95% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

ORIGINAL RESEARCH article

Front. Environ. Sci. , 11 June 2018

Sec. Agroecology

Volume 6 - 2018 | https://doi.org/10.3389/fenvs.2018.00036

This article is part of the Research Topic Options for Transition of Land Towards Intensive and Sustainable Agricultural Systems View all 13 articles

This paper investigates the potential energetic utilization of wheat chaff via combustion and necessary process steps such as pretreatment and pellet production as an example of stramineous biomass. Chaff is one out of three main fractions during harvesting and remains usually on the field. Vice versa, it is a potentially so far unexploited biomass resource, which could serve as renewable energy source. Simultaneously, exploiting wheat chaff could intensify the economic benefit of agricultural land use. The combustion application requires choosing an applicable firing system adjusted to the properties of chaff. The economic feasibility of the combustion application depends strongly on the technical effort, which depends on the fuel. Chaff consists mainly of husks and straw. Due to the low ash melting point and the high chlorine content of straw, it can be advantageous for the combustion to remove short straw from the chaff by sieving. To evaluate the combustion properties of presorted and original chaff the elemental composition, the net calorific value, the volatiles and ash content and the ash melting behavior were determined. The efficient logistic of chaff is decisive for its economic exploitation. This is in conflict with the low bulk density of chaff and the resulting high storage volume. Compressing chaff into pellets optimizes its handling. This vital step for an economic exploitation of chaff was therefore investigated by this study. Parameters such as water content of the feed, addition of binders and the geometry of the pressing die bores influence the pelletizing success significantly. Thus, these parameters were investigated in this study. The resulting pellets were characterized with standardized methods and compared to the requirements of EnPlus standards in terms of mechanical durability, amount of fines, bulk density and final moisture content. Finally, combustion experiments in a Large-scale Oven for Kinetics Investigation characterized the burnout behavior of the produced pellets. This was compared to pine wood pellets as conventional fuel. The performed investigations show that the pellet production and the subsequent combustion of wheat chaff pellets is a feasible approach for an energetic utilization.

Since the EU Directive on the promotion of electricity produced from renewable energy sources has become effective in 2001, exploiting renewable energy resources is at the center of ecopolitical attention. To achieve the goal of covering 20% of the final energy demand in the EU from renewable sources by 2020, the energetic usage of biomass residuals and the mobilization of new biomass potentials are of vital importance (Directive 2009/28/EC, 2009). Using biomass residuals have the essential advantages of not requiring an additional acreage and of not competing with the food industry. Wheat chaff is such a biomass residual with unexploited energetic potential. It is a side product of annual harvesting and remains usually on the field. There, it serves as humus and nutrient supplier for the soil. Depending on farming practices and local conditions, such as climate and soil type, crop residuals can be collected with a different rate without affecting the soil balance (Cherubini and Ulgiati, 2010; Monteleone et al., 2015). Weiser et al. (2014) estimate a removal rate of 0.33 in order to provide a stable soil balance. The total harvested material consists approximately of 50 %(w/w) corn, 25 %(w/w) straw and 25 %(w/w) chaff (Stern, 2010). With an annual harvest of 152 Mt wheat and spelt in the EU-28, chaff represents a biomass potential of 38 Mt/a (EUROSTAT, 2017). The net calorific value of spelt chaff varies in literature between 15.1 and 16.8 MJ/kg (Kiš et al., 2017; Wiwart et al., 2017). Considering the lowest calorific value of 15.1 MJ/kg and the removal rate of 0.33, wheat and spelt chaff have a theoretical potential of 191 PJ/a in the EU.

However, collecting chaff comes with more advantages than making an unexploited energy source available. Agricultural production is increasingly fighting with weed infestation of herbicide resistant weeds (Jacobs and Kingwell, 2016; Peterson et al., 2017). According to the international survey of herbicide resistant weeds, the number of resistant weeds doubled from 1998 until 2017 globally (Heap, 2018). During harvesting most of the harvested weed seeds end up in the chaff fraction and thus the collection of chaff prevents weed seeds of entering the soil bank (Walsh and Newmann, 2007; Douglas et al., 2013; Chauhan, and Mahajan, 2014). Collecting chaff can enhance the crop yield by lowering weed pollution in the following years. Simultaneously a new biomass potential is created. From an ecological point of view, the energetic use of chaff contributes to a CO2-neutral and sustainable energy supply. Furthermore, it generates additional economic benefit of agricultural fields and intensifies the agricultural land use.

Chaff is a heterogeneous mixture, consisting mainly of husks and straw. While the combustion and energetic use of straw is already well investigated and applied, for chaff it is so far not sufficiently studied. Chaff is expected to be a beneficial fuel for combustion processes due to a low chlorine content and a high ash melting point (Stern, 2010; Heidecke et al., 2014). The low ash melting temperature, the high ash content and the high content of Cl, N and alkali metals increase the technical effort for the combustion application of straw (Salzmann and Nussbaumer, 2001; Kaltschmitt et al., 2009; Wang et al., 2014). Pre-sorting chaff to sort out straw can therefore be beneficial for the combustion properties. It leads potentially to a lower technical and monetary effort for the combustion application. Untreated chaff has a low bulk density of around 56 kg/m3 (McCarntey et al., 2006). Its usage is therefore connected with high transport and logistic costs. Pelletizing chaff can optimize the logistics by reducing the transport and storage volume. To evaluate the pelletizability of chaff, optimized parameters need to be found.

This work provides a first comprehensive study about the feasibility of exploiting chaff energetically via combustion. First investigations and insights of the effect of pre-sorting, the pelletizability of chaff and the combustion behavior were done.

The examined material is winter wheat chaff from a harvest in Germany in 2015. The chaff was harvested by the company Claas Selbstfahrende Erntemaschinen GmbH and stored sealed since then. At the time of investigation the material had a water content of 7.5 %(w/w). The original chaff fraction consists mainly of husks with a length of 0.8 cm and straw with a length of 1–20 cm. The bulk density is 34 g/L.

The used pelletizing device is the press 14-175 by Amandus Kahl. It is a flat die press (Figure 1). Dies with different l/d-ratio can be applied. The dies differ in the length of the bores (l) and have a bore diameter (d) of 6 mm. A thermocouple allows checking the temperature at the outer side of the die. The press is fed manually from the top. The produced pellets fall onto a vibrating sieve with a mesh size of 4 mm and a total length of 1.3 m.

The combustion experiments were carried out in a Large-scale Oven for Kinetics Investigation (LOKI). Figure 2 shows the schematic layout of the oven. The reactor itself is a tube out of quartz glass with a diameter of 198 mm and a length of 1610 mm. A gas-permeable frit separates the tube into two oven zones (OZ1 and OZ2). The oven allows heating up to 900°C with a heating rate of maximum 40°C/min. The heating elements of the two oven zones are regulated separately. The reactor setup provides a defined atmosphere inside the oven zones. The lower oven zone (OZ1) can be supplied by technical air, nitrogen or a combination of both. The upper oven zone (OZ2) can be supplied by technical air and serves as secondary combustion chamber for the released gases. A flow regulator can set the volume flow of the respective gases. The reactor setup provides kinetic information about the sample mass and the sample temperature under heat exposure.

The sample mass is measured by a scale system. Therefore, a wide-meshed glass fiber basket is mounted on a sample suspension, which is connected to the scale. The sample is placed inside the basket. To prevent an impact on the scale, the scale system is purged continuously by nitrogen during the experimentation. The core temperature of the sample is measured by sticking the sample on a thermocouple type k (thermocouple 1). The thermocouple is fixed at a flange, which closes the lower part of the reactor. The sample suspension and the flange are moved by pneumatic linear systems. At the beginning of the investigation the sample is moved up into the middle of the OZ1. Moving up takes 3 s. Due to the movement the signal of the scale is disturbed. After reaching the end position the mass loss can be recorded without interruptions.

A gas-analysis unit allows the measurement of O2, H2O, CO2, and CO in the exhaust gas. H2O, CO2, and CO are measured by nondispersive infrared technology (NDIR). O2 is measured electrochemically. The gas pipe is heated to prevent condensation of the exhaust gases.

The scale works on the vibrating wire principle. A tensioned wire vibrates at its natural frequency after being electromagnetically induced. The mass of the sample changes the tension of the wire leading to a change of its natural frequency. This is converted into a mass.

As pre-treatment, wheat chaff was sieved using a drum screen in order to sort out straw. The sieve holes of the first half of the drum screen are circular with a diameter of 8 mm. The sieve holes of the second half of the drum screen are elongated with a length of 21 mm and a width of 8 mm. By pre-sieving, 20 %(w/w) of the original chaff fraction was sorted out as coarse fraction consisting mainly of straw. The fine fraction consists mainly of husks and small thin straw of up to 5 cm. The bulk density of the fine fraction is 50 g/L. The pelletizing and combustion experiments were performed with the original chaff and the fine fraction.

Each pelletizing trial was performed with a feedstock of 3 kg. Initially the raw material was dried in an oven at 80°C to ensure a defined water content for the experiments. The coarse chaff fraction f was milled with a cutting mill to a maximum size of 8 mm to ensure a smooth feeding of the pellet press. The fine chaff fraction did not require milling. The dry material and potential binders were mixed with tap water to adjust the intended initial water content for the pelletizing experiments. The mixing was done in a conventional cement mixer for at least 20 min or until homogeneity of the mixture.

Prior to each test, the die was preheated until the thermocouple on the outer side of the die showed >50°C, because the glass transition temperature of straw is between 53 and 63°C (Whittaker and Shield, 2017). The die was preheated by adding pre-grinded initial material to the running pellet press until the desired temperature was reached due to friction. Once the temperature was reached, the feed was switched to the desired feedstock. The produced pellets were collected after 5–10 min of pelletizing to ensure that the initial material was flushed out completely. The feeding was done manually and continuously. The speed of the rollers was adjusted depending on the pelletizing flow. The pellets cooled down at room temperature and were stored in a sealed box.

The combustion experiments were performed with pellets produced with an initial feedstock moisture content of 20 %(w/w). The water content of fine fraction chaff pellets was 9.3 %(w/w) and 9.7 %(w/w) for original chaff pellets respectively. The combustion behavior was compared to the combustion behavior of commercial pinewood pellets produced by EcoPowerPlant Sp. Z o. o. with a water content of 6.3 %(w/w) (product code: 6BFM15W100). The chaff as well as pinewood pellets have a diameter of 6 mm and a length of 16–17 mm. The weight of a single pellet differed between 0.57 and 0.61 g.

The combustion experiments included experiments to measure the core temperature and the mass loss of a single pellet as well as of a bulk of seven pellets. The combustion was performed in technical air atmosphere with 21 vol.% O2 with a sudden sample supply into the hot oven. The volume flow in OZ1 was set to 10 L/min and in OZ2 to 5 L/min. OZ2 was heated up to a temperature of 1,000°C. OZ1 was heated up to 900°C.

In order to stick the pellet on the thermocouple a hole of 1 mm width was drilled into the pellet so that the top of the thermocouple is located at the core of the pellet. After 10 min when steady conditions prevailed, the sample was moved upwards into the hot oven. The combustion experiments of a single pellet were switched off after 600 s and for 7 pellets after 1,400 s respectively. Thereafter no further mass loss and volatile release were recorded. All experiments were performed twice.

The fine and the coarse chaff fraction were characterized with regard to their elemental composition and the relevant combustion properties.

The parameters were determined according to following norms:

Net calorific value: DIN 51900 (comparable to DIN EN ISO 18125)

Ash content: DIN EN ISO 18122

Volatiles: DIN 51720 (comparable to DIN EN ISO 18123)

H2O content: DIN 51718 (comparable to DIN EN ISO 18134)

C, H, N: DIN 51732 (comparable to DIN EN ISO 16948)

S, Cl: DIN 51724-1 and DIN 51727 (comparable to DIN EN ISO 16994)

Heavy metals, nutrients: following DIN 51729-11 (comparable to DIN EN ISO 16967)

Ash melting behavior: DIN CEN/TS 15370-1

The calculation of the net calorific value on a wet basis (qnet;wb) into the net calorific value on a dry basis (qnet;db) was calculated according to

following Kaltschmitt et al. (2009).

The moisture content, the pellet durability Index (PDI), the bulk density (BD) and the amount of fines classify pellets. The pellet formation rate (PFR) is relevant to assess the pelletizing process.

To determine the moisture content, a sample of 300 g (mw) dried in an oven at a temperature of 80°C. After 24 h the sample weight was measured and the sample was placed back to the oven. After 48 h the sample was taken out of the oven and the weight (md) was measured again. If there has been no further mass loss, the moisture content (xm) was calculated according to

To evaluate the mechanical stability of the pellets, the durability of the produced pellets was determined according to DIN EN ISO 17831-1. 500 g of pellets (m0) were placed in a rotating box containing an impact crusher. The box rotated 50 times per minute for 10 min. Afterwards the sample was sieved with a hole size of 3.15 mm. The final weight of the coarse fraction (mf) was measured and the PDI was calculated according to

The bulk density of pellets was determined by using a test volume of 1 L. The mass, which filled a volume of 1 L after slight shaking, was measured. This relation is the bulk density in g/L.

To quantify the abrasion of the pellets the amount of fines (xf) was determined following DIN EN ISO 18846. Approximately 500 g of pellets (m0) were sieved manually. The used sieve had a hole size of 3.15 mm. The sieve was filled so that the surface was covered with one layer of pellets. The amount of fines was calculated according to

The PFR was evaluated by measuring the mass (mP), which was collected behind the vibrating sieve as pellets and the mass (mu), which trickled through the vibrating sieve as uncompressed material. The PFR is an orientation to quantify the pelletizing success and is given as

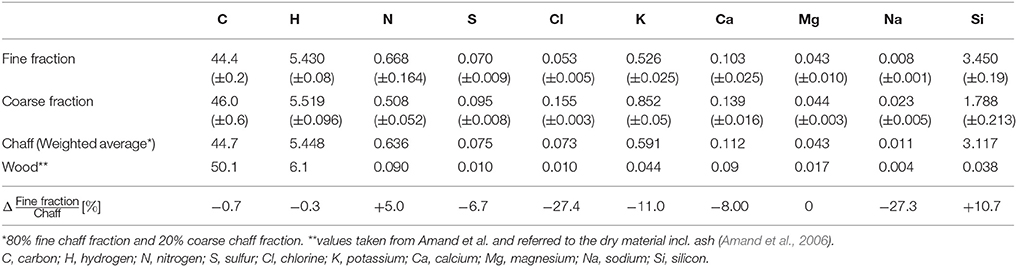

Table 1 shows the elemental composition of the fine and the coarse chaff fraction as well as the weighted average of both. 80% fine and 20% coarse fraction represent the original chaff. Pre-sorting chaff decreases the Cl content significantly. In addition, the content of the alkali metals K and Na are lower in the fine fraction compared to the original chaff. The Si content in contrast is increased. The N content of all chaff fractions is with 0.508 to 0.668 %(w/w) high in comparison to conventional biomass fuel such as wood. Table 2 shows further determined properties relevant for the combustion. The fine fraction has a 7% higher ash content compared to original chaff. The slightly lower calorific value of the fine fraction corresponds to the higher ash content.

Table 1. Elemental composition of chaff fractions after sieving in %(w/w) on a dry basis (averaged values with standard deviation).

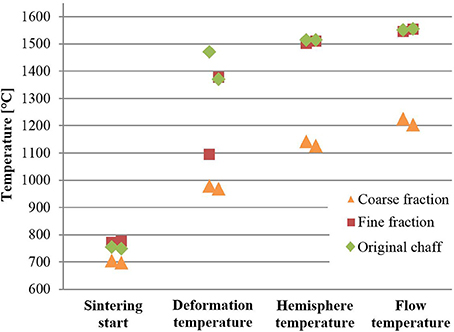

Figure 3 shows the measured characteristic temperatures of the ash melting behavior. The sintering starts for all fractions below 800°C. While the coarse fraction starts to deform at temperatures below 1,000°C, the fine fraction and the original chaff have a significantly higher deformation temperature (DT) of >1,300°C. One determined DT of the fine fraction is with 1,095°C significantly lower than the DT of the other measurement with 1,377°C. This can be explained by the determination procedure. For the determination a software evaluates the shape of the sample and characterizes it using a form factor. The software defines the DT as the temperature at which the form factor of the sample is 15% different to the form factor of the original sample. The change of the form factor does not necessarily need to be caused by rounding of the edges due to melting. Therefore, the determination of especially the DT is subject to errors. Thus, this outlier is likely due to the software evaluation. The hemisphere and the flow temperature of pre-sieved chaff and the original chaff are above 1,500°C. These values are comparable with the flow temperature of wood (Kaltschmitt et al., 2009). For the coarse fraction in contrary, the flow temperature is only slightly above 1,200°C. An effect of sorting cannot be noted by the determined values. The high ash melting temperatures of pre-sieved chaff and the original chaff can be explained by the higher Si and the lower K content in the fine fraction compared to the coarse fraction (see Table 1; Stern, 2010).

Figure 3. Characteristic temperatures of the ash melting behavior of different fractions (double determination).

The pelletizing success strongly depends on the used die and the moisture content of the feedstock. Furthermore, binders can be applied to improve the pelletizing success. The influence of the l/d ratio of the die, the moisture content of the feed and the addition of starch as a potential binder are discussed in the following.

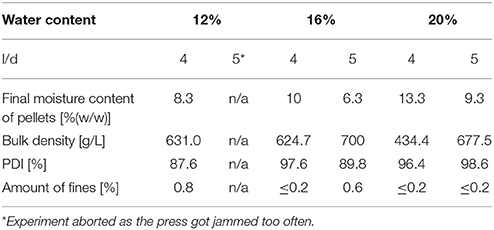

Changing the die in an industrial pellet press requires high technical effort. It is therefore preferable to choose a die, which is suitable for a wide range of feedstock parameters. To decide which die to use for further experimentation, the fine fraction was pelletized using a die with a l/d-ratio of 4 (= die 4) and of 5 (= die 5) at initial moisture contents of 12, 16 and 20 %(w/w).

During pelletizing it was observed that a higher l/d-ratio leads to increased evaporation and therefore to drier material. This is confirmed by the final moisture contents of the produced pellets. All determined pellet characteristics are summarized in Table 3. In case of dry material with an initial feedstock moisture content of ≤ 16 %(w/w), a higher l/d-ratio decreased the pellet formation and impeded the pelletizing process. At a moisture content of 12% the pelletizing process was difficult with both dies. The pellet press often got jammed and dust trickled through the die along with marginal pellet formation. With die 5 the process was terminated as the press got jammed too often. At a moisture content of 16% similar problems occurred with die 5. The pelletizing process became difficult when the material becomes too dry due to evaporation. With die 4 the problems diminished and the pelletizing was smooth. At a moisture content of 20 mass-% the pelletizing was smooth with both dies. The pellets produced with die 5 exhibited better durability, a higher bulk density and a lower final pellet moisture content (see Table 3).

Table 3. Characteristics of produced pellets with different dies and from feedstocks with different initial moisture content.

The experiments with different dies showed that pelletizing at a moisture content of 16% with die 4 and at a moisture content of 20% with die 5 exhibited good pellets in combination with an easy pelletizing. Overall, the pellets produced at 20% with die 5 showed the best characteristics of all produced pellets. Considering that die 4 only exhibited acceptable results at a moisture content of 16%, die 5 was chosen to examine a wider range of initial moisture contents for the pelletizing process. Furthermore, the difference of pelletizing the original chaff and the fine fraction was examined using die 5.

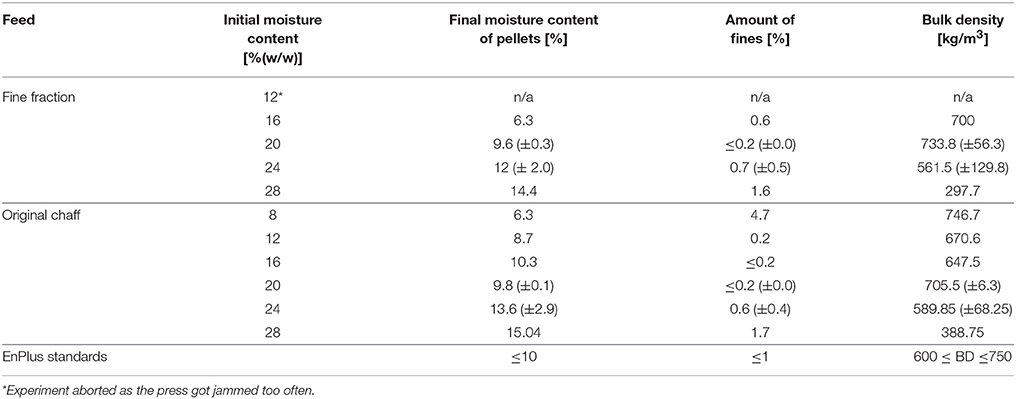

To analyze the effect of the initial moisture content of the feedstock only the experiments performed with the same die (die 5) are compared. The effect was investigated for the fine fraction as well as for the original chaff by varying the moisture content from 8 to 28 %(w/w) in 4 absolute %(w/w) steps. The performed experiments present a screening of the pelletizability of chaff at different initial moisture contents. To evaluate the reproducibility, the experiments at a moisture content of 20 and of 24% were repeated.

The experiments showed that the pelletizing process becomes easier with an increasing moisture content until a certain level. Exceeding this level decreases the stability of the produced pellets rapidly. If the material is too dry, the press often gets jammed and the pellets crumble inside the bores to dust. This shows the binding as well as the lubricating function of water during pelletizing. If the initial moisture content is too high, the densification is low and the final pellet moisture content is too high. This results in an insufficient shelf life of the pellets. At a moisture content of ≤16 %(w/w) for fine fraction chaff and ≤12 %(w/w) for original chaff, the produced pellets are bright and their lengths vary from 3 mm up to 15 mm. At a moisture content of 16 %(w/w) uniform pellets with a length of 14 to 16 mm were produced from original chaff. At moisture contents of 20 %(w/w) the pellets have a characteristic length of around 16 to 18 mm, are darker and have an external gloss. At a moisture content of 24%, the pellets of the different trials vary a lot. The pellets of one trial look the same as the ones produced at 20%. The pellets of the other trial are shorter, have no external gloss and are partly crumbly. One possible reason for such variation is insufficient mixing of water and dry feed during conditioning. Another explanation is a variation in evaporation during pressing due to varying temperatures inside the press. At a moisture content of 28 %(w/w) the pellets are short, crumbly and fall easily apart. Table 4 summarizes the determined parameters of the produced pellets. The low bulk density confirms the insufficient densification at too high moisture contents. The final pellet moisture content is depending on the moisture content of the feed as well as the evaporation during the pressing process. This explains the varying moisture content of the produced pellets. Pellets produced with a feed moisture content of 28 and 24% for the second trial exceed the limit of 10 %(w/w) final moisture in the end product clearly.

Table 4. Characteristics of produced pellets from feedstocks with different initial moisture contents (l/d = 5).

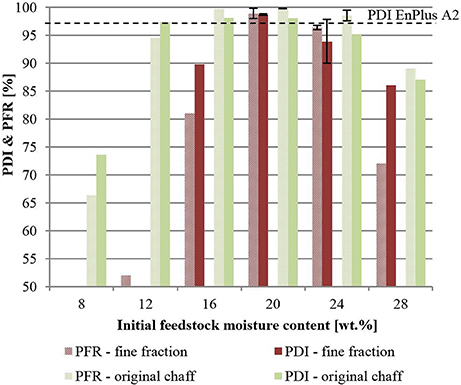

Successful pelletizing needs to offer a high PFR in combination with durable pellets. Figure 4 shows the PFR as well as the durability of the produced pellets. When pelletizing the original chaff, a moisture content of 16 and 20% showed smooth pelletizing in combination with a durability exceeding the EnPlus standards. For the fine fraction this applies only for pellets produced at 20%. The characteristics of the pellets produced at 24% vary strongly between the trials.

Figure 4. Pellet durability index (PDI) and pellet formation rate (PFR) for wheat chaff pellets of fine fraction chaff and original chaff at different moisture contents (l/d = 5).

The different pelletizing results at 24% show the difficulty to ensure a uniform process. Already small differences of the conditions can influence the pelletizing process significantly. Pelletizing at a moisture content of 20% showed a good reproducibility. The produced pellets of both trials showed the best results for the fine fraction as well as for original chaff and are in good accordance with the EnPlus standards.

To investigate the effect of a binding agent, 1 and 2 %(w/w) starch was added on a dry basis at initial feedstock moisture contents of 16 and 28 %(w/w). To examine if adding binder allows using a die with a smaller l/d-ratio while keeping the pellet quality it was added to the fine fraction at a moisture content of 16 %(w/w) using die 4. The pellets produced at 16 %(w/w) water content showed no improved characteristics. To investigate if starch requires a higher water content in order to develop its binding function, it was also added at a moisture content of 28 %(w/w). Here, also starch could not influence the pellet properties positively as the same problems of a too high moisture content occurred as well.

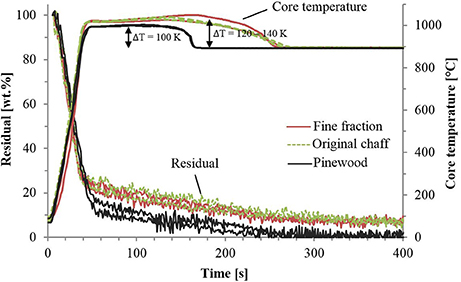

During all combustion experiments the pre-sieved and the original chaff pellets kept their form and only shrank in size. The size of the ash pellets after the combustion was measured in case they did not break after removing them from the oven. The shrinkage of the pellets was around 20% in length and 30% in diameter. Unlike wood ash, the ash of chaff was dimensionally stable (see Figure 5). This observation fits to the determined sintering temperature of <800°C. The black color of the chaff ash can be a sign that the pellet was not completely oxidized. The TOC of the ash was determined as 0.67% (±0.12). The values were at the determination limit due to the small sample weight. This shows that already small amounts of oxidizable elements can be responsible for the black color. Between the residuals at 800 and 900°C combustion temperature no difference was notable. The residuals after 1,400 s had partly white spots and were slightly brighter than the ones after 600 s. The color change may indicate that the longer dwell time in the oven allowed a further burnout. Measuring the core temperature revealed that the pellets of wood and chaff heat up with the same speed (Figure 6). While the pellet heats up pyrolysis and gasification reactions take place and determine the heating speed of the pellet. The sudden drop of the core temperature of wood pellets after around 160 s indicates that the wood pellet lost its form and fell from the thermocouple. In contrast, the chaff pellet stays on the thermocouple during the whole experiment. This is shown by the slow temperature decrease until the core temperature has declined to ambient temperature. It stays constant after 260–270 s. A constant temperature indicates that there is no further oxidation.

Figure 5. Pellets before (left) and after (right) combustion at 900°C; t = 1,400 s; above: chaff pellets of fine fraction; below: pinewood pellets.

Figure 6. Core temperature and residual of one pellet during the combustion at 900°C with V̇tech.air = 10 L/min.

During the devolatilisation in the first 45 s the mass loss of chaff and of pinewood happens with the same speed. The devolatilisation phase for chaff pellets is 5–10 s shorter than for wood pellets due to its lower volatile content. The speed of the char combustion is similar for both, chaff and wood. After around 330 s no further mass loss is registered. The higher ash content of chaff compared to wood is clearly visible by the residual curves. Between the burnout of the original chaff pellet and the pre-sieved chaff pellet, no differences are observed. The graph for the residual matches for all experiments. This shows the repeatability of the experiments and allows evaluating chaff pellets as potential fuel.

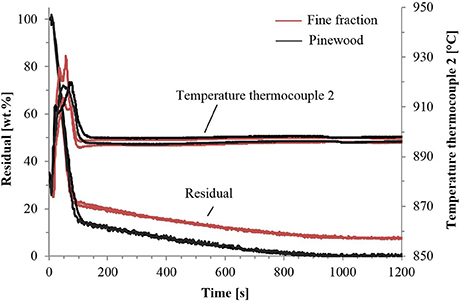

When combusting seven pellets as a bulk the different phases during the combustion are clearly visible (Figure 7). The endotherm release of free and bound water causes the temperature drop above the sample during the first 6–9 s. Afterwards the temperature increases. The temperature peak indicates the oxidation of released gases outside of the pellet. The temperature above the sample stabilizes after devolatilisation and decreases to ambient temperature. The temperature stabilizes earlier for chaff than for wood. This confirms the shorter devolatilisation time of chaff due to a lower percentage of volatiles. The end of the devolatilisation phase is 15 to 20 s earlier compared to wood. During the char combustion the oscillation of the residual measurements is lower due to the higher residual mass. After around 950 s there is no further mass loss for chaff and for wood pellets.

Figure 7. Temperature above the sample and residual of seven pellets during the combustion at 900°C with V̇tech.air = 10 L/min.

In order to achieve a comprehensive study about the feasibility of exploiting chaff energetically via combustion, this work investigated pre-sorting, pelletizing and the combustion of wheat chaff. The following evaluates the process steps pre-treatment, pelletizing and combustion based on the performed investigations. The combustion properties of chaff pellets are compared with pine wood pellets in order to derive the applicability of chaff for existing firing systems.

As potential pre-treatment, pre-sorting chaff and its effect on the physical and chemical properties of the chaff mixture was investigated. Sorting out straw increased the bulk density and eased the handling. This effect is advantageous for the pelletizing process. The pelletizing experiments showed that the small and homogeneous particle sizes of pre-sieved chaff allow feeding the pellet press without prior milling. Original chaff in contrary requires milling prior pelletizing. Pre-sieved chaff has a 7% higher ash content compared to original chaff. The ash content of pre-sieved chaff as well as original chaff is with around 8% high compared to wood. Such a high ash content requires special measures for the combustion application of pre-sieved as well as original chaff. The higher ash content after pre-sieving has therefore no direct effect on the required technical effort. Furthermore, pre-sieved chaff has a 27% lower chlorine content. The chlorine decrease combined with the decrease of the alkali metals potassium and sodium lowers the risk of high temperature chlorine corrosion in furnaces (Kaltschmitt et al., 2009; Ma et al., 2017). High temperature chlorine corrosion has a direct influence on investment and maintenance costs of a firing system. Although sieving as pre-treatment means additional effort, it is expected that it has a positive cost-benefit ratio due to the lower chlorine content together with the improved handling of pre-sieved chaff.

Pelletizing chaff exhibits a homogeneous fuel with an energy density of 9.7 MJ/m3. The storage and transport volume is decreased by around 93% compared to uncompressed chaff. As chaff accrues annually it needs to be stored throughout the year. Considering the dimensions of storing, it is expected that compressing is beneficial in order to improve the logistics even though it requires an additional process step. The pelletizing experiments showed that pre-sieved as well as original chaff can be sufficiently pelletized at a moisture content of 20%. The received pellets fulfill the ENPlus standards. Furthermore, the pelletizing experiments showed that the success of the pelletizing process requires uniform feed parameters regarding the moisture content. Therefore, the moisture content of chaff needs to be determined and maybe adjusted during processing at industrial scale.

The reaction kinetics of the chaff pellet combustion revealed that the application of chaff as fuel in combustion plants is in principle possible. The speed of the mass loss during devolatilisation was the same for chaff as for pinewood. Nevertheless, the devolatilisation time of chaff was overall shorter due to a lower volatile content. The mass loss during char combustion was similar for wood and for chaff. The type of applicable combustion technology as well as the economy of the combustion application depends strongly on the technical effort required by the fuel. Chaff has with 0.61 %(w/w) a significantly higher nitrogen content than wood (Amand et al., 2006). This makes primary measures such as air or fuel staging necessary to reduce the formation of NOx and to obey the legal limits (Salzmann and Nussbaumer, 2001). The hemisphere and flow temperature of chaff were determined as >1,500°C and are comparable with the characteristic temperatures of wood (Kaltschmitt et al., 2009). Such high deformation and flow temperatures can significantly lower the technical effort for the combustion application. Nevertheless, the determined sintering temperature of chaff was below 800°C and the combustion experiments showed the dimensional stability of the ash pellets after combustion. Such dimensional stability caused by sintering can lead to problems like inhomogeneous air distribution and difficult ash discharge in furnaces. This needs to be counteracted by stoking the material bed and by an optimized ash discharge (Wang et al., 2014). Furthermore, the ash content of pre-sieved and original chaff is with 8.4 and 7.6% significantly higher than for wood. Due to the high ash content, the technical application requires an optimized ash removal and dedusting.

Due to the low sintering temperature and the high ash content, it is expected that the application of a moving grate is necessary for the chaff pellet combustion. Moving grates are available for furnaces with a nominal heat output (NHO) of >150 kW (Kaltschmitt et al., 2009). Besides grate firing systems also bubbling fluidized bed furnaces (BFB) are applicable for biomass combustion. Compared to grate firing systems they require higher technical effort. The combustion of wheat chaff in BFB was investigated by the Fraunhofer Institute for Factory Operation and Automation IFF (Appelt and Brith, 2016). During the combustion, problems occurred due to slagging of the ash, which is why they recommend using additives to improve the ash melting behavior. Due to the technical effort and required auxiliary energy, BFB are economically feasible for plants with a NHO of >5 MW (Van Loo and Koppejan, 2008; Kaltschmitt et al., 2009). The decisions for a firing system, therefore depends on the aimed plant size.

To evaluate the energetic use of wheat chaff via combustion, a comprehensive characterization of chaff was done in this research. Furthermore, potential treatment such as sorting and pelletizing was investigated and evaluated according to its effects. Finally, the combustion behavior was analyzed in order to derive requirements for the technical firing system. Such comprehensive investigations allowed assessing the feasibility of the energetic utilization of chaff. This study showed that the combustion of chaff, with pre-sorting and pelletizing as pretreatment, is a feasible approach for the energetic use of chaff, which is worth to pursue.

The pelletizing experiments revealed ideal pelletizing parameters. Furthermore, they showed that the pelletizing success is very sensitive to the water content of the feed. This makes precise conditioning of the feed necessary. Although the experiments present a broad screening of parameters, experiments at industrial scale are necessary to evaluate if pelletizing chaff can be a continuous process without interruptions. Analyzing pre-sorted and original chaff revealed that pre-sieving is advantageous to improve the handling as well the combustion properties. To make a final judgement about the implementation of pre-sorting and pelletizing, an extended case study is necessary which takes required energy, technical, transportation and storage effort into account.

The investigations showed that chaff is a valuable fuel for energetic utilization. Because of the combustion properties and the observations during the experiments, it is concluded that the combustion of chaff requires special measures such as a moving grate and an optimized ash removal. Considering these special measures, the combustion of chaff is expected to be economical for furnaces with a nominal heat output of >150 kW. To be able to evaluate the technical requirements for an optimized burnout and ash discharge of the sintered ash, the combustion in a small-scale oven under realistic conditions is necessary. Furthermore, experiments measuring the composition of the exhaust gases need to be done in order to evaluate, if special measures are necessary to stay within legal limits.

BW and CG conceived the procedure to evaluate chaff as potential fuel. BW performed the experiments. BW and CG analyzed the data. CG drafted the structure and content of the paper, BW wrote the first draft of the paper. All authors reviewed the paper.

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

This work was done as a part of the project Sweedhart-Separation of weeds during harvesting and hygienisation to enhance biomass production in the long term. Sweedhart is a transnational research project funded in the frame of the ERA-NET Cofund FACCE SURPLUS (Sustainable and Resilient agriculture for food and non-food systems), which is formed in collaboration between the European Commission and a partnership of 15 countries in the frame of the Joint Programming Initiative on Agriculture, Food Security and Climate Change (FACCE-JPI). FACCE SURPLUS is committed to improve collaboration across the European Research Area in the range of diverse, but integrated, food and non-food biomass production and transformation systems, including biorefining. We thank the German Federal Ministry of Education and Research (project number 031B0164A) for financial support at national level. The responsibility for the contents of this publication is taken fully by the authors. We also thank our partners Christopher Vieregge and Ralf Boelling, CLAAS Selbstfahrende Erntemaschinen GmbH, Harsewinkel, Germany, for the provision of chaff samples that were used for the pelletizing experiments.

Amand, L., Leckner, B., Eskilsson, B., and Tullin, C. (2006). Deposits on heat transfer tubes during co-combustion of biofuels and sewage sludge. Fuel 85. 1313–1322. doi: 10.1016/j.fuel.2006.01.001

Appelt, B., and Brith, T. (2016). “Ergebnisse zur Verbrennung und Vergasung von Stroh und Spreu in Wir belschichtanlagen” in Proceedings of Spreu Stroh Innovationsforum Workshop 2. Leipzig, March 14th 2016. Doberschau-Gaußig: AgroSax Landtechnik e. V. (organiser).

Chauhan, B., and Mahajan, G. (eds.) (2014). Recent Advances in Weed Management. New York, NY: Springer.

Cherubini, F., and Ulgiati, S. (2010). Crop residues as raw materials for biorefinery systems – A LCA case study. Appl. Energ. 87, 47–57. doi: 10.1016/j.apenergy.2009.08.024

Douglas, A., Newman, P., Kowald, J., Micallef, B., Crook, P., and Hill, J. (2013). The Effectiveness of On-farm Methods of Weed Seed Collection at Harvest Time. Available online at: https://grdc.com.au/__data/assets/pdf_file/0032/99860/wa-weed-seed-harvest-case-studies-pdf.pdf.pdf (Accessed April 05, 2018).

Directive 2009/28/EC, (2009). Directive on the Promotion of Use of Energy of Renewable Sources and Amending and Subsequently Repealing Directives 2001/77/EC and 2003/30/EC.

EUROSTAT (2017). Wheat and Spelt by Area, Production and Humidity. Available online at: http://ec.europa.eu/eurostat/tgm/refreshTableAction.do;jsessionid=9RtD-bVDHUXBA82cd_Gfy_FKm3Do4LUXaoihLaKC-TQKaI-ZSmfS!-755574875?tab=table&plugin=1&pcode=tag00047&language=en (Accessed May 8, 2018).

Heap, I. (2018). The International Survey of Herbicide Resistant Weeds. Available online at www.weedscience.org. (Accessed January 16, 2018).

Heidecke, P., He, L., and Birth, T. (2014). “Energetische Nutzung agraischer Reststoffe mittels thermo-chemischer Wandlung in Wirbelschichtreaktoren,” in Conference Transcript DGMK-Fachbereichstagung Konversion von Biomasse. Rotenburg a. d. Fulda, 12.-14. April 2014. 203-210. Abstract retrieved from Abstracts in DGMK database.

Jacobs, A., and Kingwell, R. (2016). The harrington seed destructor: its role and value in farming systems facing the challenge of herbicide-resistant weeds. Agric. Syst. 142, 33–40. doi: 10.1016/j.agsy.2015.11.003

Kaltschmitt, M., Hartmann, H., and Hofbauer, H. (eds.) (2009). Energie aus Biomasse. Grundlagen, Techniken und Verfahren. 2 Edn. Berlin: Springer.

Kiš, D., Jovičić, N., Matin, A., Kalambura, S., Vila, S., and Guerac, S. (2017). Energy value of agricultural spelt residue (triticum spelta l.)-forgotten cultures. Technical Gazette 24, 369–373. doi: 10.17559/TV-20170406124003

Ma, P., Yang, J., Xing, X., Weihrich, S., Fan, F., and Zhang, X. (2017). Isoconversional kinetics and characteristics of combustion on hydrothermally treated biomass. Renewable Energy 114, 1069–1076. doi: 10.1016/j.renene.2017.07.115

McCarntey, D., Block, H., Dubeski, P., and Ohama, A. (2006): Review: the composition availability of straw chaff from small grain cereals for beef cattle in western Canada. Can. Vet. J. 86. 443–455. doi: 10.4141/A05-092

Monteleone, M., Cammerino, A., Garofalo, P., and Delivand, M. (2015). Straw-to-soil or straw-to-energy? An optimal trade off in a long term sustainability perspective. Appl. Energy. 154, 891–899. doi: 10.1016/j.apenergy.2015.04.108

Peterson, M. A., Collavo, A., Ovejero, R., Shivrain, V., and Walsh, M. J. (2017). The challenge of herbicide resistance around the world: a current summary. Pest Manag. Sci. doi: 10.1002/ps.4821. [Epub ahead of print].

Salzmann, R., and Nussbaumer, T. (2001). Fuel staging for NOx reduction in biomass combustion: experiments and modeling. Energy Fuels 15, 575–582. doi: 10.1021/ef0001383

Stern, W. (2010). Stroh als Quelle erneuerbarer Energie. Swiss Bull. Angewandte Geowissenschaften. 15, 95–103. doi: 10.5169/seals-227482

Van Loo, S., and Koppejan, J. (2008). The Handbook of Biomass Combustion and Co-Firing, 1st Edn. London: Earthscan.

Walsh, M., and Newmann, P. (2007). Burning narrow windrows for weed seed destruction. Field Crops Res. 104, 24–30. doi: 10.1016/j.fcr.2007.05.012

Wang, L., Skreiberg, Ø., and Becidan, M. (2014). Investigation of additives for preventing ash fouling and sintering during barley straw combustion. Appl. Ther. Eng. 70, 1262–1269. doi: 10.1016/j.applthermaleng.2014.05.075

Weiser, C., Zeller, V., Reinicke, F., Wagner, B., Majer, S., Vetter, A., et al. (2014). Integrated assessment of sustainable cereal straw potential and different straw-based energy applications in Germany. Appl. Energy 114, 749–762. doi: 10.1016/j.apenergy.2013.07.016

Whittaker, C., and Shield, I. (2017). Factors affecting wood, energy grass and straw pellet durability - A review. Renewable Sustain. Energy Rev. 71, 1–11. doi: 10.1016/j.rser.2016.12.119

Keywords: wheat chaff, stramineous biomass, harvest residues, energetic utilization, weed reduction concept, pellet production, densification, combustion behavior

Citation: Weiß BD and Glasner C (2018) Evaluation of the Process Steps of Pretreatment, Pellet Production and Combustion for an Energetic Utilization of Wheat Chaff. Front. Environ. Sci. 6:36. doi: 10.3389/fenvs.2018.00036

Received: 08 February 2018; Accepted: 11 May 2018;

Published: 11 June 2018.

Edited by:

Arne Sæbø, Norwegian Institute of Bioeconomy Research (NIBIO), NorwayReviewed by:

Pardeep Singh, University of Delhi, IndiaCopyright © 2018 Weiß and Glasner. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Christoph Glasner, Y2hyaXN0b3BoLmdsYXNuZXJAdW1zaWNodC5mcmF1bmhvZmVyLmRl

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.