- 1Xinyu Highway Survey and Design Institute, Xinyu, China

- 2Jiangxi Transportation Institute Co., Ltd., Nanchang, China

- 3Road Material and Structure Engineering Technology Research Center of Jiangxi Provincial, Nanchang, China

- 4School of Transportation and Logistics Engineering, Wuhan University of Technology, Wuhan, China

Emulsified asphalt has become a popular green material in modern road construction due to its environmentally friendly and energy-saving characteristics. The method of obtaining residues is crucial for accurately evaluating the performance of emulsified asphalt and ensuring the quality of road construction. The evaporated residues of 3% and 6% SBR modified emulsified asphalt and 6% SBS modified emulsified asphalt were obtained by the low-temperature evaporation (LTE) method and the direct heating (DH) method, respectively. The rheological properties of the modified asphalt residues were tested by the temperature frequency sweeping (TFS), multi-stress creep recovery (MSCR), and linear amplitude sweeping (LAS) tests using the dynamic shear rheometer (DSR), and their aging resistance in the form of carbonyl index was measured by the Fourier infrared spectroscopy (FTIR). The test results showed that, as compared to the DH method, the SBR modified emulsified asphalt residue obtained by the LTE method had higher elastic recovery rate, lower irrecoverable creep compliance, smaller accumulated performance deformation, longer fatigue life, and higher aging resistance, indicating that the LTE method using the low-temperature curing conditions (25°C, 24 h—60°C, 24 h) is more suitable for curing the SBR modified emulsified asphalt. However, the opposite trends of the performance indices except the aging resistance were observed for the SBS modified emulsified asphalt residue obtained from the LTE method, showing that the high-temperature curing condition (120°C, 30 min—163°C, 1 min) can give the SBS modified asphalt residue better rheological properties and higher fatigue resistance performance, but it also has the disadvantage of weakening the aging resistance. Therefore, in practical application, an appropriate curing temperature should be selected to condition the SBS modified emulsified asphalt for balancing its rheological performance and aging resistance.

1 Introduction

Depending on the production temperature, asphalt mixes can be divided into hot mix asphalt (HMA), warm mix asphalt (WMA), and cold mix asphalt (CMA). Among them, the construction temperature of HMA generally ranges between 150°C and 170°C to ensure that the conventional asphalt has sufficient fluidity to produce a homogeneous mix with the aggregates. These high construction temperatures not only consume tremendous fossil fuels but also release large amounts of volatile organic compounds (VOCs) and greenhouse gases (GHG). It has been reported that for every 10°C increased in HMA production temperature, nearly 1 L of fossil fuel consumption and 1 kg of carbon dioxide emissions will be increased from the production of 1 ton of HMA (Li et al., 2019). Therefore, to reduce energy consumption and carbon emissions, research is currently focused more on the application of CMA into asphalt pavement because the paving of CMA can be completed at relatively low or even ambient temperatures (around 15°C–40°C). This significant reduction of paving temperature is mainly owed to the use of the emulsified asphalt. Therefore, it is of great importance to study the performance of the emulsified asphalt.

It is well recognized that the synthesis of emulsified asphalt relies on the emulsification reaction between asphalt and emulsifier. In this reaction, the emulsifier acts as a bridge between asphalt-water. Its lipophilic end inserts the asphalt molecules and the hydrophilic end moves into the water molecules. Then the emulsified asphalt uses water as a continuous phase, whose viscosity is low enough to maintain workability of CMA at ambient temperatures. When the emulsified asphalt and aggregate are mixed together, the demulsification of the emulsified asphalt will be taken place spontaneously under the evaporation of water. Then the residue of emulsified asphalt will be bonded gradually with the aggregate, resulting in the mechanical performance regain of the CMA. To this effect, the residue of emulsified asphalt obtained after complete evaporation of water will directly affect the performance properties of the CMA. Considering that the performance of the common emulsified asphalt residue can somewhat be degraded due to the emulsification of the emulsifier, the application of emulsified asphalt is often limited to non-structural pavement layers.

To extend the application of emulsified asphalt, various high-performance modified emulsified asphalts have been developed by incorporating different types of emulsifiers (Yuliestyan et al., 2017; Pang et al., 2015), modifiers (Hemmati et al., 2021; Ren et al., 2021; Wang et al., 2014; Fan, 2019), fillers (Li et al., 2017), and additives (Li et al., 1998) for the purpose of improving the rheological property, fatigue resistance and aging resistance of the evaporative residue. For instance, based on the Mannich reaction, Yuliestyan et al. (2017) developed a modified lignin emulsifiers (MKL) using sulfated lignin (KL) cationic emulsifiers. It was found that with the use of the MKL, the emulsified asphalt prepared under the optimum reaction conditions (MKL dosage ≤ 2wt% and bitumen to water (B/W) ratio = 7:3) could greatly improve the viscous flow of the emulsion residue. Li et al. (2019) explored the use of waterborne epoxy-modified emulsified asphalt (WEB) for the fabrication of high-performance CMA. They found that the addition of waterborne epoxy resin (WE) significantly increased the shear modulus and decreased the phase angle of the residue. In addition, with the increase of WE, the elastic recovery rate of the residue increased while the non-recoverable creep compliance decreased. Li et al. (2017) analyzed the effect of four fillers, including a limestone filler and three types of steel slag filler on the rheological properties of CMA. The results showed that the CMA incorporated with the steel slag fillers had better high-temperature deformation resistance than the CMA modified by the limestone filler due to the enhancement of asphalt stiffness by the steel slag and the favorable chemical reaction of the asphaltene with the alkaline components of the slag fillers. In addition to the material factors, some more research efforts have identified that the curing conditions will also affect the performance of evaporation residue of emulsified asphalt. For example, Sun et al. (2020) selected two types of unmodified asphalt binders and two emulsifiers to fabricate unmodified emulsified asphalt. The rheological and fatigue properties of the residues obtained by different evaporation methods, including the JTG T0651-1993 direct heating (DH) method (JTG, 2011), EN13074 low-temperature evaporation (LTE) method, and ASTM D7497-09 (ASTM, 2009) low-temperature evaporation method (Farrar et al., 2013), were then investigated. The test results exhibited that the increase in rutting factor, recovery rate, complex modulus, and fatigue life of the residues can be ranked in the following order: ASTM D7497-09 > EN 13074 > JTG T0651-1993, indicating that the curing condition has a significant impact on the performance of evaporation residue of emulsified asphalt. However, that piece of work focused on investigating the performance change of the unmodified emulsified asphalt. Chen et al. (2020) used two curing methods (DH and LTE methods) to obtain the asphalt residues for SBR and SBS modified emulsified asphalt binders at four different evaporation temperatures (25, 60, 80, and 100°C). It was found that the higher the evaporation temperature, the greater the mass loss of the early-residues and the shorter the time required for the performance of asphalt residues to reach stability. Wang et al. (2022) prepared emulsified asphalt using five different material samples, and used three evaporation methods to obtain emulsified asphalt evaporation residues (EAERs): direct heating method, low-temperature evaporation method, and improved evaporation method. They concluded that the low-temperature evaporation method is recommended to prepare EAERs for a more realistic evaluation of the high-temperature performance of emulsified asphalt. Besides, the solid content of modified emulsified asphalt binder obtained at different evaporation temperatures was also observed to be different. That study explored the influence of curing conditions on the performance of evaporation residue of modified emulsified asphalt. However, it involves the investigation of very simple physical property change of the asphalt residue, such as the mass loss and solid content change, which is unable to unveil the performance degradation mechanism of the emulsified asphalt residue.

In conclusion, some research efforts have currently been devoted to quantifying the effect of evaporation methods on the properties of emulsified asphalt residues. However, they either selected the unmodified emulsified asphalt binders as research objects or investigated on the simple physical property change of the emulsified asphalt residue. Very few studies have involved investigating the effects of curing conditions on the performance of recovered residue of modified emulsified asphalt. To fulfill this research gap, this work will focus on studying the influence of evaporation methods on the performance of two types of commonly-used modified emulsified asphalt, including the SBR and SBS modified emulsified asphalt binders. The investigated performance properties include the rheological performance properties and aging resistance property. The findings of this study are anticipated to provide dual contributions: 1) facilitating the determination of optimum curing conditions for a specific given type of modified emulsified asphalt; and 2) identifying the best modified emulsified asphalt that has the highest compatibility with specific paving conditions.

2 Test materials and methods

2.1 Test materials

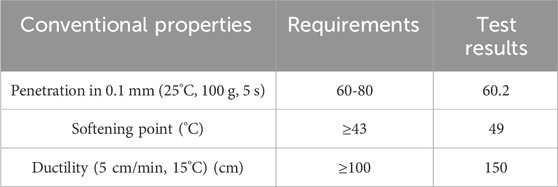

The 6% SBS modified emulsified asphalt (cationic, SBS modifier content of 6%) used in this study is supplied by Hubei Guochuang high tech materials Co., Ltd., which is labeled as 6%SBS. As different from the SBS modified emulsified asphalt, the SBR modified emulsified asphalt used was synthesized in the laboratory. The raw materials selected include #70 base asphalt, cationic quick setting asphalt emulsifier, and SBR asphalt modifier, all of which are provided by Hubei Guochuang high tech materials Co., Ltd. The conventional properties of the #70 base asphalt are listed in Table 1.

The SBR modified emulsified asphalt was prepared by emulsifying the 70 # base asphalt first with the emulsifier and then modifying with the SBR modifier. The following key steps are involved.

(1) The #70 base asphalt was heated in an oven at 135°C for 1 h to make it fluid freely.

(2) The 2% emulsifier (by mass of base asphalt) and 0.2% anhydrous calcium chloride stabilizer were dissolved in water at 55°C to prepare the emulsifier soap, of which pH value was adjusted to 2.0 by hydrochloric acid. The preparation of liquid emulsifier can be assumed to complete as long as no precipitation appears in the emulsifier soap.

(3) The mass ratio of asphalt to liquid emulsifier soap was set to 6:4. Based on this mass ratio, the #70 base asphalt was mixed with the soap at a shear speed of 2000 rmp at 135°C for 15 min to obtain the emulsified asphalt.

(4) After the emulsified asphalt cooled down to the room temperature, the SBR modifier was added into the emulsified asphalt with two dosages (3% and 6%) and sheared at 2000 rmp for 3 min.

Based on the above steps, the SBR modified emulsified asphalt with two dosages of 3% and 6% were finally fabricated, which are labeled as 3% SBR and 6% SBR, respectively. For comparison, the #70 asphalt was also emulsified and used as a control group.

2.2 The methods to obtain evaporated residues

Two standard evaporation methods were used to obtain the emulsified asphalt evaporation residues, which are the direct heating (DH) method (JTG T0651-1993) and the low-temperature evaporation (LTE) method (ASTM, 2009). Noted that the DH is a standard method used in China, while the LTE is a standard method used in the United States. Detailed procedures of these two evaporation methods are summarized as below.

(1) Direct heat (DH) method (JTG T0651-1993)

The modified emulsified asphalt was poured into a beaker and heated slowly at 120°C. A glass rod was then used to stir the emulsified asphalt during this process to ensure that the water vapor evaporated promptly during the course of demulsification, as shown in Figure 1. To eliminate the potential detrimental effects of the water, another cold glass is hung upside on the heated beaker for 30 s (Figure 2). If no water is condensed on the inner wall of the cold beaker, the demulsification of the emulsified asphalt is assumed to complete and the water is completely removed from the asphalt residue.

(2) Low-temperature evaporation (LTE) method (ASTM, 2009)

The modified emulsified asphalt was poured into a 10 cm × 10 cm silica gel plate mold and was gently vibrated to make the distribution of emulsified asphalt uniform, as shown in Figure 3. After that, the samples were placed into an oven and heated at 25°C for 24 h. Subsequently, the temperature was raised up to 60°C and continuously heated for another 24 h, as shown in Figure 3. Finally, the sample was taken out and cooled to room temperature to obtain the evaporation residue of modified emulsified asphalt.

2.3 Performance evaluation of recovered residues

In this study, the performance testing of 6% SBS modified emulsified asphalt residue and 3% and 6% SBR modified emulsified asphalt residues was carried out, which can be categorized into two groups: 1) rheological performance tests: temperature-frequency sweep test, multi-stress creep recovery (MSCR) test, and linear amplitude sweep (LAS) test; and 2) aging resistance performance test: Fourier transform infrared spectroscopy (FTIR) test. The rheological performance tests were carried out using a Dynamic Shear Rheometer (Manufactured by Erich NETZSCH GmbH and Co. Holding KG, Selb, Germany), while the aging resistance performance test was carried out by the FTIR (Manufactured by Thermo Fisher Scientific Inc., Waltham, United States). The test procedure of each test method is given in details below.

(1) Temperature-frequency sweep test

The complex shear modulus and phase angle values of the modified emulsified asphalt residues in a certain temperature-frequency range can be measured by the temperature-frequency sweep test. The data were used to plot the master curve of dynamic shear modulus G* and phase angle δ of the modified emulsified asphalt residue. In this study, the continuous sinusoidal alternating loading was applied and the strain control mode was adopted. The temperature was selected from 10°C to 70°C with a gradient of 10°C, while the loading frequency range was chosen between 0.1 and 10 Hz. To ensure that all the asphalt residue samples were retained in the linear viscoelastic stage, the loading strain level was determined as 0.2% through the strain sweep test prior to the temperature-frequency sweep test (Guo and Ni, 2014).

(2) Multi-stress creep recovery (MSCR) test

It has been reported that the MSCR test results correlate better with the rutting resistance of polymer modified asphalt materials than the rutting parameters of SHRP. Also, the higher stress level (3.2 MPa) applied in this test will result in damage or rearrangement of the polymer networks in the polymer-modified asphalt binder. Thus, the MSCR test has capability to provide a satisfactory performance evaluation on the polymer modified asphalt (Zhang et al., 2021). Due to these advantages, the MSCR test was used in this study to assess the recoverable and non-recoverable ability of the emulsified asphalt residue. The MSCR test usually selects two typical stress levels, namely, 0.1 kPa and 3.2 kPa, to load on the asphalt binder. The 0.1 kPa shear stress level is used to characterize the linear viscoelastic behavior, while the 3.2 kPa shear stress level to assess the non-linear viscoelastic behavior of the asphalt binder (Xu et al., 2017). In this study, the MSCR test was carried out on the modified emulsified asphalt residues at 64°C following the test procedures specified in AASHTOTP70-13. After the test, the raw test data were extracted from the ten creep-recovery loading cycles to calculate the mean values of the unrecoverable creep compliance Jnr (Jnr0.1 and Jnr3.2) as well as the elastic recovery rate R (R0.1 and R3.2) for the two stress levels (0.1 kPa and 3.2 kPa), respectively. The calculation formula of

Where

(3) Linear amplitude sweep (LAS) test

The LAS test is a routine test method used to determine the fatigue resistance of asphalt materials via applying cyclic loadings with linearly increasing amplitudes. By adopting this test method, the strain-controlled fatigue model can be easily developed on the basis of the viscoelastic continuum damage (VECD) theory, in which the pseudo-strain energy (PSE) is used to establish the relationship between the damage intensity D) and the material integrity C). In this study, the VECD fatigue model was selected to characterize the fatigue resistance of emulsified asphalt residue. The LAS test was performed at 25°C under the guideline of AASHTOTP101-14 (Yuan et al., 2020), which consists of two steps. In the first step, a strain loading level of 0.1% was applied on the emulsified asphalt residue samples with 12 loading frequencies selected (30, 20, 10, 8, 6, 4, 2, 1, 0.8, 0.6, 0.4, 0.2 Hz). In the second step, the asphalt samples were subjected to oscillatory shearing in strain control mode at 10 Hz and 25°C. A continuous oscillatory loading cycle with linearly increasing strain amplitude from 0.1% to 30% was then applied to accelerate the fatigue damage of asphalt residue.

The formula for the degree of damage D is shown in Eq. 3.

Where

At time t, record the values of D(t) and C(t), which can be fitted as Eq. 4.

Where

The damage value at the time of failure corresponds to the maximum peak shear stress, as shown in Eq. 3. And the fatigue equation can be represented by Eq. 5.

Where

(4) Fourier transform infrared (FTIR) test

As is well known, the asphalt aging is resulted mostly from the oxidative aging at high temperatures. This oxidative aging can change the asphalt chemical compositions and the associated distribution patterns (Das et al., 2015). For instance, it has been found that certain types of carbon and sulphur components in asphalt are susceptible to oxidation, and the carbonyl (C = O) functional groups have been identified as the main functional groups formed after the oxidative aging (Petersen and Harnsberger, 1998). These C = O functional groups can be easily detected by the FTIR, which correspond to the FTIR spectra at wave number of 1700 cm−1 (Ouyang et al., 2006; Yao et al., 2013; Xu et al., 2022; Xu and Luo, 2022). In this study, the aging resistance of the three modified emulsified asphalt residues was assessed through measuring the changes in the C = O functional groups of each modified emulsified asphalt residue sample. To facilitate the quantitative analysis, the carbonyl index

where:

3 Results and discussion

3.1 Temperature-frequency sweep test results

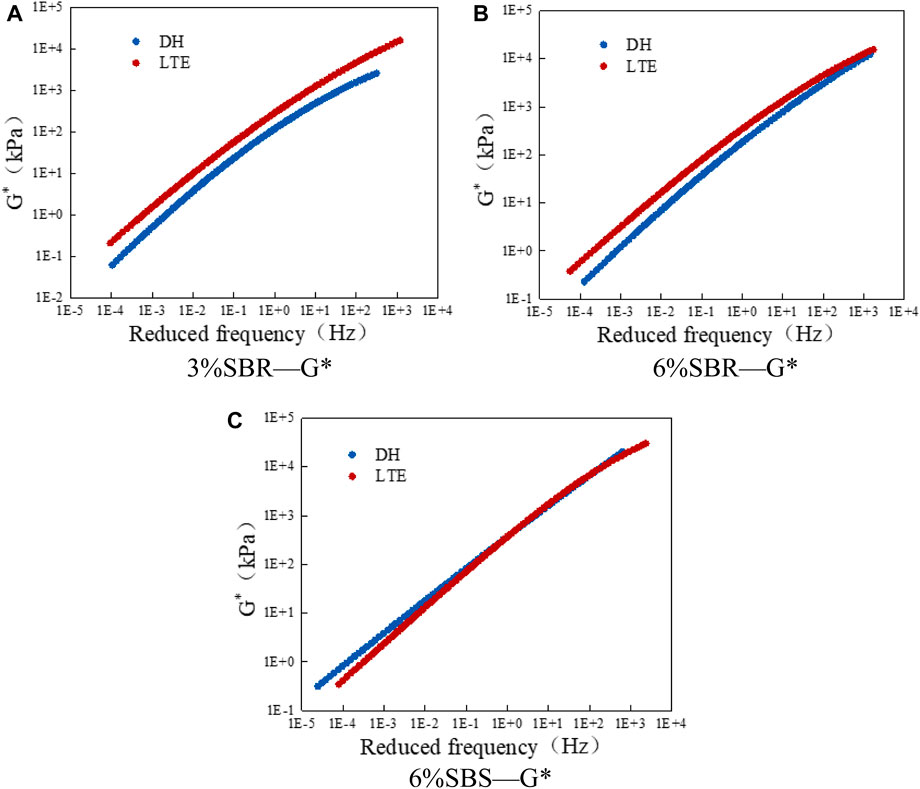

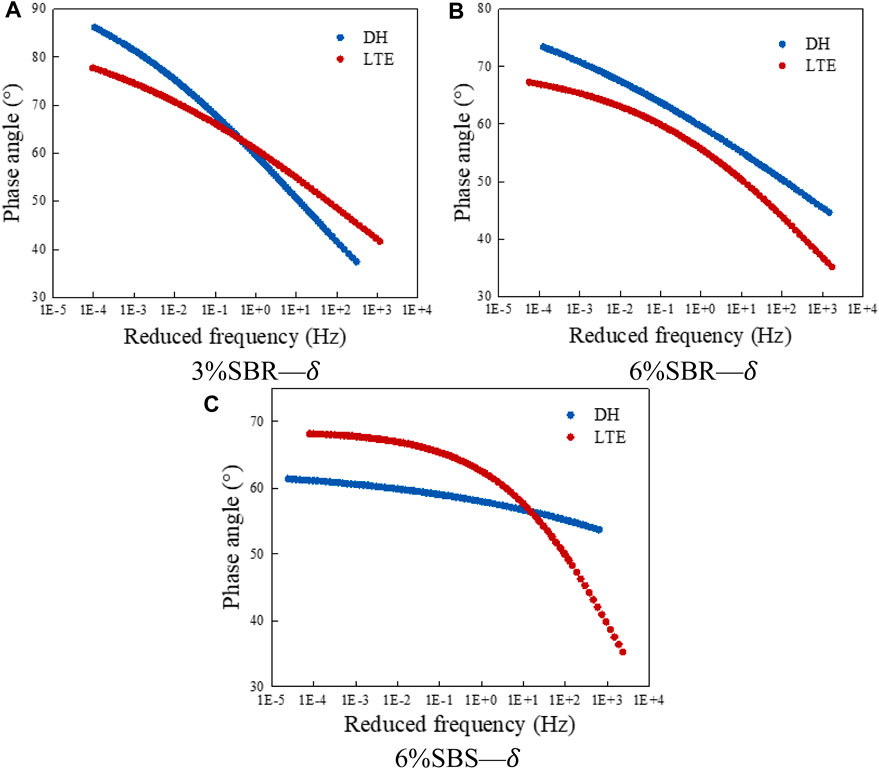

The three types of modified emulsified asphalt residue (3% and 6% SBR modified emulsified asphalt, and 6% SBS modified emulsified asphalt) obtained from the DH method and the LTE method were tested using the temperature-frequency sweep test method. The test results include the complex shear modulus (G*) and phase angle (

The complex shear modulus and phase angle master curves of evaporation residues obtained by the two different evaporation methods are summarized in Figures 4, 5. As shown in Figures 4A,B, for 3% SBR and 6% SBR modified emulsified asphalt, the master curve of complex shear modulus of residues obtained by the LTE method lies above that obtained by the DH method. Besides, the master curve of phase angle of residues obtained by the LTE method lies below that obtained by the DH method in the low frequency range (Figures 5A,B). These patterns show that the evaporation residue obtained by curing the SBR modified emulsified asphalt using the LTE method has stronger deformation resistance and higher elastic recovery ability, and the asphalt residue exhibits more elasticity with better recovery properties. However, the SBS modified emulsified asphalt exhibits the opposite trends as compared to the SBR modified emulsified asphalt. As presented in Figure 4C, the complex shear modulus master curve of SBS modified emulsified asphalt residue obtained by the DH method lies slightly above that obtained by the LTE method, while the phase angle master curve of DH method lies below than that of LTE method residue in the low frequency range (Figure 5C). These findings indicate that the DH method is more suitable for curing the SBS modified emulsified asphalt to obtain the asphalt residue with higher performance.

3.2 Multi-stress creep recovery (MSCR) test results

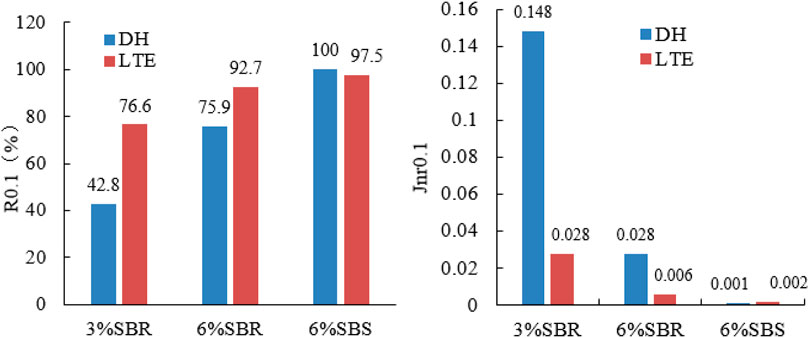

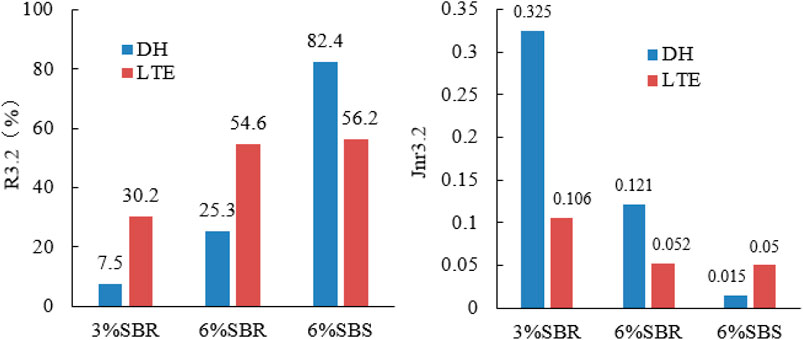

(1) Non-recoverable creep compliance and elastic recovery rate

The MSCR test results of the three modified emulsified asphalt residues are summarized in Figures 6, 7. It is obvious that as the stress increases from 0.1 kPa to 3.2 kPa, the non-recoverable creep compliance Jnr increases and the elastic recovery rate R decreases for all the three modified emulsified asphalt residues, indicating that the residues accumulate more irrecoverable deformation at higher stress levels, resulting in a decrease in the rutting resistance of the residues. At 0.1 kPa, the R value of the SBS modified emulsified asphalt residues obtained from the DH method (100%) was increased by 2.56% as compared with that obtained from the LTE method (97.5%). However, this difference was enlarged to 46.6% when the stress level was raised up to 3.2 kPa. The similar change trends can also be observed on the SBR modified emulsified asphalt residues. Besides, at the same stress level (0.1 kPa or 3.2 kPa), R value of SBS-DH is higher than that of SBS- LTE, and Jnr value of SBS-DH is lower than that of SBS- LTE. This means that the SBS-modified emulsified asphalt residues obtained by DH at high-temperature curing conditions have better elastic recovery performance. On the contrary, R value of SBR-DH is lower than that of SBR-LTE, while Jnr value of SBR-DH is higher than that of SBR-LTE when the same stress level is given. This indicates that the SBR-modified emulsified asphalt residues obtained by the LTE method with low-temperature curing conditions have better high-temperature deformation resistance performance.

(2) Accumulated strain curve

The accumulated strain versus the loading time curves of the three modified emulsified asphalt residues were plotted in Figure 8. Theoretically, under the same stress loading condition, the smaller the accumulated strain, the higher the resistance to deformation and the higher the high-temperature rheological performance of the residue. It is obvious from Figure 8 that, for the two SBR modified emulsified asphalt residues, the accumulated strain obtained by the high-temperature DH method is greater than that obtained by the LTE method. However, the accumulated strain change of the SBS modified emulsified asphalt residues exhibits an opposite pattern. These observations demonstrate that the LTE method is more suitable for the SBR modified emulsified asphalt, while the DH method is more suitable for the SBS modified emulsified asphalt for obtaining the asphalt residue with high rutting resistance performance.

Figure 8. Accumulated strain curves of three modified emulsified asphalt residues at 64°C and 3.2 kPa.

3.3 Linear amplitude sweep (LAS) test results

The fatigue resistance of emulsified asphalt residues obtained by the DH method and the LTE method were examined by the linear amplitude sweep (LAS) test. The fatigue life analysis was carried out on the basis of VECD theory. The stress-strain curve, integrity parameter and damage density curve were plotted to compare the fatigue resistance performance of the modified emulsified asphalt residues obtained by the two different evaporation methods.

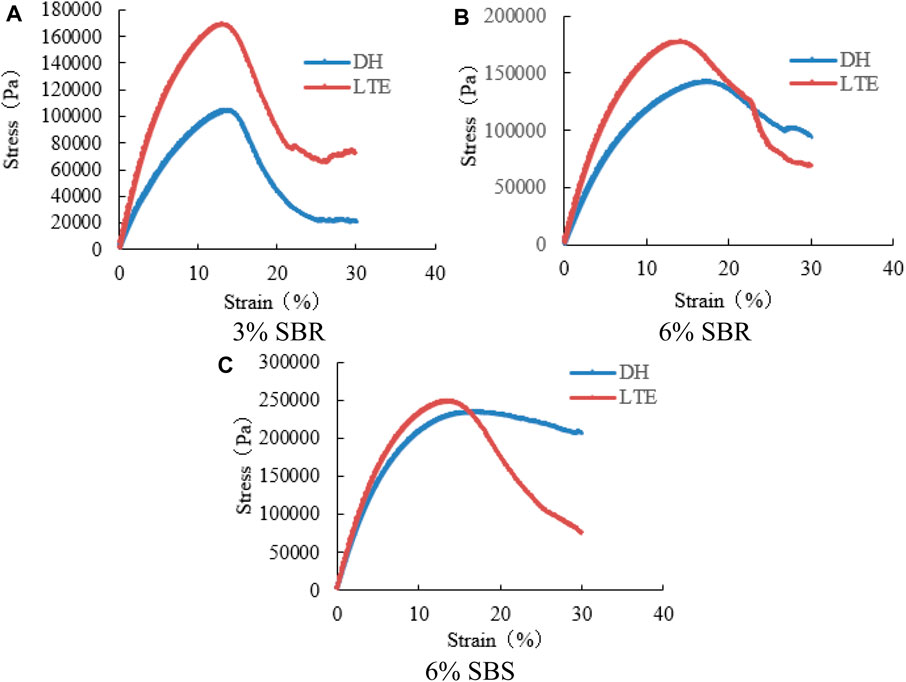

(1) Stress-strain curve

By plotting the shear stress versus the shear strain, the stress-strain curves of the three modified emulsified asphalt residues can be obtained, as shown in Figure 9. Normally, if the stress-strain curve of an asphalt residue has a higher peak value and a larger peak width, the asphalt residue should have stronger elastic deformation ability. Obviously, for the two SBR modified emulsified asphalt residues, the peak value and peak width of the stress-strain curve obtained by the LTE method are greater than those obtained by the DH method, indicating that low-temperature conditions are more suitable for curing SBR modified emulsified asphalt to obtain the evaporated residues with higher elastic deformation capacity. For SBS modified emulsified asphalt, the stress peaks of the residues obtained by the two curing methods are almost identical, but the peak width of the residues obtained by the high-temperature DH method is significantly larger than that of the LTE method, which shows that the high-temperature conditioning is more suitable for curing SBS modified emulsified asphalt to obtain asphalt residues with higher elastic deformation recovery performance.

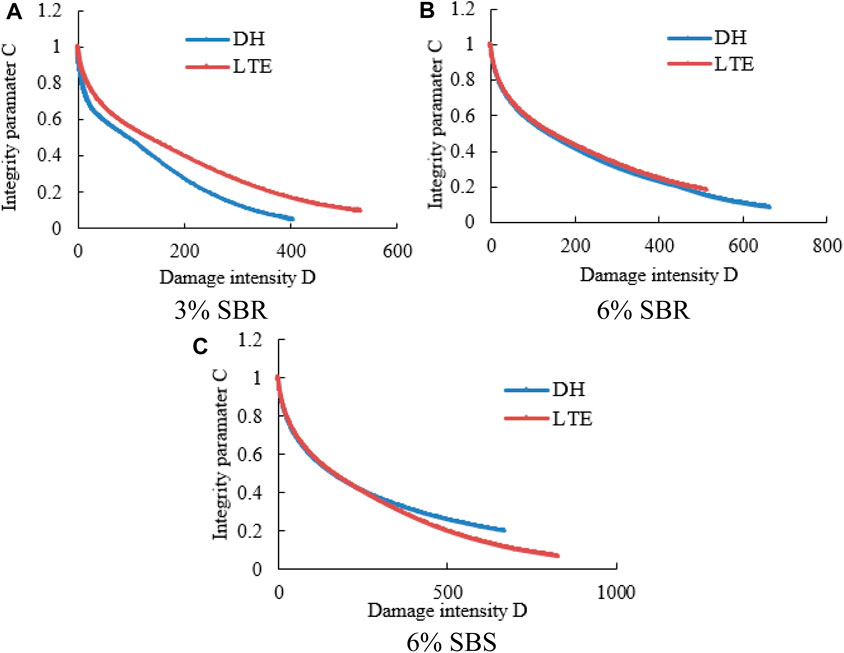

(2) Integrity parameter C and damage density curve D

To quantify the effect of evaporation methods on the fatigue resistance of each modified emulsified asphalt residue, the PSE-based VECD theory was used to plot damage intensity D against integrity parameter C to obtain the C-D curve, as shown in Figure 10. Noted that the C value represents the integrity degree of the asphalt binder. C = 1 means that the asphalt binder is intact without any damage occurred, while C = 0 indicates that the asphalt binder is completely damaged. The faster rate of decrease in C value usually signifies the worse fatigue resistance of the asphalt. As shown in Figure 10, for the two SBR modified emulsified asphalt residues, the rate of decrease in C obtained by the LTE method was lower than that of the residues obtained by the DH method, indicating that the SBR modified emulsified asphalt residue obtained by the LTE method has better fatigue resistance. In contrast, the decrease rate of C of the SBS modified emulsified asphalt evaporated residue obtained by the DH method was lower than that obtained by the LTE method, indicating that the DH method is more suitable for the emulsified asphalt modified with SBS to attain a better fatigue resistance performance.

(3) Fatigue life Nf

The fatigue life results of the three modified emulsified asphalt residues are summarized in Figure 11A. For comparison, the Nf values of the unmodified emulsified asphalt (EA) obtained by the two evaporation methods are also included in this figure. It is obvious that the Nf of the emulsified asphalt residue is enhanced after modification, and different modifiers have different modification efficiency in terms of fatigue resistance. When it comes to the quantitative analysis, the variation of the Nf between the modified emulsified asphalt residue and the unmodified one is calculated and presented in Figure 11B. Evidently, with the increase of SBR content, the Nf of the SBR modified emulsified asphalt residue obtained by the two evaporation methods increases. Besides, the Nf of 3% and 6% SBR modified emulsified asphalt residues obtained using the LTE method is greater than that obtained by the DH method. However, the opposite trend was observed for the 6% SBS modified emulsified asphalt residue, and the DH method provides a higher value of Nf than the LTE method. This phenomenon demonstrates again that the DH method is more suitable for conditioning the SBS modified emulsified asphalt to obtain the asphalt residue with higher fatigue resistance performance.

3.4 Fourier transform infrared (FTIR) test result

The two different evaporation methods may age the asphalt residue to some extent during the evaporation process. To quantify this aging effect, the carbonyl (C = O) index value of each modified emulsified asphalt residue obtained using the two different evaporation methods was measured with the FTIR equipment, as summarized in Figure 12. Normally, a higher C = O index value corresponds to a severer aging imposed on the asphalt residue. It can be seen from Figure 13 that the C = O index of all the modified emulsified asphalt residues by the DH method is greater than that by the LTE method. This is plausible because the 120°C high-temperature heating for 30 min in the DH method intensifies the oxidative aging of emulsified asphalt as compared to the 60°C low-temperature heating. Therefore, for SBR and SBS modified emulsified asphalt, the aging resistance of the residue obtained under high-temperature curing conditions will be slightly lower than that obtained under the low-temperature curing conditions. Therefore, for SBS modified emulsified asphalt, although the high-temperature curing condition can give the residue better rheological properties and higher fatigue resistance performance, it has the disadvantage of weakening the aging resistance. Thus, in practical application, an appropriate curing temperature should be selected to condition the SBS modified emulsified asphalt for obtaining the balanced performance of the asphalt residue between the mechanical performance and the aging resistance. As opposed, the LTE method can not only give the SBR modified emulsified asphalt residue better rheological properties and higher fatigue resistance but also provide higher aging resistance. Therefore, the low-temperature curing conditions are more suitable to condition the SBR modified emulsified asphalt.

4 Conclusions and future work

This study investigated the effects of temperature curing conditions on the performance of two commonly used modified emulsified asphalt residues through the rheological performance tests and the aging resistance test. The following conclusions are drawn.

(1) As compared to the DH method, the SBR modified emulsified asphalt residue obtained by the LTE method had higher elastic recovery rate, lower irrecoverable creep compliance, smaller accumulated performance deformation, longer fatigue life, and higher aging resistance, indicating that the LTE method using the low-temperature curing conditions (25°C, 24 h—60°C, 24 h) is more suitable for curing the SBR modified emulsified asphalt to achieve the higher performance.

(2) As compared to the SBR modified emulsified asphalt residue, the opposite trends of the performance indices except the aging resistance were observed for the SBS modified emulsified asphalt residue obtained from the LTE method, showing that the high-temperature curing condition (120°C, 30 min—163°C, 1 min) can give the SBS modified asphalt residue better rheological properties and higher fatigue resistance performance, but it also has the detrimental effect on the aging resistance. Therefore, in practical application, an appropriate curing temperature should be selected for the SBS modified emulsified asphalt to balance its mechanical performance and aging resistance.

(3) The performance of residues obtained by different methods varies to a certain extent. And the reason for this difference may be due to material aging or polymer degradation.

This study presents a preliminary investigation concerning the effects of two standard evaporative conditions on the performance of two types of modified emulsified asphalt residue. More evaporative conditions (various combinations of curing temperature and curing time) will be selected to cure the emulsified asphalt modified with more types of modifiers so as to identify the best combination of curing temperature and curing time for each type of modified emulsified asphalt.

Data availability statement

The original contributions presented in the study are included in the article/Supplementary Material, further inquiries can be directed to the corresponding author.

Author contributions

HH: Supervision, Writing–review and editing. ZX: Supervision, Writing–review and editing. EZ: Conceptualization, Data curation, Investigation, Methodology, Writing–review and editing. BL: Funding acquisition, Investigation, Project administration, Validation, Writing–original draft, Writing–review and editing. WX: Investigation, Methodology, Writing–original draft, Writing–review and editing.

Funding

The author(s) declare that financial support was received for the research, authorship, and/or publication of this article. Science and technology project of Jiangxi Provincial Transportation Department (2023H0026, 2023H0003). Science and technology project of Jiangxi Communications Investment Group Co., LTD. (2022JT0002).

Acknowledgments

The authors would like to express their sincere appreciation to the aforementioned organizations.

Conflict of interest

Author BL was employed by Jiangxi Transportation Institute Co., Ltd.

The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

ASTM (2009). Standard practice for recovering residue from emulsified asphalt using low temperature evaporative technique.

Chen, X., Cheng, G., and Xu, W. (2020). RETRACTED ARTICLE: influence of evaporation temperature on the rheological properties of modified emulsified asphaltic residues. J. Nanoparticle Res. 22 (8), 228. doi:10.1007/s11051-020-04952-1

Das, P. K., Balieu, R., Kringos, N., and Birgisson, B. (2015). On the oxidative ageing mechanism and its effect on asphalt mixtures morphology. Mater. Struct. 48 (10), 3113–3127. doi:10.1617/s11527-014-0385-5

Fan, K. H. (2019). Preparation of high performance SBS modified emulsified asphalt. East China: China University of Petroleum. 000125.

Farrar, M. J., Salmans, S. L., and Planche, J. P. (2013). Recovery and laboratory testing of asphalt emulsion residue application of simple aging test and 4-mm dynamic shear rheometer test. Transp. Res. Rec. 2370, 69–75. doi:10.3141/2370-09

Guo, Y. M., and Ni, F. J. (2014). Dynamic viscoelastic properties of modified asphalt and mixes based on DSR. J. Southeast Univ. Nat. Sci. Ed. 44 (02), 386–390.

Hemmati, N., Yun, J., Mazumder, M., Lee, M. S., and Lee, S. J. (2021). Laboratory characterization of asphalt binders modified with styrene butadiene rubber (SBR). Materials 14 (24), 7666. doi:10.3390/ma14247666

JTG (2011). Standard test methods of asphalt and bituminous mixtures for highway engineering. Beijing, China: China communications Press.

Li, C., Chen, Z., Wu, S., Li, B., Xie, J., and Xiao, Y. (2017). Effects of steel slag fillers on the rheological properties of asphalt mastic. Constr. Build. Mater. 145, 383–391. doi:10.1016/j.conbuildmat.2017.04.034

Li, G., Zhao, Y., Pang, S. S., and Huang, W. (1998). “Experimental study of cement-asphalt emulsion composite 11Communicated by F.W. Locher”. Editor F. W. Locher, 28, 635–641. doi:10.1016/s0008-8846(98)00038-6Cem. Concr. Res.5

Li, R., Leng, Z., Zhang, Y., and Ma, X. (2019). Preparation and characterization of waterborne epoxy modified bitumen emulsion as a potential high-performance cold binder. J. Clean. Prod. 235, 1265–1275. doi:10.1016/j.jclepro.2019.06.267

Ouyang, C., Wang, S., Zhang, Y., and Zhang, Y. (2006). Improving the aging resistance of styrene-butadiene-styrene tri-block copolymer modified asphalt by addition of antioxidants. Polym. Degrad. Stab. 91 (4), 795–804. doi:10.1016/j.polymdegradstab.2005.06.009

Pang, J., Du, S., Chang, R., Pei, Q., and Cui, D. (2015). Effect of emulsifier content on the rheological properties of asphalt emulsion residues. J. Appl. Polym. Sci. 132 (15). doi:10.1002/app.41806

Petersen, J. C., and Harnsberger, P. M. (1998). Asphalt aging: dual oxidation mechanism and its interrelationships with asphalt composition and oxidative age hardening. Transp. Res. Rec. 1638 (1), 47–55. doi:10.3141/1638-06

Ren, H., Huang, W., Cui, T., Du, J., and Meng, Q. (2021). Preparation and properties of SBR/CR composite modified emulsified asphalt. J. Wuhan Univ. Eng. Ed. 54 (11), 1022–1027.

Sun, Y., Yue, J. C., Wang, R. R., Li, R. X., and Wang, D. C. (2020). Investigation of the effects of evaporation methods on the high-temperature rheological and fatigue performances of emulsified asphalt residues. Adv. Mater. Sci. Eng. 2020, 1–12. doi:10.1155/2020/4672413

Wang, D., Hu, L., Dong, S., You, Z., Zhang, Q., and Hu, S. (2022). Assessment of testing methods for higher temperature performance of emulsified asphalt. J. Clean. Prod. 375, 134101. doi:10.1016/j.jclepro.2022.134101

Wang, W., Wu, K. H., Wang, F. H., and Yang, G. L. (2014). Development and performance study of new SBR composite modified emulsified asphalt. Chin. foreign Highw. 34 (05), 235–240.

Xu, G. J., Wang, H., and Zhu, H. (2017). Rheological properties and anti-aging performance of asphalt binder modified with wood lignin. Constr. Build. Mater. 151, 801–808. doi:10.1016/j.conbuildmat.2017.06.151

Xu, W., Guan, Y., Shah, Y. I., Luo, R., and Xu, Z. (2022). Study on curing characteristics of cold-mixed and cold-laid asphalt mixture based on electrical properties. Constr. Build. Mater. 330, 127223. doi:10.1016/j.conbuildmat.2022.127223

Xu, W., and Luo, R. (2022). Evaluation of interaction between emulsified asphalt and mineral powder using rheology. Constr. Build. Mater. 318, 125990. doi:10.1016/j.conbuildmat.2021.125990

Yao, H., You, Z., Li, L., Goh, S. W., Lee, C. H., Yap, Y. K., et al. (2013). Rheological properties and chemical analysis of nanoclay and carbon microfiber modified asphalt with Fourier transform infrared spectroscopy. Constr. Build. Mater. 38, 327–337. doi:10.1016/j.conbuildmat.2012.08.004

Yuan, H., Zhu, H. Z., and Wei, Q. (2020). Evaluation of asphalt fatigue test methods. Chin. foreign Highw. 40(03): 241–246.

Yuliestyan, A., García-Morales, M., Partal, P., and Moreno, E. (2017). Assessment of modified lignin cationic emulsifier for bitumen emulsions used in road paving. Mater. Des. 131, 242–251. doi:10.1016/j.matdes.2017.06.024

Keywords: modified emulsified asphalt, evaporation methods, residues, rheological properties, fatigue resistance

Citation: Huang H, Xu Z, Zeng E, Liu B and Xu W (2024) Effects of evaporative conditions on the performance of recovered residue of modified emulsified asphalt. Front. Built Environ. 10:1423047. doi: 10.3389/fbuil.2024.1423047

Received: 25 April 2024; Accepted: 24 June 2024;

Published: 19 July 2024.

Edited by:

Weiwei Wu, Hong Kong Polytechnic University, Hong Kong, SAR ChinaReviewed by:

Lei Xi, Hubei University of Technology, ChinaWentao Wang, University of Science and Technology Beijing, China

Hanqi Liu, Hefei University of Technology, China

Copyright © 2024 Huang, Xu, Zeng, Liu and Xu. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Bin Liu, YmlubGl1amt5QDEyNi5jb20=

Haibing Huang1

Haibing Huang1 Wen Xu

Wen Xu