- 1Centre of Energy Research and Development, University of Engineering and Technology Lahore, Lahore, Pakistan

- 2Department of Chemical Engineering, University of Engineering and Technology Lahore, Lahore, Pakistan

- 3Department of Mechanical, Mechatronics and Manufacturing Engineering, University of Engineering and Technology Lahore, Lahore, Pakistan

- 4Department of Mechanical Engineering, Kampala International University, Ishaka, Uganda

- 5Department of Mechanical Engineering, Mirpur University of Science and Technology, Mirpur, AJK, Pakistan

- 6Department of Mechanical Engineering Technology, University of Gujrat, Gujrat, Pakistan

- 7Mechanical Engineering, Faculty of Engineering and Technology, Future University in Egypt, New Cairo, Egypt

- 8Faculty of Engineering and IT, University of Technology Sydney, Ultimo, NSW, Australia

This paper presents the integrated performance of a solar-assisted desiccant dehumidifier along with Maisotsenko cycle (M-cycle) counter flow heat and mass exchanger. This system handles latent load and sensible load separately. The hybrid configuration of solar thermal collectors was analyzed for efficiency of solar collectors and solar fraction. High consumption of fossil fuels, which are already present in a limited amount, is also associated with environmental problems and climate change issues, as these increase the chances of global warming. These issues demand of us to shift towards renewable energy resources. Increase in world energy use results in a number of environmental problems, such as climate change, in addition to global warming and ozone depletion. In building services, HVAC systems are major concerns. To overcome the requirement, conventional air conditioning and vapor compression systems are mainly used for air conditioning, although these also have some environmental problems. Solar thermal applications in combination with other renewable-energy-dependent cooling practices have generated a huge interest towards sustainable solutions, keeping in view several techno-economical, environmental, and climatic advantages. The experimental investigation reveals that the maximum outlet temperature and efficiency of solar thermal collectors was 87°C and 56% respectively. The maximum cooling capacity of the system is evaluated at 4.6 kW.

Highlights

1- The solar thermal collector mainly evacuated tube collector and flat plate collector, which were used for the regeneration of solid desiccant wheel

2- The parametric analysis of operating conditions is carried out with the configuration of counter flow HMX on Process air stream

3- The minimum outlet temperatutre from the M-Cycle is 14.7°C with a low inlet temperature of 27°C

4- The Maximum cooling capacity of the system is evaluated at 4.6 kW

1 Introduction

The amount of energy consumed to perform a special action, produce or manufacture something, or simply inhabit a building is termed as energy consumption (Sikder et al., 2016). Growing populations and improved living standards around the world have had a large impact on energy consumption (Wu J. et al., 2020; Khan et al., 2020). These factors affect the economic growth of a country. Economic growth has a strong correlation with energy consumption (Wang and Wang, 2020; Knight and Schor, 2014). In China and other Asian countries during the period of 2000–2008, economic growth accelerated the demand for electricity based on coal, and resulted in emissions of carbon dioxide CO2 (Wu H et al., 2020; Farooq et al., 2019). Unfortunately, two-thirds of CO2 emissions have already been consumed, and the remaining portion will be spent by 2050, making the energy-water-environment nexus crucial to achieving the COP21 target of keeping environmental temperature increase below 2°C. Though recent technical advancements in the electricity and desalination industries have increased their efficiency, they are still only running at 35% and 10% of their thermodynamic limitations, respectively, which has a significant impact on energy consumption and carbon emissions. Desalination process research is vital to meeting the energy needs of a growing global population while also lowering per capita energy consumption and safeguarding the planet’s natural resources (Shahzad et al., 2017). It means that increase in the economic growth results in an increase in energy consumption. Energy consumption in higher education buildings make up 40% of total energy consumption in the United Kingdom (United Kingdom) (Amber et al., 2020). So, emissions can be minimized by cutting of energy consumption. In developing countries, economic development is necessary to achieve this aim.

In developed countries, the energy consumption in building sectors contributes 20%–40% to total energy usage (Bahadori-Jahromi et al., 2017), (Kashif et al., 2020). With the increasing demand of thermal comfort in buildings like offices and other industrial buildings, HVAC systems account for about 10%–20% of total energy consumption (Lu et al., 2019; González and Fiorito, 2015). It is clear that energy consumption is increasing day by day, especially in building services (Pérez-Lombard et al., 2008; Petri et al., 2017). In the modern era, fossil fuels like coal and oil used for energy production are depleting rapidly (Brandt, 2011; Murphy et al., 2011). So, there is a need to move towards an alternative source of energy generation (Halim, 2013; Berbel and Posadillo, 2018).

The Sun is the major source of life on earth; when using this source to power a system, it serves as a ‘‘free’’ source of energy for many processes at the same time. In comparison with other sources of energy, solar energy has great advantages of being remarkably clean and environmentally friendly (Mahmud et al., 2018; Choudhary and Srivastava, 2019). Solar energy is a major source of renewable energy and, based on methods of its capture and conversion, solar power can be classified as either active solar or passive solar energies (Abdelkareem et al., 2018). Rapid increases in energy consumption day by day and considerably high prices of fossil fuels demand the replacement of traditional refrigeration systems that require high amounts of energy (Moriarty and Honnery, 2019). For large systems, a number of solar-based cooling technologies exist that can be used in combination with solar thermal collectors (Baral et al., 2015; Ma et al., 2017). Solar-assisted desiccant air conditioning is a renewable technology which saves a lot of energy (Angrisani et al., 2016). Because this system does not have a compressor in it, energy consumption is very low as compared to other refrigeration systems. The energy consumption equipment’s includes axial fans and water pumps, which consumes a small amount of energy.

The emerging cooling technology hybrid indirect evaporative cooling-mechanical vapor compression (IEC-MVC) combines the benefits of IEC and MVC, allowing for precise temperature and humidity regulation, excellent energy efficiency, and little water usage (Chen et al., 2022). When compared to conventional mechanical vapor compression (MVC) chillers, the indirect evaporative cooler (IEC) is seen as a more efficient and environmentally friendly option for cooling purposes. However, IEC is a passive cooler and has no real control over the ambient temperature or humidity of the supplied air. When the relative humidity of the air is high, IEC performance suffers. We explore a hybrid approach that integrates IEC and MVC in order to get around these restrictions. In the IEC, pre-cooling occurs when energy is reclaimed from the exhausted air of a room and applied to the outside air before further processing with MV (Chen et al., 2021).

As an alternative to traditional air conditioning systems, indirect evaporative cooling technology has evolved as an energy-efficient, low-cost, and sustainable method of cooling indoor spaces. This is because it may reduce cooling costs by as much as half compared to conventional cooling methods like forced air and vapor compression, as well as desiccant cooling. Jamil et al. (2021) investigated an innovative humidifier-aided regenerative indirect evaporative cooler that reduces fouling tendency and water management difficulties by doing away with hydrophilic surfaces used in the system. The proposed setup has an optimal cooling efficiency of 83.82 percent and a performance coefficient of 44 percent. Scaling trends of the coefficient of performance are as follows: Primary air inlet temperature > primary air outlet temperature > primary air velocity. The effectiveness of the cooler scales is as follows: Secondary air outlet temperature > primary air inlet temperature > primary air humidity > primary air outlet.

In terms of coefficient of performance (COP), M-CYCLE-based desiccant air conditioning systems are 60%–65% more efficient than conventional air conditioning systems providing the same inlet conditions (Kashif Shahzad et al., 2018). The main advantage of this solution is that it can provide the required comfort level with comparatively less effective dehumidification (Cui et al., 2019). When discussing these air conditioning systems the factors air inlet temperature, regeneration air temperature, and humidity are important. An important component of the desiccant dehumidifier is the special desiccant wheel that is solely used to adsorb the moisture content from air during dehumidification (Hu et al., 2016). A lot of materials are used for thermal storage in desiccant cooling systems like silica gel, paraffin wax, stearic acid, and CaCl2.6H2O (Leng et al., 2006; Alghamdi, 2017). Choosing which material depends on the energy consumed by them. An experimental analysis shows that if a system exists without solar energy and storage material the energy consumption by it is 23.57 kW. On the other hand, the average energy saving percentage of paraffin wax, stearic acid, and CaCl2.6H2O is 75.86%, 78%, and 64.6% respectively, by using them as storage materials (Kabeel et al., 2018). This study was carried out by using Silica gel as a storage material in solar-assisted desiccant air conditioning system.

The COP of this desiccant-based cooling system is strongly contingent on the operating parameters and can be increased by unbalancing the flow of air through the dehumidifier (Wu et al., 2019). When performing the second law analysis, the reversible COP of this system is found to be 2.64 while operating in ventilation mode and around 3.03 on recirculation mode. In ventilation mode, COP can be improved 10%–15% by unbalancing the air flow. Moreover, in recirculation COP increases by 50% (Anisimov et al., 2015). A numerical technique is used to execute the thermal calculations of an indirect evaporative cooler (IEC) based on a model of combined parallel heat and mass exchanger with counter flow regenerative arrangement. The results calculated from mathematical simulation show the high effectiveness of the presented model (Kilkovský, 2020).

In Hong Kong, a hybrid configuration of solar-assisted liquid desiccant dehumidifier (LDD) along with indirect evaporative cooler was carried out in an elevated temperature region with a high humidity ratio. The results show that, by increasing the solar collector’s area, the cooling capacity as well as moisture removal rate were increased. Moreover, the air conditioning system based on LDD indirect evaporative cooler saves about 47% energy consumption when compared with a mechanical vapor compression refrigeration system (Chen et al., 2017).

From the above mentioned studies, it is clear that the working ability of the IEC is significantly affected by the humidity level of air. Furthermore, it is clear that the cooling capacity and moisture removal rate can be increased by increasing the regeneration temperature. To achieve such configuration, solar thermal collectors as a renewable energy source are used in association with SDD-IEC. Dew point evaporative cooling is a perfect option for removing the sensible heat that is produced by electronics, data centers, and electric cars since it uses so little power (Lin et al., 2021).

Due to higher building demand for HVAC applications, there is a need to use renewable energy resources for these applications to mitigate an intensive use of energy. Solar desiccant evaporative cooling is an emerging technique that can be more helpful in severe climate conditions with minimum energy requirement for its operation. In the majority of studies carried out on SDD-IEC, a cross flow heat exchanger was usually used. In this study, however, a counter flow heat exchanger was used as an indirect evaporative cooler and an integrated system of thermal collectors (evacuated tube collectors and Flat Plate Collectors) were utilized for regeneration process through hot water. The current work is carried out in UET Taxila (Latitude: 33.7660 Longitude: 72.8250), where temperature in the summer is high and the climate is humid. It is worth mentioning that the present study experimentally evaluates the effect of operational parameters such as humidity, temperature, and rotational speed of desiccant wheel on the performance of the system. The current study is novel in terms of parametric analysis of SDD-IEC by using EES, experimental evaluation of solar water heating system in term of collector’s efficiency, temperature profile and sensible heat factor, and validation of key aspects of the cooling system.

2 Materials and methods

2.1 Experimental setup

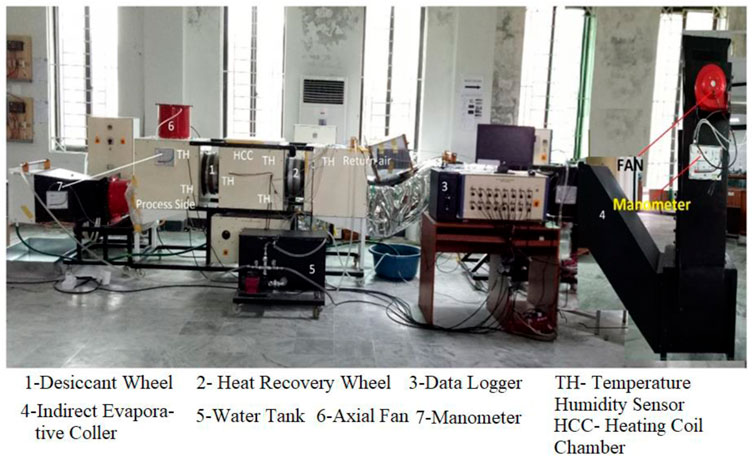

The experimental setup has a hybrid configuration of solar water heating system and solid desiccant indirect evaporative cooler.

2.1.1 Solar array for water heating

Solar thermal collectors were used as a renewable source of energy to heat water to regenerate the desiccant wheel. Solar thermal collectors consist of a hybrid configuration of flat plate collectors (FPCs) and evacuated tube collectors along with a storage tank. The FPCs are the cheapest source among collectors and it does not require the tracking of the Sun. FPCs are designed for moderate temperatures. To achieve the required regenerative temperature, FPCs are linked with evacuated tube collectors (ETCs). The space between glass and absorber is evacuated to reduce the convection losses in ETC.

The cover area of flat plate and ETC is 4.7 and 6.8 m2 respectively. An auxiliary source consisting of electric heaters is also used for backup source. The collector’s arrays are mounted on the roof of energy engineering department UET Taxila. To minimize the environmental impacts on the efficiency of collectors, the rubber foam of thickness 5 mm is used to insulate the loop circuit. To record the temperature values at different points of the solar water heating system, K type thermocouples are used. However, to control the water flow rate through the collector’s ball, valves are installed at various points. Similarly, a pressure relief valve is used in the tank to release steam. The solar water heating system works continuously throughout the day. The set value for the temperature of hot water is 75 C. The experimental setup of solar collectors is shown in Figure 1. The intensity of solar light is measured using a pyranometer.

2.1.2 Cooling system

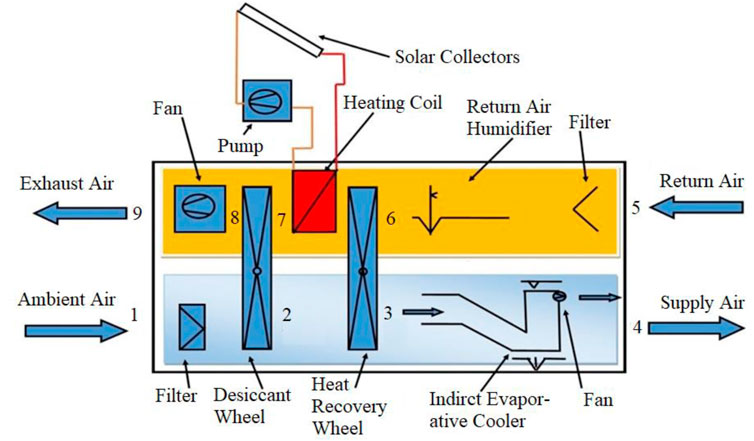

The cooling system comprises of a solid desiccant dehumidifier, enthalpy wheel, indirect evaporative cooler (counter flow heat and mass exchanger), direct evaporative cooler, and heating coils. The system handles the latent as well as sensible load separately. A solid desiccant dehumidifier is used to handle the latent load of the system whereas the indirect evaporative cooler handles the sensible load. The whole system is separated into two portions: the process side and the regeneration side. This experimental setup can be viewed in Figure 2.

2.2 Experimental procedure

Before performance evaluation of the system, the sensors are calibrated and tested initially with different operating conditions. The cooling system was tested by varying the mass flow rate, humidity level of inlet air, rpm of desiccant wheel, and regeneration temperature. After measuring the system’s initial performance, the experimental data was collected by running the system. The solar loop was stared at 8 a.m. so that it can achieve the required regenerative temperature. The desiccant cooling system works from 9 a.m. to 4 p.m. The schematic diagram of the integrated solar-assisted solid desiccant dehumidifier in the direct evaporative cooler has been represented in Figure 3. The ambient air is forced to enter in the system at 1 through a fan, goes through the desiccant wheel in the process side, and leaves at 2 as shown in Figure 3. In this process, the humidity level of air is decreased but the temperature rises up (latent heating of ambient air). Further, from processes 2–3 the dehumidified air passes through the heat recovery wheel for temperature reduction. Then air is passed through the indirect evaporative cooler for sensible cooling and leaves the system at 4. Afterwards, on the regeneration side, the room air is sensibly cooled in the direct evaporative cooler and leaves at 6. Then the heat exchange phenomena take place between the process air and regeneration air from 6 to 7. Later, the regeneration air achieves the required regenerative temperature of desiccant wheel (70°C) by passing through the heating coils. At last, from 7 to 8 this heated air moves over the desiccant wheel to absorb the moisture content in it and leave the system at 9.

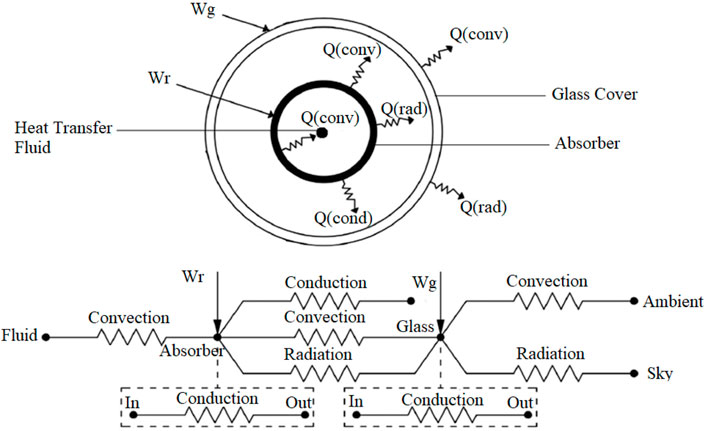

2.3 Thermal resistance model

The thermal resistance model given in Figure 4 illustrates the modes of heat transfer in an evacuated tube collector. Heat is transferred between fluid and receiver through convection.

3 Measuring instruments

At various points in the solar-assisted desiccant air conditioning system (SDAC) the parameters of air were measured to analyze the system performance. The parameters that were measured were humidity, temperature, and air flow rate. The pressure difference measured from manometers gives the air flow rate of process air and the regeneration air. DHT-22 Sensors were used to measure the temperature and humidity level of the air along with a data logger based on the Arduino program. The intensity of solar light was measured by using LI-19 data logger.

4 Results and discussion

4.1 Parametric analysis of desiccant wheel

In this section, parametric analysis of desiccant wheel for desiccant material silica gel SiO2 has been done by EES software.

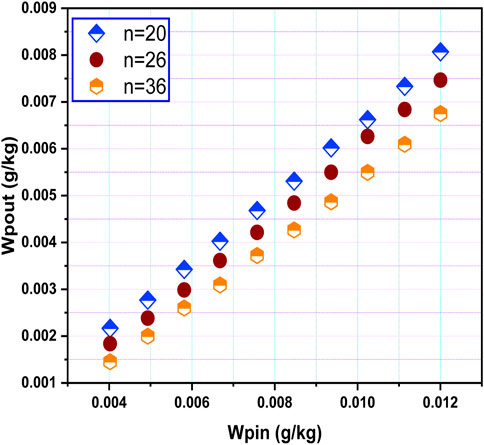

4.1.1 Effect of process inlet humidity ratio

The Process inlet parameters like Wpin and Tpin influence the other parameters of desiccant wheel. The effect of Wpin on Wpout for Silica gel desiccant wheel (DW) is shown in Figure 5. The analysis is carried out on rotation speeds of the desiccant wheel i.e., 20, 26, and 36 rph. The Wpin, has direct influence on the Wpout. At higher Wpin more moisture is removed in the air. Thus, the outlet humidity increases with inlet humidity, which causes higher moisture removal. Additionally, it can be viewed that the dehumidification of air is more favorable at lower rotation speeds. When considering the different speeds of the desiccant wheel, the graph shows that at the lowest speed the Wpout is greater as compared to the highest speed of rotation at each Wpin. This shows the moisture removal by desiccant increases with the increase of speed.

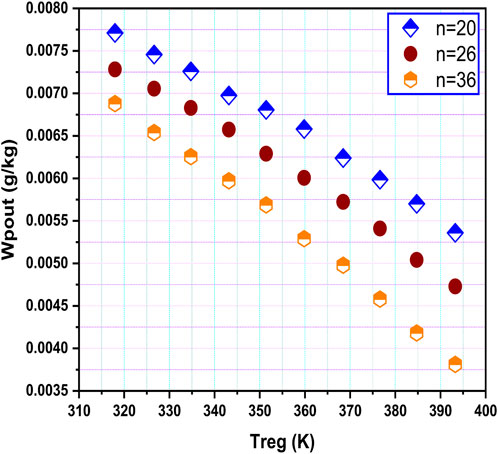

4.1.2 Effect of regeneration temperature

Regeneration air always has a dominant role on specifying process outlet conditions. The effect of Treg on Wpout and DW is as shown in Figure 6. Dehumidification by desiccant wheel is mostly exaggerated by regeneration temp. Raising the Treg improves the moisture removal capability of the desiccant material which results in lowering the process outlet humidity ratio because desiccant wheel is regenerated in a better way. However, the rotation speed also has an important effect on Wpout. At lower speeds dehumidification is minimum as compared to high speed, which results in higher humidity ratio on the process outlet.

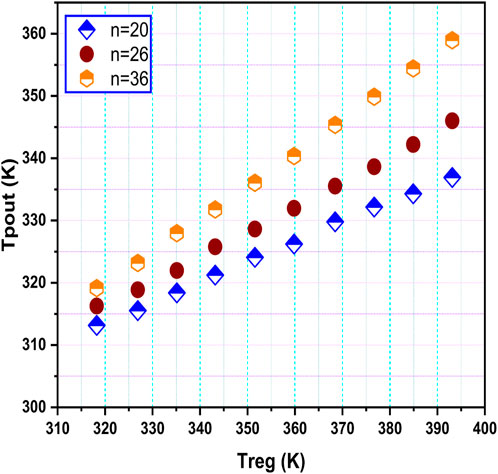

4.1.3 Effect of regeneration temperature on process outlet temperature

Additionally, Treg affects Tpout and DT of process air outlet and is as shown in Figure 7. Increases in Treg increase the outlet temperature of process air Tpout. High Treg gives high Tpout. This is due to the increase in heat of adsorption with additional latent heat to sensible heat conversion. On the other hand, at low Treg the outlet temp Tpout is close to each other at each rotation of the wheel but shows a significant effect at high Treg on the rotation speeds. At high Treg and N, DT of the air dominates as compared to less Treg and N.

4.1.4 Effect of rotation speed of desiccant wheel

The speed “n” of desiccant wheel influences the Wpout of the process outlet air with different Wpin, Tsin, and Treg. The effect of speed N on Wpout and W at different Wpin is as shown in Figure 8. The rotational speed has an important role in the accomplishment of the dehumidification process at a low rotation speed.

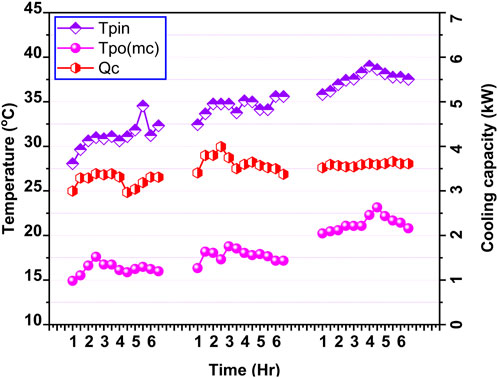

4.1.5 Variation of temperature and cooling capacity of solar desiccant coolings

The process inlet Tpin and the process outlet temperature of M-Cycle Tpo (mc) along with cooling capacity Qc is shown in Figure 9: Variation of cooling capacity and temperatures of SDC. Increases in inlet temperature results in a decrease in inlet humidity ratio, so the cooling capacity increases. The process outlet temperature increases with increases in inlet temperature. The maximum cooling capacity achieved is 4.6 kW.

4.2 Analysis of thermal collectors

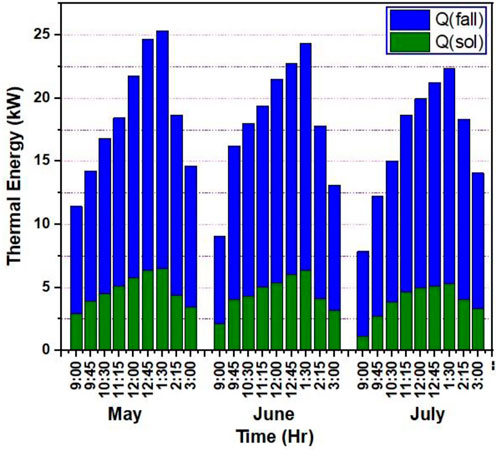

4.2.1 Thermal energy shares

The solar thermal energy flows vary as the function of time exists in Figure 10: Variation of thermal Energy flows with respect to time. Q(fall) is the solar thermal energy on earth and Q(sol) is the thermal energy provided by the solar thermal collectors. Due to higher intensities of solar light in the month of May, the Q(fall) is high. Moreover, the energy obtained from the collectors is also high in this month as compared to others. The maximum and minimum energy gain is 6.58 and 1.22 kW respectively. The average energy gain for three selected days of different months is 4.3 kW. While the average energy fall on the earth’s surface is 9.42 kW.

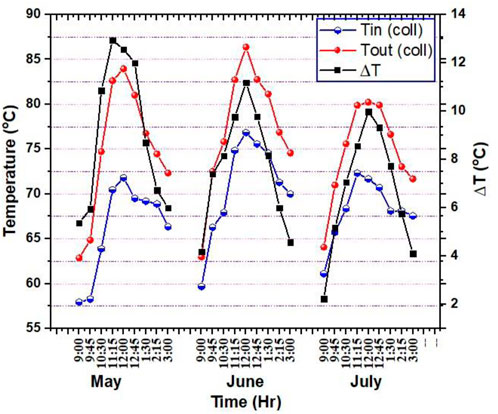

4.2.2 Temperature profile of solar water heating system

Another aspect of utilizing solar energy is for the regeneration purposes of desiccant wheel through solar thermal collectors. The variation of temperatures of a solar water heating system and the time is shown in Figure 11: Variation of temperature of collectors with respect to time of three different months. The intensity of solar radiation strongly affects the output of collectors. As seen from the figure, the temperature gradient is low in the morning because of low solar intensity in the morning. The maximum temperature outlet achieved through the collector is 87.49°C. However, the maximum temperature gain is 12.33°C, with solar intensity of 868 W/m2. While the minimum temperature gain is 2.33°C, corresponding to solar intensity of 351 W/m2. For 3 days the average outlet temperature is 76.33°C, with an average solar intensity of 671 W/m2.

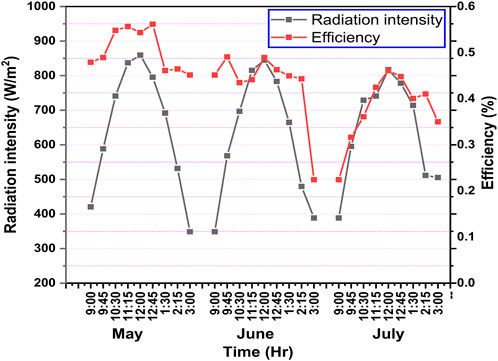

4.2.3 Effect of solar intensity on collector’s efficiency

Solar irradiance influences the efficiency of collectors. Increases in solar irradiance results in high efficiency of collectors. Variation of collector efficiency along with solar irradiance is shown in Figure 12: Variation of collector efficiency with respect to solar irradiance. When the solar intensity is low the efficiency decreases. The observation shows that maximum collector efficiency is 56% with solar irradiance of 868 W/m2. In the month of July, minimum efficiency was observed at 9 a.m. at 22%, corresponding to solar intensity of 351 W/m2. The average resulting efficiency for 3 days is 45%.

The observation shows that the moisture removal rate in desiccant wheel decreases as the rotational speed of the wheel increases for both process and regeneration streamline. When the inlet temperature of the process stream line increases, inlet humidity ratio decreases, which corresponds to enhancing the cooling capacity of the system. Moreover, the collector’s efficiency is dependent on the intensity of solar irradience.

5 Conclusion

The performance of an integrated solar desiccant cooling (SDC) system was experimentally monitored for three selected days in summer months under the hot and humid climate of Taxila, Pakistan.

• The experimental results show that, for thermal comfort conditions, the SDC system gives better output. The other systems that were based on only indirect evaporative cooler do not have the capability to produce such thermal comfort in the severe weather conditions of summer.

• The maximum outlet temperature of collectors is 87°C. However, the maximum reputed efficiency is 56%. The minimum outlet temperature from the M-Cycle is 14.7°C with a low inlet temperature of 27°C.

• An increase in the process inlet temperature results in a decrease in inlet humidity ratio, hence the cooling capacity enhances.

• The Maximum monitored cooling capacity of the system is 4.6 kW. The parametric analysis shows that the moisture removal rate is high with a low speed of rotation of desiccant wheel or vise versa.

• At 20 rph of desiccant wheel, the moisture removal rate is tremendous.

• The current study concludes that the energy consumption by the system was minimized when utilizing solar energy to regenerate the desiccant material through thermal collectors.

Data availability statement

The raw data supporting the conclusion of this article will be made available by the authors, without undue reservation.

Author contributions

AD (Writing—Original Draft; Data Curation), AT (Writing—Review and Editing; Ideas; formulation or evolution of overarching research goals and aims), MM (Formal Analysis, Writing—Review and Editing), MA (Writing—Review and Editing), AY (Writing—Review and Editing), GC (Writing—Review and Editing), LR (Writing—Review and Editing; Software), AA (Writing—Review and Editing; Funding acquisition), MK (Writing—Review and Editing).

Acknowledgments

The current work acknowledges the research Renewable Energy Research and Development Center (RERD) UET Taxila Pakistan.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Abdelkareem, M. A., Assad, M. E. H., Sayed, E. T., and Soudan, B. (2018). Recent progress in the use of renewable energy sources to power water desalination plants. Desalination 435, 97–113. doi:10.1016/j.desal.2017.11.018

Alghamdi, J. (2017). Thermal energy storage technologies for zero carbon housing in the UK. Wales: Cardiff University.

Amber, K. P., Ahmad, R., Chaudhery, G. Q., Khan, M. S., Akbar, B., and Bashir, M. A. (2020). Energy and environmental performance of a higher education sector – a case study in the United Kingdom. Int. J. Sustain. Energy 6451, 497–514. doi:10.1080/14786451.2020.1720681

Angrisani, G., Roselli, C., Sasso, M., Tariello, F., and Vanoli, G. P. (2016). Performance assessment of a solar-assisted desiccant-based air handling unit considering different scenarios. Energies 9 (9), 724. doi:10.3390/en9090724

Anisimov, S., Pandelidis, D., and Jedlikowski, A. (2015). Performance study of the indirect evaporative air cooler and heat recovery exchanger in air conditioning system during the summer and winter operation. Energy 89, 205–225. doi:10.1016/j.energy.2015.07.070

Bahadori-Jahromi, A., Rotimi, A., Mylona, A., Godfrey, P., and Cook, D. (2017). Impact of window films on the overall energy consumption of existing UK hotel buildings. Sustainability 9 (5), 731. doi:10.3390/su9050731

Baral, S., Kim, D., Yun, E., and Kim, K. C. (2015). Experimental and thermoeconomic analysis of small-scale solar organic Rankine cycle (SORC) system. Entropy 17 (4), 2039–2061. doi:10.3390/e17042039

Berbel, J., and Posadillo, A. (2018). Review and analysis of alternatives for the valorisation of agro-industrial olive oil by-products. Sustainability 10 (1), 237. doi:10.3390/su10010237

Brandt, A. R. (2011). Oil depletion and the energy efficiency of oil production: the case of California. Sustainability 3 (10), 1833–1854. doi:10.3390/su3101833

Chen, Y., Yu, W., Wu, P., Yang, H., and Luo, Y. (2017). Energy performance of solar assisted desiccant enhanced evaporative cooling air conditioning system. Procedia Eng. 205, 4195–4202. doi:10.1016/j.proeng.2017.10.181

Chen, Q., Kum Ja, M., Burhan, M., Akhtar, F. H., Shahzad, M. W., Ybyraiymkul, D., et al. (2021). A hybrid indirect evaporative cooling-mechanical vapor compression process for energy-efficient air conditioning. Energy Convers. Manag. 248, 114798. doi:10.1016/j.enconman.2021.114798

Chen, Q., Ja, M. K., Burhan, M., Shahzad, M. W., Ybyraiymkul, D., Zheng, H., et al. (2022). Experimental study of a sustainable cooling process hybridizing indirect evaporative cooling and mechanical vapor compression. Energy Rep. 8, 7945–7956. doi:10.1016/j.egyr.2022.06.019

Choudhary, P., and Srivastava, R. K. (2019). Sustainability perspectives-a review for solar photovoltaic trends and growth opportunities. J. Clean. Prod. 227, 589–612. doi:10.1016/j.jclepro.2019.04.107

Cui, X., Sun, L., Zhang, S., and Jin, L. (2019). On the study of a hybrid indirect evaporative pre-cooling system for various climates. Energies 12 (23), 4419. doi:10.3390/en12234419

Farooq, M., Saeed, M. A., Imran, M., Uddin, G. M., Asim, M., Bilal, H., et al. (2019). CO2 capture through electro-conductive adsorbent using physical adsorption system for sustainable development. Environ. Geochem. Health 42, 1507–1515. doi:10.1007/s10653-019-00318-2

González, J., and Fiorito, F. (2015). Daylight design of office buildings: Optimisation of external solar shadings by using combined simulation methods. Buildings 5 (2), 560–580. doi:10.3390/buildings5020560

Halim, M. A. (2013). Harnessing sun’s energy with quantum dots based next generation solar cell. Nanomaterials 3 (1), 22–47. doi:10.3390/nano3010022

Hu, S.-C., Shiue, A., Chiu, Y.-S., Wang, A., and Chen, J. (2016). Simplified heat and mass transfer model for cross-flow and countercurrent flow packed bed tower dehumidifiers with a liquid desiccant system. Sustainability 8 (12), 1264. doi:10.3390/su8121264

Jamil, M. A., Bin Xu, B., Dala, L., Sultan, M., Jie, L., and Shahzad, M. W. (2021). Experimental and normalized sensitivity based numerical analyses of a novel humidifier-assisted highly efficient indirect evaporative cooler. Int. Commun. Heat Mass Transf. 125, 105327. doi:10.1016/j.icheatmasstransfer.2021.105327

Kabeel, A. E., Abdelgaied, M., and Al Ali, M. (2018). Energy saving potential of a solar assisted desiccant air conditioning system for different types of storage. Environ. Prog. Sustain. Energy 37 (4), 1448–1454. doi:10.1002/ep.12795

Kashif, M., Niaz, H., Feng, Y., Niaz, Y., Ali, I., Sultan, M., et al. (2020). Study on desiccant and evaporative cooling systems for livestock thermal comfort: theory and experiments. Energies 13, 2675. doi:10.3390/en13112675

Kashif Shahzad, M., Ali, M., Ahmed Sheikh, N., Qadar Chaudhary, G., Shahid Khalil, M., and Rashid, T. U. (2018). Experimental evaluation of a solid desiccant system integrated with cross flow Maisotsenko cycle evaporative cooler. Appl. Therm. Eng. 128, 1476–1487. doi:10.1016/j.applthermaleng.2017.09.105

Khan, Z., Ali, M., Jinyu, L., Shahbaz, M., and Siqun, Y. (2020). Consumption-based carbon emissions and trade nexus : Evidence from nine oil exporting countries. Energy Econ. 89, 104806. doi:10.1016/j.eneco.2020.104806

Kilkovský, B. (2020). Review of design and modeling of regenerative heat exchangers. Energies 13 (3), 759. doi:10.3390/en13030759

Knight, K. W., and Schor, J. B. (2014). Economic growth and climate change: a cross-national analysis of territorial and consumption-based carbon emissions in high-income countries. Sustainability 6 (6), 3722–3731. doi:10.3390/su6063722

Leng, G., Navarro, H., Yu, Q., Wellio, G., Qiao, G., Li, C., et al. (2006). Design of composite materials/devices for thermal storage–A critical review. Veruscript Funct. Nanomater. 2, 1–28. doi:10.22261/ghv5w9

Lin, J., Shahzad, M. W., Li, J., Long, J., Li, C., and Chua, K. J. (2021). A robust physics-based model framework of the dew point evaporative cooler: From fundamentals to applications. Energy Convers. Manag. 233, 113925. doi:10.1016/j.enconman.2021.113925

Lu, S., Wang, W., Wang, S., and Cochran Hameen, E. (2019). Thermal comfort-based personalized models with non-intrusive sensing technique in office buildings. Appl. Sci. (Basel). 9 (9), 1768. doi:10.3390/app9091768

Ma, Y., Saha, S. C., Miller, W., and Guan, L. (2017). Comparison of different solar-assisted air conditioning systems for Australian office buildings. Energies 10 (10), 1463. doi:10.3390/en10101463

Mahmud, M. A., Huda, N., Farjana, S. H., and Lang, C. (2018). Environmental impacts of solar-photovoltaic and solar-thermal systems with life-cycle assessment. Energies 11 (9), 2346. doi:10.3390/en11092346

Moriarty, P., and Honnery, D. (2019). Energy efficiency or conservation for mitigating climate change? Energies 12 (18), 3543. doi:10.3390/en12183543

Murphy, D. J., Hall, C. A. S., Dale, M., and Cleveland, C. (2011). Order from chaos: a preliminary protocol for determining the EROI of fuels. Sustainability 3 (10), 1888–1907. doi:10.3390/su3101888

Pérez-Lombard, L., Ortiz, J., and Pout, C. (2008). A review on buildings energy consumption information. Energy Build. 40 (3), 394–398. doi:10.1016/j.enbuild.2007.03.007

Petri, I., Kubicki, S., Rezgui, Y., Guerriero, A., and Li, H. (2017). Optimizing energy efficiency in operating built environment assets through building information modeling: a case study. Energies 10 (8), 1167. doi:10.3390/en10081167

Shahzad, M. W., Burhan, M., Ang, L., and Ng, K. C. (2017). Energy-water-environment nexus underpinning future desalination sustainability. Desalination 413, 52–64. doi:10.1016/j.desal.2017.03.009

Sikder, S. K., Eanes, F., Asmelash, H. B., Kar, S., and Koetter, T. (2016). The contribution of energy-optimized urban planning to efficient resource use–A case study on residential settlement development in dhaka city, Bangladesh. Sustainability 8 (2), 119. doi:10.3390/su8020119

Wang, Q., and Wang, L. (2020). Renewable energy consumption and economic growth in OECD countries : a nonlinear panel data analysis. Energy 207, 118200. doi:10.1016/j.energy.2020.118200

Wu, H., Salles, F., and Zajac, J. (2019). A critical review of solid materials for low-temperature thermochemical storage of solar energy based on solid-vapour adsorption in view of space heating uses. Molecules 24 (5), 945. doi:10.3390/molecules24050945

Wu, H., Xu, L., Ren, S., Hao, Y., and Yan, G. (2020). How do energy consumption and environmental regulation affect carbon emissions in China ? New evidence from a dynamic threshold panel model. Resour. Policy 67, 101678. doi:10.1016/j.resourpol.2020.101678

Wu, J., Abban, O. J., Boadi, A. D., Haris, M., Ocran, P., and Addo, A. A. (2020). Exploring the relationships among CO 2 emissions , urbanization , economic growth , economic structure , energy consumption , and trade along the BRI based on income classification. Energy, Ecol. Environ. 6, 213–231. doi:10.1007/s40974-020-00176-0

Nomenclature

T Temperature (°C)

W Humidity Ratio (g/kg)

Qc Cooling capacity (kW)

N Speed of rotation of desiccant wheel (rpm)

Q(sol) Thermal energy from Collectors (kW)

Q(fall) Thermal energy fall on earth (kW)

Eta Efficiency of Collectors

∆T Temperature gain (°C)

Subscripts

Pin Process inlet conditions

Pout Process outlet conditions

reg Regeneration conditions

in(coll) Collector Inlet Conditions

o(coll) Collector outlet conditions

Keywords: HVAC, solar thermal collector, desiccant dehumidifier, evaporative cooling, solar energy research highlights

Citation: Ditta A, Tabish AN, Mujtaba MA, Amjad M, Yusuf AA, Chaudhary GQ, Razzaq L, Abdelrahman A and Kalam MA (2022) Experimental investigation of a hybrid configuration of solar thermal collectors and desiccant indirect evaporative cooling system. Front. Energy Res. 10:979942. doi: 10.3389/fenrg.2022.979942

Received: 28 June 2022; Accepted: 22 August 2022;

Published: 29 September 2022.

Edited by:

K. Sudhakar, Universiti Malaysia Pahang, MalaysiaReviewed by:

Muhammad Wakil Shahzad, Northumbria University, United KingdomShanmuga Priya S., Manipal Institute of Technology, India

Copyright © 2022 Ditta, Tabish, Mujtaba, Amjad, Yusuf, Chaudhary, Razzaq, Abdelrahman and Kalam. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: M. A. Mujtaba, bS5tdWp0YWJhQHVldC5lZHUucGs=

Allah Ditta

Allah Ditta Asif Nadeem Tabish

Asif Nadeem Tabish M. A. Mujtaba

M. A. Mujtaba Muhammad Amjad

Muhammad Amjad Abdulfatah Abdu Yusuf4

Abdulfatah Abdu Yusuf4 Ghulam Qadar Chaudhary

Ghulam Qadar Chaudhary Luqman Razzaq

Luqman Razzaq