021). Experimental study on shear mechanical properties of anchored rock mass under impact load. J. Min. Strata Control Eng. 3 (4), 26–33.

Wang, S., and Li, X. (2017). Dynamic distribution of longwall mining-induced voids in overlying strata of a coalbed. Int. J. Geomech. 17 (6), 04016124. doi:10.1061/(asce)gm.1943-5622.0000820

Wang, S., Li, X., and Wang, D. (2016). Void fraction distribution in overburden disturbed by longwall mining of coal. Environ. Earth Sci. 75, 151. doi:10.1007/s12665-015-4958-6

Wang, S., Li, X., and Wang, S. (2017). Separation and fracturing in overlying strata disturbed by longwall mining in a mineral deposit seam. Eng. Geol. 226, 257–266. doi:10.1016/j.enggeo.2017.06.015

Wang, Y., Tu, M., Fu, B., and Bu, Q. (2020). Study on the distribution of side abutment pressures and ground support for double-used entries in deep mining. J. Min. Strata Control Eng.

Wu, Y., Gao, F., Chen, J., and He, J. (2019). Experimental study on the performance of rock bolts in coal burst-prone mines. Rock Mech. Rock Eng. 52, 3959–3970. doi:10.1007/s00603-019-01794-9

Wu, Y., and Kang, H. (2017). Pressure relief mechanism and experiment of directional hydraulic fracturing in reused coal pillar roadway. J. China Coal Soc. 42 (5), 1130–1137.

Xie, J., Xu, J., and Wang, F. (2018). Mining-induced stress distribution of the working face in a kilometer-deep coal mine—A case study in tangshan coal mine. J. Geophys. Eng. 15, 2060–2070. doi:10.1088/1742-2140/aabc6c

Xie, L. X., Lu, W. B., Zhang, Q. B., Jiang, Q. H., Chen, M., and Zhao, J. (2017). Analysis of damage mechanisms and optimization of cut blasting design under high in-situ stresses. Tunn. Undergr. Space Technol. 66, 19–33. doi:10.1016/j.tust.2017.03.009

Xie, S., Pan, H., Zeng, J., Wang, E., Chen, D., Zhang, T., et al. (2019). A case study on control technology of surrounding rock of a large section chamber under a 1200-m deep goaf in Xingdong coal mine, China. Eng. Fail. Anal. 104, 112–125. doi:10.1016/j.engfailanal.2019.05.039

Yang, J. H., Jiang, Q. H., Zhang, Q. B., and Zhao, J. (2018). Dynamic stress adjustment and rock damage during blasting excavation in a deep-buried circular tunnel. Tunn. Undergr. Space Technol. 71, 591–604. doi:10.1016/j.tust.2017.10.010

Yongzheng, W. (2018). Study on de-stressing mechanism of directional hydraulic fracturing to control deformation of reused roadway in longwall mining with two gateroad layout and its onsite practices. Beijing: Graduate School of China Coal Research Institute.

Yuanjie, W., Gang, X., Fabing, C., and Yangpo, L. (2022). Mining pressure weakening mechanism by ground fracturing and fracturing evaluation of hard rock strata. J. Min. Strata Control Eng. 4 (2), 15–23.

Zhang, W., Li, C., Jin, J., Qu, X., Fan, S., and xin, C. (2021). A new monitoring-while-drilling method of large diameter drilling in underground coal mine and their application. Measurement 173, 108840.

Zhang, W., Ma, N., Ma, J., Li, C., Ren, J., and Jiang, B. (2020). Mechanism of rock burst revealed by numerical simulation and energy calculation. Shock Vib. 2020, 1–15. doi:10.1155/2020/8862849

Zhang, W., Qu, X., Li, C., Xu, X., Zhang, S., Jin, G., et al. (2019). Fracture analysis of multi-hard roofs based on microseismic monitoring and control techniques for induced rock burst: A case study. Arab. J. Geosci. 12, 784. doi:10.1007/s12517-019-4972-1

Zhao, K., Jiang, P., Feng, Y., and Sun, X. (2021). Investigation of the characteristics of hydraulic fracture initiation by using maximum tangential stress criterion. J. Min. Strata Control Eng.

Zhao, Z. (2014). Mechanism of surrounding rock deformation and failure and control method research in large deformation mining roadway. Beijing): China University of mining and technology.

Zhu, S., Jiang, F., Wang, X., Jiang, Y., Ning, T., and Sun, S. (2019). Energy accumulation characteristics and rockburst mechanism of surrounding rock at heading face of extra-thick coal seam. Chin. J. Geotechnical Eng. 41 (11), 2071–2078.

Keywords: Datong mining area, thick coal seams, gob side gateway, support failure, top cutting and pressure relief, ground pressure monitoring

Citation: Peng C (2023) Research on the breaking mechanism of bolts and cables in the gateway driven along a small coal pillar in the Datong mining area and the corresponding control technology. Front. Earth Sci. 10:1021436. doi: 10.3389/feart.2022.1021436

Received: 17 August 2022; Accepted: 21 September 2022;

Published: 09 January 2023.

Edited by:

Lishuai Jiang, Shandong University of Science and Technology, ChinaReviewed by:

Shun Liang, China University of Mining and Technology, ChinaCopyright © 2023 Peng. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Cheng Peng, Y3BoYXBweUAxNjMuY29t

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.