- 1State Key Laboratory of Animal Nutrition and Feeding, College of Animal Science and Technology, China Agricultural University, Beijing, China

- 2New Hope Liuhe Co., Ltd., Chengdu, China

The objective of this study was to evaluate the nutritional values of three new corn varieties (high-iron corn, cadmium-resistant corn, low-phytate phosphorus corn) cultivated with molecular marker-assisted selection breeding technique fed to growing pigs and broilers. Exp. 1 was conducted to compare the nutritional values of high-iron corn, high-chromium corn, low-phytate phosphorus corn and conventional corn fed to growing pigs based on a 15 × 2 Youden square design. Exp.2 was conducted to compare the nutritional values of high-iron corn, low-phytate phosphorus corn and conventional corn fed to broilers based on a completely randomized design. Parameters including nutrient digestibility, available energy and amino acids, and mineral deposition were measured. The results shows that the iron content in the high-iron corn and the cadmium content in the cadmium-resistant corn were 29.608 mg/kg and 0.0057 mg/kg, respectively, both were greater than those in the other three kinds of corns. When fed to growing pigs, the neutral detergent fiber digestibility of the high-iron corn group was lower than that of the conventional corn group (p < 0.05), and the acid detergent fiber digestibility of the high-iron group and the low-phytate phosphorus corn group was lower than that of the conventional corn group (p < 0.01). In addition, the digestible energy value of the high-iron corn in growing pigs was lower than that of the conventional corn (p < 0.05). When fed to broilers, it was observed that the tibia length of the low-phytate phosphorus corn group and the high-iron corn group was lower than that of the conventional corn group (p < 0.05). Moreover, the iron emission in feces of broilers fed the low-phytate phosphorus corn was lower than those fed the conventional corn and the high-iron corn (p < 0.05). In conclusion, modern breeding techniques could provide new plant ingredients which have potential benefits to pig and broiler production, but the comprehensive effects may be better when applied to growing pigs considering growth performance and environment effects. The breeding techniques related to the current study rarely changed the available energy values of the corn in growing pigs and broilers.

1 Introduction

Corn is indigenous to South America, with current distribution predominantly found in North and Central America. It ranks among the three highest-yielding cereal crops globally, and is a multipurpose crop, which can serve as a source of animal feed, fuel ethanol, food, and other industrial materials. China is among the greatest global producers of corn, with cultivation on an area of 41.26 million hectares and an estimated production of 260.67 million tons in 2021 (1). In China, corn has greater prominence as feed, thereby impacting the production of animal husbandry as an energy source. In 2020, U.S. corn exports reached $9.2 billion, an increase of $1.6 billion (20%) over the same period last year, and China’s strong feed demand contributed to this sharp increase (2).

The digestible energy (DE) value of corn on growing pigs is 3,451 kcal/kg (3) and the metabolizable energy (ME) value on poultry is 3,084 kcal/kg (4). The high available energy value of corn is mainly contributed to its high content of starch (can reach 72%) (5), and the low content of soluble non-starch polysaccharides (6). The crude protein (CP) content in corn is relatively low, ranging from 7 to 9% (7), and the essential amino acids contents are also low, containing only 0.25% lysine and 0.07% tryptophan (8). However, the fat content in corn is relatively high, about 3 to 4%, and is rich in oleic acid and linoleic acid, which is approximately 27 and 59%, respectively (2). In terms of mineral content, corn is low in calcium (Ca, only 0.01%) (8) and high in phosphorus (P, approximately 0.28%), of which 68% is phytate phosphorus (9). Among the trace elements, the levels of iron (Fe), copper (Cu), manganese (Mn), zinc (Zn), and selenium (Se) are all low. Phosphorus is required for diverse biological processes in animals, such as the skeletal system, and the cell membrane structure, but is primarily stored in the form of phytates in plant seeds, thus being poorly available for monogastric livestock including pigs and poultry. In addition, phytate has the capacity to chelate positively charged cations, especially calcium, iron and zinc, and can probably compromise the utilization of other dietary nutrients, including protein, starch and lipids (10). Iron also plays important role in animal health because it is a vital component of the hemoglobin in the erythrocyte. Thus, decreasing the phytate phosphorus content or increasing the iron content in plant seeds through breeding techniques can greatly benefit the utilization of those plant materials in animal feed. On the contrary, cadmium (Cd), as a nonessential trace transition metal, is a carcinogen and a possible mutagen to animals and humans. The high-cadmium pollution in soil also inhibits the normal growth and production of plants. Production of high-cadmium resistant breeds through breeding techniques can greatly take advantages of those polluted soil resources. But it is still under exploration of how to use those plant materials in the downstream production.

Therefore, the objective of this study was to evaluate the nutritional values of three new corn varieties (high-iron corn, cadmium-resistant corn, low-phytate phosphorus corn) cultivated with molecular marker-assisted selection technique fed to growing pigs and broilers.

2 Materials and methods

The three new corn varieties used in this study were developed with molecular marker-assisted selection breeding technique using the Complete-diallel design plus Unbalanced Breeding-like Inter-Cross (CICUB) population developed by Prof. Jianbing Yan from Huazhong Agricultural University (11). All corn samples were cultured and provided by Prof. Daiyin Chao from Chinese Academy of Science Center for Excellence in Molecular Plant Sciences.

2.1 Exp.1: chemical compositions, available energy, and amino acid digestibility in three new corn varieties fed to growing pigs

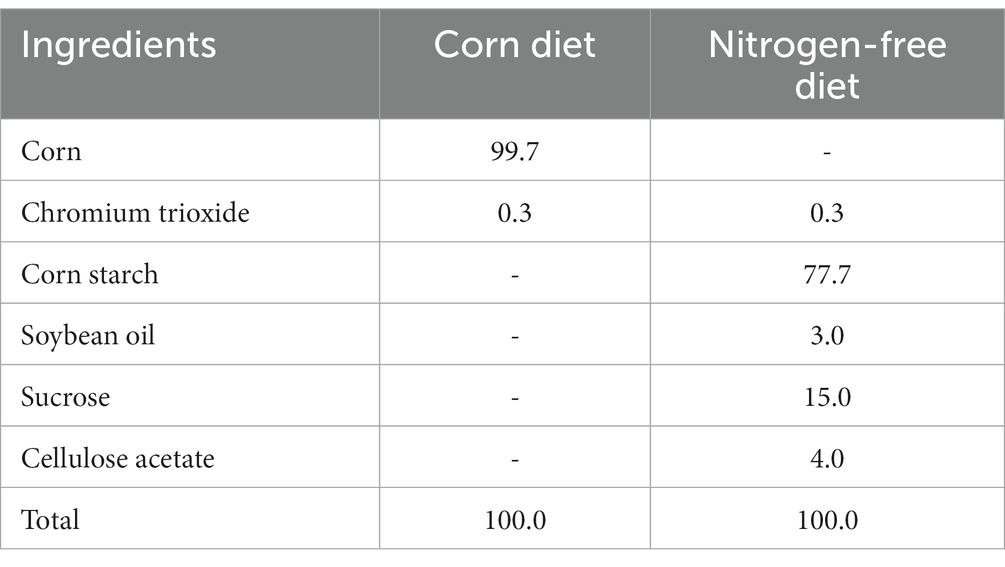

The animal trial was carried out in Fengning Animal Experiment Base of China Agricultural University (Hebei, China). Fifteen healthy barrows (Duroc × Landrace × Yorkshire) with an initial body weight of 29.73 ± 1.73 kg, fitted with T-shaped cannula were selected. After two weeks of recovery from surgery, all pigs were allotted to 5 experimental diets based on a 15 × 2 Youden square design. Specifically, the 5 experimental diets included 1 diet with the conventional corn, 3 test diets with the three new corn varieties, and 1 nitrogen-free diet. The animal trial contained 2 phases, each phase with 14 days, including 5 days for diet adaptation, 3 days for feces and urine collection, 2 days for digesta collection, 3 days for total heat production measurement in respiration calorimeter (chambers), and 1 day for fasting heat production measurement in respiration chamber. In each phase, the 5 experimental diets were randomly allotted to 15 pigs with 3 pigs per replicate. The compositions of the experimental diets are shown in Table 1. While commercial diets were provided for pigs for feeding ad libitum after surgery, the experimental diets were provided as an amount of 4% of the pig’s initial body weight in powder form. The daily feeding was divided into two equal meals and supplied twice at 0830 and 1,630. All pigs had free access to water via duckbill waterers. To ensure accurate assessment of feed intake, all scattered and leftover feeds were collected, dried, and weighed during the trial.

Table 1. Ingredient compositions of the experimental diets used in Experiment 1 fed to growing pigs (as-fed basis, %).

Feces and urine samples from all pigs were promptly collected and were stored in −20°C until the end of the collection period, followed those described by Song et al. (12) and Ren et al. (13). The collected feces for 3 days were mixed and weighed, and the initial moisture content was measured. Subsequently, 20% of the total fecal collection was dried at 65°C for 72 h, kept at room temperature for 24 h, weighed, and then stored as a fecal sample at −20°C for further analysis. Urine was collected once daily at 1400, and 10 mL of 6 mol/L hydrochloric acid was added to the collection bucket to maintain a pH below 5.5 to prevent nitrogen loss by ammonia volatilization. The collected urine was passed through 4 layers of gauze, and a fixed proportion of 1% of the filtered urine was collected into bottles, then immediately stored at −20°C for further analysis.

The digesta of each pig was collected on days 9–10 followed the method developed by Adeola (14). A sample bag was placed at the outer end of the cannula after feeding at 0830, and digesta were collected continuously for 8 h until 1,630 every day. To minimize the impact of collection on the wound, the sample bag was changed when it was filled to a capacity, and then immediately stored at −20°C to prevent microbial fermentation in the collected digesta. After the collection period, all the digesta collected in two days were thawed naturally and mixed, and 500 mL subsample from each pig was freeze-dried using freeze-drier (Dongfulong Freeze-Drying System, Shanghai, China), and then went through 60-mesh filter and were bagged for further analysis.

On days 11–14 of each experimental phase, pigs were transferred to open-circuit respiration chambers for calorimetry test. The chambers were designed and built specially for pigs by China Agricultural University. Pigs in the respiration chambers were fasted on day 14. To avoid the influence of heat production from activity, data in respiration chambers used for fasting heat production calculation were collected from 2,230 on day 14 (about 31 h of fasting) to 0630 on day 15. The data of oxygen consumption and carbon dioxide and methane production for the 8 h were extrapolated to 24 h to estimate the daily maintenance energy. All pigs were weighed before entering the respiration chambers on day 11, before the fasting stage on day 14, and at the end of the fasting stage on day 15 in each phase.

The dry matter (DM), CP, ether extract (EE), ash and neutral detergent fiber (NDF) contents in samples of corn and diets were determined followed the procedures of GB/T 6435–2014 (15), GB/T 6432–2018 (16), GB/T 6433–2006 (17), GB/T 6438–2007 (18) and GB/T 20806–2006 (19), respectively. Total starch content in corn and diets was determined followed the procedures in AOAC (procedure 979.10; AOAC 2006) (20). Acid detergent fiber (ADF) content in corn and diets was determined followed the procedures of NY/T 1459–2007 (21). The gross energy (GE) content in corn, diets, feces and urine samples was measured using an oxygen bomb calorimeter (Model 6,400, Parr Corporation, USA) followed the ISO 9831:1998 standard (22). The contents of 15 amino acids in corn, diets and feces were determined followed the procedures of GB/T 18246–2000 (23), with the samples being hydrolyzed with 6 mol/L HCl at 110°C for 24 h and then determined using an automatic amino acid analyzer (Hitachi L-8900, Hitachi Group, Japan). The determination of sulfur-containing amino acids followed the procedures of GB/T 15399–2018 (24), with the samples being oxidized by performic acid at 0°C for 16 h, hydrolyzed by HCl for 24 h, and then determined using an automatic amino acid analyzer (Hitachi L-8800, Hitachi Group, Japan). The determination of tryptophan followed the procedures in Appendix A of GB/T 18246–2000 (23), with the samples being hydrolyzed at 110°C for 22 h with 4 mol/L sodium hydroxide, and then determined using a high-performance liquid chromatograph (Agilent 1,200, Agilent Technologies, Inc., USA). The determination of Ca, Cu, Fe, Zn and Mn content in corns using atomic absorption spectrophotometer followed the procedures of GB/T 13885–2017 (25). The determination of total P content followed the procedures of GB/T 6437–2018 (26). The determination of Cd content followed the procedures of GB/T 13082–1991 (27).

The major formula used for calculation in Exp. 1 was as follows:

(1) The exchanged gas volume in the standard state (0°C, 1,013 hPa):

(2) The oxygen consumption and carbon dioxide production of each animal:

(3) The heat production of each animal (28):

(4) The apparent total tract digestibility (ATTD) of nutrients in diets and corns14:

(5) The DE, ME and net energy (NE) values of corn:

(8) The apparent ileal digestibility (AID) and standardized ileal digestibility (SID) of CP and AAs of corn (29):

2.2 Exp.2: The digestibility, emission, and deposition of minerals in two new corn varieties fed to broilers

The animal trial was conducted in the New Hope Liuhe Technology Research and Development Center in Pingdu (Shandong, China). One-hundred and twenty-six 10-day-old healthy Ross 308 broilers with similar initial body weight of 249.89 ± 1.47 g were selected and randomly divided into 3 treatments groups, with 6 replicated metabolic cages per treatment and 7 chickens per cage. The experiment diet containing 99.6% corn and 0.4% Cr2O3 as insert indicator. Due to high sensitivity of broilers to relative high levels of Cd, only the conventional corn, low-phytate phosphorus corn and high-iron corn were used in this trial. All diets were meshed and went through 2.5 mm sieve. The animal trial lasted for 15 days, including 8 days for diet and metabolic cages adaptation, and 7 days for total feces collection. Broilers had free access to feed and drink, and a constant light–dark cycle of L16D8 and a constant temperature of 26°C were kept in the room. In addition, conventional feeding operation procedures and routine immunization procedures were conducted.

The feces collected for 7 days were mixed and weighted, then dried at 65°C for 48 h and kept at room temperature for 24 h. Approximately 200 g of subsamples was taken and kept at −20°C for further analysis. The contents of DM, CP, GE, and mineral contents (e.g., Ca, P, Fe) in feces were determined followed the same procedure in Exp. 1. At the end of the animal trial, one chicken close to the average body weight of each treatment group from each replicate cage was chosen for slaughter. The liver and left tibia of each chicken was collected and kept at −20°C for further analysis. The length and width of the tibia were measured before storage. Moreover, the digesta in the ileum (with the last 4 cm discarded) was collected and kept at −20°C, and the Fe, P and Cr content in digesta were determined followed the same procedure in Exp. 1.

Approximately 1 ~ 5 g of liver sample and tibia sample (need to be degreased with petroleum ether before analysis) were dried at 130°C until completely carbonized, and then kept at 550 ± 20°C for ashing for 3 h and dissolved in hydrochloric acid for analysis. The Fe content in liver and tibia samples and the contents of Ca and P in tibia samples were determined following the same procedure in Exp. 1.

The major formula used for calculation in Exp. 2 were the same as those in Exp. 1 except for:

Ca or P deposition in tibia:

2.3 Statistical analyses

All data were checked for normality and homogeneity of variance using the PROC UNIVERIATE procedure in SAS 9.4 (SAS Institute Inc., Carry, NC, USA), and outliers were detected and removed. One-way ANOVA was conducted using the PROC MIXED procedure in SAS 9.4. In Exp.1, the statistical model included the fixed effect of the dietary treatment and the random effects of the chamber and phase. In Exp.2, dietary treatment was the only fixed effect. The mean values for each treatment were calculated using the LSMEANS statement of SAS 9.4, and multiple comparisons were adjusted using Tukey’s test, with p < 0.05 as significant difference and 0.05 ≤ p < 0.10 as a trend of difference.

3 Results and discussion

3.1 Exp.1: chemical compositions, available energy, and amino acid digestibility in three new corn varieties fed to growing pigs

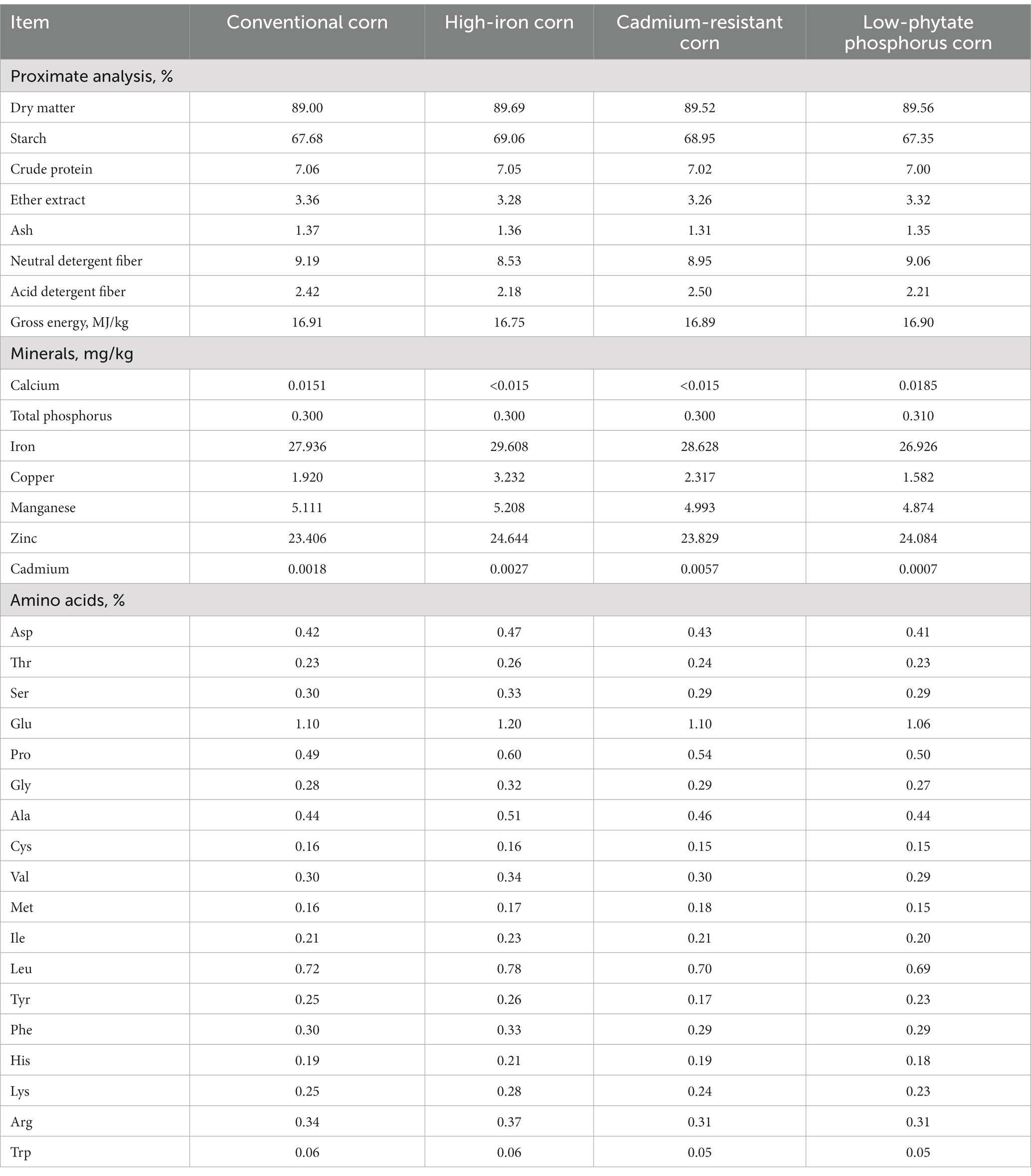

The chemical compositions of the 3 new corn varieties and the conventional corn are shown in Table 2. The starch content of the high-iron corn and the cadmium-resistant corn was numerically greater than that of the low-phytate phosphorus corn and the conventional corn, all slightly greater than previously reported values (30, 31), possibly due to differences in corn varieties or analytical methods used. The CP content in all 4 corn varieties was around 7%, all slightly lower than previously reported values (30, 32–34), which was in accordance with their increased starch content. The NDF, ADF and GE contents of the high-iron corn were numerically lower than those of the other 3 corn varieties. The iron content in the high-iron corn and the cadmium content in the cadmium-resistant corn were numerically greater than those in the other corns varieties, while the phosphorus content in the low-phytate phosphorus corn was numerically slightly greater than the other corn varieties, indicating the new varieties have achieved the designed goal of corn breeding. Except for cystine, methionine and tryptophan, all the other 15 amino acids contents were numerically greater in the high-iron corn than in the other three corn varieties, which may be attributed to the significance of iron as a cofactor for several functional proteins (35). In high-iron corn, the contents of calcium, copper, manganese, and zinc were all numerically greater than those in the conventional corn, exhibiting the interactive effects for mineral accumulation that could be influenced by genetic factors.

Table 2. Analyzed chemical compositions and amino acid contents of three new corn varieties and the conventional corn used in this study (% of dry matter, unless otherwise indicated).

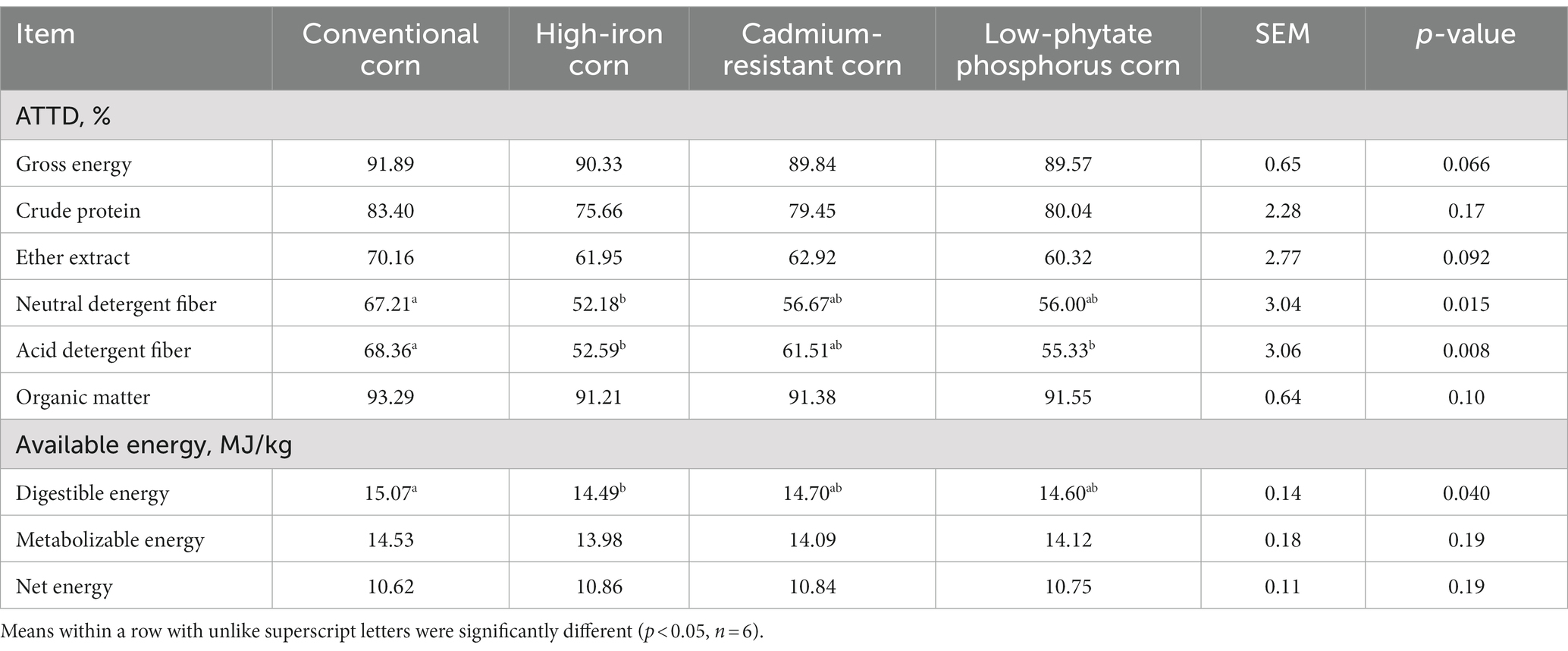

The ATTD of nutrients and available energy contents of the 3 new corn varieties and the conventional corn fed to growing pigs are shown in Table 3. The ATTD of NDF was significantly lower in the high-iron corn than that in the conventional corns (p = 0.015), while the ATTD of ADF was significantly lower in the high-iron corn and the low-phytate phosphorus corn than the other two corn varieties (p = 0.008), which may be due to the low NDF and ADF levels in the high-iron corn. In addition, the ATTD of GE and EE in the low-phytate phosphorus corn tended to be lower than those in the conventional corn (p = 0.066 and 0.092, respectively). There were no significant differences in ATTD of CP and organic matter (OM) of the 4 corn varieties in growing pigs, which was in accordance with the similar CP and ash contents in those 4 corn varieties.

Table 3. The apparent total tract digestibility (ATTD) of nutrients and available energy contents of the three new corn varieties and the conventional corn fed to growing pigs (as-fed basis).

In the current study, the DE, ME and NE values of the 4 corn varieties ranged from 14.49 MJ/kg to 15.07 MJ/kg, 13.98 MJ/kg to 14.53 MJ/kg, and 10.62 MJ/kg to 10.86 MJ/kg, respectively, comparable to the DE and ME values but lower than the NE value provided by NRC (2012) (3), which may be because the latter is a calculated value using prediction equation. Moreover, the DE value of the high iron corn in growing pigs were significantly lower than those of the conventional corn (p = 0.040), and there were no significant differences on the ME and NE values among the 4 corn varieties, indicating that the reference energy values may not be a particular concern when formulating a swine diet with the 4 different corn varieties, especially when using the ME or NE system.

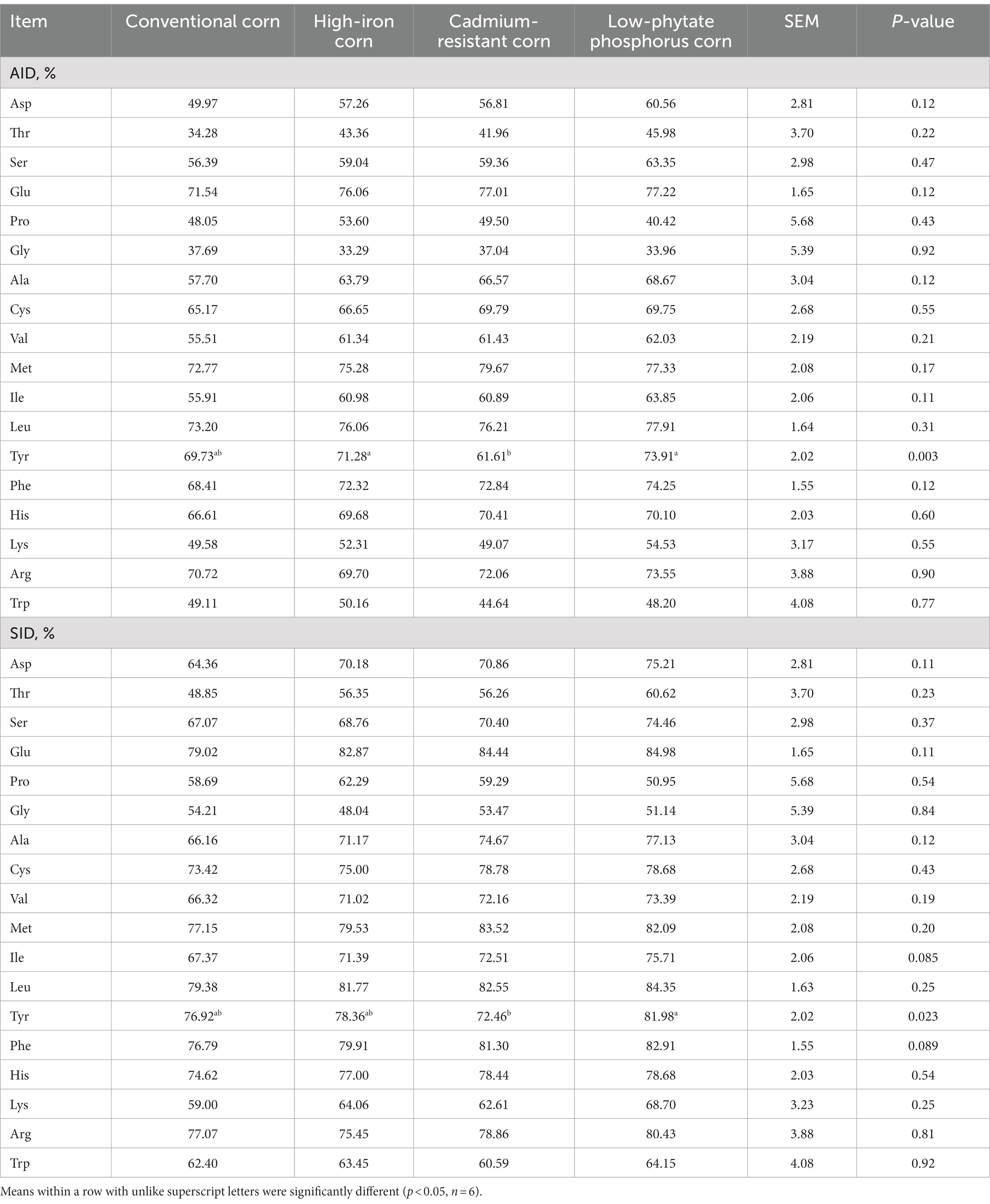

The AID and SID of AAs of the 3 new corn varieties and the conventional corn fed to growing pigs are shown in Table 4. The AID of Tyr was significantly greater in the low-phytate phosphorus corn and the high-iron corn than that in the cadmium-resistant corn (p = 0.003), and the SID of Tyr was significantly greater in the low-phytate phosphorus corn than that in the cadmium-resistant corn (p = 0.023). For the other AAs, the AID and SID were similar among the 4 different corn varieties, indicating that the reference AAs contents may also not be a particular concern when formulating a swine diet with the 4 different corn varieties, especially when using the AID and SID system.

Table 4. The apparent ileal digestibility (AID) and standardized ileal digestibility (SID) of amino acids of the three new corn varieties and the conventional corn fed to growing pigs.

3.2 The digestibility, emission, and deposition of minerals in two new corn varieties fed to broilers

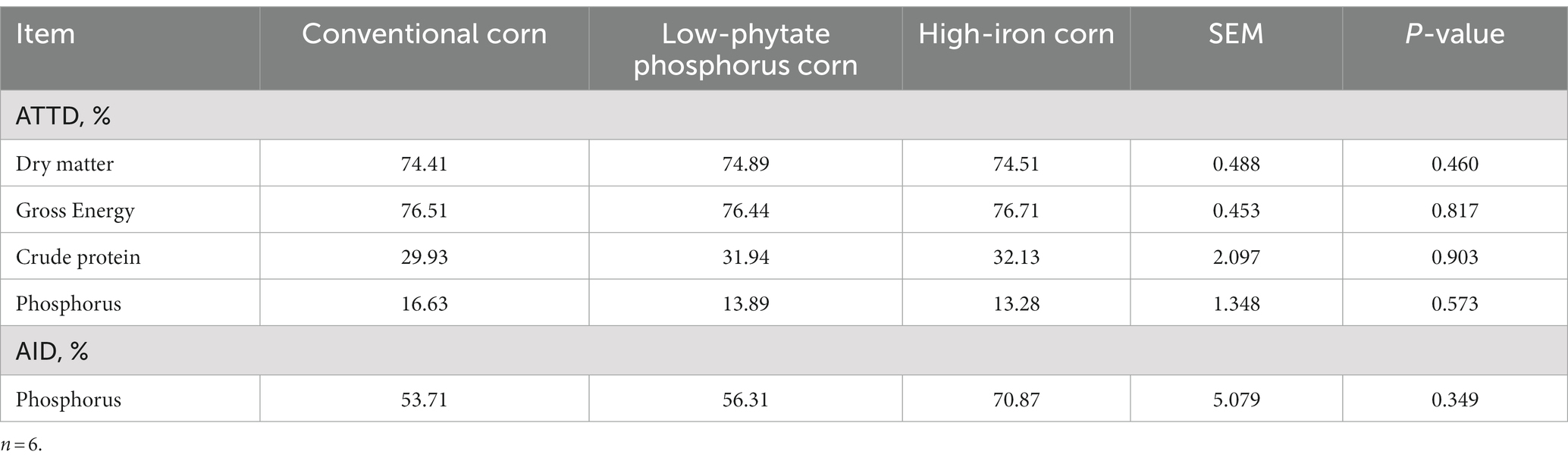

In this animal trial, the average feed intake of all broilers was about 20 g, and the average daily gain ranged from 2 ~ 13 g, among which 10 cages showed negative growth (data not shown), which may be due to the unbalanced nutrition of the designed diets that only contained corn. The ATTD and AID of nutrients of 2 new corn varieties and the conventional corn fed to broilers are shown in Table 5. The ATTD of Fe, Cu, Mn, and Zn were all negative, and the AID of iron in each group was also negative (data not shown), which may be due to the endogenous secretion in the upper intestine. There is no significant difference in the ATTD of DM, GE, CP, and phosphorus among the 3 treatment groups, and there is also no significant difference in the AID of phosphorus among the 3 treatment groups. Based on the ATTD of GE and the determined GE values in the corn, the apparent metabolizable energy (AME) values of the conventional corn, the low-phytate phosphorus corn and the high-iron corn on broilers were 12.94 MJ/kg, 12.92 MJ/kg and 12.85 MJ/kg, respectively, which had no significant differences. However, those determined AME values were all lower than the values of 14.016 MJ/kg reported in NRC (1994) (36), which may be due to the differences in chicken breeds used.

Table 5. The apparent total tract digestibility (ATTD) and apparent ileal digestibility (AID) of nutrients of two new corn varieties and the conventional corn fed to broilers.

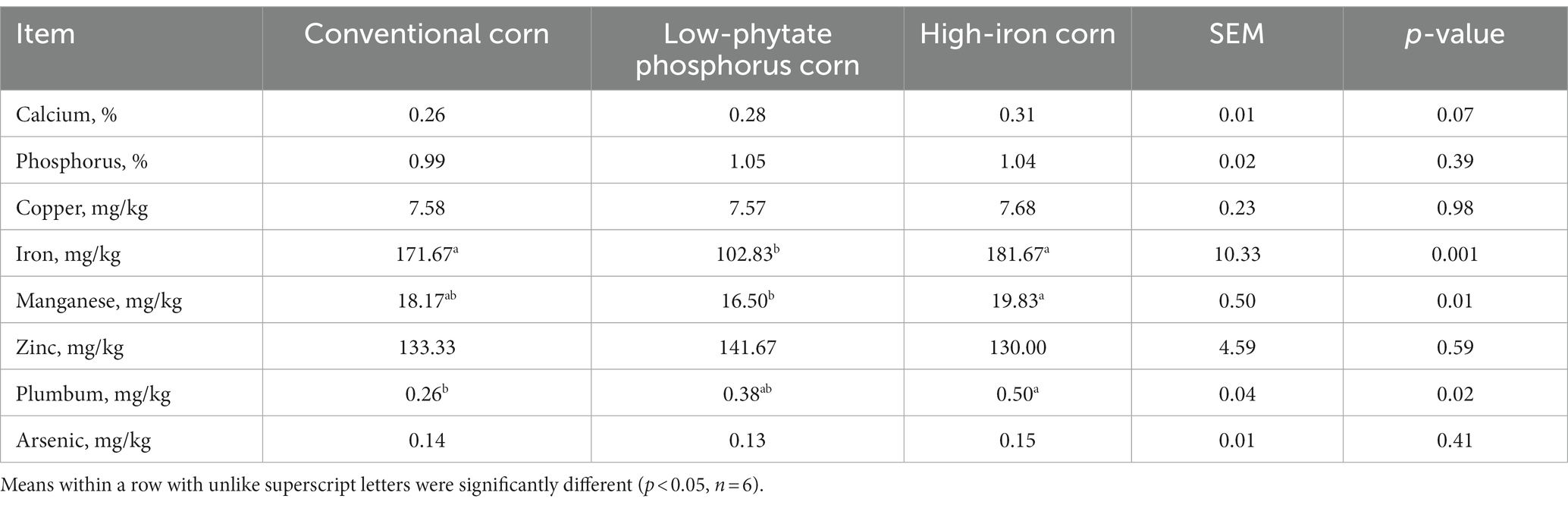

The emission of minerals in feces of broilers fed 2 new corn varieties and the conventional corn is shown in Table 6. The iron emission in feces of broilers fed the low-phytate phosphorus corn was significantly lower than those fed the conventional corn and the high-iron corn (p = 0.023), which may be related to the fact that the iron content in the low-phytate phosphorus corn was lower than that in the other two groups. Moreover, broilers fed the high-iron corn showed significantly greater manganese (Mn) emission in feces compared with those fed the low-phytate phosphorus corn (p = 0.01) and significantly greater plumbum (Pb) emission in feces compared with those fed the conventional corn (p = 0.02), and tended to show greater Ca emission in feces compared with the other two groups (p = 0.07), indicating that utilization of the new high-iron corn in broiler feed may cause some environment problems considering the mineral emission in feces.

Table 6. The emission of minerals in feces of broilers fed 2 new corn varieties and the conventional corn.

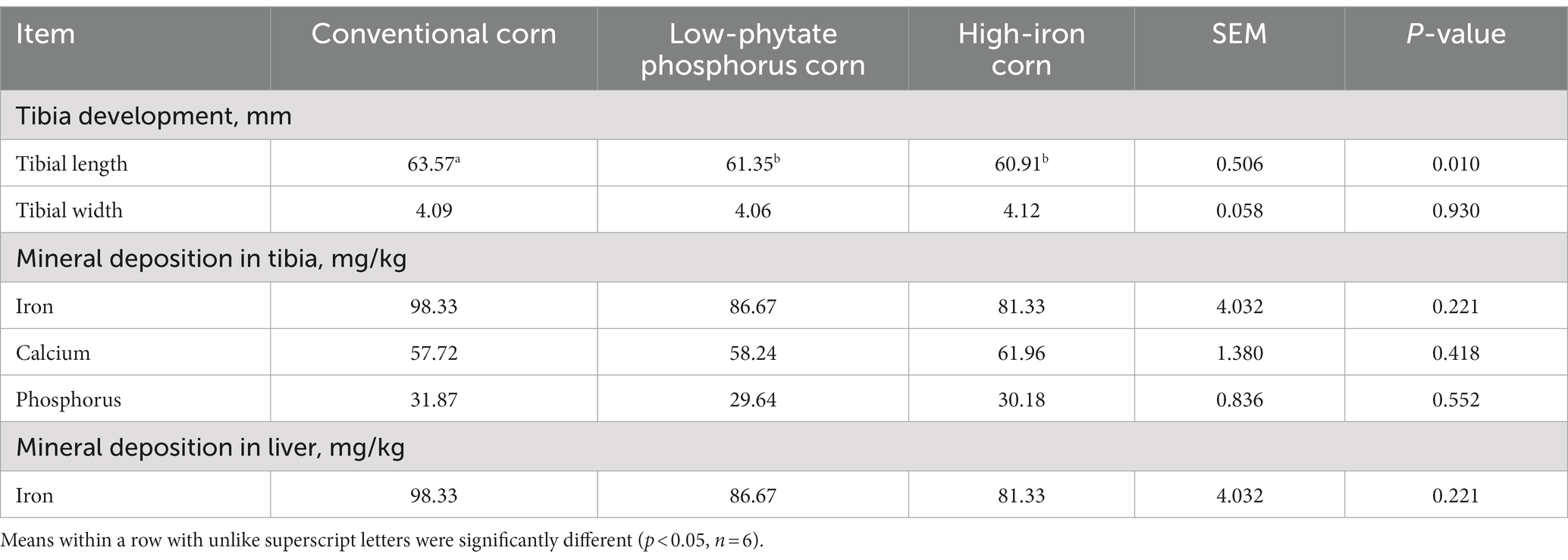

The tibia development and deposition of minerals in tibia and liver of broilers fed 2 new corn varieties and the conventional corn is shown in Table 7. The tibial length of broilers fed the low-phytate phosphorus corn and the high-iron corn is significantly lower than those fed the conventional corn (p = 0.01), but the tibial width was not affected. There was no significant difference in the levels of iron deposition in tibia and liver, as well as the levels of calcium and phosphorus deposition in tibia. Lack of calcium and phosphorus in the diet or an unreasonable ratio of calcium and phosphorus will lead to poor bone development in broilers. In broilers aged 1–21 days, phosphorus deficiency-related skeletal dysplasia is characterized by widening of the growth plate at the end of the bone epiphysis (37). In the current study, the reduced tibia length of broilers in the low-phytate phosphorus corn group may indicate that the low-phytate phosphorus corn did not achieve the breeding goal to some extent.

Table 7. The tibia development and deposition of minerals in tibia and liver of broilers fed two new corn varieties and the conventional corn.

4 Conclusion

The chemical compositions varied among the 3 new corn varieties developed through modern breeding techniques. However, those breeding techniques rarely changed the nutrient digestibility and the available energy values of the corn when fed to growing pigs and broilers. Those techniques could provide new plant ingredients that which have potential benefits to pig and broiler production, but the comprehensive effects may be better when applied to growing pigs considering both the growth performance and the environmental effects. However, additional animal trials with larger populations and more balanced diets are needed to further explore the utilization of those new corn varieties in animal feed.

Data availability statement

The original contributions presented in the study are included in the article/Supplementary material, further inquiries can be directed to the corresponding authors.

Ethics statement

The animal studies were approved by Institutional Animal Care and Use Committee of China Agricultural University. The studies were conducted in accordance with the local legislation and institutional requirements. Written informed consent was obtained from the owners for the participation of their animals in this study.

Author contributions

HC: Methodology, Writing – original draft, Writing – review & editing. LY: Formal analysis, Investigation, Writing – review & editing. XS: Investigation, Writing – review & editing. LL: Investigation, Writing – review & editing. SX: Project administration, Writing – review & editing. SH: Project administration, Supervision, Writing – review & editing. SZ: Conceptualization, Project administration, Supervision, Writing – review & editing.

Funding

The author(s) declare financial support was received for the research, authorship, and/or publication of this article. This work was supported by the National Natural Science Foundation of China (NSFC, 32072764), the National Key Research and Development Program of China funded by the Ministry of Science and Technology of the People’s Republic of China (MOST, 2021YFD1300205-8 and 2021YFD1300205-9), the National Center of Technology Innovation for Pigs (NCTIP-XD/C01), Sichuan Science and Technology Program (2018HH0160) and the 2115 Talent Development Program of China Agricultural University (00109011).

Acknowledgments

The authors thank the farmers in Fengning Animal Experiment Base and New Hope Liuhe Technology Research and Development Center for willingly volunteering to participate in this study.

Conflict of interest

LY, SX, and SH were employed by New Hope Liuhe Co., Ltd.

The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Supplementary material

The Supplementary material for this article can be found online at: https://www.frontiersin.org/articles/10.3389/fvets.2024.1358773/full#supplementary-material

References

1. National Bureau of Statistics. China statistical yearbook. Beijing: China Statistical Publishing House (2021).

2. U.S. Department of Agriculture Foreign Agricultural Service. (2021). Available at: https://www.fas.usda.gov/index[Accessed July 5, 2021].

4. Liu, W, Liu, GH, Liao, RB, Chang, YL, Huang, XY, Wu, YB, et al. Apparent metabolizable and net energy values of corn and soybean meal for broiler breeding cocks. Poult Sci. (2017) 96:135–43. doi: 10.3382/ps/pew195

5. Weurding, RE, Veldman, A, Veen, WA, van der Aar, PJ, and Verstegen, MW. Starch digestion rate in the small intestine of the chicken differs among feedstuffs. J Nutr. (2001) 131:2329–35. doi: 10.1093/jn/131.9.2329

6. Choct, M. Feed non-starch polysaccharides: chemical structures and nutritional significance. Feed Milling Int. (1997) 191:13–26.

7. Aaron, J, and Cowieson, A. Factors that affect the nutritional value of maize for broilers. Anim Feed Sci Technol. (2004) 119:293–305. doi: 10.1016/j.anifeedsci.2004.12.017

8. Pedersen, C, Boersma, MG, and Stein, HH. Energy and nutrient digestibility in NutriDense corn and other cereal grains fed to growing pigs. J Anim Sci. (2007) 85:2473–83. doi: 10.2527/jas.2006-620

9. Eeckhout, W, and De Paepe, M. Total phosphorus, phytate-phosphorus and phytase activity in plant feedstuffs. Anim Feed Sci Technol. (1994) 47:19–29. doi: 10.1016/0377-8401(94)90156-2

10. Humer, E, Schwarz, C, and Schedle, K. Phytate in pig and poultry nutrition. J Anim Physiol Anim Nutr (Berl). (2015) 99:605–25. doi: 10.1111/jpn.12258

11. Liu, HJ, Wang, X, Xiao, Y, Luo, J, Qiao, F, Yang, W, et al. CUBIC: an atlas of genetic architecture promises directed maize improvement. Genome Biol. (2020) 21:20. doi: 10.1186/s13059-020-1930-x

12. Song, GL, Li, DF, Piao, XS, Chi, F, and Yang, WJ. Apparent ileal digestibility of amino acids and the digestible and metabolizable energy content of high-oil corn varieties and its effects on growth performance of pigs. Arch Anim Nutr. (2003) 57:297–306. doi: 10.1080/00039420310001594432

13. Ren, P, Zhu, Z, Dong, B, Zang, J, and Gong, L. Determination of energy and amino acid digestibility in growing pigs fed corn distillers’ dried grains with solubles containing different lipid levels. Arch Anim Nutr. (2011) 65:303–19. doi: 10.1080/1745039X.2011.588849

14. Adeola, O. Digestion and balance techniques in pigs In: AJ Lewis and LL Southern, editors. Swine nutrition. New York: CRC Press (2001). 903–16.

15. Meng, F, Zhang, S, Su, S, Liu, J, Liang, M, Li, H, et al. Determination of moisture in feedstuffs, National Standard of the People's Republic of China. Beijing: China Zhijian Publishing House (2015).

16. Xiao, Z, Fan, X, Ma, D, Li, L, Wang, S, Jia, Z, et al. Determination of crude protein in feedstuffs, Kjeldahl nitrogen determination, National Standard of the People's Republic of China. Beijing: China Zhijian Publishing House (2019).

17. Zhang, S, Li, L, Fan, Z, Yang, S, and Su, X. Determination of ether extract in feed, National Standard of the People's Republic of China. Beijing: China Zhijian Publishing House (2006).

18. Wu, R, Yang, L, He, Y, Qian, F, Zhong, M, Yang, A, et al. Determination of crude ash in feed, determination of crude ash in feed GB/T 6438–2007. Beijing: China Zhijian Publishing House (2007).

19. Wang, J, Yu, J, Wu, K, Lu, D, Liu, J, Hou, X, et al. Determination of neutral detergent fiber in feedstuffs, National Standard of the People's Republic of China. Beijing: China Zhijian Publishing House (2006).

21. Li, H, Zhao, C, Jia, Q, Li, S, and Zhang, M. Ministry of Agriculture of the People's Republic of China. NY/T 1459–2007. Method for the determination of acid detergent fiber in feed. Beijing: China Zhijian Publishing House (2008).

22. Animal feeding stuffs. UNE-EN ISO 9831-2004, animal feeding stuffs, animal products, and feces or urine - determination of gross calorific value - bomb calorimeter method (ISO 9831:1998). (1998).

23. Chang, B, Zhang, Y, Yan, H, Zhang, M, Liang, W, and Li, J. Determination of amino acids in feeds, National Standard of the People's Republic of China. Beijing: China Zhijian Publishing House (2001).

24. Zhao, G, Jia, J, Li, L, Song, J, Zhao, Y, and Zhang, F. Determination of sulfur-containing amino acids in feedstuffs by ion exchange chromatography, National Standard of the People's Republic of China. Beijing: China Zhijian Publishing House (2019).

25. Meng, F, Zhao, S, Jia, Z, Li, B, Yang, Z, Zhu, L, et al. Determination of calcium, copper, iron, magnesium, manganese, potassium, sodium and zinc in feedstuffs atomic absorption spectrometry, National Standard of the People's Republic of China. Beijing: China Zhijian Publishing House (2018).

26. Shang, J, Hua, X, Huang, S, Lu, C, Cao, Y, Tian, K, et al. Determination of phosphorus in feeds—Spectrophotometry, National Standard of the People's Republic of China. Beijing: China Zhijian Publishing House (2019).

27. Yuan, J, and Xia, T. Method for determination of cadmium in feeds, National Standard of the People's Republic of China. Beijing: China Zhijian Publishing House (1992).

28. Brouwer, E. Report of subcommittee on constants and factors. Energy Metab. Troonn Publ. Academic, London. (1965). p. 441–443.

29. Stein, HH, Seve, B, Fuller, MF, Moughan, PJ, and de Lange, CFM. Invited review: amino acid bioavailability and digestibility in pig feed ingredients: terminology and application. J Anim Sci. (2007) 85:172–80. doi: 10.2527/jas.2005-742

30. Jaworski, NW, Lærke, HN, Bach Knudsen, KE, and Stein, HH. Carbohydrate composition and in vitro digestibility of dry matter and non-starch polysaccharides in corn, sorghum, and wheat and coproducts from these grains. J Anim Sci. (2015) 93:1103–13. doi: 10.2527/jas.2014-8147

31. D’Alfonso, T. Global maize quality variability. In Proceedings of the Multi-state Poultry Meeting, Indianapolis, USA. (2002).

32. Park, CS, Son, AR, Kil, DY, and Kim, BG. Digestible and metabolizable energy in corn grains from different origins for growing pigs. Anim Sci J. (2015) 86:415–21. doi: 10.1111/asj.12315

33. Gwirtz, JA, and Garcia-Casal, MN. Processing maize flour and corn meal food products. Ann N Y Acad Sci. (2014) 1312:66–75. doi: 10.1111/nyas.12299

34. Cervantes-Pahm, SK, Liu, Y, and Stein, HH. Comparative digestibility of energy and nutrients and fermentability of dietary fiber in eight cereal grains fed to pigs. J Sci Food Agric. (2014) 94:841–9. doi: 10.1002/jsfa.6316

35. Kobayashi, T, and Nishizawa, NK. Iron uptake, translocation, and regulation in higher plants. Annu Rev Plant Biol. (2012) 63:131–52. doi: 10.1146/annurev-arplant-042811-105522

Keywords: new corn variety, nutritional value, growing pig, broiler, iron, cadmium, phytate phosphorus

Citation: Cao H, Yan L, Song X, Liu L, Xu S, Hu S and Zhang S (2024) Determining the nutritional values of new corn varieties on pigs and broilers. Front. Vet. Sci. 11:1358773. doi: 10.3389/fvets.2024.1358773

Edited by:

Yangchun Cao, Northwest A&F University, ChinaReviewed by:

Xilong Li, Feed Research Institute (CAAS), ChinaMaghsoud Besharati, University of Tabriz, Iran

Copyright © 2024 Cao, Yan, Song, Liu, Xu, Hu and Zhang. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Shuai Zhang, emhhbmdzaHVhaTE2QGNhdS5lZHUuY24=; Shengdi Hu, aHVzaGVuZ2RpQDE2My5jb20=

†These authors have contributed equally to this work and share first authorship

‡These authors have contributed equally to this work and share last authorship

Hongrui Cao1†

Hongrui Cao1† Ling Liu

Ling Liu Shuai Zhang

Shuai Zhang