- Exploration and Development Research Institute of Jilin Oilfield Company PetroChina, Songyuan, China

Introduction

Recently, there has been an increase in the desire to recover hydrocarbons from formations with extremely low porosity (˂15%) and low permeability (˂0.1 mD), like coalbed methane reservoirs, methane hydrate, tight reservoirs, and shales (Yekeen et al., 2018). For these reservoirs to produce, horizontal drilling and multi-stage hydraulic fracturing techniques must be used to create artificial fractures that allow the flow of the gas to the wellbore (Hou et al., 2015). Water-based fracturing fluids have been in use for decades; however, the costs associated with formation damage, excessive water use, and environmental degradation have limited their field applications. To address the challenges of water-based fracturing fluids, development of non-water-based fracturing fluids such as gas-based and foam-based fluids with high apparent viscosities and low water requirements have been invented (Verma and Ojha, 2021).

These fluids may efficiently transfer the desired hydraulic pressure into the fracture zone and effectively transport the proppants to the created fractures. Foam is a mixture of gas and liquid, with the gas as the internal phase (CO2, N2, or their mixture) and the liquid as the external phase. This includes water, oil, or even alcohol characterized by low density, high viscosity, high compressibility, and non-Newtonian rheology (Elgibaly et al., 2021; Agarwal and Kudapa, 2022). To preserve foam stability during the treatment, both phases of foam generation must be combined with a suitable surfactant at the recommended ratio (Wanniarachchi et al., 2015). Surfactants reduce the surface tension by adsorbing at the gas–liquid interface of the bubble, thus stabilizing the foam.

Significance of foam fluids

As the surfactants contact the oil in the reservoirs, the foam collapses and surfactants are released, further lowering the interfacial tension between oil and water. Additionally, the foams fill the higher permeability zones in the heterogeneous reservoirs and prevent further passage of gases into these channels. The passage of the injected gas will be through the lower permeability zones of the formation, enhancing the sweep efficiency and oil recovery (Hou et al., 2018). The success of foam-based fluids over water-based fluids is due to 1) the minimal water volume and high gas content, making it useful in water-sensitive formations; 2) the fracking process, especially the under-pressured or depleted reservoir as it provides a faster clean up rate. The expansion of the gas in the foam acts as a driver to remove the fluid away from the fractured region without the aid of the formation pressure. This can also reduce the effect of formation damage and pore clogging due to the residue being left behind by the inefficient cleanup process caused by other types of fluids (Xu et al., 2016); 3) the excellent proppant transporter due to its high apparent viscosity; and 4) eliminating the need for extra chemical additives such as gel breakers or crosslinkers. Minimal use of water in foam can reduce the cost needed for waste water disposal or treatment (Li et al., 2016).

Comprehensive evaluation

Foams used as drilling fluids

Apart from other minimum conditions of the foam for drilling in unconventional reservoirs (shale gas formation), it must withstand the high-temperature conditions of the reservoir. This is because the shale hydrocarbon producing zones are found deeper and experience a higher temperature than conventional formations (Li et al., 2014). Also, due to the compressibility of the gas phase in the foam mixture, the control of the total flow rate and foam quality is crucial at reservoir pressure and temperature conditions. Foam quality, defined as the proportion of the gas volume to the total volume, and foam texture, defined as the size and distribution of the gas bubbles, are two terms used to describe and determine the application of foams (Quintero, 2002). Foam-based drilling fluid application offers more advantages for drilling from both an operational and economic perspective: 1) Its ability to efficiently carry drilling cuttings from the wellbore to the surface ( Vaziri et al., 2020), 2) increased bit life and penetration rate, thus reducing drilling costs, and 3) less tendency to induce formation damage as it contains reduced amount of water. The gas phase in the foam causes the wellbore to unplug due to collected formation fluids and hydrocarbons (Edrisi and Kam, 2014).

Foams used as fracturing fluids

The optimal characteristics that foam-based fracturing fluids possess are 1) high viscosity, 2) proper mixing with other additives and reservoirs fluids, 3) the little liquid phase brought into the formation with foams (Gandossi, 2016), and 4) being cheap, available, and environmentally friendly (Gonzalez Perdomo & Wan Madihi, 2022). However, the main challenges of foam-based fluids are instability and deterioration at high-temperature (over 150°C) and high-pressure (69 MPa) reservoirs (Zeng et al., 2016). Reduced fluid viscosity is the major cause (Gonzalez Perdomo & Wan Madihi, 2022). Nanoparticles can be added to stabilize the foam due to its larger adhesion energy. Polymer-stabilized foams are not recommended in unconventional reservoirs because of their detrimental effects like formation damage, blockage, and poor flowback (Zhou et al., 2020).

Foam used as the fracture blocking agent to inhibit gas channeling

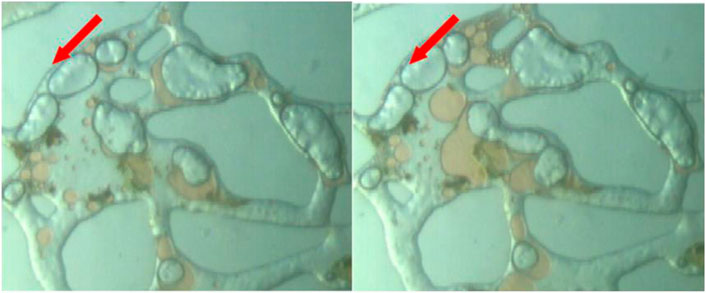

The blocking of highly permeable sections with a foam system to minimize reservoir heterogeneity has become a focus of researchers. During foam flow in a porous medium, lamellae migrate, collapse, and regenerate as they pass through the pore throat due to shearing, stretching, and deformation (Wang et al., 2012). Despite gas injection’s ability to improve recovery in shale reservoirs, the procedure is hindered by gas channeling. The injected gas travels more quickly in the higher permeability zones, bypassing the lower permeable zones (Zhang et al., 2019). In order to ensure that gas flows uniformly toward the wellbore, the foams tend to flow in larger pores and collect along the walls of the pore, increasing flow resistance, and preferentially block large pore paths (Wang et al., 2022). The selective blocking performance is influenced by the Jamin effect buildups and the increased apparent viscosity of the foam system in larger holes (Li et al., 2022). As shown in Figure 1. Thus, the injected gas is channeled to the medium and less permeable zones which contain higher residual oil saturation (Xiaofei and Jiaping, 2021).

FIGURE 1. Preferential blocking action of foams (Li et al., 2022).

Conclusion

The ability of the foam to transport and suspend drilling cuttings increases with elevated foam quality due to the viscosity increase. The apparent increase in viscosity is attributed to the expansion of gas in the foam due to elevated pressure. The little liquid phase brought into the formation with foams is easily recovered by the expansion of the gas when pressure in the well is released after the fracturing process is complete. This abrupt expansion of the gas boosts the flow of the leftover fracture fluid back into the well and then to the surface.

Foams preferentially block big pore channels by moving into larger pores and accumulating along their walls, which increases flow resistance due to the Jamin effect and the increased apparent viscosity of the foam system in larger pores directing the flow of the injected gas into the medium and less permeable zones which have higher residual oil saturation.

Research on foam-based fluids continues to focus on the improving stability, the flow behavior in porous media, and the higher pumping pressures due to low hydrostatic pressure. Moreover, reservoir uncertainty needs to be taken into account when comparing laboratory, simulation, and field data for effective utilization of the technology.

Author contributions

ZL: investigation and research, and writing the manuscript draft; WW: resources and conceptualization; SH: modification of analysis; XM: typesetting; NZ: supervision.

Funding

This work is funded by PetroChina (Project ID: 2021DJ1603).

Conflict of interest

Authors ZL, WW, SH, XM, and NZ were employed by the company Exploration and Development Research Institute of Jilin Oilfield Company PetroChina. The authors declare that this study received funding from PetroChina. The funder had the following involvement in the study: study design and data analysis.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors, and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Agarwal, M., and Kudapa, V. K. (2022). Foam based fracking in unconventional shale reservoir. Mater. Today Proc. 2022. doi:10.1016/j.matpr.2022.06.419

Edrisi, A. R., and Kam, S. L. (2014). A new foam model in pipes for drilling and fracturing applications. SPE J. 19 (4), 576–585. doi:10.2118/162709-pa

Elgibaly, A. A., Salem, A. M., and Soliman, Y. A. (2021). Improving hydraulic fracturing effectiveness in depleted and low-pressure reservoirs using N2-energized fluids. J. Pet. Explor. Prod. Technol. 11 (2), 857–873. doi:10.1007/s13202-020-01060-7

Gandossi, L. (2016). State of the art report on waterless stimulation techniques for shale formations. doi:10.2790/010310

Gonzalez Perdomo, M. E., and Wan Madihi, S. (2022). Foam based fracturing fluid characterization for an optimized application in HPHT reservoir conditions. Fluids 7 (5), 156. doi:10.3390/fluids7050156

Hou, J., Luo, M., and Zhu, D. (2018). Foam-EOR method in fractured-vuggy carbonate reservoirs: Mechanism analysis and injection parameter study. J. Petroleum Sci. Eng. 164, 546–558. doi:10.1016/j.petrol.2018.01.057

Hou, Z., Xie, H., Zhou, H., Were, P., and Kolditz, O. (2015). Unconventional gas resources in China. Environ. Earth Sci. 73 (10), 5785–5789. doi:10.1007/s12665-015-4393-8

Li, D., Xin, G., and Ren, S. (2022). Dynamic behaviors and mechanisms of air-foam flooding at high pressure and reservoir temperature via microfluidic experiments. ACS Omega 7, 36503–36509. doi:10.1021/acsomega.2c04317

Li, J., Pan, R., Guo, B., and Shan, J. (2014). Thermal stability of brine foams for shale gas drilling. J. Nat. Gas Sci. Eng. 17, 131–135. doi:10.1016/j.jngse.2014.01.009

Li, Z., Xu, H., and Zhang, C. (2016). Liquid nitrogen gasification fracturing technology for shale gas development. J. Petroleum Sci. Eng. 138, 253–256. doi:10.1016/j.petrol.2015.10.033

Quintero, L. (2002). An overview of surfactant applications in drilling fluids for the petroleum industry. J. Dispers. Sci. Technol. 23 (1–3), 393–404. doi:10.1081/DIS-120003327

Vaziri, E., Simjoo, M., and Chahardowli, M. (2020). Application of foam as drilling fluid for cuttings transport in horizontal and inclined wells: A numerical study using computational fluid dynamics. J. Petroleum Sci. Eng. 194, 107325. doi:10.1016/j.petrol.2020.107325

Verma, A., and Ojha, K. (2021). Application of response surface methodology for the optimization of viscosity of foam fracturing fluids for the unconventional reservoir. J. Nat. Gas Sci. Eng. 94, 104086. doi:10.1016/j.jngse.2021.104086

Wang, Ji, Luo, X., Rogers, S., Li, P., and Feng, Y. (2022). Stabilization of CO2 aqueous foams at high temperature and high pressure: Small-angle neutron scattering and rheological studies. Colloids Surfaces A Physicochem. Eng. Aspects 647, 129015. doi:10.1016/j.colsurfa.2022.129015

Wang, Jing, Liu, H., Ning, Z., and Zhang, H. (2012). Experimental research and quantitative characterization of nitrogen foam blocking characteristics. Energy fuels. 26 (8), 5152–5163. doi:10.1021/ef300939j

Wanniarachchi, W. A. M., Ranjith, P. G., Perera, M. S. A., Lashin, A., Al Arifi, N., and Li, J. C. (2015). Current opinions on foam-based hydro-fracturing in deep geological reservoirs. Geomech. Geophys. Geo-energ. Geo-resour. 1 (3–4), 121–134. doi:10.1007/s40948-015-0015-x

Xiaofei, X., and Jiaping, S. (2021). Experimental study on foam-assisted gas injection huff and puff in jimsar shale reservoir. Petroleum Drilling Tech 49 (4), 39–45. doi:10.11911/syztjs.2022017

Xu, X., Saeedi, A., Zhang, Y., and Liu, K. (2016). “Laboratory investigation on CO2 foam flooding for mature fields in Western Australia,” in Offshore Technology Conference Asia 2016, 2437–2448. doi:10.4043/26415-ms

Yekeen, N., Padmanabhan, E., and Idris, A. K. (2018). A review of recent advances in foam-based fracturing fluid application in unconventional reservoirs. J. Industrial Eng. Chem. 66, 45–71. doi:10.1016/j.jiec.2018.05.039

Zeng, Y., Farajzadeh, R., Eftekhari, A. A., Vincent-Bonnieu, S., Muthuswamy, A., Rossen, W. R., et al. (2016). Role of gas type on foam transport in porous media. Langmuir 32 (25), 6239–6245. doi:10.1021/acs.langmuir.6b00949

Zhang, P., Ren, S., Shan, Y., Zhang, L., Liu, Y., Huang, L., et al. (2019). Enhanced stability and high temperature-tolerance of CO2 foam based on a long-chain viscoelastic surfactant for CO2 foam flooding. RSC Adv. 9 (15), 8672–8683. doi:10.1039/c9ra00237e

Keywords: foam, drilling fluid, enhanced gas recovery (EGR), fracturing fluid, blocking materials

Citation: Li Z, Wu W, Hua S, Meng X and Zhou N (2023) Application of foam fluids in the development of unconventional gas reservoirs. Front. Energy Res. 10:1081514. doi: 10.3389/fenrg.2022.1081514

Received: 27 October 2022; Accepted: 14 November 2022;

Published: 18 January 2023.

Edited by:

Qi Zhang, China University of Geosciences Wuhan, ChinaReviewed by:

Zhao Zhongcong, Yangtze University, ChinaJie Zou, Chengdu University of Technology, China

Copyright © 2023 Li, Wu, Hua, Meng and Zhou. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Xiangcan Meng, d3VtaW5nMjAyMjEwMjZAMTYzLmNvbQ==

Zhongcheng Li

Zhongcheng Li Xiangcan Meng

Xiangcan Meng