- 1College of Food Science and Engineering, Shandong Agricultural University, Tai'an, China

- 2College of Resources and Environment, Shandong Agricultural University, Tai'an, China

- 3Institute of Food and Nutrition Development, Ministry of Agriculture and Rural Affairs, Beijing, China

- 4Crop Research Institute, Shandong Academy of Agricultural Sciences, Jinan, China

Improving zinc (Zn) content in wheat and its processed foods is an effective way to solve human Zn deficiency, which can cause a variety of diseases. This article summarizes the works on Zn in wheat grain, wheat processing, and wheat-derived foods. Grain Zn content in wheat was 31.84 mg·kg−1 globally but varied across continents, for example, 25.10 mg·kg−1 in Europe, 29.00 mg·kg−1 in Africa, 33.63 mg·kg−1 in Asia, and 33.91 mg·kg−1 in North America. Grain Zn content in wheat improved from 28.96 to 36.61 mg·kg−1 and that in flour increased from 10.51 to 14.82 mg·kg−1 after Zn fortification. Furthermore, Zn content varied in the different processed components of wheat; that is, Zn content was 12.58 mg·kg−1 in flour, 70.49 mg·kg−1 in shorts, and 86.45 mg·kg−1 in bran. Zinc content was also different in wheat-derived foods, such as 13.65 mg·kg−1 in baked food, 10.65 mg·kg−1 in fried food, and 8.03 mg·kg−1 in cooking food. Therefore, the suitable Zn fortification, appropriate processing, and food type of wheat are important to meet people's Zn requirement through wheat.

Introduction

Zinc is a blue-white metal element that accounts for ~0.02% of the earth's crust and is the twenty-third largest element in abundance (1). Zinc is an essential trace element for the growth and development of humans (2), animals (3), and plants (4). The health benefits of Zn have received much attention since the 1960s. According to the Zn intake reference of the World Health Organization (WHO), the recommended daily Zn intake of infants aged 7–12 months is 5 mg·day−1, children aged 1–10 years is 10 mg·day−1, males and females aged 11–51 years is 15 mg·day−1, and pregnant women is 20–25 mg·day−1, and the daily Zn tolerance is 100 mg·day−1. However, at least 25% of the global population is at risk of Zn deficiency (5). Insufficient Zn intake can cause loss of appetite, growth retardation, rough and peeling skin, and immune system dysfunction (6). On the one hand, Zn deficiency in pregnant women may cause fetal malformations (7), and nearly 82% of pregnant women worldwide have insufficient Zn intake (5). On the other hand, excessive Zn intake can cause nausea, vomiting, lethargy, and fatigue. Therefore, maintaining the balance of Zn in the human body, including increasing Zn intake for people with Zn deficiency, is an important long-term task.

Wheat is one of the major grains worldwide, which provides nearly 20% calorie and protein per capita worldwide (8). Therefore, improving the daily Zn intake through wheat-derived processed foods is an important way to solve Zn deficiency.

Grain Zn content in wheat is usually low in several areas and is therefore the first and essential concern in this study. Wheat processing is another important factor that can remarkably affect the actual Zn intake of people because the aleurone and bran layers of wheat are usually removed during processing. Different processing technologies of wheat also lead to a large loss of Zn (9). In addition, the content of phytic acid and the molar ratio of phytic acid to Zn, which can affect Zn absorption, are among the important factors to be considered.

This article summarizes the results in the list of fields in recent years, including (1) zinc content in wheat, wheat processing, and wheat-derived foods and (2) the bioavailability of Zn in wheat.

Grain Zinc Content in Wheat

Wheat is one of the important sources of daily diet in developing countries, but its Zn content is relatively low. The Zn content of wheat grains need to reach 45.00 mg·kg−1 to meet the Zn needs of the human body (10). However, statistics show that the average Zn content in wheat grains worldwide is only 28.48 mg·kg−1, which is lower than the internationally recommended amount. The grain Zn content of wheat in different countries since the 1960s (Table S1) ranged from 8.00 to 88.20 mg·kg−1 with an average value of 31.84 mg·kg−1 (5, 9–47).

The grain Zn contents of wheat among different countries varied (Figure 1). For example, grain Zn content is 38.87 mg·kg−1 in Turkey, 37.51 mg·kg−1 in China, 34.43 mg·kg−1 in Iran, 34.21 mg·kg−1 in the United States, 34.20 mg·kg−1 in Italy, 33.76 mg·kg−1 in Mexico, 33.13 mg·kg−1 in Pakistan, 29.00 mg·kg−1 in Zambia, 28.40 mg·kg−1 in Kazakhstan, 28.31 mg·kg−1 in India, 25.68 mg·kg−1 in Hungary, 24.09 mg·kg−1 in Belgium, and 23.58 mg·kg−1 in France. The average grain Zn contents of wheat among different continents were 25.10 mg·kg−1 in Europe, 29.00 mg·kg−1 in Africa, 33.63 mg·kg−1 in Asia, and 33.91 mg·kg−1 in North America. The reasons for these differences in grain Zn content may be as follows: (1) The amount of Zn available in the soil in these areas is different. For example, the available Zn in the soil in China was 0.37 mg·kg−1, 0.53 mg·kg−1 in India, 0.55 mg·kg−1 in Pakistan, and 1.46 mg·kg−1 in Zambia (12). (2) Grain Zn content is different among wheat varieties. For example, the grain Zn content was 28.48 mg·kg−1 in common wheat, 34.80 mg·kg−1 in white wheat, 34.40 mg·kg−1 in red wheat, and 36.45 mg·kg−1 in black wheat (13). (3) Different wheat cultivation types, environments, climates, and biofortification methods result in the different grain Zn contents of wheat. For example, the mean Zn content was 31.42 mg·kg−1 in winter wheat and 30.13 mg·kg−1 in spring wheat (Figure S1).

Figure 1. Zinc content of wheat among different countries and continents. These data come from references (5, 9–47). Letters a and b indicate a significant difference at the level of P < 0.05.

Zinc content can be enhanced by fortification during breeding and by adding nutrients during food processing (48). Biofortification can quickly increase grain Zn content in wheat because of agronomic measures, such as the application of Zn fertilizer (49); therefore, field fertilization was gradually accepted and liked by farmers. The main application methods of Zn fertilizer include soil application, foliar application, and seed treatment (50). As shown in Figure S1, grain Zn content in wheat by soil Zn application ranged from 8.00 to 54.40 mg·kg−1, with an average value of 29.39 mg·kg−1 (5, 9, 10, 12, 14, 19, 22, 25, 27, 28, 30, 31, 34, 35, 51); that by foliar fertilization ranged from 25.1 to 88.20 mg·kg−1, with an average value of 42.30 mg·kg−1 (5, 15, 18, 20, 22, 31, 32); and that by seed soaking treatment ranged from 25.70 to 31.10 mg·kg−1, with an average value of 30.30 mg·kg−1 (19, 41). Furthermore, grain Zn content by the combined treatment of soil application and foliar fertilization ranged from 25.10 to 70.00 mg·kg−1 with an average value of 40.45 mg·kg−1 (5, 22, 25, 31, 33), and that by the combined treatment of soil fertilization and seed soaking reached 34.30 mg·kg−1 (19).

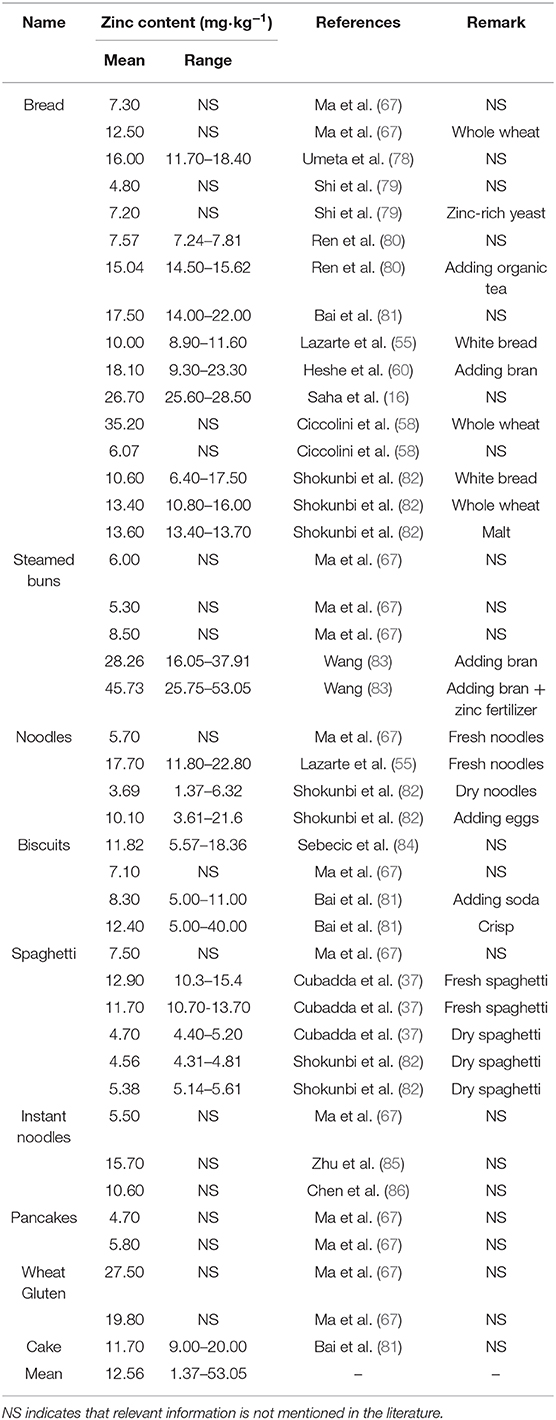

In general, the average grain Zn content in wheat without Zn fertilizer was 28.96 mg·kg−1, which increased to 36.61 mg·kg−1 after Zn fortification (Figure 2). Interestingly, the available Zn concentration in soil could exceed 4.09 mg·kg−1, and grain Zn content could reach 40–60 mg·kg−1 (52) when 50 kg·hm−2 ZnSO4·7(H2O) was added to the soil.

Figure 2. Zinc content in fortified and unfortified wheat. Letters a and b indicate a significant difference at the level of P < 0.05; n is the total number of samples.

Therefore, the most effective way to increase grain Zn content in wheat may be combining soil fertilization and foliar fertilization or directly applying foliar fertilization. However, local environment and wheat varieties should also be considered when choosing a suitable fertilization method to increase grain Zn content in wheat.

Zinc in Different Components of Wheat

The grain structure of wheat is generally divided into bran, embryo, and endosperm, which account for 14–16, 2–3, and 81–84% of the grain, respectively (53). Wheat peeling is the process of separating the endosperm and bran of wheat and grinding them into flour (28). Wheat flour processing has two purposes: one is to grind the endosperm into small and fine particles, and the other is to remove the bran as much as possible. The traditional method of flour making breaks wheat directly to separate the bran and endosperm and obtains the pure wheat core through flour cleaning, which is further ground into flour. The other milling method carries out the peeling process before wheat milling. Generally, wheat peeling is carried out by a friction machine or scraping machine equipment. A friction machine mainly carries out peeling through friction between wheat grains. The scraping machine uses a sand roller to scrape off wheat bran (54). According to reported results since 1980s (Table S2), the basic law of Zn content in wheat components after milling is: bran > shorts > flour. Zinc content over the years and across countries ranged from 3.73 to 36.53 mg·kg−1 in flour with an average value of 12.58 mg·kg−1 (22, 23, 29, 37, 38, 42, 45, 55–69), ranged from 26.60 to 139.84 mg·kg−1 in shorts with an average of 70.49 mg·kg−1 (29, 38, 42, 56, 59, 62, 66, 70), and ranged from 23.80 to 159.80 mg·kg−1 in bran with an average of 86.45 mg·kg−1 (21, 22, 29, 32, 38, 42, 46, 56, 59, 61, 62, 66, 68, 70).

The results showed that Zn was mainly concentrated in the cortex and embryo of wheat grain. For example, Zn content in bran was about three times higher than that in endosperm (71, 72) and approximately six times higher than that in flour after milling (42, 70).

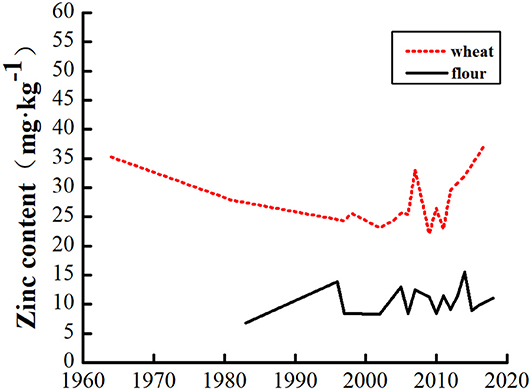

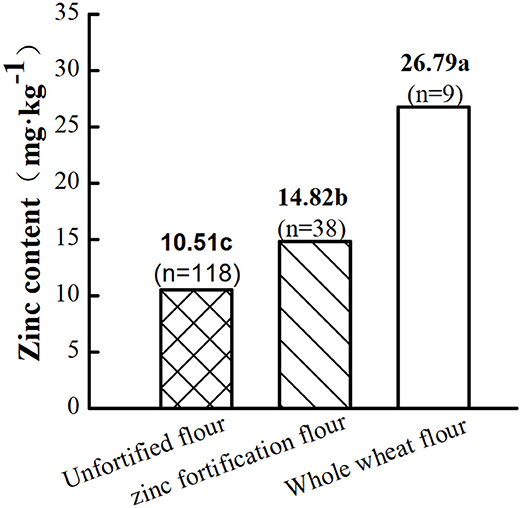

The overall trend of grain and flour Zn content gradually increased with year (Figure 3). In particular, grain and flour Zn content increased remarkably since the launch of the Harvest Plus project in 2003 possibly owing to biological strengthening, such as Zn fertilization. Flour Zn content could reach 14.82 mg·kg−1 after Zn fortification but was only 10.51 mg·kg−1 in unfortified flour and 26.79 mg·kg−1 in whole wheat flour (Figure 4).

Figure 4. Comparison of wheat flour with different treatments. Data are from references (22, 23, 29, 37, 38, 42, 45, 55–69). Letters a, b, and c indicate a significant difference at the level of P < 0.05; n is the total number of samples.

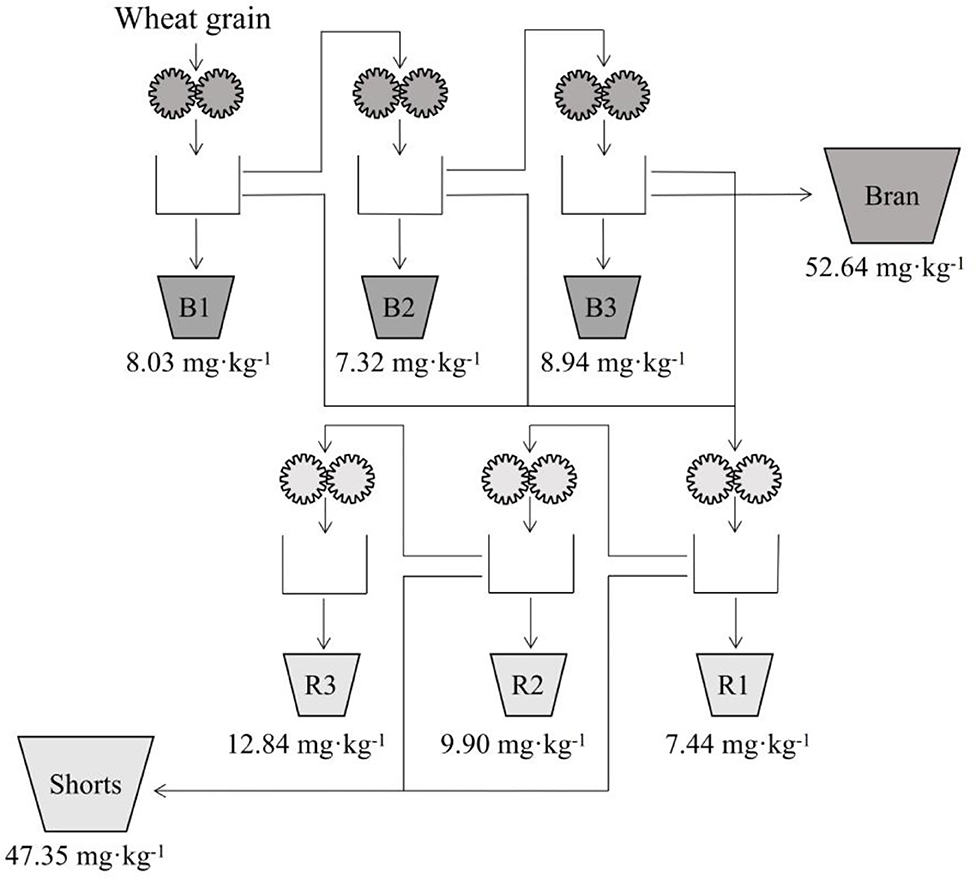

The technological process of wheat milling is called “flour road.” Eight milling parts can be obtained after wheat milling, including six flour parts [i.e., three “broken” (B) and three “reduced” (R) milling parts] and two kinds of bran parts (i.e., bran and shorts). The flour collected by B1, R1, B2, R2, B3, and R3 is standard flour; that by B1, R1, B2, and B3 is bread flour; and that by B1 and R1 is refined flour (59). The powder path schematic diagram of Bühler MLU 202 mill and the Zn content of each powder path after passing the wheat grain through the mill are shown in Figure 5. The Zn content in each component was in the following order: bran > R (powder) > B (powder). Zinc content was 12.84 mg·kg−1 in R1, 9.90 mg·kg−1 in R2, 7.44 mg·kg−1 in R3, 8.03 mg·kg−1 in B1, 8.94 mg·kg−1 in B2, and 7.32 mg·kg−1 in B3. The Zn content in bran was remarkably higher than that of the other components. So the processing with higher flour extraction rate including aleurone layer would enhance retention of more Zn. However, this may also affect overall flour quality (57).

Figure 5. Schematic diagram of zinc content in the powder path. These data are from references (38, 59, 70).

In summary, Zn content in flour can be increased in two ways. One is to increase grain Zn content through agronomic treatments. However, the enhancement of the target on a large scale by field fertilization is difficult to achieve (Table S1), and long-term fertilization may also cause pollution to the soil and other environments. The other way is to choose an appropriate wheat processing. This approach may be a direct way to reach Zn reference target by whole wheat flour. Zinc was not lost in flour; however, whole wheat flour is rough, its dough is poorly fermented, and the taste of its derived food taste is not good. Safety risks may even occur owing to pesticides and heavy metals in the seed coat (73). Thus, Zn-rich flour from aleurone flour mixed with ordinary flour in a certain proportion was used to meet the standards of first-grade flour, and this flour had no effect on food's taste despite the addition of 5% aleurone flour (74, 75). We also could decrease the influence of pesticides and heavy metals while maintaining Zn content by controlling the peeling rate and flour extraction rate. For example, the Zn content of flour could reach 19.40 mg·kg−1, which exceeds the fortification standard of 10.00 mg·kg−1 when flour extraction rate was 65–75% (61).

Therefore, we should pay attention to improve grain Zn content and also consider wheat processing to control the peeling rate while keeping Zn content to a suitable level.

Zinc in Wheat Processed Foods

Foods from processed wheat, such as bread, steamed buns, and biscuits, are the main traditional staple food that occupy an important position in people's dietary structure (76). For example, wheat-related traditional foods in China account for 75% of China's total wheat consumption (77).

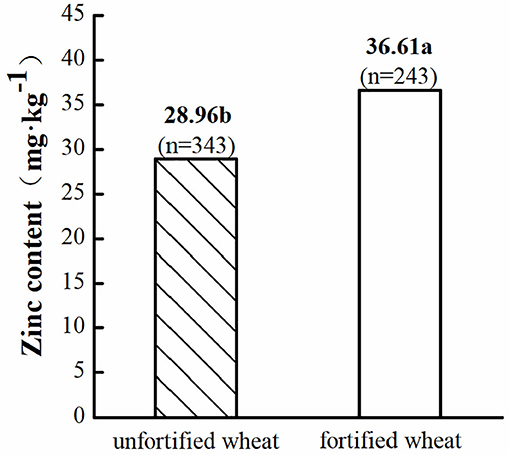

Table 1 shows a list of the Zn content of processed foods from wheat in the past 15 years. The Zn content of processed wheat foods ranged from 1.73 to 53.05 mg·kg−1 with an average of 12.56 mg·kg−1 (16, 37, 55, 58, 60, 67, 78–86). The processed wheat food with the highest Zn content was steamed buns, which has a Zn content of 53.05 mg·kg−1. Cooked noodles have the lowest Zn content, which was only 1.73 mg·kg−1.

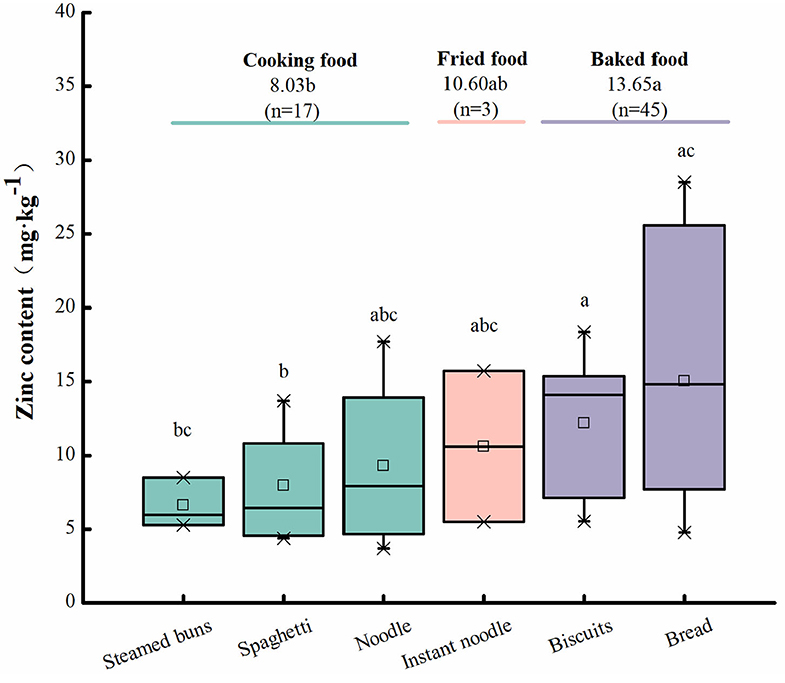

Zinc content was remarkably different among processed wheat foods. For example, Zn content was 15.03 mg·kg−1 in bread, 12.20 mg·kg−1 in biscuits, 10.60 mg·kg−1 in instant noodles, 9.30 mg·kg−1 in noodles, 7.94 mg·kg−1 in spaghetti, and 6.60 mg·kg−1 in steamed buns (Figure 6). The Zn contents of different foods are in the following order: baked food (13.65 mg·kg−1) > fried food (10.60 mg·kg−1) > cooking food (8.03 mg·kg−1). Baked foods have a remarkably higher Zn content than cooking foods and fried foods. This difference in Zn content may be ascribed to the following: (1) The Zn content of the flour used in these foods was different and ranged from 3.73 to 36.53 mg·kg−1. For example, the Zn content of unfortified flour was 10.51 mg·kg−1, whereas that of Zn-fortified flour and whole wheat flour was 14.82 and 26.79 mg·kg−1, respectively (Figure 4). Meanwhile, these foods require different kinds of flour, in which protein contents often vary. For example, in the same growth environment, protein content of strong gluten wheat could reach 148.86 mg·kg−1, weak gluten wheat was only 108.51 mg·kg−1, and middle gluten wheat was 137.41 mg·kg−1 (87). Zn mainly binds to proteins in plants. So protein content may affect the amount of Zn binding, which indirectly affects Zn content. (2) Different food processing methods might also affect zinc content. For example, fried foods usually need oil, and cooking food need water. Yet Zn dissolves more easily in water than in oil, which might result in more Zn loss in cooking food processing than fried foods processing (88).

Figure 6. Zinc content in different wheat processed foods. Letters a, b, and c indicate a significant difference at the level of P < 0.05; n is the total number of samples.

Zinc Bioavailability in Wheat

Bioavailability refers to the ratio of an animal's ingested nutrients that can be absorbed by the small intestine and participate in metabolic processes or stored in animal tissues. The bioavailability of Zn in wheat is affected by many factors, of which phytic acid is the main factor. Phytic acid has a strong chelating ability and can be combined with Zn2+ in food to form insoluble complexes. This insoluble Zn is difficult to hydrolyze by the human digestive process; therefore, the combination of Zn and phytic acid inhibits Zn absorption. Furthermore, humans lack phytase. Zinc can be linked to phytate; thus, the utilization of Zn in the intestine is reduced (89).

The bioavailability of Zn in wheat is usually expressed as the molar ratio of phytic acid to Zn. Zinc bioavailability is only 10–15% when the molar ratio is >15. Zinc bioavailability is medium and ranges from 30 to 35% when the molar ratio is 5–15. Zinc bioavailability is high at up to 45–55% when the molar ratio is < 5 (90). For instance, if the Zn content in flour is 15.2 mg·kg−1 and the phytic acid content is 272 mg·100 g−1, then the phytic acid/Zn ratio is 17.7, which means that the Zn bioavailability is low (55).

Wheat processing affects the phytic acid/Zn molar ratio. Peeling can remarkably influence the phytic acid content in flour because phytic acid is mainly distributed in the aleurone layer. The phytic acid content of flour initially increased and then decreased with the increase in peeling rate (63). Researchers also found that the phytic acid content of flour increased remarkably with the increase in flour yield. The increase in phytic acid content in flour was because more wheat cortex and aleurone layer were mixed in flour with the increase in flour yield (20). For example, phytic acid was 158 mg·100 g−1 when peeling rate was 4%. However, phytic acid/Zn molar ratio reached the highest value (20.69) when the peeling rate was 10% and had the lowest value (13.86) when the peeling rate was 0 (63).

Different foods also have different levels of Zn bioavailability. For example, white bread has a Zn content of 10.00 mg·kg−1, a phytic acid content of 99 mg·100 g−1, and phytic acid/Zn molar ratio of 9.8. In contrast, fresh noodles have Zn content and phytic acid content of 17.7 mg·kg−1 and 468 mg·100 g−1, respectively; and their phytic acid/Zn molar ratio is 27.4 (55). The average content of Zn and phytic acid in 14 kinds of common Chinese processed wheat foods was 9.34 mg·kg−1 and 114.20 mg·100 g−1, and their average phytic acid/Zn ratio was 14.4. Among these foods, the phytic acid/Zn molar ratios of wheat bread, instant noodles, whole wheat biscuits, and pasta were more than 15 (67).

Adding phytase to food in the market has not been reported until now. However, researchers found that phytase can rapidly degrade phytic acid in flour after adding phytase to flour; thus, phytase increases the bioavailability of Zn (91). Moreover, Zn deficiency can be solved by cultivating wheat with low phytic acid content. However, mutants with low phytic acid may have a reduced grain yield and may even affect human safety (92).

The current methods to improve Zn bioavailability in wheat and its derived foods mainly included two aspects. One was to increase Zn content in grain, flour, and its derived foods. The other was to reduce the inhibitors that reduce Zn bioavailability in processed wheat foods.

Conclusions and Future Direction

Grain Zn content in wheat worldwide is 31.84 mg·kg−1, which was lower than that suggested by the reference of WHO. Zinc fortification is the primary way to increase the grain Zn content of wheat and could be achieved by Zn fertilizer. In general, the average grain Zn content in wheat could reach 36.61 from 28.96 mg·kg−1 after applying Zn fertilizer (Figure 2). Grain Zn content could reach 40–60 mg·kg−1 and achieve the reference of WHO under 50 kg·hm−2 ZnSO4·7(H2O) treatment.

Wheat milling has remarkable effects on Zn content. For example, Zn contents in flour, shorts, and bran were 12.58, 70.49, and 86.45 mg·kg−1, respectively. The change rule of Zn content in different components of wheat is bran > shorts > flour; the change rule of Zn content in each powder path is bran > B flour > M flour, B3 > B1 > B2, and M3 > M2 > M1. However, only a few studies have been conducted in this area. Moreover, Zn content in different wheat-derived foods is remarkably different, for example, 13.65 mg·kg−1 in baked food, 10.65 mg·kg−1 in fried food, and 8.03 mg·kg−1 in cooking food. This difference in Zn content may be due to the method of food processing.

Zinc deficiency is a comprehensive problem. Rotation and other cultivation methods may be used to increase Zn content to a certain extent. For example, the rotation of corn and wheat results in a higher Zn content in the second quarter compared with that in the first quarter (5). Although the application of Zn fertilizer can improve the Zn content, we should also consider the possible pollution of Zn to the environment by long-term application of Zn fertilizer under the premise of achieving the recommended Zn level (19).

Developing wheat varieties with grains that are rich in Zn is a new approach. Conventional wheat breeding and modern biotechnology methods (93), such as transferring a high Zn accumulation gene from wheat relatives, may be promising.

In the future, we should focus on how to preserve Zn as much as possible during milling, such as the effects of wheat grain pre-treatment and milling procedures on flour Zn content. Moreover, we should also explore the impact of food processing methods on Zn content.

Phytic acid is an important indicator that affects the effectiveness of Zn. Current research has focused on phytic acid content in wheat grains and flour. However, research on phytic acid content in wheat-derived foods is scarce. Next, we should strengthen the study of the effects of different processing methods on phytic acid content and Zn bioavailability.

Zinc deficiency is a worldwide problem. Zinc fortification should strengthen international cooperation through international schemes, such as Harvest Plus. Moreover, we should raise public awareness of the dangers of Zn deficiency and obtain as much support as possible, such as sustained funding, from the local government.

Therefore, suitable Zn fortification, appropriate processing, reasonable food type, international collaboration, and government support are important to meet people's Zn requirements through wheat.

Author Contributions

MW collected and analyzed the data. MW and XZ wrote this paper. XZ, FK, RL, and QF conceived and modified this paper. All authors contributed to the article and approved the submitted version.

Funding

This paper was supported by Agricultural Variety Improvement Project of Shandong Province (2019LZGC010) and the National Natural Science Foundation Project of Shandong Province (ZR2018MC016).

Conflict of Interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Supplementary Material

The Supplementary Material for this article can be found online at: https://www.frontiersin.org/articles/10.3389/fnut.2020.00124/full#supplementary-material

References

1. Brown KH, Wuehler SE, Peerson JM. The importance of zinc in human nutrition and estimation of the global prevalence of zinc deficiency. Food Nutr Bull. (2001) 22:113–25. doi: 10.1177/156482650102200201

2. Salgueiro MJ, Zubillaga M, Lysionek A, Sarabia MI, Caro R, De Paoli T, et al. Zinc as an essential micronutrient: a review. Nutr Res. (2000) 20:737–55. doi: 10.1016/S0271-5317(00)00163-9

3. Ren DX, Yin S, Xu QM, Hu SM, Zhao XF. Effect of different levels of Ca, Fe, Zn in diet on the nutritional status and reproduotion of female rats. Acta Nutr Sinica. (1999) 21:28–33.

4. Broadley MR, White PJ, Hammond JP, Zelko I, Lux A. Zinc in plants. N Phytol. (2007) 173:677–702. doi: 10.1111/j.1469-8137.2007.01996.x

5. Wang JW, Mao H, Zhao HB. Different increases in maize and wheat grain zinc concentrations caused by soil and foliar applications of zinc in loess plateau, China. Field Crops Res. (2012) 135:89–96. doi: 10.1016/j.fcr.2012.07.010

6. Tiber AM, Mukherjee MD. Clinical manifestations of zinc deficiency. Am Fam Phys. (1982) 26:167–72.

7. Prasad AS. Zinc deficiency in women, infants and children. J Am Coll Nutr. (1996) 15:113–20. doi: 10.1080/07315724.1996.10718575

8. Long DY. Molecular Cytogentic Identification of BC1F8 Generation of Common Wheat–Aegilops Geniculata Roth SY159 Progeny. Xianyang: Northwest A&F University (2019).

9. Oury FX, Leenhardt F, Remesy C, Chanliaud E, Duperrier B, Balfourier F, et al. Genetic variability and stability of grain magnesium, zinc and iron concentrations in bread wheat. Eur J Agron. (2006) 25:177–85. doi: 10.1016/j.eja.2006.04.011

10. Liu DY. Zinc Nutrition of High-Yielding Wheat and Maize and Its Management on Calcareous Soil. Beijing: China Agricultural University (2017).

11. Kaur N, Kaur H, Mavi GS. Assessment of nutritional and quality traits in biofortified bread wheat genotypes. Food Chem. (2020) 302:125342. doi: 10.1016/j.foodchem.2019.125342

12. Rashid A, Ram H, Zou CQ, Rerkasem B, Duarte AP, Simunji S, et al. Effect of zinc-biofortified seeds on grain yield of wheat, rice, and common bean grown in six countries. J Plant Nutr Soil Sci. (2019) 182:791–804. doi: 10.1002/jpln.201800577

13. Huang X, Li YG, Sun W, Hou JF, Ma Y, Jian Z, et al. Variation of grain iron and zinc contents and their bioavailability of wheat cultivars with different-colored grains under combined nitrogen and phosphorus fertilization. Acta Agron Sin. (2018) 44:1506–16. doi: 10.3724/SP.J.1006.2018.01506

14. Rehman A, Farooq M, Nawaz A, Al Sadi AM, Al-Hashmi KS, Nadeem F, et al. Characterizing bread wheat genotypes of pakistani origin for grain zinc biofortification potential. J Sci Food Agric. (2018) 98:4824–36. doi: 10.1002/jsfa.9010

15. Zhang MY. Investigations of the Effects of Zn Biofortification in Different Wheat Genotypes. Yangzhou: Yangzhou University (2017).

16. Saha S, Chakraborty M, Sarkar D, Batabyal K, Mandal B, Murmu S, et al. Rescheduling zinc fertilization and cultivar choice improve zinc sequestration and its bioavailability in wheat grains and flour. Field Crops Res. (2017) 200:10–17. doi: 10.1016/j.fcr.2016.09.006

17. Magallanes-López AM, Hernandez-Espinosa N, Velu G, Posadas-Romano G, Ordoñez-Villegas VMG, Crossa J, et al. Variability in iron, zinc and phytic acid content in a worldwide collection of commercial durum wheat cultivars and the effect of reduced irrigation on these traits. Food Chem. (2017) 237:499–505. doi: 10.1016/j.foodchem.2017.05.110

18. Sadeghzadeh EE, Abdoli M, Mousavi SB, Sadeghzadeh B. Impact of foliar zinc application on agronomic traits and grain quality parameters of wheat grown in zinc deficient soil. Plant Physiol Rep. (2016) 21:263–70. doi: 10.1007/s40502-016-0225-4

19. Liu JH. The Effects of Foliar Zn Application on Grain Zn Bioavailability Under Different Growth Conditions. Yangzhou: Yangzhou University (2016).

20. Zhang Q. The Effects of Foliar Zn Application on Grain Zn Bioavailability Under Different Growth Conditions. Yangzhou: Yangzhou University (2016).

21. Guttieri MJ, Seabourn BW, Liu C, Baenziger PS, Waters BM. Distribution of Cadmium, Iron, and Zinc in millstreams of hard winter wheat (Triticum aestivum L.). J Agric Food Chem. (2015) 63:10681–8. doi: 10.1021/acs.jafc.5b04337

22. Li M, Wang S, Tian X, Zhao J, Li H, Guo C, et al. Zn distribution and bioavailability in whole grain and grain fractions of winter wheat as affected by applications of soil N and foliar Zn combined with N or P. J Cereal Sci. (2015) 61:26–32. doi: 10.1016/j.jcs.2014.09.009

23. Guttieri MJ, Baenziger PS, Frels K, Carver B, Arnall B, Waters BM. Variation for grain mineral concentration in a diversity panel of current and historical great plains hard winter wheat germplasm. Crop Sci. (2015) 55:1035–52. doi: 10.2135/cropsci2014.07.0506

24. Zhang MY, Yang YH, Feng CN, Guo WS, Li CY, Zhu XK, et al. Responses of concentration of mineral to zinc biofortification in different wheat genotyes. J Triticeae Crops. (2014) 34:489–94. doi: 10.7606/j.issn.1009-1041.2014.04.009

25. Bharti K, Pandey N, Shankhdhar D, Srivastava PC, Shankhdhar SC. Improving nutritional quality of wheat through soil and foliar zinc application. Plant Soil Environ. (2013) 59:348–52. doi: 10.17221/158/2013-PSE

26. Velu G, Singha RP, Huerta-Espinoa J, Pena RJ, Arunc B, Mahendru-Singhd A, et al. Performance of biofortified spring wheat genotypes in target environments for grain zinc and iron concentrations. Field Crops Res. (2012) 137:261–7. doi: 10.1016/j.fcr.2012.07.018

27. Cakmak I, Kutman UB, Yildiz B. Effect of nitrogen on uptake, remobilization and partitioning of zinc and iron throughout the development of durum wheat. Plant Soil. (2011) 342:149–64. doi: 10.1007/s11104-010-0679-5

28. Li XL. Effects of Zinc Supply on Zinc Bioavailabilty in Wheat Pearling Fractions. Xianyang: Northwest A&F University (2011).

29. Zhang MY, Yu YF, Feng CN, Guo WS, Zhu XK, Li CY, et al. Difference of calcium and zinc contents aming flour, grain and bran of different wheat variety. J Triticeae Crops. (2011) 31:240–45. doi: 10.7606/j.issn.1009-1041.2011.02.009

30. Joshi AK, Crossa J, Arun B, Chand R, Trethowan R, Vargas M, et al. Genotype × environment interaction for zinc and iron concentration of wheat grain in eastern gangetic plains of India. Field Crops Res. (2010) 116:268–77. doi: 10.1016/j.fcr.2010.01.004

31. Cao YX. Study on Factors Affecting Zinc Nutritional Quality in Wheat Grain. Xianyang: Northwest A&F University (2010).

32. Zhang YQ, Shi R, Rezaul KM, Zhang F, Zou C. Iron and zinc concentrations in grain and flour of winter wheat as affected by foliar application. J Agric Food Chem. (2010) 58:12268–74. doi: 10.1021/jf103039k

33. Cakmak I, Kalayci M, Kaya Y, Torun AA, Aydin N, Wang Y, et al. Biofortification and localization of zinc in wheat grain. J Agric Food Chem. (2010) 58:9092–102. doi: 10.1021/jf101197h

34. Ficco DBM, Riefolo C, Nicastro G, De Simone V, Di Gesu AM, Beleggia R, et al. Phytate and mineral elements concentration in a collection of Italian durum wheat cultivars. Field Crops Res. (2009) 111:235–42. doi: 10.1016/j.fcr.2008.12.010

35. Zhao FJ, Su YH, Dunham SJ, Rakszegi M, Bedo Z, McGrath SP, et al. Variation in mineral micronutrient concentrations in grain of wheat lines of diverse origin. J Cereal Sci. (2009) 49:290–5. doi: 10.1016/j.jcs.2008.11.007

36. Karami M, Afyuni M, Khoshgoftarmanesh AH, Papritz A, Schulin R. Grain zinc, iron, and copper concentrations of wheat grown in central iran and their relationships with soil and climate variables. J Agric Food Chem. (2009) 57:10876–82. doi: 10.1021/jf902074f

37. Cubadda F, Aureli F, Raggi A, Carcea M. Effect of milling, pasta making and cooking on minerals in durum wheat. J Cereal Sci. (2009) 49:92–97. doi: 10.1016/j.jcs.2008.07.008

38. Tang J, Zou C, He Z, Shi R, Ortiz-Monasterio I, Qu Y, et al. Mineral element distributions in milling fractions of Chinese wheats. J Cereal Sci. (2008) 48:821–8. doi: 10.1016/j.jcs.2008.06.008

39. Morgounov A, Gomez-Becerra HF, Abugalieva A, Dzhunusova M, Yessimbekova M, Muminjanov H, et al. Iron and zinc grain density in common wheat grown in central Asia. Euphytica. (2007) 155:193–203. doi: 10.1007/s10681-006-9321-2

40. Zhang Y, Wang DX, Zhang Y, He ZH. Variation of major mineral elements concentration and their relationships in grain of Chinese wheat. Sci Agric Sin. (2007) 40:1871–6. doi: 10.3321/j.issn:0578-1752.2007.09.004

41. Harris D. Development and testing of “on-farm” seed priming. Adv Agron. 90:129–78. doi: 10.1016/S0065-2113(06)90004-2

42. Ruibal-Mendieta NL, Delacroix DL, Mignolet E, Pycke J, Marques C, Rozenberg R, et al. Spelt (Triticum aestivum ssp. spelta) as a source of breadmaking flours and bran naturally enriched in oleic acid and minerals but not phytic acid. J Agric Food Chem. (2005) 53:2751–9. doi: 10.1021/jf048506e

43. Daniel F, Calderini IO. Are synthetic hexaploids a means of increasing grain element concentrations in wheat? Euphytica. (2003) 134:169–78. doi: 10.1023/B:EUPH.0000003849.10595.ac

44. Monasterio I, Graham RD. Breeding for trace minerals in wheat. Food Nutr Bull. (2000) 21:392–6. doi: 10.1177/156482650002100409

45. Wang S. Analysis of trace elements in wheat and flour in china and france. J Zhengzhou Grain Inst. (1998) 41–45. doi: 10.16433/j.cnki.issn1673-2383.1998.02.008

46. Peterson CJ, Johnson VA, Mattern PJ. Evaluation of variation in mineral element concentrations in wheat flour and bran of different cultivars. Cereal Chem. (1983) 60:450–5.

47. Czerniejewski CP, Shank CW, Bechtel WG, Bradley WB. The minerals of wheat, flour, and bread. Cereal Chem. (1964) 2:65–72.

48. Hao YF, Zhang Y, He ZH. Progress in zinc biofortification of crops. Chin Bull Life Sci. (2015) 27:1047–54. doi: 10.13376/j.cbls/2015144

49. Liu JH, Guo HC, Chen YL, Jia Z, Tian XH. Effect of Zn source and application method on Zn form and availability in soil. J Northwest A&F Univ. (2017) 45:149–156. doi: 10.13207/j.cnki.jnwafu.2017.04.021

50. Wang L, Qiao YT, Kong WY, Gong KL, Fan QJ, Wang ZS, et al. Research progress on zinc nutrition in wheat grains. Shandong Agric Sci. (2019) 51:158–66. doi: 10.14083/j.issn.1001-4942.2019.10.030

51. Guzmán C, Medina-Larqué AS, Velu G, González-Santoyo H, Singh RP, Huerta-Espino J, et al. Use of wheat genetic resources to develop biofortified wheat with enhanced grain zinc and iron concentrations and desirable processing quality. J Cereal Sc. (2014) 60:617–22. doi: 10.1016/j.jcs.2014.07.006

52. Cakmak I. Enrichment of cereal grains with zinc: agronomic or genetic biofortification? Plant Soil. (2008) 302:1–17. doi: 10.1007/s11104-007-9466-3

53. Mousia Z, Edherly S, Pandiella SS, Webb C. Effect of wheat pearling on flour quality. Food Res Int. (2004) 37:449–59. doi: 10.1016/j.foodres.2004.02.012

54. Liu LN. Effects of Different Peeling Rates on Wheat Flour Quality and Steamed Bread Processing Characteristics. Beijing: China Agricultural University (2007).

55. Lazarte CE, Carlsson N, Almgren A, Sandberg A, Granfeldt Y. Phytate, zinc, iron and calcium content of common Bolivian food, and implications for mineral bioavailability. J Food Compost Anal. (2015) 39:111–19. doi: 10.1016/j.jfca.2014.11.015

56. Gong HY, Li M, Liu HY, Lu DX. Iron and Zinc content variances in wheat milling fractions and their influencing factors. J Nucl Agric Sci. (2019) 33:1765–73. doi: 10.11869/j.issn.100-8551.2019.09.1765

57. Gao SS. Effect of Different Flour Yield on Nutrients and Cooking Quality of Wheat Flour. Zhengzhou: Henan University of Technology (2018).

58. Ciccolini V, Pellegrino E, Coccina A, Fiaschi AI, Cerretani D, Sgherri C, et al. Biofortification with Iron and Zinc improves nutritional and nutraceutical properties of common wheat flour and bread. J Agric Food Chem. (2017) 65:5443–52. doi: 10.1021/acs.jafc.7b01176

59. Zhang W, Liu D, Liu Y, Chen X, Zou C. Overuse of phosphorus fertilizer reduces the grain and flour protein contents and zinc bioavailability of winter wheat (Triticum aestivum L.). J Agric Food Chem. (2017) 65:1473–82. doi: 10.1021/acs.jafc.6b04778

60. Heshe GG, Haki GD, Woldegiorgis AZ, Gemede HF. Effect of conventional milling on the nutritional value and antioxidant capacity of wheat types common in ethiopia and a recovery attempt with bran supplementation in bread. Food Sci Nutr. (2016) 4:534–43. doi: 10.1002/fsn3.315

61. Li M, Wang S, Tian X, Li S, Chen Y, Jia Z, et al. Zinc and iron concentrations in grain milling fractions through combined foliar applications of Zn and macronutrients. Field Crops Res. (2016) 187:135–41. doi: 10.1016/j.fcr.2015.12.018

62. Brier N, Gomand SV, Donner E, Paterson D, Delcour JA, Lombi E, et al. Distribution of minerals in wheat grains (Triticum aestivum L.) and in roller milling fractions affected by pearling. J Agric Food Chem. (2015) 63:1276–85. doi: 10.1021/jf5055485

63. Zou EK, Wang XX, Zhai XC, Liang WL. Effect of debranning on minerals and phytic acid cotent in wheat flour. Cereal Food Ind. (2015) 22:57–62. doi: 10.3969/j.issn.1672-5026.2015.03.015

64. Zhang YQ, Sun Y, Ye Y, Karim MR, Xue Y, Yan P, et al. Zinc biofortification of wheat through fertilizer applications in different locations of China. Field Crops Res. (2012) 125:1–7. doi: 10.1016/j.fcr.2011.08.003

65. Akhter S, Saeed A, Irfan M, Malik KA. In vitro dephytinization and bioavailability of essential minerals in several wheat varieties. J Cereal Sci. (2012) 56:741–6. doi: 10.1016/j.jcs.2012.08.017

66. Shi R, Zhang Y, Chen X, Sun Q, Zhang F, Römheld V, et al. Influence of long-term nitrogen fertilization on micronutrient density in grain of winter wheat (Triticum aestivum L.). J Cereal Sci. (2010) 51:165–70. doi: 10.1016/j.jcs.2009.11.008

67. Ma GS, Jin Y, Piao J. Phytate, calcium, iron, and zinc contents and their molar ratios in foods commonly consumed in China. J Agric Food Chem. (2005) 53:10285–90. doi: 10.1021/jf052051r

68. Anjum FM, Butt MS, Ahmad N, Ahmad I. Phytate and mineral content in different milling fractions of some Pakistani spring wheats. Int J Food Sci Technol. (2002) 37:13–17. doi: 10.1046/j.1365-2621.2002.00540.x

69. Pomeranz ED. Minerals and protein contents in hard red winter wheat flours. Cereal Chem. (1983) 1:80–82.

70. Liu Z, Wang H, Wang X, Xu H, Gao D, Zhang G, et al. Effect of wheat pearling on flour phytase activity, phytic acid, iron, and zinc content. LWT - Food Sci Technol. (2008) 41:521–7. doi: 10.1016/j.lwt.2007.04.001

71. Liu ZH, Wang HY, Wang XE, Zhang GP, Chen PD, Liu DJ. Phytase activity, phytate, iron, and zinc contents in wheat pearling fractions and their variation across production locations. J Cereal Sci. (2007) 45:319–26. doi: 10.1016/j.jcs.2006.10.004

72. Welch RM, Graham RD. A new paradigm for world agriculture: meeting human needs: productive, sustainable, nutritious. Field Crops Res. (1999) 60:1–10. doi: 10.1016/S0378-4290(98)00129-4

73. Deng YM, Zhang H, Hu HH, Li XY, Zhang L. Development and application of wheat aleurone layer and its products. Food Sci Technol. (2019) 44:157–61.

74. Wu DJ, Wang FC, Lan XG. The effect of flour content in aleurone layer on dough characteristics and quality of steamed bread. Modern Flour Mill Ind. (2014) 28:27–30. doi: 10.3969/j.issn.1674-5280.2014.04.009

75. Gu XC. On manufacture of foods by processing wheat bran— bran flour and aleurone layer flour. Cereal Feed Ind. (2005) 9–12. doi: 10.3969/j.issn.1003-6202.2005.06.005

76. Wang XX, Jia AX, Y ZL. Distribution of mineral elements in wheat milling process. Modern Flour Mill Ind. (2012) 26:23–6. doi: 10.3969/j.issn.1674-5280.2012.01.010

77. Wang CC, Wang XX, Sen M. Research progress on the effect of particle size on the quality of wheat flour and flour products. Cereals Oils. (2017) 30:8–10.

78. Umeta M, West CE, Fufa H. Content of zinc, iron, calcium and their absorption inhibitors in foods commonly consumed in ethiopia. J Food Composit Anal. (2005) 18:803–17. doi: 10.1016/j.jfca.2004.09.008

79. Shi CB, Yan XS. Application of enriched calcium, iron and zinc yeast to bread. Sci Technol Food Ind. (2005) 78–79. doi: 10.3969/j.issn.1002-0306.2005.02.026

80. Ren TY, An YH. Processing technique of bread with zinc-rich and selenium-rich organic tea. Sci Technol Cereals Oils Foods. (2009) 17:6–8. doi: 10.16210/j.cnki.1007-7561.2009.06.005

81. Bai J, Huang XD, Zhu YX, Liang JF. Analys is on conetnst and bioavailabiliy of iron, zinc and calclum in biscuit and cake. Food Sci Hum Wellness. (2009) 30:131–4. doi: 10.3321/j.issn:1002-6630.2009.01.031

82. Shokunbi OS, Adepoju OT, Mojapelo PEL, Ramaite IDI, Akinyele IO. Copper, manganese, iron and zinc contents of nigerian foods and estimates of adult dietary intakes. J Food Compost Anal. (2019) 82:103245. doi: 10.1016/j.jfca.2019.103245

83. Wang HN. Study on the Quality Change in the Process of Zinc-Rich Wheat Steamed Bread Making. Tai'an: Shandong Agricultural University (2019).

84. Sebecic B, Vedrina-Dragojevic I. Wheat flour confectionery products as a source of inorganic nutrients: zinc and copper contents in hard biscuits. Nahrung. (2004) 48:141–4. doi: 10.1002/food.200300390

85. Zhu QH, Zhang XP, Wang EY, Zhang Y. Determination of zinc content in hair and zinc of 20 foods in 118 middle school students in Wuhan. In: The First Symposium on Trace Elements of the Chinese Nutrition Society. Qingdao (1985).

86. Chen Z, Du HS. Nutritional strengthening of instant noodles. Food Sci Technol. (2002) 55–57. doi: 10.3969/j.issn.1005-9989.2002.06.020

87. Wang QY. Effects of Zinc Application on Nutrition Absorbtion and Grain Protein Components of Winter Wheat Genotypesvarying Gluten Content. Zhengzhou: Henan Agricultural University (2015).

88. Qi HY, Yang J, Tang L, Liu FF. Changes of mineral contents and retention factors in food materials cooked by different methods. J Food Ind. (2016) 37:21–24.

90. Qi YT, Zhou SN, Zhang Q, Yang LX, Wang YX. The effect of foliar Zn application at grain filling stage on zn bioavailability in grain fractions of modern winter wheat cultivars. J Agro Environ Sci. (2013) 32:1085–91.

91. Hurrell RF, Reddy MB, Juillerat M, Cook JD. Degradation of phytic acid in cereal porridges improves iron absorption by human subjects. Am J Clin Nutr. (2003) 77:1213–19. doi: 10.1093/ajcn/77.5.1213

92. Wang ZH. Advances in research into low-phytic-acid mutants in crops. Chin Bull Bot. (2005) 22:463–70. doi: 10.1360/aps040074

Keywords: wheat, zinc, flour, fortification, bioavailability

Citation: Wang M, Kong F, Liu R, Fan Q and Zhang X (2020) Zinc in Wheat Grain, Processing, and Food. Front. Nutr. 7:124. doi: 10.3389/fnut.2020.00124

Received: 27 March 2020; Accepted: 30 June 2020;

Published: 18 August 2020.

Edited by:

Jinsong Bao, Zhejiang University, ChinaReviewed by:

Velu Govindan, International Maize and Wheat Improvement Center, MexicoChuan Tong, Zhejiang Academy of Agricultural Sciences, China

Copyright © 2020 Wang, Kong, Liu, Fan and Zhang. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Qingqi Fan, ZmFucWluZ3FpJiN4MDAwNDA7MTYzLmNvbQ==; Xiaocun Zhang, eGN6aGFuZyYjeDAwMDQwO3NkYXUuZWR1LmNu

Min Wang1

Min Wang1 Fanmei Kong

Fanmei Kong Rui Liu

Rui Liu Xiaocun Zhang

Xiaocun Zhang