- 1College of Food Science and Engineering, Xinjiang Institute of Technology, Aksu, Xinjiang Province, China

- 2College of Food Science and Engineering, Tarim University, Alar, Xinjiang Province, China

- 3School of Food Science and Technology, Shihezi University, Shihezi, Xinjiang Province, China

High hydrostatic pressure (HHP) treatment is an effective technique for processing heat-sensitive fruits and causes changes in volatile compounds and their precursors while maintaining quality. We investigated the changes and correlations of volatile compounds, related enzyme activities and precursor amino acids, and fatty acids in Hami melon juice under 350–500 MPa pressure. The application of HHP treatment resulted in a considerable reduction of esters and a substantial increase in aldehydes and alcohols in C6 and C9. Activities of lipoxygenase (LOX), alcohol acyltransferase (AAT), and phospholipase A2 (PLA2) were lower than those of the untreated group, alcohol dehydrogenase (ADH) activity was reversed. When compared to fresh cantaloupe juice, there was an increase in both the types and contents of amino acids with lower total fatty acid contents than the control group. Positive correlations were observed among six ester-related substances and eight alcohol-related substances. Additionally, the correlations between volatile compounds and fatty acids were more substantial compared to those between volatile compounds and amino acids. HHP treatment increases Hami melon flavor precursors and is an effective way to maintain the aroma volatile compounds and flavor of Hami melon juice.

1. Introduction

Hami melon (Cucumis melo L. var. reticulatus naud.) is a characteristic fruit of Xinjiang Uygur Autonomous Region, a melon with a thick skin, oval shape, reticulated rind, sweet taste and pleasant aroma. In addition, the unique geographical environment facilitates photosynthesis of the fruit during the day, reduces respiratory consumption, and deposits more nutrients at night, such as long daylight hours and a DIF (diurnal temperature difference) of about 15°C, which is particularly suitable for cultivation and development of Hami melon (1). As a special agricultural product of Xinjiang, the annual production of this melon is about 2.34 million tons, but it is rather intolerant to storage and transportation. In addition, it is a heat-sensitive fruit that causes severe flavor losses during thermal processing, such as a 20% reduction in total esters and a large reduction in the content of C6 and C9 alcohols and aldehydes after heat treatment (2), so it is important to find an innovative food process to preserve its nutritional and unique flavor.

High hydrostatic pressure (HHP) is a non-thermal processing technology that uses water as a medium to treat raw materials under ultrahigh pressure (100–1,000 MPa) at room temperature or under mild conditions, raw materials treated in this way can effectively avoid the loss of nutrients and retain their freshness, flavor and color (1). HHP can be able to destroy cellular tissue, inactivate microorganisms, in fruit and vegetable processing is mainly used to sterilize (3), improve the extraction rate of bioactive substances (4) and passivation of enzyme activity (5). Furthermore, HHP treatment can be carried out at room temperature, which reduces the heating and cooling of the required energy consumption, and not in direct contact with the processing equipment, avoiding the occurrence of secondary contamination after pasteurization, and can achieve the recycling of pressure transfer media, it also has the advantages of lower energy consumption and pollution, is a relatively environmentally friendly processing technology (6). Mild heating is another way to improve the efficiency of high pressure enzyme inactivation, study have shown that a better degree of microbial and enzyme inactivation can be achieved at lower pressures (300–500 MPa) combined with mild heating (40–70°C) treatment. Moreover, the retention and activation of enzymes by high pressure also contribute to improving the texture of processed fruit and vegetable products, creating new structures that are different from those achieved by thermal processing (7), this was demonstrated in our previous study, in which Hami melon juice treated at 45°C significantly controlled the level of microbial and some enzyme activities by combining HHP treatment with different temperatures (25–55°C), while maintaining the original good quality (8). The changes in aroma components and catalytic reactions of flavor enzymes when fruit and vegetable juices are treated under ultrahigh pressure inevitably have their characteristics and patterns (9, 10). On the one hand, the form and structure of aroma components in fruit and vegetable juices treated by ultrahigh pressure underwent different degrees of change (11, 12). On the other hand, flavor enzymes in fruit and vegetable juices treated with HHP are partially inactivated or activated, further influencing the composition and content of the catalyst (13). The effect of residual enzyme activity on the actual fruit system during or after HHP may be a contributing factor (14).

Some compounds of the aliphatic series or aromatic groups, including esters, alcohols, acids, and aldehydes, are products or intermediates in the metabolism of amino acids, are usually found in animals and plants in the form of protein structures, bound to other macromolecules or free amino acids. Differences in food system processing and storage conditions, such as temperature, time, pressure, and substrate, will result in different changes in amino acid and protein structures (15). Fatty acids are precursors of many flavor substances and play a key role in the flavor changes of fruits. Fatty acids mainly produce some branched chain fatty alcohols, aldehydes, ketones and esters during their metabolism. The fresh odor in fruits and vegetables comes from C6 and C9 aldehydes and alcohols, which are converted from fatty acids to hydroperoxides by LOX and then converted to the corresponding aldehydes and alcohols by oxidation, dissociation and dehydrogenation to form esters, among others (16).

To assess the alterations in the aroma substances of Hami juice following HHP treatment, we researched the correlation between the juice’s aroma compounds, precursors (fatty acids and amino acids), and associated changes in enzyme activity. Four different pressures were employed to treat Hami melon juice. The study analyzed the changes in aroma precursors, the enzymes involved in relevant metabolic pathways and the volatile compounds. Furthermore, the correlation between the four substances throughout the metabolic process was explored using correlation analysis. This provides a theoretical basis for the effect of HHP treatment on the flavor substances of Hami melon juice.

2. Materials and methods

2.1. Preparations of melon samples and melon juice

Nine boxes of Hami melons were selected at random from “Fruit and Vegetable Wholesale Market” in Shihezi City. These late-maturing melons were grown in Jiashi County, Xinjiang province, and were fully mature, with no visible lesions or rot. The soluble solid content of melons was approximately 12% with a pH range of 5.6 to 5.8. The melons were then placed in pre-sterilized cold storage at 4°C, to keep them fresh for later use. Hami melon juice was processed using a HHP machine (HHP.L.2–600/0.6, Huatai Senmiao Biotechnology Co., Tianjin, China).

2.2. High hydrostatic pressure treatment

Using water as the pressure transmission medium, four pressure gradients were set, 350, 400, 450 and 500 MPa, the temperature and pressure were kept at 45°C and 15 min, and the sub-packed Hami melon juice was put into the autoclave after the temperature of the ultrahigh pressure sterilizer was raised to 45°C by hot water circulation, then its water level was adjusted, and the pressure was set for 15 min, then the pressurization started, and after completion release the pressure automatically. Put the processed samples into the refrigerator at 4°C and stand for no more than 4 h from placement to measurement.

2.3. Extraction of volatiles compounds and analysis of GC–MS

After HHP processing, volatiles were extracted from juice by HS-SPME, by using SPME (Supelco, Inc.) after preprocessing polydimethylsiloxane (PDMS) fiber at 250°C for 30 min. Eight mL juice was transferred quickly to a headspace bottle (15 mL) containing 2.1 g NaCl, the juice was equilibrated through magnetic heating plate (HMS-901D, Bdjk Biotechnology Co., Ltd.) at 40°C for 10 min. The volatile components in the headspace were extracted at 40°C for 30 min by a stable flex PDMS fiber placed at 1 cm away from the liquid surface under 100 rpm/min magnetic stirring.

GC–MS analysis was performed by GC–MS (HP 7890/5975, Agilent Technologies) equipped with DB-5 (5% cross-linked phenylmethyl silicone) column (30 m × 0.25 mm i.d. × 0.25 μm, Agilent Technologies). The fiber was inserted into the sample hole and desorbed at 250°C for 1 min and run for 30 min. The fiber head is held for 5 min to remove impurities in the sample hole, injected in splitless mode. The carrier gas (He, 99.999%) is added for 1 min and the flow rate was set to 40 cm/s. The initial temperature of the GC is maintained at 50°C for 1 min, then raised to 100°C (5°C/min), then raised to 250°C (10°C/min) and maintained for 9 min. The carrier gas was Helium (1.2 mL/min) with splitless injection. The quadrupole mass spectrometer was utilized in 70 eV electron ionization mode, with an ion source temperature of 200°C, a quadrupole temperature of 106°C, and a continuous scan range of 33–350 m/z.

2.4. Determining method of ADH activity

The ADH crude enzyme extract was extracted with a modification of the method described by Ntsoane et al. (17), combing Hami melon juice (4 mL) and 12 mL ADH extraction solution containing 10 mL of MES buffer (100 mM, pH = 6.5), 2 mM DTT, 1% (w/v) PVPP in a centrifuge tube, then stirred well to digestion (4°C, 30 min). The solution was centrifuged (GR21G, Hitachi Koki Co., Ltd., Tokyo, Japan) for 30 min (12,000 × g, 4°C), the supernatant as crude enzyme extract stored at 4°C for use. Two-point five mL MES buffer (100 mM pH = 6.5), 0.15 mL NADH (1.6 mM), 0.15 mL acetaldehyde (80 mM) and finally 0.3 mL of crude enzyme extract were added and completely mixed. The ADH activity was determined by measuring the change in absorbance value at 340 nm (recorded every 20 s for 3 min).

2.5. Determination method of LOX activity

According to Zhang et al. (18) methodology with modifications. Briefly, The LOX assay utilized sodium linoleate as a substrate. To prepare, 60 μL linoleic acid (LA) is extracted and placed in nitrogen gas at 15°C, degassed distilled water (4 mL) was added to the LA together with Tween 20 (120 μL), then 60 μL NaOH (5 M) is added and the solution is diluted to 25 mL with distilled water. Next, a mixture of Hami melon juice (3 mL) and 3 mL of LOX extraction buffer [with 1% (w/v)TritonX-100, 1% (w/v) PVP, 0.05 M phosphate buffer at pH = 6.8] was combined and left for 30 min. The supernatant was stored at 4°C after subjecting the mixture to centrifugation (12,000 rpm/min, 4°C, 10 min). Next, enzyme extract (0.02 mL) was added into a quartz cuvette containing the reacting mixture, which consisted of sodium linoleate (0.1 mL) and 2.88 mL of borate buffer (0.05 M, pH = 6.8). The LOX activity was determined by measuring the change in absorbance value at 234 nm (recorded every 20 s for 3 min).

2.6. Determination method of ATT activity

The AAT crude enzyme extract was extracted and assayed by the Zhu et al. (19) method with modifications. Hami melon juice (8 mL), potassium phosphate solution (16 mL, 100 mM, pH = 7.5) and 2.5 g PVPP were mixed thoroughly and digested (4°C, 30 min), then centrifuged for 30 min (12,000 × g, 4°C), the supernatant as crude enzyme extract stored at 4°C for use. Two point two 5 mL potassium phosphate buffer (100 mM, pH = 7.5), 0.3 mL DTNB (10 mM), 0.03 mL MgCl2 (1 M), 0.06 mL isoamyl alcohol (20 mM), 0.06 mL acetyl coenzyme (50 mM) and finally 0.3 mL of crude enzyme extract were mixed thoroughly. The ATT activity was determined by measuring the change in absorbance value at 234 nm (recorded every 20 s for 3 min).

2.7. Determination method of PLA2 activity

Hami melon juice (3 mL) was homogenized in 5 mL of pre-cooled 0.1 M phosphate buffered saline (Na2HPO4·12H2O, NaH2PO4·2H2O). The mixture was centrifuged (12,000 × g, 4°C, 2 min). The supernatant was immediately collected as crude enzyme extract, and PLA2 activity was detected by ELISA kit (DUMABIO, Shanghai, China). During the unit time, the absorbance variation 0.001 of 1 mL of enzyme solution was defined as 1 mL of PLA2 activity.

2.8. Analysis of amino acids

Hami melon juice sample’s amino acid content was analyzed using an amino acid analyzer (L-8900, Hitachi) in accordance with the Chinese Standard (GB/T 5009.124–2016). Following hydrolysis into free amino acids using HCl, the proteins in the juice samples were derivatized with ninhydrin solution, separated on an ion-exchange column, and their spectrophotometric absorbance was measured at 440/570 nm. To determine the amino acid content (g/100 g), the retention time of each amino acid was measured and compared to the standard mixed solution.

2.9. Analysis of fatty acids

The fatty acids were determined using the third method outlined in the Chinese Standard (GB/T 5009.168–2016), the specific methodology is based on our previous research (8). For total lipid extraction, 50 mL of the juice was mixed with 10 mL of 95% ethanol. The resulting mixture was then transferred using a separatory funnel containing a 50 mL mixture of ethyl ether/petroleum ether and shaken for 5 min before being left to settle for 10 min. The extract from the ether layer was gathered in a 250 mL flask and dried using rotary evaporation, resulting in the fat extract. The fat extract was mixed with an 8 mL solution of 2% (w/v) NaOH in methanol, thereafter converting the total fatty acid into fatty acid methyl esters. The organic phase was dried using nitrogen stream, upon which 20 mL of n-heptane was added and shaken for 2 min, followed by the addition of saturated aqueous NaCl. After allowing the mixture to stand and stratify, 5 mL of the upper heptane extraction solution was transferred into a 25 mL test tube. Around 3–5 g of anhydrous sodium sulfate was added, shaken for 1 min, and left untouched for 5 min, before transferring the upper phase of the solution into the sample bottle.

Fatty acid analysis was performed using a Shimadzu GC-2010, which was equipped with a capillary column (100 m × 0.2 μm × 0.25 mm i.d). The detector and sample injector were set to temperatures of 280°C and 270°C, respectively. The heating protocol proceeded as follows: the initial temperature was set to 100°C and maintained for 13 min, then increased to 180°C (10°C/min), then held for 6 min. Subsequently, the temperature was further raised to 200°C (1°C/min) and held for a duration of 20 min. Finally, the temperature was increased to 230°C (4°C/min) and kept for a total of 10.5 min. The results of the analysis of fatty acids were presented in percentage content (percentage of certain fatty acids to total fat).

2.10. Statistical analysis

Data analysis utilized SPSS to analyze variance, Origin was adopted for charting. and all experiments were repeated three times. GC–MS Data was acquired using HP ChemStation software (Agilent Technologies) and compared to a NIST library to determine the composition. Spectral library was used initially to determine the composition, while retention times, mass spectra, actual compositions, and retention indices were used for determine most compositions, quantification of the components was achieved by adding n-heptanol as an internal standard at a certain concentration. Relative quantification was then performed using the area normalization method. Moreover, the principal component analysis used the ade4 package of R-3.5.3 language for drawing, and thermograph adopted the complex heatmap package of the R-3.5.3 language for charting. Correlation analysis made use of spearman for correlation analysis and cytoscape for visualization.1

3. Results

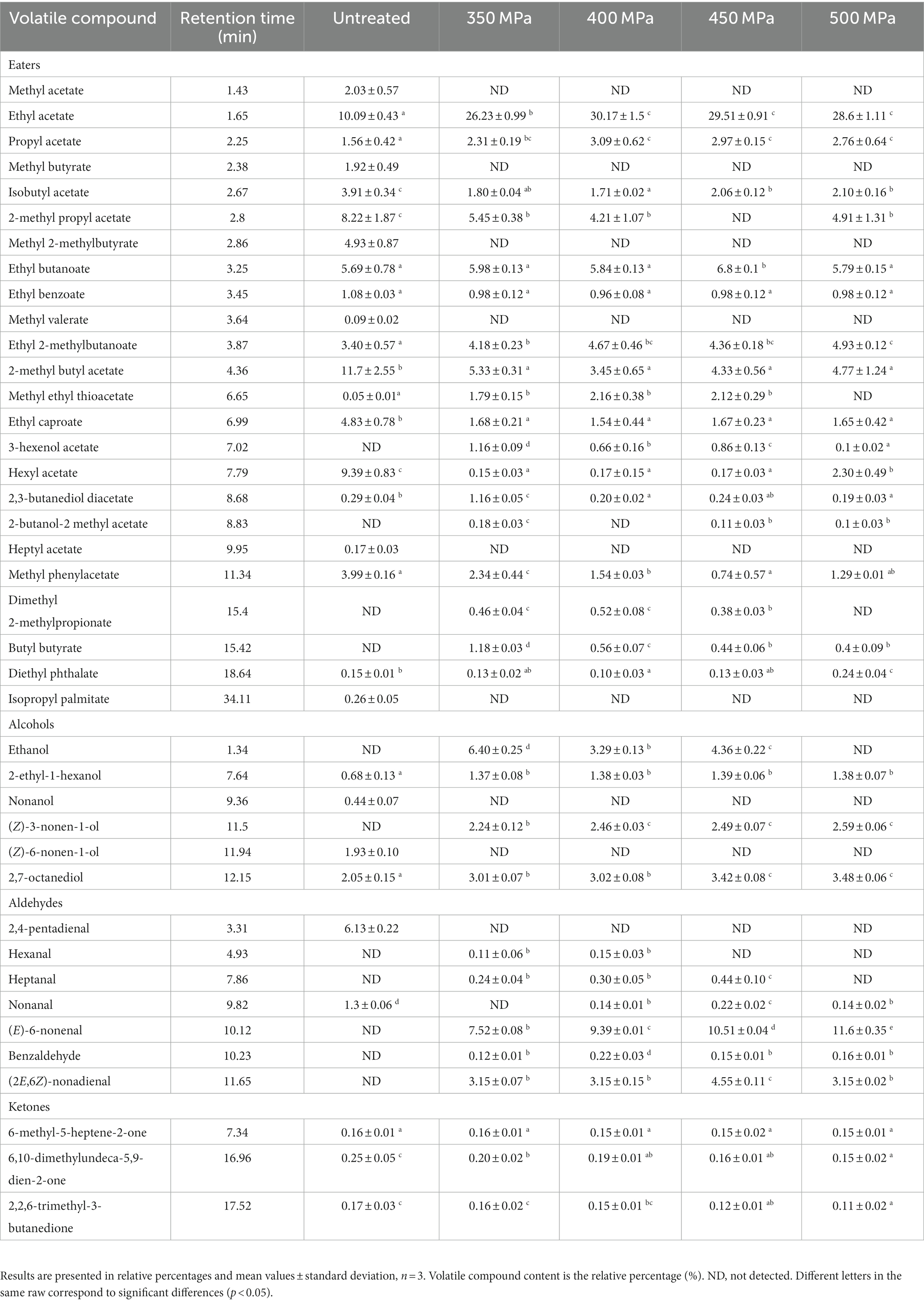

3.1. Change in aroma volatile compounds

As shown in Table 1, there were 30 compounds in the untreated group, mainly including 20 esters, 4 alcohols, 3 aldehydes and 3 ketones. There were 30, 31, 29 and 25 categories of compounds in the group from 350 to 500 MPa. The 350 MPa group contained 18 esters, 4 alcohols, 5 aldehydes, 3 ketones. The 400 MPa group contained 18 esters, 4 alcohols, 6 aldehydes, 3 ketones, the 450 MPa group contained 17 esters, 4 alcohols, 5 aldehydes, 3 ketones, the 500 MPa group contained 15 esters, 3 alcohols, 4 aldehydes, 3 ketones. Compared to the untreated group, at different pressures, the treated groups were reduced by 2 to 4 esters and their content decreased significantly. Additionally, the content of alcohols and aldehydes increased after treatment at different pressures, but the content of alcohols decreased with increasing pressure and the content of aldehydes increased significantly.

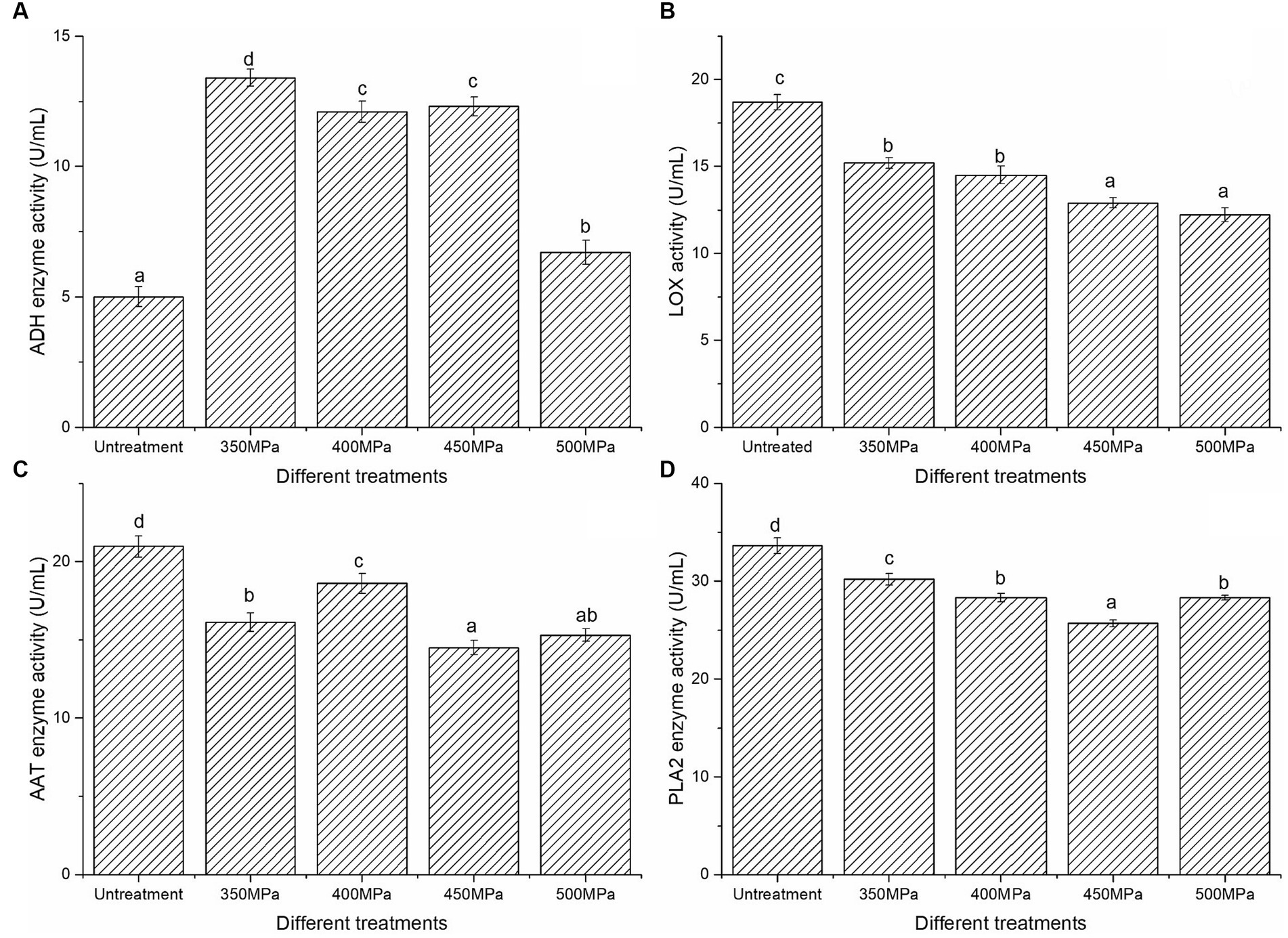

3.2. Changes in enzyme activity

The major enzymes generated by the metabolism of aromatic substances included ADH, LOX, AAT and PLA2. Compared with untreated group, all the activities of ADH (Figure 1A) increased significantly (p < 0.05) under HHP treatments, of which the activity was highest under 350 MPa (13.4 U/mL), the activity of ADH decreased with increasing pressure. The activity of LOX after HHP treatment was lower than that of the untreated group and decreased with increasing pressure (Figure 1B). The activity of ADH decreased in samples between 400 MPa and 450 MPa, while it decreased significantly in samples at 500 MPa (p < 0.05), with an activity of 6.7 U/mL. The activity of AAT after HHP treatment was much lower than in the untreated group. Furthermore, the activity of AAT (Figure 1C) was obviously different between 4 types of pressure (p < 0.05), of which the activity of AAT was highest in the 400 MPa (18.6 U/mL). In addition, the activity of PLA2 (Figure 1D) was greatly reduced (p < 0.05), and it also showed a downward trend with increasing pressure, but got some upturn at 500 MPa.

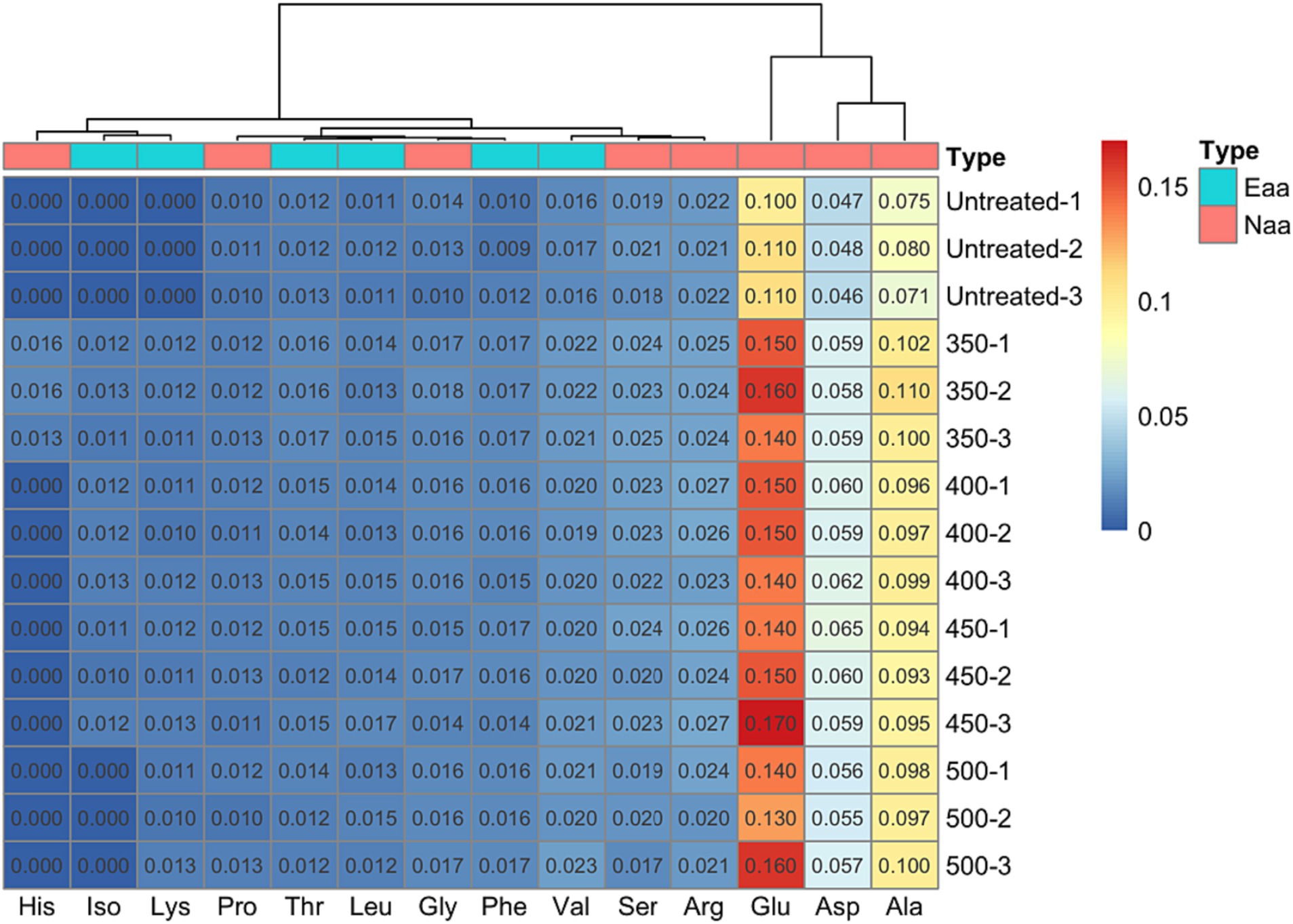

3.3. Change in amino acid contents

As shown in Figure 2, untreated Hami melon juice is rich in 11 amino acids, namely aspartic acid (Asp), threonine (Thr), serine (Ser), glutamic acid (Gly), proline (Pro), glycine (Glu), alanine (Ala), valine (Val), leucine (Leu), phenylalanine (Phe) and arginine (Arg). Among these, there are 4 essential amino acids and 7 non-essential amino acids. The number of amino acids increases with increasing pressure. 350 MPa treatment contained 14 amino acids, with increases in histidine (His), isoleucine (Iso) and lysine (Lys) compared to the untreated group. 400 MPa and 450 MPa treatments contained 13 amino acids with increases in Iso and Lys. 500 MPa treatment contained 12 amino acids, with a higher level of Lys. Across all treatments, Glu, Asp and Ala had notably higher contents when compared to other amino acids. However, the concentrations of Pro, Glu, Lys and Phe remained unchanged as pressure increased. Essential and non-essential amino acids, as well as total amino acids, experienced a marked increase in HHP treated groups. Nevertheless, there was an observed tendency toward decreasing contents with greater pressure, with the 400 and 450 MPa treatment groups demonstrating a decreasing trend, no significant differences were found between the 400 and 450 MPa treatment groups.

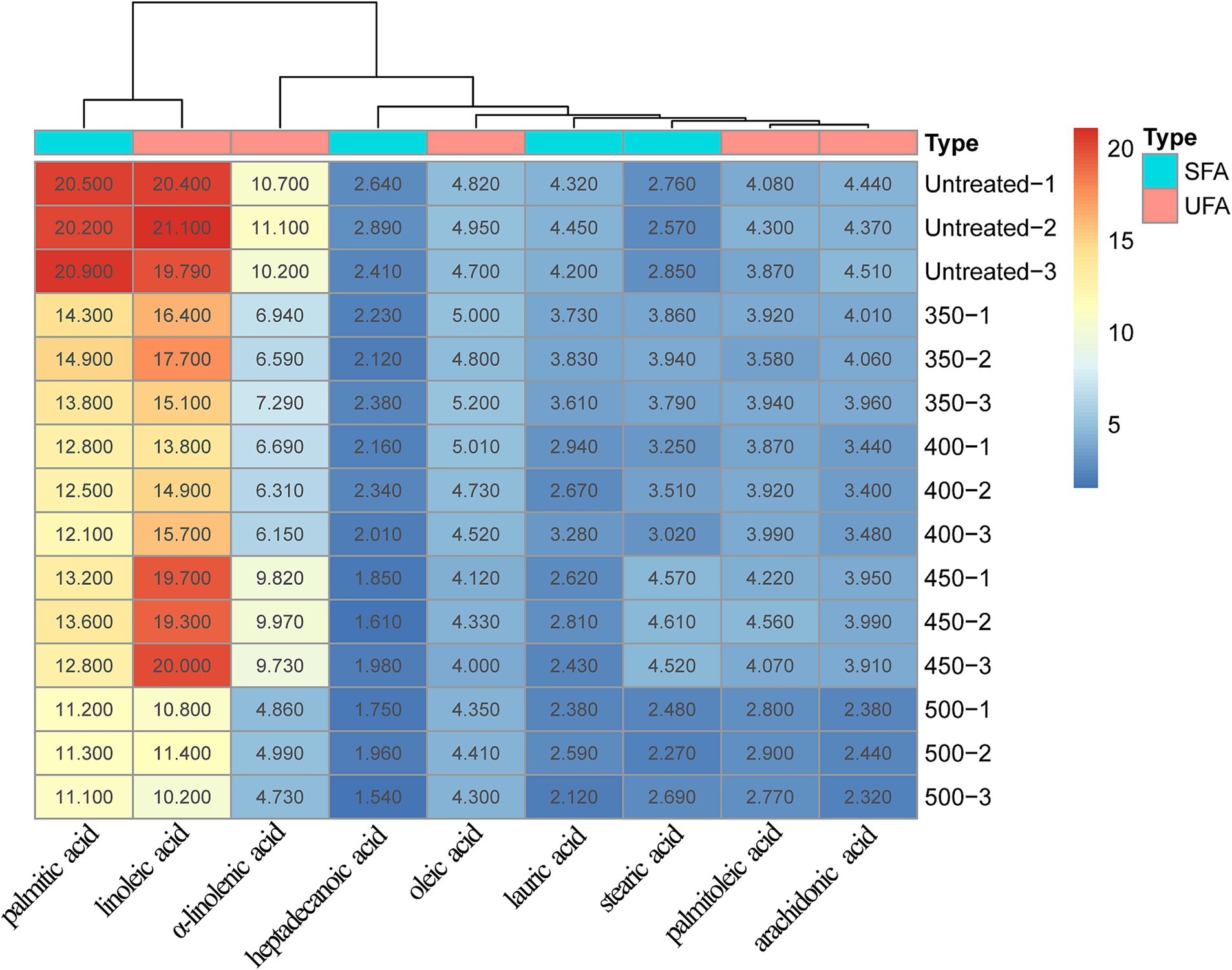

3.4. Change in fatty acids contents

Hami melon juice was analyzed for its fatty acid composition and a total of nine fatty acids were identified, comprising five unsaturated and four saturated fatty acids (Figure 3). Within the untreated group, palmitic acid and linoleic acid had the highest fatty acid content, 20.53 and 20.33% respectively, and were significantly reduced after HHP treatment (p < 0.05), heptadecanoic acid had the lowest content (2.65%), accounting for only 3.55% of the total fatty acid content. In the HHP treatment group, linoleic acid had the highest quantity followed by palmitic acid and α-linolenic acid in underwent treatment at 450 MPa. When the pressure was increased from 350 MPa to 500 MPa, the levels of palmitoleic, linoleic acid and α-linolenic acid significantly rose, with the exception of 450 MPa. Conversely, the levels of other fatty acids declined with an increase in pressure.

3.5. Correlation analysis

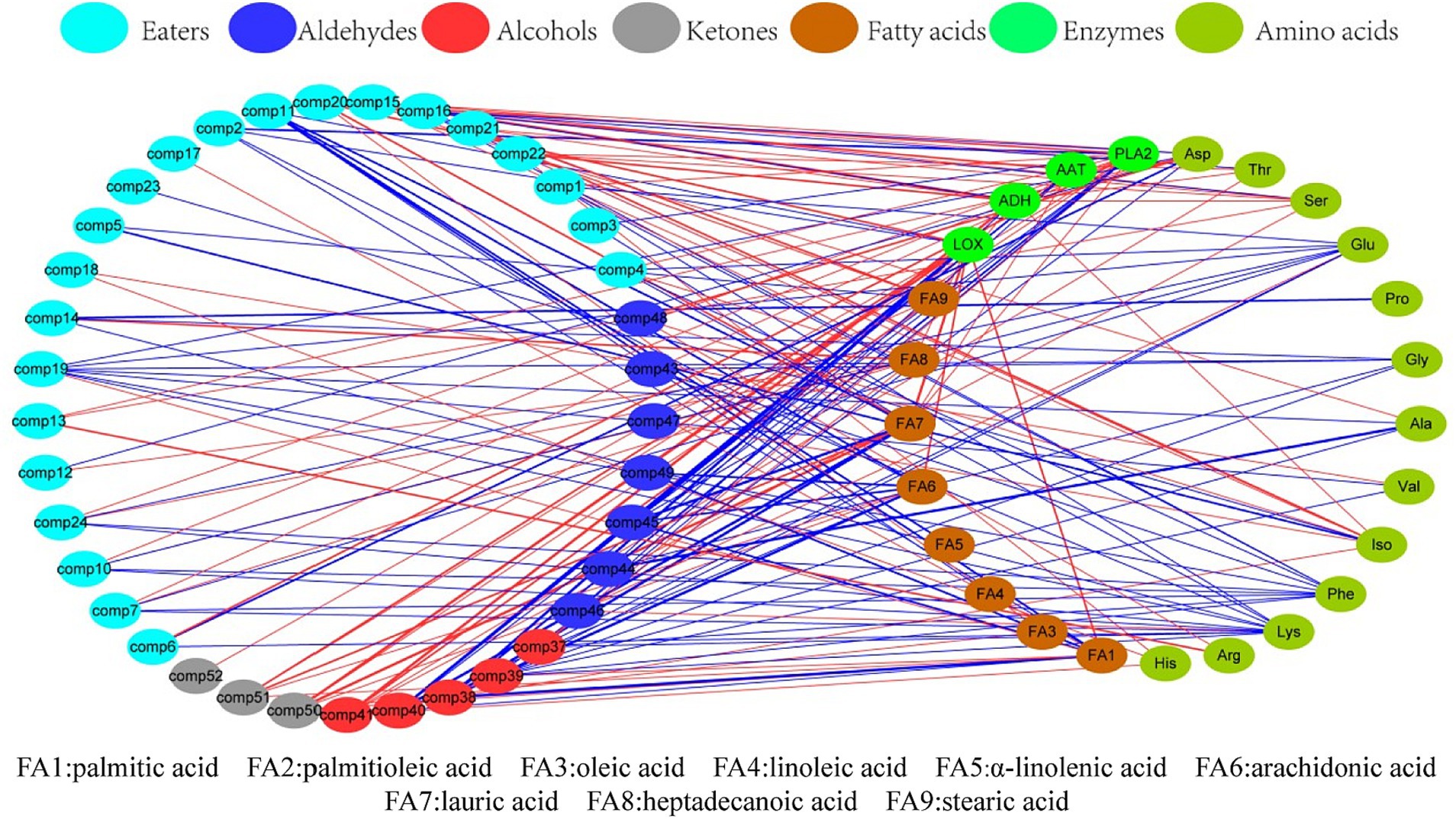

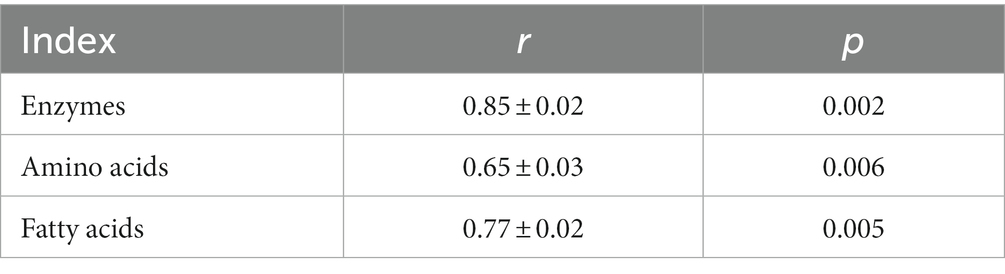

Figure 4 shows the correlation between aroma volatile compounds, amino acids, fatty acids and enzymes, with the red line indicating a positive correlation and the blue line a negative correlation. PLA2 had the most related volatile compounds (nine esters, three alcohols, two aldehydes and two ketones), of which 10 were positively and 6 negatively correlated. Lys was associated with 12 volatile compounds, 11 of which were negatively correlated while only one exhibited a positive correlation, namely 2E, 6Z-nonadienal. Palmitic acid was found to have a correlation with 11 volatile compounds, of which six showed a negative correlation, while five showed a positive correlation. Based on the analysis in the right circle, ADH displayed positive associations with Asp., Thr, and Ser, as well as with Iso and stearic acid (FA9). Meanwhile, LOX exhibited positive correlations with palmitic acid (FA1), arachidonic acid (FA6), lauric acid (FA7), and heptadecanoic acid (FA8). These findings indicate that ADH mainly relates to amino acid metabolism while LOX is primarily involved in fatty acid metabolism. In addition, there is a correlation between six substances and esters, with three showing a positive correlation (FA8, AAT, PLA2) and the remaining three displaying a negative correlation (Lys, Pro, Asp). Eight substances are associated with alcohol, all of which demonstrate a positive correlation. As for aldehydes, Leu is positively correlated with eight substances, while LOX, AAT, PLA2, FA1, FA3, FA6, and FA7 exhibit negative correlations.

Table 2 shows a ranked list of correlations between enzymes, amino acids, fatty acids and volatile compounds. The most notable correlations were observed between enzymes and volatile compounds, with a coefficient of 0.85. Fatty acids came in second with a correlation coefficient of 0.77, followed by amino acids with 0.65. The greater r value noted in fatty acids than that of amino acids suggests a more robust metabolic response to fatty acid exposure compared to amino acids, following HHP processing in Hami melon juice.

4. Discussion

In comparison with the untreated group, the number of esters in HHP treatment decreased significantly, possibly because the pressure increased the decomposition reaction of the solvent, which nucleophilically attacked the esters and promoted their hydrolysis into various acids and alcohols (20). Similar findings have been reported in previous studies, such as the research conducted by Yi et al. (21), which indicated a significant reduction in ester levels in turbid apple juice following HHP treatment. Furthermore, HHP treatment resulted in altered levels of alcohols and aldehydes in Hami melon juice at different pressures. In contrast to other studies, Liu et al. (22) found that 6Z-nonenal (3E,6Z)-nonadienol had no significant changes (p > 0.05), and (2E,6Z)-nonadienal as well as 2E-nonenal had an obvious increase, making the cucumber odor fresher, which agreed with our results. Viljanen et al. (23) investigated the effects of 800 MPa treatment on tomatoes, revealing changes in key flavor compounds such as 3Z-hexenal and 2Z-pentenal. Two reasons were given for the changes in flavor caused by HHP treatment, firstly, the content of flavor compounds may have increased after pressure was applied, resulting in increased contact between enzymes and their substrates and automatic oxidation of lipids (24). Secondly, HHP treatment is likely to impact the interaction between protein and flavor compounds (21).

The changes in LOX observed in this study were consistent with those reported in other studies, for instance, LOX in tomato juice lost more activity at higher pressures (550 MPa, 12 min/600 MPa, 10 min) according to the research of Rodrigo et al. (25), the activity of ADH was highest after ultrahigh pressure treatment, but decreased with increasing pressure. The research conducted by Denoya et al. (26) supports our conclusion regarding the ADH of two varieties of freshly cut peaches. The study determined that pressure has an impact on the activity of ADH, with a significant decrease observed when the pressure increased from 500 MPa to 700 MPa. Enzyme activity changes aligned not only with external factors such as pressure, temperature, and duration but with enzyme properties and internal factors such as substances like ethylene and tannin in fruit. Our results, similar to previous research, were substantiated by the crucial AAT that transformed alcohols to esters (10, 27). Shan et al. (28) found close links between the activity of the AAT in various melon cultivars and their aroma compounds. They showed that this activity directly impacted the production of volatile aldehydes and alcohols.

The HHP treatment process influenced the functioning of metabolic substrates such as amino acids and fatty acids, as well as enzymes related to volatile compounds, resulting in the modification of aroma substances. According to findings by Contreras et al. (29), differences in processing methods were able to alter the release of volatile compounds by affecting the correlation between factors in amino acid and fatty acid metabolism. For instance, the compounds, such as hexyl alcohol, hexyl ester, and caproic aldehyde, along with their metabolites, originated from the actions of LOX on linoleic acid. Moreover, LOX on linolenic acid predominantly resulted in the production of 3Z-hexenal and 2E-hexenal. El-Hadi et al. (30) discovered that the monomer amino acids contributing to fruit aroma metabolism primarily consisted of Val, Leu, Iso, Ala, Cys, and Phe, which are consistent with the results of our study. The association of numerous amino acids with flavor substances arose primarily due to the involvement of amino acid invertase in breaking them down, which was released during protein hydrolysis, and its activities led to the production of various volatile compounds (31, 32). Zhang et al. (33) reported that some alcohols of synthetic linear esters were also derived from LOX, which acted on aldehydes produced by fatty acids and was reduced to alcohols with the participation of ADH. In Shi et al.’s study (34), the decrease in aromatic ester showed a positive correlation with the change in ADH activity and the levels of oleic acid and linoleic acid, and a negative correlation with the activities of lipase, phospholipase D (PLD), LOX, and the rate of membrane permeability. Wang et al. (35) found that the LOX in tomatoes exerted large impacts on saturated and unsaturated C6 and C9 alcohols and aldehydes, by studying the effects of high-pressure treatment on volatile ingredients and odors in tomatoes. The literature suggests that specific enzymes and substrates can influence the aroma in metabolic processes, which supports our conclusions.

5. Conclusion

HHP treatment had an effect on the species and contents of esters, alcohols and aldehydes in the volatile compounds of juice, mainly a substantial decrease in esters and a substantial increase in aldehydes and C6 and C9 alcohols. HHP treatment decreased the activities of four vital enzymes, of which PLA2 and AAT activities were similar to LOX, and the activity of ADH was opposite to LOX. the activity of ADH was significantly increased, but decreased with the increase of pressure. The types and contents of amino acids in Hami melon juice increased, and the total amount of amino acids was also elevated, although the total amount of fatty acids decreased. By correlation analysis, there were six ester-related substances and eight alcohol-related, ketone-related and aldehyde-related substances in high pressure-treated Hami melon juice, and the correlation between fatty acids and volatile compounds was greater than the correlation between amino acids and volatile flavor compounds.

Data availability statement

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

Author contributions

LP: Methodology, Validation, Writing – original draft, Data curation, Investigation. WL: Data curation, Investigation, Writing – review & editing, Formal analysis, Validation. LJ: Conceptualization, Data curation, Writing – review & editing, Visualization. HX: Conceptualization, Data curation, Formal analysis, Writing – review & editing. LL: Data curation, Software, Visualization, Validation, Writing – review & editing. XW: Data curation, Formal analysis, Software, Writing – review & editing. ML: Software, Visualization, Writing – review & editing. BA: Investigation, Writing – review & editing, Validation. HZ: Investigation, Writing – review & editing. JC: Funding–acquisition, Methodology, Project–administration, Writing – review & editing.

Funding

The author(s) declare financial support was received for the research, authorship, and/or publication of this article. This work gained support from the National Science Foundation of China (31560461) and Xinjiang Institute of Technology project (ZT202101).

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Footnotes

References

1. Gómez-García, R, Campos, DA, Aguilar, CN, Madureira, AR, and Pintado, M. Valorization of melon fruit (Cucumis melo L.) by-products: phytochemical and biofunctional properties with emphasis on recent trends and advances. Trends Food Sci Technol. (2020) 99:507–19. doi: 10.1016/j.tifs.2020.03.033

2. Luo, D, Pan, X, Zhang, W, Bi, S, and Wu, J. Effect of glucose oxidase treatment on the aroma qualities and release of cooked off-odor components from heat-treated Hami melon juice. Food Chem. (2022) 371:131166. doi: 10.1016/j.foodchem.2021.131166

3. Li, F, Chen, G, Zhang, B, and Fu, X. Current applications and new opportunities for the thermal and non-thermal processing technologies to generate berry product or extracts with high nutraceutical contents. Food Res Int. (2017) 100:19–30. doi: 10.1016/j.foodres.2017.08.035

4. García-Parra, J, and Ramírez, R. New preservations technologies: hydrostatic high pressure processing and high pressure thermal processing. Ref Module Food Sci. (2018). 473–480. doi: 10.1016/b978-0-08-100596-5.22428-1

5. Grassino, AN, Ostojić, J, Miletić, V, Djaković, S, Bosiljkov, T, Zorić, Z, et al. Application of high hydrostatic pressure and ultrasound-assisted extractions as a novel approach for pectin and polyphenols recovery from tomato peel waste. Innov Food Sci Emerg Technol. (2020) 64:102424. doi: 10.1016/j.ifset.2020.102424

6. Zhang, S, Zheng, Z, Zheng, C, Zhao, Y, and Jiang, Z. Effect of high hydrostatic pressure on activity, thermal stability and structure of horseradish peroxidase. Food Chem. (2022) 379:132142. doi: 10.1016/j.foodchem.2022.132142

7. Huang, H, Hsu, P, and Wang, C. Healthy expectations of high hydrostatic pressure treatment in food processing industry. J Food Drug Anal. (2020) 28:1–13. doi: 10.1016/j.jfda.2019.10.002

8. Pei, L, Hou, S, Wang, L, and Chen, J. Effects of high hydrostatic pressure, dense phase carbon dioxide, and thermal processing on the quality of Hami melon juice. J Food Process Eng. (2018) 41:e12828. doi: 10.1111/jfpe.12828

9. Zhu, D, Zhang, Y, Kou, C, Xi, P, and Liu, H. Ultrasonic and other sterilization methods on nutrition and flavor of cloudy apple juice. Ultrason Sonochem. (2022) 84:105975. doi: 10.1016/j.ultsonch.2022.105975

10. Terefe, NS, Buckow, R, and Versteeg, C. Quality-related enzymes in fruit and vegetable products: effects of novel food processing technologies, part 1: high-pressure processing. Crit Rev Food Sci Nutr. (2014) 54:24–63. doi: 10.1080/10408398.2011.566946

11. Zhou, L, Bi, X, Xu, Z, Yang, Y, and Liao, X. Effects of high-pressure CO2 processing on flavor, texture, and color of foods. Crit Rev Food Sci Nutr. (2015) 55:750–68. doi: 10.1080/10408398.2012.677871

12. Yang, Y, Xia, Y, Wang, G, Tao, L, Yu, J, and Ai, L. Effects of boiling, ultra-high temperature and high hydrostatic pressure on free amino acids, flavor characteristics and sensory profiles in Chinese rice wine. Food Chem. (2019) 275:407–16. doi: 10.1016/j.foodchem.2018.09.128

13. Dars, AG, Hu, K, Liu, Q, Abbas, A, Xie, B, and Sun, Z. Effect of thermo-sonication and ultra-high pressure on the quality and phenolic profile of mango juice. Foods. (2019) 8:298. doi: 10.3390/foods8080298

14. Wang, C, Huang, H, Hsu, C, and Yang, B. Recent advances in food processing using high hydrostatic pressure technology. Crit Rev Food Sci Nutr. (2016) 56:527–40. doi: 10.1080/10408398.2012.745479

15. Zeng, X, Jiao, D, Yu, X, Chen, L, Sun, Y, Guo, A, et al. Effect of ultra-high pressure on the relationship between endogenous proteases and protein degradation of yesso scallop (Mizuhopecten yessoensis) adductor muscle during iced storage. Food Chem X. (2022) 15:100438. doi: 10.1016/j.fochx.2022.100438

16. Yue, J, Zhang, Y, Jin, Y, Deng, Y, and Zhao, Y. Impact of high hydrostatic pressure on non-volatile and volatile compounds of squid muscles. Food Chem. (2016) 194:12–9. doi: 10.1016/j.foodchem.2015.07.134

17. Ntsoane, M, Luca, A, Zude-Sasse, M, Sivakumar, D, and Mahajan, PV. Impact of low oxygen storage on quality attributes including pigments and volatile compounds in “Shelly” mango. Sci Hortic. (2019) 250:174–83. doi: 10.1016/j.scienta.2019.02.041

18. Zhang, C, Jin, Y, Liu, J, Tang, Y, Cao, S, and Qi, H. The phylogeny and expression profiles of the lipoxygenase (LOX) family genes in the melon (Cucumis melo L.) genome. Sci Hortic. (2014) 170:94–102. doi: 10.1016/j.scienta.2014.03.005

19. Zhu, Y, Rudell, DR, and Mattheis, JP. Characterization of cultivar differences in alcohol acyltransferase and 1-aminocyclopropane-1-carboxylate synthase gene expression and volatile ester emission during apple fruit maturation and ripening. Postharvest Biol Technol. (2008) 49:330–9. doi: 10.1016/j.postharvbio.2008.03.01

20. González-Cebrino, F, García-Parra, J, Contador, R, Tabla, R, and Ramírez, R. Effect of high-pressure processing and thermal treatment on quality attributes and nutritional compounds of “Songold” plum purée. J Food Sci. (2012) 77:C866–73. doi: 10.1111/j.1750-3841.2012.02799.x

21. Yi, J, Kebede, BT, Hai Dang, DN, Buvé, C, Grauwet, T, van Loey, A, et al. Quality change during high pressure processing and thermal processing of cloudy apple juice. Lebensm Wiss Technol. (2017) 75:85–92. doi: 10.1016/j.lwt.2016.08.041

22. Liu, F, Zhang, X, Zhao, L, Wang, Y, and Liao, X. Potential of high-pressure processing and high-temperature/short-time thermal processing on microbial, physico- chemical and sensory assurance of clear cucumber juice. Innov Food Sci Emerg Technol. (2016) 34:51–8. doi: 10.1016/j.ifset.2015.12.030

23. Viljanen, K, Lille, M, Heiniö, R-L, and Buchert, J. Effect of high-pressure processing on volatile composition and odor of cherry tomato purée. Food Chem. (2011) 129:1759–65. doi: 10.1016/j.foodchem.2011.06.046

24. Terefe, NS, Buckow, R, and Versteeg, C. Quality-related enzymes in plant-based products: effects of novel food-processing technologies part 3: ultrasonic processing. Crit Rev Food Sci Nutr. (2015) 55:147–58. doi: 10.1080/10408398.2011.586134

25. Rodrigo, D, Jolie, R, Loey, AV, and Hendrickx, M. Thermal and high pressure stability of tomato lipoxygenase and hydroperoxide lyase. J Food Eng. (2007) 79:423–9. doi: 10.1016/j.jfoodeng.2006.02.005

26. Denoya, GI, Vaudagna, SR, Chamorro, VC, Godoy, MF, Budde, CO, and Polenta, GA. Suitability of different varieties of peaches for producing minimally processed peaches preserved by high hydrostatic pressure and selection of process parameters. LWT-Food Sci Technol. (2017) 78:367–72. doi: 10.1016/j.lwt.2017.01.006

27. Kumar, P, Kermanshahi-Pour, A, Brar, SK, He, QS, and Rainey, JK. Influence of elevated pressure and pressurized fluids on microenvironment and activity of enzymes. Biotechnol Adv. (2023) 68:108219. doi: 10.1016/j.biotechadv.2023.108219

28. Shan, W, Zhao, C, Fan, J, Cong, H, Liang, S, and Yu, X. Antisense suppression of alcohol acetyltransferase gene in ripening melon fruit alters volatile composition. Sci Hortic. (2012) 139:96–101. doi: 10.1016/j.scienta.2012.03.010

29. Contreras, C, Tjellström, H, and Beaudry, RM. Relationships between free and esterified fatty acids and LOX-derived volatiles during ripening in apple. Postharvest Biol Technol. (2016) 112:105–13. doi: 10.1016/j.postharvbio.2015.10.00

30. El-Hadi, MA, Zhang, FJ, Wu, FF, Zhou, CH, and Tao, J. Advances in fruit aroma volatile research. Molecules. (2013) 18:8200–29. doi: 10.3390/molecules18078200

31. Bas, D, Kendirci, P, Salum, P, Govce, G, and Erbay, Z. Production of enzyme-modified cheese (EMC) with ripened white cheese flavor: I-effects of proteolytic enzymes and determination of their appropriate combination. Food Bioprod Process. (2019) 117:287–301. doi: 10.1016/j.fbp.2019.07.016

32. Espino-Díaz, M, Sepúlveda, DR, González-Aguilar, G, and Olivas, GI. Biochemistry of apple aroma: a review. Food Technol Biotechnol. (2016) 54:375–97. doi: 10.17113/ftb.54.04.16.4248

33. Zhang, L, Wang, J, Li, G, Zhou, X, Fu, WW, Jiang, YG, et al. Exogenous ATP alleviated aroma fading by regulating LOX pathway and fatty acids synthesis in “Nanguo” pears after refrigeration. Sci Hortic. (2018) 240:522–9. doi: 10.1016/j.scienta.2018.06.062

34. Shi, F, Zhou, X, Zhou, Q, Tan, Z, Yao, M, Wei, B, et al. Transcriptome analyses provide new possible mechanisms of aroma ester weakening of “Nanguo” pear after cold storage. Sci Hortic. (2018) 237:247–56. doi: 10.1016/j.scienta.2018.04.013

Keywords: Hami melon juice, high hydrostatic pressure, aroma enzymes, aroma volatile compounds, amino acids, fatty acids

Citation: Pei L, Liu W, Jiang L, Xu H, Liu L, Wang X, Liu M, Abudureheman B, Zhang H and Chen J (2023) Effect of high hydrostatic pressure on aroma volatile compounds and aroma precursors of Hami melon juice. Front. Nutr. 10:1285590. doi: 10.3389/fnut.2023.1285590

Edited by:

Peng Wang, Shaanxi Normal University, ChinaReviewed by:

Ma Lukai, Zhongkai University of Agriculture and Engineering, ChinaFilipa Mandim, Centro de Investigação de Montanha (CIMO), Portugal

Ye Liu, Beijing Technology and Business University, China

Copyright © 2023 Pei, Liu, Jiang, Xu, Liu, Wang, Liu, Abudureheman, Zhang and Chen. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Jiluan Chen, Y2hlbmppbHVhbkAxNjMuY29t

Longying Pei

Longying Pei Wei Liu2

Wei Liu2