94% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

ORIGINAL RESEARCH article

Front. Mater. , 05 March 2025

Sec. Structural Materials

Volume 12 - 2025 | https://doi.org/10.3389/fmats.2025.1560181

This article is part of the Research Topic Advanced Materials and Technologies for Sustainable Development of Underground Resources View all 42 articles

Research on the dynamic mechanical properties of concrete under sulfate attack is the basis for the reasonable design and performance evaluation of anti-explosion and impact resistance in concrete structures under the erosion environment. In this study, the mechanical properties of concrete specimens subjected to sulfate attack under impact compression were measured using the split Hopkinson pressure bar (SHPB) test system. The basic mechanical properties (stress-strain curve, compressive strength, elastic modulus, peak strain) of concrete specimens subject to sulfate attack under high strain rate were obtained, and the variation laws of macroscopic failure characteristics and characteristics of energy dissipation of concrete specimens subject to sulfate attack with the loading strain rate were summarized. The results show that the compressive strength and elastic modulus of concrete specimens under different sulfate concentrations exhibit a significant strain rate effect. As the strain rate increases, the compressive strength and elastic modulus of concrete specimens gradually increase; compared with concrete free from sulfate attack, the compressive strength and elastic modulus of concrete subject to sulfate attack are more significantly influenced by strain rate. Overall, the peak strain of concrete increases with the increase of strain rate, but when the strain rate increases to a certain extent, the peak strain changes little. Under the same sulfate concentration, the macroscopic failure degree of concrete specimens increases obviously with the increase of strain rate. The dissipation energy of concrete subject to sulfate attack is more sensitive to the strain rate compared with concrete free from sulfate attack, and the increase of strain rate will obviously decrease the energy utilization rate of concrete subject to sulfate attack.

The service life of China’s coastal ports, cross-sea bridges and other large-scale concrete structures has been significantly reduced due to their long-term exposure to the harsh marine erosion environment. Durability is a very important factor for the service life of concrete structures (Verre, 2021). Among many erosion hazards, sulfate attack has become one of the primary environmental factors affecting structural durability. In the engineering project, damage caused by sulfate attack in concrete structure is extremely common.

At present, significant progress has been made in the experimental research on the mechanical properties of concrete under sulfate attack (Liang et al., 2022; Gan et al., 2021; Li, 2024; Zang et al., 2022; Cao et al., 2022). To investigate the effect of sulfate solution concentration and erosion time on the mechanical properties of concrete, Gao et al. (2010) and Feng et al. (2010) studied the influence of sulfate solution concentration and the number of wetting-drying cycles on the mechanical properties of concrete. The study obtained the attenuation laws of the elastic modulus and compressive strength of concrete, and summarized the triaxial compressive strength criterion of concrete under sulfate attack. In terms of the anti-corrosion performance of concrete with different mix proportions, Wang et al. (2020) analyzed the influence of basalt fiber content on the durability of concrete under sodium sulfate attack. The study found that the crack resistance of concrete in the early stage can be significantly improved by adding basalt fiber in an appropriate amount, and the corrosion resistance of the test block with the basalt fiber content of 0.1% was the best. Serag Faried et al. (2021) and He (2017) conducted a comparative study on the influence of different nano-materials and their dosages on the resistance of high-performance concrete to sulfate attack. Wang et al. (2021) explored the effect of polycarboxylic acid water reducer with different side chain lengths on the sulfate corrosion resistance of concrete. The findings revealed that PCE with the shortest side chain provides the most effective enhancement of sulfate corrosion resistance. Hong et al. (2018) investigated the corrosion resistance of subway concrete exposed to magnesium sulfate solution at different concentrations. It was concluded that the concrete with a water-binder ratio of 0.35 and fly ash content of 30% showed the best corrosion resistance. Regarding the influence of sulfate attack on the mechanical properties of concrete, Zhang et al. (2020) studied the influence of sulfate attack on the failure mode of concrete under the conditions of semi-immersion and full immersion. The results indicated that the failure mode of the shear surface of the corroded specimen was mainly in the form of aggregate tumbling, peeling and matrix extrusion and sliding near the shear surface under the conditions of full immersion, while under the semi-immersion, matrix cracking and dilatancy slip were dominant in the shear surface. Song et al. (2023), Wu et al. (2024), Wu et al. (2022), Wu et al. (2020) established a residual strength calculation model for concrete using ultrasonic methods, providing an economical and convenient calculation method for engineering applications.

The existing research focuses on the mechanical properties of concrete subjected to sulfate attack under static loading. However, some important civil or military protective concrete components in service are not only subject to static loading, but also bear various dynamic loads, such as vehicle load, wind load, earthquake action, wave and explosion impact. Therefore, these concrete components must have sufficient explosion resistance and seismic resistance. Some scholars have conducted preliminary research on the mechanical properties of concrete under the combined action of sulfate corrosion and impact load. Wei et al. (2023) Investigated the dynamic mechanical properties of corroded coral concrete. The results showed that Coral concrete exhibited great dynamic properties under chemical attacks and higher damping capacity under sulfate attack than that of other erosion. Demei et al. (2016) analyzed the flexural strength, relative dynamic elastic modulus under sulfate attack incorporating with dynamic flexural loading, and also analyzed the microstructure and atom ratio of attached specimens via SEM and EDS. Liu et al. (2020) analyzed the effects of erosion form and erosion age on the dynamic properties of concrete.

In summary, over the past few years, research on the mechanical properties of concrete under sulfate attack has primarily focused on static loading. Relatively few studies have addressed on the mechanical properties of concrete subjected to sulfate attack and impact loading. There is a lack of systematic research on the strain rate effect on dynamic mechanical properties of concrete under the erosion by different concentrations of sulfate. Moreover, there is currently limited research on the energy dissipation of eroded concrete under impact loads. The dynamic mechanical properties of concrete materials after sulfate erosion should be studied comprehensively.

Therefore, this paper conducts research on the mechanical properties and energy dissipation of sulfate eroded concrete under impact load, obtaining the correlation between strain rates and dynamic mechanical properties (stress-strain curve, compressive strength, elastic modulus and peak strain), as well as energy dissipation characteristics of concrete under different concentrations of sulfate attack. The research results can provide important reference for the establishment of damage evolution models and dynamic response calculations.

The concrete specimens were prepared in accordance with the relevant provisions of the Code for Construction of Concrete Structures (Ministry of Housing and Urban-Rural Development of the People’s Republic of China, 2011). The strength of concrete specimens was prepared in accordance with C60, with the continuous particle size of crushed stone ranging from 5–8 mm. The specimen preparation process was as follows: (1) According to Table 1, the coarse aggregate (stone), fine aggregate (sand) and cement were put into the mixer and mixed for about 1 min, then the water was added and mixed for 2 min, and then the water reducer was added and mixed for 1 min. (2) The mixed concrete was then placed into a cube mold with a size of 100 × 100 × 100 mm and vibrated on the vibrating table; the surface of the test piece was smoothed and placed indoors at the room temperature; after 24 h, the specimen was demoulded. (3) The demoulded specimen was then placed into the standard curing room for 28 days (see Figure 1). (4) The specimen was processed into a cylindrical specimen with a standard size of Φ 74 * 37 mm (see Figure 2), and the unevenness of the two end faces was kept within 0.02 mm to improve the test accuracy.

(1) Firstly, the sulfate erosion test was conducted on the specimens in accordance with the Test Method of Sulfate Resistance of Cement Concrete (T0582-2020) (Ministry of Transport of the People’s Republic of China, 2020). The detailed experimental steps are as follows: The Na2SO4 solutions with concentrations of 0.0%, 3.0%, 6.0% and 9.0% were prepared; The concrete specimens were placed into Na2SO4 solutions with different concentrations, and test specimens were completely immersed. Subsequently, the erosion test on concrete specimens was conducted (see Figure 3).

(2) After the erosion of 270 days, the concrete specimen was taken out and subject to uniaxial impact compression tests (see Figure 4). The basic dynamic mechanical parameters were determined by the split Hopkinson pressure bar (SHPB) testing system (with a diameter of 74 mm) in the State Key Laboratory for Geomechanics and Deep Underground Engineering of China University of Mining and Technology. The impact pressure was divided into four levels of 0.3, 0.4, 0.5 and 0.6 MPa. Each level of the impact air pressure was repeated 3–4 times, and the impact load was changed by adjusting the external air pressure.

Based on the uniaxial impact compression test data, the dynamic mechanical properties of concrete specimens subjected to sulfate erosion were obtained under different strain rates.

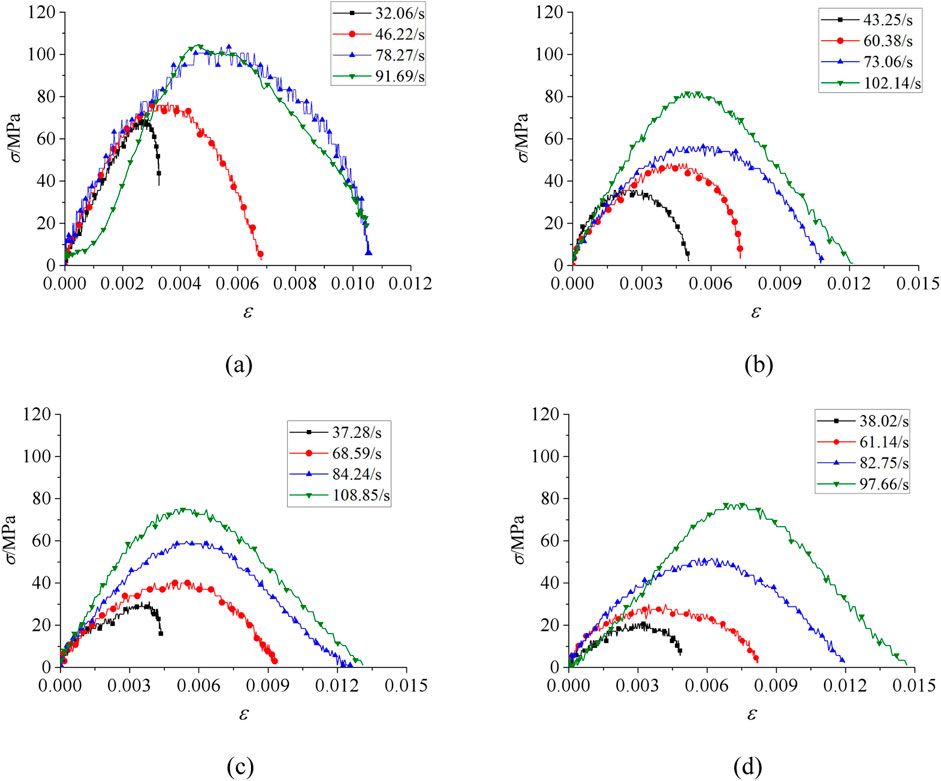

Based on the uniaxial compression test data of concrete specimens subject to sulfate attack under high strain rate, the change of stress-strain curve of concrete specimen with strain rate

Figure 5. Variation law of stress-strain curve of concrete specimens with different stress rates. (A) C = 0.0% (B) C = 3.0%. (C) C = 6.0% (D) C = 9.0%.

As shown in Figure 5, the stress-strain curves of eroded specimens under high strain rates are essentially identical. The stress-strain curve can be divided into the following three stages: the approximate linear elastic stage, microcrack evolution and unstable propagation stage, and strain softening stage. In the first stage, the stress-strain curve is approximately linear, with continuous accumulation of elastic energy. In the microcrack evolution and unstable propagation stage, the stress-strain curve presents an upward convex form; existing cracks in the specimen expand, new cracks form, and the stress reaches the maximum value at the end of this stage. In the strain softening stage, the stress decreases with the increase of strain, the bearing capacity of the concrete specimen decreases rapidly, and the concrete specimen undergoes rapid deformation.

By comparing the characteristics of the stress-strain curves of concrete specimens under different strain rates, it is evident that there are certain differences in the basic characteristics of the curves under different strain rates.

(1) As the strain rate

(2) As the strain rate

(3) As the strain rate

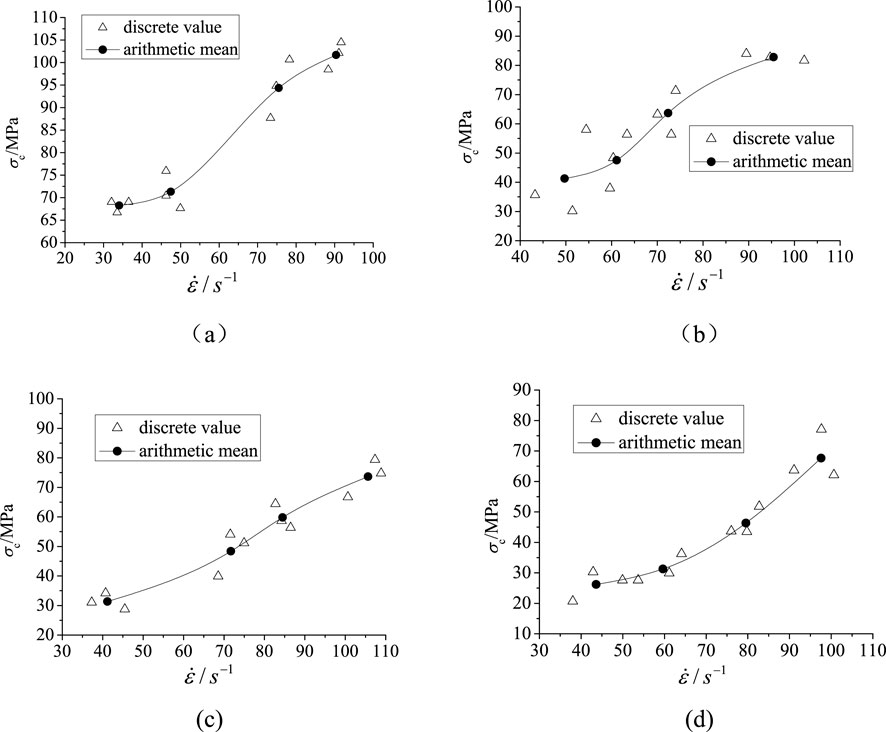

Based on the stress-strain curve of the specimen under high strain rate, the variation of the specimen’s compressive strength σc with the strain rate

Figure 6. Variation curve of dynamic peak strength σC of specimens subject to sulfate attack with the high strain rate

Figure 7. Comparison of the variation law of the compressive strength (σc) of the specimen with the strain rate (

As shown in Figure 6, with the increase of strain rate

(1) When C = 0.0%, as the strain rate increases from 34.05/s to 90.38/s, the compressive strength of the specimen increases from 68.26 MPa to 101.67 MPa, with an increase of 48.95%; (2) When C = 3.0%, as the strain rate increases from 49.71/s to 95.43/s, the compressive strength of the specimen increases from 41.28 MPa to 82.82 MPa, with an increase of 100.63%; (3) When C = 6.0%, as the strain rate increases from 41.16/s to 105.62/s, the compressive strength of the specimen increases from 31.34 MPa to 73.63 MPa, with an increase of 134.94%; (4) When C = 9.0%, as the strain rate increases from 43.62/s to 96.47/s, the compressive strength of the specimen increases from 26.21 MPa to 67.64 MPa, with an increase of 158.07%.

The compressive strength σc and strain rate

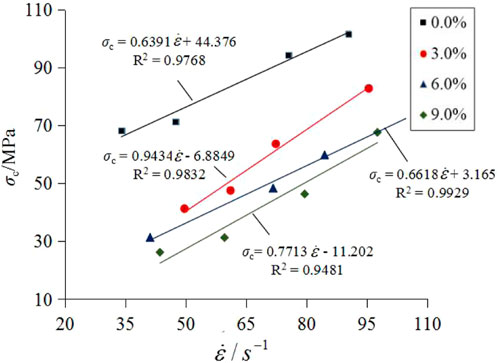

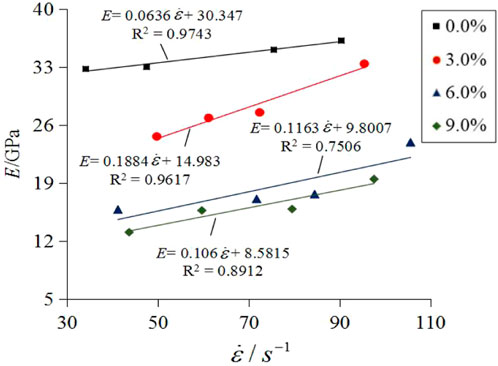

Based on the stress-strain curve of the eroded specimen under high strain rate, the variation of the elastic modulus E with the strain rate

Figure 8. Variation curve of elastic modulus E of specimens subject to sulfate attack with the high strain rate

Figure 9. Comparison of the variation law of the elastic modulus E of the specimen with the strain rate

As shown in Figure 8, with the increase of strain rate

With the increase of strain rate, the elastic modulus increases, indicating that the deformation resistance of the specimen gradually increases. In fact, at a higher strain rate, the lateral deformation in the middle of the specimen is limited due to the inertial effect. The higher the strain rate

The elastic modulus E and strain rate

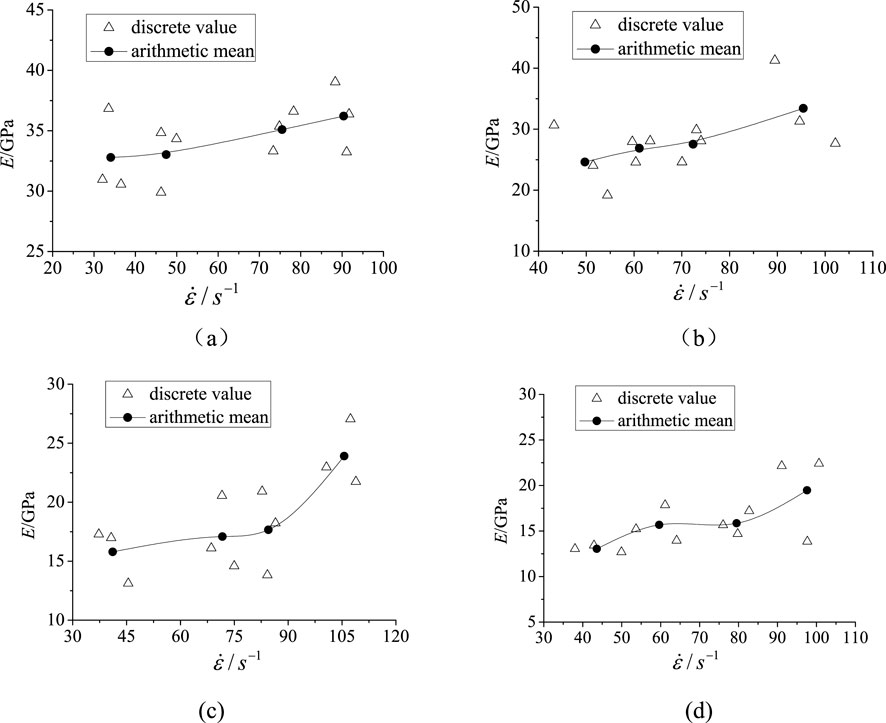

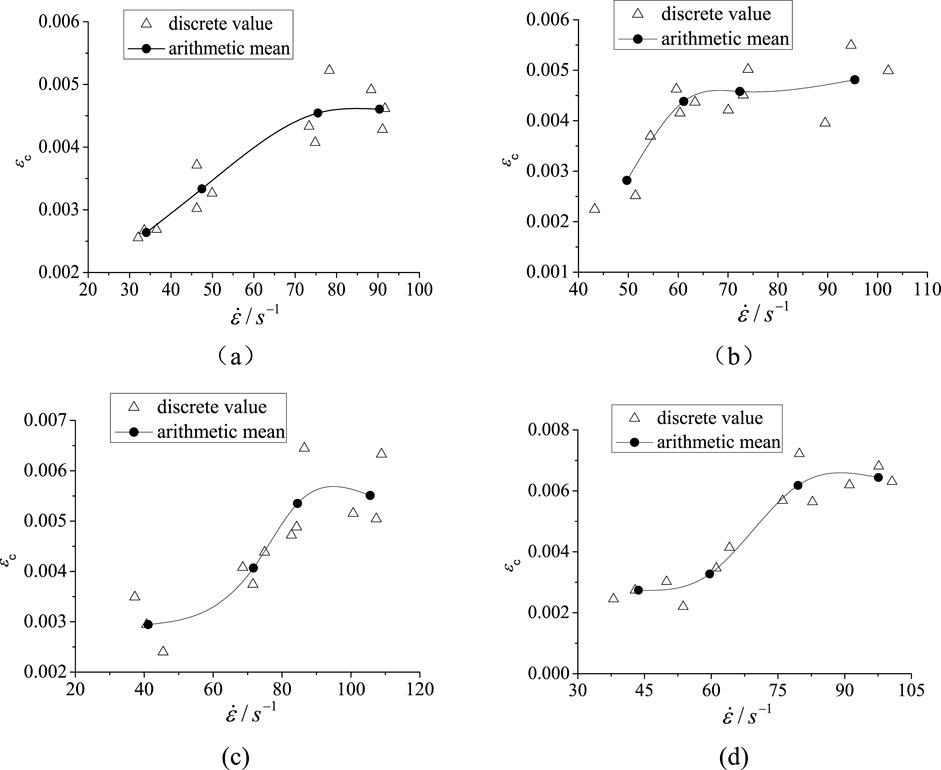

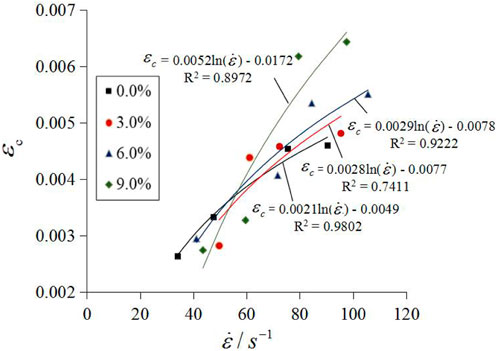

Figures 10, 11 shows the variation of peak strain of concrete with strain rate

Figure 10. Variation curve of peak strain εc of specimens subject to sulfate attack with the high strain rate

Figure 11. Comparison of the variation law of the peak strain (εc) of the specimen with the strain rate (

Under different concentrations of sulfate erosion, the peak strain of the specimen shows a significant strain rate effect (see Figure 10). Overall, the peak strain of the specimen gradually increases with the increase of strain rate, and at higher strain rates, the slope of the change curve shows a decreasing trend. The specific change process is as follows: (1) When C = 0.0%, as strain rate increases from 34.05/s to 90.38/s, the peak strain of the specimen increases from 0.002637 to 0.004604, with an increase of 74.59%; (2) When C = 3.0%, as strain rate increases from 49.71/s to 95.43/s, the peak strain of the specimen increases from 0.002818 to 0.004812, with an increase of 70.76%; (3) When C = 6.0%, as strain rate increases from 41.16/s to 105.62/s, the peak strain of the specimen increases from 0.002945 to 0.005509, with an increase of 87.06%; (4) When C = 9.0%, as strain rate increases from 43.62/s to 96.47/s, the peak strain of the specimen increases from 0.002738 to 0.006436, with an increase of 135.06%.

In fact, as the strain rate increases, the number of cracks generated increases, and the deformation of the specimen at the peak strength increases, resulting in an increase in peak strain. However, as the strain rate increases, the load application time shortens, leading to a shorter deformation time for specimen. Therefore, the combined effect of these two factors may cause the peak strain to increase more slowly with increasing strain rate at higher strain rates.

The logarithmic function provides a good fit for the relationship between the peak strain and strain rate of specimens under sulfate erosion (see Figure 11). The linear coefficients corresponding to concentrations of 0.0%, 3.0%, 6.0%, and 9.0% are 0.0021, 0.0028, 0.0029, and 0.0052, respectively. The strain rate effect on the peak strain of the specimens subjected to sulfate erosion at concentrations of 3.0% and 6.0% shows little change compared to the specimens without erosion. However, the strain rate effect on the peak strain of the eroded specimens at a concentration of 9.0% is significantly enhanced compared to the non-eroded specimens. This indicates that under erosion at a concentration of 9.0%, the effect of strain rate on the toughness of concrete is more significant.

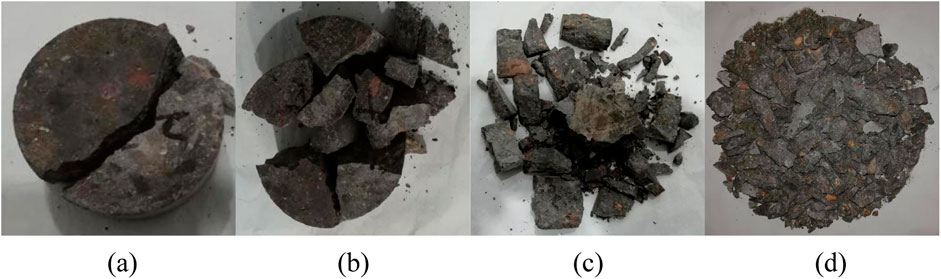

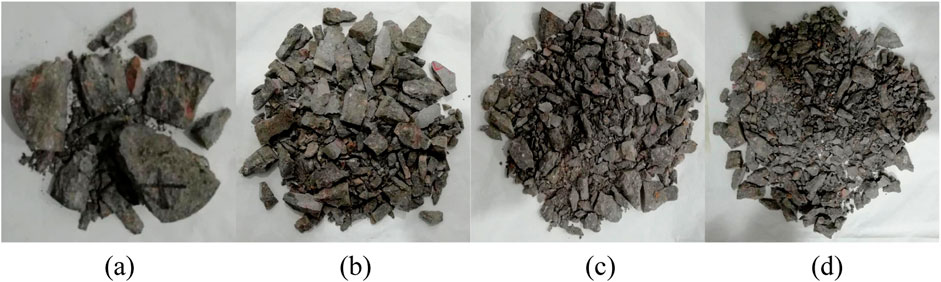

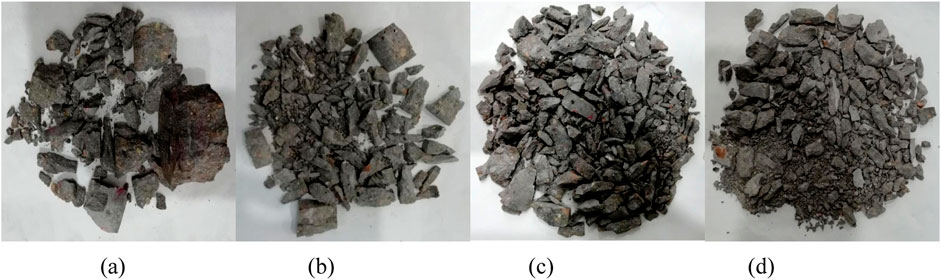

Figures 12–15 show the failure modes of specimens subject to sulfate erosion under different loading strain rates

(1) Under the same concentration of sulfate attack, the breakage degree of specimens increases with the increase of strain rate

(2) There are three fracture forms of concrete specimens under dynamic load: (1) the breaking of cement colloid, (2) the interface separation caused by the loss of adhesive force between cement and aggregate, and (3) the fracture of aggregate. These three fracture forms coexist in specimens under different strain rates in this study.

Figure 12. Macro failure mode of concrete specimens under different strain rates (C = 0.0%). (A)

Figure 13. Macro failure mode of concrete specimens under different strain rates (C = 3.0%). (A)

Figure 14. Macro failure mode of concrete specimens under different strain rates (C = 6.0%). (A)

Figure 15. Macro failure mode of concrete specimens under different strain rates (C = 9.0%). (A)

Under the impact load, the concrete fracture caused by stress inevitably consumes a portion of the stress wave energy for crack propagation and the formation of new surface area (Shi et al., 2023; Shi et al., 2024). The energy consumption for crack propagation and new crack formation during concrete fragmentation is significantly different under different loading conditions. Therefore, to effectively crush or reinforce concrete, it is important to understand the differences in energy consumption for concrete crushing under various loading conditions.

According to the test principle, the energy dissipation of concrete specimens during impact loading can be calculated through the input and output of energy in the pressure rod system. According to the elastic wave theory, the calculation functions for the incident energy W I (J), reflected energy WR (J), and transmitted energy WT (J) in the SHPB experimental system are as shown in Equation 1.

Where W I, WR and WT represent the incident energy, reflected energy, and transmitted energy in the system; A0, C0 and E0 represent the cross-sectional area, (m2), wave velocity (m/s), and elastic modulus of the compression rod (Pa);σI, σR and σT represent the stress (Pa) generated by incident waves, reflected waves, and transmitted waves in the compression rod.

Since butter is applied on the end face of the specimen to reduce the frictional effect, the frictional energy between the specimen and the compression rod can be ignored. Therefore, in the SHPB experiment, the absorbed energy WL can be expressed as shown in Equation 2.

where WL represents the absorbed energy (or dissipated energy) during specimen failure.

In the SHPB experiment, energy dissipation mainly includes the energy dissipation caused by specimen crack propagation (WLD), fragment motion energy dissipation (WLV), and other energy dissipation (WLS) such as frictional energy consumption. However, WLV and WLS account for a small proportion of WL, and over 95% of the energy is used for crack propagation in the specimen. Therefore, it can be roughly assumed that WL≈WLd.

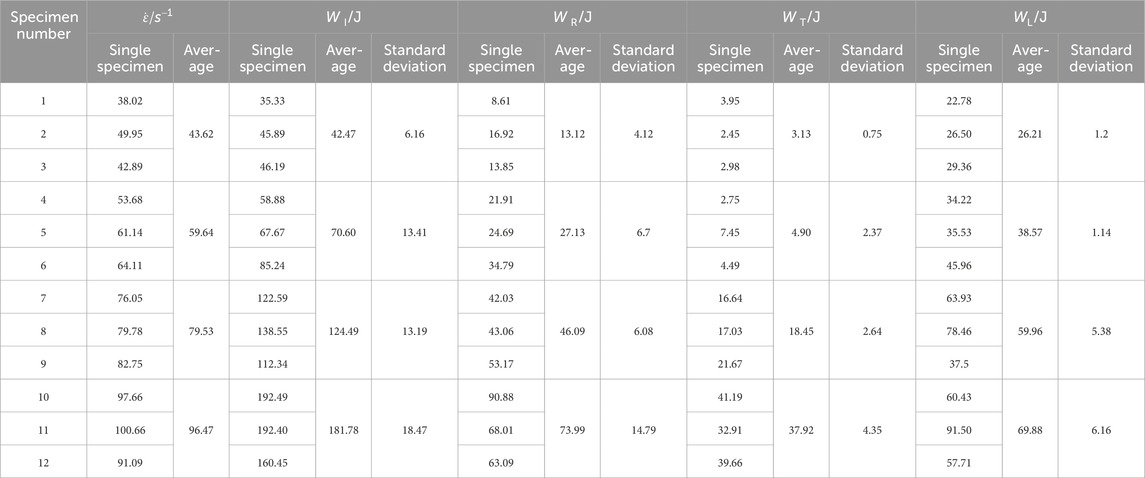

Based on the experimental results, the energy eigenvalues of non-eroded and eroded specimens (C = 9.0%, t = 270 days) under different strain rates were calculated (see Tables 2, 3). And standard deviations were also calculated, indicating that the experimental results are relatively stable.

Table 3. Energy calculation results of uniaxial impact compression of eroded specimens (C = 9.0%, t = 270 days).

Figure 16 shows the curves of energy WJ with strain rate of the non-eroded specimen. It can be seen from Figure 16 that with the increase of strain rate, the energies of non-eroded specimens show an increasing trend under impact loading. The change process is as follows: when the strain rate

The fitting relationship between energy WJ and strain rate

Figure 17 shows the curves of energy WJ with strain rate of the eroded specimen (C = 9.0%). It can be seen from Figure 17 that with the increase of strain rate, the energies of eroded specimens show an increasing trend under impact loading. The change process is as follows: when the strain rate increases from 43.62/s to 96.47/s, the incident energy WI increases from 42.47 J to 181.78 J (a 8.35-fold increase); the reflected energy WR increases from 13.12 J to 73.99 J (a 5.64-fold increase); the transmitted energy WT increases from 3.13 J to 37.92 J (a 12.12-fold increase); and the dissipated energy WL increased from 26.21 J to 69.88 J (a 2.67-fold increase).

The fitting relationship between energy WJ and strain rate of eroded specimen (C = 9.0%,t = 270 days) is as shown in Equation 4.

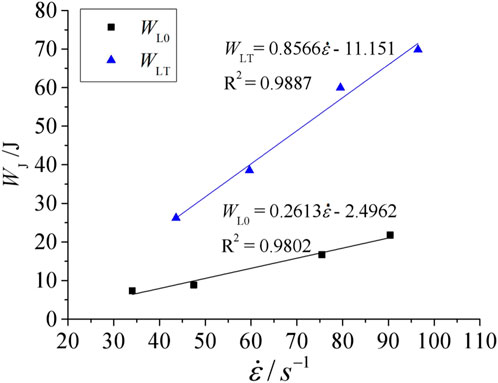

The sensitivity of energy absorption capacity to strain rate

Figure 18. Curve of dissipation energy WL of specimen changing with strain rate

As shown in Figure 18, the dissipation energy WL of both non-eroded and eroded specimens increases with the increase of strain rate. In fact, at high strain rates, the micro-structure inside the concrete (such as the inter-facial transition zone between cement paste and aggregate) is more susceptible to damage. Under high strain rate impact, micro-cracks rapidly propagate and form more fracture surfaces, thereby absorbing more energy and leading to an increase in dissipated energy. Moreover, the sensitivity of the dissipation energy WLT of eroded specimens to strain rate is higher than that of non-eroded specimens WL0. This phenomenon may be due to the loose deformation of the eroded specimen, and the dissipation energy WL is more sensitive to the strain rate under impact loading.

At the same strain rate, a comparison of the dissipation energy WL of non-eroded and eroded concrete specimens reveals that the energy absorption capacity of eroded specimens is obviously higher than that of non-eroded specimens. In fact, after being subjected to sulfate attack, the internal physical characteristics of concrete are altered, primarily due to changes in the internal joints and fractures. Under sulfate attack, some materials within the concrete, such as calcium hydroxide, undergo chemical reactions, leading to a loss of internal material volume and the formation of new joints and fractures. Meanwhile, the generated ettringite causes the joints and fractures to expand. The increase in the number of cracks, joints, and defect surfaces reduces the stability of the concrete, thereby diminishing its ability to resist damage. Under high strain rate, more cracks, joints, and defect surfaces are involved in the development and expansion of fractures. This leads to an increase in the dissipated energy of the eroded concrete compared to the non-eroded concrete, enhancing its energy absorption capacity. Therefore, the macroscopic damage of the concrete under impact loading becomes more severe after erosion.

To further investigate the effect of strain rate on the energy utilization rate during the failure process of the specimen, the variation of the ratios of the reflected energy (WR), transmitted energy (WT) and the dissipation energy (WL) to the incident energy (WI) with the strain rate were studied. Figures 19, 20 show the ratios of these energies to incident energy (WI) with strain rate for non-eroded and eroded specimens under impact loading.

As seen in Figure 19: the proportion of reflected energy to incident energy of the non-eroded specimen increases with the increase of strain rate, while the proportion of transmitted energy decreases with the increase of strain rate. The ratio of dissipation energy changes little with the increase of strain rate. The change process is as follows: when the strain rate increases from 34.05/s to 90.38/s, the proportion of reflected energy increases from 9.52% to 28.97%, with an increase of 204.43%; the proportion of transmitted energy decreases from 77.51% to 59.43%, with an decrease of 23.32%; the proportion of dissipation energy decreases slightly from 12.97% to 11.59%, with an decrease of 10.61%.

As seen in Figure 20: with the increase of strain rate, the proportion of reflected energy and transmitted energy to incident energy of the eroded specimen (C = 9.0%, t = 270 days) increases, while the proportion of dissipation energy decreases. The change process is as follows: when the strain rate increases from 43.62/s to 96.47/s, the proportion of reflected energy increases from 30.90% to 40.70%, with an increase of 31.72%; the proportion of transmitted energy increases from 7.36% to 20.86%, with an increase of 183.35%; the proportion of dissipation energy decreases from 61.72% to 38.44%, with an decrease of 37.72%.

It indicates that the increase of strain rate will decrease the energy utilization ratio during the failure process of eroded concrete. The reason may be that the strength of the specimen decreases greatly and the structure becomes loose under the effect of sulfate attack. When the strain rate is high, the specimen can not absorb enough energy before it is destroyed. Moreover, the extent of increase of dissipation energy with the strain rate is less than that of the incident energy. Therefore, the ratio of dissipation energy decreases with the increase of strain rate.

In this study, the Split Hopkinson pressure bar (SHPB) test system was used to conduct the uniaxial impact compression test of concrete specimens under sulfate attack. The variation laws of the stress-strain curve, compressive strength, elastic modulus, characteristics of energy dissipation and macroscopic failure characteristics of concrete under different concentrations of sulfate attack with strain rate were analyzed. The research results can provide important reference for the establishment of damage evolution models and dynamic response calculations which are the basis for reasonable design of building structures and the evaluation of the blast and impact resistance performance of concrete structures in existing marine erosion environments. The main conclusions are as follows:

(1) The compressive strength and elastic modulus of concrete under different concentrations of sulfate show a certain strain rate effect. As the strain rate increases, both the compressive strength and elastic modulus of concrete gradually increase. The strain rate effect on the compressive strength and elastic modulus of eroded concrete is stronger than that of the non-eroded concrete. Overall, the peak strain of concrete gradually increases with the increase of strain rate, but after exceeding a certain strain rate, the change in peak strain becomes less significant.

(2) Under the same concentration of sulfate attack, with the increase of strain rate, the fragmentation degree of specimens increases, and the crushing area also expands. Finally, the concrete is completely broken into small pieces under high strain rate, leading to a explosive failure of the concrete specimen.

(3) As the strain rate increases, the incident energy, reflected energy, transmitted energy, and dissipated energy of the specimen all show an increasing trend; the dissipated energy of the eroded specimen is more sensitive to the strain rate, however an increase of strain rate will significantly reduce the energy utilization efficiency during the failure process of the eroded specimen.

The raw data supporting the conclusions of this article will be made available by the authors, without undue reservation.

RL: Writing–original draft. XM: Conceptualization, Writing–review and editing. BL: Writing–review and editing, Data curation. YL: Writing–review and editing. LZ: Writing–review and editing.

The author(s) declare that financial support was received for the research, authorship, and/or publication of this article. This work was supported by the National Science Foundation of China (52274140).

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

The authors declare that no Generative AI was used in the creation of this manuscript.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Cao, J., Han, Z., and Du, Z. (2022). Creep properties of axially compressed fly ash concrete under sulfate corrosion. Adv. Mater. Sci. Eng. 1 (1), 1–8. doi:10.1155/2022/6307740

Demei, Y., Bowen, G., He, R., Xiong, R., and Liu, Z. (2016). Sulfate attack of Portland cement concrete under dynamic flexural loading: a coupling function. Constr. and Build. Mater. 115, 478–485. doi:10.1016/j.conbuildmat.2016.02.052

Feng, Z., Liu, X., and Shucai, L. (2010). Study on triaxial strength criterion of concrete after seawater erosion. Eng. Mech. 27 (9), 209–210. doi:10.6040/j.issn.1672-3961.0.2022.240

Gan, L., Wu, J., Shen, Z., and Xianwei, F. (2021). Deterioration law of basalt fiber reinforced concrete under sulfate attack and dry-wet cycle. China Civ. Eng. J. 54 (11), 37–46. doi:10.19936/j.cnki.2096-8000.20230228.010

Gao, R., Shunbo, Z., Qingbin, L., and Chen, J. (2010). Experimental study of the deterioration mechanism of concrete under sulfate attack in wet-dry cycles. China Civ. Eng. J. 43 (2), 48–54.

He, J. (2017). Study on sulfate resistance of nano-concrete foundation. Harbin, Heilongjiang, China: Journal of Northeast Forestry University.

Hong, Q., Lucheng, X., and Hui, G. C. (2018). Experiment on durability of metro-concrete under action of double factors of sulfate and magnesium-salt. J. Lanzhou Univ. Technol. 44 (5), 144–149. doi:10.3969/j.issn.1673-5196.2018.05.026

Li, C. (2024). Study on compressive strength and sulfate corrosion resistance of limestone powder and waste glass powder mixed concrete. Mater. Res. Express 11 (2), 025502. doi:10.1088/2053-1591/ad1ef6

Liang, X., Cheng, H., Ma, Z., and Guan, B. (2022). Effects of manufactured sand lithology and gradation on sulfate resistance of concrete. Bull. Chin. Ceram. Soc. 41 (06), 1974–1980. doi:10.1007/s11595-014-1070-9

Liu, P., Chen, Y., Yu, Z., Lu, Z., and Shi, W. (2020). Evolution of the dynamic properties of concrete in a sulfate environment. Constr. Build. Mater. 245, 118468. doi:10.1016/j.conbuildmat.2020.118468

Ministry of Housing and Urban-Rural Development of the People's Republic of China (2011). Code for construction of concrete structures: gb 50666-2011. Beijing: China Architecture and Building Press.

Ministry of Transport of the People's Republic of China (2020). Test method for sulfate resistance of cement concrete (T0582-2020). Beijing: People's Communications Press.

Serag Faried, A., Mostafa, S. A., Tayehc, B. A., and Tawfikd, T. A. (2021). Mechanical and durability properties of ultra-high performance concrete incorporated with various nano waste materials under different curing conditions. J. Build. Eng. 43, 102569. doi:10.1016/j.jobe.2021.102569

Shi, H., Chen, W., Zhang, H., Song, L., Ming, L., Wang, M., et al. (2023). Dynamic strength characteristics of fractured rock mass. Eng. Fract. Mech. 292, 109678. doi:10.1016/j.engfracmech.2023.109678

Shi, H., Zhang, H., Chen, W., Song, L., and Li, M. (2024). Pull-out debonding characteristics of rockbolt with prefabricated cracks in rock: a numerical study based on particle flow code. Comput. Part. Mech. 11 (1), 29–53. doi:10.1007/s40571-023-00607-9

Song, H., Fan, S., Zhang, S., and Gong, M. (2023). Strength deterioration prediction of pervious concrete in sulfate and dry-wet cycle environments utilizing ultrasonic velocity. PLoS One 18 (6), e0286948. doi:10.1371/journal.pone.0286948

Verre, S. (2021). Effect of different environments’ conditioning on the debonding phenomenon in fiber-reinforced cementitious matrix-concrete joints. Materialsy 14 (24), 7566. doi:10.3390/ma14247566

Wang, C., Kong, F., and Pan, L. (2021). Effects of polycarboxylate superplasticizers with different side-chain lengths on the resistance of concrete to chloride penetration and sulfate attack. J. Build. Eng. 43, 102817. doi:10.1016/j.jobe.2021.102817

Wang, Z., Zong, M., Kai, Z., Zhe, L., and Jianbo, T. (2020). Experimental study on corrosion resistance and mechanical properties of basalt fiber concrete in sodium sulfate environment. Build. Struct. 20, 118–123. doi:10.19701/j.jzjg.2020.20.019

Wei, J., Cheng, B., Li, L., Long, W. J., and Khayat, K. H. (2023). Prediction of dynamic mechanical behaviors of coral concrete under different corrosive environments and its enhancement mechanism. J. Build. Eng. 63, 105507. doi:10.1016/j.jobe.2022.105507

Wu, J. Y., Jing, H. W., Gao, Y., Meng, Q. B., Yin, Q., and Du, Y. (2022). Effects of carbon nanotube dosage and aggregate size distribution on mechanical property and microstructure of cemented rockfill. Cem. Concr. Compos. 127, 104408. doi:10.1016/j.cemconcomp.2022.104408

Wu, J. Y., Jing, H. W., Yin, Q., Yu, L. Y., Meng, B., and Li, S. C. (2020). Strength prediction model considering material, ultrasonic and stress of cemented waste rock backfill for recycling gangue. J. Clean. Prod. 276, 123189. doi:10.1016/j.jclepro.2020.123189

Wu, J. Y., Wong, H. S., Zhang, H., Yin, Q., Jing, H. W., and Ma, D. (2024). Improvement of cemented rockfill by premixing low-alkalinity activator and fly ash for recycling gangue and partially replacing cement. Cem. Concr. Compos. 145, 105345. doi:10.1016/j.cemconcomp.2023.105345

Zang, X., Wang, G., Zhang, Z., Duan, X., and Hu, X. (2022). Study on mechanical behavior of reinforced concrete beams under sulfate attack. Adv. Civ. Eng. 1 (1). doi:10.1155/2022/3465281

Keywords: concrete, sulfate attack, strain rate, dynamic mechanical properties, characteristics of energy dissipation

Citation: Liu R, Mao X, Li B, Li Y and Zhang L (2025) Experimental study on dynamic mechanical properties of concrete under sulfate attack. Front. Mater. 12:1560181. doi: 10.3389/fmats.2025.1560181

Received: 14 January 2025; Accepted: 12 February 2025;

Published: 05 March 2025.

Edited by:

Hao Shi, Anhui University of Science and Technology, ChinaReviewed by:

Salvatore Verre, University of eCampus, ItalyCopyright © 2025 Liu, Mao, Li, Li and Zhang. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Lianying Zhang, emhhbmdsaWFueWluZ0AxMjYuY29t

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.