- Star Refrigeration Ltd., Glasgow, United Kingdom

Despite continual development over more than two centuries there is still great scope for significant development in the realms of mechanical cooling and heating. This paper reviews the nature of the historical development and identifies key motivations for technical development. It seeks to highlight where there is greatest need for future development in this ubiquitous technology. The story of the development of mechanical refrigeration is dominated by the choices made with regard to the working fluid used in the system. These choices dictate the operating parameters of temperature and pressure that the system must withstand as well as introducing constraints related to material compatibility, so the agenda for the mechanical development of systems is set by the selection of the refrigerant. All of these systems are classed as heat pumps because they extract heat from one location and deliver it to another. The commercial demand for mechanical cooling in the 19th century meant that all of these early heat pump systems were used for cooling. The concept of using the same cycle to deliver useful heat was not commercialised until the mid-twentieth century and in some ways this application of the heat pump is still in the early stages of development, particularly with regard to market penetration.

Introduction

The technology of mechanical refrigeration has been well established for over one hundred and 50 years, having taken about one hundred years to develop from the initial ideas of the 18th century to a position of commercial stability (Thévenot, 1977). The earliest experiments in mechanical cooling were conducted by Dr William Cullen, founder of the world’s first Department of Chemistry at the University of Glasgow, from about 1750 onwards. Throughout that first hundred years very little progress was made; partly because materials science was not sufficiently well developed and partly because the commercial world did not yet appreciate the benefits that mechanical refrigeration would bring. Cullen’s initial experiments in the evaporation of liquids, including the forerunners of absorption refrigeration and vacuum chilling, did not lead directly to any commercial development and it was almost 80 years until Jacob Perkins built the first technically successful vapour compression system, in London in 1834. Even this did not lead directly to commercial success and it was another 20 years before James Harrison, also in London, started manufacturing ice making machines. The hundred year gestation was finally coming to an end and Harrison sparked a flurry of creativity on both sides of the Atlantic as many new concepts came to the market. Now, as mechanical cooling technology moves towards its third century, there is a further need for significant development to meet the challenges of the 21th century.

Different schools of thought

The burgeoning refrigeration industry in the mid-to late-nineteenth century created several strongly held schools of thought regarding the most suitable approach. They were driven, to a greater or lesser extent by three competing factors which gained and lost significance as the industrial world developed, and they attracted devout proponents to champion their advantages and struggle to overcome their drawbacks. The three competing factors were safety, reliability and efficiency; all tempered by the commercial reality of economic viability. Cost of manufacture could be considered to be a fourth factor but it operates in a different manner, continually pressurising designers and manufacturers to skimp on all three of the factors in order to be more competitive. The way in which these factors rose and declined in significance can be illustrated using the development of marine refrigeration as an example, but the same story was played out on-shore as well as off-shore.

Early marine systems were developed for the transportation of meat from Australia, New Zealand and South America to Europe and after a few trials of ether-based vapour compression systems the air cycle was initially favoured because it was inherently safe and simple. Provided the steam engines driving the ship remained in operation the refrigeration system would also function. Proponents of the ether systems included James Harrison in Australia and Charles Tellier in France. Air cycle was preferred by Mort and Nicolle in Australia and the Bell-Coleman company in Britain who received support and encouragement from Lord Kelvin. Absorption systems, developed by Ferdinand Carré, were also tried but were found to require too much fuel to make them economic on a long sea voyage.

Once the reliability of vapour compression improved sufficiently to make it acceptable in the marine market, air cycle also started to lose market share on grounds of efficiency. Most refrigerants at the time were highly flammable (dimethyl ether and diethyl ether) or highly toxic (ammonia and sulphur dioxide) so, despite the engineering challenges of making systems efficient and reliable, carbon dioxide became the preferred solution for the marine market as it was non-flammable and was perceived to be non-toxic. Many of the early adopters of air cycle systems, such as J&E Hall, switched their allegiance to carbon dioxide and by 1890 it was the preferred solution for almost all marine installations.

There were eight separate types of refrigerant and refrigeration system instigated in the 50 year period from 1835 to 1885. These were ether (c.1835), aircycle (c.1845), absorption (c.1860), carbon dioxide (c.1865), light hydrocarbon distillates (c.1865), ammonia (c.1870), sulfur dioxide (c.1875) and methyl chloride (c.1885). However there were none from 1885 to 1925. This was a period of consolidation and refinement. Many refrigerant options fell out of favour in the second 40 years period, so that for the industrial market, both on- and off-shore, only ammonia and carbon dioxide remained in use by 1925. Each of these alternatives brought advantages to overcome previous deficiencies but also introduced new challenges. For example, air cycle systems did not use a toxic or flammable working fluid but they operated on either the Brayton or Stirling cycle and were extremely inefficient so incurred a high fuel consumption. Efficiency was critical when the application was cooling of produce on long sea voyages because all of the fuel had to be carried on board and so limited the payload of the vessel. Hence, once suitable working fluids for the more efficient vapour compression systems were found the absorption and air cycle systems declined in popularity. Sulfur dioxide was introduced relatively late in the 50 years transition period to address the mechanical challenges of making reliable compressors for the other working fluids. It is an unusual refrigerant because it acts as its own lubricant, but the severe toxicity risk it presented meant that it was ultimately rejected in favour of ammonia, also toxic but easier to handle, once the challenges of constructing sufficiently robust ammonia compressors had been overcome.

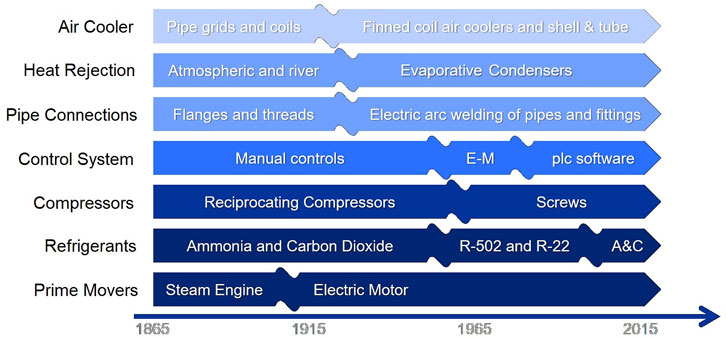

Over the same period new technologies in materials science, working fluids, heat exchanger design and many other fields were being introduced to the industrial refrigeration market. Figure 1 (Pearson, 2018) shows timelines of significant changes in the field over the 150 year period from 1865 to 2015. The wrinkle in each time line shows the point of transition where a new technology supplanted a former method. Note that this was not always a complete takeover. For example while steam engines are no longer used as prime movers and almost all compressors are electrically driven, reciprocating compressors have not been completely replaced by screws and in fact have made something of a comeback in recent years as the system efficiency becomes more important again.

Note that in Figure 1, A&C is ammonia and carbon dioxide, which have made something of a comeback in the industrial market in recent years and E-M is electro-mechanical controls, which largely replaced manual and mechanical controls in the post-war period before being replaced in turn by programmable logic controllers from the 1980s onwards.

From about 1910 onwards significant development had been achieved in the field of domestic cooling systems including refrigerators and air-conditioners, although the latter tended to be centralised plants serving whole apartment buildings. Neither ammonia nor carbon dioxide were suitable for these applications and so systems using sulphur dioxide and methyl chloride (both highly toxic) were initially developed. Following several fatal accidents, propane was promoted in the 1920s as “the safety refrigerant” due to its benign toxicology, but the market was primed for the development of fluorinated compounds addressing issues of toxicity and flammability in equipment that could be easily mass-produced. The introduction of dichlorodifluoromethane (R-12) in 1930 led to half a century of rapid and comprehensive development of a broad range of products from domestic refrigerators to industrial test chambers, including domestic heat pumps and large scale water chillers. However since the mid 1980s there have been a succession of replacements for the chlorofluorocarbons (CFCs) prompted by increased awareness of the threat posed by persistent man-made chemicals to the environment. These threats include ozone depletion, acid rain, the anthropogenic greenhouse effect and the bioaccumulation of polyfluoroalkyl substances (PFASs).

There are two important trends to note from the last two hundred and 50 years of mechanical refrigeration development. It took one hundred years to move from William Cullen’s laboratory curiosity to James Harrison’s commercial success. It took 80 years to move from Harrison’s beginnings to the need for non-flammable, non-toxic fluids for the domestic market and it took 60 years for the CFCs to move from phase-in to phase-out. That phase-out started 40 years ago—a period that has seen a succession of fluorinated successors to CFCs ushered in as “the solution” only to be identified as a key component of a further environmental concern. CFCs were replaced with HCFCs, then HFCs then HFOs. Now the HFOs are under scrutiny due to rapidly increasing levels of trifluoroacetic acid in free water, which has been linked to the replacement of R-134a by R-1234yf in mobile air-conditioning. It is extremely concerning to note that these increases have been observed within the first 10 years of the increased use of R-1234yf in car air-conditioning in Europe, although other industrial processes, not related to refrigeration, have also been suggested as sources of fluorinated acids in water courses (Jourdan et al., 2021).

The second trend of note from the development cycle is the way in which people like to take sides in the debate and will tend to hold to their views long after it would seem reasonable to change opinion. Swiss physicist Raoul Pictet, best known for the liquefaction of oxygen and nitrogen, was a lifelong proponent of sulphur dioxide as a refrigerant from his first system in 1874. Everard Hesketh of J&E Hall developed his carbon dioxide compressor in the late 1880s and didn’t add ammonia to the company’s catalogue until 1910. James Harrison persisted with diethyl ether, despite its inherent hazards, from his early success on 1855 until his death in 1893 by which time he had spent all his money on pursuing his dream, and died in poverty. The modern era has seen similar fanaticism. One side of the debate likes to refer to their favoured solutions as “natural” refrigerants (meaning that they are found in abundance in natural cycles) although their opponents are quick to point out that the refrigerant used in manufactured systems comes almost entirely from huge chemical plants. Conversely the “natural” advocates describe their opponents’ preferred substances as “synthetic” or “chemical” with the implication that these are unnatural and therefore unhealthy. It is ironic to note that according to the branch of chemistry covering the fluorinated alkanes they should properly be referred to as “organic” refrigerants (although this would also include propane and butane). The debate could therefore be characterised as being between “natural” fluids and “organic” compounds.

It seems reasonable to conclude that neither side in the modern debate has a monopoly on truth and many of their claims owe more to marketing than science. In addition to the valid complaint about the term “natural” described above, the use of the term “hydrofluoroolefin” is open to criticism (RTOC, 2018). These HFOs are touted as being significantly different to the HFCs that they are tipped to replace but this is only a half-truth. All the compounds in question, including R-134a and its successor, R-1234yf, are compounds containing hydrogen, fluorine and carbon. They are all hydrofluorocarbons. The characteristic difference is that the olefin descriptor signifies that there is a carbon to carbon double bond in the molecule. It would therefore be more honest to call them unsaturated HFCs (or uHFCs) rather than hydrofluoroolefins. The double bond means that the molecule has a shorter atmospheric life and therefore has a lower global warming potential than the long-lasting CFCs or HFCs. However this prompts the question of the effect of the products of disassociation on the environment. The answer to this question is complicated, but it is reasonable to assume that those products are more stable than the initial compound and, while they might not have any significant effect as greenhouse gases, they may cause other environmental challenges. It is also disingenuous to claim that HFOs have a hundred year global warming potential of “less than one” while reporting that the most accurate estimate that can be given for hydrocarbons is “less than twenty” due to uncertainties in the atmospheric science. Furthermore the value of “less than one” does not include the effect of energy use during manufacturing. A simple comparison with HFCs indicates the difficulty of this approach. R-134a has a global warming potential of 1300 on a 100 years time horizon according to the IPCC’s fifth assessment report. However this estimate has an uncertainty of ± 30% meaning that the value lies somewhere between 910 and 1690. It is estimated that the emissions from the manufacturing of R-134a account for a further GWP of about 5—negligible in comparison to the margin of error in the base estimate. In contrast, R-1234yf is said to have a GWP of “less than 1” but is also stated to be more energy intensive to produce than R-134a. It is reasonable to assume that the indirect GWP effect of the production process will be significantly higher than the estimated figure for R-134a; one study estimated it to be about 14, almost three times higher than for R-134a and clearly not insignificant in comparison to the direct effect on the environment.

On the other side of the debate the proponents of the fluorinated organic refrigerants point out that the effect of energy efficiency on the life cycle climate performance of an installed system can be much more significant than the direct effect of refrigerant emissions, particularly in economies that are primarily powered by fossil fuels. The major flaw in carbon dioxide systems is that they become very inefficient in warm weather as the heat rejection temperature approaches, or even exceeds the critical temperature of the refrigerant. This creates what is known as a “transcritical cycle,” where the heat extraction, by evaporation of the refrigerant occurs below the critical temperature but the heat rejection is at an elevated temperature above the critical point of 31°C. It is often said that this makes the coefficient of performance under these conditions very poor, although what actually happens is that the amount of flash gas at the inlet to the evaporator increases, causing a reduction in the cooling effect without reducing the work input required. Countering this effect requires additional cost and complexity in the design of the refrigeration system which leads to the observation that “organic” systems could also be significantly improved if they had the same amount spent on them. However a significant proportion of the market for refrigeration systems, particularly consumer goods like refrigerators and air-conditioners or commercial cabinets for the retail sector, values low price more than high efficiency.

This leads to a further dichotomy in the debate between “natural” and “organic” refrigerants. The science behind the balancing of efficiency, safety, reliability and economy is obviously complex and nuanced but there is a need among lawmakers, standards writers, marketers and indeed the general public for simple metrics to help them differentiate between right and wrong. These two requirements are mutually exclusive. Any simplification to aid decision making is likely to be open to the charge of “dumbing-down” the complex issues in play and in the worst case could lead to inappropriate decisions or even expensive mistakes.

Current research gaps

A review paper like this can only touch briefly on the topics under research and hint at where the gaps might be. Stepping back and looking at the two hundred and 50 years history of mechanical refrigeration can help by indicating where priorities should lie. The developments from the mid-nineteenth to the early 20th century were driven by the increasing sophistication of the demands of the market, starting with what has been described as “whatever worked” and then progressing through phases of “safety and durability” to “ozone protection” and most recently more general climate protection (Calm, 2012). The division of refrigerants into the two competing factions described above could be characterised as a split between direct climate protection on the one hand (using refrigerants that are flammable or toxic) and cheap, efficient, reliable solutions on the other hand (that perhaps do not give full confidence that there will be no pervasive, persistent environmental effect). Each side in this battle should be looking to adopt the perceived benefits claimed by the opposition. The research gaps are therefore in the field of making the cheap, efficient reliable fluorinated organic compounds more environmentally friendly and developing cheaper, more reliable, safer and more efficient systems for the environmentally friendly natural refrigerants. There are some significant fields of study in some of these areas, for example the minimisation of charge (Hrnjak, 2019) or the reduction of leakage in fluorocarbon systems (Gartshore, 2013), or the use of expanders (Barta et al., 2019) and ejectors (Hafner et al., 2014) to boost the performance of transcritical carbon dioxide systems. However there are many other fields of study that are not currently widely exploited. Some examples are discussed below.

The application of materials science to the construction of ammonia systems to make them as cheap to manufacture as fluorocarbon systems could yield significant benefits in the commercial and light industrial market (Expósito-Carrillo et al., 2018). Currently the fluorocarbon systems make extensive use of copper components joined by brazing, a cheap and quick process, whereas most ammonia systems use carbon steel or stainless steel pipe which has to be welded and is therefore much more expensive. A high strength polymer that could be cold-joined with a suitable adhesive could revolutionise the ammonia market. There are now a few semi-hermetic compressors for ammonia coming to market but most systems still rely on mechanical shaft seals to keep the system leak tight (Lindborg, 2007; Pachai, 2014).

In hydrocarbon systems and in fluorocarbon systems there would be great advantages, albeit for different reasons, in developing an additive for the refrigerant that didn’t interfere with the normal operation of the system, but adsorbed the refrigerant within the pressure envelope in the event of a leak. For hydrocarbons this could greatly expand their use in the domestic and commercial market by enabling larger charge sizes to be used safely. For fluorocarbons it would reduce the climate effect of leakage, although in the latter case if the development encouraged system owners to pay less attention to the tightness of their system it could prove to be counter-productive.

For all types of refrigerant there is scope to enhance the system efficiency in order to use less energy. Urban population growth, particularly in sub-Saharan Africa is likely to drive the expansion of the cold chain significantly faster than the underlying global population growth and the demands on the energy infrastructure need to be constrained somehow. Greater use of machine learning, digital twin modelling and adaptive control, all techniques that are widely used in other industries, could provide great benefits, particularly if they can be retrofitted to existing systems in a cost-effective way.

The energy pinch caused by phase-out of fossil fuels coupled with urban population growth will also cause a substantial increase in the demand for efficient and effective heat pump systems. The global market for heat pumps has the potential to be up to ten times larger than the current market for refrigeration and air-conditioning. As the refrigeration and cooling market is already estimated to use one-sixth of the world’s electrical generating capacity it is clear that a step-change in efficiency for cooling and heating systems is urgently required. Restrictions on the use of fossil fuels have also prompted a growing interest in heat pump technology. Heat pumps are frequently described as “refrigeration systems in reverse” but this is not strictly true, since the basic vapour compression cycle operates in the same manner. The difference is that the focus of the thermal effect of the device is on the heat output end (the condenser) not the heat input end (the evaporator). However there are still many research needs to make heat pumps more widely accepted, including operation at higher temperatures and pressures than are required for refrigeration, operation with new forms of evaporator or condenser and lower production costs to make systems economically viable (Hu et al., 2020).

Conclusion

The three influencing factors of safety, reliability and efficiency are still as relevant today as they ever were. The current position is that safety, which in its broadest sense includes environmental protection, is heavily regulated but the regulations continue to develop particularly in the field of environment. This motivates ongoing research into new working fluids and alternatives to vapour-compression. Efficiency is increasingly regulated in terms of new equipment design but is much more difficult to control for systems in operation and relies on market forces to maintain focus on the issues. Reliability is a given, but tempered by built-in obsolescence and non-technical factors such as fashion and aesthetics which may result in functional systems being replaced on a 5–7 years life cycle, for example during the refurbishment of a supermarket. The research need in this case is for systems that are cheap to manufacture but sufficiently robust to maintain their performance over their operating life. Despite two hundred and 50 years of development in the mechanical cooling sector there is therefore still a very large need for technical enhancement in all three respects. Looking to the next 30 years shows the opportunity for transformational development in a wide range of engineering disciplines including the mechanics of machines, materials science, artificial intelligence, electrical and electronic engineering and many more. It is a good time to be an engineer in the refrigeration industry.

Data availability statement

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

Author contributions

This article was written by the named corresponding author, AP.

Conflict of interest

AP was employed by Star Refrigeration Ltd.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Barta, R., Ziviani, D., Hugenroth, J., and Groll, E. (2019). “Dynamic modeling and control strategy of a transcritical CO2 cycle for a multi-temperature refrigerated container system for military applications,” in Proc 25th int congress of refrigeration (Montreal: IIR).

Calm, J. M. (2012). “Refrigerant transition again,” in Proc ASHRAE/NIST refrigerants conference (Gaithersburg.

Expósito-Carrillo, J., Sánchez de la Flor, F., and Salmerón-Lissen, J. (2020). “‘Experimental performance analysis of an air condensed ammonia chiller with critical charge,” in Proc 14th gustav lorentsen conf. (Kyoto: IIR).

Gartshore, J. (2013). “Guide to the top lessons the industry should have learned from real zero,” in Inst ref annual conf (London.

Hafner, A., Schönenberger, J., Banasiak, K., and Girotto, S. (2014). “R744 ejector supported parallel vapour compression system,” in Proc 3rd int conf on cold chain and sustainability (London: IIR).

Hrnjak, P. (2019). “Rational approach to heat pump refrigerant charge reduction,” in Proc 25th int congress of refrigeration (Montreal: IIR).

Hu, B., Wu, D., Liang, J., and Wang, R. (2020). “Natural refrigerants in heat pump systems,” in Proc 14th gustav lorentsen conf. (Kyoto: IIR).

Jourdan, S., De Silva, A., and Young, C. (2021). Insufficient evidence for the existence of natural trifluoroacetic acid. Environ. Sci. Process. Impacts 23, 1641–1649. doi:10.1039/d1em00306b

Lindborg, A. (2007). “Ammonia’s future as a refrigerant,” in Proc IIR conference ammonia refrigeration technology for today and tomorrow (Ohrid: IIR).

Pachai, A. (2014). “Next generation of efficient NH3 refrigeration system,” in Proc 3rd int conf on cold chain and sustainability (London: IIR).

Pearson, A. (2018). “Innovation in refrigeration and air-conditioning,” in Proc herrick conferences (W Lafayette: Purdue University).

RTOC (2018). “Air conditioning and heat pumps technical options committee,” in 2018 report of the refrigeration (UN Environment Programme).

Keywords: refrigeration, heat pump, history, efficiency, safety, reliability

Citation: Pearson A (2022) Development of refrigeration and heat pump systems. Front. Therm. Eng. 2:1042347. doi: 10.3389/fther.2022.1042347

Received: 12 September 2022; Accepted: 10 October 2022;

Published: 24 October 2022.

Edited by:

Zhibin Yu, University of Glasgow, United KingdomReviewed by:

Hui Wang, Northwestern Polytechnical University, ChinaCopyright © 2022 Pearson. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Andy Pearson, YXBlYXJzb25Ac3Rhci1yZWYuY28udWs=

Andy Pearson

Andy Pearson