94% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

ORIGINAL RESEARCH article

Front. Nutr. , 13 March 2025

Sec. Nutrition and Food Science Technology

Volume 12 - 2025 | https://doi.org/10.3389/fnut.2025.1553942

This article is part of the Research Topic AI-Driven Advances in Personalized Nutrition through Optimization in Food Manufacturing View all articles

This study aims to explore the transformative role of Artificial Intelligence (AI) in food manufacturing by optimizing production, reducing waste, and enhancing sustainability. This review follows a literature review approach, synthesizing findings from peer-reviewed studies published between 2019 and 2024. A structured methodology was employed, including database searches and inclusion/exclusion criteria to assess AI applications in food manufacturing. By leveraging predictive analytics, real-time monitoring, and computer vision, AI streamlines workflows, minimizes environmental footprints, and ensures product consistency. The study examines AI-driven solutions for waste reduction through data-driven modeling and circular economy practices, aligning the industry with global sustainability goals. Additionally, it identifies key barriers to AI adoption—including infrastructure limitations, ethical concerns, and economic constraints—and proposes strategies for overcoming them. The findings highlight the necessity of cross-sector collaboration among industry stakeholders, policymakers, and technology developers to fully harness AI's potential in building a resilient and sustainable food manufacturing ecosystem.

The escalating demands for sustainable solutions in food manufacturing emphasize the industry's critical role in addressing global environmental challenges, resource inefficiencies, and quality inconsistencies. Artificial intelligence (AI) is emerging as a transformative force, offering innovative pathways to optimize production, minimize waste, and enhance sustainability. However, despite rapid advancements, there remains a significant gap in understanding how AI applications can be effectively integrated into food manufacturing to meet sustainability goals. The integration of advanced technologies, including AI-driven tools, predictive analytics, and automation, has redefined traditional processes, emphasizing the inseparability of technological advancement and ecological sustainability (1). These developments align with the overarching concept of planetary health, which highlights the interconnection between human wellbeing and the Earth's ecosystems (2).

This study aims to fill this knowledge gap by systematically analyzing AI's role in transforming food manufacturing processes, focusing on efficiency improvements, environmental benefits, and real-world implementation challenges. Recent advancements in Industry 4.0 & 5.0 technologies, such as cyber-physical systems, Internet of Things (IoT) devices, and data-driven methodologies, have enabled significant improvements in the food supply chain (3). These innovations facilitate real-time monitoring and optimization of production processes, enhancing resource allocation, reducing waste, and improving product quality (4). Furthermore, AI-driven tools have proven instrumental in predictive maintenance and operational efficiency, transforming conventional systems into highly optimized and scalable frameworks (5, 6). Despite these technological breakthroughs, many food manufacturers face barriers to AI adoption, including a lack of clear implementation strategies, high infrastructure costs, and resistance to change.

The increasing consumer demand for environmentally friendly production methods and healthier food products has also driven a shift toward sustainability-focused manufacturing. Digitalization strategies, including AI-enabled analytics and smart sensors, offer practical solutions for reducing resource consumption and ensuring consistent product quality (7, 8). AI further supports the implementation of circular economy principles by enabling the repurposing of food by-products and improving demand forecasting to prevent overproduction (2, 9). However, several challenges hinder the widespread adoption of AI in food manufacturing. These include the difficulty of integrating AI into legacy systems, a shortage of skilled professionals, and ethical concerns related to data privacy and algorithmic bias (3, 10). Overcoming these barriers is imperative to unlocking the full potential of AI and ensuring its transformative impact extends across the entire food manufacturing ecosystem, from production to distribution and waste management.

To ensure a structured and comprehensive assessment of AI applications in food manufacturing, this study follows a literature review methodology. The review process involved a structured search across databases including Scopus, and Web of Science, applying predefined inclusion and exclusion criteria. Studies published between 2019 and 2024 were considered, focusing on peer-reviewed journal articles and conference proceedings. Gray literature and non-English studies were excluded to maintain research quality. Keywords such as “Artificial Intelligence in Food Manufacturing," “AI for Sustainability in Food Processing," and “AI-driven Quality Control in Food Industry" were used to retrieve relevant articles. To enhance reliability, two independent reviewers conducted data extraction and categorized the findings.

Building on this foundation, this study provides a comprehensive review of AI-driven advancements in food manufacturing, addressing key industry needs such as:

• Optimizing efficiency: using AI tools like predictive analytics and machine learning (ML) to streamline workflows and reduce waste.

• Advancing sustainability: reducing environmental footprints and supporting circular economy practices.

• Addressing critical adoption barriers: including infrastructural challenges, ethical considerations, and economic constraints, with innovative strategies to ensure seamless integration into legacy systems.

• Proposing forward-looking solutions: aligning AI advancements with global sustainability goals, fostering resilience and scalability within the food manufacturing ecosystem.

• Bridging technological innovation with ecological responsibility: offering actionable frameworks for stakeholders to navigate opportunities and challenges.

By systematically analyzing existing literature and industry trends, this study bridges the gap between AI's potential and its practical implementation in food manufacturing. The insights presented in this review could serve as a valuable resource for industry stakeholders, policymakers, and researchers seeking to leverage AI for sustainable, efficient, and high-quality food production.

This literature review adhered to the Preferred Reporting Items for Systematic Reviews and Meta-Analyses (PRISMA) guideline (11). A comprehensive search was conducted across Scopus, and Web of Science to identify relevant peer-reviewed studies published between 2019 and 2024. The search terms were designed using a combination of controlled vocabulary and free-text keywords related to AI applications in food manufacturing, sustainability, and quality assurance. The search strings included:

• “Artificial Intelligence" OR “AI-driven technologies" AND “Food Manufacturing" OR “Food Processing".

• “Machine Learning" OR “Deep Learning" AND “Sustainable Food Systems".

• “Predictive Analytics" AND “AI for Food Waste Management".

Searches were concluded in January 2025, ensuring the inclusion of the most recent advancements in AI-driven food manufacturing innovations.

The inclusion criteria were:

• Peer-reviewed primary research articles, systematic reviews, and meta-analyses focused on AI applications in food manufacturing, sustainability, and quality assurance.

• Studies that explicitly discuss the implementation of AI in food production, waste management, or sustainability efforts.

• Research published in English-language journals within the time-frame 2019–2024 to ensure relevance to current technological trends.

• Studies providing empirical insights into AI-driven predictive modeling, resource optimization, quality control, and circular economy practices in food manufacturing.

The exclusion criteria were:

• Protocol papers, gray literature (e.g., dissertations, white papers, and technical reports), editorials, and opinion pieces.

• Non-English publications due to language constraints in this review.

• Studies that lacked substantial discussion of AI applications in food manufacturing or focused on unrelated industries.

• Publications prior to 2019, as AI's role in food manufacturing has significantly evolved over the past decade, making older studies less relevant.

The selection process followed a rigorous two-stage screening process to ensure the relevance and quality of the included studies. Initially, titles and abstracts were screened using COVIDENCE program (12) and a custom Python algorithm developed by the authors to filter studies based on predefined inclusion and exclusion criteria. Studies that passed the preliminary screening underwent a full-text review, where two independent reviewers (KA and PG) assessed the articles based on relevance, quality, and methodological rigor. Any discrepancies in selection were resolved through consensus or consultation with a third reviewer. The review methodology followed a narrative synthesis approach, summarizing key themes across selected studies, identifying emerging trends, technological gaps, and challenges in AI-driven food manufacturing.

Data extraction was performed using a structured data extraction form developed in Microsoft Excel and a custom Python algorithm developed by the authors for qualitative synthesis. The key variables collected included:

• AI implementation details: type of AI technology used (e.g., machine learning, deep learning, predictive analytics).

• Sustainability impact: resource optimization, waste reduction, energy efficiency, and circular economy applications.

• Quality control measures: AI-driven food safety solutions, real-time monitoring, and process automation.

• Challenges and adoption barriers: ethical concerns, regulatory challenges, infrastructure limitations, and economic constraints.

• Key findings and recommendations: summary of results, proposed AI-driven strategies, and future research directions.

All extracted data were independently verified by two reviewers, ensuring accuracy and consistency in analysis. Any disagreements were resolved through discussion to maintain methodological integrity. The synthesized findings from the reviewed studies are presented in the following sections, detailing AI's transformative impact on food manufacturing.

Food manufacturing involves the large-scale production, processing, and packaging of food products for distribution and sale (13–15). It transforms raw agricultural materials, such as grains, fruits, vegetables, meat, and dairy, into finished goods that are safe, convenient, and appealing to consumers. This process includes sourcing raw materials from farms, fisheries, or other agricultural enterprises, followed by processing through mechanical techniques (e.g., cutting, grinding, mixing), thermal treatments (e.g., cooking, pasteurizing, sterilizing), and chemical methods to enhance shelf life and quality (16–20).

Processed food products are packaged in containers such as cans, boxes, bottles, or pouches to maintain freshness and enable efficient storage and transportation. Quality control is of crucial importance for food manufacturing (21), with stringent checks conducted to meet regulatory standards, such as those set by the Food and Drug Administration (FDA)1 in the United States or the Food Safety and Standards Authority of India (FSSAI).2 These measures ensure that the final products are safe for consumption and free of contaminants (22, 23).

The industry encompasses diverse products, including processed foods, ready-to-eat meals, beverages, and functional foods enriched with nutrients. However, traditional food manufacturing faces significant challenges:

• Resource-intensive processes: conventional food manufacturing heavily relies on energy, water, and raw materials. Processes like cooking, freezing, and sterilization consume vast amounts of energy (24), while cleaning and preparation require substantial water usage (25).

• High waste generation: by-products such as peels and residues are often discarded rather than repurposed, contributing to inefficiencies and environmental harm (26).

• Supply chain inefficiencies: poor coordination and logistical gaps lead to significant food losses, with ~14% of food globally lost between harvest and retail (27).

• Limited traceability: traditional systems often lack the ability to track products effectively through the supply chain, impacting food safety and recall efficiency (28).

• Overprocessing and overpackaging: excessive processing and packaging waste resources, degrade product quality, and increase environmental footprints (29).

• Environmental impact: energy consumption and waste decomposition contribute to greenhouse gas emissions (30), while water-intensive processes exacerbate water stress in vulnerable regions.

Table 1 summarizes these critical challenges, linking them to their respective environmental, operational, and societal impacts, along with key references supporting each aspect. Addressing these challenges requires a paradigm shift in traditional food manufacturing practices. Technological advancements, such as IoT, AI, and robotics, are pivotal in overcoming these inefficiencies by optimizing resource utilization, improving traceability, and reducing waste (37, 41). Integrating sustainable practices, such as repurposing by-products into bioenergy or animal feed (42), and adopting energy-efficient technologies can significantly mitigate environmental impacts while enhancing productivity and reliability.

Food manufacturing is a critical component of the global food supply chain (43), yet it faces persistent inefficiencies and remains highly resource-intensive, creating challenges for sustainability, economic viability, and environmental health (44). The industry relies heavily on energy, water, and raw materials (45, 46). Thermal processes, such as cooking, drying, and freezing, are particularly energy-intensive, with refrigerated warehouses alone accounting for up to 20% of the industry's energy consumption (24). Similarly, water usage is significant (25), required for washing, cleaning, and preparing raw materials. The water footprint of processed foods often exceeds that of raw counterparts. Additionally, food processing generates considerable waste (26), including by-products such as peels and residues, much of which is underutilized or discarded.

Supply chain inefficiencies and logistical challenges exacerbate these issues (32). Poor coordination leads to significant food losses, with the FAO estimating that 14% of food is lost globally between harvest and retail (27). Equipment failures, unoptimized workflows, and production downtime further hinder operational efficiency, increasing costs and resource wastage. Over-processing and over-packaging degrade product quality, consume excess resources, and contribute to higher energy usage, with over-processing often diminishing the nutritional profile of food products (29). These inefficiencies collectively impact environmental sustainability. Energy consumption and waste decomposition contribute to greenhouse gas emissions (30), intensifying climate change. Water-intensive processes exacerbate water stress, particularly in regions where freshwater resources are already scarce. Additionally, the underutilization of food by-products adds to landfill waste, further straining environmental systems.

The food manufacturing sector exerts a profound influence on environmental sustainability due to its intensive energy use, significant water consumption, and extensive waste generation. As a pivotal element of global food production, the sector's ecological footprint has come under increasing scrutiny (34). Energy-intensive processes, such as cooking, sterilization, and freezing, are primary contributors to greenhouse gas emissions, with refrigerated storage accounting for a substantial portion of energy consumption, further intensifying the industry's carbon footprint (33). Similarly, water-intensive operations, including washing raw materials and cleaning equipment, exacerbate water stress, particularly in regions already facing freshwater scarcity (47).

The challenge of waste generation compounds these issues, as substantial by-products, including peels, husks, and residues, are often discarded or underutilized, leading to increased methane emissions from landfill decomposition (31). Alarmingly, up to 40% of global food waste occurs during the manufacturing stage, representing a significant loss of both resources and economic value (48). The environmental burden is further heightened by effluents containing chemical additives, fertilizers, and preservatives, which pollute water systems and strain ecosystems (39). Additionally, the reliance on nonrenewable resources and linear production models undermines sustainability efforts, with limited adoption of circular economy practices, such as converting food waste into bioenergy or animal feed (40).

To address these pressing environmental challenges, systemic transformations in food manufacturing are imperative. Enhancing resource efficiency, reducing waste, and adopting innovative waste management solutions are essential for mitigating the industry's environmental impact. Advancements in waste valorization technologies and the integration of renewable energy systems offer significant potential to align the sector with global climate objectives and the United Nations Sustainable Development Goals (SDGs), fostering a more sustainable and resilient food manufacturing ecosystem (39, 49).

Food manufacturing is a cornerstone of the global food supply chain, yet maintaining consistent product qualityposes significant challenges due to the inherent complexity of processes and variability in raw materials (35, 36). Product quality in this industry is affected by numerous factors, including inconsistent moisture content, temperature fluctuations during processing, and deviations in raw material properties (50). These variations can lead to production inefficiencies, diminished product quality, and increased waste, ultimately impacting consumer satisfaction and market competitiveness (51). For instance, in food extrusion processes, undetected abnormalities in feed materials, such as varying moisture content, can compromise the texture and quality of final products (50).

Moreover, ensuring quality standards across diverse product lines remains a daunting task. Traditional quality control measures, including manual inspections and routine sampling, are often inadequate in detecting subtle deviations, especially in high-speed production environments (52). While advanced technologies, such as near-infrared spectroscopy and process modeling, have demonstrated potential in addressing these limitations, their implementation requires significant investments and skilled operators (36). Inconsistent quality not only increases economic losses due to rework and recalls but also poses risks to brand reputation and regulatory compliance. Addressing these challenges demands a strategic integration of real-time monitoring tools, predictive quality control systems, and continuous process optimization to ensure consistency and uphold consumer trust in the evolving landscape of food manufacturing (38, 53).

The challenges faced by traditional food manufacturing, such as resource-intensive processes, waste generation, and inconsistent product quality, demand innovative solutions to achieve sustainability goals. AI has emerged as a transformative tool to address these issues by optimizing processes, enhancing quality, and reducing environmental impacts. AI-powered heat drying technologies, for example, improve energy efficiency and reduce carbon footprints while preserving the nutritional and sensory properties of food products (54). Similarly, real-time AI monitoring in supply chain management minimizes food loss, ensures efficient resource utilization, and improves traceability (7, 55). Additionally, AI-based additive manufacturing enables personalized food production while maintaining high quality and safety standards through advanced data analysis (56). Figure 1 provides a visual representation of the diverse applications of AI in sustainable food manufacturing, highlighting its potential to streamline production, enhance efficiency, and foster innovation. Moreover, a detailed summary of key AI-driven applications and their associated benefits is provided in Table 2.

Figure 1. Illustration of AI-driven innovations enhancing sustainability in food manufacturing processes.

Despite its transformative potential, AI integration faces barriers, including ethical concerns, data privacy issues, and the need for robust datasets (7, 55). However, the adoption of AI technologies offers significant opportunities to mitigate environmental impacts, optimize production, and align food manufacturing with global sustainability objectives. By addressing inefficiencies and environmental challenges, AI not only reshapes the industry but also sets a foundation for more resilient and eco-conscious food systems.

Product optimization is vital for sustainable food manufacturing, focusing on maximizing efficiency while minimizing resource usage. AI has transformed this domain, enabling precise control and adaptability in production workflows. By leveraging advanced data analytics algorithms, manufacturers can forecast production demands, automate scheduling, and optimize resource allocation, reducing errors and environmental impact. Advanced tools like Digital Twin (DT) systems allow manufacturers to simulate processes, benchmark sustainability metrics, and refine operations for greater efficiency (67, 68). AI-driven process optimization enhances shelf-life extension, particularly in dairy production, where it predicts spoilage risk and optimizes storage conditions (69). Additionally, AI-driven resource allocation models inspired by frameworks such as Unified Modeling Language (UML) enhance production adaptability (70, 71).

Streamlining workflows and optimizing resource allocation are critical to improving sustainability in food manufacturing. Lean manufacturing strategies, particularly in regions like Brazil and Peru, have reduced inefficiencies and waste, achieving annual research growth of 5.96% since 2019 (67). Technologies such as IoT and DT systems provide real-time tracking and virtual simulations to optimize production processes and benchmark sustainability metrics (68). AI enhances these efforts by enabling predictive analytics and automating resource allocation. Models inspired by biological systems, like endocrine regulation principles, and frameworks such as UML align dynamic production needs with available resources (70, 71). These innovations reduce bottlenecks, improve scheduling, and minimize idle time, contributing to cost savings and environmental sustainability.

Predictive maintenance (PdM) uses advanced data analytics and ML to preempt equipment failures, ensuring smooth operations and reducing downtime. Techniques like Xtreme Gradient Boosting and ARIMA-ANN hybrid models enable early fault detection, while vibration sensors provide real-time monitoring to prevent interruptions (57, 58). Hybrid algorithms improve accuracy in identifying potential issues, which is critical in preventing spoilage and delays. By extending equipment lifespan and improving operational reliability, PdM reduces energy use and material waste, contributing to sustainability goals. Additionally, data mining offers insights into performance trends, helping manufacturers maintain consistent quality and reliability (72–74). This proactive approach ensures economic efficiency while minimizing environmental impact.

Ingredient and process optimization leverage tools like data envelopment analysis (DEA) and AI to enhance cost-efficiency without compromising quality. DEA evaluates multiple input-output relationships, facilitating cost-effective mixture designs (75). AI systems generate least-cost formulations based on real-time ingredient costs and inventory data, optimizing resource utilization and reducing expenses (76). Case studies highlight innovations such as incorporating vegetable proteins in chicken nuggets, which improve nutritional value and texture while reducing costs (77). Heat exchanger efficiency is significantly improved through AI-based modeling, which predicts and regulates thermal exchange in food manufacturing environments (78). These approaches demonstrate how targeted optimization can balance economic gains, product quality, and sustainability, fostering growth in the food manufacturing industry.

The food manufacturing industry plays a dual role as a critical economic driver and a significant contributor to waste and environmental challenges (79–81). Integrating AI into food manufacturing offers transformative solutions to reduce waste and align practices with circular economy principles (60, 82). Waste reduction focuses on minimizing excess production, optimizing resource utilization, and mitigating environmental harm. The circular economy further advances these efforts by promoting the reuse, recycling, and repurposing of materials to create a closed-loop system that maximizes resource efficiency (59, 83).

AI-driven technologies empower manufacturers to implement smarter production strategies, minimize inefficiencies, and repurpose by-products, reducing environmental footprints (80, 82). For example, predictive analytics and real-time monitoring enable precise inventory management and energy optimization (79, 81). By aligning production with market demand and utilizing by-products, manufacturers achieve cost savings and sustainability goals (59, 60). The following subsections explore specific AI-driven solutions in preventing overproduction, optimizing energy efficiency, and utilizing food by-products for secondary purposes.

Overproduction in food manufacturing leads to significant waste, primarily due to inaccurate demand forecasting and inefficient resource management. AI-driven analytics provide advanced solutions to align production volumes with actual market demands, thereby mitigating overproduction. AI systems can analyze extensive datasets, including historical sales, market trends, and external factors such as weather patterns, to predict consumer demand with high precision. This process, known as demand sensing, enables manufacturers to adjust production schedules proactively in response to real-time data, reducing the likelihood of overproducing perishable goods (84).

For instance, technologies like digital twins simulate production processes and optimize resource use in real-time, minimizing inefficiencies (80). Big data analytics further enhance demand forecasting by providing insights into consumer behavior and market trends. These capabilities enable just-in-time production strategies, reducing excess inventory and associated waste. The adoption of Industry 4.0 technologies, including AI, has also addressed barriers to circular economy practices in food supply chains (79). However, the effectiveness of AI-driven analytics depends on the quality and comprehensiveness of the data collected. Manufacturers must invest in robust data collection and management systems to ensure accurate demand forecasting. Moreover, integrating AI solutions requires addressing challenges such as high implementation costs, the need for skilled personnel, and the development of standardized governance frameworks to manage ethical considerations (85).

Energy efficiency is pivotal for sustainable food manufacturing, addressing both environmental impacts and operational costs. Optimization techniques, such as those applied in agricultural systems, demonstrate potential for enhancing energy efficiency in food production (82). AI-powered heat drying technologies improve energy efficiency and reduce carbon footprints while preserving the nutritional and sensory properties of food products (86). Digitalization amplifies these efforts by enabling precise control and resource management, facilitating cost-effective production aligned with circular economy principles (81). AI and IoT technologies monitor energy usage across production lines, optimizing processes to minimize waste and reduce carbon emissions. These integrated strategies offer dual benefits: advancing sustainability goals and delivering economic advantages. To fully leverage these benefits, widespread adoption of energy-efficient practices remains critical.

Utilizing food by-products offers a transformative approach to sustainable food manufacturing, fully embracing circular economy principles. By reimagining by-products as resources rather than waste, manufacturers can reduce environmental impact and enhance product portfolios. Studies highlight the potential of by-products, such as dietary fibers, to serve as functional ingredients in various applications (59, 60). Innovative uses of by-products include incorporating fruit peels into health-oriented powders or enriching bakery items with dietary fibers. This not only minimizes waste but also caters to the rising demand for sustainable and health-conscious products. However, consumer acceptance is critical. Effective marketing and communication strategies are needed to ensure the success of value-added products derived from food waste (83). Challenges such as high initial technology costs and regulatory uncertainties remain barriers to widespread adoption. Collaborative efforts among industry stakeholders, researchers, and policymakers are vital for scaling up these practices. Developing cost-effective technologies, understanding consumer preferences, and establishing supportive regulatory frameworks can further promote the integration of by-products into mainstream production.

Maintaining high standards of quality control and assurance in food manufacturing is essential not only for consumer safety but also for sustainability. AI technologies are increasingly being integrated into these processes to address challenges like contamination, spoilage, and over-processing. The application of ML algorithms and computer vision enables real-time monitoring, predictive analytics, and automation, which help identify defects and deviations from quality benchmarks at every step of production. By leveraging these advanced technologies, manufacturers can ensure that products meet regulatory standards and consumer expectations, while simultaneously reducing waste and enhancing efficiency. This proactive approach to quality assurance is a key component in achieving sustainable food manufacturing practices.

Advancements in AI and smart sensing technologies have transformed real-time quality monitoring in the food supply chain. Integration of advanced sensors and biosensors in food packaging allows continuous assessment of quality parameters such as gas production, humidity, temperature, and microbial growth (61). These technologies provide immediate feedback on food quality, enabling timely interventions to prevent foodborne illnesses and ensure consumer safety. For example, portable handheld devices for food quality inspection are increasingly used across production stages, reflecting the trend toward automated monitoring systems (61). In a complementary innovation, Wang et al. (62) developed a fluorescent metal-organic framework (MOF) system for real-time visual monitoring of food freshness, specifically tested on raw fish samples. The system provides immediate and accurate feedback on quality, enhancing assurance processes in food manufacturing. The incorporation of smartphone-based platforms for inspection further underlines the growing accessibility and efficiency of quality monitoring solutions (62). These advancements play a crucial role in modern food manufacturing, ensuring food safety while reducing waste.

The application of computer vision and sensor technologies in food manufacturing is gaining traction for its ability to enhance precision in quality assessment. Computer vision techniques, as highlighted by Jackman et al. (63), have significantly improved the accuracy of quality evaluations in fresh meats. By leveraging image processing, manufacturers can automate inspections, reducing reliance on subjective evaluations and improving defect detection efficiency. Deep learning (DL) algorithms are instrumental in advancing precision assessment techniques. For instance, Imani et al. (64) explored the use of layerwise imaging profiles in quality control, demonstrating how ML and advanced imaging techniques can yield more reliable assessments. These technologies enable real-time monitoring, allowing manufacturers to address potential quality issues early in the production cycle. Such innovations enhance the integrity and safety of food products while maintaining high standards of quality (64).

Automation of inspection processes is essential for maintaining consistent quality standards in food manufacturing. Intelligent food packaging systems, as discussed by Dodero et al. (65), are a promising innovation for real-time quality monitoring during production and storage. These systems utilize responsive materials to provide continuous data on key quality parameters such as temperature, humidity, and gas composition, ensuring product freshness and safety while reducing waste. Additionally, ML-based systems offer transformative potential in automating inspections. Hemamalini et al. (66) proposed an approach using efficient image segmentation and ML techniques to enhance quality grading and assurance processes. These automated systems provide precise and rapid quality assessments, minimizing reliance on manual inspections and ensuring only high-quality products reach consumers. By integrating these technologies, food manufacturers can achieve consistent quality control, compliance with safety standards, and improved operational efficiency (66).

The integration of artificial AI in the food industry holds significant promise; however, it is accompanied by several challenges and limitations that hinder its widespread adoption. Table 3 summarizes the key barriers, including technical and infrastructural constraints, ethical considerations, and financial viability issues, which are further detailed in the subsections below.

The adoption of AI in food manufacturing is hindered by significant technical and infrastructural challenges, which limit its full integration and impact on the industry. One critical barrier lies in the need for advanced data processing capabilities and reliable infrastructure, such as high-speed internet and cloud computing, to support the seamless operation of AI systems (91). Many food manufacturers, particularly small and medium-sized enterprises (SMEs), lack access to these resources, which are essential for deploying AI-driven solutions in real-time production environments (88). Additionally, the high computational requirements for AI algorithms, such as neural networks and predictive models, pose further constraints on existing hardware and software systems (92).

Another key challenge is the integration of AI technologies with legacy systems in food manufacturing facilities. Most traditional production lines are not equipped to accommodate advanced technologies like IoT sensors or digital twins, which are crucial for real-time monitoring and optimization (89). Retrofitting these systems requires significant investment and technical expertise, making it economically unfeasible for many manufacturers (90). Furthermore, the lack of standardized frameworks for data collection and sharing exacerbates these issues, preventing seamless interoperability between AI-driven tools and existing operational systems (87).

Addressing these barriers requires a collaborative effort among stakeholders, including policymakers, technology providers, and industry leaders. Investment in affordable and scalable solutions, such as edge computing and distributed ledger technologies, can enable broader adoption of AI in food manufacturing (88, 104). Moreover, initiatives to build robust digital infrastructures and provide training in AI technologies can empower manufacturers to transition toward smarter and more sustainable production processes. The integration of digital twin models and IoT-enabled monitoring systems has further potential to optimize resource use and enhance efficiency in production (89, 90). Additionally, advanced sensing technologies like near-infrared spectroscopy (NIRS) offer green analytical solutions that can facilitate real-time decision-making and promote sustainability (87). These efforts are essential to overcoming infrastructural limitations and unlocking the transformative potential of AI in the food industry (92, 105).

The integration of AI in food manufacturing introduces complex ethical challenges, particularly concerning data privacy and security. AI-driven systems increasingly collect and analyze large volumes of sensitive data, including proprietary business information and consumer-related data, to optimize supply chains, enhance food safety, and predict market trends. However, this reliance on data raises critical questions about its secure storage, accessibility, and ethical use. According to Jacobs et al. (98), transparency and trust in digital collaborations are essential for maintaining ethical practices in data management. The absence of clear governance frameworks for data privacy can undermine stakeholder confidence and lead to significant ethical and operational risks.

The WHO's guidance on the Ethics and Governance of Artificial Intelligence for Health (99) offers a robust framework for addressing ethical considerations in AI. It outlines six core ethical principles—autonomy, human wellbeing, transparency and explainability, responsibility and accountability, inclusiveness and equity, & responsive and sustainable systems. These principles emphasize the need for inclusive and equitable AI systems that protect user privacy while fostering innovation. In the context of food manufacturing, such principles provide a foundation for self-governance and equitable data practices, ensuring that AI solutions serve the interests of all stakeholders, including marginalized communities (95, 96).

A major concern in this domain is the lack of standardized data governance practices, which can expose the food sector to significant risks. Karanth et al. (97) emphasize that breaches in data privacy can compromise predictions related to food safety and supply chain efficiency, ultimately impacting both consumer wellbeing and business sustainability. AI platforms that predict contamination risks or assess vulnerabilities in the supply chain, as highlighted by Chavan et al. (94), rely on comprehensive data analytics. However, without robust security protocols, these systems may inadvertently expose sensitive data to unauthorized access or misuse, creating vulnerabilities across the industry.

To address these challenges, a proactive approach to ethical AI application is essential. Collaboration among technology providers, regulators, and industry leaders can help establish guidelines that prioritize data privacy and foster trust. Friedlander and Zoellner (100) suggest that designing transparent and accountable AI systems is critical for mitigating ethical risks. Furthermore, incorporating explainability into AI algorithms, as advocated by Goktas (93), enhances stakeholder confidence by ensuring that AI decisions align with ethical standards and societal values. By adopting robust data governance policies and investing in secure, transparent AI solutions, the food manufacturing sector can balance innovation with the protection of privacy, ensuring ethical progress in the digital era.

The financial viability and resource constraints of adopting AI technologies significantly influence their implementation in the food industry. The high initial investment required for infrastructure, training, and operational adaptation presents a substantial challenge, particularly for SMEs. As noted by Jäggi et al. (101), globalization has intensified the complexity of food markets, necessitating advanced technological solutions to enhance supply chain management, productivity, and sustainability. However, these advancements often demand resources that are beyond the reach of smaller stakeholders, creating economic barriers that limit equitable adoption. Beyond initial investments, the ongoing costs of maintaining and upgrading AI systems further complicate their feasibility. For instance, Tsakiridis et al. (102) illustrate that while IoT-enabled AI tools such as precision irrigation systems deliver significant efficiency gains and waste reduction, their high installation and maintenance costs remain a deterrent for widespread adoption. Addressing these barriers requires innovative solutions, including the development of low-cost sensors and explainable AI models, which can increase both affordability and trustworthiness, thereby enabling broader access to AI-driven systems in agriculture and food production.

Another critical challenge lies in the data infrastructure required for AI applications. As Qureshi (103) observes, data-driven AI solutions necessitate extensive and high-quality datasets, which are often inaccessible in under-resourced regions. This data divide risks marginalizing vulnerable populations and regions, exacerbating existing inequalities (95). Bridging this divide demands targeted policies that foster equitable access to digital resources and investments in inclusive data collection systems. Public-private partnerships can play a pivotal role in sharing the financial burden, promoting collaboration, and scaling AI solutions in a manner that benefits diverse stakeholders in the food industry.

The food manufacturing sector is undergoing a paradigm shift, driven by the convergence of technological advancements and the imperative for sustainable practices. Emerging technologies such as green AI and blockchain are poised to transform production processes by enhancing efficiency, reducing waste, and ensuring superior food safety and quality. Additionally, the adoption of circular economy principles and renewable energy solutions is reshaping the industry's operational landscape, aligning it with global sustainability objectives. As detailed in Table 4, the integration of cutting-edge technologies such as sustainable AI, IoT, robotics, and blockchain in food manufacturing addresses critical challenges while unlocking significant environmental and economic benefits. The following sub-sections delve deeper into the key areas highlighted in the table, offering a detailed overview of their applications, benefits, and implications for the future of food manufacturing:

The integration of advanced technologies, such as sustainable AI, IoT, and Robotics and Autonomous Systems (RAS), is redefining the future of food manufacturing. These innovations are pivotal in addressing critical challenges like sustainability, food safety, and adaptability to evolving market demands while simultaneously driving operational efficiency and resilience. As highlighted by Moses and Anandharamakrishnan (114), these technologies are vital in transforming traditional practices into highly automated and optimized systems aligned with Industry 5.0 principles.

The convergence of AI and IoT enables real-time monitoring and data-driven decision-making across the food manufacturing supply chain. According to Misra et al. (28) and Ding et al. (106), AI-powered precision farming utilizes sensor-driven data to optimize resource utilization, improve crop yields, and enhance production efficiency. IoT devices, coupled with AI algorithms, offer predictive maintenance capabilities, minimizing equipment downtime and reducing waste in food processing operations. In logistics and supply chain management, AI optimizes resource allocation and reduces carbon footprints through intelligent routing and scheduling, contributing to the overall sustainability of food manufacturing (110). Emerging research further highlights the role of blockchain integrated with AI and IoT in ensuring end-to-end traceability in the supply chain, enhancing transparency, and reducing fraud (111). This synergy is expected to address scalability and interoperability challenges, paving the way for a seamless and efficient supply chain network.

The advent of RAS further amplifies the impact of AI in food manufacturing. As noted by Kumar and Konar (112), robotic systems not only automate these tasks but also improve consistency and reduce labor costs. Integration with AI allows for precise control over production processes, ensuring standardized quality and efficiency. For instance, robotic sorting systems equipped with machine vision can detect and remove defective products with remarkable accuracy, maintaining high food safety standards. Autonomous vehicles in manufacturing facilities further streamline material handling, optimizing workflow efficiency and reducing operational costs (110). Additionally, collaborative robots, or “cobots," are increasingly being utilized to enhance human-robot interactions in production environments, fostering a safer and more efficient workplace.

The application of DT technology represents a significant leap in the optimization of food manufacturing processes. By creating virtual replicas of physical processes, DT facilitates real-time simulation, monitoring, and optimization of production workflows. According to Grewal et al. (113), DT enhances resource management, minimizes waste, and optimizes energy utilization, aligning with sustainability objectives. The adaptability and scalability of DT make it a valuable tool for addressing the dynamic demands of the food industry. Future advancements in DT are expected to integrate ML models for predictive analytics, enabling manufacturers to anticipate potential bottlenecks and implement proactive measures. This approach contributes to greater resilience and sustainability in the food manufacturing ecosystem (114).

Industry 5.0 represents the next phase in industrial evolution, building upon the digital transformation of Industry 4.0 by integrating human-centric, sustainable, and resilient manufacturing principles. Unlike Industry 4.0, which emphasized automation, cyber-physical systems, and AI-driven decision-making, Industry 5.0 focuses on collaborative intelligence, where humans and advanced technologies work together to optimize production processes, enhance sustainability, and improve overall resilience (110, 118).

Key principles of Industry 5.0 in food manufacturing should sinclude:

• Human-AI collaboration: unlike fully automated systems in Industry 4.0, Industry 5.0 emphasizes human-machine interaction, where AI assists human workers in making informed decisions while ensuring flexibility and adaptability in manufacturing (119).

• Sustainability-driven production: the shift toward circular economy practices is accelerated under Industry 5.0, where AI, IoT, and robotics are leveraged to minimize waste, repurpose by-products, and reduce energy consumption (120).

• Resilient and adaptive systems: industry 5.0 fosters resilience by enabling smart manufacturing systems that can quickly adapt to supply chain disruptions, ensuring a stable and sustainable food production process (121).

The integration of Industry 5.0 principles into food manufacturing offers significant advantages, such as enhancing AI-driven predictive maintenance, promoting sustainable production models, and supporting customized food manufacturing through robotics and personalized nutrition technologies. By leveraging these innovations, the food industry can transition toward a more efficient, environmentally responsible, and consumer-focused production ecosystem (110).

Emerging AI technologies are driving innovations in personalized nutrition and quality assurance in food manufacturing. ML models enable the customization of food products to cater to individual nutritional needs and preferences, as emphasized by Viejo et al. (115). Additive manufacturing, powered by AI, facilitates the creation of tailored food items with enhanced nutritional profiles, bridging the gap between health and convenience (56). AI-based quality control systems are also advancing food safety protocols by leveraging computer vision and DL to detect contaminants, assess freshness, and monitor shelf life. These technologies significantly enhance the accuracy and efficiency of quality assurance processes, ensuring compliance with stringent regulatory standards (115, 116).

Despite the transformative potential of AI technologies, several challenges hinder their widespread adoption in food manufacturing. High implementation costs, data dependency, and ethical concerns related to privacy and bias remain significant barriers (122). Addressing these challenges requires collaborative efforts among governments, academia, and industry stakeholders to develop cost-effective solutions and establish robust regulatory frameworks (87). Future research should focus on enhancing the interpretability and transparency of AI models to build trust among stakeholders. Moreover, initiatives to upskill the workforce and promote interdisciplinary collaboration are essential for maximizing the potential of these technologies. The road ahead involves leveraging AI to achieve a balance between innovation, sustainability, and ethical considerations in food manufacturing (110, 114).

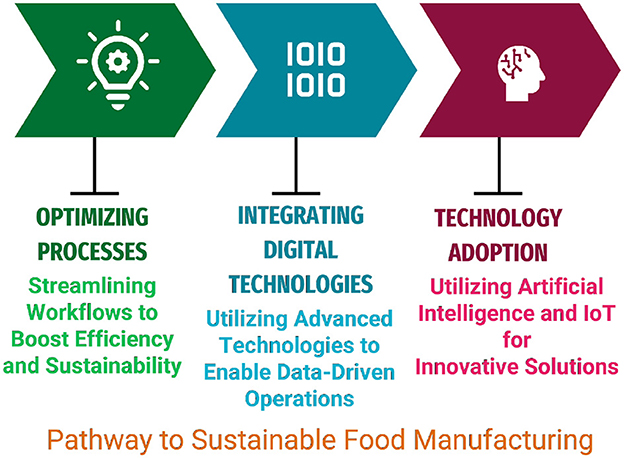

The integration of AI with big data and IoT is driving significant advancements in sustainability within food manufacturing. These technologies improve operational efficiency, optimize resource utilization, and reduce waste. Misra et al. (28) emphasize how real-time monitoring and predictive capabilities enable manufacturers to enhance workflows, minimize losses, and address environmental challenges, aligning with global sustainability targets. Koebe (108) underline the broader applicability of digital technologies, including AI, in advancing the United Nations' SDGs. Leveraging scalable AI-driven models and digital platforms supports sustainable practices and fosters global adaptability, even in emerging markets. One impactful innovation in food manufacturing is AI-driven 3D food printing, which reduces material waste while enabling precision production of customized food items tailored to individual preferences. By incorporating surplus ingredients and by-products into formulations, manufacturers actively promote circular economy principles, significantly reducing food waste (117). The broader framework for sustainable food manufacturing, as depicted in Figure 2, highlights the three essential pillars: optimizing processes, integrating digital technologies, and adopting AI and IoT solutions. This framework underlines the importance of combining technological innovation with process efficiency to achieve long-term sustainability goals.

Figure 2. A framework illustrating the three pillars of sustainable food manufacturing: optimizing processes, integrating digital technologies, and the adoption of AI and IoT technologies for innovative and efficient production.

AI-powered energy management systems further advance sustainability by optimizing energy consumption across the food supply chain, reducing carbon footprints, and lowering operational costs (28). Furthermore, the integration of AI into waste management systems fosters sustainable urban growth, as highlighted by Singagerda et al. (107), who emphasize AI's ability to influence public behavior, enhance resource efficiency, and align with SDGs 11, 12, and 13. Despite these advancements, challenges such as high implementation costs and the need for skilled personnel persist. However, the adoption of low-code AI platforms and Industrial IoT (IIoT) solutions, as demonstrated by Redchuk et al. (109), showcases a pathway for achieving energy efficiency and resource optimization while maintaining centrality of human expertise within the Industry 5.0 framework. Ultimately, AI's potential to foster resilience, reduce waste, and enhance customization paves the way for a sustainable, adaptive, and efficient food manufacturing ecosystem (28, 108, 117).

The integration of AI technologies into food manufacturing redefines the industry, enabling sustainable and efficient production systems. By addressing critical challenges such as resource optimization, waste reduction, and quality assurance, AI, together with IoT and robotics, transforms traditional processes into intelligent, interconnected systems capable of real-time monitoring and adaptive decision-making. This study contributes to the field by providing a structured analysis of AI applications in food manufacturing, offering practical insights for industry adoption, and identifying research gaps that need further exploration.

Findings from this review highlight that AI has the potential to:

• Enhance operational efficiency by automating workflows and optimizing resource use.

• Reduce food waste and environmental impact through AI-driven predictive analytics.

• Improve product quality control by integrating AI-based defect detection and real-time monitoring systems.

• Facilitate the transition to circular economy practices by repurposing food by-products.

Advanced sustainable AI applications are expected to seamlessly integrate into existing infrastructures, improving predictive maintenance, quality control, and operational efficiency. The adoption of AI-driven solutions accelerates the shift toward circular economy practices, optimizing the utilization of by-products and enabling precise resource allocation. However, realizing these benefits requires addressing existing challenges such as high implementation costs, ethical concerns, and the need for standardized AI governance frameworks. Thus, this study emphasizes the importance of multi-stakeholder collaboration among policymakers, technology developers, and food industry professionals to unlock AI's full potential in food manufacturing. By overcoming adoption barriers and leveraging AI-driven innovations, the industry can achieve a balance between technological advancement, environmental sustainability, and economic viability. The insights provided in this review contribute to ongoing discussions on the role of AI in shaping the future of sustainable food production, laying the groundwork for further research and policy development.

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

KA: Conceptualization, Data curation, Formal analysis, Investigation, Methodology, Project administration, Writing – original draft. PG: Conceptualization, Data curation, Formal analysis, Investigation, Methodology, Project administration, Writing – original draft, Writing – review & editing. MH: Writing – review & editing. CB: Conceptualization, Funding acquisition, Project administration, Writing – review & editing. NK: Conceptualization, Project administration, Writing – original draft, Writing – review & editing.

The author(s) declare that no financial support was received for the research and/or publication of this article.

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

The author(s) declare that no Gen AI was used in the creation of this manuscript.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

1. Hassoun A, Aït-Kaddour A, Abu-Mahfouz AM. The fourth industrial revolution in the food industry—Part I: industry 40 technologies. Crit Rev Food Sci Nutr. (2023) 63:6547–63. doi: 10.1080/10408398.2022.2034735

2. Hassoun A, Bekhit AED. The fourth industrial revolution in the food industry—Part II: emerging food trends. Crit Rev Food Sci Nutr. (2024) 64:407–37. doi: 10.1080/10408398.2022.2106472

3. Nath PC, Mishra AK, Sharma R. Recent advances in artificial intelligence towards the sustainable future of agri-food industry. Food Chem. (2024) 447:138945. doi: 10.1016/j.foodchem.2024.138945

4. Meemken EM, Becker-Reshef I. Digital innovations for monitoring sustainability in food systems. Nat Food. (2024) 5:656–60. doi: 10.1038/s43016-024-01018-6

5. Markovic M, Li A. Embedding AI-enabled data infrastructures for sustainability in agri-food: soft-fruit and brewery use case perspectives. Sensors. (2024) 24:7327. doi: 10.3390/s24227327

6. Ali ZA, Zain M, Pathan MS. Contributions of artificial intelligence for circular economy transition leading toward sustainability: an explorative study in agriculture and food industries of Pakistan. Environ Dev Sustain. (2024) 26:19131–75. doi: 10.1007/s10668-023-03458-9

7. Zatsu V, Shine AE, Tharakan, Ranganathan TV, Alotaibi SS, Mugabi R, et al. Revolutionizing the food industry: the transformative power of artificial intelligence-a review. Food Chem. X. (2024) 24:101867. doi: 10.1016/j.fochx.2024.101867

8. Moulahoum H, Ghorbanizamani F. Navigating the development of silver nanoparticles based food analysis through the power of artificial intelligence. Food Chem. (2024) 445:138800. doi: 10.1016/j.foodchem.2024.138800

9. Agnusdei L, Krstić M. Digitalization as driver to achieve circularity in the agroindustry: a SWOT-ANP-ADAM approach. Sci Total Environ. (2023) 882:163441. doi: 10.1016/j.scitotenv.2023.163441

10. Konfo TRC, Djouhou FMC. Recent advances in the use of digital technologies in agri-food processing: a short review. Appl Food Res. (2023) 3:100329. doi: 10.1016/j.afres.2023.100329

11. Page MJ, McKenzie JE, Bossuyt PM, Boutron I, Hoffmann TC, Mulrow CD, et al. The PRISMA 2020 statement: an updated guideline for reporting systematic reviews. BMJ. (2021) 372:n71OI. doi: 10.1136/bmj.n71OI

12. Babineau J. Product review: covidence (systematic review software). J Can Health Libr Assoc. (2014) 35:68–71. doi: 10.5596/c14-016

13. Knorr D. Food processing: legacy, significance and challenges. Trends Food Sci Technol. (2024) 143:104270. doi: 10.1016/j.tifs.2023.104270

14. Leal Filho W, Setti AFF, Azeiteiro UM, Lokupitiya E, Donkor FK, Etim NN, et al. An overview of the interactions between food production and climate change. Sci Total Environ. (2022) 838:156438. doi: 10.1016/j.scitotenv.2022.156438

15. Petkoska AT, Daniloski D, D'Cunha NM, Naumovski N, Broach AT. Edible packaging: sustainable solutions and novel trends in food packaging. Food Res Int. (2021) 140:109981. doi: 10.1016/j.foodres.2020.109981

16. Ogwu MC, Ogunsola OA. Physicochemical methods of food preservation to ensure food safety and quality. In: Ogwu MC, Izah SC, Ntuli NR, editors. Food Safety and Quality in the Global South. Cham: Springer (2024), p. 263–98. doi: 10.1007/978-981-97-2428-4_9

17. Señorans FJ, Ibáñez E, Cifuentes A. New trends in food processing. Crit Rev Food Sci Nutr. (2003) 43:507–26. doi: 10.1080/10408690390246341

19. Fellows PJ. Food Processing Technology: Principles and Practice. Cambridge: Woodhead Publishing (2022).

20. Man CD, Jones AA. Shelf Life Evaluation of Foods. Cham: Springer (1994). doi: 10.1007/978-1-4615-2095-5

21. Lees R. Food Analysis: Analytical and Quality Control Methods for the Food Manufacturer and Buyer. London: Leonard Hill Books (1975).

22. Prokopov T, Tanchev S. Methods of food preservation. In: McElhatton A, Marshall RJ, editors. Food Safety: A Practical and Case Study Approach. Cham: Springer (2007), p. 3–25. doi: 10.1007/978-0-387-33957-3_1

23. Gould GW. New Methods of Food Preservation. Cham: Springer Science & Business Media (1995). doi: 10.1007/978-1-4615-2105-1

24. Dong Y, Coleman M, Miller SA. Greenhouse gas emissions from air conditioning and refrigeration service expansion in developing countries. Annu Rev Environ Resour. (2021) 46:59–83. doi: 10.1146/annurev-environ-012220-034103

25. Kirby RM, Bartram J, Carr R. Water in food production and processing: quantity and quality concerns. Food Control. (2003) 14:283–99. doi: 10.1016/S0956-7135(02)00090-7

26. Despoudi S, Bucatariu C, Otles S, Kartal C. Food waste management, valorization, and sustainability in the food industry. In: Galanakis CM, editor. Food Waste Recovery. Amsterdam: Elsevier (2021), p. 3–19. doi: 10.1016/B978-0-12-820563-1.00008-1

27. FAO U. The State of Food and Agriculture: Moving Forward on Food Loss and Waste Reduction. Rome: FAO. (2019).

28. Misra N, Dixit Y, Al-Mallahi A, Bhullar MS, Upadhyay R, Martynenko A. IoT, big data, and artificial intelligence in agriculture and food industry. IEEE Internet Things J. (2020) 9:6305–24. doi: 10.1109/JIOT.2020.2998584

29. Akkerman R, Van Donk DP. Balancing environmental and economic performance in the food processing industry. Int J Entrep Innov Manag. (2010) 11:330–40. doi: 10.1504/IJEIM.2010.031906

30. Yue Q, Xu X, Hillier J, Cheng K, Pan G. Mitigating greenhouse gas emissions in agriculture: From farm production to food consumption. J Clean Prod. (2017) 149:1011–9. doi: 10.1016/j.jclepro.2017.02.172

31. Aït-Kaddour A, Hassoun A, Tarchi I, Loudiyi M, Boukria O, Cahyana Y, et al. Transforming plant-based waste and by-products into valuable products using various “Food Industry 4.0” enabling technologies. Sci Total Environ. (2024) 955:176872. doi: 10.1016/j.scitotenv.2024.176872

32. George AS. Leveraging industry 4.0 for efficiency gains in food production. Partn Univers Int Res J. (2024) 3:86–108. doi: 10.5281/zenodo.10823006

33. Fagodiya RK, Singh A, Singh R, Rani S, Kumar S, Rai AK, et al. The food-energy-water-carbon nexus of the rice-wheat production system in the western Indo-Gangetic Plain of India. Sci Total Environ. (2023) 860:160428. doi: 10.1016/j.scitotenv.2022.160428

34. Pandey D, Sarkar A. Food Security in the Changing Environment: Challenges and Solutions. Hauppauge, NY: Nova Science Publishers, Inc. (2017), p. 221–35.

35. Onyijen OH, Oyelola S, Ogieriakhi OJ. Food Manufacturing, Processing, Storage, and Marketing Using Artificial Intelligence. Edo State, Ogwa: Elsevier (2024). doi: 10.1016/B978-0-443-24001-0.00012-9

36. Glassey J, Barone A, Montague GA, Sabou V. Case Studies in Modelling, Control in Food Processes, Vol. 161. Cham: Springer (2017), p. 93–120. Available online at: www.scopus.com/inward/record.uri?eid=2-s2.0-85027394051&doi=10.1007%2f10_2017_13&partnerID=40&md5=1fd6df953c4b5810ab34f9b85b182c66 (accessed March 1, 2025).

37. Leadley C. Innovation and Future Trends in Food Manufacturing and Supply Chain Technologies. Cambridge: Woodhead Publishing (2015).

39. Bhat R, Sharma M, Rätsep R, Malenica D, Jõgi K. Challenges and prospects of tackling food loss and wastes in the circular economy context. In: Narula SA, Raj SP, editors. Sustainable Food Value Chain Development. Cham: Springer (2023), p. 15–36. doi: 10.1007/978-981-19-6454-1_2

40. Garcia-Garcia G, Woolley E, Rahimifard S. Optimising Industrial Food Waste Management. Procedia Manuf . (2017) 8:432–9. doi: 10.1016/j.promfg.2017.02.055

41. Singh RP, Heldman DR. Introduction to Food Engineering. Houston, TX: Gulf Professional Publishing (2001).

42. Rabbi MF, Amin MB. Circular economy and sustainable practices in the food industry: a comprehensive bibliometric analysis. Clean Responsible Consum. (2024) 14:100206. doi: 10.1016/j.clrc.2024.100206

43. Logatcheva K, van Galen MA. Primary Food Processing: Cornerstone of Plant-Based Food Production and the Bio-economy in Europe. The Hague: LEI. (2015).

44. Adelaja AO, Nayga Jr RM, Schilling BJ, Tank KR. Understanding the challenges facing the food manufacturing industry. J Food Prod Mark. (2000) 6:35–55. doi: 10.1300/J038v06n02_04

45. FT Avelino A, Dall'erba S. What factors drive the changes in water withdrawals in the US Agriculture and food manufacturing industries between 1995 and 2010? Environ Sci Technol. (2020) 54:10421–34. doi: 10.1021/acs.est.9b07071

46. Ladha-Sabur A, Bakalis S, Fryer PJ, Lopez-Quiroga E. Mapping energy consumption in food manufacturing. Trends Food Sci Technol. (2019) 86:270–80. doi: 10.1016/j.tifs.2019.02.034

47. Garcia-Garcia G, Woolley E, Rahimifard S, Colwill J, White R, Needham L. A methodology for sustainable management of food waste. Waste Biomass Valorization. (2017) 8:2209–27. doi: 10.1007/s12649-016-9720-0

48. Mlambo V, Dibakoane SR, Mashiloane T, Mukwevho L, Wokadala OC, Mnisi CM. Rethinking food waste: exploring a black soldier fly larvae-based upcycling strategy for sustainable poultry production. Resour Conserv Recycl. (2023) 199:107284. doi: 10.1016/j.resconrec.2023.107284

49. Pikaar I, Matassa S, Rabaey K, Laycock B, Boon N, Verstraete W. The urgent need to re-engineer nitrogen-efficient food production for the planet. In: Hülsmann S, Ardakanian R, editors. Managing Water, Soil and Waste Resources to Achieve Sustainable Development Goals. Cham: Springer (2018), p. 35–69. doi: 10.1007/978-3-319-75163-4_3

50. Gilmour J, Wang L. Detection of process abnormality in food extruder using principal component analysis. Chem Eng Sci. (2002) 57:1091–8. doi: 10.1016/S0009-2509(01)00432-8

51. Simmer K, Hartmann B. The knowns and unknowns of human milk banking. Early Hum Dev. (2009) 85:701–4. doi: 10.1016/j.earlhumdev.2009.08.054

52. Van Der Spiegel M, Luning PA, Ziggers GW, Jongen WMF. Evaluation of performance measurement instruments on their use for food quality systems. Crit Rev Food Sci Nutr. (2004) 44:501–12. doi: 10.1080/10408690490489350

53. Gao J, Wu M, Du S, Zhang H, Wang S, Ling B. Recent advances in food processing by radio frequency heating techniques: a review of equipment aspects. J Food Eng. (2023) 357:111609. doi: 10.1016/j.jfoodeng.2023.111609

54. Yudhistira B, Adi P, Mulyani R, Chang CK, Gavahian M, Hsieh CW. Achieving sustainability in heat drying processing: leveraging artificial intelligence to maintain food quality and minimize carbon footprint. Compr Rev Food Sci Food Saf . (2024) 23:e13413. doi: 10.1111/1541-4337.13413

55. Kataria P. Technology at the table: incorporating AI into contemporary food industry operations. Food Sci Nutr Cases. (2024) doi: 10.1079/foodsciencecases.2024.0003

56. Yu Q, Zhang M, Mujumdar AS, Li J. AI-based additive manufacturing for future food: potential applications, challenges and possible solutions. Innov Food Sci Emerg Technol. (2024) 92:103599. doi: 10.1016/j.ifset.2024.103599

57. Fernandez-Pelaez F, Etxegarai M, Moreno, Campins G, Lopez C, Rojo R, et al. Predictive Maintenance in the Food Industry: A Case Study Using Vibration Sensors and Machine Learning Techniques. London: IOS Press (2024). doi: 10.3233/FAIA240407

58. Kaynak G, Ervural B. Predictive maintenance planning using a hybrid ARIMA-ANN model. Bitlis Eren Univ Fen Bilimleri Dergisi. (2024) 13:618–32. doi: 10.17798/bitlisfen.1466339

59. Sharma SK, Bansal S, Mangal M, Dixit AK, Gupta RK, Mangal AK. Utilization of food processing by-products as dietary, functional, and novel fiber: a review. Crit Rev Food Sci Nutr. (2015) 56:1647–61. doi: 10.1080/10408398.2013.794327

60. Zhao X, Chen J, Du F. Potential use of peanut by-products in food processing: a review. J Food Sci Technol. (2011) 49:521–9. doi: 10.1007/s13197-011-0449-2

61. Yousefi H, Su HM, Imani SM. Alkhaldi, Didar TF. Intelligent food packaging: a review of smart sensing technologies for monitoring food quality. ACS Sens. (2019) 4:808–21. doi: 10.1021/acssensors.9b00440

62. Wang J, Li D, Ye Y, Qiu Y, Liu, Liang B, et al. A fluorescent metal-organic framework for food real-time visual monitoring. Adv Mater. (2021) 33:e2008020. doi: 10.1002/adma.202008020

63. Jackman P, Sun DW, Allen P. Recent advances in the use of computer vision technology in the quality assessment of fresh meats. Trends Food Sci Technol. (2011) 22:185–97. doi: 10.1016/j.tifs.2011.01.008

64. Imani F, Chen R, Diewald E, Reutzel E, Yang H. Deep learning of variant geometry in layerwise imaging profiles for additive manufacturing quality control. J Manuf Sci Eng. (2019) 141:111001. doi: 10.1115/1.4044420

65. Dodero A, Escher A, Bertucci S, Castellano M, Lova P. Intelligent packaging for real-time monitoring of food-quality: current and future developments. Appl Sci. (2021) 11:3532. doi: 10.3390/app11083532

66. Hemamalini V, Rajarajeswari S, Nachiyappan S. Sambath, Singh BK, Raghuvanshi A. Food quality inspection and grading using efficient image segmentation and machine learning-based system. J Food Qual. (2022) 2022:1–6. doi: 10.1155/2022/5262294

67. Ferrer-Blas RI, Galarcep-Barba I, Solano-Gaviño JC. Lean Manufacturing in food production: systematic review, bibliometric analysis and proposed application. Sci Agropecu. (2024) 15:569–79. doi: 10.17268/sci.agropecu.2024.042

68. Aivaliotis P, Georgoulias K, Chryssolouris G. The use of digital twin for predictive maintenance in manufacturing. Int J Comput Integr Manuf . (2019) 32:1067–80. doi: 10.1080/0951192X.2019.1686173

69. Oztuna Taner O, Çolak AB. Improve the energy efficiency of the fruit freeze-drying through the predictive analysis. Food Bioprod Process. (2025) 149:261–71. doi: 10.1016/j.fbp.2024.11.028

70. Gu W. Manufacturing resources coordination organisation and tasks allocation approach inspired by the endocrine regulation principle. IET Collab Intell Manuf . (2020) 2:37–44. doi: 10.1049/iet-cim.2019.0031

71. Reijers HA. Resource Allocation in Workflows. Berlin: Springer Berlin Heidelberg (2003), p. 177–206. doi: 10.1007/3-540-36615-6_5

72. Mathew A, Kaur S. Predictive maintenance for manufacturing using data mining techniques. In: 2024 2nd World Conference on Communication & Computing (WCONF). Raipur (2024). p. 1–5. doi: 10.1109/WCONF61366.2024.10692226

73. Hosseinzadeh A, Frank Chen F, Shahin M, Bouzary H. A predictive maintenance approach in manufacturing systems via AI-based early failure detection. Manuf Lett. (2023) 35:1179–86. doi: 10.1016/j.mfglet.2023.08.125

74. Belim M, Meireles T, Gonsalves G, Pinto R. Forecasting models analysis for predictive maintenance. Front Manuf Technol. (2024) 4:1475078. doi: 10.3389/fmtec.2024.1475078

75. Tsai CW, Tong LI, Wang CH. Using DEA to optimize a mixture design with multiple responses incorporating cost considerations. (2008) Available online at: http://nopr.niscpr.res.in/bitstream/123456789/1790/1/JSIR%2067%287%29%20479-485.pdf (accessed March 1, 2025).

76. Saravacos G, Maroulis Z. Food Process Economics. New York, NY: Springer (2010), p. 219–36. doi: 10.1007/978-1-4419-7475-4_9

77. Erdogdu F. Optimization in Food Engineering, 1st Edn. New York, NY: CRC Press (2008). doi: 10.1201/9781420061420

78. Sridharan M. Chapter 15 - applications of artificial intelligence techniques in heat exchanger systems. In: Pekař L, editor. Advanced Analytic and Control Techniques for Thermal Systems with Heat Exchangers. San Diego, CA: Academic Press (2020), p. 325–4. doi: 10.1016/B978-0-12-819422-5.00015-3

79. Schoggl JP, Rusch M, Stumpf L, Baumgartner RJ. Implementation of digital technologies for a circular economy and sustainability management in the manufacturing sector. Sustain Prod Consum. (2023) 35:401–20. doi: 10.1016/j.spc.2022.11.012

80. Nasirahmadi A, Hensel O. Toward the next generation of digitalization in agriculture based on digital twin paradigm. Sensors. (2022) 22:498. doi: 10.3390/s22020498

81. Gomez M, Martinez MM. Fruit and vegetable by-products as novel ingredients to improve the nutritional quality of baked goods. Crit Rev Food Sci Nutr. (2017) 58:2119–35. doi: 10.1080/10408398.2017.1305946

82. Kaab A, Sharifi M, Mobli H, Nabavi-Pelesaraei A, Chau KW. Use of optimization techniques for energy use efficiency and environmental life cycle assessment modification in sugarcane production. Energy. (2019) 181:1298–320. doi: 10.1016/j.energy.2019.06.002

83. Pagotto M, Halog A. Towards a Circular Economy in australian agri-food industry: an application of input-output oriented approaches for analyzing resource efficiency and competitiveness potential. J Ind Ecol. (2015) 20:1176–86. doi: 10.1111/jiec.12373

84. Hübner N, Caspers J, Coroamă VC, Finkbeiner M. Machine-learning-based demand forecasting against food waste: life cycle environmental impacts and benefits of a bakery case study. J Ind Ecol. (2024) 28:1117–31. doi: 10.1111/jiec.13528

85. Espina-Romero L, Gutiérrez Hurtado H, Ríos Parra D, Vilchez Pirela RA, Talavera-Aguirre R, Ochoa-Díaz A. Challenges and opportunities in the implementation of AI in manufacturing: a bibliometric analysis. Science. (2024) 6:60. doi: 10.3390/sci6040060

86. Oztuna Taner O, Çolak AB. Dairy factory milk product processing and sustainable of the shelf-life extension with artificial intelligence: a model study. Front Sustain Food Syst. (2024) 8:1344370. doi: 10.3389/fsufs.2024.1344370

87. Czaja TP, Engelsen SB. Why nothing beats NIRS technology: the green analytical choice for the future sustainable food production. Spectrochim Acta A: Mol Biomol Spectrosc. (2025) 325:125028. doi: 10.1016/j.saa.2024.125028

88. Singh PD, Maurya S, Verma R, Singh KD, Joshi K, Khanna LS. Justifiable agriculture productivity with nimble, cost-effective, and optimized resource framework - a MIST computing approach for smart agriculture. In: 2024 International Conference on Smart Devices, ICSD 2024. Institute of Electrical and Electronics Engineers Inc. (2024). Available online at: www.scopus.com/inward/record.uri?eid=2-s2.0-85211932387&doi=10.1109%2fICSD60021.2024.10751375&partnerID=40&md5=25d73eed009985fc75904316f1a97c62 (accessed March 1, 2025).

89. Helmy M, Elhalis H, Rashid MM, Selvarajoo K. Can digital twin efforts shape microorganism-based alternative food? Curr Opin Biotechnol. (2024) 87:103115. doi: 10.1016/j.copbio.2024.103115

90. Vocaturo E, Rani G, Dhaka VS, Zumpano E. AI-driven agriculture: opportunities and challenges. In: 2023 IEEE International Conference on Big Data, BigData 2023. Institute of Electrical and Electronics Engineers Inc (2023), p. 3530–7. Available online at: www.scopus.com/inward/record.uri?eid=2-s2.0-85184978597&doi=10.1109%2fBigData59044.2023.10386314&partnerID=40&md5=3567894e655deaedc43c6731ad7968fb (accessed March 1, 2025).

91. Sachithra V, Subhashini LDCS. How artificial intelligence uses to achieve the agriculture sustainability: systematic review. Artif Intell Agric. (2023) 8:46–59. doi: 10.1016/j.aiia.2023.04.002

92. Yan Y, Feng CC, Wan MPH, Chang KTT. Multiple regression and artificial neural network for the prediction of crop pest risks. In: Lecture Notes in Business Information Processing, Vol. 233. Cham: Springer International Publishing (2015), p. 73–84. Available online at: www.scopus.com/inward/record.uri?eid=2-s2.0-84951845090&doi=10.1007%2f978-3-319-24399-3_7&partnerID=40&md5=1a2dc55f4c4015aec48e759ae22b8f78 (accessed March 1, 2025).

93. Goktas P. Ethics, transparency, and explainability in generative AI decision-making systems: a comprehensive bibliometric study. J Decis Syst. (2024). doi: 10.1080/12460125.2024.2410042

94. Chavan Y, Paul K, Kolekar N. Food Safety and Hygiene: Current Policies, Quality Standards, and Scope of Artificial Intelligence. (2024), p. 319–31. Available online at: www.scopus.com/inward/record.uri?eid=2-s2.0-85191480669&doi=10.1007%2f978-3-031-51647-4_26&partnerID=40&md5=e307b7c8aeaa261290d4feb67209dc36 (accessed March 1, 2025).

95. Atasoy ZBK, Avery A, Goktas P. Artificial intelligence-powered nutrition strategies: a focus on vulnerable populations. Kompass Nutr Diet. (2024) 4:49–52. doi: 10.1159/000538139

96. Atasoy ZBK, Avcı E, Beydoğan R, Ozdemir E, Goktas P. In: Göç C, editor. Artificial Intelligence and Nutrition. Istanbul: Efeakademi Yayınlar (2023). doi: 10.59617/efepub202367

97. Karanth S, Benefo EO, Patra D, Pradhan AK. Importance of artificial intelligence in evaluating climate change and food safety risk. J Agric Food Res. (2023) 11:100485. doi: 10.1016/j.jafr.2022.100485

98. Jacobs N, Brewer S, Craigon PJ, Frey J, Gutierrez A, Kanza S, et al. Considering the ethical implications of digital collaboration in the food sector. Patterns. (2021) 2:100335. doi: 10.1016/j.patter.2021.100335

99. WHO. Ethics and Governance of Artificial Intelligence for Health. (2021). Available online at: www.who.int/publications/i/item/9789240029200 (accessed March 1, 2025).

100. Friedlander A, Zoellner C. Artificial intelligence opportunities to improve food safety at retail. Food Protect Trends. (2020) 40:272–8.

101. Jäggi CJ. Nutrition, Food Markets and Agriculture: Economic Issues Against the Background of Globalization. Meggen: Springer Fachmedien Wiesbaden (2021). doi: 10.1007/978-3-658-34672-0

102. Tsakiridis NL, Diamantopoulos T, Symeonidis AL, Theocharis JB, Iossifides A, Chatzimisios P, et al. Versatile internet of things for agriculture: an eXplainable AI approach. In: IFIP Advances in Information and Communication Technology, Vol. 584. Cham: Springer (2020), p. 180–191. Available online at: www.scopus.com/inward/record.uri?eid=2-s2.0-85086181553&doi=10.1007%2f978-3-030-49186-4_16&partnerID=40&md5=62df3a310d4be25bb7caddf927de2ab3 (accessed March 1, 2025).

103. Qureshi S. Why data matters for development? Exploring data justice, micro-entrepreneurship, mobile money and financial inclusion. Inf Technol Dev. (2020) 26:201–13. doi: 10.1080/02681102.2020.1736820

104. Villalobos JR, Soto-Silva WE, González-Araya MC, González-Ramirez RG. Research directions in technology development to support real-time decisions of fresh produce logistics: a review and research agenda. Comput Electron Agric. (2019) 167:105092. doi: 10.1016/j.compag.2019.105092

105. Mondejar ME, Avtar R, Diaz HLB, Dubey RK, Esteban J, Gmez-Morales A, et al. Digitalization to achieve sustainable development goals: steps towards a smart green planet. Sci Total Environ. (2021) 794:148539. doi: 10.1016/j.scitotenv.2021.148539