95% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

MINI REVIEW article

Front. Nutr. , 11 May 2022

Sec. Food Chemistry

Volume 9 - 2022 | https://doi.org/10.3389/fnut.2022.888245

This article is part of the Research Topic Physical-Chemical Interactions and Composition-Structure-Property Modifications During Processing: Food Quality, Nutrition, and Health View all 15 articles

Food processing technology is an important part of modern life globally and will undoubtedly play an increasingly significant role in future development of industry. Food quality and safety are societal concerns, and food health is one of the most important aspects of food processing. However, ensuring food quality and safety is a complex process that necessitates huge investments in labor. Currently, machine vision system based image analysis is widely used in the food industry to monitor food quality, greatly assisting researchers and industry in improving food inspection efficiency. Meanwhile, the use of deep learning in machine vision has significantly improved food identification intelligence. This paper reviews the application of machine vision in food detection from the hardware and software of machine vision systems, introduces the current state of research on various forms of machine vision, and provides an outlook on the challenges that machine vision system faces.

The food industry is becoming more competitive and dynamic, and consumers’ awareness of what they are eating is increasing (1). Consumers’ desires for diversified functions of food have gradually increased over the last few years (2). This is due to new demands not only for food’s nutritional needs but also for its health and quality (3). In order to improve the efficiency and quality of food production, efficient and advanced food processing detection methods need to be developed (4).

Food quality and safety are the foundations of food processing and human health, thus classification and inspection of food are critical in the food processing (5). Traditionally, the quality of ingredients was mainly determined by human sensory testing, which is inefficient and subjective (6). The machine vision system can capture various information of food including size and dimensions, appearance and shape, and surface color, etc. It can accurately capture the detailed information of food products, improve the accuracy of monitoring and monitor food processing with limited human errors (7). Because of the advancement of computer technology, machine vision system has been applied in industrial applications, including the food processing industry (8).

The main function of computer vision is to simulate the video and graphic information seen by human eyes and to monitor and process existing data image information, which can facilitate technicians to quickly capture sensitive detection indicators in the process of data entry, information integration, data analysis and data labeling (9). Machine vision systems usually include two parts: image information capture and image information

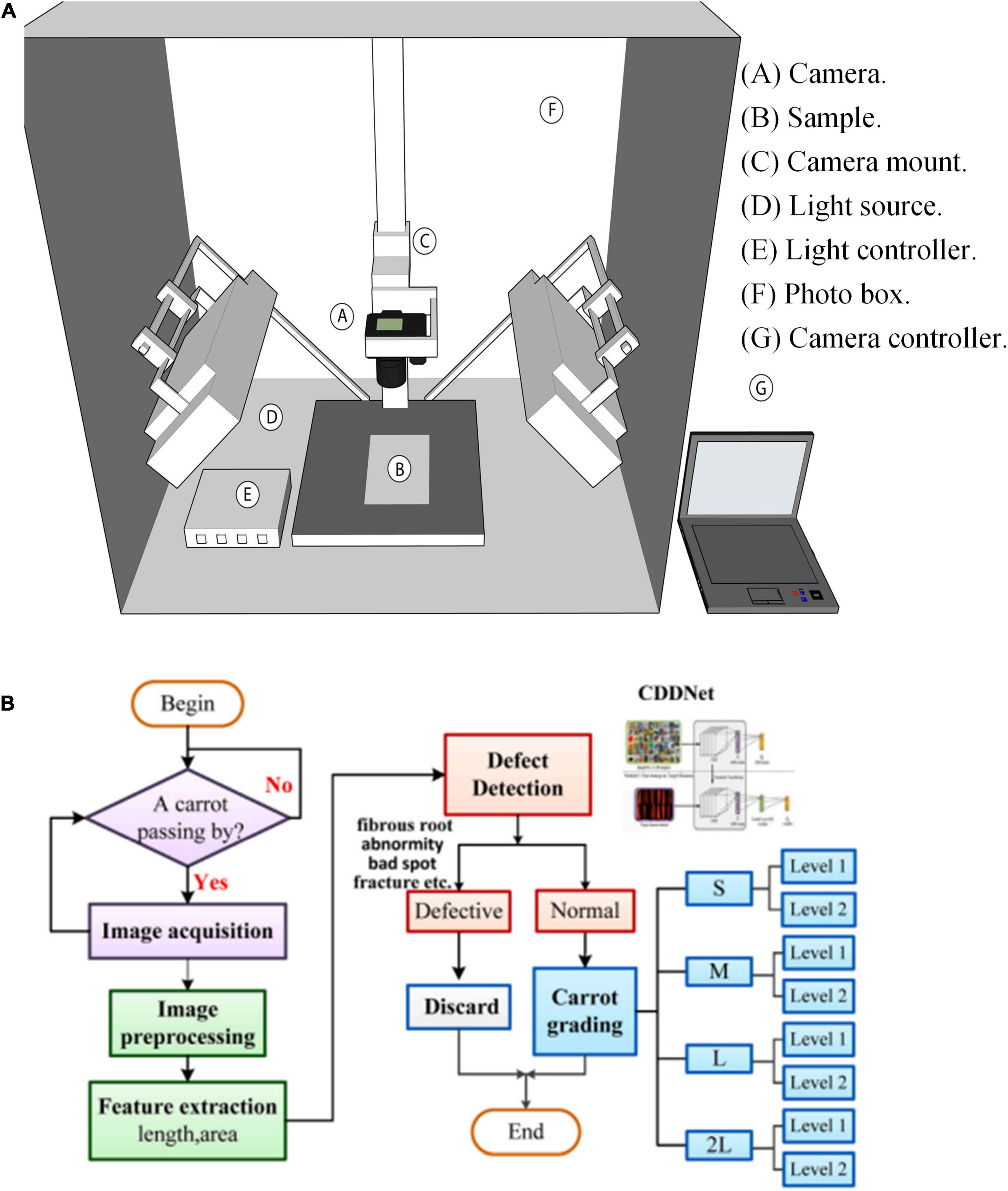

sprocessing. Image information capture is mainly through a variety of hardware devices for real-time acquisition of food image information. Information processing is through the setting of scientific operating procedures, the core stored information for secondary evaluation, to facilitate the technical staff to timely probe, receive, and understand the actual state of low level visual inspection information (10). computer technology is primarily used for food material classification and defect analysis (11). Through machine vision and deep learning, computer technology provides an accurate, efficient, and non-destructive method for detecting and grading agricultural products (12). The computer vision system and deep learning framework are shown in Figure 1.

Figure 1. Computer technology applied to food engineering, (A) Computer vision systems; (B) overall flowchart of deep learning (13).

The purpose of this review is to review the impact of computer technology on food detection and assortment, and to provide a reliable reference for further research on the intelligence and efficiency of the food industry.

Machine vision system consists of an image acquisition equipment and an image information processing system. Among them, the image acquisition equipment has a variety of acquisition forms, including X-ray, thermal imaging, remote sensing imaging, magnetic resonance imaging, and other acquisition equipment in addition to the common high definition camera (14). Image information processing is the analysis of the acquired food information, mainly extracting and identifying the acquired image information. This process of image acquisition can be seen as the acquisition of image signals and does not involve changes in the interpretation of the image content or meaning (15).

Machine vision for recognizing food information is becoming increasingly popular, such as food defect recognition and ripeness analysis (16). For food defect detection, Patel et al. (17) developed a method using monochrome cameras for automatic mango sorting, and result showed that the system’s detection efficiency and accuracy reached 97.88% and 88.75%, respectively. Noor Fatima et al. (18) used industrial cameras combined with deep learning to develop a device for tracking the adulteration of papaya seeds in black pepper. Furthermore, machine vision can identify and classify food products based on their color. Burce Atac et al. (19) proposed a method to extract average or characteristic color information from digital images of food products, and discussed specific applications for different food products. Ayustaningwarno et al. (20) used computer image analysis to quantify the color distribution of fried mangoes. To verify the efficiency of machine vision, Fitriyono Ayustaningwarno et al. (21) experimentally compared the ability of sensory testing, Hunterlab colorimeter, a commercial machine vision system (IRIS-Alphasoft), and the custom-made machine vision system (Canon) techniques to discriminate among nine vacuum-fried fruit samples.

With the increasingly widespread use of machine vision, it becomes increasingly common to use stereo systems to collect depth information about the environment for object recognition and environmental modeling. To increase the accuracy and authenticity of image information collection, 3D stereo cameras are used in food inspection (22). Stereo camera prototypes are used to capture pairs of images for estimating the size of target foods (23). Su et al. (24) used a depth camera based on machine vision technique to successfully assess the sample quality in 3D space of potatoes. Sepehr Makhsous et al. (25) stated that 3D detection system can monitor food volume for accurate monitoring of diabetic patients’ dietary intake. Yao et al. (26) proposed a potato volume measurement method based on RGB-D camera to achieve automatic monitoring of potato volume. The prediction errors were found to be 9% for regular potatoes and 30% for irregular potatoes through experiments.

Due to the diversity and complexity of the food industrial identification objectives, high definition camera has a number of problems in its application (27). Firstly, high definition camera requires high working conditions and cannot handle image information with high noise and low brightness. In addition, when the quality characteristics are mainly determined by the inherent properties of the sample (composition and internal physical properties), computer vision techniques appear less effective because they are not easily detected from the surface. Furthermore, high definition cameras has limitations in recognizing defects with high color similarity. To improve the recognition ability of machine vision, some corresponding acquisition devices have been developed for the application in food inspection.

Due to the development and maturity of imaging spectroscopy technology, hyperspectral imaging sensors are used for the accurate detection of food appearance (28). Xi et al. (29) investigated the effect of different peel colors on soluble solids content using hyperspectral imaging and developed a prediction model for soluble solids content. To improve identification efficiency, Li et al. (17) developed an improved watershed segmentation algorithm with morphological gradient reconstruction and marker extraction, which is different from the traditional segmentation algorithm, and applied it to analyze multispectral images. The test results showed that the recognition accuracy of the algorithm was found to be 100%. Zhang et al. (30) developed a multispectral image classification algorithm for the detection of common citrus defects based on visible-NIR hyperspectral imaging technology, and successfully applied it to the detection of citrus defects. For internal food inspection, the information acquisition equipment can use X-ray and magnetic resonance imaging. X-ray devices are used to detect foreign objects inside food by using X-rays through the food surface, and Kazuya Urazoe et al. (31) used X-rays combined with deep learning to successfully apply them to the detection of fish bones.

Magnetic resonance imaging can non-destructively detect and image the structure of food (32). Nakashima (33) developed a set of handheld magnetic resonance sensors consisting of a planar RF coil and a single-sided magnetic circuit for the measurement of the internal fat content of tuna. The temperature of food is one of the key factors affecting the quality of food, and thermal imaging can monitor and control the temperature of food at various points in the process (34). Zeng et al. (35) built a thermal imaging system for pear detection and used an improved deep learning algorithm based on a small sample dataset of thermal images to classify pears with or without bruises. For large-scale agri-food detection, remote sensing technology is used to increase agricultural yields and reduce input losses (36). Romanko and Matthew (37) assessed the effectiveness of remote sensing technology in modeling several important agrochemical parameters, noting that remote sensing technology can promote modern agriculture, improve the efficiency of agrochemical use and reduce environmental pollution. Lin et al. (38) used high resolution (6 m) multispectral satellite imagery SPOT-6 for monitoring powdery mildew in winter wheat in areas with severe disease infection and pointed out the great potential of high resolution multispectral satellite imagery data for crop disease monitoring.

In the food inspection process, image information processing and analysis is at the core of computer vision inspection. The purpose of image processing is to improve picture quality and to address defects such as picked geometric distortion, incorrect focus, picture noise, uneven illumination and camera motion. Image analysis is the process of distinguishing objects (objects to be detected) from the background and generating quantitative information that is used in the subsequent control system for decision making. The processing of image information can be divided into three levels: low level processing (image acquisition and pre-processing), mid-level processing (image segmentation and description) and high level processing (recognition and interpretation).

Computer processing can only process data in digital form, so it is necessary to transform the food information acquired by various collection devices. The relevant information acquired through hardware has certain defects due to the acquisition environment (light, humidity) as well as the equipment (device motion, transmission distance). In order to improve the recognition accuracy of machine vision, pre-processing of the information, including noise reduction, contrast adjustment, etc., is required. Among them, Che et al. (39) performed low order processing of the acquisition information and reflection calibration of the image information in order to reduce the effects of different configurations of camera quantum efficiency and hyperspectral imaging systems, thus improving the subsequent recognition accuracy. Fan et al. (40) corrected the original hyperspectral images using white and dark reference images in order to improve the recognition rate of internal bruises in blueberries, thus eliminating current-induced image noise and errors caused by non-uniform illumination.

Intermediate processing focuses on image segmentation, image representation and description. Its main purpose is to select the overall information collected to detect the object region. Image segmentation is one of the most important steps in the whole image processing technique, which can improve the accuracy and recognition efficiency of the subsequent advanced processing. Intermediate level processing has important applications in machine vision. Li et al. (41) proposed an improved watershed segmentation algorithm based on morphological filtering and morphological gradient reconstruction and marker constraints for segmenting rotten points on apples in order to achieve fast automatic recognition of whether a fruit is rotten or not. Che et al. (39) built and compared different bruise extraction models after selecting the region of interest by certain rules. The comparison revealed that the random model algorithm was more suitable than other algorithms for classifying bruises on apples. Luo et al. (42) used an improved watershed segmentation algorithm for bruise detection analysis on multispectral principal component analysis images and obtained an overall detection accuracy of 99.5%. Li et al. (43) used bi-dimensional empirical pattern decomposition for removing noise from multispectral images and further reconstructing the images. And an improved watershed segmentation method with morphological gradient reconstruction, marker extraction and image correction is proposed to segment the decayed regions in fruits using the reconstructed multispectral images.

Common techniques for evaluating food quality include deep learning techniques, statistical learning, fuzzy logic and genetic algorithms. In the last few years, deep learning methods have shown excellent computational performance in several fields, among which the field of computer vision is one of the most prominent application areas of deep learning. Among the various deep learning neural networks, convolutional neural networks have been applied to computer vision, which is particularly suitable for handling various tasks in the field of computer vision, such as image classification, object detection, and semantic segmentation. With the advancement of machine learning, especially the development of convolutional neural networks, the collected food pictures can be further processed to classify the food (44). A CNN model of image recognition is shown in Figure 2. Deep learning automatically extract the features of food shape through neural grid learning, which has the advantage of intelligent recognition compared with traditional image processing methods (45).

Researchers are currently conducting extensive studies on the applications of deep learning in food safety and quality assessment. The recognition steps of conventional deep learning are to collect a large number of required building datasets, then use the datasets to train a network model, and finally use the training model for the detection and recognition of food images (46). Xie et al. (47) used five classical CNN (Densenet-121, ResNet-50, Inception-V3, VGG-16 and VGG-19) models to identify defective carrots and found that CNN models can be an effective method to identify defective carrots through experiments. As an upgrade to machine vision systems, Deng et al. (48) used machine vision combined with deep learning to achieve automatic grading of carrots and improve the intelligence of recognition. Zhu et al. (49) proposed an improved dense capsule network model (Modified-DCNet) for carrot appearance quality detection. This modified model introduces a self-attention layer, which reduces the interference of background information on the recognition task. Moreover, the capsule layer of the modified model uses a locally constrained dynamic routing algorithm to reduce the size of the network parameters and the training load of the network. To improve the accuracy of identification, Rong et al. (50) used deep learning to detect peach varieties and established a VIS-NIR spectral database containing five peach varieties to achieve accurate identification of peach varieties. After testing, it was found that the deep learning-based model achieved the accuracy of 100% in the validation dataset and the accuracy of 94.4% in the test dataset. To improve the recognition efficiency of deep learning, Muoz et al. (51) used different deep learning networks to detect the intramuscular fat content in dry cured ham and found that CNNs can accurately identify and takes less time on the network development by comparison.

Despite its accuracy in image recognition, deep learning has some inherent disadvantages: (1) it requires a large number of food images for input training when performing grid training, (2) deep learning requires high computing performance of the computer, and (3) it takes a lot of time during training.

By summarizing the basic concepts and technologies of machine vision systems, as well as the latest developments and applications of systems in the food detection industry, the following conclusions have been drawn.

(1) The application of computer vision technology in food detection has greatly improved the efficiency of food inspection and promoted the development of food safety, which is an important part of the intelligent process of food engineering. The use of computer vision systems enables automated, objective, rapid and hygienic inspection of a wide range of raw and processed foods.

(2) Machine vision has high recognition accuracy, however, under low light, high humidity, and high noise conditions, there are corresponding detection errors. Therefore, it is necessary to develop high-resolution acquisition devices to improve the quality/accuracy of inspection.

(3) Image processing is considered to be the core of computer vision. With same acquired information, advanced processing software can improve processing efficiency and recognition accuracy. Therefore, it is significant to develop more efficient algorithms to make machine vision more suitable for food inspection.

ZX: information collection and writing. JW: figure preparation and proofreading. LH: manuscript framework and writing. SG and QC: writing. All authors contributed to the article and approved the submitted version.

This study was supported by the Young Scholars Program of Shandong University, the Undergraduate Education Teaching Reform and Research Programs of Shandong University (2021Y220), and the Shandong Provincial Natural Science Foundation (ZR2019BEE062).

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

1. Xun S, Shuai L, Zhang XY, Yang T, Grzegorz B, Joon YY, et al. Recent advances in hydrodynamic cavitation-based pretreatments of lignocellulosic biomass for valorization. Bioresour Technol. (2021) 345:126251. doi: 10.1016/j.biortech.2021.126251

2. Knorr D, Augustin MA. Food processing needs, advantages and misconceptions. Trends Food Sci Technol. (2020) 108:103–10. doi: 10.1016/j.tifs.2020.11.026

3. Li CJ, Zhu HM, Li CY, Qian H, Yao WR, Guo YH. The present situation of pesticide residues in China and their removal and transformation during food processing. Food Chem. (2021) 354:129552. doi: 10.1016/j.foodchem.2021.129552

4. Xu L, Zheng Y, Zhou C, Pan DD, Geng F, Cao JX, et al. Kinetic response of conformational variation of duck liver globular protein to ultrasonic stimulation and its impact on the binding behavior of n-alkenals. LWT. (2021) 150:111890. doi: 10.1016/j.lwt.2021.111890

5. Bei M, Domua C, Jude E, Osvat M, Dragoi AE, Mitrica B. The impact of food quality and safety on consumer perception and attitude to food choices in Romania. Opportunities under Green Deal. Glob Econ Observer. (2021) 9:156–65.

6. Pedreschi F, Mery D, Bunger A, Yanez V. Computer vision classification of potato chips by color. J Food Process Eng. (2011) 34:1714–28. doi: 10.1111/j.1745-4530.2009.00540.x

7. Zhu LL, Spachos P, Pensini E, Plataniotis KN. Deep learning and machine vision for food processing: a survey. Curr Res Food Sci. (2021) 4:233–49. doi: 10.1016/j.crfs.2021.03.009

8. Bhargava A, Bansal A, Goyal V. Machine learning - based detection and sorting of multiple vegetables and fruits. Food Anal Meth. (2021) 15:228–42. doi: 10.1007/10_2016_51

9. Bi X. Machine vision. In: X Bi editor. Environmental Perception Technology for Unmanned Systems. Singapore: Springer Singapore (2021). p. 105–41.

10. Patel KK, Kar A, Jha SN, Khan MA. Machine vision system: a tool for quality inspection of food and agricultural products. J Food Sci Technol. (2012) 49:123–41. doi: 10.1007/s13197-011-0321-4

11. Bhargava A, Bansal A. Fruits and vegetables quality evaluation using computer vision: a review. J King Saud Univ Comput Inf Sci. (2021) 33:243–57. doi: 10.1080/10408398.2013.777020

12. Zhang B, Huang W, Li J, Zhao C, Fan S, Wu J, et al. Principles, developments and applications of computer vision for external quality inspection of fruits and vegetables: a review. Food Res Int. (2014) 62:326–43. doi: 10.1016/j.foodres.2014.03.012

13. Li S, Zhang R, Lei D, Huang YQ, Cheng SY, Zhu ZZ, et al. Impact of ultrasound, microwaves and high-pressure processing on food components and their interactions. Trends Food Sci Technol. (2021) 109:1–15. doi: 10.1016/j.tifs.2021.01.017

14. Xie J, Zheng Y, Du R, Xiong WY, Cao YF, Ma ZY, et al. Deep learning-based computer vision for surveillance in ITS: evaluation of state-of-the-art methods. IEEE Trans Veh Technol. (2021) 70:3027–42. doi: 10.3390/s21227543

15. Zhang B, Gu B, Tian GZ, Zhou J, Huang JC, Xiong YJ. Challenges and solutions of optical-based nondestructive quality inspection for robotic fruit and vegetable grading systems: a technical review. Trends Food Sci Technol. (2018) 81:213–31. doi: 10.1016/j.tifs.2018.09.018

16. Gila A, Bejaoui MA, Beltrán G, Marquez AJ. Rapid method based on computer vision to determine the moisture and insoluble impurities content in virgin olive oils. Food Control. (2020) 113:107210. doi: 10.1016/j.foodcont.2020.107210

17. Li JB, Chen LP, Huang WQ. Detection of early bruises on peaches (Amygdalus persica L.) using hyperspectral imaging coupled with improved watershed segmentation algorithm. Postharvest Biol Technol. (2018) 135:104–13. doi: 10.1016/j.postharvbio.2017.09.007

18. Fatima N, Areeb QM, Khan IM, Khan MM. Siamese network-based computer vision approach to detect papaya seed adulteration in black peppercorns. J Food Process Preserv. (2021). doi: 10.1111/jfpp.16043

19. Mogol BA, Kmen V. Computer vision-based analysis of foods: a non-destructive colour measurement tool to monitor quality and safety. J Sci Food Agric. (2014) 94:1259–63. doi: 10.1002/jsfa.6500

20. Ayustaningwarno F, Ginkel EV, Vitorino J, Dekker M, Verkerk R. Nutritional and physicochemical quality of vacuum-fried mango chips is affected by ripening stage, frying temperature, and time. Front Nutr. (2020) 7:95. doi: 10.3389/fnut.2020.00095

21. Ayustaningwarno F, Fogliano V, Verkerk R, Dekker M. Surface color distribution analysis by computer vision compared to sensory testing: vacuum fried fruits as a case study. Food Res Int. (2021) 143:110230. doi: 10.1016/j.foodres.2021.110230

22. Vázquez-Arellano M, Griepentrog HW, Reiser D, Paraforos DS. 3-D imaging systems for agricultural applications—a review. Sensors. (2016) 16:618. doi: 10.3390/s16050618

23. Smith LN, Zhang W, Hansen MF, Hales LJ, Smith ML. Innovative 3D and 2D machine vision methods for analysis of plants and crops in the field. Comput Ind. (2018) 97:122–31. doi: 10.1016/j.compind.2018.02.002

24. Su Q, Naoshi K, Li M, Sun H, Firmanda A, Harshana H. Potato quality grading based on machine vision and 3D shape analysis. Comput Electron Agric. (2018) 152:261–8. doi: 10.1016/j.compag.2018.07.012

25. Makhsous S, Mohammad HM, Schenk JM, Mamishev A, Kristal AA. Novel mobile structured light system in food 3D reconstruction and volume estimation. Sensors. (2019) 19:564. doi: 10.3390/s19030564

26. Long Y, Wang YH, Zhai ZM, Wu L, Li MZ, Sun H, et al. Potato volume measurement based on RGB-D camera. IFAC-PapersOnLine. (2018) 51:515–20. doi: 10.1016/j.ifacol.2018.08.157

27. Fan S, Li J, Zhang YH, Tian X, Wang QY, He X, et al. On line detection of defective apples using computer vision system combined with deep learning methods. J Food Eng. (2020) 286:110102. doi: 10.1016/j.jfoodeng.2020.110102

28. Behmann J, Mahlein AK, Paulus S, Dupuis J, Kuhlmann H, Oerke E, et al. Generation and application of hyperspectral 3D plant models: methods and challenges. Mach Vis Appl. (2016) 27:611–24. doi: 10.1007/s00138-015-0716-8

29. Tian X, Li J, Wang Q, Fan SX. A bi-layer model for nondestructive prediction of soluble solids content in apple based on reflectance spectra and peel pigments. Food Chem. (2018) 239:1055–63. doi: 10.1016/j.foodchem.2017.07.045

30. Zhang H, Zhang S, Dong W, Wei L, Huang YF, Zhan BS, et al. Detection of common defects on mandarins by using visible and near infrared hyperspectral imaging. Infrared Phys. Technol. (2020) 108:103341. doi: 10.1016/j.infrared.2020.103341

31. Urazoe K, Kuroki N, Maenaka A, Tsutsumi H, Iwabuchi M, Fuchuya K, et al. Automated fish bone detection in X-Ray images with convolutional neural network and synthetic image generation. IEEJ Trans Electr Electron Eng. (2021) 16:1510–7. doi: 10.1002/tee.23448

32. Ebrahimnejad H, Ebrahimnejad H, Salajegheh A, Barghi H. Use of magnetic resonance imaging in food quality control: a review. J Biomed Phys Eng. (2018) 8:127–32.

33. Nakashima Y. Development of a hand-held magnetic resonance sensor for the nondestructive quantification of fat and lean meat of fresh tuna. J. Food Meas. Charact. (2020) 14:2947–55. doi: 10.1007/s11694-020-00539-5

34. Vadivambal R, Jayas DS. Thermal imaging in agriculture and food industry-a review. Food Bioprocess Technol. (2011) 4:186–99.

35. Zeng XY, Miao Y, Ubaid S, Gao XM, Zhang SL. Detection and classification of bruises of pears based on thermal images. Postharvest Biol. Technol. (2020) 161:111090. doi: 10.1016/j.postharvbio.2019.111090

36. Sishodia RP, Ray RL, Singh SK. Applications of remote sensing in precision agriculture: a review. Remote Sens. (2020) 12:3136. doi: 10.3390/rs12193136

37. Romanko M. Remote Sensing in Precision Agriculture: Monitoring Plant Chlorophyll, and Soil Ammonia, Nitrate, and Phosphate in Corn and Soybean Fields. Bowling Green, OH: Bowling Green State University (2017).

38. Yuan L, Pu R, Zhang J, Wang JH, Yang H. Using high spatial resolution satellite imagery for mapping powdery mildew at a regional scale. Precision Agric. (2016) 17:332–48. doi: 10.1007/s11119-015-9421-x

39. Che WK, Sun LJ, Zhang Q, Tan WY, Ye DD, Zhang D, et al. Pixel based bruise region extraction of apple using Vis-NIR hyperspectral imaging. Comput Electron Agric. (2018) 146:12–21. doi: 10.1016/j.compag.2018.01.013

40. Fan SX, Li CY, Huang WQ, Chen LP. Detection of blueberry internal bruising over time using NIR hyperspectral reflectance imaging with optimum wavelengths. Postharvest Biol Technol. (2017) 134:55–66. doi: 10.1016/j.postharvbio.2017.08.012

41. Li JB, Luo W, Wang Z, Fan SX. Early detection of decay on apples using hyperspectral reflectance imaging combining both principal component analysis and improved watershed segmentation method. Postharvest Biol Technol. (2019) 149:235–46. doi: 10.1016/j.postharvbio.2018.12.007

42. Luo W, Zhang H, Liu X. Hyperspectral/Multispectral reflectance imaging combining with watershed segmentation algorithm for detection of early bruises on apples with different peel colors. Food Analytical Methods. (2019) 12:1218–28. doi: 10.1007/s12161-019-01456-0

43. Li J, Zhang RY, Li JB, Wang ZL, Zhang HL, Zhan B, et al. Detection of early decayed oranges based on multispectral principal component image combining both bi-dimensional empirical mode decomposition and watershed segmentation method. Postharvest Biol Technol. (2019) 158:110986. doi: 10.1016/j.postharvbio.2019.110986

44. Sun Y, Lu R, Lu YF, Lu YZ, Pan LQ. Detection of early decay in peaches by structured-illumination reflectance imaging. Postharvest Biol. Technol. (2019) 151:68–78. doi: 10.1016/j.postharvbio.2019.01.011

45. Barrowclough OJD, Muntingh G, Nainamalai V, Stangeby I. Binary segmentation of medical images using implicit spline representations and deep learning. Comput Aided Geom Des. (2021) 85:101972. doi: 10.1016/j.cagd.2021.101972

46. Potka S, Wlodarczyk T, Szczerba R, Pokita P, Komisarek O, Matthews BA, et al. Convolutional neural networks in orthodontics: a review. arXiv [Preprint] (2021): doi: 10.48550/arXiv.2104.08886

47. Xie WJ, Wei S, Zheng ZH, Jiang Y, Yang DY. Recognition of defective carrots based on deep learning and transfer learning. Food Bioprocess Technol. (2021) 14:1–14.

48. Deng L, Li J, Han Z. Online defect detection and automatic grading of carrots using computer vision combined with deep learning methods. LWT-Food Sci. Technol. (2021) 149:111832. doi: 10.1016/j.lwt.2021.111832

49. Zhu HF, Yang LH, Sun YX, Han ZZ. Identifying carrot appearance quality by an improved dense CapNet. Trends Food Sci Technol. (2020) 44:e13586.

50. Rong D, Wang HY, Ying YB, Zhang ZY, Zhang YS. Peach variety detection using VIS-NIR spectroscopy and deep learning. Comput Electron Agric. (2020) 175:105553. doi: 10.1016/j.compag.2020.105553

Keywords: machine vision system, deep learning, food detection, food classification, food Image analysis

Citation: Xiao ZF, Wang JL, Han L, Guo SB and Cui QH (2022) Application of Machine Vision System in Food Detection. Front. Nutr. 9:888245. doi: 10.3389/fnut.2022.888245

Received: 02 March 2022; Accepted: 22 April 2022;

Published: 11 May 2022.

Edited by:

Qiang Xia, Ningbo University, ChinaReviewed by:

Yang Tao, Nanjing Agricultural University, ChinaCopyright © 2022 Xiao, Wang, Han, Guo and Cui. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Jilai Wang, amx3YW5nQHNkdS5lZHUuY24=; Lu Han, amwud2FuZ0Bjb25uZWN0LnBvbHl1Lmhr

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.