- 1Department of Industrial Engineering, University of Salerno, Fisciano, Italy

- 2Department of Food Engineering, University of Bío-Bío, Concepción, Chile

- 3ProdAl Scarl C/o University of Salerno, Fisciano, Italy

Introduction: This study aimed to investigate the effects of semolina characteristics and pasta-making processing on the quality of durum wheat spaghetti (A, B, and C) using a reverse engineering approach.

Methods: Proximate composition, color, granulometry, pasting and thermal properties were determined to characterize semolina, while pasting, thermal and cooking properties, microstructure and sensory profile were evaluated for spaghetti.

Results and Discussion: The sensory profile of sample A, in terms of higher yellowness and hardness, lower stickiness, agreed with the higher transition temperatures (60.07–74.6 °C) and enthalpy of amylose-lipid complexes, degree of starch gelatinization, pasting viscosities and compression force, lower water absorption, cooking losses (4.78 g/100 g), and adhesiveness (0.39 N/mm). Moreover, the microstructural analysis showed a network with denser areas, and starch granules strongly embedded in the gluten matrix for sample A with respect to samples B and C. These results might be ascribed to the semolina characteristics. Sample A was richer in starch (71.4%), lipid (1.6%), and protein (14.0%), and the higher drying temperatures affected protein crosslinking, starch organization, cooking properties, and appearance of spaghetti. The approach used in this study could be suitable in gathering the different phenomena occurring in pasta production process which concur to give spaghetti its distinctive quality.

Highlights

• Reverse engineering approach was used to identify factors affecting pasta quality.

• Three commercial spaghetti were comparatively characterized.

• Thermal, structural, sensorial properties were assessed to discriminate spaghetti.

• Semolina composition and drying process were relevant in determining pasta features.

1 Introduction

Pasta is one of the most consumed food product in the world, standing out for its long shelf life, ease of preparation and nutritional value (Lupu et al., 2023). Worldwide, about 14.0 million tons of pasta are produced annually (Dello Russo et al., 2021; Bresciani et al., 2022), with Italy representing the leading country with almost 4 million tons of pasta produced (Statista Global Consumer Survey, 2022). Pasta is an excellent source of carbohydrates (starch), protein, fiber and contains a low concentration of fat (Fuad and Prabhasankar, 2010). Several investigations have reported that the structure of pasta, in which the gluten protein network surrounds the starch granules, contributes to the progressive release of sugars during digestion, reducing and modulating postprandial glycemia and the risk of esophageal cancer compared with other cereal-based foods (Falciano et al., 2022; Lupu et al., 2023). In addition, pasta can be used as a suitable carrier of bioactive compounds promoting healthier lifestyles and keeping consumption habits almost unchanged (Fares and Menga, 2012; Spinelli et al., 2019; Carpentieri et al., 2022).

Among the raw materials used for pasta production, durum wheat semolina is considered the best one due to its distinctive yellow color, high protein and gluten content, and excellent nutritional properties (Krawęcka et al., 2021; Bresciani et al., 2022).

Particle size distribution and proximate composition of semolina represent the key factors affecting the quality of the final product (Dimitrios, 2023).

In many countries such as Italy, France, and Greece, it is mandatory by law that pasta should be produced solely from 100% durum wheat semolina. Indeed, durum wheat pasta has the potential to exhibit good cooking and chewing quality even when overcooked (Dimitrios, 2023).

Nevertheless, the formation of the resulting structure, which is responsible for the peculiar sensorial and nutritional properties of pasta, relates to the characteristics of the raw materials but also to the steps involved in the transformation process (Bonomi et al., 2012).

Although some structural modifications occur during the extrusion step, due to starch damaging, most of the changes occurring in pasta are due to the drying process. Given similar raw materials, the extent of these modifications could be dependent on drying temperature, which is the main processing variable affecting the drying rate (De Noni and Pagani, 2010).

Traditionally pasta was dried at low temperature (LT, about 50°C), however high temperature (HT, about 70°C) and very high-temperature (VHT, above 80°C) drying methods have been rapidly introduced and implemented by pasta industries (Ogawa et al., 2017). HT drying, regardless of raw material properties, increases the extent of protein denaturation, resulting in increased network rigidity and pasta firmness, improved cooking quality and sauce retention capacity, reduced drying time and microbial contamination (Masato et al., 2021; Tagliasco et al., 2021; Ohmura et al., 2023).

To the best of our knowledge, no work so far aimed at comprehensively and comparatively identifying and discriminating the factors determining the different physicochemical characteristics of commercial pasta samples, by correlating the raw materials’ composition and the pasta-making process.

Therefore, this work aims to determine the correlation among the final characteristics of commercial spaghetti, namely, the characteristics of semolina, the drying process conditions, and the semolina components modifications. A comprehensive approach is used to understand the interlinked effects of the production process, mainly the drying process as the most impacting step, on the physicochemical, thermal, structural, and sensorial properties of durum wheat spaghetti from three well-known Italian companies, affecting their peculiar quality.

2 Materials and methods

2.1 Chemicals and raw materials

Commercial spaghetti (coded as “A,” “B,” and “C”) and the corresponding durum wheat semolina samples used to produce the spaghetti A, B, and C were provided by the three Italian pasta producers and stored in sealed biaxially oriented polypropylene (BOPP) bags until use.

Detailed pasta-making parameters could not be reported due to non-disclosure agreement stated with the companies.

Chemicals and reagents used in the analyses were purchased from Sigma Aldrich (Steinheim, Germany). The commercial kit used to determine the total dietary fiber and the total starch content was purchased from Megazyme K-TSHK (Wicklow, Ireland).

2.2 Proximate analysis of semolina

AOAC (2005) methods were employed for the analysis of moisture content (AOAC 925.10), protein content (AOAC 920.87), ash content (AOAC 923.03), and fat content (AOAC 922.06) of semolina samples. Total dietary fiber was determined by a commercial kit (K-TDFR, Megazyme, Wicklow, Ireland) according to the methods AACC 32-05.01 and AOAC 985.29 (AOAC, 2005). The extraction of gluten was carried out manually in accordance with the method described by Tateo (1980). The total starch (TS) content was determined using a commercial kit (Amyloglucosidase/α-Amylase Method, Megazyme, Wicklow, Ireland) according to the methods AOAC 996.11 and AACC 76-13.01. The amylose content of semolina was determined using a standard enzymatic test kit (K-Amyl 06/18, Megazyme, Wicklow, Irlanda). All the results were reported on a dry weight basis.

2.3 Color determination

Absolute measurements of lightness (L*), redness (a*), and yellowness (b*) (CIE 1976) coordinates of semolina samples were determined by using a colorimeter CR-400 (Konica Minolta Inc., Tokyo, Japan), according to the official method CieLab. Briefly, 10 g of semolina sample were poured in the center of a petri dish with a white background. The “b” value was directly used to measure the yellowness as described by Sissons et al. (2012). The color difference (ΔΕ*) between the samples was calculated with Eq. 1.

2.4 Particle size distribution

Particle size distribution (PSD) of semolina was measured by light diffraction according to the Fraunhofer diffraction theory using a Mastersizer 2000 (Malvern Instruments Ltd., Worcestershire, United Kingdom). The resulting PSD was expressed in volume percent. Characteristic diameters, corresponding to the 10th [d(0.1)], 50th [d(0.5)], and 90th [d(0.9)] percentile of the cumulative size distribution, were evaluated. The surface-weighted mean diameter D[3,2] and volume-weighted mean diameter D[4,3] were also evaluated according to Eqs 2, 3, respectively:

2.5 Thermal properties

The thermal properties of semolina and ground spaghetti were evaluated. For the preparation of the ground spaghetti a mincer (Kenwood Corporation, Tokio, Japan) was used to reduce the sample size to size comparable to that of semolina samples and load the sample holder. A differential scanning calorimeter DSC 204 (Phoenix, Netzsch, Wittelsbacherstraße, Germany) was used and the method reported by Marti et al. (2011), with slight modifications was followed.

Briefly, 5 mg of sample were directly weighed into DSC stainless steel pans, and distilled water (3:1, water to sample) was added. Pans were hermetically sealed, and an empty pan was used as a reference. DSC measurements were carried out through an isothermal phase (25°C for 3 min) and then scanned at a dynamic phase at 10°C/min from 25°C to 120°C. Onset temperature (Ton, °C), peak temperature (Tpeak,°C), endset temperature (Tend, °C), and total enthalpy (ΔHd, J/g of sample) were estimated with the Proteus Analysis Software provided by the manufacturer (Version 4.2/3, Netzsch, Wittelsbacherstraße, Germany).

2.6 Pasting properties

The pasting properties of semolina and ground spaghetti samples were determined according to the method reported by Mirzababaee et al. (2022), using a controlled stress and strain rheometer (AR2000, TA instruments, New Castle, DE, United States) provided with the starch cell. For the analysis, 6 g of sample was poured into the cell, and 40 mL of distilled water was added. A short stirring of 10 s was applied to homogenize the mixture before starting the analysis. The sample was kept at 50°C for 1 min, heated from 50°C to 95°C at 6°C/min, and kept at 95°C for 5 min. Afterwards, it was cooled down at a rate of 6°C/min up to 50°C and kept at this temperature for 2 min. The sample was stirred at 960 rpm for 10 s and then at 160 rpm for rest of the analysis. Pasting analyses were carried out in triplicate.

2.7 Cooking quality

The determination of the optimal cooking time (OCT) of spaghetti and cooking loss was carried out according to the official method AACC 66.50. Water absorption, which is the weight increase of pasta before and after cooking, was determined and expressed as percent weight gain with respect to the uncooked pasta (Bonomi et al., 2012).

2.8 Textural properties

2.8.1 Flexibility and snap force

The flexibility (cm) and snap force (N) required to bend until break one strand of dry spaghetti was determined by using a texture analyzer (TA-XT2, Texture Technologies Corp., United Kingdom) coupled with a spaghetti flexure rig (A/SFR) adjusted to the height of the sample. Bending test on samples was carried out at 2.5 mm/s and the maximum force and distance at break were calculated from force vs. distance curves (Bourne, 2002).

2.8.2 Cooked pasta texture

Cooked spaghetti firmness and adhesiveness was determined according to the official method AACC 66-52.01 using a texture analyzer (TA-XT2, Stable MicroSystems, United Kingdom), equipped with a 5-kg load cell.

For the analysis, 5 strands of spaghetti samples were loaded on the equipment platform and compression cycles were carried out using a Pasta Firmness/Stickiness Rig, up to attaining the 50% of sample deformation. Compression-decompression runs were performed at 2 mm/s, to generate force-time curves. Firmness (N) and adhesiveness (-N/mm) values were calculated from the recorded data as the maximum positive force and maximum negative force, respectively. Six measurements were carried out per sample under controlled temperature.

2.9 Microstructure

The dry and cooked pasta surface and cross-section microstructures were observed using a field emission scanning electron microscope (FESEM, mod. LEO 1525, Carl Zeiss SMT AG, Oberkochen, Germany). Pasta samples were cooked at the OCT, drained, and frozen. Frozen spaghetti strands were freeze-dried. Dry pieces (3 mm length) were attached to the specimen holders using carbon tape and sputter-coated with a gold layer (Agar Auto Sputter Coater mod. 108 A, Stansted, United Kingdom) at 40 mA for 120 s. Sample images were captured with secondary electron mode at 5 kV at a maximum magnification of ×5,000 (Renoldi et al., 2021).

2.10 Sensory

Descriptive analysis was used to determine the sensory profiles of spaghetti samples, following the procedure described by Sicignano, (2015), with some modifications. A panel of fifteen judges was trained for the sensory evaluation of pasta performed in the ProdAl Scarl laboratory. The characteristic parameters monitored were brightness, roughness, yellow color, beige color, smell (visual and olfactory evaluation); stickiness, brittleness (tactile evaluation); taste, hardness, and grainy mouthfeel (taste perception evaluation). An open discussion with the panel leader as a moderator was conducted.

Pasta samples were cooked in unsalted boiling water until reaching OCT and immediately drained for 30 s before the tasting. During each session the samples were identified with a three-digit numeric code. Water was used for oral rinsing before tasting each sample.

The sensory descriptors, their definition, and the evaluation scales are reported in Table 1.

2.11 Statistical analysis

All the experiments and analyses, unless specified, were performed in triplicate and the results were reported as means ± standard deviations. Differences among mean values were analyzed by one-way variance (ANOVA), by using SPSS 20 (SPSS IBM., Chicago, United States) statistical package. The significance of the differences was thereafter tested with the Tukey test at p < 0.05.

3 Results

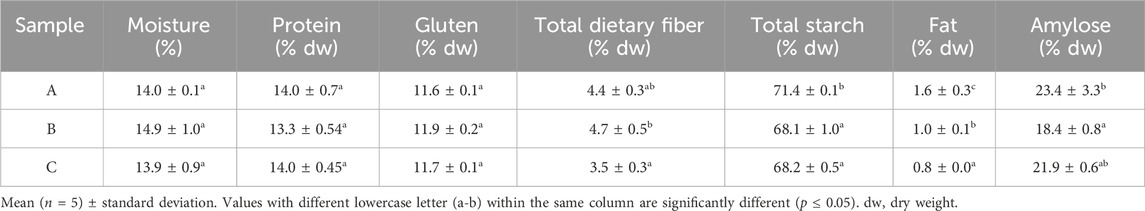

3.1 Proximate composition of durum wheat semolina

Durum wheat semolina is the raw material for the production of high-quality pasta and its physicochemical characteristics play an essential role in the pasta production process (De Noni and Pagani, 2010). The physical and chemical characteristics of durum wheat semolina were determined to address the nature and role of the occurring molecular changes which affect the resulting appearance and sensorial characteristics of dry pasta (Bonomi et al., 2012).

The results obtained, reported in Table 2, showed that the chemical properties of semolina samples are in accordance with the characteristics of semolina for the production of high-quality pasta. For instance, moisture content (14%–14.9%), gluten (11.6%–11.9%), protein content (13.3%–14%), and starch (68.1%–71.4%), which are decisive parameters for the quality of pasta, fell within the characteristic values of high-quality semolina (Sissons et al., 2012; De Cindio and Baldino, 2015). In particular, a better semolina should have a protein content within an optimum range of 12%–15% dw, with gluten content higher than 11% dw, and starch within 74%–76% dw (Garcia-Valle et al., 2021; Carpentieri et al., 2023).

Despite the semolina samples investigated presented similar proximate compositions, statistically different values of starch, amylose (representing on average the 30% of starch), and fat content were observed. Specifically, the sample A showed slightly higher amounts of starch, amylose and lipids that, despite their low content, significantly impact the functionality of semolina and dough formation due to the interactions between gluten proteins and starch (Cutignano et al., 2021). Moreover, the higher amount of amylose and lipids may lead to the formation of amylose-lipid complexes inducing higher hardness and compactness in the cooked pasta, restricted swelling of starch, and increased values of pasting viscosities (Niu et al., 2017).

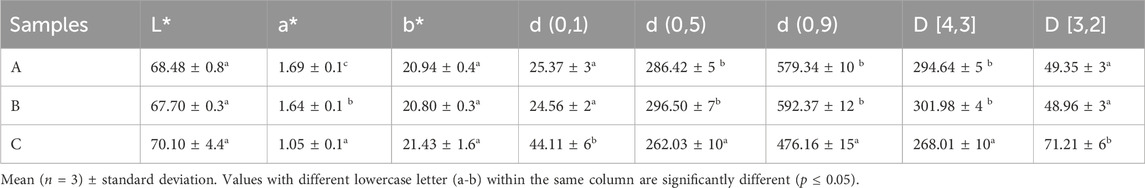

3.2 Color and particle size distribution of durum wheat semolina

The color of a food product is an important quality parameter which strongly affect consumers perception. Coarse-grained and uniformly sized durum wheat semolina is characterized by its typical deep yellow color (b*) responsible for the most critical visual attribute of pasta (Sissons et al., 2012). Carotenoids provide the yellow pigmentation to semolina, which has important implications for the marketing of end products based on durum wheat (Ficco et al., 2014). Table 3 shows the values of the semolina colorimetric parameters. Traditionally, yellow color values (b*) equal to or greater than 20 correspond to color levels characteristic of high-quality pasta (Sissons et al., 2012). L*, a* and b* values of semolina A, B, and C ranged from 67.70 to 70.10, 1.05 to 1.69, and 20.80 to 21.43, respectively (Table 3). Considering the values of the parameter b*, it can be concluded that both samples have the typical color of a good-quality semolina.

Some color differences were observed in the redness of the samples, the A and B semolina exhibiting a higher red index (a*) compared to the sample C.

The slightly higher redness of samples A and B might be due to the presence of higher amount of anthocyanins in the aleurone or pericarp of durum wheat. These differences are probably related to the wheat cultivars and localization of the pigments inside the wheat kernels (Ficco et al., 2014). However, ΔE values (ranging from 0.79 to 2.55) suggest that the overall differences in color between the samples A and B, A and C, B and C, might be noticeable at the human eye (Kubo et al., 2013).

Apart from the composition and color profile, granulometry has been demonstrated to be one of the most critical factors influencing the quality of the semolina and the consequent performance of the pasta-making process (Carpentieri et al., 2022). Semolina with smaller mean particle sizes may be characterized by damaged water binding sites of starch granules due to excessive grinding and, therefore, reduced capacity of binding water. Likewise, pasta made with coarser semolina may have higher absorption weight during cooking (Sacchetti et al., 2011).

For these reasons, to further discriminate and attribute the characteristics of spaghetti samples to the raw materials used, the particle size of semolina was determined. The analysis of particle size of semolina A, B, and C, shown in Figure 1, revealed a bimodal distribution of granules size with a major fraction (90%) of large size (476.16–592.37 μm) and a minor fraction (10%) of smaller size (24.56–44.11 μm). Data are reported in Table 3.

The samples presented similar and overlapping PSD with comparable homogeneity.

However, the samples possessed a volume mean diameter D[4,3] ranging from 268.01 to 301.98 μm, in line with the preferred size range (250–350 μm) for semolina suitable for commercial applications (Banach et al., 2021).

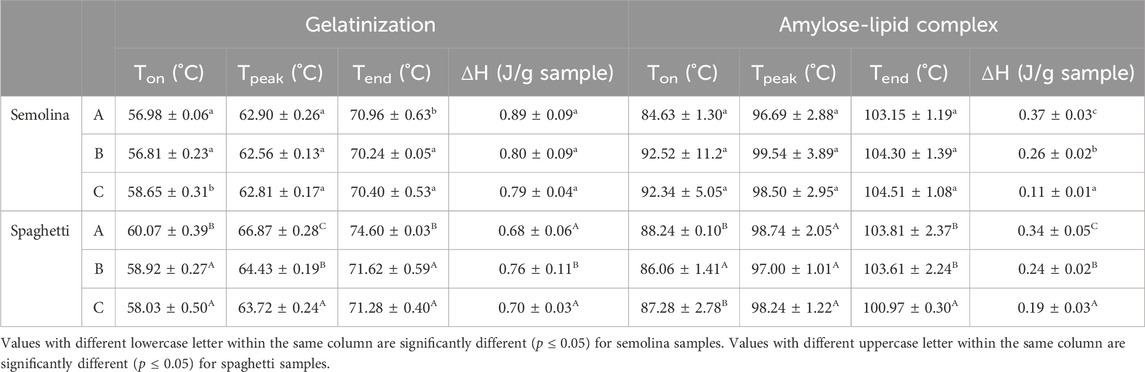

3.3 Thermal properties

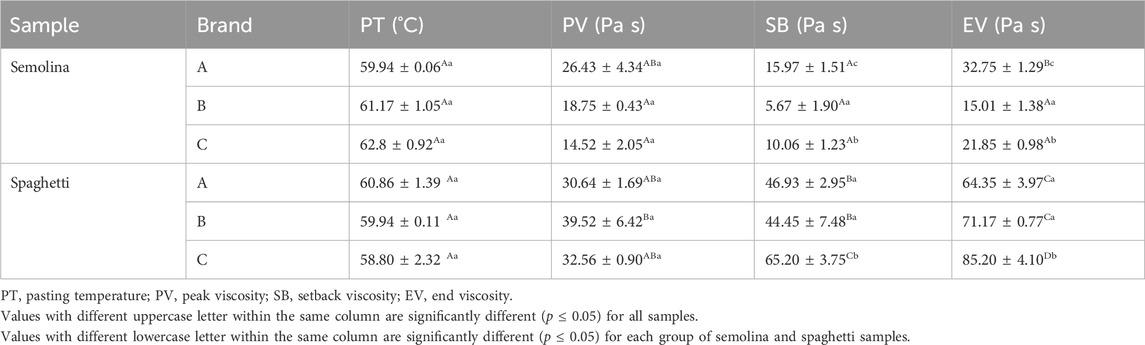

The thermal properties of starch, as the main component of semolina, are crucial in providing structure and texture to spaghetti during dough formation step and pasta cooking (Sozer et al., 2007). Two peaks were observed during thermal explorations for durum wheat starch, the first, with transition peak temperature (Tpeak) generally ranging between 51°C and 79°C (Romano et al., 2015), refers to the gelatinization of starches, while the second, with a Tpeak between 90°C and 120°C (Detchewa et al., 2016), represents the melting/dissociation of amylose-lipid complexes. Table 4 displays the transition temperatures and transition enthalpy of the different samples. It can be observed that the gelatinization temperatures varied between 62.56°C and 66.87°C, falling within the ranges associated with wheat starches, and spaghetti samples showed significantly higher temperatures than semolina. Furthermore, spaghetti sample A exhibited higher gelatinization temperatures compared to samples B and C which could be attributed to the different production processing conditions.

Table 4. Thermal properties of the analyzed semolina and spaghetti samples: Ton, onset temperature; Tpeak, peak temperature; Tend, end temperature; ΔH, transition enthalpy.

According to the data obtained from the manufacturers, the maximum drying processing temperatures applied to produce samples A, B, and C were 90°C, 80°C, and 65°C, respectively.

This direct relation between drying and gelatinization temperatures was also observed by Masato et al. (2021) when studying the effect of drying methods on the thermal properties of spaghetti.

The gelatinization enthalpy of spaghetti A was significantly lower than that of the semolina A, suggesting that starch was partially gelatinized during the drying step of spaghetti. The reduction in the degree of gelatinization of the latter samples is likely due to the limited moisture content that hinders the swelling of starch granules, as observed in a study conducted by Güler et al. (2002). Additionally, it can be observed that spaghetti samples dried at lower temperatures (B and C), despite having higher values of the transition area, exhibited narrower peaks. This could be attributed to the reorganization of the starch structure within the matrix.

The peak corresponding to the amylose-lipid complex show significant differences in the enthalpy values in all samples. In particular, the enthalpy of the second endotherm is higher for spaghetti dried at higher temperatures (A) than for spaghetti B and C. These results are in agreement with the previous findings reported in this study, regarding the proximate composition of semolina, where the content of amylose and lipids is higher in the semolina used for the production of spaghetti A (Table 2).

3.4 Pasting properties

The ability of pasta and semolina to undergo structural changes with temperature and under excess of water can be accounted through a pasting analysis (BeMiller, 2019). Moreover, for pasta this analysis give valuable information on the interaction between starch and other compounds of semolina, starch granules swelling, gelatinization and retrogradation.

The pasting properties of semolina and spaghetti samples are presented in Table 5. From the data reported in Table 5, it can be clearly noticed that no significant differences were detected in the pasting temperature of semolina and spaghetti samples (p > 0.05). However, the peak viscosity of semolina A was significantly higher than that of semolina B (p < 0.05), which could be attributed to its higher starch content (Table 2) and to the capacity of this polysaccharide to interact to larger extent with the other components of semolina, this reinforcing the network and contributing to increase viscosity values (BeMiller, 2019).

Semolina B, instead, exhibited the lowest setback and end viscosity values, which account for the rearrangement of amylose molecules that leached from swollen starch granules during the final period of the holding phase at 95°C and the entire cooling process. This can be explained by the lower amylose content of semolina B compared to semolina A.

Noticeably, an opposite trend was found in the pasting properties of spaghetti samples. In particular, spaghetti B, dried at lower temperatures, showed higher peak viscosity than spaghetti A, dried at higher temperatures. It could be hypothesized that more severe drying conditions caused more damage to the starch, which may have led to a decrease in viscosity values due to lower granule hydration (Aidoo et al., 2022). This structural damage strongly influenced the retrogradation tendency of spaghetti samples due to the lower end viscosity values found in spaghetti A compared to B and C spaghetti samples.

These results suggest that the pasting properties of pasta are correlated to the effects of drying conditions rather than to the chemical composition of semolina.

3.5 Cooking properties

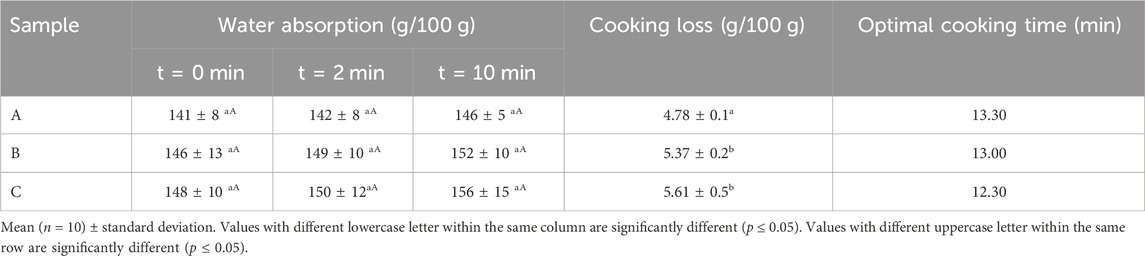

As regards cooking behavior, the water absorption capacity (WAC), cooking losses (CL), and OCT of the samples are reported in Table 6.

The amount of water absorbed per 100 g of dry pasta during cooking for the different spaghetti is also reported in Table 6. No significant differences among the samples were detected, and WAC values were stable even after 10 min from the end of the cooking step. Results also demonstrate that the weight of cooked pasta was 2.4–2.6 times higher than the weight of dry pasta, in agreement with the expected ideal weight of durum wheat cooked pasta that should not exceed more than three times the dry weight (Piwińska et al., 2016). Nevertheless, despite no significant differences were detected, sample A showed the lowest WAC compared to those of samples B and C. This can be attributed to the proximate composition of semolina A, namely, higher protein and lipid content, leading to a more compact network, or to a higher degree of damaged starch granules due to harsher drying conditions, making the starch less available for imbibing water. It is worth noting that the higher is the water uptake, the higher are the amylose leaching, cooking losses, and loss of starch crystalline structure (Syah et al., 2022). Sample A showed the lowest cooking losses, however, all types of spaghetti studied, as reported in Table 6, showed values of CL comparable to those of high-quality durum wheat pasta, which should not exceed 7–8 g/100 g (Piwińska et al., 2016). Several authors (Cubadda et al., 2007; Piwińska et al., 2016; Jalgaonkar et al., 2018) highlighted the pivotal role played by drying temperature in determining pasta cooking quality, almost regardless of protein and fat content of semolina. Higher drying temperatures allow to form a more compact gluten network leading starch to absorb less water, as also demonstrated by the low change in weight during cooking.

OCT related positively to the transition temperatures of starch gelatinization and protein and lipid content of semolina that also might reduce swelling of starch granules and pasta stickiness while improving its firmness. Generally, high values for WAC and low values for CL are desirable for good quality pasta (Bresciani et al., 2022).

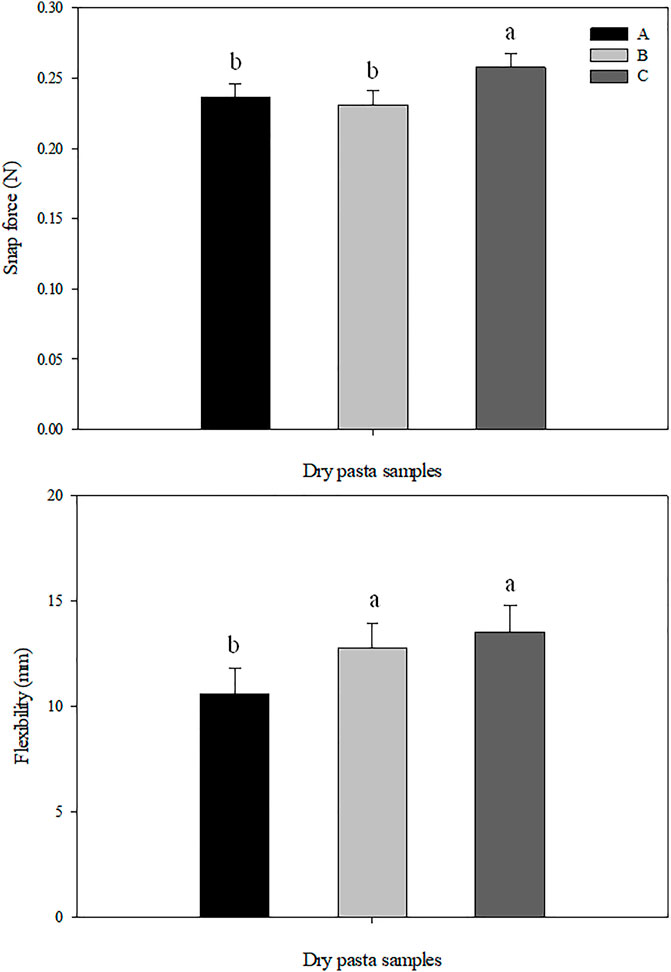

3.6 Texture properties

The texture of dry and cooked spaghetti samples was evaluated by bending and compression tests, and the resulting parameters are presented in Figures 2, 3. Figure 2 depicts the force required to bend and break one strand of dry spaghetti which is of interest to unveil possible structural weakness due to drying process and/or semolina characteristics. As can be observed in Figure 2, spaghetti C displayed a higher snap force and flexibility compared to spaghetti B and A, which is directly correlated to the less severe drying process conditions used in spaghetti C production. It has been demonstrated that the stresses caused by the drying process at high temperatures can produce imbalances in the gluten network causing its separation from starch granules, thus affecting the pasta compactness and increasing the occurrence of product breakage (Baiano et al., 2019).

Figure 2. Snap force and Flexibility of dry pasta samples. Different letters above the bars indicate statistically significant difference (p ≤ 0.05).

Figure 3. Firmness and adhesiveness values of cooked pasta samples as a function of time after cooking (samples kept at room temperature). Different letters above the bars indicate statistically significant difference among the three samples at the same cooling time (p ≤ 0.05).

Figure 3 shows the texture properties of cooked spaghetti. It can be observed that spaghetti A and C exhibited greater firmness than spaghetti B, which could be attributed to the different drying conditions. Surprisingly, it has been reported that drying at high and lower temperature conditions can equally increase cooking properties of pasta products only differing in the mechanism (Carpentieri et al., 2022). For instance, while drying at lower temperatures (LT) preserves the stability of the interactions determining the starch-gluten matrix formation, high-temperature (HT) drying improved cooking properties by promoting the formation of strong gluten networks that are less sensitive to undergo structure modifications (Masato et al., 2021). This is clearly confirmed analyzing the data of firmness after 10 and 60 min from the end of the cooking step, with sample A displaying higher firmness values. According to previous studies, spaghetti dried at high temperatures showed the highest firmness and lowest bulkiness and stickiness associated to low CL and amylose leaching (Baiano et al., 2006).

Spaghetti B and C had higher adhesiveness than spaghetti A, mostly related to the higher cooking losses of samples B and C (Table 6), which significantly increase with time after cooking. Drying at high temperatures hinders starch swelling and amylose leaching, leading to an increase of starch gelatinization temperature (Ogawa et al., 2017).

Moreover, some authors have reported that HT dried pasta is characterized by lower cooking losses, higher firmness, and lower stickiness, mostly favored by the higher proportion of amylose in the starch, than LT dried pasta (Giannetti et al., 2021a; Giannetti et al., 2021b; Masato et al., 2021).

3.7 Microstructure

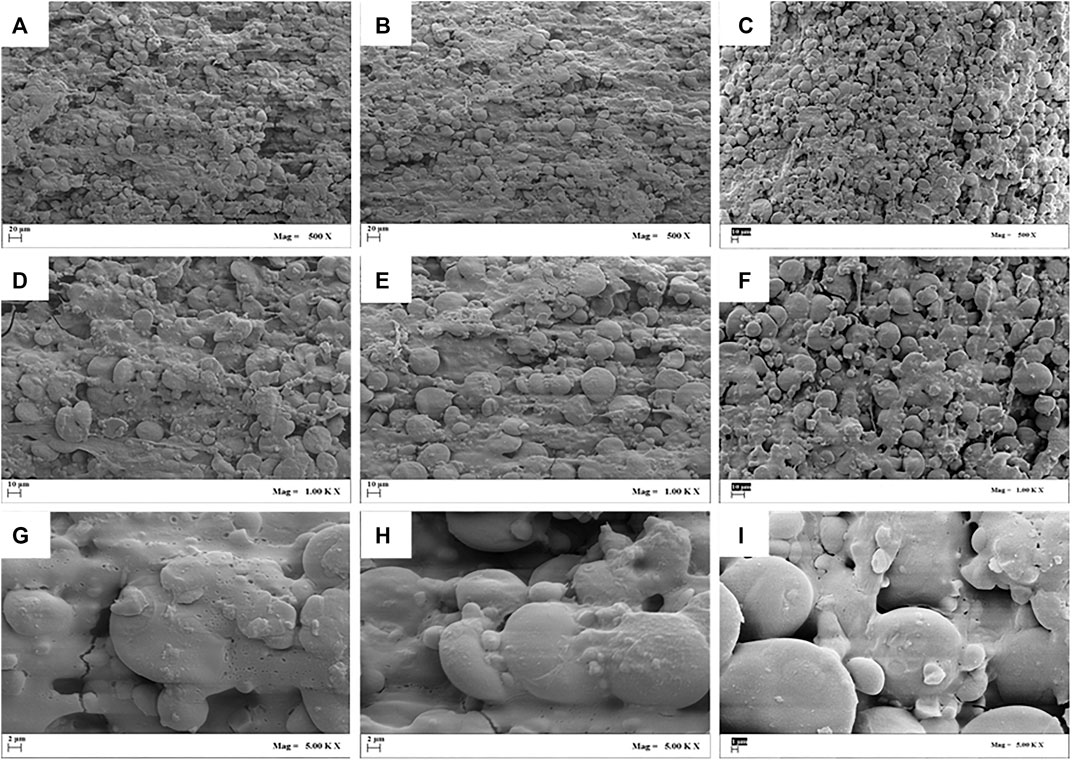

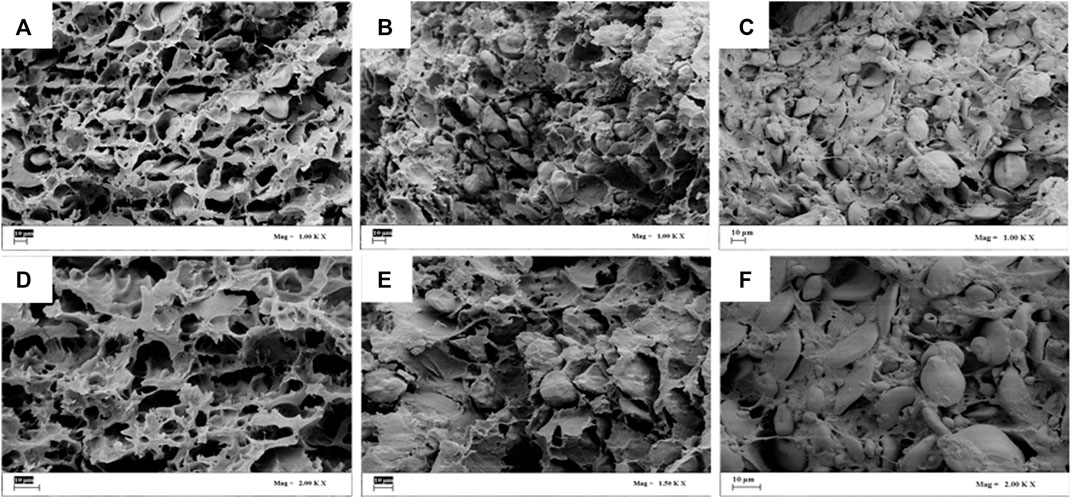

Scanning electron microscopy (SEM) was used to investigate the structure of the surface and cross section of dry spaghetti and the structure surface of the cooked samples. The micrographs at increasing magnifications are reported in Figures 4–6, respectively. The microstructural analysis of the different spaghetti were coherent with the results of cooking properties, texture profile, thermal and pasting properties of pasta samples.

Figure 4. Scanning Electron Microscopic images of the surface of dry pasta [(A, D, G) Sample A at increasing magnification of 500 X, 1.00K X; 5.00K X, (B, E, H) Sample B at increasing magnification of 500 X, 1.00K X; 5.00K X; (C, F, I) Sample C at increasing magnification of 500 X, 1.00K X; 5.00K X].

Figure 5. Scanning Electron Microscopic images of the section of dry pasta [(A, D) Sample A at increasing magnification of 1.00K X; 5.00K X, (B, E) Sample B at increasing magnification of 1.00K X; 5.00K X; (C, F) Sample C at increasing magnification of 1.00K X; 5.00K X].

Figure 6. Scanning Electron Microscopic images of the section of cooked pasta [(A, D) Sample A at increasing magnification of 1.00K X; 2.00K X, (B, E) Sample B at increasing magnification of 1.00K X; 2.00K X; (C, F) Sample C at increasing magnification of 1.00K X; 2.00K X].

Specifically, the surface area of sample A (Figures 4A, D, G) was characterized by a reduced roughness, a network with denser areas, and starch granules strongly embedded in the glutinous matrix. This may be due to the greater interactions occurring between starch, gluten, lipids and macromolecules, fibers and proteins, that tend to exert a protective effect on starch granules coated by a smooth film, as well as to the strong impact of processing on the outer pasta surface (friction through the bronze extruder die and high temperature during drying) (Aravind et al., 2012; Lu et al., 2018). Moreover, some cracks and small holes at the surface of the glutinous matrix can be attributed to the surface tensions occurring during drying and to possible shrinkage during the preparation for SEM analyses (Petitot et al., 2009). Sample A was also characterized by expanded and gelatinized starch granules whose size usually increases with increasing the drying temperature. Indeed, the size of starch granules in pasta dried at very high temperature (VHT) was larger than that in pasta dried at low temperature (LT) and high temperature (HT) (Zhang et al., 2013).

These considerations were confirmed analyzing the micrographs of the cross-section of dry spaghetti (Figure 5). Indistinguishable starch granules, disperse and continuous phases were observed in the case of samples A and B, while highly visible starch granules were present in the gluten network of sample C.

As expected, the micrographs of cooked spaghetti, shown in Figure 6, confirmed that they exhibited larger starch granules compared to uncooked pasta, surrounded by the coagulated protein matrix. In sample A (Figures 6A, D) the presence of voids surrounding the swollen starch granules can be explained considering their shrinkage and the limited and/or non-homogeneous absorption of water, associated with a starch pre-gelatinization phenomenon, due to HT drying (Renoldi et al., 2021). The results of SEM analyses were in agreement with the rheological (Table 5) and cooking properties (Table 6), indicating that a decrease of starch granules swelling in the case of sample A was likely to take place.

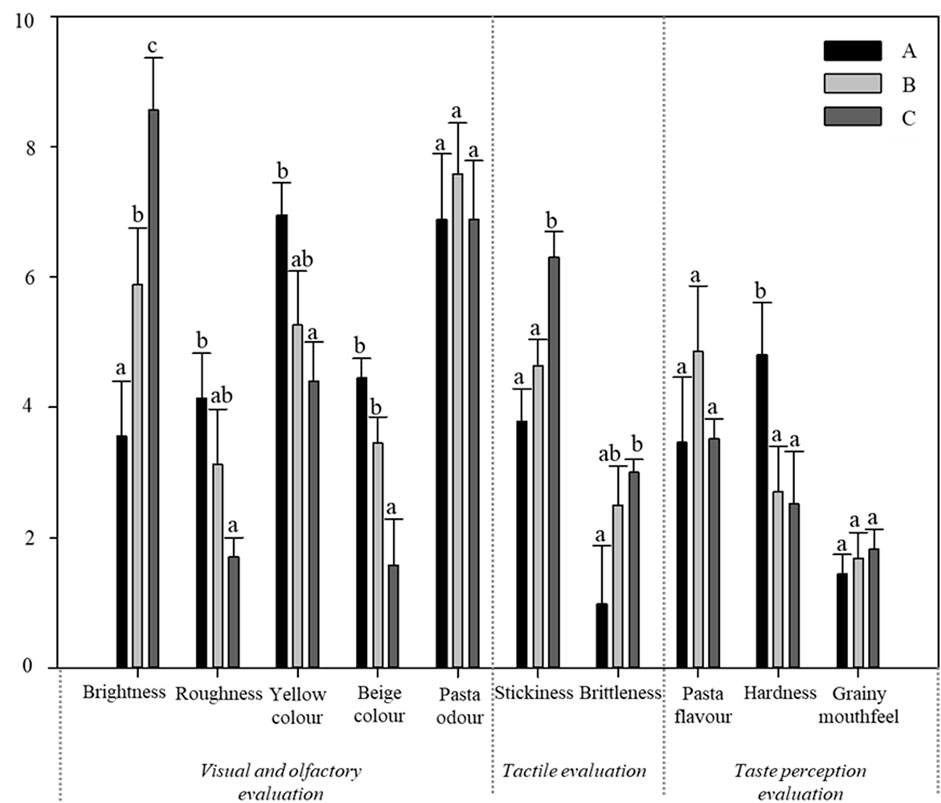

3.8 Sensorial properties

The sensory characteristics of the cooked spaghetti are reported in Figure 7. Sample A exhibited a sensorial profile significantly different from the other two samples. In particular, as regards the visual and nasal evaluation, it received high scores for the beige color. Color is one of the most influencing factors for durum wheat-based products (Ficco et al., 2014). A negative color profile, used as a marker of heat damages, was linked to a dark yellow and a greater perception of beige color associated with compounds derived from the Maillard reactions taking place during drying at high temperatures (Giannetti et al., 2021a). Sample C, instead, was negatively evaluated since it was characterized by higher whiteness (low yellowness) and excessive presence of water at the surface (greater brightness). Indeed, this sample received higher scores in terms of brightness associated with the highest CL and greater amylose released. This observations are in line with the main findings of Bonomi et al. (2012) who stated that in sensory evaluations the LT dried pasta received the lowest scores.

Figure 7. Sensory characteristics of spaghetti samples. Different letters above the bars indicate statistically significant difference among the three samples (p ≤ 0.05).

The results of the sensory analysis are consistent with those obtained analyzing the texture profile. According to in-hand and in-mouth evaluations, sample A was characterized by the lowest scores in terms of stickiness, in line with the adhesiveness values measured (Figure 3), the lowest brittleness and the highest hardness (Figure 7).

Typical characteristics for HT dried pasta consist in high firmness and low stickiness, due to the increased amount of stronger starch-protein interactions (Masato et al., 2021; Ohmura et al., 2023). Indeed, the higher lipid content detected in the semolina A could have contributed to strengthening the bonding of the other semolina compounds with starch granules resulting in a compact and harder network.

Interestingly, results revealed that sample B showed intermediate values between samples A and C, being evaluated by the panelists as the product closest to the characteristics of a good quality pasta and with a perfect balance between flavor and color.

4 Conclusion

The results obtained in this study have led to relevant conclusions regarding the influence of the physicochemical characteristics of durum wheat semolina and pasta-making process on structural, mechanical and sensory properties of three commercial spaghetti, allowing at the same time a complete view of the interconnected phenomena that concur in giving a staple food, such as pasta, its typical characteristics.

Higher starch, amylose, and lipid contents in semolina A favored the development of “amylose-lipid” complexes that could have affected the thermal and pasting properties of spaghetti A, increasing their compactness, limiting the access of water, improving the cooking properties, and giving an “al dente” feeling after cooking.

Moreover, the severity of the pasta production processing conditions could have affected the physicochemical properties of spaghetti, with sample A, subjected to HT drying, characterized by more damaged starch, less stickiness, higher hardness and beige color (Maillard reaction favored during HT drying).

Compared to semolina, spaghetti A showed a lower enthalpy of gelatinization (−15%), possibly associated with damages of starch granules during the production process, a phenomenon confirmed by microstructural analysis. In fact, micrographs corroborated the conclusion that spaghetti B, both dry and cooked, showed a structured matrix with a more homogeneous and less porous surface than sample A.

Ultimately, the comprehensive approach presented in this study may be helpful in identifying the parameters, related to both the raw materials characteristics and the pasta processing conditions, that influence the distinctive characteristics of dry spaghetti.

However, since pasta is a technologically complex product, future studies should be conducted on a larger number of samples to validate these results, assigning the contribution of each processing parameter involved in the whole pasta-making process to the final characteristics of pasta.

Data availability statement

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

Author contributions

SC: Conceptualization, Data curation, Formal Analysis, Investigation, Methodology, Writing–original draft. DL-W: Conceptualization, Data curation, Investigation, Methodology, Writing–original draft. GF: Conceptualization, Supervision, Writing–review and editing.

Funding

The authors declare that no financial support was received for the research, authorship, and/or publication of this article.

Acknowledgments

Authors are indebted to dott. Mariarosa Scognamiglio for her invaluable help with SEM analyses.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

The authors declared that they were an editorial board member of Frontiers, at the time of submission. This had no impact on the peer review process and the final decision.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Aidoo, R., Oduro, I. N., Agbenorhevi, J. K., Ellis, W. O., and Pepra-Ameyaw, N. B. (2022). Physicochemical and pasting properties of flour and starch from two new cassava accessions. Int. J. Food Prop. 25, 561–569. doi:10.1080/10942912.2022.2052087

Aravind, N., Sissons, M., Egan, N., and Fellows, C. (2012). Effect of insoluble dietary fibre addition on technological, sensory, and structural properties of durum wheat spaghetti. Food Chem. 130, 299–309. doi:10.1016/j.foodchem.2011.07.042

Asmeda, R., Noorlaila, A., and Norziah, M. H. (2016). Relationships of damaged starch granules and particle size distribution with pasting and thermal profiles of milled MR263 rice flour. Food Chem. 191, 45–51. doi:10.1016/j.foodchem.2015.05.095

Baiano, A., Conte, A., and Del Nobile, M. A. (2006). Influence of drying temperature on the spaghetti cooking quality. J. Food Eng. 76, 341–347. doi:10.1016/j.jfoodeng.2005.05.030

Baiano, A., Di Chio, A. G., and Scapola, D. (2019). Analysis of cracking and breakage in dried pasta: a case study. Qual. Assur. Saf. Crops Foods 11 (8), 713–717. doi:10.3920/QAS2019.1580

Banach, J. K., Majewska, K., and Żuk-Gołaszewska, K. (2021). Effect of cultivation system on quality changes in durum wheat grain and flour produced in North-Eastern Europe. PLoS One 16, e0236617–e0236625. doi:10.1371/journal.pone.0236617

BeMiller, J. N. (2019). Carbohydrate chemistry for food scientists. 3rd ed. MS, United States: AACC International.

Bonomi, F., D’Egidio, M. G., Iametti, S., Marengo, M., Marti, A., Pagani, M. A., et al. (2012). Structure-quality relationship in commercial pasta: a molecular glimpse. Food Chem. 135, 348–355. doi:10.1016/j.foodchem.2012.05.026

Bresciani, A., Pagani, M. A., and Marti, A. (2022). Pasta-making process: a narrative review on the relation between process variables and pasta quality. Foods 11, 256. doi:10.3390/foods11030256

Carpentieri, S., Ferrari, G., and Donsì, F. (2023). All-natural wheat gliadin-gum Arabic nanocarriers for encapsulation and delivery of grape by-products phenolics obtained through different extraction procedures. Food Chem. 424, 136385. doi:10.1016/j.foodchem.2023.136385

Carpentieri, S., Larrea-Wachtendorff, D., Donsì, F., and Ferrari, G. (2022). Functionalization of pasta through the incorporation of bioactive compounds from agri-food by-products: fundamentals, opportunities, and drawbacks. Trends Food Sci. Technol. 122, 49–65. doi:10.1016/j.tifs.2022.02.011

Cubadda, R. E., Carcea, M., Marconi, E., and Trivisonno, M. C. (2007). Influence of gluten proteins and drying temperature on the cooking quality of durum wheat pasta. Cereal Chem. 84, 48–55. doi:10.1094/CCHEM-84-1-0048

Cutignano, A., Mamone, G., Boscaino, F., Ceriotti, A., Maccaferri, M., and Picariello, G. (2021). Monitoring changes of lipid composition in durum wheat during grain development. J. Cereal Sci. 97, 103131. doi:10.1016/j.jcs.2020.103131

De Cindio, B., and Baldino, N. (2015). Pasta: manufacture and composition. 1st ed. Elsevier Ltd. doi:10.1016/B978-0-12-384947-2.00522-5

Dello Russo, M., Spagnuolo, C., Moccia, S., Angelino, D., Pellegrini, N., Martini, D., et al. (2021). Nutritional quality of pasta sold on the Italian market: the food labelling of Italian products (FLIP) study. Nutrients 13, 171–183. doi:10.3390/nu13010171

De Noni, I., and Pagani, M. A. (2010). Cooking properties and heat damage of dried pasta as influenced by raw material characteristics and processing conditions. Crit. Rev. Food Sci. Nutr. 50, 465–472. doi:10.1080/10408390802437154

Detchewa, P., Thongngam, M., Jane, J. L., and Naivikul, O. (2016). Preparation of gluten-free rice spaghetti with soy protein isolate using twin-screw extrusion. J. Food Sci. Technol. 53, 3485–3494. doi:10.1007/s13197-016-2323-8

Dimitrios, A. (2023). “Durum wheat: uses, quality characteristics, and applied tests,” in Wheat [working title] (IntechOpen). doi:10.5772/intechopen.110613

Falciano, A., Sorrentino, A., Masi, P., and Di Pierro, P. (2022). Development of functional pizza base enriched with jujube (ziziphus jujuba) powder. Foods 11, 1458. doi:10.3390/foods11101458

Fares, C., and Menga, V. (2012). Effects of toasting on the carbohydrate profile and antioxidant properties of chickpea (Cicer arietinum L.) flour added to durum wheat pasta. Food Chem. 131, 1140–1148. doi:10.1016/j.foodchem.2011.09.080

Ficco, D. B. M., Mastrangelo, A. M., Trono, D., Borrelli, G. M., De Vita, P., Fares, C., et al. (2014). The colours of durum wheat: a review. Crop Pasture Sci. 65, 1–15. doi:10.1071/CP13293

Fuad, T., and Prabhasankar, P. (2010). Role of ingredients in pasta product quality: a review on recent developments. Crit. Rev. Food Sci. Nutr. 50, 787–798. doi:10.1080/10408390903001693

Garcia-Valle, D. E., Bello-Pérez, L. A., Agama-Acevedo, E., and Alvarez-Ramirez, J. (2021). Structural characteristics and in vitro starch digestibility of pasta made with durum wheat semolina and chickpea flour. LWT 145, 111347. doi:10.1016/j.lwt.2021.111347

Giannetti, V., Boccacci Mariani, M., and Colicchia, S. (2021a). Furosine as marker of quality in dried durum wheat pasta: impact of heat treatment on food quality and security – a review. Food control. 125, 108036. doi:10.1016/j.foodcont.2021.108036

Giannetti, V., Boccacci Mariani, M., Marini, F., and Biancolillo, A. (2021b). Effects of thermal treatments on durum wheat pasta flavour during production process: a modelling approach to provide added-value to pasta dried at low temperatures. Talanta 225, 121955. doi:10.1016/j.talanta.2020.121955

Güler, S., Köksel, H., and Ng, P. K. W. (2002). Effects of industrial pasta drying temperatures on starch properties and pasta quality. Food Res. Int. 35, 421–427. doi:10.1016/S0963-9969(01)00136-3

Jalgaonkar, K., Jha, S., and Mahawar, M. (2018). Optimization and functionality of millet supplemented pasta. Food Sci. Technol. 35, 626–632. Available at:. doi:10.1590/1678-457X.6745

Krawęcka, A., Sobota, A., Pankiewicz, U., Zielińska, E., and Zarzycki, P. (2021). Stinging nettle (Urtica dioica l.) as a functional component in durum wheat pasta production: impact on chemical composition, in vitro glycemic index, and quality properties. Molecules 26, 6909. doi:10.3390/molecules26226909

Kubo, M. T. K., Augusto, P. E. D., and Cristianini, M. (2013). Effect of high pressure homogenization (HPH) on the physical stability of tomato juice. Food Res. Int. 51, 170–179. doi:10.1016/J.FOODRES.2012.12.004

Lu, X., Brennan, M. A., Serventi, L., Liu, J., Guan, W., and Brennan, C. S. (2018). Addition of mushroom powder to pasta enhances the antioxidant content and modulates the predictive glycaemic response of pasta. Food Chem. 264, 199–209. doi:10.1016/j.foodchem.2018.04.130

Lupu, M. I., Canja, C. M., Padureanu, V., Boieriu, A., Maier, A., Badarau, C., et al. (2023). Insights on the potential of carob powder (ceratonia siliqua L.) to improve the physico-chemical, biochemical and nutritional properties of wheat durum pasta. Appl. Sci. Switz. 13, 3788. doi:10.3390/app13063788

Marti, A., Pagani, M. A., and Seetharaman, K. (2011). Understanding starch organisation in gluten-free pasta from rice flour. Carbohydr. Polym. 84, 1069–1074. doi:10.1016/j.carbpol.2010.12.070

Masato, O., Kentaro, M., Tatsuro, M., Akio, F., Yukako, H., and Yasuki, M. (2021). Effects of drying temperature on the properties of starch in pasta. LWT 145, 111171. doi:10.1016/j.lwt.2021.111171

Mirzababaee, S. M., Ozmen, D., Hesarinejad, M. A., Toker, O. S., and Yeganehzad, S. (2022). A study on the structural, physicochemical, rheological and thermal properties of high hydrostatic pressurized pearl millet starch. Int. J. Biol. Macromol. 223, 511–523. doi:10.1016/j.ijbiomac.2022.11.044

Niu, M., Hou, G. G., Kindelspire, J., Krishnan, P., and Zhao, S. (2017). Microstructural, textural, and sensory properties of whole-wheat noodle modified by enzymes and emulsifiers. Food Chem. 223, 16–24. doi:10.1016/j.foodchem.2016.12.021

Ogawa, T., Chuma, A., Aimoto, U., and Adachi, S. (2017). Effects of drying temperature and relative humidity on spaghetti characteristics. Dry. Technol. 35, 1214–1224. doi:10.1080/07373937.2016.1236812

Ohmura, M., Matsumiya, K., Maeda, T., Fujita, A., Hayashi, Y., and Matsumura, Y. (2023). Effect of drying profiles on surface structure changes of durum wheat pasta during the boiling process. LWT 173, 114175. doi:10.1016/j.lwt.2022.114175

Padalino, L., Caliandro, R., Chita, G., Conte, A., and Del Nobile, M. A. (2016). Study of drying process on starch structural properties and their effect on semolina pasta sensory quality. Carbohydr. Polym. 153, 229–235. doi:10.1016/j.carbpol.2016.07.102

Petitot, M., Abecassis, J., and Micard, V. (2009). Structuring of pasta components during processing: impact on starch and protein digestibility and allergenicity. Trends Food Sci. Technol. 20, 521–532. doi:10.1016/j.tifs.2009.06.005

Piwińska, M., Wyrwisz, J., Kurek, M. A., and Wierzbicka, A. (2016). Effect of drying methods on the physical properties of durum wheat pasta. CYTA - J. Food 14, 523–528. doi:10.1080/19476337.2016.1149226

Renoldi, N., Brennan, C. S., Lagazio, C., and Peressini, D. (2021). Evaluation of technological properties, microstructure and predictive glycaemic response of durum wheat pasta enriched with psyllium seed husk. LWT 151, 112203. doi:10.1016/j.lwt.2021.112203

Romano, A., Di Luccia, A., Romano, R., Sarghini, F., and Masi, P. (2015). Microscopic and thermal characteristics of experimental models of starch, gliadins, glutenins and gluten from semolina. Chem. Eng. Trans. 43, 163–168. doi:10.3303/CET1543028

Sacchetti, G., Cocco, G., Cocco, D., Neri, L., and Mastrocola, D. (2011). Effect of semolina particle size on the cooking kinetics and quality of spaghetti. Procedia Food Sci. 1, 1740–1745. doi:10.1016/J.PROFOO.2011.09.256

Sicignano, D. A. (2015). Effects of raw material, technological process and cooking procedure on quality of pasta from durum wheat semolina, 71. Italy: University Degli Studi Di Napoli Federico. PhD. Thesis.

Sissons, M., Abecassis, J., Marchylo, B., and Cubadda, R. (2012). Methods used to assess and predict quality of durum wheat, semolina, and pasta. 2nd ed. MS, United States: AACC International, Inc. doi:10.1016/B978-1-891127-65-6.50017-9

Sozer, N., Dalgiç, A. C., and Kaya, A. (2007). Thermal, textural and cooking properties of spaghetti enriched with resistant starch. J. Food Eng. 81, 476–484. doi:10.1016/j.jfoodeng.2006.11.026

Spinelli, S., Padalino, L., Costa, C., Del Nobile, M. A., and Conte, A. (2019). Food by-products to fortified pasta: a new approach for optimization. J. Clean. Prod. 215, 985–991. doi:10.1016/j.jclepro.2019.01.117

Statista Global Consumer Survey (2022). Leading countries in pasta consumption per capita in 2022. Available at: https://www.statista.com/statistics/1379424/per-capita-consumption-pasta-by-country/ (Accessed August 10, 2023).

Syah, I. T., Irundu, D., Bahmid, N. A., and Karim, I. (2022). “Changes in functional properties during fermentation of Amorphophallus paeoniifolius (Dennst.) Nicolson yam using Lactobacillus plantarum,” in IOP conference series: earth and environmental science (Bristol, England: IOP Publishing Ltd). doi:10.1088/1755-1315/978/1/012015

Tagliasco, M., Fogliano, V., and Pellegrini, N. (2021). Pasta regrind: the effect of drying temperature on its functionality as a novel ingredient. Food Struct. 30, 100230. doi:10.1016/j.foostr.2021.100230

Tateo, F. (1980). “Sfarinati di frumento,” in Chiriotti Editori, Analisi dei prodotti alimentari. 1st ed., 219–2020.

Wang, K., Pozniak, C. J., Ruan, Y., and Fu, B. X. (2023). Unveiling the impact of durum wheat protein quantity and quality on textural properties and microstructure of cooked pasta. Cereal Chem. 100, 484–499. doi:10.1002/cche.10627

Keywords: durum wheat semolina, commercial spaghetti, pasta-making process, technofunctional properties, sensory profile

Citation: Carpentieri S, Larrea-Wachtendorff D and Ferrari G (2024) Influence of semolina characteristics and pasta-making process on the physicochemical, structural, and sensorial properties of commercial durum wheat spaghetti. Front. Food. Sci. Technol. 4:1416654. doi: 10.3389/frfst.2024.1416654

Received: 12 April 2024; Accepted: 21 May 2024;

Published: 07 June 2024.

Edited by:

José S. Câmara, Universidade da Madeira, PortugalReviewed by:

Sunil C. K., National Institute of Food Technology, Entrepreneurship and Management, Thanjavur (NIFTEM-T), IndiaMaria Simona Chis, University of Agricultural Sciences and Veterinary Medicine of Cluj-Napoca, Romania

Copyright © 2024 Carpentieri, Larrea-Wachtendorff and Ferrari. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Serena Carpentieri, c2NhcnBlbnRpZXJpQHVuaXNhLml0

Serena Carpentieri

Serena Carpentieri Dominique Larrea-Wachtendorff

Dominique Larrea-Wachtendorff Giovanna Ferrari

Giovanna Ferrari