- 1Bioengineering Department, Agricultural Engineering Research Institute (AEnRI), Agricultural Research Center (ARC), Giza, Egypt

- 2Medicinal and Aromatic Plants Research Department, Horticulture Research Institute, Agricultural Research Center (ARC), Giza, Egypt

A Corrigendum on

Applied insight: studying reducing the carbon footprint of the drying process and its environmental impact and financial return

by Ibrahim A, Amer A, Elsebaee I, Sabahe A and Amer MA (2024). Front. Bioeng. Biotechnol. 12:1355133. doi: 10.3389/fbioe.2024.1355133

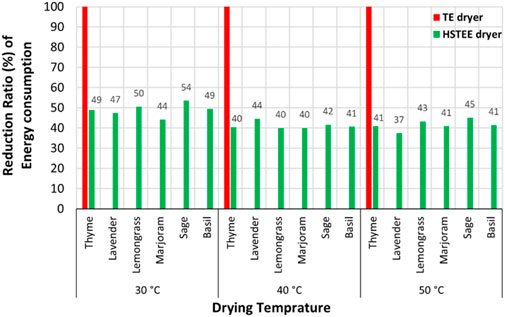

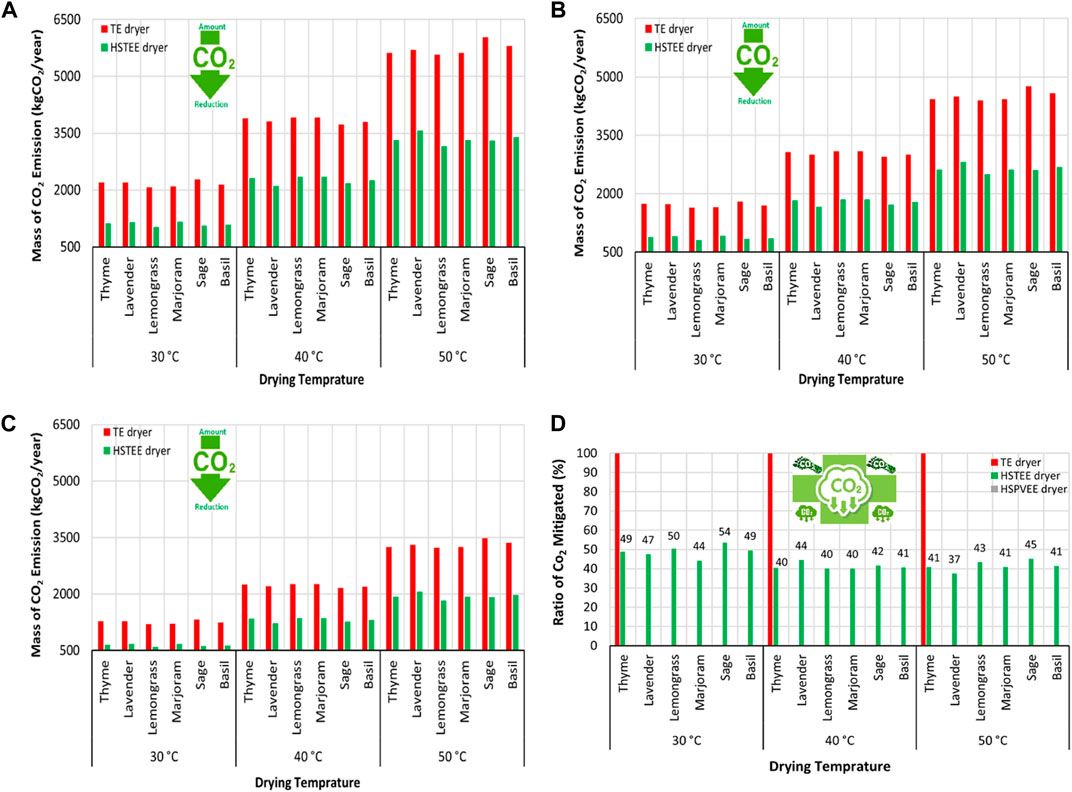

In the published article, there was an error in Figures 2, 3D as published. There was an error in the arrangement of ratio values on the columns. The corrected Figures 2, 3D appear below.

Figure 2. Schematic representation of the energy reduction ratio of the HSTEE dryer compared to the TE dryer.

Figure 3. Schematic representation of the CO2 mitigated/year using the HSTEE dryer and hybrid solar dryer based on proposed photovoltaic solar energy (HSPVSE dryer) vs. TE dryer at different CO2 emission factors. (A) Coal emission factor (kgCO2/kWh), (B) oil emission factor (kgCO2/kWh), (C) natural gas emission factor (kgCO2/kWh), and (D) annual CO2 mitigated ratio.

In the published article, there was an error. As a result of modifying Figures 2, 3D, it was necessary to amend paragraphs in the Abstract, Results and discussions, and Conclusion sections.

A correction has been made to Abstract. This sentence previously stated:

“The highest CO2 mitigated ratio using the HSTEE dryer was recorded in thyme, marjoram, and lemongrass samples, with values ranging from 45% to 54% at 30, 40, and 50°C.”

The corrected sentence appears below:

“The highest CO2 mitigated ratio using the HSTEE dryer was recorded in lavender, thyme, basil, lemongrass, and sage samples with values ranging from 45% to 54% at 30, and 50°C.”

A correction has been made to 3 Results and discussions, Paragraph 3. This sentence previously stated:

“The highest ratio of energy reduction for the HSTEE dryer compared to the TE dryer was recorded for thyme samples at 30, 40, and 50°C with values of 49%, 50%, and 54%, respectively. The lowest ratio of energy reduction for the HSTEE dryer ranged between 37% and 40% for basil, lavender, and sage at 30°C and 40°C.”

The corrected sentence appears below:

“The highest ratio of CO2 mitigated was noted for lavender, thyme, basil, lemongrass, and sage samples with values ranging from 45% to 54% at 30, and 50°C. The lowest ratio of energy reduction for the HSTEE dryer ranged between 37% and 40% for lavender, marjoram, lemongrass, and thyme at 40 °C and 50°C.”

A correction has been made to Results and discussions, Paragraph 6. This sentence previously stated:

“The highest ratio of CO2 mitigated was noted for thyme, marjoram, and lemongrass samples with values ranging from 45% to 54% at 30, 40, and 50°C.”

The corrected sentence appears below:

“The highest ratio of CO2 mitigated was noted for lavender, thyme, basil, lemongrass, and sage samples with values ranging from 45% to 54% at 30, and 50°C.”

A correction has been made to 4 Conclusion, Paragraph 1. This sentence previously stated:

“However, for sage, lavender, and basil at 30°C and 40°C, the lowest energy reduction ratio obtained using the HSTEE dryer varied from 37% to 40%.”

The corrected sentence appears below:

“However, for lavender, marjoram, lemongrass, and thyme at 40°C and 50°C, the lowest energy reduction ratio obtained using the HSTEE dryer varied from 37% to 40%.”

The authors apologize for these errors and state that they do not change the scientific conclusions of the article in any way. The original article has been updated.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Keywords: drying, solar energy, hybrid solar dryer, energy consumption, greenhouse gas emissions, carbon footprint

Citation: Ibrahim A, Amer A, Elsebaee I, Sabahe A and Amer MA (2024) Corrigendum: Applied insight: studying reducing the carbon footprint of the drying process and its environmental impact and financial return. Front. Bioeng. Biotechnol. 12:1431416. doi: 10.3389/fbioe.2024.1431416

Received: 11 May 2024; Accepted: 28 May 2024;

Published: 12 June 2024.

Edited and reviewed by:

Pedro Romano, Federal University of Rio de Janeiro, BrazilCopyright © 2024 Ibrahim, Amer, Elsebaee, Sabahe and Amer. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Ayman Ibrahim, aymanelgizawee@gmail.com; Alia Amer, aliaamer@arc.sci.eg

Ayman Ibrahim

Ayman Ibrahim