- 1School of Economics and Management, Harbin University of Science and Technology, Harbin, China

- 2Finance Department, Mudanjiang Normal University, Mudanjiang, China

- 3School of Management, Harbin University of Science and Technology, Harbin, China

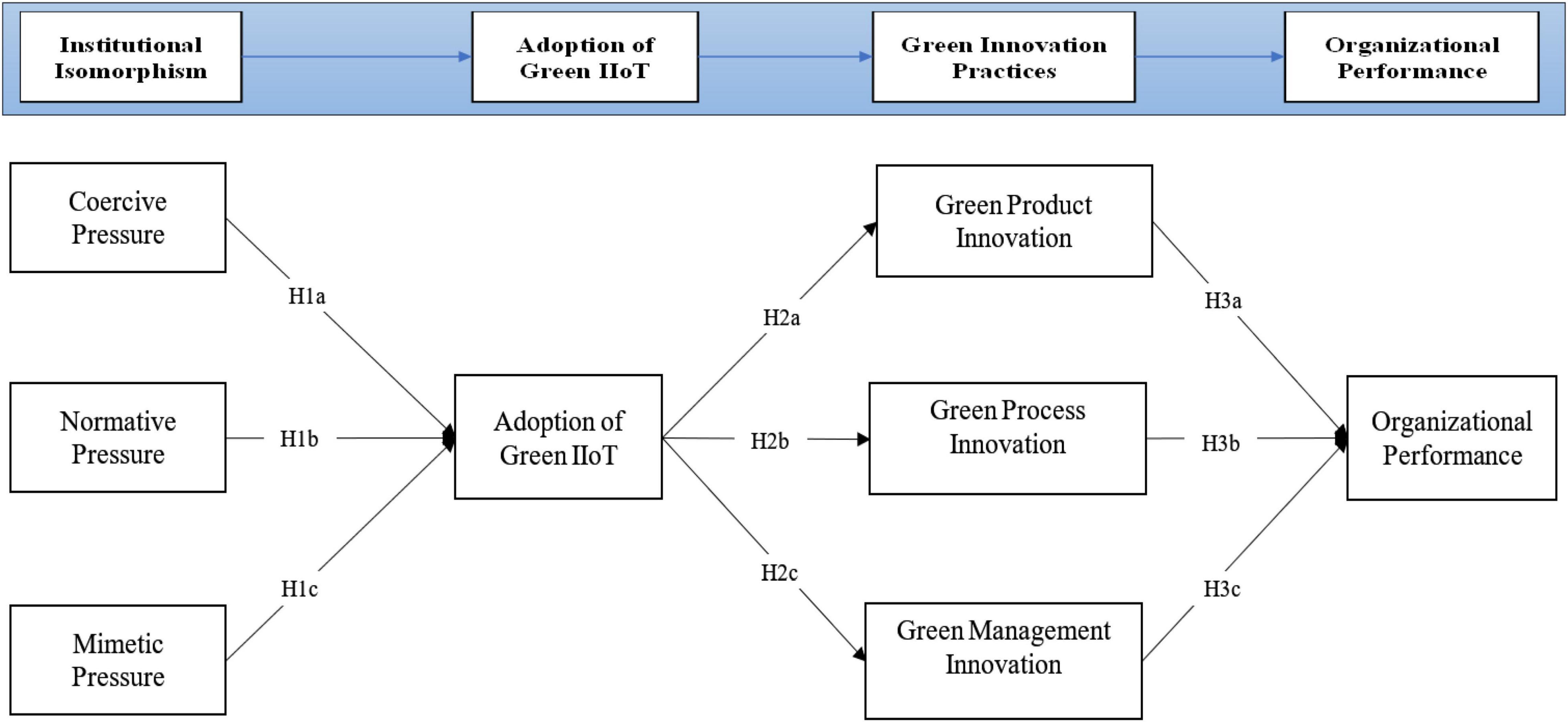

Emerging technology developments and functions of the Internet of Things (IoT) in industrial systems are leading the development of the Industrial IoT (IIoT). Greener, i.e., cleaner environmental goals can be achieved by putting green IIoT (GIIoT) into practice. This research aims to explore the reasons for the adoption of GIIoT in organizational decision-making and to explore its impact on organizational performance. The proposed research model was tested by collecting data through a structured questionnaire. The findings suggest that institutional isomorphism has a positive impact on the adoption of GIIoT. Moreover, GIIoT is positively associated with green innovation (GI) practices (e.g., product, process, and management) that lead to organizational performance. The potential impact of various types of institutional isomorphism described in this study can help organizations better comprehend the institutional pressures they enforce and/or appease their stakeholders, especially as they adopt GIIoT, to manage production issues and potential compliance pressures in the process.

Introduction

Organizations often adopt information technology (IT) due to institutional pressure from stakeholders (Ainin et al., 2016). With the fast advancement of industrial informatization, the Internet of Things (IoT) has emerged as a critical and promising feature in the transition of modern industrial automation (Wang et al., 2016). IoT is thought to provide widespread benefits in many IT systems, as well as a substantial influence on the industry by lowering costs and enabling more efficient and effective monitoring and management (Khan et al., 2020). IoT vows to bring innovation and advances to the standard Industrial IoT (IIoT). The IIoT is a new vision for the IoT in the industrial sector through automated smart objects to sense, collect, process, and communicate temporal events in industrial systems (Khan et al., 2020). IIoT technologies enable enterprises to gather and analyze a large volume of data, which can then be utilized to improve the overall operation of industrial systems while delivering a variety of services (Park, 2019; Liebl et al., 2020). The application of these elements in the context of energy management makes the concept of the green IIoT (GIIoT) a reality, and the use of the IIoT in the context of green environmental development becomes more demanding (Tabaa et al., 2020).

Meanwhile, green innovation (GI) is the transformation of the operations and processes in such a way that it benefits the natural environment (Xue et al., 2019). GI is pivotal in achieving sustainable environmental goals by reducing the harmful impacts of business operations (Wu, 2013). GI is beneficiary in maintaining the firm’s positive image by reducing carbon footprint, environmental degradation, hazardous waste, energy waste, and toxic chemicals (Lisi et al., 2020). Firms can also obtain the advantage of higher market share, better firm performance, social recognition, and good relations with the government (Zhang et al., 2020b). Through the GI practice, a business transforms its products, processes, structures, and management and business operations from traditional to novel, thereby promoting business development and ensuring environmental protection (Ma et al., 2018). Prior studies have categorized GI into subsets, namely, green product innovation (GPdI), green process innovation (GPcI), and green management innovation (GMI) (Tang et al., 2018; Xie et al., 2019; Xue et al., 2019; Hu et al., 2022).

The literature has moved away from considering the importance of different factors that influence the adoption of technological innovations and has turned to examine the precise impact of institutional isomorphism on the adoption of GIIoT, which can lead to organizational performance (Gadre and Gadre, 2016; Hsu and Yeh, 2017; Affia et al., 2019; Sam et al., 2021). Based on the dearth of literature, what needs to be studied is that the current relationship, institutional isomorphism of GIIoT adoption, competes with organizational performance. Therefore, to fill this gap, the current study empirically analyses the impact of institutional isomorphism on the adoption of GIIoT that may lead to overall organizational performance. This study also measures the mediating role of GI practices between GIIoT adoption and organizational performance.

Theoretical Framework and Hypothesis Development

Institutional Theory

From the perspective of institutional theory, a firm’s operations and decisions are highly reflected by the social and cultural environment (Ngah et al., 2017; Joardar and Sarkis, 2021). The institutional theory posits how a firm should tackle and respond to the pressure from the external environment (Yen, 2018). The institutional theory proposed the norms, rules, and strategies to comply expected from the firm’s institutional entities by putting pressure on the firm (Liu et al., 2010). Pressure from external stakeholders emphasized that the firms comply with environment-friendly activities in their production and operations (Vanalle et al., 2017). The institutional theory argues that business activities are not necessarily rational in a commercial sense but are driven by the broader institutional environment (McDougall et al., 2022). The study of Dubey et al. (2015) explained that under the institutional theory, firms expand the objective of their existence by giving value to their society and environment and just not focusing only on making a profit. In addition, the absence of institutional pressures diverts the firm’s focus from environment-friendly activities; conversely, the higher the pressure firm would receive from its stakeholders, the greater the chances of complying with the firm’s resources in managing the environment efficiently effectively (Vanalle et al., 2017). For instance, firms employ several green practices to avoid the penalty from regulatory pressures by following their commandments (Yen, 2018). In the institutional theory, social reality is overseen by a set of discriminated, specialized, cognitive, normative, and regulatory systems, i.e., institutional logic (Kros et al., 2020). The institutional theory highlights the importance of institutional pressure in employing green practices and determines the firm’s behavior toward social values, norms, and technological advancement in society (Yen, 2018; Oliveira et al., 2019). However, the adoption of GIIoT has not been discussed from the perspective of IT. The current study aims to investigate the firm’s adoption behavior of GIIoT by using the institutional theory as a theoretical lens. The institutional theory splits the institutional pressure into three isomorphisms, namely, coercive pressure (CP), normative pressure (NP), and mimetic pressure (MP).

Coercive Pressure

The CP is the extent to which firms are influenced by the regulations of those entities in power (Imamoglu et al., 2010). CP is caused by powerful stakeholders, such as government organizations, NGOs, customers, and suppliers (Latif et al., 2020). Firms adopt innovative technologies by exerting pressure from influencing entities, such as government, regulatory authorities, parent companies, competitors, and resource dominant organizations (Oliveira et al., 2019). In this stream, the study of Jan et al. (2012) marked that two major entities put CP on firms, namely, regulatory forces and competitors. Resource-dependent organizations follow dominant organizations’ directions to comply with certain mechanisms for their survival (Sherer et al., 2016). Organizations take that pressure to stay competitive and avoid the penalties from government and regulatory authorities (Jan et al., 2012). Coercion of these entities on a firm’s technological adoption has been studied in various contexts (Messerschmidt and Hinz, 2013; Soares et al., 2020), electronic health record adoption (Sherer, 2010), and electronic supply chain management (SCM) adoption (Liu et al., 2010). Based on these arguments, this study has also supported the following hypothesis.

H1a: CP is positively associated with the adoption of GIIoT.

Normative Pressure

The NP refers to the influence of the firms in the same industry or people in the same group to behave legitimately (Jayarathna, 2015). NP arises when informal agents (e.g., customers and suppliers) constitute a set of codes and values to be followed by a firm in a society or industry (Dubey et al., 2015). NP comes from the expectations, values, norms, and standards in the corporate culture (Latif et al., 2020). Demands of the customers and suppliers are considered the core NP for the firms to act in a certain way (Imamoglu et al., 2010). Firms learn about the techniques and technologies to adopt, which are deemed effective by the community in which they operate (Sherer et al., 2016). According to Jan et al. (2012), social players forced the firms to adopt a particular behavior or technology when employed by several other firms in a similar industry or society. Sharing the knowledge about the benefits of particular technology adoption persuaded the non-adopters toward adoption intention, and this sharing can be done in a network of customers, suppliers, trading agencies, and firms (Messerschmidt and Hinz, 2013). NP is found to be a significant predictor of the adoption in prior literature (Sherer, 2010; Zailani et al., 2012; Hsu et al., 2013; Saeed et al., 2018). Based on the abovementioned argument, this study has also supported the following hypothesis:

H1b: NP is positively associated with the adoption of GIIoT.

Mimetic Pressure

The MP refers to the degree to which a firm imitates the established strategies and behavior of another firm enjoying high status (Jan et al., 2012). MP is caused by peers, professional associations, or competitors (Ben Boubaker et al., 2021). Adopting the similar strategy and technology that the rival firm has already employed allows the firms to stay competitive and avoid errors in the adoption process (Messerschmidt and Hinz, 2013). In general, firms usually take MP when the outcomes of a particular technology are not clear and then the firms tend to mimic the legitimate structure and technology (Dubey et al., 2015). MP allows the firms to enjoy a second-mover advantage by reducing experimentation costs, the risk associated with new technology adoption, and a clear insight into which technology works well (Sherer, 2010). Notwithstanding, copying is not necessarily always right; if it is not operated effectively and efficiently, it could cost the focal firm (Liu et al., 2010). When a large number of firms behave in a particular manner, it is requisite for other firms to follow to avoid the humiliation and join the race sever competition (Sherer et al., 2016). On the ground of arguments mentioned earlier, it can be rationally posited that MP forces organizations to adopt the advancement that will ensure innovation in the firm’s operations. Therefore, this study supported the following hypothesis:

H1c: MP is positively associated with the adoption of GIIoT.

Green Industrial Internet of Things

The IIoT is defined as the interconnected objects which is able to manage the data mining and accesses the data that are generated (Boyes et al., 2018). In this vein, the GIIoT is the mechanism of interlinked systems, actuators, and sensors for implementing GI practices, effective decision-making, and better manufacturing processes by extracting reliable information (Hu et al., 2022). Rapid changes in the environment due to hazardous waste and awareness about the drastic impacts of these changes result in the adoption of GIIoT (Tabaa et al., 2020). GIIoT endeavors to prevent environmental pollution, energy waste, efficient resource usage, and effective technological services (Albreem et al., 2018). The study by Wang et al. (2016) marked several benefits of GIIoT on industry and the environment, such as reducing the negative impacts of technology on human health, carbon footprints, toxic emissions, environmental degradation, and industrial cost. According to the study by Hu et al. (2022), GIIoT is constructive and significant for GI. The goal of GIIoT is to decarbonize and optimize environmental protection and monitoring, and reduce operational costs and energy usage for long-term growth (Varjovi and Babaie, 2020). Thus, based on the abovementioned arguments, this study supported the following hypotheses:

H2a: GIIoT is positively associated with GPdI.

H2b: GIIoT is positively associated with GPcI.

H2c: GIIoT is positively associated with GMI.

Green Innovation and Performance

The GPdI defines as launching new or alternations to the existing products that have less or no harmful impact on the ecosystem during the whole lifecycle of the product (Tang et al., 2018). GPdI payoff in terms of higher firm performance when it is properly promoted in the market (Xie et al., 2019). GPdI is an alternative to conventional products designed to minimize hazardous impact, achieve a competitive edge, and improve firm performance (Wong, 2012). A study by Xue et al. (2019) stated that GPdI has become a key source of environmental sustainability and firm performance. GPdI reflects the product’s sustainability at the stage of designing, manufacturing, and marketing that product (Lisi et al., 2020). In addition, GPdI secures the firms from penalties for damaging the environment and protest of saving the ecosystem and helps in achieving competitive advantage and opportunity of a new market with a new product (Xie et al., 2019).

The GPcI refers to employing technologies, operations, and activities within the firm that do not negatively impact the organization’s internal and external environment (Wu, 2013; Wang et al., 2021). GPcI is the extent to which the firm tries to meet those environmental standards set by the firm’s management, the society, or the market in which they are operating by adopting environmental protecting technologies, mechanisms, and tactics (Wong, 2012). In implementing GPcI, the firm’s internal sources are required and could be costlier for the firm yet it is considered the best green practice for environmental sustainability and the firm’s performance (Xie et al., 2019). GPcI helps achieve sustainable competitive advantage (Tang et al., 2018), which is the ultimate source of better firm performance. Reducing adverse environmental impacts, achieving the firm’s environmental compliance, and employing cleaner technologies and end-of-pipe technologies are pivotal activities of GPcI that sustain the firm’s differentiation advantage (Xie et al., 2019).

Similar to GPdI and GPcI, GMI is the firm’s strategic compliance with environmental protection activities designed by its management (Shu et al., 2016). In comparison with other innovations, GMI is the philosophy to change the working norms of managers at the organizational level (Ma et al., 2018). GMI helps in effective decision-making, establishing environmental policies, and reallocating the resources within the firm to handle waste and save the cost, which enhance the firm’s performance (Zhang et al., 2020b). The main purpose of GMI is to adopt managerial policies and strategies that are new to the focal firm and protect the environment from its negative impacts (Shu et al., 2016). GMI improves competitiveness, firm performance, and market value (Zhang et al., 2020a). Based on these arguments, this study supported the following hypotheses:

H3a: GPdI is positively associated with organizational performance.

H3b: GPcI is positively associated with organizational performance.

H3c: GMI is positively associated with organizational performance.

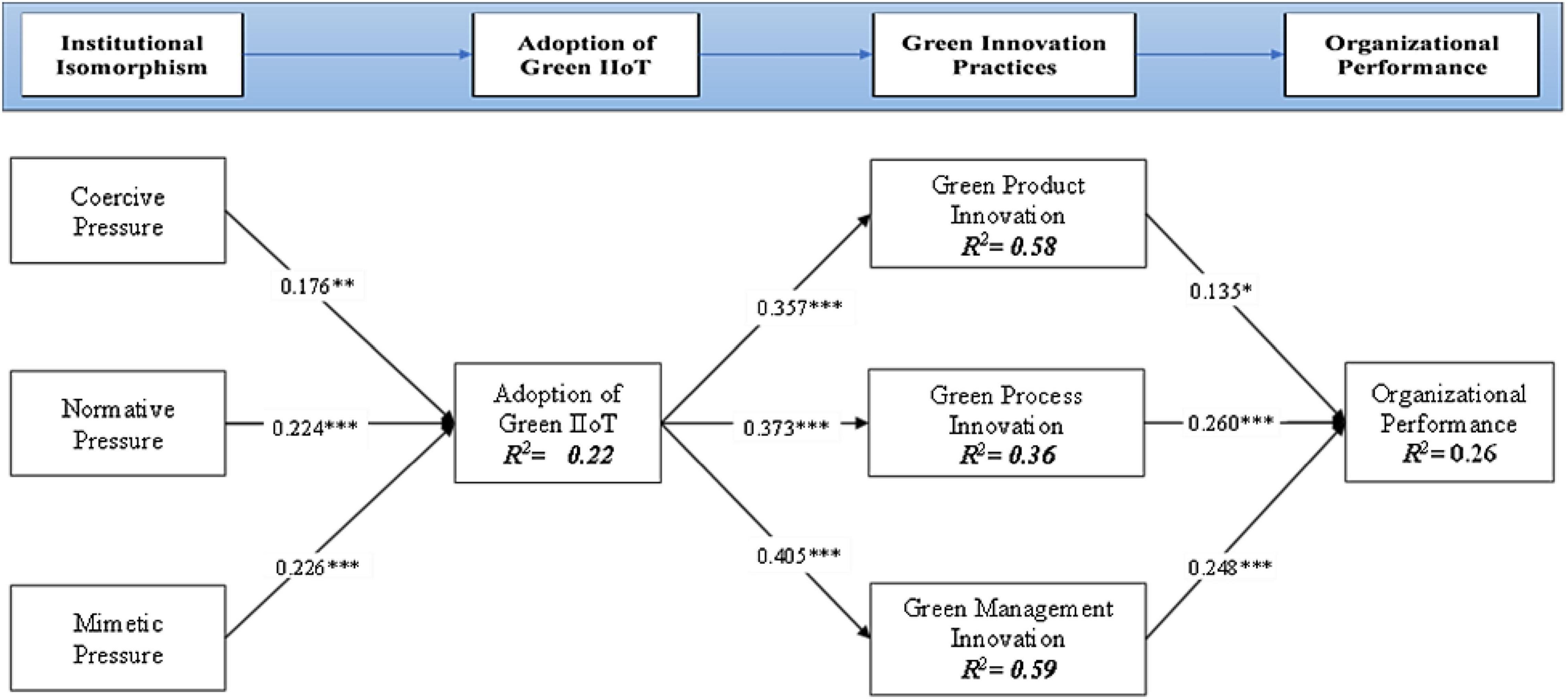

Figure 1 presents the proposed research model.

Materials and Methods

Measures

The study to preserve the content validity adapted the measuring items from prior studies in a simpler context. The four-item scale of CP, three-item scale of NP, and three-item scale of MP were adapted from Liu et al. (2010). Six-item scale of GIIoT adoption was adapted from Molla and Abareshi (2012). Furthermore, four-item scale of GPdI and four-item scale of GPcI were adapted from Kong et al. (2016), and four-item scale of GMI was adapted from Ma et al. (2018). Moreover, five-item scale of OP was adapted from Ma et al. (2018). As the study considered gender, education, and age as control variables, therefore, the sited demographical information of respondents was also collected. The study used a seven-point Likert-type scale for a survey.

Sample Size, Data Collection, and Analysis Technique

The manufacturing organizational employees in Harbin, China, were the population of the study. China has massive issues in keeping a balance between economic and ecological demands because of its industrial expansion. Furthermore, to verify the questionnaire’s content validity, three bilingual researchers translated the questionnaire into Chinese and then back into English. Further changes were made to enhance the understanding and appropriateness of Chinese manufacturing methods. Questionnaires were sent to the employees of randomly selected manufacturing organizations via an online survey link in November 2021. Based on the literature, the study ensured that the sample size of more than 200 is considered suitable for applying SEM (Kline, 2015). In February 2022, we received 330 filled questionnaires, of which 12 incomplete questionnaires were discarded. The study considered 318 valid responses for final analyses. As the study selected SEM to analyze the relationships among variables, the Smart PLS is used to run the SEM as it is among the best tool to run the SEM (Henseler et al., 2016).

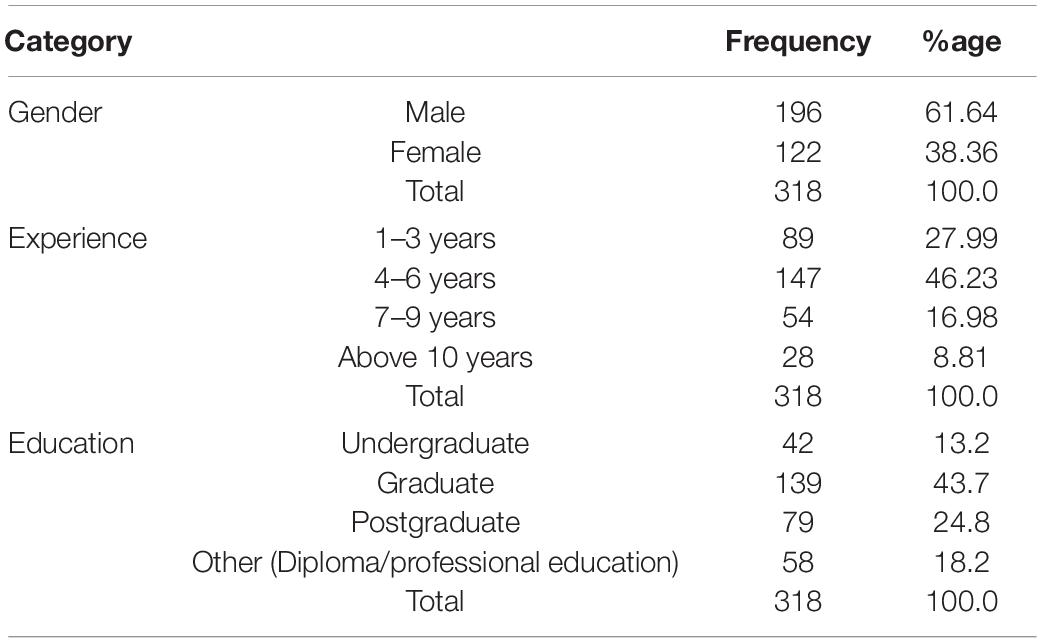

Demographical Information

Table 1 presents the demographical data of the respondents of this study. According to the results, 61.64% of respondents are men, 73% of respondents have more than 3 years of experience, and 68% of respondents are degree holders. Therefore, the study has both male and female respondents who are experienced and educated.

Common Method Bias

Common method bias (CMB) is an important issue to be focused on when data were collected from the same point of time and one source (Podsakoff et al., 2012). To address this issue, the study used a single-factor test of Harman. The study divides all the items into eight subgroups and the first factor only explains the 35.80% of variance which is under the threshold point of 40% (Podsakoff et al., 2006, 2012). The study validates the inner variance factor (VIF) as a single Harman factor is not sufficient for CMB. The values of VIF should be less than 3.3 (Kock, 2015). The values of VIF are ranging from 1.35 to 1.71 which are under the threshold. Results of the study demonstrate that there is no issue with CMB in the research.

Results

Measurement Model

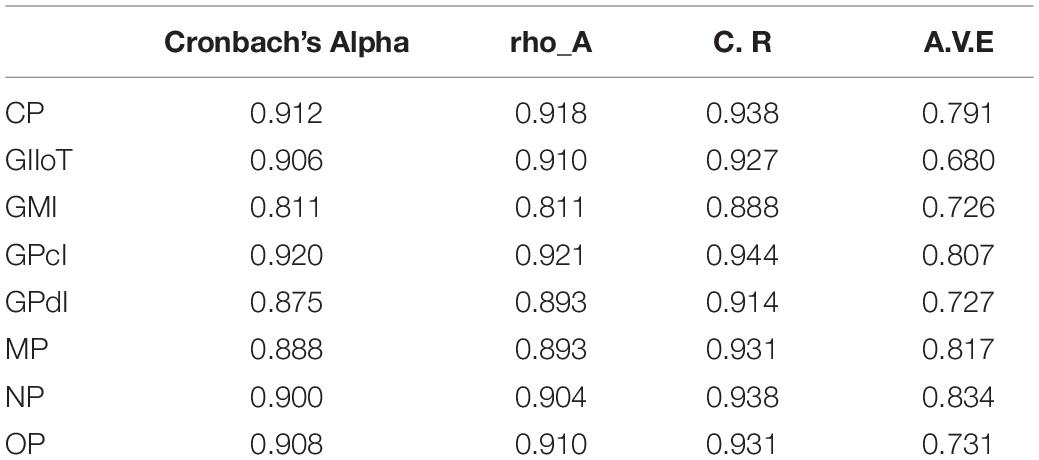

For measuring the convergent validity composite reliability (CR), Cronbach’s alpha and average variance extracted (AVE) were tested. The values of convergent validity analysis are presented in Table 2, which demonstrates that all values are above the threshold values. Threshold values for Cronbach’s alpha, CR, and AVE are 0.70, 0.70, and 0.50, respectively (Fornell and Lacker, 1981a). No critical issue was found in convergent validity as all the values of Cronbach’s alpha, CR, and AVE are under the acceptance range.

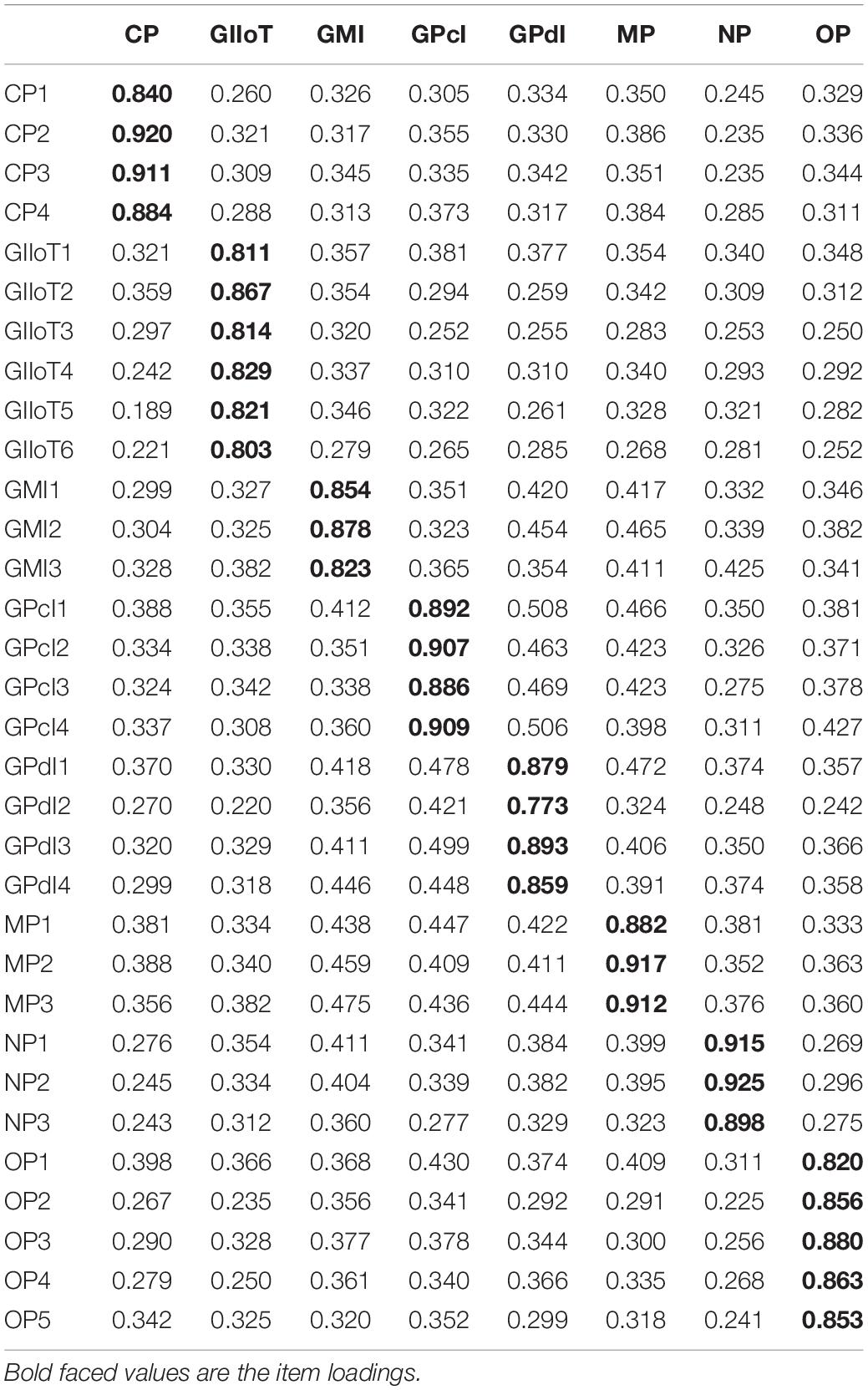

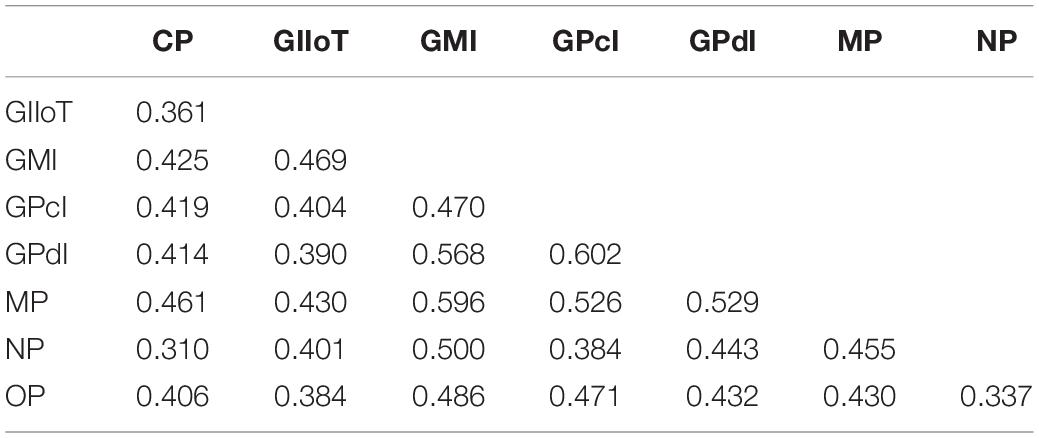

Discriminant validity is tested by following the three techniques proposed by Gefen (2005). The first technique was to ensure the association between the correlation of factors and the square root of AVE which is considered the best technique for discriminant validity (Fornell and Lacker, 1981b). The second technique is to examine item loadings and cross-loadings to verify the correlation, and the third technique is to demonstrate the heterotrait-monotrait ratio (HTMT) (Hair et al., 2014; Henseler et al., 2016). Table 3 presents the values of AVE that are higher than the coefficient of correlation of all variables.

Item loadings and cross-loadings of their parallel variables are also greater than the item loadings and cross-loadings of their explanatory variable presented in Table 4, which proves that discriminant validity has no critical issue.

The HTMT ratio is the upper boundary of the factors whose value should be less than 1 to differentiate the two factors (Henseler et al., 2016). Table 5 presents the value of HTMT which is under the acceptance range and demonstrates that there is no concern in discriminant validity.

Structural Equation Modeling

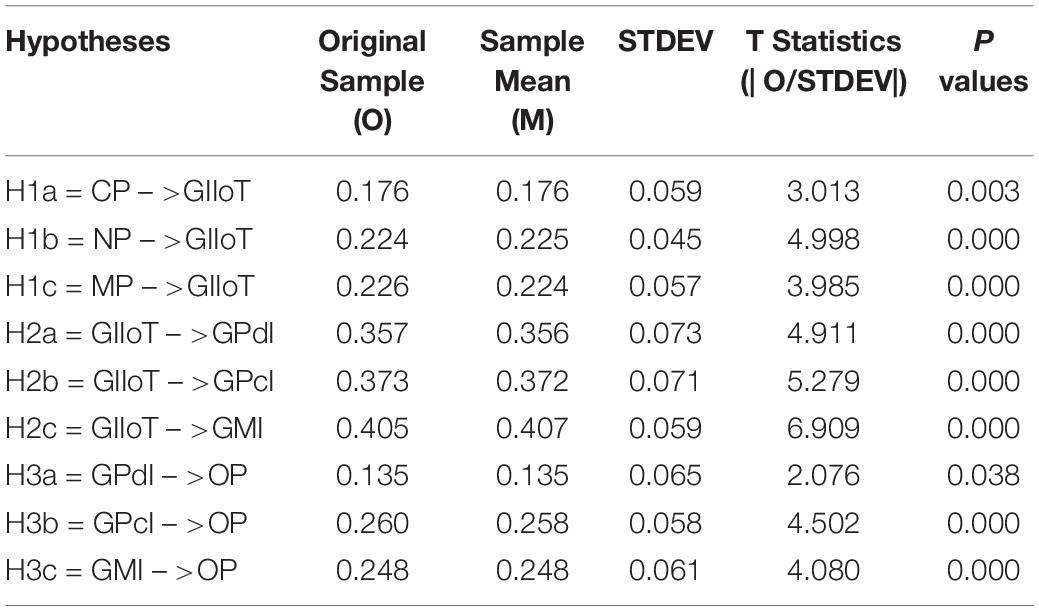

To examine the relationship among variables, Smart PLS was used based on standardized paths (Dijkstra and Henseler, 2015). Path coefficient, p-value, and t-value are shown in Table 6. Results present that there is a 22% variance in GIIoT, 58% in GPdI, 36% in GPcI, 59% in GMI, and 26% in organizational performance.

Figure 2 demonstrates that CP (β = 0.176, p = 0.003), NP (β = 0.224, p = 0.000), and MP (β = 0.226, p = 0.000) have significant association with adoption of GIIoT, according to which H1a, H1b, and H1c are accepted. Moreover, adoption of GIIoT also shares a significant relationship with GPdI (β = 0.357, p = 0.000), GPcI (β = 0.373, p = 0.000), and GMI (β = 0.405, p = 0.000) basis on which H2a, H2b, and H2c are accepted. Similarly, GPdI (β = 0.135, p = 0.038), GPcI (β = 0.260, p = 0.000), and GMI (β = 0.248, p = 0.000) have significant innovation with organizational innovation; hence, H3a, H3b, and H3c are accepted. On the ground of all results, the study accepts the proposed research model.

Discussion

Globalization and industrialization have facilitated technological advancements for efficient business operations. Due to the serious impact of industrial waste on the environment, companies are forced to adopt green technologies to reduce their negative impacts under various external pressures (Saeed et al., 2018). In this context, this study strives to consolidate institutional pressures that compel firms to adopt green technologies and practices.

The results demonstrate a significant association between CP and GIIoT adoption. Several regulatory firms and policies from the government enforce coercion on neglecting and damaging the natural environment. Parent companies also establish a set of rules for managing resources, data, and the environment. Overlooking these rules and policies will cost penalties to business, impacting business reputation and performance. Furthermore, the findings of the study revealed that NP has a positive association with the adoption of GIIoT adoption. Satisfying the customer demand is the basic goal of an organization. In addition, MP also proved to be a significant positive relationship with GIIoT adoption in manufacturing organizations. It described that once the competitors adopt new technology; focal firms also get the pressure to adopt it to maintain a competitive edge. Mimicking the competitor’s technology firms reduces the risks of failure in particular technology adoption. In the emerging era of technological advancement, it is deemed to stay one step ahead to ensure a competitive advantage over rival firms. These outcomes are aligned with the previous studies that define the positive impact of institutional isomorphism on technology adoption (Lai et al., 2006; Shubham et al., 2018; Soares et al., 2020).

Moreover, the results of the study also ensure a significant positive relationship between GIIoT adoption with GI practices. According to the study results, GIIoT helps implement GI practices. GIIoT help to provide the firm with real-time information about their customers which facilitates the firm for effective decision-making and manages their resources. These results also extend the result of a previous study showing a positive impact of GIIoT on GI practice (Hu et al., 2022).

Similarly, results that validate those GI practices positively affect organizational performance. With GI practices, firms revise their operations throughout the manufacturing process to ensure low carbon emission, toxic material, and waste material in the ecosystem, increasing organizational performance (Tang et al., 2018; Wang et al., 2021). GI practices that are backed by GIIoT will facilitate the firms to protect their internal and external environment which will have an ultimate impact on organizational performance.

Conclusion, Implications, Limitations, and Prospects

Based on the institutional theory, this research observes the different external pressures on Harbin’s manufacturing firms to adopt green technologies and practices. The results revealed that the adoption of GIIoT was positively correlated with CP, NP, and MP. These pressures, e.g., making the adoption of GIIoT by businesses, make them firmly committed to achieve their environmental goals. Furthermore, results also determine the adoption of GIIoT as the pillar for implementing GI practices, which will secure the internal and external environment of the firm. GI practices improve organizational performance by reducing costs, saving resources, dealing with waste, and reducing carbon and toxic emissions.

Based on the outcomes, this study has certain theoretical and managerial implications. First, this study contributes to the limited literature on the adoption of emerging technologies, such as GIIoT and GI practices, in the context of manufacturing organizations. The research uses institutional theory as a theoretical lens, demonstrating its importance in the adoption of GIIoT. Furthermore, this study reveals that GIIoT is a helpful tool and strategy for implementing multiple GI practices for efficient resource utilization and environmental protection, which also contribute to the existing knowledge. Third, the findings also show that GI practices are significant predictors of organizational performance. In addition, the research also provides practitioners with a clear perspective to understand technological advancements and adoption in business operations. Research shows that GIIoT-assisted GI practices have a dramatic impact on organizational performance by minimizing industrial costs, waste disposal, and efficient decision-making. Managers need to define such strategies to effectively utilize the corresponding processes and policies for better organizational performance. It has been seen that our environment has changed dramatically, and some changes are about to happen due to the advancement of the IoT. It is estimated that the GIIoT will bring substantial changes to our industry and will lead to a greener environment. GIIoT not only helps other industries reduce the greenhouse effect but also reduces the environmental impact of the IoT itself. Therefore, the application of GIIoT has been committed by the managers to save energy and reduce carbon dioxide emissions and pollution hazards. Therefore, organizations can improve GI practices by adopting GIIoT.

Nonetheless, the current study has some limitations and based on this, some future research directions are proposed. The study was limited to developing countries, and results in developed countries may vary. Thus, future investigations should be performed in developed countries to better understand. Furthermore, these data are only collected in one provincial capital, which may hide its generalizability. Future researchers could collect data in different cities in the country or add different organizations from other countries. This study was conducted over a limited period and was not longitudinal. Therefore, future investigators should conduct longitudinal studies to avoid bias in the findings. Finally, this study only mentions the impact of institutional theory on the adoption of GIIoT while ignoring other organizational factors, such as perceived critical mass, organizational support, and external factors that affect the adoption of GIIoT. Therefore, future research can extend this model by incorporating these internal and external factors to measure GIIoT adoption.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors, without undue reservation.

Ethics Statement

The studies involving human participants were reviewed and approved by the Harbin University of Science and Technology, China. Written informed consent for participation was not required for this study in accordance with the National Legislation and the Institutional Requirements.

Author Contributions

NX: conceptualization, writing—original draft preparation, data curation, software, and formal analysis. XF: supervision, methodology, fund acquisition, writing, review, and editing. RH: data analysis, writing—review and editing. All authors contributed to the article and approved the submitted version.

Conflict of Interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s Note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Affia, I., Putu, L., Yani, E., and Aamer, A. (2019). “Factors affecting iot adoption in food supply chain management,” in Proceedings of the 9th International Conference on Operations and Supply Chain Management, Vietnam, 1–11. doi: 10.1504/ijlsm.2021.10040905

Ainin, S., Naqshbandi, M. M., and Dezdar, S. (2016). Impact of adoption of green IT practices on organizational performance. Qual. Quant. 50, 1929–1948. doi: 10.1007/s11135-015-0244-7

Albreem, M. A. M., El-Saleh, A. A., Isa, M., Salah, W., Jusoh, M., Azizan, M. M., et al. (2018). “Green internet of things (IoT): an overview,” in Proceedings of the 2017 IEEE International Conference on Smart Instrumentation, Measurement and Application ICSIMA, Piscataway, NJ: IEEE, 1–6. doi: 10.1109/ICSIMA.2017.8312021

Ben Boubaker, K., Harguem, S., and Nyrhinen, M. (2021). IT governance modes choice: an institutional theory perspective. Int. J. Manag. Data Anal. 1, 1–10.

Boyes, H., Hallaq, B., Cunningham, J., and Watson, T. (2018). The industrial internet of things (IIoT): an analysis framework. Comput. Ind. 101, 1–12. doi: 10.1016/j.compind.2018.04.015

Dijkstra, T. K., and Henseler, J. (2015). Consistent and asymptotically normal PLS estimators for linear structural equations. Comput. Stat. Data Anal. 81, 10–23. doi: 10.1016/j.csda.2014.07.008

Dubey, R., Gunasekaran, A., and Samar Ali, S. (2015). Exploring the relationship between leadership, operational practices, institutional pressures and environmental performance: a framework for green supply chain. Int. J. Prod. Econ. 160, 120–132. doi: 10.1016/j.ijpe.2014.10.001

Fornell, C., and Larcker, D. F. (1981a). “Discriminant validity assessment: use of Fornell & Larcker criterion versus HTMT criterion,” in Proceedings of the Journal of Physics: Conference Series PAPER (Bristol: IOP Publishing Ltd), 6.

Fornell, C., and Larcker, D. F. (1981b). Structural equation models with unobservable variables and measurement error: algebra and statistics. J. Mark. Res. 18:382. doi: 10.2307/3151312

Gadre, M., and Gadre, C. (2016). Green Internet of Things (IoT): Go Green with IoT. Gandhinagar: IJERT, 1–6.

Gefen, D. (2005). A practical guide to factorial validity using PLS-graph: tutorial and annotated example. Commun. Assoc. Inf. Syst. 16, 91–109.

Hair, J. F., Sarstedt, M., Hopkins, L., and Kuppelwieser, V. G. (2014). Partial least squares structural equation modeling (PLS-SEM): an emerging tool in business research. Eur. Bus. Rev. 26, 106–121. doi: 10.1108/EBR-10-2013-0128

Henseler, J., Hubona, G., and Ray, P. A. (2016). Using PLS path modeling in new technology research: updated guidelines. Ind. Manag. Data Syst. 116, 2–20. doi: 10.1108/IMDS-09-2015-0382

Hsu, C. C., Tan, K. C., Zailani, S. H. M., and Jayaraman, V. (2013). Supply chain drivers that foster the development of green initiatives in an emerging economy. Int. J. Oper. Prod. Manag. 33, 656–688. doi: 10.1108/IJOPM-10-2011-0401

Hsu, C. W., and Yeh, C. C. (2017). Understanding the factors affecting the adoption of the internet of things. Technol. Anal. Strateg. Manag. 29, 1089–1102. doi: 10.1080/09537325.2016.1269160

Hu, R., Shahzad, F., Abbas, A., and Liu, X. (2022). Decoupling the influence of eco-sustainability motivations in the adoption of the green industrial IoT and the impact of advanced manufacturing technologies. J. Clean. Prod. 339:130708. doi: 10.1016/j.jclepro.2022.130708

Imamoglu, O., Karaman, A., and Omurtag, Y. (2010). “Green supply chain management applications in Turkey,” in Proceedings of the 31st Annual National Conference of the American Society for Engineering Management 2010, Singapore: ASEM, 661–667.

Jan, P. T., Lu, H. P., and Chou, T. C. (2012). The adoption of e-learning: an institutional theory perspective. Turkish Online J. Educ. Technol. 11, 326–343.

Jayarathna, B. (2015). “Building a conceptual model for adopting green supply chain practices,” in Proceedings of the 4th ISERD International Conference, Kuala Lumpur, 46–48.

Joardar, A., and Sarkis, J. (2021). An examination of sustainable development of supply chain using foreignness perspective. Bus. Strateg. Environ. 30, 630–642. doi: 10.1002/bse.2643

Khan, W. Z., Rehman, M. H., Zangoti, H. M., Afzal, M. K., Armi, N., and Salah, K. (2020). Industrial internet of things: recent advances, enabling technologies and open challenges. Comput. Electr. Eng. 81:106522. doi: 10.1016/j.compeleceng.2019.106522

Kline, R. B. (2015). Principles and Practices of Structural Equation Modelling, 4th Edn. New York, NY: The Guilford Press.

Kock, N. (2015). Common method bias in PLS-SEM: a full collinearity assessment approach. Int. J. e Collab. 11, 1–10. doi: 10.4018/ijec.2015100101

Kong, T., Feng, T., and Ye, C. (2016). Advanced manufacturing technologies and green innovation: the role of internal environmental collaboration. Sustain 8, 9–11. doi: 10.3390/su8101056

Kros, J. F., Kwaramba, C. S., and Liao, Y. (2020). Supply chain traceability: an institutional theory perspective. Int. J. Logist. Econ. Glob. 8:193. doi: 10.1504/ijleg.2020.10031648

Lai, K. H., Wong, C. W. Y., and Cheng, T. C. E. (2006). Institutional isomorphism and the adoption of information technology for supply chain management. Comput. Ind. 57, 93–98. doi: 10.1016/j.compind.2005.05.002

Latif, B., Mahmood, Z., Tze San, O., Mohd Said, R., and Bakhsh, A. (2020). Coercive, normative and mimetic pressures as drivers of environmental management accounting adoption. Sustainability 12:4506. doi: 10.3390/su12114506

Liebl, S., Lathrop, L., Raithel, U., and Matthias, S. (2020). “Threat analysis of industrial internet of things devices threat analysis of industrial internet of things devices,” in Proceedings of the Eleventh International Conference on Cloud Computing, GRIDs, and Virtualization Threat, Nice.

Lisi, W., Zhu, R., and Yuan, C. (2020). Embracing green innovation via green supply chain learning: the moderating role of green technology turbulence. Sustain. Dev. 28, 155–168. doi: 10.1002/sd.1979

Liu, H., Ke, W., Wei, K. K., Gu, J., and Chen, H. (2010). The role of institutional pressures and organizational culture in the firm’s intention to adopt internet-enabled supply chain management systems. J. Oper. Manag. 28, 372–384. doi: 10.1016/j.jom.2009.11.010

Ma, Y., Hou, G., Yin, Q., Xin, B., and Pan, Y. (2018). The sources of green management innovation: does internal efficiency demand pull or external knowledge supply push? J. Clean. Prod. 202, 582–590. doi: 10.1016/j.jclepro.2018.08.173

McDougall, N., Wagner, B., and MacBryde, J. (2022). Leveraging competitiveness from sustainable operations: frameworks to understand the dynamic capabilities needed to realise NRBV supply chain strategies. Supply Chain Manag. An Int. J. 27, 12–29. doi: 10.1108/SCM-11-2018-0393

Messerschmidt, C. M., and Hinz, O. (2013). Explaining the adoption of grid computing: an integrated institutional theory and organizational capability approach. J. Strateg. Inf. Syst. 22, 137–156. doi: 10.1016/j.jsis.2012.10.005

Molla, A., and Abareshi, A. (2012). Organizational green motivations for information technology: empirical study. J. Comput. Inf. Syst. 52, 92–102. doi: 10.1080/08874417.2012.11645562

Ngah, A. H., Zainuddin, Y., and Thurasamy, R. (2017). Applying the TOE framework in the Halal warehouse adoption study. J. Islam. Account. Bus. Res. 8, 161–181. doi: 10.1108/JIABR-04-2014-0014

Oliveira, T., Martins, R., Sarker, S., Thomas, M., and Popovič, A. (2019). Understanding SaaS adoption: the moderating impact of the environment context. Int. J. Inf. Manage. 49, 1–12. doi: 10.1016/j.ijinfomgt.2019.02.009

Park, J. H. (2019). Advances in future internet and the industrial internet of things. Symmetry (Basel) 11:244. doi: 10.3390/sym11020244

Podsakoff, P. M., Bommer, W. H., Podsakoff, N. P., and MacKenzie, S. B. (2006). Relationships between leader reward and punishment behavior and subordinate attitudes, perceptions, and behaviors: a meta-analytic review of existing and new research. Organ. Behav. Hum. Decis. Process. 99, 113–142. doi: 10.1016/j.obhdp.2005.09.002

Podsakoff, P. M., MacKenzie, S. B., and Podsakoff, N. P. (2012). Sources of method bias in social science research and recommendations on how to control it. Annu. Rev. Psychol. 63, 539–569. doi: 10.1146/annurev-psych-120710-100452

Saeed, A., Jun, Y., Nubuor, S., Priyankara, H., and Jayasuriya, M. (2018). Institutional pressures, green supply chain management practices on environmental and economic performance: a two theory view. Sustainability 10:1517. doi: 10.3390/su10051517

Sam, T. H., Wong, W. Y., Gwadabe, Z. L., Balakrishnan, R., Poopalaselvam, R., Adam, A., et al. (2021). The adoption of loT technology in the Malaysian manufacturing industry. AIP Conf. Proc. 2355:030002. doi: 10.1063/5.0053240

Sherer, S. A. (2010). Information systems and healthcare XXXIII: an institutional theory perspective on physician adoption of electronic health records. Commun. Assoc. Inf. Syst. 26, 127–140. doi: 10.17705/1cais.02607

Sherer, S. A., Meyerhoefer, C. D., and Peng, L. (2016). Applying institutional theory to the adoption of electronic health records in the U.S. Inf. Manag. 53, 570–580. doi: 10.1016/j.im.2016.01.002

Shu, C., Zhou, K. Z., Xiao, Y., and Gao, S. (2016). How green management influences product innovation in China: the role of institutional benefits. J. Bus. Ethics 133, 471–485. doi: 10.1007/s10551-014-2401-7

Shubham Charan, P., and Murty, L. S. (2018). Organizational adoption of sustainable manufacturing practices in India: integrating institutional theory and corporate environmental responsibility. Int. J. Sustain. Dev. World Ecol. 25, 23–34. doi: 10.1080/13504509.2016.1258373

Soares, A. L. V., Mendes-Filho, L., and Gretzel, U. (2020). Technology adoption in hotels: applying institutional theory to tourism. Tour. Rev. 76, 669–680. doi: 10.1108/TR-05-2019-0153

Tabaa, M., Monteiro, F., Bensag, H., and Dandache, A. (2020). Green Industrial internet of things from a smart industry perspectives. Energy Rep. 6, 430–446. doi: 10.1016/j.egyr.2020.09.022

Tang, M., Walsh, G., Lerner, D., Fitza, M. A., and Li, Q. (2018). Green innovation, managerial concern and firm performance: an empirical study. Bus. Strateg. Environ. 27, 39–51. doi: 10.1002/bse.1981

Vanalle, R. M., Ganga, G. M. D., Godinho Filho, M., and Lucato, W. C. (2017). Green supply chain managementAn investigation of pressures, practices, and performance within the Brazilian automotive supply chain. J. Clean. Prod. 151, 250–259. doi: 10.1016/j.jclepro.2017.03.066

Varjovi, A. E., and Babaie, S. (2020). Green internet of things (GIoT): vision, applications and research challenges. Sustain. Comput. Informatics Syst. 28:100448. doi: 10.1016/j.suscom.2020.100448

Wang, H., Khan, M. A. S., Anwar, F., Shahzad, F., Adu, D., and Murad, M. (2021). Green innovation practices and its impacts on environmental and organizational performance. Front. Psychol. 11:1–15. doi: 10.3389/fpsyg.2020.553625

Wang, K., Wang, Y., Sun, Y., Guo, S., and Wu, J. (2016). Green industrial internet of things architecture: an energy-efficient perspective. IEEE Commun. Mag. 54, 48–54. doi: 10.1109/MCOM.2016.1600399CM

Wong, S. K. S. (2012). The influence of green product competitiveness on the success of green product innovation: empirical evidence from the Chinese electrical and electronics industry. Eur. J. Innov. Manag. 15, 468–490. doi: 10.1108/14601061211272385

Wu, G. (2013). The influence of green supply chain integration and environmental uncertainty on green innovation in Taiwan’s IT industry. Supply Chain Manag. An Int. J. 18, 539–552. doi: 10.1108/SCM-06-2012-0201

Xie, X., Huo, J., and Zou, H. (2019). Green process innovation, green product innovation, and corporate financial performance: a content analysis method. J. Bus. Res. 101, 697–706. doi: 10.1016/j.jbusres.2019.01.010

Xue, M., Boadu, F., and Xie, Y. (2019). The penetration of green innovation on firm performance: effects of absorptive capacity and managerial environmental concern. Sustain 11:2455. doi: 10.3390/su11092455

Yen, Y. X. (2018). Buyer–supplier collaboration in green practices: the driving effects from stakeholders. Bus. Strateg. Environ. 27, 1666–1678. doi: 10.1002/bse.2231

Zailani, S. H. M., Eltayeb, T. K., Hsu, C. C., and Tan, K. C. (2012). The impact of external institutional drivers and internal strategy on environmental performance. Int. J. Oper. Prod. Manag. 32, 721–745. doi: 10.1108/01443571211230943

Zhang, Y., Sun, J., Yang, Z., and Wang, Y. (2020a). Critical success factors of green innovation: technology, organization and environment readiness. J. Clean. Prod. 264:121701. doi: 10.1016/j.jclepro.2020.121701

Keywords: green IIoT, green innovation, IoT, performance, isomorphism

Citation: Xu N, Fan X and Hu R (2022) Adoption of Green Industrial Internet of Things to Improve Organizational Performance: The Role of Institutional Isomorphism and Green Innovation Practices. Front. Psychol. 13:917533. doi: 10.3389/fpsyg.2022.917533

Received: 11 April 2022; Accepted: 25 April 2022;

Published: 01 June 2022.

Edited by:

Fakhar Shahzad, Jiangsu University, ChinaReviewed by:

Sheikh Farhan Ashraf, Jiangsu University, ChinaMuhammad Abdullah, Khwaja Fareed University of Engineering and Information Technology, Pakistan

Copyright © 2022 Xu, Fan and Hu. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Nan Xu, c2hhcmsxMjM0QDE2My5jb20=; Xingyu Fan, ZmFueHk5MEAxNjMuY29t

Nan Xu

Nan Xu Xingyu Fan2*

Xingyu Fan2*