An Erratum on

Visualization and evaluation of concrete damage in-service headworks by X-ray CT and non-destructive inspection methods

by Morozova, N., Shibano, K., Shimamoto, Y., Tayfur, S., Alver, N., and Suzuki, T. (2022). Front. Built Environ. 8:947759. doi: 10.3389/fbuil.2022.947759

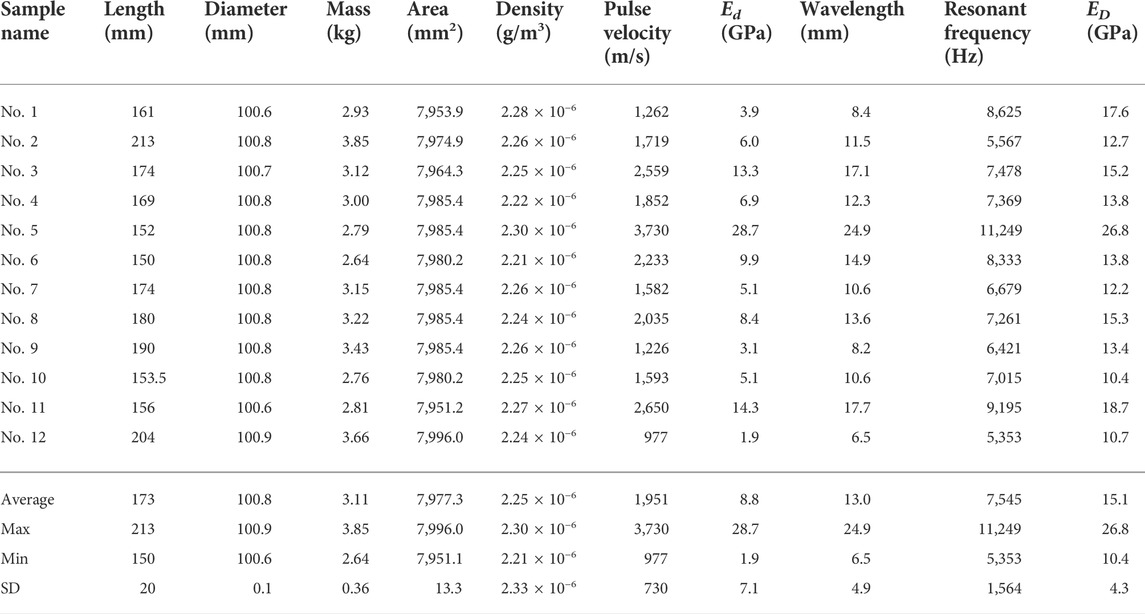

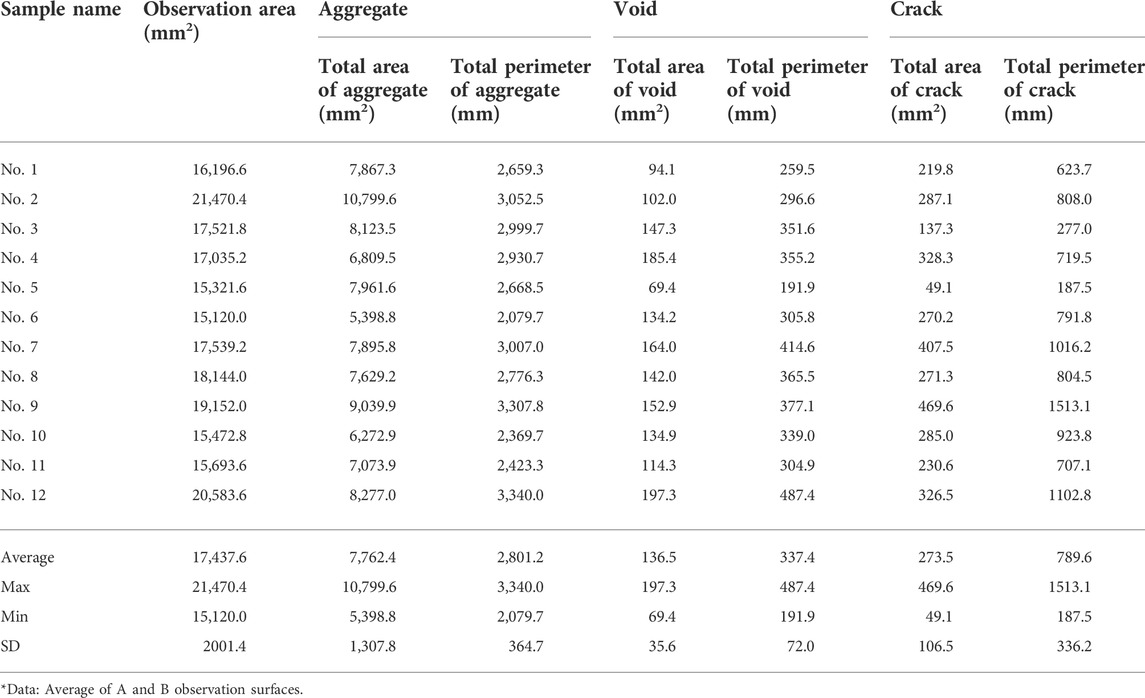

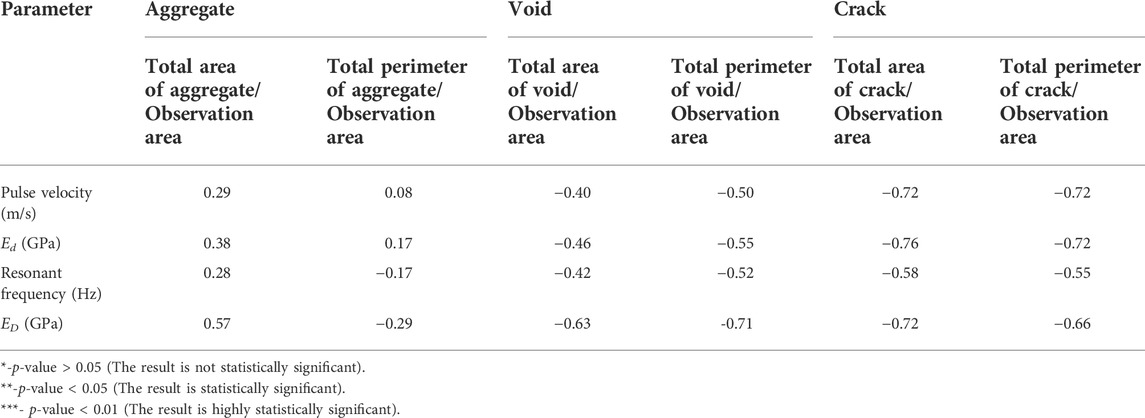

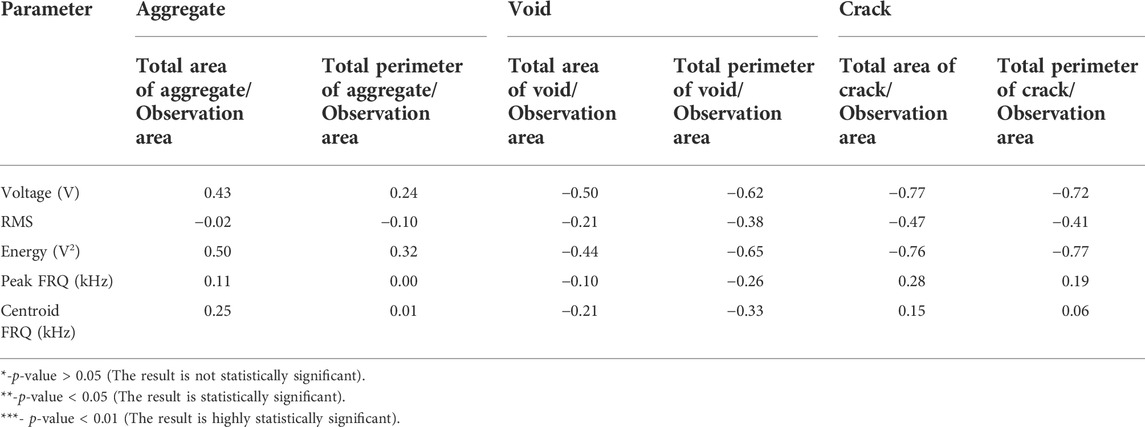

Due to a production error, there was a mistake in Tables 3,4,6,7 as published. The table columns were left aligned instead of right aligned. The corrected tables appear below.

Due to a production error, the text of the last paragraph of the Introduction on page 3 was duplicated.

The corrected paragraph is as follows:

“In this study, damage evaluation of concrete core samples is investigated by applying NDT parameters. The samples were taken from an in-service reinforced concrete structure, which has been subjected to the influence of aggressive environmental effects. Then, X-ray CT procedure was conducted on the specimens to detect and visualize the crack distributions After scanning, concrete damage was evaluated by the dynamic modulus of elasticity measured by UPV and resonant frequency tests. Results indicate that the decrease in mechanical properties of the concrete could be evaluated by comparing the geometrical properties of cracks with the dynamic modulus of elasticity, because both these parameters are affected by the internal actual cracks, thus, the damage of concrete could be quantitatively evaluated.”

The publisher apologizes for these mistakes. The original version of this article has been updated.

Keywords: in-service concrete headworks, concrete damage estimation, dynamic modulus of elasticity, X-ray computed tomography, segmentation

Citation: Frontiers Production Office (2022) Erratum: Visualization and evaluation of concrete damage in-service headworks by X-ray CT and non-destructive inspection methods. Front. Built Environ. 8:1037104. doi: 10.3389/fbuil.2022.1037104

Received: 05 September 2022; Accepted: 05 September 2022;

Published: 21 October 2022.

Approved by:

Frontiers Editorial Office, Frontiers Media SA, SwitzerlandCopyright © 2022 Frontiers Production Office. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Frontiers Production Office, cHJvZHVjdGlvbi5vZmZpY2VAZnJvbnRpZXJzaW4ub3Jn

Frontiers Production Office*

Frontiers Production Office*