- State Grid Jiangsu Integrated Energy Service Co., LTD, Nanjing, China

At present, energy storage in industrial and commercial scenarios has problems such as poor protection levels, flexible deployment, and poor battery performance. Aiming at the pain points and storage application scenarios of industrial and commercial energy, this paper proposes liquid cooling solutions. In this paper, the box structure was first studied to optimize the structure, and based on the liquid cooling technology route, the realization of an industrial and commercial energy storage thermal management scheme for the integrated cabinet was studied to ensure that the temperature between the cabinets was consistent and reduce the system capacity loss caused by the liquid-cooled battery module was inconsistent. The industrial and commercial energy storage integrated cabinet comprehensively considers the flexible deployment of the system, enhances the protection level of the cabinet, and the structural strength of the cabinet, and improves the temperature balance characteristics of the battery module in the cabinet.

1 Introduction

In industrial and commercial energy storage scenarios, energy storage batteries need to be flexible, have high energy density, safe operation, and high battery consistency. Therefore, distributed energy storage meets the needs of an industrial and commercial energy storage flexible layout, and modular energy storage configuration can be selected according to the power and energy requirements and area limits within the plant (Yang et al., 2023).

In the present industrial and commercial energy storage scenarios, there are two solutions: air-cooled integrated cabinets and liquid-cooled integrated cabinets. An air-cooled converged cabinet uses fans and air conditioners to dissipate heat from lithium batteries. A liquid-cooled converged cabinet uses coolant to dissipate heat. The integrated design of the battery module heat dissipation and power conversion system (PCS) provides higher battery energy density, a stronger protection level, and better battery consistency, which helps to improve battery life and save maintenance costs.

Literature (ZincFive, 2022a; ZincFive, 2022b) designed an uninterruptible power supply battery cabinet and introduced the manufacturing of a green nickel-zinc UPS battery cabinet provided by a Wyoming ultra-large-scale white box. However, the specific liquid cooling design, energy management design, and cabinet design of energy storage battery cabinets were mentioned less. Other literature (C and C Power Inc, 2016; C and C Power Inc, 2019) focuses on the study of layered batteries. Compared with single batteries, layered batteries improve safety and stability and are more suitable for the development of energy storage batteries. Some studies (C and C Power Inc, 2015; Researchers Submit Patent Application, 2015; Researchers Submit Patent Application, 2016) examine large and layered battery cabinets, as well as the internal structure of battery cabinets, and have good application value. Meng et al. (2015) analyzed the thermal management system of outdoor batteries and conducted numerical research but did not explicitly propose strategies to reduce the operating temperature of outdoor batteries. C and C Power Inc. (2013) and Patents (2015) researched and developed battery cabinets, battery systems, and layered battery systems. Other studies (Battery Cabinets, 2011; IntelliBatt, 2012; Saleh et al., 2023) analyzed the operation strategy of cold storage and heat storage tanks in the optimal design of a multi-power generation system. The energy flow characteristics of a multi-current cogeneration system are defined. The above articles do not address battery cabinet liquid cooling systems but do systematically study the battery cabinet frame design and temperature and energy analysis. Therefore, this topic will take the liquid-cooled integrated cabinet as the research object and carry out the research and development of the key technologies of the liquid-cooled integrated cabinet. Based on the current research status of industrial and commercial energy storage cabinets, this project intends to study the integrated technology of industrial and commercial energy storage with high energy density and design a cabinet with high protection levels, high structural strength, and consistent temperature.

The main research contents are:

(1) Industrial and commercial energy storage battery technology design, PMS + energy management system (EMS) joint management, eliminate the (Station to Grid) difference between clusters to ensure long-term system consistency.

(2) Improve the box design by providing a high protection level, high structural strength, and meet the International Protection Rating (IP) standards for overall cabinets, IP55, and key components, IP67, to cope with the harsh outdoor environment in industrial and commercial scenarios;

3) Design the temperature consistency of the energy storage battery cabinet and the liquid cooling circuit to cover each battery

The resulting cabinet will have more uniform heat dissipation, lower cell temperature differences, and use an intelligent temperature control strategy. Compared with conventional air cooling, power consumption is reduced. The temperature consistency design of the energy storage battery cabinet and the balanced control of the whole life cycle ensure consistent energy storage operations.

2 Design of high energy density industrial and commercial energy storage battery technology

2.1 Battery system

The storage medium of the battery system is a lithium iron phosphate battery with high safety and high cycle life, which is modular and easy to install and maintain (Battery Cabinets, 2011; IntelliBatt, 2012).

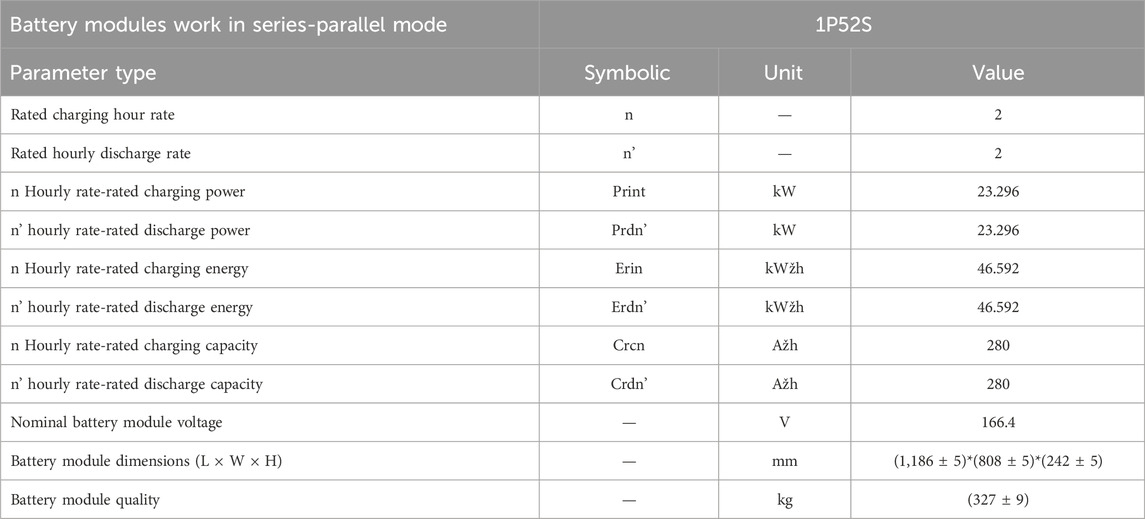

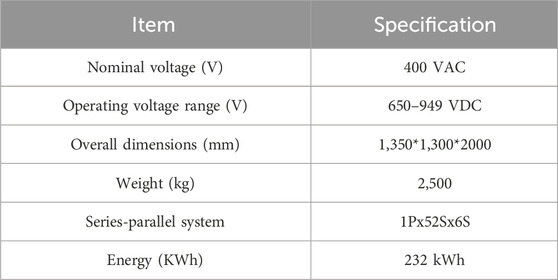

Laser spot welding technology is used to form the battery PACK box, model 1P52S from BatteroTech, Jiaxing City, China, and the parameter is 166.4 V/280Ah (46.6 kWh). The modules of five battery boxes are connected in series to form a cluster with a capacity of 232 kWh, and the battery pack voltage is normal. Table 1 describes battery module parameters.

2.2 High-pressure box design

The battery cluster high-voltage control box is equipped with total positive contactors, total negative contactors, pre-charging circuits, fuses, molded case circuit breakers, etc. All contractors should be able to accept the control of the battery management system.

The battery cluster is directly connected to the PCS bus. A 35 mm2/1000VDC high-voltage copper cable connects the battery cluster to the PCS.

Figure 1 shows the schematic diagram of the connection of the high-pressure box. The electrical topology shown in Figure 2 is as follows:

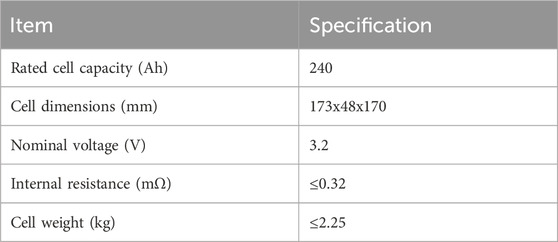

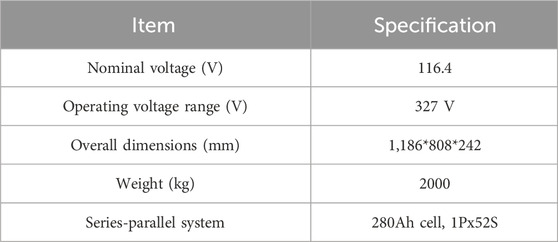

Table 2 shows the cell parameters, Table 3 shows the module parameters, and Table 4 shows the parameters of a single battery cabinet.

3 Cabinet design with high protection level and high structural strength

The key system structure of energy storage technology comprises an energy storage converter (PCS), a battery pack, a battery management system (BMS), an energy management system (EMS), and a container and cabin equipment, among which the cost of the energy storage battery accounts for nearly 60%, and the core component energy storage converter (PCS) accounts for nearly 20%. Protecting the stable operation of the battery pack and PCS is particularly critical. In a compact space, improving the safety of the core components helps to improve the system’s working ability. At present, there is a certain gap in the field of integrated and multi-functional integrated cabinets made in China.

The commonly used low-voltage power distribution integrated power cabinet is an indoor structure (Ochmann et al., 2023; Saleh et al., 2023; Yang et al., 2023), waterproof, anti-foreign body level that only meets the requirements of IP30 (Kumar and Varghese, 2023; Tianfu et al., 2023; Vechi et al., 2023). This cabinet cannot meet the requirements of outdoor IP55 protection. IP30 requirements of IP30 state that the contents of the cabinet must be protected against penetration by a test rod larger than 2.5 mm test rod. IP30 does not address waterproof performance. IP44 requirements can be understood as follows: a test rod with a diameter of 1 mm and a length of 100 mm cannot reach the danger source in the cabinet, and the contents of the cabinet are protected against water and splash. Therefore, the integrated power cabinet can only be used indoors; it cannot be used in any location where it might be subject to rain or splashing water. It does not have standardized design and construction design management. There is a need for a power cabinet structure that can be used outdoors to meet the IP44 protection requirements with a manufacturing design that is simple and easy to standardize.

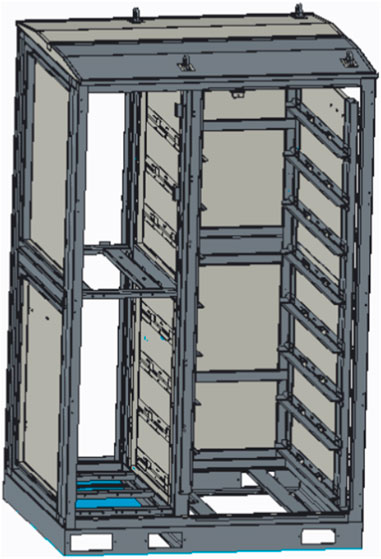

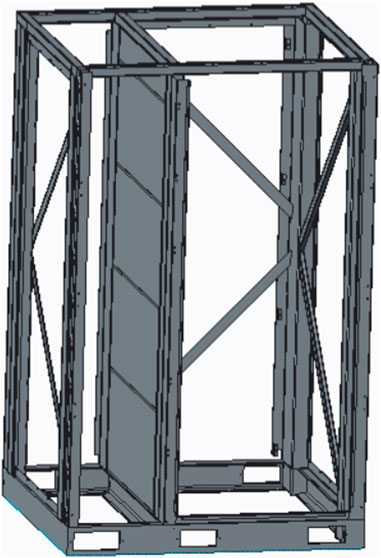

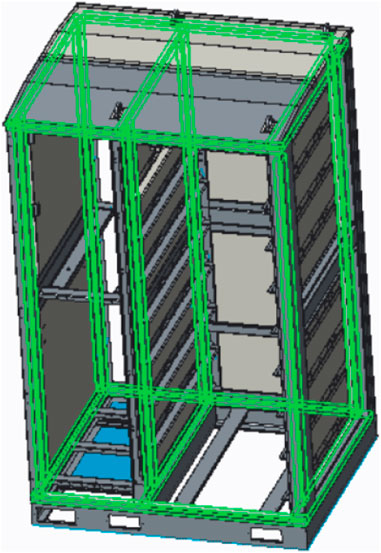

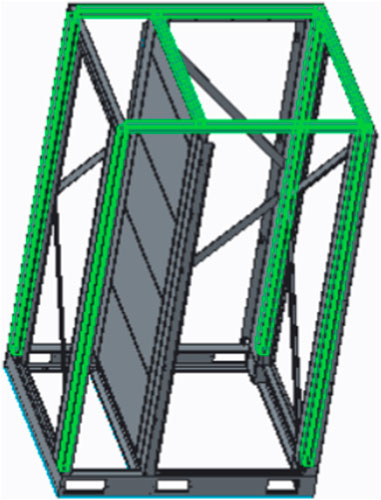

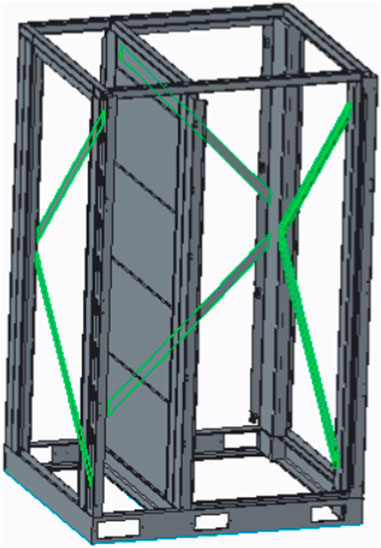

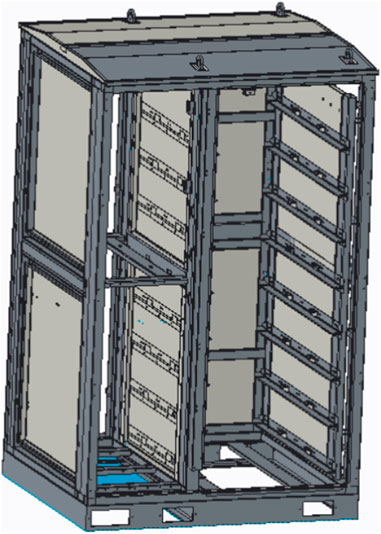

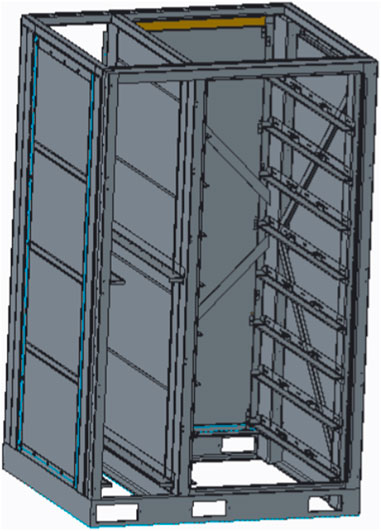

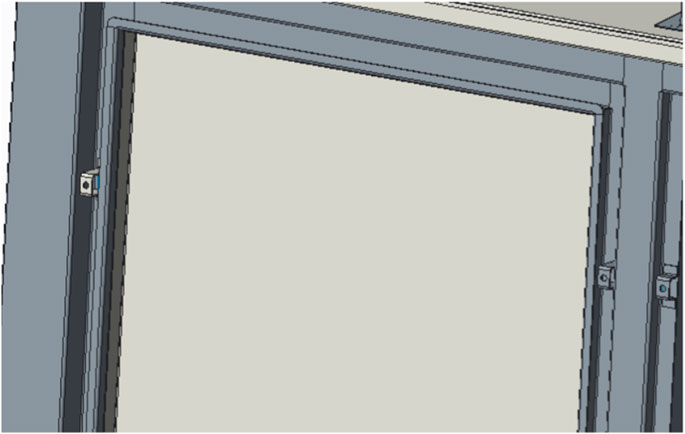

Some requirements for a high-protection outdoor integrated power cabinet structure include a waterproof door device, a waterproof door device including protection strip assembly and water bar assembly, and a waterproof door device arranged on both sides of the general cabinet frame. The cabinet needs a ventilation device on the power cabinet door comprising a louver assembly. The louver assembly must be provided with a double layer (Ghamari et al., 2022; Zhang et al., 2022; Wang et al., 2023). The upper surface waterproof device comprises an upper cover and a lower cover, and the lower cover is connected with an inner cavity of the upper cover. The top surface waterproofing device is arranged on the top surface of the general cabinet frame. The utility model uses a general cabinet to ensure universality and be conducive to standardized management, adopts a common cabinet when high protection is not required, and only needs to add parts and manufacturing processes to meet the IP44 protection requirements when protection must be improved. The cabinet must support standardized product maintenance, reduce the cost of management, be simple and effective, and be useable outdoors. This standard changes the restriction that limits the use of the integrated power cabinet to indoors. Figure 3 shows the prototype welded frame, and Figure 4 shows the improved welded frame.

First, this version has been greatly improved in the framework structure. The sealing plate of the facade and the top cover plate assembly have been changed to the assembled type, and the weight of the single welded frame is greatly reduced compared with the original prototype. Because the frame is not a semi-closed structure, it is conducive to excluding excess surface treatment materials, so either painting or spraying will achieve better surface coverage.

Column structure: The original prototype is made of profiles, and to meet the existing inventory, the thickness of the profile plate is 5 mm, but the welded frame is overweight. The improved version of the column adopts full welding around the upper profile of the machine, and the thickness of the plate is 3 mm. At the same time, due to the height reduction of 190 mm, the weight and cost can be reduced. Figure 5 shows the original prototype column, and Figure 6 shows the improved version of the column.

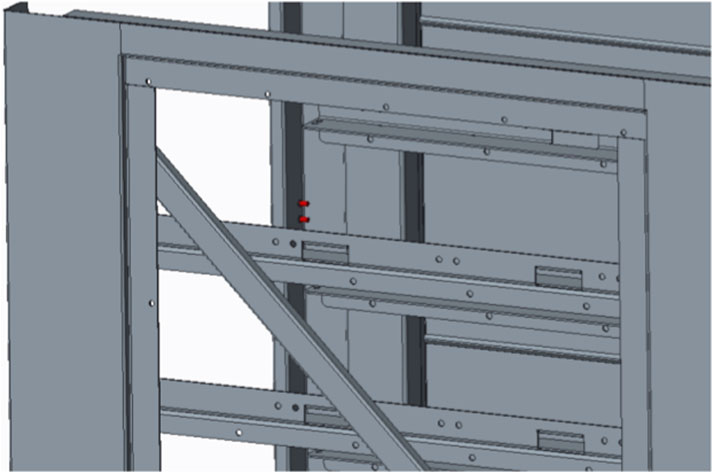

Reinforcement structure: the original prototype is only strengthened through the intermediate bending sheet metal or profiles. A cable-stayed structure is added to the improved model, and the cabinet reinforcement structure is more reasonable concerning the structure. Figure 7 shows the reinforcement bar of the original prototype, and Figure 8 shows the reinforcement bar of the improved version of the column.

Equipment installation structure: The original prototype supports sheet metal welded parts, and the accuracy and flatness requirements are high. There are many assembly problems. In the improved version, the installation columns are bent sheet metal attached with internal welding or rivet nuts to form a prefabricated structure that meets the installation accuracy and reduces the welding workload. Figure 9 shows the installation structure of the original prototype, and Figure 10 shows the installation structure of the improved version of the column.

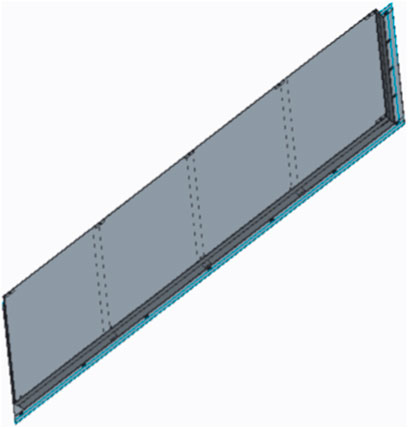

Thermal insulation design: In the original prototype structure, the outer facade was broken by the middle reinforcement. Due to the existence of a waterproof edge, the bent edge could not be affixed with a thermal insulation layer. The improved version adopts the whole-plate prefabricated assembly structure, which has a better thermal insulation effect, but it needs to be sealed by glue. Figure 11 shows the installation structure of the improved side cover plate.

Bending difficulty: The column side of the original prototype is formed in one piece, and the required structure is formed by bending. The original machine had a watertight edge with more bending and a bending time of h. In the improved version of the structure. As a result, the same-position bending times have been reduced by about 1/2.

Firefighting equipment: The original prototype firefighting equipment is integrated with two boxes, but the height takes up more space. In the improved version, the fire equipment is in a scattered arrangement, so that the cabinet height can be further reduced. Figure 12 shows the prototype firefighting equipment.Waterproof structure: The waterproof structure adopted by the original prototype used a waterproof edge plus a sealing pad structure. The waterproof structural design is relatively simple: the complex point is the welding and bending structure at the joint. In the improved version of the design, a baffle forms a waterproof edge, and a gasket is attached. The gasket then covers the insulation layer as a whole, crushing the gasket and sealing the cabinet. Glue is applied to the threaded screw to seal it. The disadvantage of this structure is that a large amount of glue is required, and the structure needs to be designed to prevent the screw from tightening too tightly, exceeding the compression of the gasket. Figure 13 shows the waterproof structure of the original prototype, Figure 14 shows the improved waterproof structure, and Figure 15 shows the cover plate of the thermal insulation layer, which acts as a waterproof cover plate.

The cabinet structure is improved: the column raw material thickness, the number of profiles, and the bending times reduce the difficulty of welding and improve the standardization of parts (reduce the type of insulation layer, reduce the type of parts) and other aspects of cost reduction.

4 Research on temperature consistency technology of energy storage battery cabinet

4.1 Consistent temperature control in the battery module

The liquid-cooled battery module uses the temperature monitoring system and the liquid-cooled temperature control system to ensure a consistent temperature of the battery cell inside the module.

The liquid-cooled battery module is equipped with 16 temperature measuring points inside, and a maximum of 52 temperature measuring points can be arranged to monitor the temperature of the battery cells in each position inside the module. The temperature monitoring system collects the temperature of the battery cells inside the battery module in real time through the battery management unit (BMU).

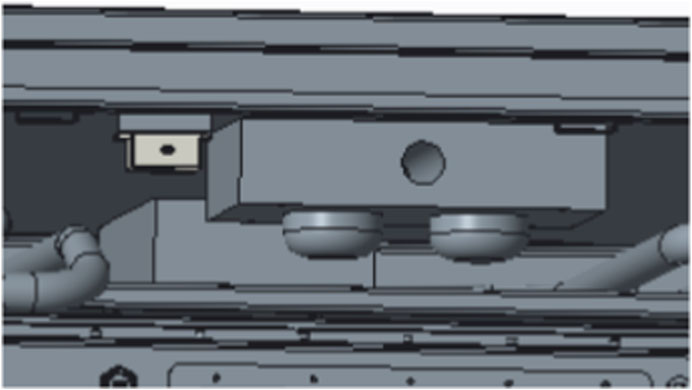

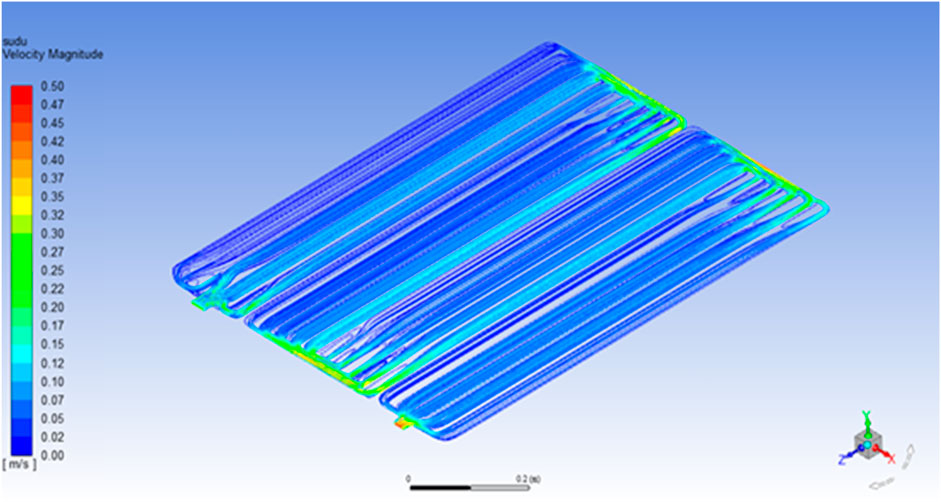

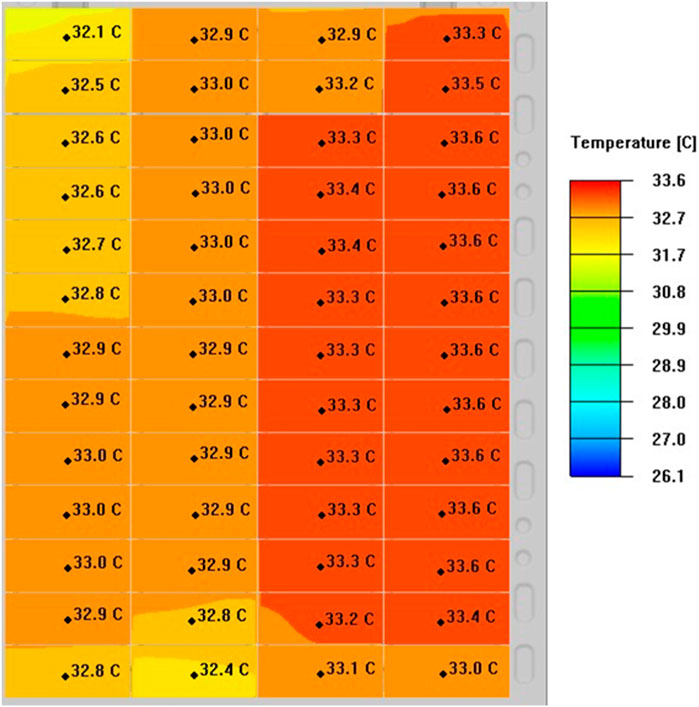

The liquid cooling temperature control system cools the battery through the uniform flow of the coolant in the liquid cooling plate at the bottom of the module so that the battery has a good working environment and consistent temperature. Figure 16 shows the velocity distribution of the cold plate coolant. Figure 17 shows the temperature rise distribution of the cell.

4.2 Temperature consistency control in battery cluster

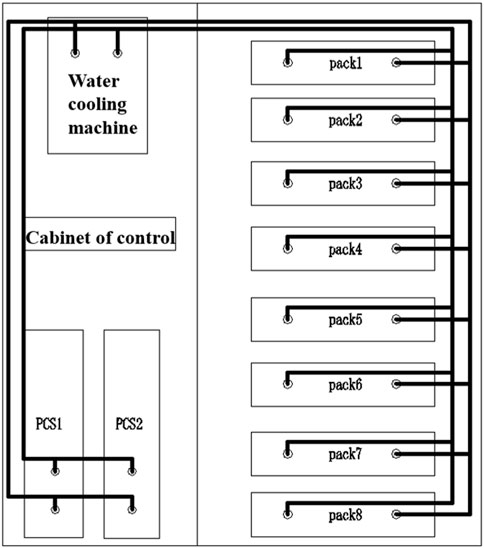

The PCS converter radiator and pack radiator are rated at 5 L/min, with a minimum flow rate of 4 L/min and a maximum flow rate of 6 L/min.

At a flow rate of 5 L/min, the flow resistance of the pack radiator is 7.2 kPa, and that of the PCS radiator is 23.5 kPa.

The ambient temperature is designed to be −40°C–50°C. The cooling medium requires antifreeze treatment. The volume concentration of ethylene glycol is 50%, and the specific heat capacity is 3.068 kJ/(kg°C).

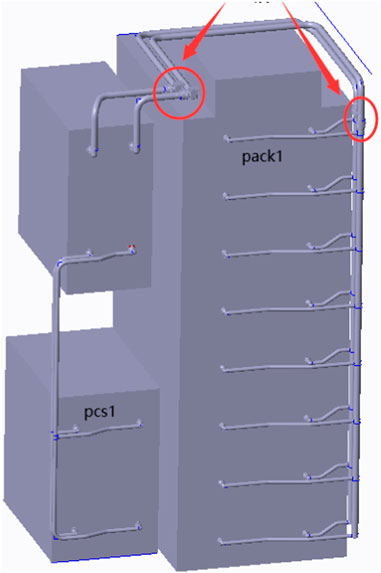

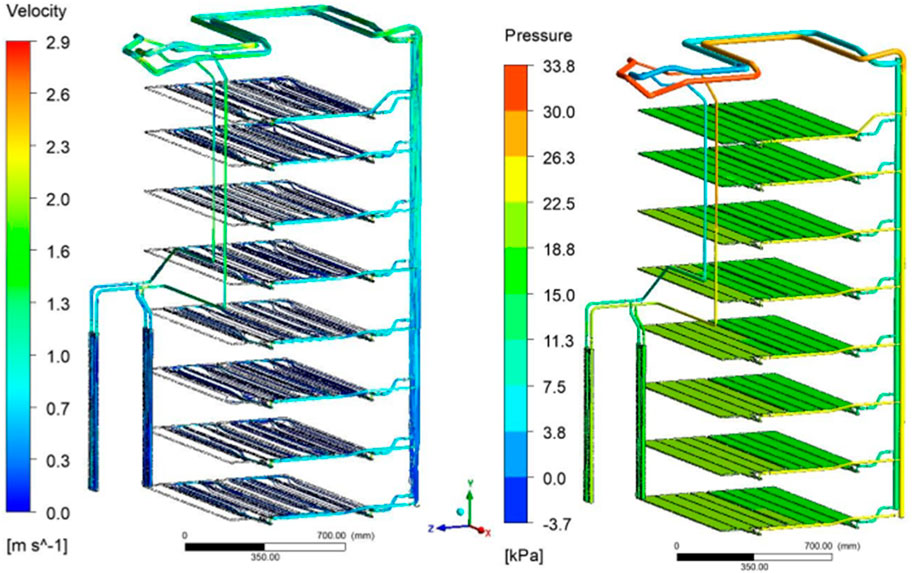

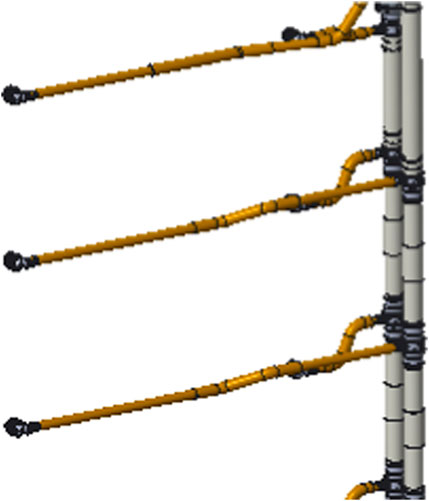

The water cooler is divided into two main water pipes: one inlet and one outlet, and the main water pipe is divided into nine parallel pipes. Two PCSs are connected to one pipeline in parallel, and the remaining eight pipelines supply water to the seven packs, respectively. See Figure 18 below for a specific diagram.

Flow uniformity plays an important role in the temperature consistency of the battery module. For this purpose, the flow was simulated, and the actual flow of the liquid-cooled integrated cabinet was measured. The flow rate of the whole tank is simulated using the pipeline trim theory. Figure 19 shows the overall 3D diagram of the liquid freezer, and Figure 20 shows the thermal simulation diagram of the liquid-cooled battery cluster. Figure 21 shows a detailed schematic diagram of the liquid cooling circuit.

In the simulation, the flow is measured by the flow test platform. The radiator and the water cooler are placed inside the platform and connected with the pipeline, and the flow test is carried out for a single PCS. Both the simulation and the measurement show that the maximum deviation of the flow rate between battery modules is less than 5% of the average flow rate. Refer to Figure 20 for a schematic diagram of the thermal simulation of a liquid-cooled battery cluster and to Figure 21 for a schematic diagram of a liquid-cooled battery cluster. Each layer has a liquid cooling circuit. The simulation values in Figure 20 show that the variation between battery modules is less than 5% of the average flow rate.

5 Article summary

Based on the device status and research into industrial and commercial energy storage integrated cabinets, this article further studies the integration technology of high energy density industrial and commercial energy storage liquid cooling integrated cabinet, cabinet design with high protection level and high structural strength, and temperature consistency design of an energy storage battery cabinet. The article reports on the development of a 116 kW/232 kWh energy storage liquid cooling integrated cabinet. In this article, the temperature equalization design of a liquid cooling medium is proposed, and a cooling pipeline of a liquid cooling battery cabinet is analyzed. The proposed system realizes the flow rate equilibrium, flow resistance equilibrium, and temperature equilibrium targets for a battery and a PCS in the whole life cycle. The proposed design addresses the circulation problems caused by PCS inconsistency and the abnormal capacity attenuation caused by battery inconsistency.

Industrial and commercial energy storage battery technology design with PMS + EMS joint management can eliminate the SOC difference between clusters to ensure long-term system consistency. Improved box design, high protection level, and high structural strength meet the overall cabinet IP55 and key components IP67 design standards to cope with harsh outdoor environments in industrial and commercial settings. The proposed system provides consistent battery storage cabinet temperatures. The liquid cooling loop covers each battery to provide more uniform heat dissipation. Cell temperature differences are limited to 3°C through the use of an intelligent temperature control strategy. Compared with conventional air cooling, power consumption is reduced by 10%.

Data availability statement

The original contributions presented in the study are included in the article/Supplementary Material, further inquiries can be directed to the corresponding author.

Author contributions

XZ: Data curation, Formal analysis, Funding acquisition, Methodology, Project administration, Resources, Supervision, Validation, Visualization, Conceptualization, Investigation, Software, writing–original draft, writing–review and editing. CL: writing–review and editing. YQ: writing–review and editing. ZB: writing–review and editing. MY: writing–review and editing.

Funding

The author(s) declare that financial support was received for the research, authorship, and/or publication of this article. The work was supported by State Grid Jiangsu Comprehensive Energy Service Co., Ltd. The funder was not involved in the study design, collection, analysis, interpretation of data, the writing of this article, or the decision to submit it for publication.

Acknowledgments

Thanks to the unit for the research of this article.

Conflict of interest

Authors XZ, CL, YQ, ZB, MY were employed by State Grid Jiangsu Integrated Energy Service Co., LTD.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

C and C Power Inc (2013). Agency reviews patent application approval request for “tiered battery cabinet”. Politics and Government Week.

Ghamari, V., Hajabdollahi, H., Dehaj, M. S., and Saleh, A. (2022). Investigating the effect of energy storage tanks on thermoeconomic optimization of integrated combined cooling, heating, and power generation with a desalination plant. J. Energy Storage 56, 106120. doi:10.1016/j.est.2022.106120

IntelliBatt (2012). IntelliBatt rolls out the world's First intelligent battery cabinet. Technology and Business Journal.

Kumar, J. J., and Varghese, J. (2023). Modeling, optimizing, and sizing a solar air conditioning system with refrigerant storage for meeting the 24-hour cooling load of a restaurant building. Int. J. Thermofluids 20, 100472. doi:10.1016/j.ijft.2023.100472

Meng, X. Z., Lu, Z., Jin, L. W., Chai, J. C., Hu, W., Wei, L., et al. (2015). Experimental and numerical investigation on thermal management of an outdoor battery cabinet. Appl. Therm. Eng. 91, 210–224. doi:10.1016/j.applthermaleng.2015.08.004

Ochmann, J., Rusin, K., and Bartela, Ł. (2023). Comprehensive analytical model of energy and exergy performance of the thermal energy storage. Energy 283, 128783. doi:10.1016/j.energy.2023.128783

Patents (2015). “Storage battery cabinet and storage battery system” in patent application approval process. Energy Weekly News.

Researchers Submit Patent Application (2015). “Tiered battery cabinet”, for approval. Politics and Government Week.

Researchers Submit Patent Application (2016). “Cabinets and methods for removing undesirable gas in cabinets”, for approval (USPTO 20150373868). Politics and Government Business.

Saleh, A., Hajabdollahi, H., Ghamari, V., and Shafiey Dehaj, M. (2023). Evaluation of operational strategy of cooling and thermal energy storage tanks in optimal design of multi-generation system. Energy 284, 129256. doi:10.1016/j.energy.2023.129256

Tianfu, L., Shen, Q., Qishan, Z., Chen, D., Fu, C., and Zhang, Z. (2023). Leakage failure analysis of a 60 m3 LNG storage tank. Eng. Fail. Anal. 153, 107591. doi:10.1016/j.engfailanal.2023.107591

Vechi, N. T., Falk Julie, M., Fredenslund Anders, M., Edjabou Maklawe, E., and Scheutz, C. (2023). Methane emission rates averaged over a year from ten farm-scale manure storage tanks. Sci. Total Environ. 904, 166610. doi:10.1016/j.scitotenv.2023.166610

Wang, X., Chen, X., Yang, J., Xie, P., and Yang, W. (2023). Research on torsional laminated extrusion for improving the permeability and mechanical properties of HDPE/PA6 composite for type IV storage tank liners. J. Appl. Polym. Sci. 140 (42). doi:10.1002/app.54567

Yang, Z., Zhang, H., Zhang, Z., Xian, M., Yong, S., Gong, X., et al. (2023). Sub-ambient daytime cooling effects and cooling energy efficiency of a passive sub-ambient daytime radiative cooling coating applied to telecommunication base stations— Part 1: distributed base stations and long-lasting self-cleaning properties. Energy 283, 128750. doi:10.1016/j.energy.2023.128750

Zhang, D. Y., Wu, J. Y., Zhou, H., and Gong, M. S. (2022). A benchmark shaking table test on the seismic responses of an extra-large LNG storage tank. Earthq. Eng. Struct. Dyn. 52 (2), 439–459. doi:10.1002/eqe.3767

ZincFive (2022a). ZincFive to provide green nickel-zinc UPS battery cabinets to Wyoming hyperscale white box. Manufacturing Close-Up.

Keywords: cabinet, structural strength, battery module, temperature equalization, thermal management

Citation: Zhou X, Liu C, Qian Y, Bi Z and Yang M (2024) Research and design for a storage liquid refrigerator considering the characteristics of energy storage batteries. Front. Energy Res. 12:1419427. doi: 10.3389/fenrg.2024.1419427

Received: 01 May 2024; Accepted: 14 June 2024;

Published: 09 August 2024.

Edited by:

Amir Riaz, University of Maryland, United StatesReviewed by:

Xiaodi Qin, State Grid Corporation of China (SGCC), ChinaZhiyuan Sun, Guanxi power Grid, China

Copyright © 2024 Zhou, Liu, Qian, Bi and Yang. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Xianwei Zhou, emhvdXhpYW53ZWlfemhueUAxMjYuY29t

Xianwei Zhou

Xianwei Zhou Chuncheng Liu

Chuncheng Liu