94% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

ORIGINAL RESEARCH article

Front. Nutr. , 22 June 2023

Sec. Food Chemistry

Volume 10 - 2023 | https://doi.org/10.3389/fnut.2023.1160954

This article is part of the Research Topic Flavors and Nutrition in Beverages: Formation Mechanisms, Interactions, and Stabilizations View all 10 articles

To investigate the specific differences in flavor characteristics of Huangjiu fermented with different rice varieties, dynamic sensory evaluation, comprehensive two-dimensional gas chromatography-quadrupole mass spectrometry (GC × GC–qMS) and multivariate statistical analysis were employed. Dynamic sensory evaluation methods including temporal dominance of sensations (TDS) and temporal check all that apply (TCATA) were applied to explore the differences and variations in sensory attributes. The sensory results showed that the intensity of astringency and post-bitterness in the Huangjiu fermented with glutinous rice was weaker while ester and alcoholic aroma were more prominent than the one fermented with japonica rice. The results of free amino acids and aroma compounds analysis indicated that the amino acids were mainly sweet and bitter amino acids, and some key aroma compounds were predominant in the Huangjiu fermented with glutinous rice, such as ethyl butyrate (OAV: 38–59), 3–methylthiopropionaldehyde (OAV: 47–96), ethyl caprylate (OAV: 30–38), while nonanal, phenyl acetaldehyde and vanillin contributed significantly to the Huangjiu fermented with japonica rice. The multivariate statistical analysis further confirmed that 17 compounds (VIP > 1 and p < 0.05) could be supposed to be the key compouns that cause significant flavor differences in Huangjiu samples fermented with different brewing rice. Moreover, partial least-squares analysis revealed that most compounds (ethyl butyrate, 3-penten-2-one, isoamyl acetate, and so on) correlated with ester and alcoholic aroma. The results could provide basic data and theoretical basis for the selection of raw materials in Huangjiu.

Huangjiu (Chinese rice wine), with a strong ester aroma and taste of rich and full-bodied, is one of the oldest fermented alcoholic beverages in the world and popular among consumers in East Asia (1). It is typically fermented with unique raw materials (brewing rice, brewing water and saccharification starter). The main rice varieties used in Huangjiu are glutinous rice and japonica rice, and their differences in amylopectin, protein and fat will affect the flavor quality of Huangjiu. The flavors of different Huangjiu brewed from indica glutinous rice, japonica glutinous rice and daily rice were compared and analyzed, and found that the content of volatile flavor compounds such as ethyl esters in Huangjiu brewed from japonica glutinous rice was significantly higher than that of the other two kinds of rice (2). In addition, there were significant differences in the concentrations of sweet, bitter, fresh and astringent amino acids in Chinese rice wine brewed from different rice varieties (3). The old saying that “rice is the flesh of Shaoxing Huangjiu” intuitively further reveals the importance of brewing rice to Huangjiu.

The unique raw materials and fermentation process endowed Huangjiu in Shaoxing region with the taste characteristics of fresh, sweet, mellow, and refreshing (4). At present, the taste evaluation of Huangjiu was mainly based on descriptive sensory analysis, which focused on static judgment of the sensory attributes or intensity of the sample within a given time (5), ignoring that the perception of sensory attributes may change with the residence time in the mouth (6). Dynamic sensory evaluation techniques represented by temporal dominance of sensation (TDS) and temporal check-all-that-apply (TCATA) can clearly captured the dynamic changes of various taste attributes and simultaneously compared and analyzed multiple taste attributes. Therefore, dynamic sensory evaluation techniques have been applied in the taste evaluation of beverages and wines (7, 8). Comparative analysis on the differences in physicochemical indexes and flavor characteristics of Huangjiu brewed with different rice varieties were studied (9, 10). Descriptive analysis is the main sensory evaluation method to reveal the flavor characteristics of Huangjiu. To our knowledge, there is no research on the flavor characteristics of Huangjiu brewed with different rice using dynamic sensory evaluation method.

Alcohols, esters, acids, aldehydes and ketones are the main volatile aroma compounds of Huangjiu, which has been extensively studied by researchers using gas chromatography–mass spectrometry (11, 12). However, due to the low resolution, sensitivity and insufficient separation ability of one-dimensional GC–MS (13), the actual flavor components were more abundant than those detected. Comprehensive two-dimensional gas chromatography (GC × GC) can overcome the defects with the advantages of high selectivity and sensitivity, large peak capacity and higher recognition ability. Two-dimensional gas chromatography is widely combined with rapid scanning quadrupole mass spectrometry (qMS) and time-of-flight mass spectrometry (TOF-MS) to analyze the aroma compounds in wine (14, 15). In our previous study, GC × GC-qMS was used to analyze the aroma characteristics of Huangjiu in Shaoxing region with different vintage (16) and different brewing water (17). The conclusions of these researches showed that the coverage of aroma compounds of GC × GC-qMS was much higher than that of GC–MS. However, current research mainly applied GC–MS to compare and analyze the aroma compounds of Huangjiu brewed by different rice varieties, the identification of aroma component involving GC × GC-qMS analysis are still insufficient.

The objectives of this study are (1) to evaluate the differences in taste and aroma characteristics of Huangjiu fermented with different brewing rice by using quantitative description sensory analysis and dynamic sensory evaluation techniques (TDS and TCATA) combined with electronic tongue; (2) to reveal the molecular difference of flavor compounds among the samples by using GC × GC-qMS and high performance liquid chromatography (HPLC), respectively; and (3) to further clarify the difference of aroma characteristics by multivariate statistical analysis, and to analyze the influence of brewing rice on the flavor characteristics by analyzing the correlation between the aroma-active compounds and sensory attributes among the samples. This study would improve the understanding of the influence of the brewing rice on the flavor compounds and provide a scientific basis for the selection of rice varieties to brew high-quality Huangjiu.

Huangjiu samples in Shaoxing region (S1, S2) fermented by glutinous rice and japonica rice, respectively, were provided by Zhejiang Pagoda Brand Shaoxing Rice Wine Co., Ltd., Shaoxing City, Zhejiang Province, China. The samples were brewed using the same Jianhu water, wheat Qu (a saccharification starter) and Jiuyao (a fermentation starter) with the same ratio. And the same brewing technique including soaking and steaming rice, fermentation (primary fermentation at 28°C for 3–5 days, then secondary fermentation at medium-low temperatures for about 90 days), filtration, pressing, clarification and storage was applied. All of the samples were stored at 4°C and they were analyzed within 1 month after being transferred to the laboratory.

The regents, aspartate, leucine, lysine, proline, histidine, arginine, 2-octanol (internal standard) and n-alkane standards (C5–C30) of chromatographic grade and purity ≥98.0% were obtained from Sigma Aldrich (Shanghai, China).

The training and sensory analyzes were performed in a professional sensory laboratory at 20°C following ISO 8586-1:2012. Ten sensory panelists (5 males and 5 females, 23–27 years old) were selected from 40 candidates (20 males and 20 females, 23–30 years old) from the School of Perfume and Aroma Technology, Shanghai Institute of Technology (Shanghai, China). The taste sensory evaluation training was conducted for using the taste reference solution and Shaoxing Huangjiu samples for 4 weeks (1 h each time and 3 times a week). The panelists were specially trained to use taste description attributes and interval scale of 10 points for evaluation. During the taste sensory evaluation, Huangjiu sample (20 mL) was placed in a covered and odorless glass cup vial marked with a random three-digit code. The taste attributes included acidity (stated as the taste of citric acid aqueous solution), sweet (sucrose aqueous solution), bitter (quinine sulfate aqueous solution), astringent (alum aqueous solution), and umami (sodium glutamate aqueous solution). The intensities of the taste attributes were quantitatively determined on the interval scale of 10 points, where 0 indicated none and 9 indicated very intense. The methods and procedures of dynamic sensory evaluation including TCATA and TDS analysis were performed as described in our previous research (18).

Quantitative descriptive analysis (QDA) was similar to above taste sensory training, its methods and procedures were performed as described by our previous research (19). According to preliminary experiment discussion by the panelists, and referenced to a relevant literature (20), eight aroma attributes were selected, including sour (the aroma of acetic acid), sauce (4-ethylphenol), ester (ethyl acetate), sweet (vanillin), alcoholic (3-methylbutanol), caramel (caramel), fruit (ethyl isovalerate) and wheat (wheat qu aroma extract) aroma attributes. Prior to the formal sensory evaluation, the panelists were asked to smell each aroma attributes of standard reference sample and evaluated repeatedly according to the interval scale of 10 points. Additionally, for each one of the sensory evaluation indicated below, the sensory evaluation glasses used were ISO standard black glasses to eliminate the influence of sample color on the panelists. All sensory tests were conducted in triplicate, and a 10-min interval was maintained between each evaluation step.

The TS-5000Z electronic tongue system (Insent Inc., Atsugi-Shi, Japan) including CAO, GL1, COO, AE1, AAE and Aftertaste-B sensors was used to collect the information of sour, sweet, bitter, astringent, fresh and post-bitter of the samples at 25°C. With tartric acid/potassium chloride solution as the reference solution, the sampling time was set to 120 s with the frequency was1 time/s, and each sample was were measured in triplicate.

Qualitative and quantitative analysis of 17 free amino acids in two kinds of Huangjiu samples was carried out by referring to QB/T 4356–2012 (National Standards of China). The C18 column (250 mm × 4.6 mm, 5 μm) was purchased from Agilent Technologies. The column temperature was maintained at 40°C. mobile phase A was 20 mmol/L sodium acetate buffer containing 0.05% v/v triethylamine. Mobile phase B was 80% acetonitrile and 20% water. The gradient elution procedure was as follows: 8–100% B from 0 to 33 min, 100% B from 33 to 36 min, 100–8% B from 36 to 38 min, and 8% B from 38 to 45 min. The injection volume was set to 10 μL, and the flow rate and detection wavelength were set to 1.0 mL/min and 254 nm, respectively. The amino acids in the samples were identified by comparing their retention times with those of the amino acid standards, and the concentration of each amino acid was analyzed according to the standard working curve of each amino acid standard solution.

SAFE analysis was performed as described in our previous research (17), Huangjiu sample (60 mL), 200 μL internal standards (2-octanol, 315 μg/mL) and dichloromethane (60 mL) were placed in 250 mL conical flask, and extracted for 60 min at 250 r/min (20°C) in a shaker (ME104E, Mettler Toledo Instruments Co., Ltd., Shanghai, China). The extract was collected into a centrifuge tube (50 mL), and centrifuged at 4°C for 5 min (8,000 r/min) to collect the organic phase. The procedures of extraction were duplicated three times. The collected extract (about 180 mL) was combined, dried by nhydrous sodium sulfate and separated by SAFE apparatus (Glasbläserei Bahr, Manching, Germany). Liquid nitrogen was added to the cold trap and the turbine pump was turned on. When the required pressure (approximately 3 × 10−3 Pa) was reached, the sample was slowly and evenly controlled to drop into the distillation bottle. After extraction, the extract was dried and collected by rotary evaporation. Finally, the SAFE distillate was blown to 1 mL with nitrogen and stored at −20°C.

The parameters and procedures for GC × GC-qMS (Shimadzu Co., Kyoto, Japan) analysis was described in our previous study (20, 21). An Agilent (Santa Clara, CA) HP-Innowax (60 m × 0.25 mm × 0.25 μm) and a Restek (Philadelphia, United States) BPX-1 (2 m × 0.1 mm × 0.1 μm) were used as column 1 and column 2, respectively. The column flow rate was 0.95 mL/min and split ratio was 20:1. The conditions were as follows: the oven temperature was held at 40°C and held for 5 min, then increased at 3°C/min to 150°C, finally increased at 4°C/min to 230°C. The temperature of column 2 was set to 5°C higher than that of column 1. And the modulation period was set to 8 s. The electron ionization energy was set to 70 eV, the ion source temperature was set at 200°C with high scanning frequency (20,000 Hz), and the total ion currents were recorded from m/z of 20 to 350. The analyzes were conducted in triplicate.

The volatile compounds were comprehensively characterized by GC-Image software (GC-Image LLC, Lincoln, NE), retention index and NIST 2014 (NIST, Gaithersburg-MD, United States) database and peak library matching factor. And the retention index was calculated based on C5-C30 alkane standards (Sigma-Aldrich, St. Louis, MO, United States).

The contribution of a certain compound to the aroma characteristics of the samples was evaluated by its OAV (ratio of the mass concentration and the odor threshold value) (17). The odor threshold values were taken from available information in the compilation (22) and based on water or ethanol solution matrix. The characteristic aroma compounds in the samples were screened according to OAV > 1.

Sensory data were analyzed by Duncan’s multiple range tests using SPSS Statistics 21 (SPSS Inc., Chicago, United States). Heat map was generated by using the pheatmap package of the R program. The multivariate analyzes were performed by SIMCA-PTM14.1 (UMetrics AB, Umea, Sweden) software.

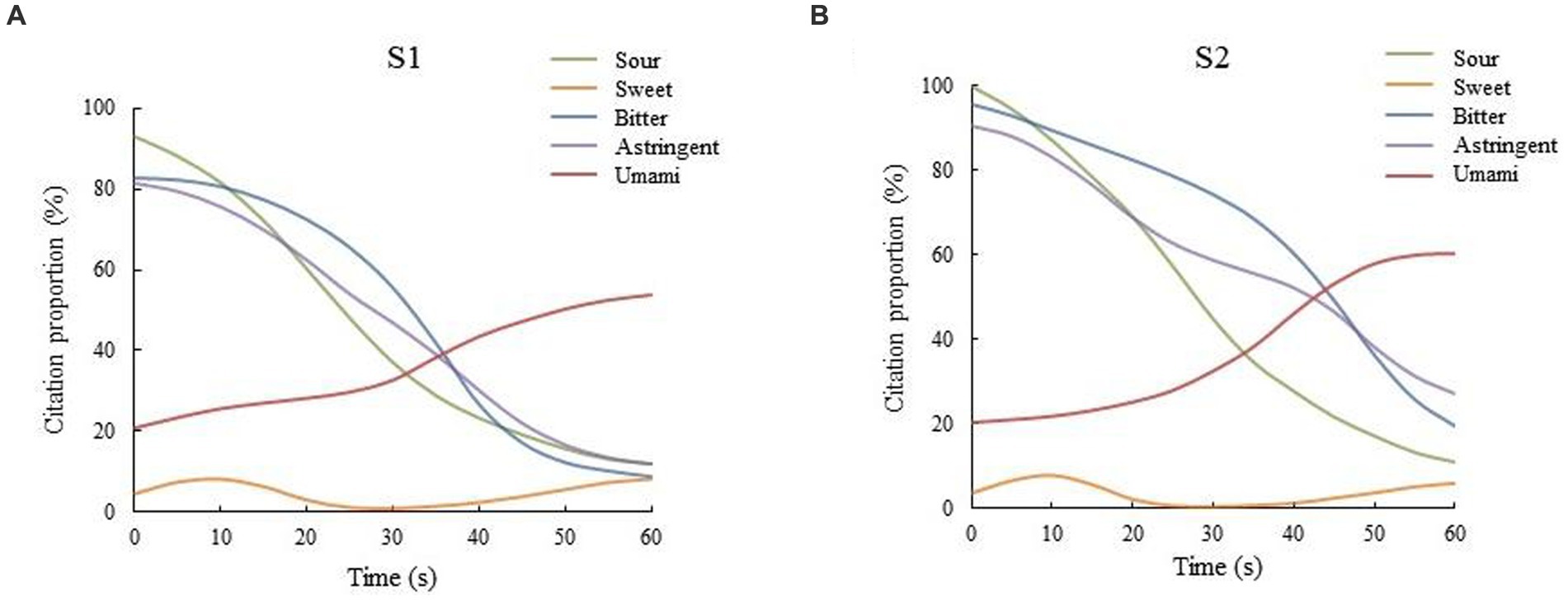

In the process of drinking, the taste attributes were not static, and the dynamic changes of tastes will also affect the judgment on the taste quality of Huangjiu. Therefore, the taste properties of Huangjiu samples fermented with different brewing rice were analyzed by dynamic sensory evaluation methods including TCATA and TDS. By collecting the citation proportion of each taste attribute of the samples within 60s, the TCATA test can intuitively reflect the dynamic changes of taste attributes of the samples with time during drinking. As shown in Figure 1, the variation trends of the taste attributes of Huangjiu samples fermented with different brewing rice were basically similar. Among them, the taste attributes of Huangjiu samples fermented with glutinous rice and japonica rice that were noted more than 50% of the time were mainly sour, bitter and astringent at the early stage, and sweet and umami in the late stage. The citation proportion of sour, bitter and astringent tastes in two kinds of Huangjiu samples gradually decreased after drinking, while the umami taste was the opposite, which may be related to the fact that the sauce flavor in Huangjiu was transformed into post-nose taste after being drunk in the mouth, thus gradually enhancing the perception of umami taste of the panelists (23). Complex oral processing can also enhance the umami taste in the middle and late stages of digestion (24). On the whole, the citation proportion of taste attributes of the Huangjiu fermented with japonica rice was slightly higher than that of the Huangjiu fermented with glutinous rice, and the taste characteristic was relatively richer. However, the taste of the former was more sour and bitter, and the citation proportion of bitter at the end of the 60s test was 19.5%, which was also significantly higher than that of S1 sample (8.9%).

Figure 1. TCATA curves of the taste of the two types of Huangjiu samples fermented with different rice varieties (A,B represent the Huangjiu fermented with glutinous rice and japonica rice, respectively).

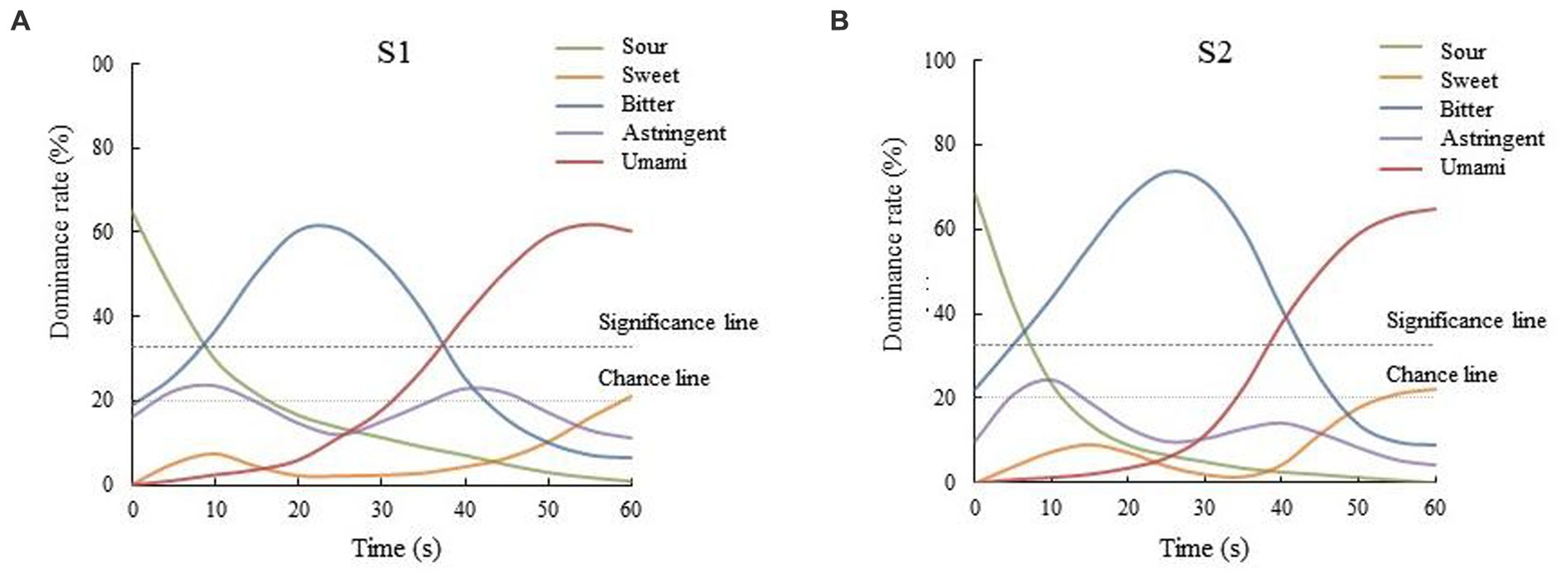

Compared with TCATA, a sensory analysis method that is close to consumer testing (25), the TDS method can better reflect the influence of some dominant taste attributes on sensory attributes during drinking. The dominance rates of taste attributes of two types of Huangjiu samples within 60s after drinking were collected to clarify the changes of dominant taste attributes. The TDS analysis results among the Huangjiu samples are shown in Figure 2. The taste attributes of the two types of Huangjiu samples had similar dynamic trends that the order of sour, bitter and umami was maintained. At the beginning of the test (0 s), the sour taste dominated in the two types of Huangjiu samples. In the first 20s, with the decrease of the dominant rate of sour taste over time, the dominance of bitter taste gradually increased, which may be related to the symmetrical inhibition of sour and bitter. After 20s of the TDS test, the dominant rates of sour and bitter tastes among the samples gradually decreased, while umami taste broke through the chance level and significance level, and then occupied the dominant taste attribute. The curve above the line of chance level indicated that taste attributes can be accidentally perceived, and the significance level revealed that the cut-off above, the probability of taste attributes being selected was significantly greater than chance (26). The above feature was not only consistent with the taste characteristics of umami taste in the late stage, but also related to the inhibition of umami taste on sour and bitter taste (27). In general, although the variation trends of the taste attributes during drinking among the samples were basically similar, the bitter taste maintained shorter time and lower dominance rate in the overall drinking process of Huangjiu fermented with glutinous rice, indicating that the bitterness of Huangjiu fermented with glutinous rice was lighter and easier to dissipate than that of Huangjiu fermented with japonica rice, and the overall palatability was higher than that of the latter.

Figure 2. TDS curves of the taste of the two types of Huangjiu samples fermented with different rice varieties (A and B represent the Huangjiu fermented with glutinous rice and japonica rice, respectively).

To further analyze the taste of Huangjiu samples and test the results of TCATA and TDS, the taste of two types of Huangjiu fermented by different brewing rice was evaluated by intelligent sensory electronic tongue technology. The taste evaluation of Huangjiu samples was shown in Table 1. The response values of astringency and post-bitterness taste of S1 sample were weaker than those of S2 sample (p < 0.05), but there were no difference in other taste attributes. Additionally, the response value of umami taste was slightly better than the latter, which was consistent with the above dynamic sensory test results. The combination of artificial sensory evaluation and electronic tongue was conducive to fully characterize the taste evaluation of Huangjiu.

Huangjiu contained a large amount of amino acids, which endowed Huangjiu with a rich taste level such as delicious, soft and mellow. The concentrations of free amino acids determined by high performance liquid chromatography (HPLC) in two kinds of Huangjiu samples are shown in Table 2. The total content of free amino acids in Huangjiu fermented with japonica rice (S2) was slightly higher than that in Huangjiu fermented with glutinous rice (S1), which was related to the higher protein content in japonica rice. The concentrations of free amino acids imparting sweet, bitter, umami, astringent and sour tastes were significantly different among the samples. The contents of aspartic acid and glutamic acid in S1 sample were higher, which played an important contribution to the umami and mellow taste. In addition, bitter amino acids were found to account for more than 40% of the total amino acids in the Huangjiu samples (40.2–43.9%), which was consistent with that of Liang et al. (28). Among them, the concentrations of histidine and leucine with bitter taste in S2 sample were higher than those of S1 sample, while isoleucine, phenylalanine and arginine were lower than the latter. Arginine imparted little bitter tastes, and bitterness was enhanced at high concentrations.

The umami and sweet taste of tea soup had a positive correlation, while the umami and bitter taste negatively correlated (29). The same taste interaction may also exist in Huangjiu, where the umami taste provided by glutamic acid and aspartic acid may enhance the perception of sweet taste and weaken the perception of bitter taste. Therefore, the perception of sweet taste in S1 sample was stronger than that of S2 sample, while the bitterness perception was weaker. The contents of sour and astringent amino acids in Huangjiu samples fermented with glutinous rice were significantly lower (p < 0.05), which was consistent with the results of electronic tongue and artificial sensory tests on the whole.

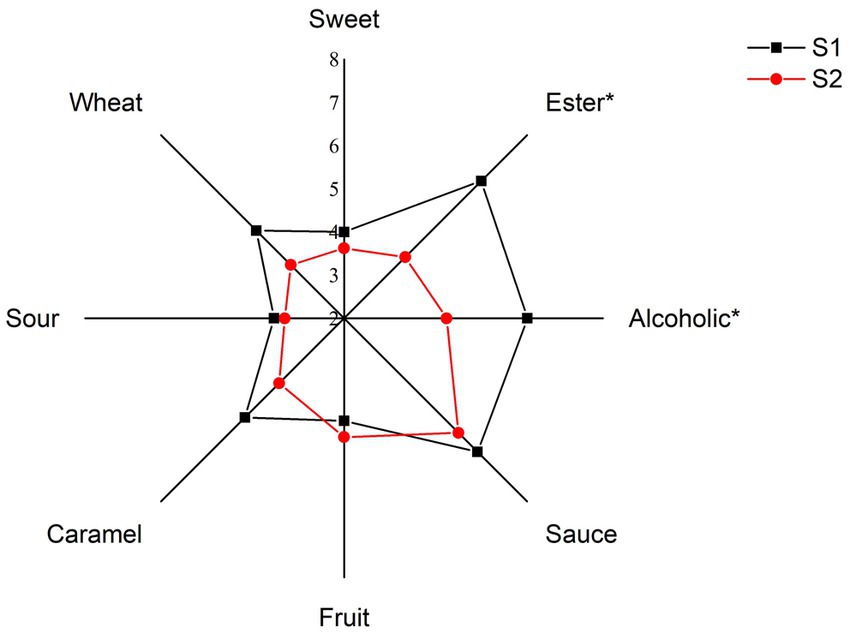

To determine the aroma difference among the samples fermented with different brewing rice, quantitative descriptive analysis was analyzed and the results were shown in Figure 3. Ester, alcoholic, sauce and fruit aroma were the representative aroma in the two kinds of Huangjiu. Statistical analysis showed that the attributes of ester and alcoholic aroma in S1 sample were significantly higher (p < 0.05). Additionally, the scores of sweet, sauce, caramel and sour aroma were abundant, while there was no significant difference between these aroma attributes, which was consistent with the research of Chen et al. (19). The results of sensory evaluation indicated that Huangjiu fermented with glutinous rice was more prominent in ester and alcoholic aroma, and had better aroma quality.

Figure 3. Quantitative descriptive sensory radar chart of Huangjiu fermented with different different rice varieties (*represents p < 0.05, S1 and S2 correspond to the Huangjiu samples fermented by glutinous rice and japonica rice, respectively).

The volatile characteristics of Huangjiu fermented with different brewing rice were systematically analyzed by GC × GC-qMS. The three-dimensional chromatograms of the volatile distribution of two kinds of Huangjiu samples are shown in Figure 4. DB-INNOWAX column was used to successfully separate the volatile compounds in the first dimension, and the BPX-5 column was also successfully separated in the second dimension. The aroma components of the Huangjiu samples were analyzed and their results were listed in Supplementary Table S1. A total of 111 volatile compounds were identified, of which 101 and 99 were identified in S1 sample and S2 sample, respectively, which consisted of 32 esters, 20 alcohols, 12 aldehydes, 19 acids, 9 ketones, 5 phenols, 1 ether, 6 amines, 1 epoxide and 6 other compounds. Although the composition of volatile compounds in the two samples was basically similar, there were obvious differences in the concentrations of specific compounds.

Figure 4. Three dimensional chromatograms of volatile components of Huangjiu fermented with (A) glutinous rice and (B) japonica rice were determined by GC × GC/qMS.

The content of esters in the Huangjiu samples fermented with different brewing rice was abundant, and most of which were ethyl esters. Ethyl ester was mainly formed by esterification of fatty acids and ethanol (30) and endowed Huangjiu with fruity, sweet and floral aroma. Among the esters detected, monoethyl succinate, ethyl 3-hydroxybutyrate, diethyl succinate, ethyl butyrate, propyl nonolactone and ethyl caprylate were the major esters with the highest concentrations. Among them, the OAVs of ethyl butyrate (OAV: 38–59), ethyl caprylate (OAV: 30–38) and propyl nonolactone (OAV: 4–7) were all greater than 1. These three compounds had apple, banana and peach aroma, respectively, indicating they were important compounds that affected the aroma characteristics of Huangjiu. In addition, isoamyl acetate (OAV = 5) and sugar lactone (OAV = 6) with low concentrations were only indentified in S1 sample. The compound isoamyl acetate contributed to sweet and fruity aroma and was an important precursor for the formation of many aroma compounds. The compound sugar lactone was a key compound for the aroma characteristics of Huangjiu, which endowed Huangjiu with caramel aroma at low concentrations while curry aroma at high concentrations (31). This result was consistent with the scores of sweet and caramel aroma in descriptive sensory analysis. However, the compound 2-methylbutyl acetate (OAV = 14) with low concentration was only detected in S2 sample and was a characteristic aroma compound endowing Huangjiu with fruity aroma.

Alcohols were the important source of aroma in Huangjiu and were precursors of esters, which endowed Huangjiu with mellow and sweet. The concentrations of total alcohols in S1 sample (93.35–101.92 μg/g) were significantly higher than those in S2 sample (84.92–94.97 μg/g). This trend may be related to the higher content of amylopectin in glutinous rice, and the easy gelatinization of amylopectin, which promoted the conversion of sugars to alcohols during Huangjiu fermentation and thus improving the alcohol yield. Among the alcohols detected, 3-methylbutanol had the highest content, followed by phenylethanol, isobutanol, 2,3-butanediol, 3-methylthiopropanol and 1-butanol. The sum of these six alcohols accounted for 97.2–97.3% of the total alcohols among the samples. Among them, the OAVs of phenylethyl alcohol (OAV: 3–4) and 3-methylthiopropanol (1–3) were both greater than 1. The compound phenylethyl alcohol with rose and honey aromas can be synthesized by pentose phosphate or glycolytic pathway (32), and under anaerobic conditions, valine and phenylalanine can be converted into isobutanol and phenylethanol, respectively (33). The compound 3-methylthiopropanol with sweet and potato aromas may be derived from the degradation of sulfur-containing amino acids.

Aldehydes and ketones were conducive to enhancing the aroma and soft taste of Huangjiu. Most aldehydes were produced by the oxidation of higher alcohols or Maillard reaction during Huangjiu fermentation. The content of aldehydes in S1 sample was higher than that in S2 sample. The main aldehydes with high concentrations in the samples were n-hexanal, furfural and 5-methyl furfural. The concentrations of furfural and syringaldehyde with sweet taste in S1 sample were higher than that in S2 sample, while nonaldehyde, benzaldehyde and phenylacetaldehyde in S2 sample were significantly higher than that in S1 sample. Among them, the compound phenylacetaldehyde (OAV = 292) with sweet and floral aroma was only detected in S2 sample, and was an important odorant in Huangjiu (34). In S1 sample, the compound 3-hydroxy-2-butanone with sweet and creamy aroma had the highest concentration, which was the key compound for the synthesis of 2,3-butanedione and 2,3-butanediol. Additionally, 4-ethylphenol, 4-vinyl-2-methoxyphenol and guaiacol had high relative concentrations. Among them, the compound 4-ethylphenol endowed a smoky aroma (35) and was only detected in S1 sample. And the concentration of 4-vinyl-2-methoxyphenol with clove aroma in S1 sample was much higher than that in S2 sample. The abundance of acids increased the body of Huangjiu and facilitated the formation of aromatic esters. Appropriate amount of acids can also increase the sweet taste and weaken the bitterness of wine, which may be the reason why Huangjiu fermented with glutinous rice was less bitter and astringent than Huangjiu fermented with japonica rice. A total of 19 acid compounds were detected in the samples. The contents of acids in S1 sample (11.31–11.34 μg/g) were significantly higher than those in S2 sample (8.31–7.49 μg/g). This may be due to the low protein content and dispersed structure in glutinous rice (36). Among them, the concentration of butyric acid was the highest, followed by acetic acid, palmitic acid and hexanoic acid. The production of these organic acids were closely related to the raw materials in Huangjiu brewing, including the process of alcohol fermentation or aging (37).

In conclusion, the total contents of alcohols, aldehydes, acids and characteristic flavor compounds in Huangjiu sample fermented with glutinous rice were higher than those of Huangjiu sample fermented with japonica rice. The compound ethyl butyrate, isoamyl acetate, 3–methylthiopropionaldehyde and ethyl caprylate were the characteristic flavor compounds of S1 sample, while nonanal, phenyl acetaldehyde and vanillin contributed greatly to the flavor of S2 sample.

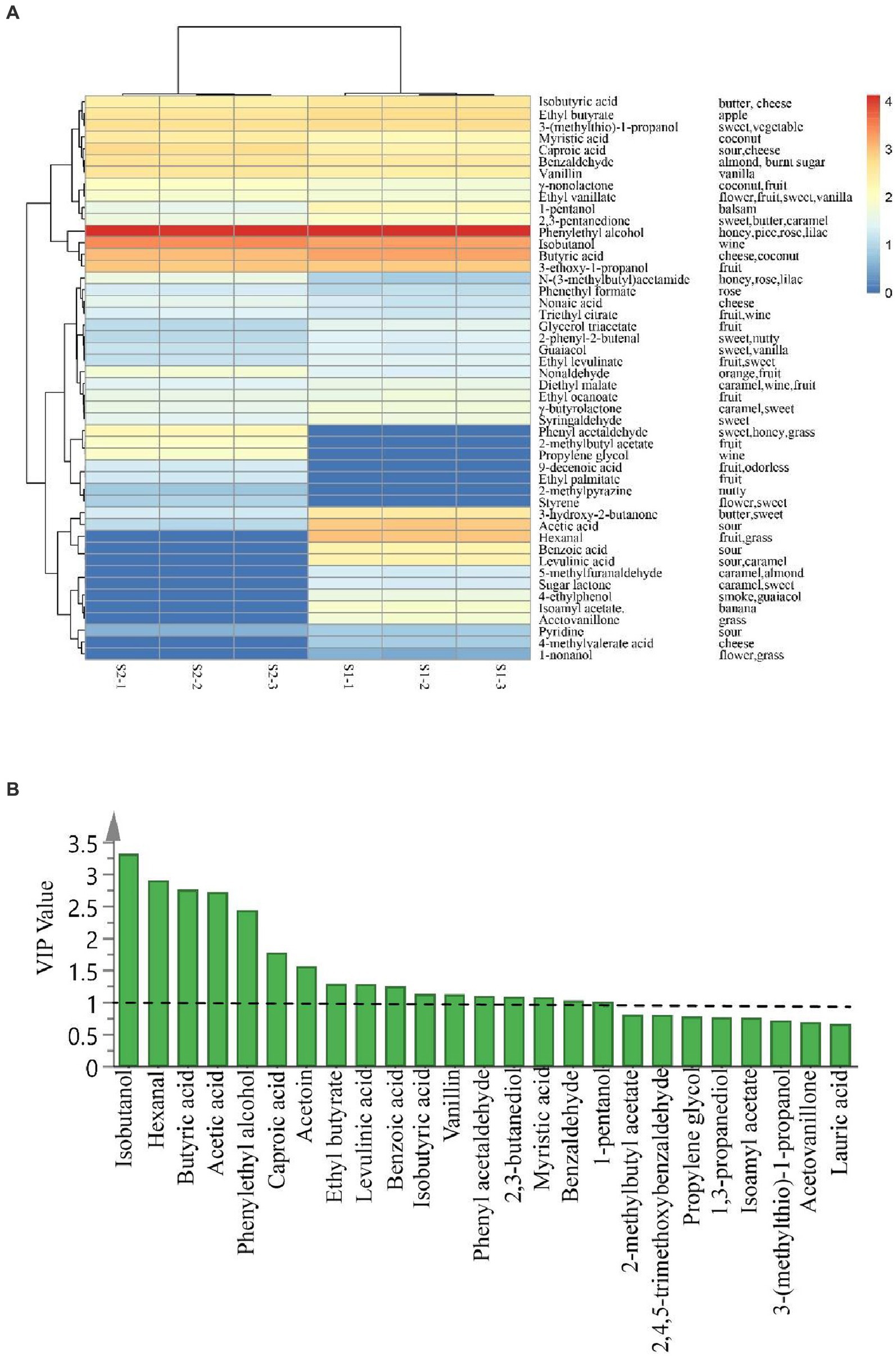

To fully explore the data of aroma compounds obtained by GC × GC-qMS, one-way ANOVA was performed on 111 identified volatile compounds. The results showed that there were significant differences in 64 compounds among the samples. Among them, 48 compounds had clear aroma descriptions, including 15 esters, 6 alcohols, 7 aldehydes, 10 acids, 2 phenols, 1 ether, 2 ketones, 4 aromatics and 1 amine compound. The correlation between the samples and the 48 important aroma compounds (p < 0.05) with aroma description was visualized by heatmap, and the results were shown in Figure 5A.

Figure 5. Heat map and HCA clustering results of 48 aroma compounds with a significant difference (p < 0.05) and aroma descriptors in Huangjiu samples (A) (S1 and S2 correspond to the Huangjiu samples fermented by glutinous rice and japonica rice, respectively); The VIP plot of the aroma compounds based on the OPLS-DA regression model (B).

The VIP values were usually used to assess the contributions of X-variables to the model, and variables with VIP > 1 were considered important variables (Figure 5B). The VIP values of 17 volatile compounds were greater than 1, including 7 acids (butyric acid, acetic acid, hexanoic acid, levulinic acid, benzoic acid, isobutyric acid and myristic acid), 4 alcohols (isobutanol, phenethyl alcohol, 2,3-butanediol and 1-pentanol), 3 aldehydes (hexanal, phenylacetaldehyde and benzaldehyde), ethyl butyrate, acetoin and vanillin. These volatile compounds could be conducive to distinguishing the Huangjiu samples fermented with different rice varieties.

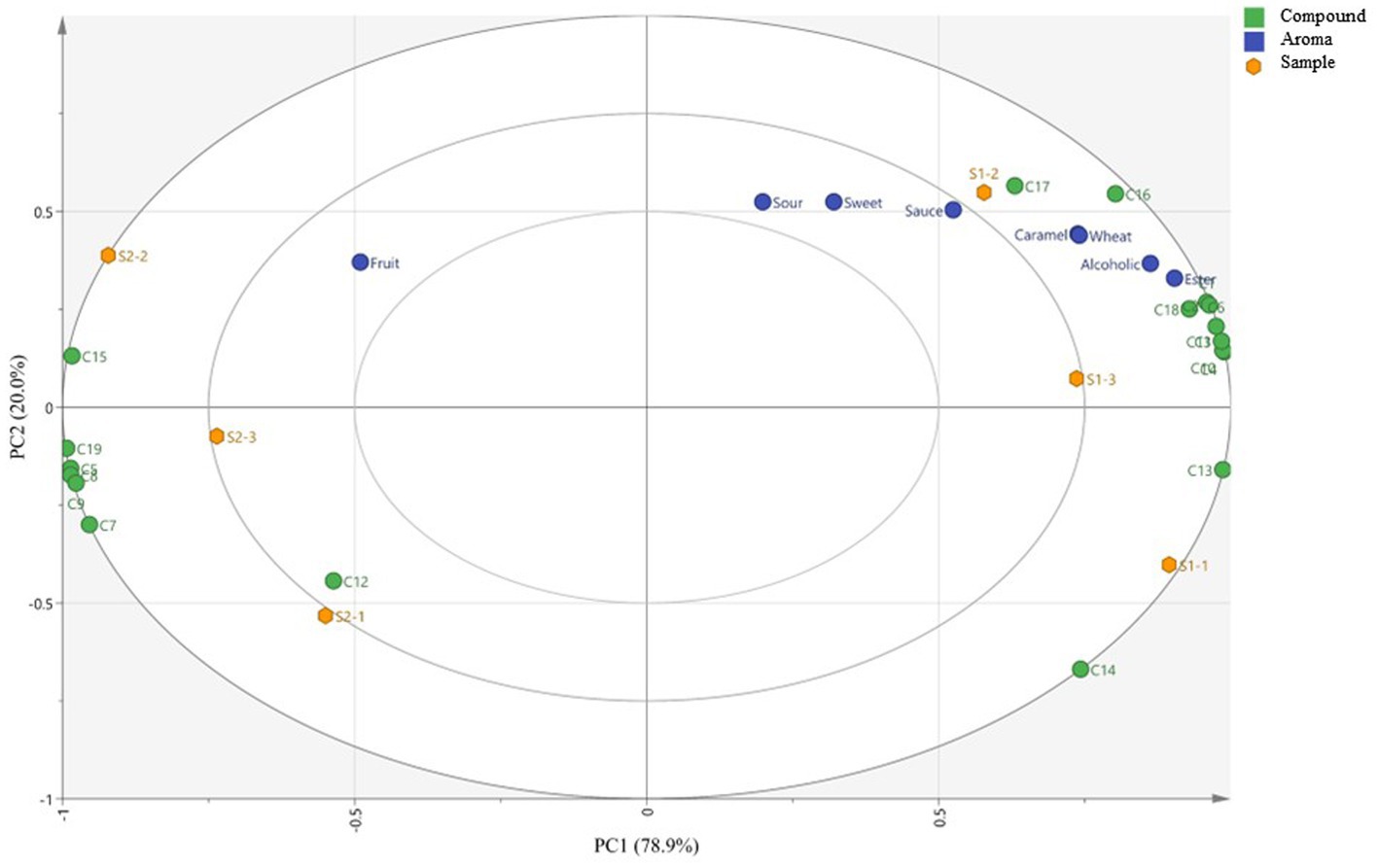

To further determine the correlation between the aroma compounds and sensory attributes, and analyze their contributions to the aroma of the Huangjiu samples fermented with different rice varieties, PLS regression was performed and the results are shown in Figure 6. The values of cumulated R2X (0.907) and R2Y (0.902) corresponding to the relationships between the explanatory variables (X, aroma-active compounds) and dependent variables (Y, intensity of the aromas of the compounds) were close to 1. And the model quality (Q2 = 0.701) was appropriate as Q2 > 0.50, indicating that the correlation between the two variables can be well represented by PLS analysis.

Figure 6. Correlation of aromas with aroma-active compounds. Yellow dots represent two Huangjiu samples. Blue dots represent 7 aroma attributes. Green dots represent the active-aroma compounds with OAV >1 shown in Supplementary Table S1 (C1: ethyl butyrate, C2: 3-penten-2-one, C3: isoamyl acetate, C4: 1-pentanol, C5: nonanal, C6: butyric acid, C7: γ-nonanolactone, C8: Phenyl acetaldehyde, C9: vanillin, C10: hexanal, C11: sugar lactone, C12: 3-ethoxy-1-propanol, C13: 3-(methylthio)-1-propanol. C14: phenylethyl alcohol, C15: ethyl hexanoate, C16: 2-octanone, C17: ethyl caprylate, C18: 3-(methylthio)propionaldehyde, C19: 2-methylbutyl acetate).

S1 sample was correlated with ‘ester’, ‘alcoholic’, ‘wheat’, ‘caramel’, ‘sauce’, ‘sweet’ and ‘sour’ aromas, while S2 sample was correlated with ‘fruit’ aroma. And the volatile compounds ethyl octanoate and 2-octanone were strongly associated with ‘sauce’, ‘caramel’, ‘wheat’ and ‘alcoholic’ aromas. The ‘ester’ and ‘alcoholic’ aromas were strongly associated with most compounds, including ethyl butyrate, 3-penten-2-one, 3-(methylthio)propanal, isoamyl acetate, and so on. Collcetively, most aroma-active compounds were correlated with ‘ester’ aroma in Huangjiu sample fermented with glutinous rice, which was consistent with the results of QDA analysis.

The effect of different rice varieties on the taste and aroma characteristics of Huangjiu was investigated using dynamic sensory evaluation, GC × GC-qMS and multivariate statistical analysis. The results revealed that the flavor characteristics and profiles of two kinds of Huangjiu had remarkable differences. Compared with Huangjiu fermented with japonica rice, the tastes of bitter and astringency in Huangjiu fermented with glutinous rice were weaker, and the ester and alcoholic aromas were more prominent. Ethyl butyrate, isoamyl acetate, 3–methylthiopropionaldehyde and ethyl caprylate contributed greatly to the flavor of Huangjiu sample fermented with glutinous rice, while nonanal, phenyl acetaldehyde and vanillin were the characteristic flavor compounds in Huangjiu sample fermented with japonica rice. Furthermore, the total contents of alcohols, acids and aldehydes were higher in the Huangjiu sample fermented with glutinous rice, and the important aroma compounds (especially key esters) were more abundant. Correlation analysis further proved that most aroma-active compounds significantly correlated with ester and alcoholic aroma in the Huangjiu sample fermented with glutinous rice. The comprehensive analysis of taste and aroma characteristics showed that the Huangjiu fermented by glutinous rice had higher flavor quality. Our results would provide a certain guiding effect on the quality control and taste improvement of Huangjiu. However, the exact factors that cause the differences in aroma and taste of the two kinds of Huangjiu are still unclear, and further research from the microbial perspective is needed.

The original contributions presented in the study are included in the article/Supplementary material, further inquiries can be directed to the corresponding author.

HY: conceptualization, methodology, formal analysis, resources, writing–original draft, and writing–review and editing. QL: methodology, formal analysis, investigation, and writing–original draft. WG: methodology and formal analysis. LA: resources and supervision. CC: resources, supervision, and project administration. HT: writing–review and editing and project administration. All authors contributed to the article and approved the submitted version.

The research was supported by the National Natural Science Foundation of China (No. 32172336) and the Capacity Project of Local Colleges and Universities of the Science and Technology Commission of Shanghai, China (No. 21010504100).

The authors would like to thank all those who contributed directly or indirectly to the project.

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

The Supplementary material for this article can be found online at: https://www.frontiersin.org/articles/10.3389/fnut.2023.1160954/full#supplementary-material

1. Jiao, A, Xu, X, and Jin, Z. Research progress on the brewing techniques of new-type rice wine. Food Chem. (2017) 215:508–15. doi: 10.1016/j.foodchem.2016.08.014

2. Ge, D, Long, X, Yang, C, Zhan, Z, and Guo, Z. Comparative study on flavor quality of rice wine made from different raw materials based on electronic nose and GC-MS. Food Res Dev. (2019) 40:137–42. doi: 10.3969/j.issn.1005-6521.2019.09.023

3. You, H, Mao, J, and Zhou, Z. Characteristics of Chinese rice wine with different varieties of rice. J Food Sci Biotech. (2019) 38:39–45. doi: 10.3969/j.issn.1673-1689.2019.03.006

4. Liu, S, Chen, Q, Zou, H, Yu, Y, Zhou, Z, Mao, J, et al. A metagenomic analysis of the relationship between microorganisms and flavor development in Shaoxing mechanized Huangjiu fermentation mashes. Int J Food Microbiol. (2019) 303:9–18. doi: 10.1016/j.ijfoodmicro.2019.05.001

5. Richter, VB, De Almeida, TCA, Prudencio, SH, and De Toledo Benassi, M. Proposing a ranking descriptive sensory method. Food Qual Prefer. (2010) 21:611–20. doi: 10.1016/j.foodqual.2010.03.011

6. Sudre, J, Pineau, N, Loret, C, and Martin, N. Comparison of methods to monitor liking of food during consumption. Food Qual Prefer. (2012) 24:179–89. doi: 10.1016/j.foodqual.2011.10.013

7. Frost, SC, Blackman, JW, Ebeler, SE, and Heymann, H. Analysis of temporal dominance of sensation data using correspondence analysis on merlot wine with differing maceration and cap management regimes. Food Qual Prefer. (2018) 64:245–52. doi: 10.1016/j.foodqual.2016.11.011

8. Ma, X, Sun, B, and Zhao, X. Application of TDS combined with TI sensory evaluation method in acid-reducing mountain wine. Food Ferment Ind. (2018) 44:231–5. doi: 10.13995/j.cnki.11-1802/ts.017417

9. Qian, M, Tang, S, Zhao, W, Huang, M, and Li, B. Effects of raw rice on fermentation and γ-aminobutyric acid production of Guangdong Hakka rice wine. Sci Tech Food Ind. (2018) 39:15–9. doi: 10.13386/j.issn1002-0306.2018.07.004

10. Shi, L, Li, A, Mou, F, and Zhang, W. Effects of different millet varieties on flavor of Chinese rice wine. China Brew. (2021) 40:54–63. doi: 10.11882/j.issn.0254-5071.2021.03.011

11. Zhao, P, Cai, J, Gu, S, Qian, B, Wang, L, Lv, F, et al. Analysis of Characteristic Flavor Substances of Traditional Shaoxing Rice Wines of Different Ages. Food Sci. (2020) 41:231–237. doi: 10.7506/spkx1002-6630-20191021-214

12. Yu, H, Xie, J, Xie, T, Chen, C, Ai, L, and Tian, H. Identification of key odorants in traditional Shaoxing-jiu and evaluation of their impacts on sensory descriptors by using sensory-directed flavor analysis approaches. J Food Meas Charact. (2021) 15:1877–88. doi: 10.1007/s11694-020-00769-7

13. Song, X, Jing, S, Zhu, L, Ma, C, Song, T, Wu, J, et al. Untargeted and targeted metabolomics strategy for the classification of strong aroma-type baijiu (liquor) according to geographical origin using comprehensive two-dimensional gas chromatography-time-of-flight mass spectrometry. Food Chem. (2020) 314:126098. doi: 10.1016/j.foodchem.2019.126098

14. He, Y, Liu, Z, Qian, M, Yu, X, Xu, Y, and Chen, S. Unraveling the chemosensory characteristics of strong-aroma type baijiu from different regions using comprehensive two-dimensional gas chromatography–time-of-flight mass spectrometry and descriptive sensory analysis. Food Chem. (2020) 331:127335. doi: 10.1016/j.foodchem.2020.127335

15. Zhou, Z, Ji, Z, Liu, S, Han, X, Zheng, F, and Mao, J. Characterization of the volatile compounds of Huangjiu using comprehensive two-dimensional gas chromatography coupled to time of flight mass spectrometry (GC×GC-TOFMS). J Food Process Preserv. (2019) 43:e14159. doi: 10.1111/jfpp.14159

16. Yu, H, Xie, T, Qian, X, Ai, L, Chen, C, and Tian, H. Characterization of the volatile profile of Chinese rice wine by comprehensive two-dimensional gas chromatography coupled to quadrupole mass spectrometry. J Sci Food Agric. (2021) 99:5444–56. doi: 10.1002/jsfa.9806

17. Yu, H, Guo, W, Ai, L, Chen, C, and Tian, H. Unraveling the difference in aroma characteristics of Huangjiu from Shaoxing region fermented with different brewing water, using descriptive sensory analysis, comprehensive two-dimensional gas chromatography–quadrupole mass spectrometry and multivariate data analysis. Food Chem. (2022) 372:131227. doi: 10.1016/j.foodchem.2021.131227

18. Yu, H, Guo, W, Xie, J, Ai, L, Chen, C, and Tian, H. Evaluation of taste characteristics of chinese rice wine by quantitative description analysis, dynamic description sensory and electronic tongue. J Food Meas Charact. (2022) 17:824–35. doi: 10.1007/s11694-022-01637-2

19. Yu, H, Xie, T, Xie, J, Ai, L, and Tian, H. Characterization of key aroma compounds in Chinese rice wine using gas chromatography-mass spectrometry and gas chromatography olfactometry. Food Chem. (2019) 293:8–14. doi: 10.1016/j.foodchem.2019.03.071

20. Chen, S, Wang, D, and Xu, Y. Characterization of odor-active compounds in sweet-type Chinese rice wine by aroma extract dilution analysis with special emphasis on sotolon. J Agric Food Chem. (2013) 61:9712–8. doi: 10.1021/jf402867m

21. Zhu, Y, Zhang, N, Jiang, S, Liu, J, and Liu, Y. The research progress on food umami perception. J Chinese Inst Food Sci. Tech. 21. (2021) 21:1–16. doi: 10.16429/j.1009-7848.2021.01.001

22. Van Gemert, L . Compilations of odour threshold values in air, water and other media. The Netherlands: Oliemans Punter and Partners (2003).

23. Jestrović, I, Coyle, JL, and Sejdić, E. Decoding human swallowing via electroencephalography: a state-of-the-art review. J Neural Eng. (2015) 12:051001. doi: 10.1088/1741-2560/12/5/051001

24. Poveromo, AR, and Hopfer, H. Temporal check-all-that-apply (TCATA) reveals matrix interaction effects on flavor perception in a model wine matrix. Foods. (2019) 8:641. doi: 10.3390/foods8120641

25. Olegario, LS, González-Mohino, A, Estevez, M, Madruga, MS, and Ventanas, S. Impact of ‘free-from’and ‘healthy choice’labeled versions of chocolate and coffee on temporal profile (multiple-intake TDS) and liking. Food Res Int. (2020) 137:109342. doi: 10.1016/j.foodres.2020.109342

26. Hartley, IE, Liem, DG, and Keast, R. Umami as an ‘alimentary’taste. A new perspective on taste classification. Nutrients. (2019) 11:182. doi: 10.3390/nu11010182

27. Liang, Z, Su, H, Lin, X, He, Z, Li, W, and Deng, D. Microbial communities and amino acids during the fermentation of Wuyi Hong Qu Huangjiu. LWT. (2020) 130:109743. doi: 10.1016/j.lwt.2020.109743

28. Wang, C, Chen, S, Wang, D, and Xu, Y. Development and validation of a quantitative method for key caramel aroma compound (sotolon) in Chinese rice wine and its contribution to the aroma of Chinese rice wine. Food Ferm. Indus. (2021) 44:246–251. doi: 10.13995/j.cnki.11-1802/ts.016909

29. Liu, P, Deng, Y, Yin, J, Chen, G, Wang, F, Yuan, H, et al. Study on quantification of green tea flavor and its correlation with chemical components. J Chin Inst Food Sci Technol. (2018) 14:173–81. doi: 10.16429/j.1009-7848.2014.12.029

30. Yu, H, Guo, W, Xie, T, Ai, L, Tian, H, and Chen, C. Aroma characteristics of traditional Huangjiu produced around winter solstice revealed by sensory evaluation, gas chromatography–mass spectrometry and gas chromatography–ion mobility spectrometry. Food Res Int. (2021) 145:110421. doi: 10.1016/j.foodres.2021.110421

31. Wang, J, Yuan, C, Gao, X, Kang, Y, Huang, M, Wu, J, et al. Characterization of key aroma compounds in Huangjiu from northern China by sensory-directed flavor analysis. Food Res Int. (2020) 134:109238. doi: 10.1016/j.foodres.2020.109238

32. Huang, X, Qian, M, Ruan, F, Li, X, and Bai, W. Research progress of alcohols in Chinese rice wine. Food Ind. (2022) 43:237–40.

33. Chen, S, Xu, Y, and Qian, MC. Comparison of the aromatic profile of traditional and modern types of Huang Jiu (Chinese rice wine) by aroma extract dilution analysis and chemical analysis. Flavour Frag J. (2018) 33:263–71. doi: 10.1002/ffj.3440

34. Fan, W, and Qian, MC. Headspace solid phase microextraction and gas chromatography–olfactometry dilution analysis of young and aged Chinese “Yanghe Daqu” liquors. J Agric Food Chem. (2005) 53:7931–8. doi: 10.1021/jf051011k

35. Mao, Q, and Yu, G. Study on the characteristics of different varieties of rice in Huangjiu production. Liquor Making. (2010) 37:70–3. doi: 10.3969/j.issn.1002-8110.2010.04.027

36. Feng, T, Hu, Z, Chen, L, Chen, D, Wang, X, Yao, L, et al. Quantitative structure-activity relationships (QSAR) of aroma compounds in different aged Huangjiu. J Food Sci. (2020) 85:3273–81. doi: 10.1111/1750-3841.15421

Keywords: Huangjiu (Chinese rice wine), rice varieties, flavor characteristics, dynamic sensory evaluation, comprehensive two-dimensional gas chromatography–mass spectrometry

Citation: Yu H, Li Q, Guo W, Ai L, Chen C and Tian H (2023) Unraveling the difference in flavor characteristics of Huangjiu fermented with different rice varieties using dynamic sensory evaluation and comprehensive two-dimensional gas chromatography–quadrupole mass spectrometry. Front. Nutr. 10:1160954. doi: 10.3389/fnut.2023.1160954

Received: 07 February 2023; Accepted: 30 May 2023;

Published: 22 June 2023.

Edited by:

Predrag Putnik, University North, CroatiaReviewed by:

Krishan K. Verma, Guangxi Academy of Agricultural Sciences, ChinaCopyright © 2023 Yu, Li, Guo, Ai, Chen and Tian. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Huaixiang Tian, dGlhbmh4QHNpdC5lZHUuY24=

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.