95% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

HYPOTHESIS AND THEORY article

Front. Educ. , 10 May 2021

Sec. Leadership in Education

Volume 6 - 2021 | https://doi.org/10.3389/feduc.2021.498661

This article is part of the Research Topic Social Innovation in Education View all 11 articles

New digital solutions are often lacking integration and acceptance by potential users. Therefore, only a small amount of innovative software solutions is really in use. The article describes a co-creation process by integrating end-users and relevant stakeholders right in the beginning in a social innovation process. Within this process, technology is seen as an enabler of innovation getting its relevance from new social practices of the people using it (e.g. working practices). Against the background of EU funded projects conducted by the authors (GT-VET, GREEN STAR, COCOP, and ROBOHARSH) the relevance of mutual learning processes of engineers / researchers / trainers on the one side and end-users / beneficiaries / learners on the other side will become evident. Moreover, new (digital and analogue) skills of employees have been identified as key for a successful digital transformation. Thereby, this article shows a twofold perspective on social innovation in education: new skills demands for employees and mutual learning processes of developers and users/stakeholders. To obtain needed skills, traditional innovation practices have to be changed by setting up a social innovation process. Such a process design has to include stakeholder and user involvement beyond pure feedback on a new technology. Co-creation means that experience, knowledge and ideas of users will be considered to ensure high usability and impact of the new technology framed by organisational and people related measures. In this respect, the innovation process and the innovation itself is much more than technological functionality–it is a contribution to new social practices and performances of the people that innovate and use the technology.

Innovation in technological contexts needs a social component, such as social innovation. Especially because digital transformation is leading to high demands on the provision of the right skills for future working practices. There is an increasing need to align the demand side (companies, individuals) and the supply side of skills (vocational education and training (VET), training providers) in shorter time. To solve this problem in a sustainable way a coherent approach is needed, engaging relevant actors and stakeholders from all societal sectors: companies, employers’ associations, trade unions, training providers, vocational education and training, and policy but also the employees and workers themselves. Co-creation and comprehensive processing have to put this challenge further on an overarching level integrating relevant actors from different societal sectors (quadruple helix or social innovation ecosystem of companies, education and training providers, policy, and research and innovation).

The current hype about industry 4.0 is boosting the debate on future skills needed for the digital transformation. There is a consensus of scientists that digitalization will deeply affect the future of work and related skills (The Royal Society and the British Academy, 2018). In particular, Artificial Intelligence (AI) will have significant impact on skills demand: “The utilization of general-purpose technologies based on artificial intelligence in society will change the world of work and the skills needed in it extensively” (Koski and Husso, 2018). The demand of new skills is reflected by the report of the European High-Level Expert Group on the impact of the digital transformation on EU labour markets (European Commission, 2019): “The digital transformation is rapidly changing the demand for workers’ skills and task competencies. This way, the digital transformation is contributing to skill mismatch and shortages that require investments in employee training.”

Digital transformation requires faster adaptation of skills demands in supplying training to improve work practices. The skills mismatch of the current workforce and the lack of up-to-date digital skills remains a current problem in many economic sectors. Despite the ongoing debate on the need for new skills for digitization (Davies et al., 2011; acatech, 2016; Berger and Frey, 2016; CEEMET, 2016; Gambin et al., 2016; Hirsch-Kreinsen, 2016; World Economic Forum, 2016; Bakhshi et al., 2017; Chuh et al., 2017; Hoberg et al., 2017; Lamb et al., 2017; Cedefop, 2018; Grundke et al., 2018), no distinctive strategies amongst employees to achieve better and more appropriate skills are appearing.

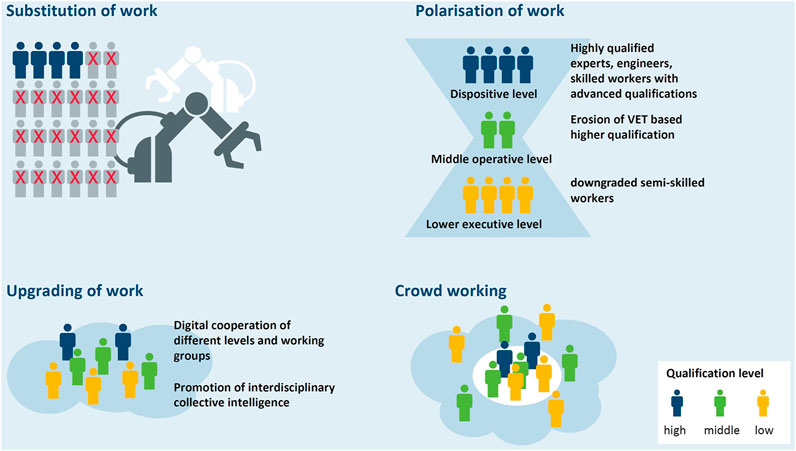

From the labor market perspective, digitalisation today is not only a matter of substitution of work via robots. It could also lead to a polarization and change from the middle operative level to higher and lower qualifications and tasks, new cooperation between different levels and working areas as well as crowd working on virtual or digital connected platforms (see Figure 1 below). For example, Abel et al. (2019) describe how the introduction of 4.0 technologies in the industry requires different strategies to promote understanding of the new technologies, but also to avoid barriers to acceptance. Some of these strategies are employee training and direct experience of employees with the new technology, so that they can perceive it as a positive experience.

FIGURE 1. Scenarios of the impact of industry 4.0 on work (Abel et al., 2019, own translation, permission obtained).

One of the main results of the ongoing skills debate is while there are different estimations on polarization or upgrading of skills due to digitalization, high-skilled employees tend to be winners of the digital transformation. This is called the “skill-biased technology trends” (Berman and Machin, 2000; Green, 2016) and illustrates the demand for providing (more and higher) digital skills. While, due to digital transformation, on the one hand improved competitiveness and “greener” production are creating new jobs and a higher skilled workforce, on the other side disadvantages of digital transformation according to several studies are the impact of digitalization on job losses, job creation and skills demand (Frey and Osborne 2017; Arntz et al., 2016; Berger and Frey, 2016). As a substantial share of jobs seems to be susceptible to automation, related skills (esp. for routine tasks) might be less demanded in the future. At the same time, other jobs will change in terms of tasks and new jobs will be created (The Royal Society and the British Academy, 2018). Other skills will be needed to fulfill requirements of changing or new jobs. Particularly, current development of artificial intelligence technologies leads to expect extensive changes of needed skills (Koski and Husso, 2018). “This change will reduce certain kinds of jobs and increase the number of others. At the same time, the demand will decrease for certain skills and grow for others. Without corrective actions, this will worsen the labour market mismatch and exacerbate structural unemployment” (Koski and Husso, 2018).

From a company perspective, rejection of digitalisation by the employees seems not to be the problem, but the increasing shortage of skilled labour. A survey in 2020 with about 600 companies in Germany shows that while 55% of users or planners of Industry 4.0 solutions see shortages of skilled labour as a barrier for digitalization, only 20% are facing a lack of acceptance among the staff (Nier, 2016). Another survey by the German Economic Institute showed that costs and shortages of skilled workers is the highest risk for 61% of the companies (Grömling and Matthes, 2019). Skills shortages are raising due to the increasing demand for digital skills in Europe (Berger and Frey, 2016). Particularly for the IT sector, substantial skills shortages are expected due to increasing demand for workers in this sector; a shortage of 756,000 ICT professionals is estimated (European Commission, 2016). It can be argued that skills will become a bottleneck for the diffusion of digital technologies: “With a view to the gap between the skills needed and the skills available internally, access to personnel with specialized digital skills is likely the main bottleneck for future transformation initiatives” (Hoberg et al., 2017).

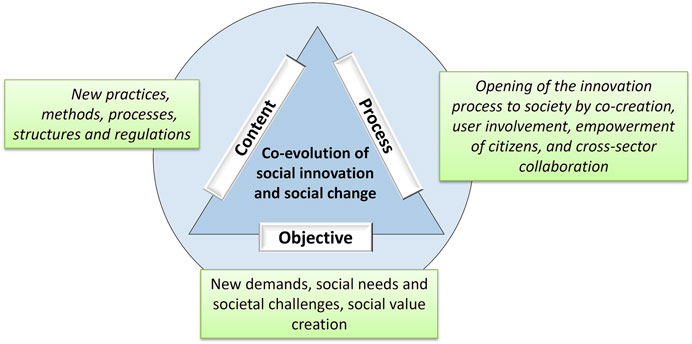

The combination of technological and social innovation as part of a new innovation paradigm (Colla et al., 2017; Howaldt et al., 2017; Kohlgrüber et al., 2019) comprises a broader understanding of innovation by considering social needs and societal challenges (see Figure 2). By opening the innovation process to society, co-creation as a (social innovation) process has to be started getting all relevant stakeholders involved. Co-creation is a collaborative method (Sanders and Stappers, 2008) and process (Brandsen and Honingh, 2018) involving different stakeholders in the framework of a social innovation (Hochgerner, 2018; Eckhardt et al., 2020).

FIGURE 2. A new innovation paradigm (modified version of Howaldt et al., 2016, p. 40, permission obtained).

Research on social innovation in education shows how a more systemic approach is needed in innovation, an approach that includes new forms of cooperation and collaboration as well as new governance structures (Schröder and Krüger, 2019; Maldonado-Mariscal, 2020). Additionally, a literature review on social innovation recognized that social innovation can be identified through new institutions, new social relations, new processes or organisational processes, or new networks of institutions that pursue to provide better solutions (Maldonado-Mariscal, 2017:39).

Against this background, a combined view on technological and social innovation includes two aspects:

(1) Implementing new technologies changes the way of working in many jobs. It creates new social practices which represent social innovation according to the definition of (Howaldt and Schwarz, 2010, p. 21). In line with this our argumentation in this article is based on: “A social innovation is new combination and/or new configuration of social practices in certain areas of action or social contexts prompted by certain actors or constellations of actors in an intentional targeted manner with the goal of better satisfying or answering needs and problems than is possible on the basis of established practices.” In the context of technological innovation, new social practices include new working and organizational practices, such as using a new software and new ways of (cross-process) collaboration, new ways of combining data, better process understanding and practical knowledge to make better decisions based on digitalisation. Skills are an integrated part of social practices (Shove et al., 2012) and thereby a part of social innovation.

(2) Another aspect of integrating technological and social innovation is the innovation process. This article is based on the understanding that technological innovation is embedded in a social innovation process which means a co-creation process. In distinction to other approaches of user involvement, co-creation includes not only gaining feedback from users on mock-ups or prototypes, but playing a role as co-developers of the new solutions. This includes proposals for new or different features, integrating new solutions into existing IT infrastructure (such as a Manufacturing Execution Systems) and embedding the technological solution into a fitting work organization.

A social innovation process is needed to unfold the potential of (digital) innovations and solutions by combining technology with personnel expertise and skills development and optimising organisation (at the workplace). Thereby, the social innovation process encompasses the dimensions of technology, organisation and people (Hirsch-Kreinsen, 2016; Ittermann et al., 2016). However, this approach of integrating technological and social innovations requires mutual learning processes of the involved actors. A joint optimization of sociotechnical systems that aligns technology, people (skills) and organization requires harmonization of cultures and languages of technical developers and human factors experts. Without these mutual learning processes, technical requirement specifications and human factor requirements exist in parallel and will not affect each other.

So, using social innovation in education for technological innovation processes is based on two arguments: If social innovations are successful they deliver new social practices solving societal challenges and social demands in a better way than this was done before. This is one argument for applying the social innovation approach to education. The second argument is that a social innovation process (including all relevant stakeholders) is needed to avoid in a concerted action skills shortages and mismatches.

To summarize, the general concept of social innovation in education has to be customized for different applications. Depending on specific fields of application, social innovation in education takes different forms1 that include common elements (such as stakeholder integration) and different elements (such as the specific workflows for defining human factors requirements). This article presents practical evidence due to the described approaches and research-leading theses above by four different pilot projects embedding technological/educational innovation within a social innovation, co-creation and mutual learning process, conceptually described above.

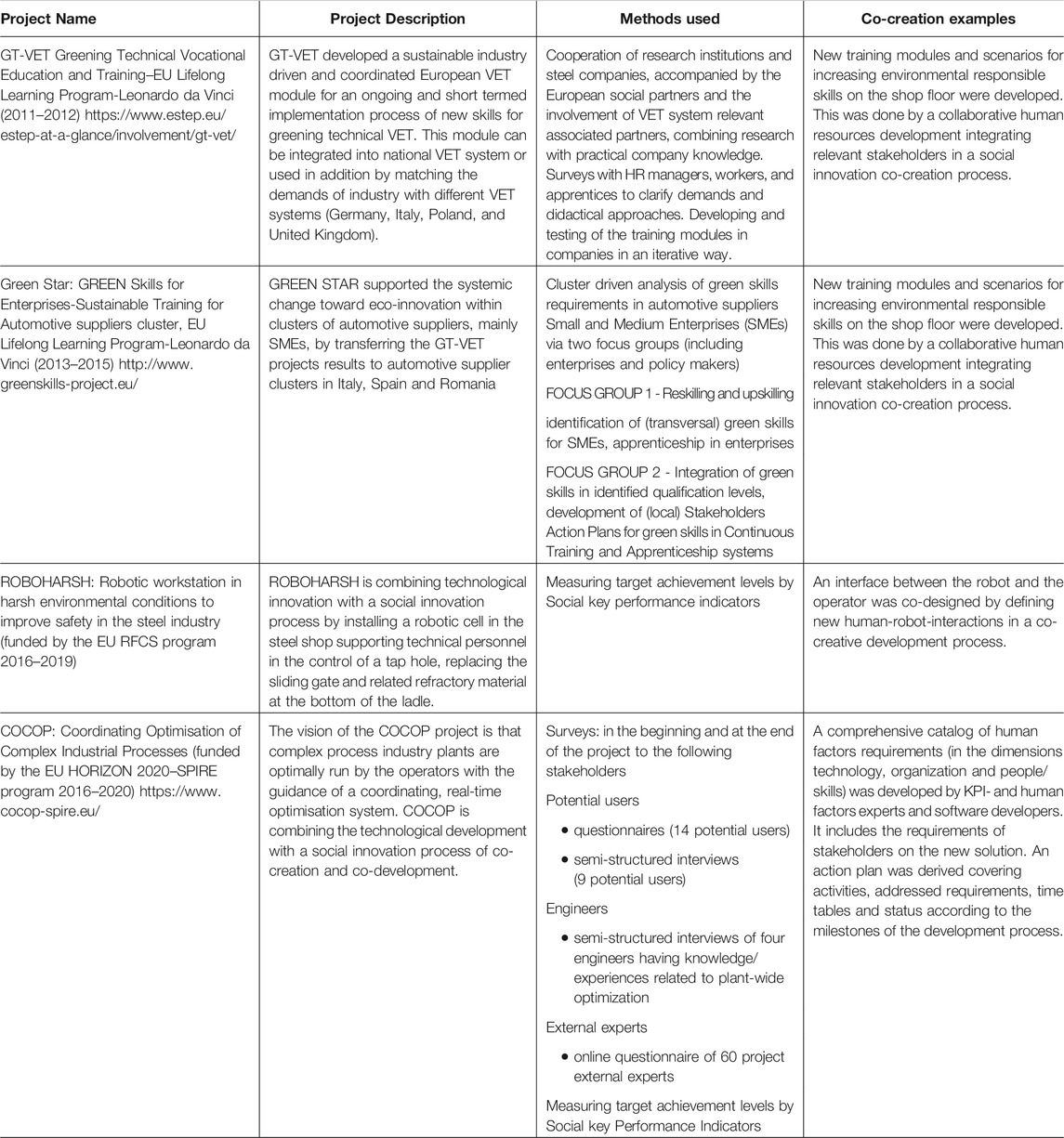

The following projects present different examples of co-creation processes in diverse projects but also in different social innovation processes. The empirical results in this article are based on European research and innovation projects where innovation in technological processes, innovation in Vocational Education and Training (VET) or both took place. Some of the co-creation processes identified are innovative learning arrangements and development of new digital solutions. In this section, we analyze the conceptual implementation of the described social innovation approach on a micro level, like within companies. We present an overview of the projects in the following Table 1.

TABLE 1. Summary of analyzed projects and co-creation practices. Source: self-elaborated based on the projects GT-VET, Green Star, COCOP and ROBOHARSH.

In this paper, we analyzed four different projects and its co-creation practices in a framework of social innovation and technological innovation. First, through empirical results of GT-VET and Green Star, we identify co-creation practices of developing innovative learning arrangements for greening technical VET. Second, through empirical results of COCOP and ROBOHARSH, we identify co-creation practices of identifying and adjusting digital skills because of the digitalization of production and maintenance processes. The analysis in all four projects mainly consists on a qualitative analysis, which is accompanied by interviews, surveys, and measurement of different indicators.

The method used in GT-VET is the common development of the training module by a research institution in close cooperation with a steel company (in four different countries representing different VET systems). During the social innovation process of developing the training module with workshops, interviews, surveys of the stakeholders from the companies, VET systems, and social partners the topics, content, and didactical approach were developed and tested. Performing it in this way, a planned eLearning module was replaced by a more action-oriented learning by doing and stepwise approach fostering the self-responsibility for learning.

In the Green Skills project innovation transfer based on the GT-VET training blueprint took place from a big company approach of the steel industry to a Small and Medium Enterprises (SME) cluster-oriented framework. Within two Focus Groups stakeholders from the involved regional automotive clusters (SME, VET system and training providers, public policy, research institutions) discussed the adjustment possibilities and necessities in an iterative way leading to accepted and concrete action plans.

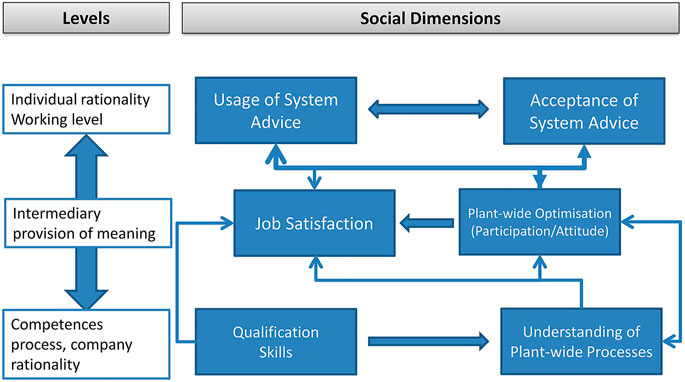

Methods used in both ROBOHARSH and COCOP projects were the measurement of technical Key Performance Indicators (KPIs) completed by social Key Performance Indicators (social KPIs). Besides the usual technical KPIs the additional social KPIs monitor the user involvement and co-creation on the workplace and company level, introducing in this way a social dimension in the measurement of the development process. These indicators measure progress and target achievement levels of the co-creation process (see Figure 3). They are built on three perspectives: 1) Perspective of developers; 2) Company perspective; and 3) Users’ perspective. Some of the questions including these indicators are:

1. Perspective of developers: Do operators and managers really use the system and do they accept advice of the system?

2. Company perspective: Do users understand and contribute to plant-wide optimisation?

3. Users’ perspective: Do users have/develop the right skills and does the solution improve job satisfaction?

FIGURE 3. Social Key Performance Indicators (OPT et al., 2017, p. 11, permission obtained).

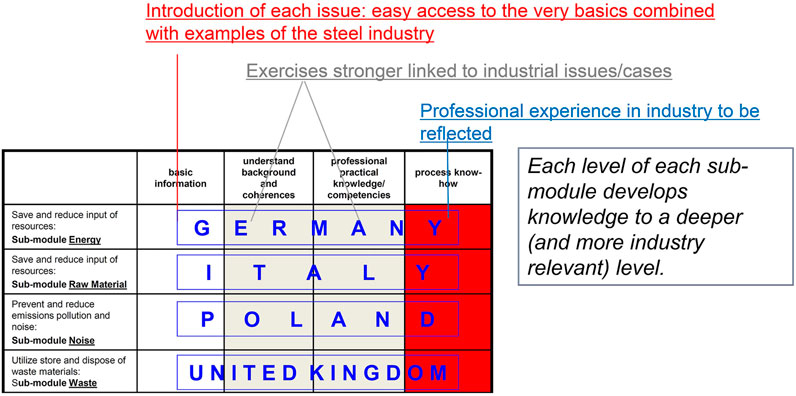

FIGURE 4. GT-VET training module (Schröder et al., 2013, permission obtained).

From a quantitative and statistical point of view, the number of companies, stakeholders, involved workers, apprentices, and interviewees (counting nevertheless more than about 300 concerned actors across all for projects) are low and therefore individual opinions have a high weight but no statistical representativeness and significance could be claimed. However, the qualitative analysis integrating different stakeholders and target groups perspectives led to fruitful discussions and iterative alignment processes – in the end to accepted effective common and better solutions than planned.

In both projects Greening Technical Vocational Education and Training (GT VET) and GREEN STAR training modules and scenarios for increasing environmental responsible skills on the shop floor of different companies were developed. This was done by a collaborative human resources development integrating relevant stakeholders in a co-creation process. In the GT-VET project, research and training institutions worked closely together with steel companies, accompanied by the European social partners and the involvement of VET system relevant associated partners. Such collaboration took place especially by involving company representatives for human resources development and apprentices in interviews and workshops. Very important result of this empirical work was to substitute the planned eLearning tool (where no one was really interested in) by an action and workplace based training handbook2.

The GT VET training module is of high relevance to reduce waste, energy, noise and emissions (Schröder, 2014, 2015; Kohlgrüber and Schröder, 2019) and to sensitize workers and apprentices for “greener” working practices. An effective, efficient and accepted way of learning and training became an evident part of the development of the training module. Within this project, we observed that social innovation consists on integrating relevant stakeholders and future learners. Integration of trainees and experts of the companies right from the beginning of the innovation process was the guarantee to identifying the concrete needs of the company and the workers and apprentices, the relevant topics and learning outcomes, and the accepted didactics. In the end, a common training module was developed, reflecting the main content requirements of the companies in four submodules: energy, waste, noise, and raw material reduction. Additionally, the didactical requirements of the learners were: starting with basic information, understanding background and coherences and later focusing on practical exercises and projects, linked to the concrete workplaces (see sub-modules and levels of training as axes in the Figure below).

The co-creation process took mainly place through the introduction and development of a new training module. This training module was tested and improved by putting a strong focus on the workplace experience and implications, fostering own responsibility, project planning and involving workers and apprentices. Such interaction and collaboration generate a bottom-up workplace innovation (Dhondt et al., 2017; Howaldt et al., 2017), leading to a “learn-learn-learn” situation for all stakeholders, such as trainees, trainers or teachers, and workers or management. An improvement of context knowledge by a comprehensive approach for learning and training, a generic understanding of green skills and the identification of parameters for changing behavior in the maintenance area was achieved. The module improves through its activity the awareness and skills for self-reliant work, reduction of resources, and saving of money, proved by the results of training inherent projects of workers and apprentices (energy savings through LED lights and new production procedures). The developed GT VET training module is seen as a link for short-termed reaction to technological changes. One of the main results was an improvement of the existing cooperation between companies and vocational schools.

Knowledge and awareness of the target group about environmental issues of the steel industry before the training was not given, there was no interest and motivation for such activities. Engagement and motivation had to be risen by the trainers and the concept of the training module looking for interesting tasks and own activities of the trainees.

The co-creation process of developing the training module led in the end not only to an increasing but also to a high engagement and enthusiasm of the trainees (see video of GET-VET https://www.estep.eu/estep-at-a-glance/involvement/gt-vet/), especially because they found more efficient solutions on the workplace (saving money, work place innovation) within their training related tasks and projects. It led to a new view on the production process and a change of conscience and behavior (including correction of behavior of other colleagues).

GT-VET was awarded by the European Commission as one of the best projects of the funding period, due to its success. Such recognition and success led to the reproduction of this innovation practice. Therefore, the framework module was transferred from the steel to the automotive supplier sector within the GREEN STAR project. GREEN STAR adapted and modified the industry-driven process of the iron and steel sector, mainly consisting of large enterprises, to the Small and Medium Enterprises (SME), and to regional clusters of automotive suppliers related to several sectors, e.g. metal works, microelectronics, and plastic materials through the implementation of a cluster-driven approach. This solution has enabled the development of suitable competences for sustainable innovation in the training paths addressed to workers (“reskilling”) and apprentices (“upskilling”), in order to reduce the environmental impact in the production chain as well as service activities, better managing available resources.

Integrating some SMEs which had a leading role in the relevant clusters led to specific action plans implemented in participating regional clusters in Italy, Romania, and Spain. Transfer activities were supported by a partnership made up of enterprises and VET representatives associated in a consortium. Both in its structure and in its working methodology, this coordination was based on the triple helix model, which includes public authorities, the industry sector, and universities. Such structure aimed at strengthening cooperation for sustainable innovation between public bodies, service organisations and enterprises, universities and VET centres-creating favourable conditions for cooperation across the stakeholders (companies and their cluster associations, regional policy, and training providers), combining knowledge, policies and innovation.

To sum up, the development of training programmes and modules require a high level of commitment of stakeholders, especially in a co-creative social innovation process. However, taking this approach leads to better fitting companies and learners needs, choosing the right didactics and learning arrangements and leading to better learning outcomes through tailor-made solutions.

In the project ROBOHARSH, the interface between a new robotic station and the operator was co-designed by defining new human-robot-interaction. Manual maintenance operations at a steel converter were deeply analyzed and decomposed into elementary operations (tasks). New subdivision of tasks the robot could perform and the ones left in the hand of operators was defined in a co-creation process of operators and robot developers. The development of the new interface led to a drastic reduction of manual tasks still to be conducted by the operator (from 39 before to 8 remaining manual tasks). The main tasks are done now by the robot, especially the most hazardous and heavy ones. The results show that the robot handles all the heavy weights procedures and the exposure to high temperatures has decreased drastically: from 63% to 15% in the view of the developers and from 71% to 37% in the opinion of the operators. Additionally, new skills demands were considered to enable the operator to make best use of the new solution. Furthermore, affecting work organization, the new robotic cell is generating a new allocation of tasks between robot and human and a totally new way of working for the operators (doing major parts of their job from a pulpit).

The co-creation process in this project took place through a high involvement of both developers and operators within the introduction of a new technology. This means that operators were sufficiently involved in the development process, their opinions were heard, the developers took up their suggestions, and the management of the company was supporting the operator involvement. According to the developers, there was a high integration of users or operators, and stakeholders in the co-creation process, depending on the stage and subject of development.

This high involvement led to an important mutual learning effect: The number of improvement suggestions from users or operators and stakeholders are ranging from 5 to 50 suggestions (depending on the different developer person), with an average of 21 suggestions made. Respectively the number of changes based on these suggestions is ranging from 4 to 30 up-taken advices with an average of 12 proposals that were considered improving the technological solution. Overall, two of three suggestions were executed. This underlines that the developers and the future users are mutually learning from each other; for example, the developers by integrating the user suggestions and the users by learning the robotic software step-by-step and on the job. Developers learned by integrating the experiences and knowledge of the operators to come to better solutions, e.g. what works and what not or how to design the robot support practical effectively. Operators learned how to use, monitor and control the robot.

In spite of this mutual and cross-fertilizing learning and development process, questionnaires with the operators and developers underlined that new skills are required. This was especially stressed by the operators. Training for robot assistance could be integrated in existing trainings schemes (but has to be clearly exposed). The operators claim that the recent training measures could be extended and new skills and a mix of methods should meet training demands: Mainly by learning on the job, training by the robot providers and general training courses (see Figure 5). Beside the general importance, the developers prefer more learning on the job while the operators prioritize training by the robot providers.

To summarize, a common technological development within a social innovation process is a clear win-win-situation for all the people concerned: developers/technicians, operators/end users, management, and project participants. It is a mutual learning on the job process across the borders of hierarchical, technological and workplace related levels, leading to an optimized and accepted solution and an effective and efficient implementation (with no or minimized follow-up costs). The disruptive change from a manual operation to a robot assisted and digital controlled and operated job is changing the skills demands of the concerned operators drastically. For example, one of the involved operators mentioned it is a “change from an operator to a supervisor” (see Figure 6).

FIGURE 6. Job profile change: from operator to supervisor (Colla, 2019, permission obtained).

To minimize the problems of such a drastic transformation (from manual work to robot supervising) the integration and learning by doing of the operators in a co-creation process of two years was important. Besides the own learning process the involved operators informed their colleagues at similar work places and they function as experts in a peer-to-peer skills adjustment and learning process.

In the project COCOP the social innovation process includes the skills dimension explicitly. COCOP as a technological oriented project aims at developing a system for a plant-wide optimization in process industries, piloted in a steel and a copper company. The challenge was to integrate a new system for plant-wide optimization within a collaborative and integrated social innovation process. Within this process, skill needs for plant-wide optimization were estimated (which comprises more than using a new tool).

The skill needs estimation (as part of human factors requirements) consists of four stages:

1. Measurement of the involvement of future users/stakeholders by surveys: At the first stage, a team was established including human factors (HF) experts, KPI experts and software developers. The HF experts analyzed the key staff of the factory that would be affected by the new plant-wide optimization system. They comprise the main tasks of the future users of the COCOP systems, their position in the organization chart, the involved production processes and relevant stakeholders. Together with KPI experts, a new set of indicators were defined. These indicators measure the improvements of the new system in social terms, such as job satisfaction, acceptance/usage of the new system, participation, needed skills and understanding of plant-wide processes (see defined social KPIs above and Figure 3). In the course of the project and the software development and implementation, different surveys and interviews took place with future users, other relevant stakeholders and technical experts measuring the social KPIs.

2. Transforming indicators into human factors requirements: In order to harness the results of the survey for software developers, they were transformed into a format that is compatible to the logic of technological development processes. The requirements had to be clear, measurable and subject of validation whether a requirement is fulfilled or not. Actions are linked to validate human factors requirements and their connection to the milestones of the project.

3. Drawing up an action plan: To make the list of requirements manageable for the HF team and the involved company, an action plan was drawn. This plan summarized all HF related activities at every milestone of the project. The action plan included the needs of participants, time and benefits of any human factor requirement.

4. Validating human factors requirements: The current status of validating a human factor requirement was shown by graphical symbols. It provides an overview of to what extent HF requirements are fulfilled and the full impact of a new solution on human factors issues is visible through the social KPIs.

Results from the human factors workflow (Kohlgrüber et al., 2019) should be carefully interpreted by the fact that only 14 future users of the system were interviewed. However, surveys with external experts (n = 60) compared with the user’s opinion show that nearly two of three persons of both groups stress that integrating a plant-wide perspective in their work requires new skills. Approximately only one of four users or experts claimed that there is enough training for plant-wide processes. While both groups underline the need of special training measures, the majority of the future users prefer (process) simulation (93%), followed by general training courses (79%), and finally, learning on the job (64%). External experts, on the contrary, prioritize learning on the job (54%) (see Figure 7).

Results from face-to-face interviews with future users and company internal stakeholders show that based on experiences with existing software tools and cross-process optimization, most of the interviewed persons expected that education and training will be a relevant condition for a successful implementation of the planned COCOP system. According to our results, it is important that handling of a new system is learned mainly at the workplace. However, some interviewees preferred training courses; others favored additional education that is integrated in working processes. It was stated that theoretical knowledge should be imparted before practical knowledge.

To sum up, the COCOP project aimed at building explicit links between the digitalization strategy of the pilot company and related skills improvement. Choosing the co-creation approach human factor requirements are understood, integrated and validated in a mutual (learning) process of the technicians (software developers) and the end users (operators, foremen, managers).

As introduced in this article, social innovation can be identified through new institutions, new social relations, new processes or organisational processes, or new networks of institutions that pursue to provide better solutions than the ones before (Maldonado-Mariscal, 2017:39). In this sense, social innovation in education refers to new forms of cooperation or even new governance structures (Schröder and Krüger, 2019; Maldonado-Mariscal, 2020).

Current research on social innovation in education have some limitations since it is usually based on case studies in very specific contexts. Despite these restrictions, this article contributes to a broader understanding of social innovation in general, especially in the specific context of education and training combined with co-creation in technological developments. The presented projects are limited to examples of involved project partners (companies, research institutions, etc.) and its transferability of the concept to sectoral, national or EU level. However, these examples show the advantages of social innovation processes in companies and training institutions for innovative training and technology development by serving a blueprint of involving stakeholders, developers and end users through co-creation and mutual learning.

At the project and company level, related results of the analyzed projects show the heterogeneity of social innovation processes by different co-creation practices, for example:

1. The GT-VET and GREEN STAR projects show very similar co-creation practices, such as the introduction of a new training module (know-how process and scenarios for increasing environmental responsible skills) involving relevant stakeholders and future learners. This integration process took place from the beginning of the training module development and changed the outcome during the course of the process in a learner and company demanded way. The process strengthened also cooperation between companies and vocational schools. Within the GREEN STAR project, especially new partnerships were achieved, such as a partnership of enterprises and VET representatives, and between companies and their cluster associations, regional policy, and training providers. Beside co-creation GT-VET and GREEN STAR made evident that also new digital and didactical learning arrangements are needed, including new didactical concepts, such as action and workplace-oriented learning, self-responsible learning, trainer as learning coach, learning communities.

2. ROBOHARSH showed co-design practices to define new applications of human-robot interaction. A development process dividing together with the operators in a first step the former manual work in different tasks, and then allocating step by step as much tasks as possible to the robotic assistance in a co-creation process with the developing engineers – leading to mutual learning processes for both engineers and operators.

3. In the COCOP project the integration of a new system was developed through a collaborative process, including the needs for human factor and integrating them with the learning needs of technicians. This led also to the necessity to change the view and responsibility of the operators/managers from the own area to a plant-wide production.

The presented co-creation practices based on social innovation processes show how new alliances and ecosystems are created (regional and local authorities, economic clusters and sector stakeholders, training providers and departments, companies and social partners) but also how new internal processes are implemented within companies and their employees in a collaborative way.

Based on the empirical results of this article, some recommendations to improve the process matching of skills to needs are:

– Define concrete co-creation processes in new technology projects to facilitate acceptance of new technology and faster learning among technicians, operators, end-users and managers.

– Provide examples of successful practices to operators and managers to open their vision for co-creation and mutual learning.

– Use social KPI and relate it to the technical KPI to make progress by co-creation processes transparent.

– Include mutual learning processes for technicians and engineers in the project by introducing new digital skills and new didactic concepts.

– Define clear actions of the co-creation process addressing all relevant project members to make changes in the development process happen.

– Document the implemented co-creation practices and their elements of success and failure for future use.

– Create learning communities with new technologies and mutual learning in the workplace.

The holistic social innovation approach is looking at “innovation as an enabler” (FORA, 2009) and is going further than traditional design thinking (Brown and Katz, 2009) and socio-technical system approaches (Hirsch-Kreinsen, 2016). While technological design and socio-technological system approaches are “indirectly” integrating end-users as research objects, the social innovation co-creation process is integrating end users and stakeholders of concerned organisations directly as subjects in the development and implementation process from the idea over invention and implementation to institutionalisation (Schröder, 2011). Additionally, the social innovation process comprises a more comprehensive and holistic concerted action by integrating stakeholders from relevant societal sectors: industry/economy, policy, education and research, as well as (if relevant) civil society (e.g. NGO’s)–establishing a social innovation ecosystem with a triple or quadruple helix.

First, the four presented projects show the evidence of skill demands due to digital transformation and the effectivity of the integration of innovations within a social innovation process. They show as well that integrating the end users and other relevant stakeholders, such as management and human resources department, in the development process clarifies the demand of skills and the supply of how skills have to be delivered and implemented. Second, these projects indicate the importance of a holistic social innovation approach integrating all stakeholders, such as developers and researchers as well as the end users. Third, they show that perceptions and expectations between engineers and workers, technological and human requirements have to be bridged. Mutual learning of the engineers, developers and the end users, e.g. operators and learners, leads to better or new outcomes (as in the case of GT-VET), more effective and more accepted technological solutions and learning arrangements. Finally, mutual learning processes integrating the competences of the end users and other relevant stakeholders into the development process has led to clear win-win situations. For example, more effective solutions for the users, companies, and developers; reduced follow-up costs because of the higher acceptance of the common solution; more effective learning results based on learning by doing and learning on the workplace; development of tailor-made training programs; managerial and organisational supporting measures detected and implemented during the development process; new solutions found by the trainees and operators, and improved job satisfaction. And, not at least, this co-creation and mutual learning social innovation processes help to unfold the full potential of digital solutions in and for the workplace.

However, we also recognised that, beside the directly in the co-creation process involved people, transfer to other stakeholders and users (workers, management, trainers) is still a challenge because it requires acceptance, understanding and taking over this new perspective and approach. Concerning the social innovation process the main gap is between introducing a prototype and the actual implementation and institutionalisation in the company (esp. COCOP) and in formal VET training programs (e.g. in GT-VET the training module was implemented in the companies but only informally combined with vocational school curricula, due to given leeway). To bridge this gap (transfer to other users and areas and further implementation and development on the workplace), leadership becomes not only more important but has to change its role, esp. concerning the application of new digital solutions. Leaders are required to get technological solutions and organisational framework conditions aligned. In the case of COCOP, the technologically facilitated plant-wide optimization would be in contradiction with sub-process-oriented targets and incentives for workers when it comes to a sustainable implementation. Therefore, leaders are challenged to take care for a fit of technological, organisational and people-related solutions.

This article has so far focused on co-creation processes and the role of mutual learning and competence needs in individual projects defined by pilot developments for specific companies and applications. What is not yet explicitly addressed here are scalable solutions that meet the challenges of the digital transformation for entire industries, if not the entire EU economy. For future research, it should be considered that the approach of social innovation processes is rolled out to identify future skill demands and solutions on how to meet these needs - at different levels (sectoral, regional, national and EU). As an outlook, we present some recently started projects taking up these requirements.

To achieve a successful matching of skills demands and supply, providing skills should be organized as a social innovation process as described by the example above: development of training modules (GT-VET/GREEN STAR), the robot-human interface (ROBOHARSH), and the optimization system (COCOP). Co-creation in these projects combined technology with training modules, where developers, research institutions, social partners, users/operators/apprentices, and stakeholders of companies and VET institutions were involved with their different perspectives, knowledge and responsibilities–leading to practical tailor-made training blueprints and implementations as well as to company and regional action plans (GREEN STAR).

Regarding the future skills demands, it can be stated that skills needs are not only limited to digital, technological or high-tech skills. Certainly, digital or high-tech skills are needed to meet the challenges of a digital future. This includes basic digital skills, advanced digital skills but also skills for e-leadership (Berger and Frey, 2016). But there is a broad consensus in literature that also non-technical skills are needed in a digitalized world. Many researchers consider a mix of technical and non-technical skills as a requirement for a digitalized future (Berger and Frey, 2016; CEEMET, 2016; Pfeiffer et al., 2016; Lamb et al., 2017; Kirchherr et al., 2019; Servoz, 2019). For example, Rampelt et al. (2019) recognize a need for “hybrid skills” as a mix of specific and general skills. This combination of specific and general skills is also called “T-Shaped Skills.” The T-Shape approach combines skills of a specialist and of a generalist resp. professional skills and transversal skills (PWC, 2018). PWC (2018) conceptualize high-tech T-shaped skills as a mix of high-tech skills (e.g. basic/advanced digital skills) and complementary skills, such as collaboration, innovation, emotional intelligence. Pot et al. (2019) argue that organizations have to become T-shaped in order to enable T-shaped personalities. First results of the ESSA project (described below) underline the high importance of transversal soft skills within the T-shape approach.

Whereas demand is formulated in terms of tasks and needed skills, indicators for skills supply are defined by qualifications or test data (Green, 2016). Matching skills requirements and Vocational Education and Training (VET) support we have to rethink the “process of matching labour market demand and supply” (Servoz, 2019). While the supply side trains and educates people for occupations and qualification it does often not meet employers’ requirements in terms of needed skills. Therefore, both sides (stakeholders from the demand and supply side) have to be integrated into the development process to ensure matching of provided and needed skills. “The education and skill system has a vital role to play in equipping individuals with the skills, competences and attributes necessary to cope and manage with labor market and other shifts over their life course” (Barnes et al., 2016). As employees are often lacking basic skills (literacy, numeracy, basic digital skills), VET systems should have a “repair component” to compensate such education deficits (Servoz, 2019). This is also valid for secondary education: “It is not acceptable that there are currently 61 million Europeans […] who do not have these basic skills: without them, people become unemployable” (Servoz, 2019). Higher education “should focus more on soft and interdisciplinary skills” (Servoz, 2019). This should include a combination of different skills, of technical and general skills, of training in the university and on the job in a company (ibid). Preliminary insights from the ESSA project with steel companies (see below) confirm that graduates are lacking interdisciplinary skills, project management skills and communication skills.

While there is a lot of literature dealing with the impact of digital technologies on occupations and labour market (e.g. Brynjolfsson and McAfee, 2014) and researchers predict strong negative impact of digital technologies on employment (Frey and Osborne, 2017), skills are not systematically addressed in such studies. Particularly on EU level, scientific research on the impact of digital transformation on skills is still lacking. At the same time, skills are playing a vital role for the digital transformation: to avoid structural unemployment due to skills mismatches, to include low skilled people in labour, to be an enabler for job creation (filling job vacancies with skilled people) and to make full use of new technologies by well skilled users, developers and leaders. Therefore, the skills debate is an essential part within innovative research, for instance the (Erasmus + funded) European Sectoral Blueprint Program but also Horizon2020 and the new SPIRE Program “Processes for Planet.”

Within the “New Skills Agenda” of the European Commission the authors developed the social innovation process approach illustrated above (focusing on the micro level of specific innovations and companies) further and extended it to an overarching (meso level) approach of two European sectoral skills alliances combining technological innovation with skills requirements and adjustments in a co-creation process (of up to 40 partners each from industry, policy, education and training, research and innovation) across Europe and energy intensive industry sectors:

• ESSA: Blueprint “New Skills Agenda Steel”-Industry-driven sustainable European Steel Skills Agenda and Strategy (funded by the EU ERASMUS + program 2019-2022) https://www.estep.eu/essa/ ESSA is realizing an industry driven, sustainable and coordinated blueprint for a European Steel Skills Agenda. A strategy for human capital development through a Sector Skills Alliance is delivered within a social innovation process involving a broad range of key stakeholders of the steel industry: companies, education and training providers, research institutions, social partners (European and national steel associations and trade unions as well as sector experts).

• SPIRE SAIS: Skills Alliance for Industrial Symbiosis–A Cross-sectoral Blueprint for a Sustainable Process Industry funded by the EU ERASMUS + program 2020-2023 https://www.spire2030.eu/ SPIRE-SAIS realizes a Blueprint strategy for human capital development through a Cross-Sector Skills Alliance on Energy Intensive Industries. It involves a broad range of key stakeholders (sector associations or technology platforms, training providers, and research partners) from the eight sectors of the public-private partnership “Sustainable Process Industry through Resource and Energy Efficiency” (SPIRE): Steel, Chemicals, Minerals, Non-ferrous Metals, Water, Engineering, Ceramics, and Cement. New skill demands and adjustments for energy efficiency, industrial symbiosis and related Vocational Education and Training are in focus.

Additionally, within the Beyond 4.0 project (Inclusive Futures for Europe– BEYOND the Impacts of Industry 4.0 and Digital Disruption, funded by the EU HORIZON 2020 program, 2019-2022, http://beyond4-0.eu) we examine further on the macro level the societal impact of the new technologies on the future of jobs, business models and welfare via a multidisciplinary research approach.

The datasets generated for this study are available on request to the corresponding author.

Ethical review and approval was not required for the study on human participants in accordance with the local legislation and institutional requirements. Written informed consent for participation was not required for this study in accordance with the national legislation and the institutional requirements.

MK contributed to every chapter, the depiction and analysis of the skills debate, the discussion section and insights from the projects COCOP and BEYOND 4.0. KM-M contributed to every chapter, to the scientific discussion on social innovation in education and co-creation methods, to the discussion section and the systematization of the presented projects. AS contributed to every chapter, the depiction and analysis of the skills debate, the discussion section and insights from the projects ESSA, SPIRE-SAIS, GT-VET, Green Star and ROBOHARSH.

The mentioned projects have received funding from the European Union. The projects SPIRE SAIS (Grant agreement No. 612429) and ESSA (Grant agreement No. 600886) received funding under the ERASMUS+ programme. The projects BEYOND 4.0 (Grant agreement No. 822296) and COCOP (Grant agreement No. 723661) received under the Horizon 2020 research and innovation programme. The projects GREEN STAR (Project No. 2013-1-IT1-LEOO5-03983) and GT-VET (Project No. 2010-4096 / 510172-DE-LMP/GT VET) have received funding under the Lifelong Learning programme.

This article reflects only the authors views and the Commission is not responsible for any use that may be made of the information contained therein.

The insights of this article are based on the projects COCOP, ROBOHASRH, GT-VET, Green Star, BEYOND 4.0, ESSA and SPIRE-SAIS. The Social Research Centre/TU Dortmund received funding from the European Commission for participating in these projects. We acknowledge financial support by Deutsche Forschungsgemeinschaft and Technische Universität Dortmund within the funding programme Open Access Publishing.

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

1An overview of different manifestations of social innovation cases in education and lifelong learning worldwide could be found in Schröder et al. (2017); Schröder and Kuschmiertz (2017).

2https://www.estep.eu/assets/GT-VET/GT-VET-European-Framework-Module-Green-skills-for-mechanical-industrial-and-electrical-technicians-Training-Handbook.pdf.

Abel, J., Hirsch-Kreinsen, H., Steglich, S., and Wienzek, T. (2019). Akzeptanz von Industrie 4.0. (München: oekom verlag).

acatech (2016). Kompetenzentwicklungsstudie Industrie 4.0: Erste Ergebnisse und Schlussfolgerungen. (München: oekom verlag).

Arntz, M., Gregory, T., and Zierahn, U. (2016). The Risk of Automation for Jobs in OECD Countries: A Comparative Analysis. Paris: OECD Publishing.

A. Schröder (2015). in Green Skills along the Value Chain of the Automotive Suppliers Industry (Milano: McGraw-Hill Education).

Bakhshi, H., Downing, J. M., Osborne, M. A., and Schneider, P. (2017). The Future of Skills: Employment in 2030. London: Pearson and Nesta. doi:10.1145/3132515.3132524

Barnes, S.-A., Brown, A., and Warhurst, C. (2016). Education as the Underpinning System: Understanding the Propensity for Learning across the Lifetime. London: Foresight, Government Office for Science.

Berger, T., and Frey, C. B. (2016). Digitalization, Jobs, and Convergence in Europe: Strategies for Closing the Skills Gap.

Berman, E., and Machin, S. (2000). Skill-biased Technology Transfer Around the World. Oxf. Rev. Econ. Policy 16 (3), 12–22. doi:10.1093/oxrep/16.3.12

Brandsen, T., and Honingh, M. (2018). “Definitions of Co-Production and Co-creation,” in Co-production and Co-creation. Engaging Citizens in Public Services. Editors T. Brandsen, B. Verschuere, and T. Steen (New York: Routledge), 9–17. doi:10.4324/9781315204956-2

Brown, T., and Katz, B. (2009). Change by Design. How Design Thinking Can Transform Organizations and Inspire Innovation. New York NY: HarperCollins Publishers.

Brynjolfsson, E., and McAfee, A. (2014). The Second Machine Age: Work, Progress and Prosperity in a Time of Brilliant Technologies. New York: Norton.

Chuh, S. K. W., Reynolds, R. B., Tavares, N. J., Notari, M., and Lee, C. W. Y. (2017). 21st Century Skills Development through Inquiry-Based Learning: Form Theory to Practice. Singapore: Springer. doi:10.1007/978-981-10-2481-8

Colla, V. (2019). Robotic Workstation in Harsh Environmental Conditions to Improve Safety in the Steel Industry: Final Technical Report. Oxford, United Kingdom: University of Oxford.

Colla, V., Schröder, A., Buzzelli, A., Abbà, D., Faes, A., and Romaniello, L. (2017). Introduction of Symbiotic Human-Robot-Cooperation in the Steel Sector: an Example of Social Innovation. Matériaux Tech. 105, 505. doi:10.1051/mattech/2018017

Davies, A., Fidler, D., and Gorbis, M. (2011). Future Work Skills 2020. Palo Alto, CA: Institute for the Future for University of Phoenix Research Institute.

Dhondt, S., Totterdill, P., Boermans, S., and Žiauberytė-Jakštienė, R. (2017). “Five Steps to Develop Workplace Innovation,” in Workplace Innovation: Theory, Research and Practice. Editors P. R. A. Oeij, D. Rus, and F. D. Pot (Cham: s.l. Springer International Publishing), 301–319. doi:10.1007/978-3-319-56333-6_18

Eckhardt, J., Kaletka, C., Krüger, D., Maldonado-Mariscal, K., and Schulz, A. C. (2020). Ecosystems of Co-creation. Front. Sociol. 6 (6), 1–11. doi:10.3389/fsoc.2021.642289

European Commission (2016). New Skills Agenda for Europe. Employment, Social Affairs & Inclusion. 7. Retrieved from: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:52016DC0381&from=EN

European Commission (2019). Report of the High-Level Expert Group on: The Impact of the Digital Transformation on EU Labour Markets. Luxembourg: Publications Office of the European Union.

Frey, C. B., and Osborne, M. A. (2017). The Future of Employment: How Susceptible Are Jobs to Computerisation?. Technol. Forecast. Soc. Change 114, 254–280. doi:10.1016/j.techfore.2016.08.019

Gambin, L., Horgarth, T., Murphy, L., Spreadbury, K., Warhurst, C., and Winterbotham, M. (2016). Research to Understand the Extent, Nature and Impact of Skills Mismatches in the Economy. London.

Green, F. (2016). Skills Demand, Training and Skills Mismatch: A Review of Key Concepts, Theory and Evidence. London: Government Office for Science.

Grömling, M., and Matthes, J. (2019). Welche Risiken gefährden die deutsche Wirtschaft? Wirtschaftdienst 99, 855–862. doi:10.1007/s10273-019-2540-7

Grundke, R., Marcolin, L., Nguyen, T. L. B., and Squicciarini, M. (2018). Which Skills for the Digital Era? Returns to Skill Analysis. Paris.

Hirsch-Kreinsen, H. (2016). Digitization of Industrial Work: Development Paths and Prospects. J. Labour Market Res. 49, 1–14. doi:10.1007/s12651-016-0200-6

Hoberg, P., Krcmar, H., and Welz, B. (2017). Skills for Digital Transformation: Research Report 2017. Germany: Technical University of Munich.

Hochgerner, J. (2018). “Empowerment, Co-creation and Social Innovation Ecosystems,” in Atlas of Social Innovation - New Practices for a Better Future. Editors J. Howaldt, C. Kaletka, A. Schröder, and M. Zirngiebl (Dortmund: Sozialforschungsstelle, TU Dortmund University).

Howaldt, J., Kopp, R., and Schultze, J. (2017). “Why Industrie 4.0 Needs Workplace Innovation-A Critical Essay about the German Debate on Advanced Manufacturing,” in Workplace Innovation: Theory, Research and Practice. Editors P. R. A. Oeij, D. Rus, and F. D. Pot (Cham: s.l. Springer International Publishing), 45–60. doi:10.1007/978-3-319-56333-6_4

Howaldt, J., Schröder, A., Kaletka, C., Rehfeld, D., and Terstriep, J. (2016). Mapping the World of Social Innovation: A Global Comparative Analysis Acros Sectors and World Regions. SI-DRIVE D1.4 Comparative Analysis. Germany: TU Dortmund.

Howaldt, J., and Schwarz, M. (Editors) (2018). Soziale Innovation im Fokus: Skizze eines Gesellschaftstheoretisch Inspirierten Forschungskonzepts. Bielefeld, Germany: Transcript Verlag.

Howaldt J., and Schwarz M. (2010). in „Soziale Innovation“ im Fokus: Skizze eines gesellschaftstheoretisch inspirierten Forschungskonzepts (Bielefeld: transcript Verlag).

Ittermann, P., Niehaus, J., Hirsch-Kreinsen, H., Dregger, J., and Hompel, M. t. (2016). Social Manufacturing and Logistics: Gestaltung von Arbeit in der digitalen Produktion und Logistik. Berlin: VDI/VDE Innovation + Technik GmbH.

Kirchherr, J., Klier, J., Lehmann-Brauns, C., and Winde, M. (2019). Future Skills: Welche Kompetenzen in Deutschland Fehlen. Diskussionspapier 1. Essen, Germany: Stifterverband fr die Deutsche Wissenschaft e.V.

Kohlgrüber, M., Schröder, A., Bayón Yusta, F., and Arteaga Ayarza, A. (2019). A New Innovation Paradigm: Combining Technological and Social Innovation. Matériaux Tech. 107, 107. doi:10.1051/mattech/2018065

Kohlgrüber, M., and Schröder, A. (2019). “Innovation Reloaded: The Social Character of Digitalisation in Industry,” in Atlas of Social Innovation: 2nd Volume: A World of New Practices. Editors J. Howaldt, C. Kaletka, A. Schröder, and M. Zirngiebl (München: oekom verlag).

Koski, O., and Husso, K. (2018). Work in the Age of Artificial Intelligence: Four Perspectives on the Economy, Employment, Skills and Ethics. Finland: Ministry of Economic Affairs and Employment.

Lamb, S., Maire, Q., and Doecke, E. (2017). Key Skills for the 21st Century: An Evidence-Based Review: Future Frontiers Analytical Report. Parramatta, NSW: NSW Department of Education.

Maldonado-Mariscal, K. (2020). Social Change in Brazil through Innovations and Social Movements. J. Dev. Soc. 36 (4), 415–438. doi:10.1177/0169796X20963332

Maldonado-Mariscal, M. K. (2017). Subsystems of Social Innovation in Brazil: The Society of Sao Paulo as a New Actor in the Education System and Innovation. Dissertation for Doctoral Degree of PhilosophyFaculty of Culture, Social Sciences and Education. Berlin, Germany: Humboldt University of Berlin. doi:10.18452/18568

Nier, H. (2016). Hemmnisse für Unternehmen bei der Digitalisierung. Available at: https://de.statista.com/infografik/4876/hemmnisse-fuer-unternehmen-bei-digitalisierung/ (Accessed August 27, 2019) doi:10.5089/9781513502137.051

OPTTUDOOUTSidenor (2017). Impact Evaluation Criteria. Available at: https://www.cocop-spire.eu/sites/cocop.drupal.pulsartecnalia.com/files/documents/D2.2_ImpactEvaluationCriteria_final.pdf (Accessed October 1, 2019).

Pfeiffer, S., Lee, H., Zirnig, C., and Suphan, A. (2016). Industrie 4.0 - Qualifizierung 2025. Nürnberg, Germany: Institut für Arbeitsmarkt- und Berufsforschung.

Pot, F., Dhondt, S., Oeij, P., Rus, D., and Totterdill, P. (2019). “Complementing Digitalisation with Workplace Innovation,” in Atlas of Social Innovation: 2nd Volume: A World of New Practices. Editors J. Howaldt, C. Kaletka, A. Schröder, and M. Zirngiebl (München: oekom verlag).

PWC (2018). Skills for Smart Industrial Specialisation and Digital Transformation: Interim Report. Brussels, Berlgium: European Commision.

Rampelt, F., Orr, D., and Knoth, A. (2019). Bologna Digital 2020: White Paper on Digitalisation in the European Higher Education Area. Berlin. doi:10.1163/9789004409149

Sanders, E. B.-N., and Stappers, P. J. (2008). Co-creation and the New Landscapes of Design. CoDesign 4 (1), 5–18. doi:10.1080/15710880701875068

Schröder, A., Kaletka, C., Echterhoff, V., Szulc, W., Bujakowska, M., Tropeoli, A., et al. (2013). European Framework Module: Green Skills for Mechanical/Industrial and Electrical Technicians. Training Handbook D8. Dortmund. Available at: https://www.estep.eu/assets/GT-VET/GT-VET-European-Framework-Module-Green-skills-for-mechanical-industrial-and-electrical-technicians-Training-Handbook.pdf. (Accessed November 13, 2018).

Schröder, A. (2014). “Greening Technical Vocational Education and Training in the European Steel Industry.” in Greener Skills and Jobs, OECD Green Growth Studies. Paris: OECD Publishing, 155–166.

Schröder, A. (2011). Implementing Innovative Structures to Improve Lifelong Learning - a Social Innovation Process, the Example HESSENCAMPUS; CHALLENGE SOCIAL INNOVATION. Innovating Innovation by Research - 100 Years after Schumpeter, Vienna, September 19 - 21, (ZSI Discussion Paper, Nr. 28). Vienna: Zentrum für Soziale Innovation.

Schröder, A., Krüger, D., and Kuschmiertz, L. (2017). Social Innovation: Creating Innovative Spaces for Education and Lifelong Learning. Dortmund: Technische Universität Dortmund.

Schröder, A., and Krüger, D. (2019). Social Innovation as a Driver for New Educational Practices: Modernising, Repairing and Transforming the Education System. Sustainability 11 (4), 1070. MDPI AG. doi:10.3390/su11041070

Schröder, A., and Kuschmiertz, L. (2017). Social Innovation in Education and Lifelong Learning: Case Study Results. Policy Field Education and Lifelong Learning. Dortmund: Technische Universität Dortmund.

Servoz, M. (2019). AI Report - the Future of Work? Work of the Future! on How Artificial Intelligence, Robotics and Automation Are Transforming Jobs and the Economy in Europe. Brussels: European Commission.

Shove, E., Pantzar, M., and Watson, M. (2012). The Dynamics of Social Practice: Everyday Life and How it Changes. Los Angeles: SAGE. doi:10.4135/9781446250655

Keywords: Social innovation, Technological innovation, Innovation process, Socio-digital transformation, Co-creation, participation, mutual learning

Citation: Kohlgrüber M, Maldonado-Mariscal K and Schröder A (2021) Mutual Learning in Innovation and Co-Creation Processes: Integrating Technological and Social Innovation. Front. Educ. 6:498661. doi: 10.3389/feduc.2021.498661

Received: 17 September 2019; Accepted: 22 April 2021;

Published: 10 May 2021.

Edited by:

Andreas Schröer, University of Trier, GermanyReviewed by:

Inga Truschkat, University of Hildesheim, GermanyCopyright © 2021 Kohlgrüber, Maldonado-Mariscal and Schröder. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Michael Kohlgrüber, bWljaGFlbC5rb2hsZ3J1ZWJlckB0dS1kb3J0bXVuZC5kZQ==; Karina Maldonado-Mariscal, a2FyaW5hLm1hbGRvbmFkb0B0dS1kb3J0bXVuZC5kZQ==; Antonius Schröder, YW50b25pdXMuc2Nocm9lZGVyQHR1LWRvcnRtdW5kLmRl

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.