1 Introduction

Construction and demolition (C&D) waste represents up to 50% of the waste filling New Zealand's (NZ) landfills (Level, 2020), with plastics contributing about 4% (Ministry for the Environment, 2007). This percentage is high compared to the global rate for C&D waste, estimated to represent 36% of waste going to landfills (Alhawamdeh et al., 2024). In Auckland, NZ's most populous city, ~25,000 tons of plastic waste are deposited in landfills annually (Berry et al., 2022). Additionally, NZ's waste management processes lag those in the United Kingdom (UK) and Europe, as most construction waste in NZ is not sorted on-site and instead co-mingled (Low et al., 2020). Berry et al. (2022) ask, “For a single sector that produces such large quantities of waste, including plastics, why is there a lack of any significant focus on waste management?”

The process of extracting fossil fuels and creating plastics emits vast amounts of greenhouse gases, which is a critical driver of climate change. The global call to embrace a circular economy through reuse, renew and reduce practices drives a shift toward earth-based, bio-based and low-carbon materials (Ministry of Business, Innovation and Employment, 2024). To prevent the worst consequences of climate change, humanity needs to limit global temperature increase to 1.5°C. New Zealand has committed to this goal under the Paris Agreement, aiming for net-zero carbon emissions by 2050 [Climate Change Commission NZ (He Pou a Rangi), 2024]. However, the 2022 Global Status Report for Buildings and Construction revealed that the sector has fallen behind its decarbonization target of 2050 (United Nations Environment Programme, 2022). This problem is increasing as the use of plastics in construction has risen in recent years due to the industry's growing reliance on plastic products. This includes new products such as plastic building shrink wrap, and the replacement of traditional materials with plastic alternatives, like plastic pipes (Office of the Prime Minister's Chief Science Advisor, 2023).

The vast array of construction plastics needs to be sorted if they are to be reused or recycled. The most preferred approach is to reduce the amount of plastic used (waste minimization), working through the stages of reuse and recycling before the last resort of landfill disposal (waste management). It is important that there is continued focus on reducing the use of raw virgin materials, which occurs mainly during the design stage of construction and should be supported by a sustainable procurement strategy (Poon et al., 2003; Osmani et al., 2008; Andrews, 2015).

So why is NZ lagging so far behind? This opinion piece consolidates findings from recent research studies to understand the plastic waste problem, and explore both on-site and off-site barriers to reducing, reusing, and recycling plastic waste. Drawing on insights from case studies, we aim to identify solutions to these barriers. First, let us examine the factors in the broader environment that influence plastic waste recycling before construction begins on-site.

2 Discussion

2.1 Off-site factors

To understand specific barriers to waste management, Ferriz-Papi et al. (2024) examined 54 research articles and applied the PESTLE network (Political, Economic, Social, Technological, Legal, and Environmental) to study challenges to C&D waste management. These barriers included high investment requirements, lack of regulations, cultural attitudes, technological limitations, and the need for better data management and innovation in waste segregation. The challenges most discussed in the literature (which could be classified as off-site barriers) were inadequate regulations and additional costs of sustainable waste management. Similarly, Alhawamdeh et al. (2024) undertook a systematic literature review of 55 scientific articles (2020–2023) to determine the drivers that support C&D waste management for a circular economy. The main drivers identified were: a more regulated, digitally connected, collaborative and skilled sector; consideration of the full supply chain in the whole life cycle of a construction project; the waste value chain.

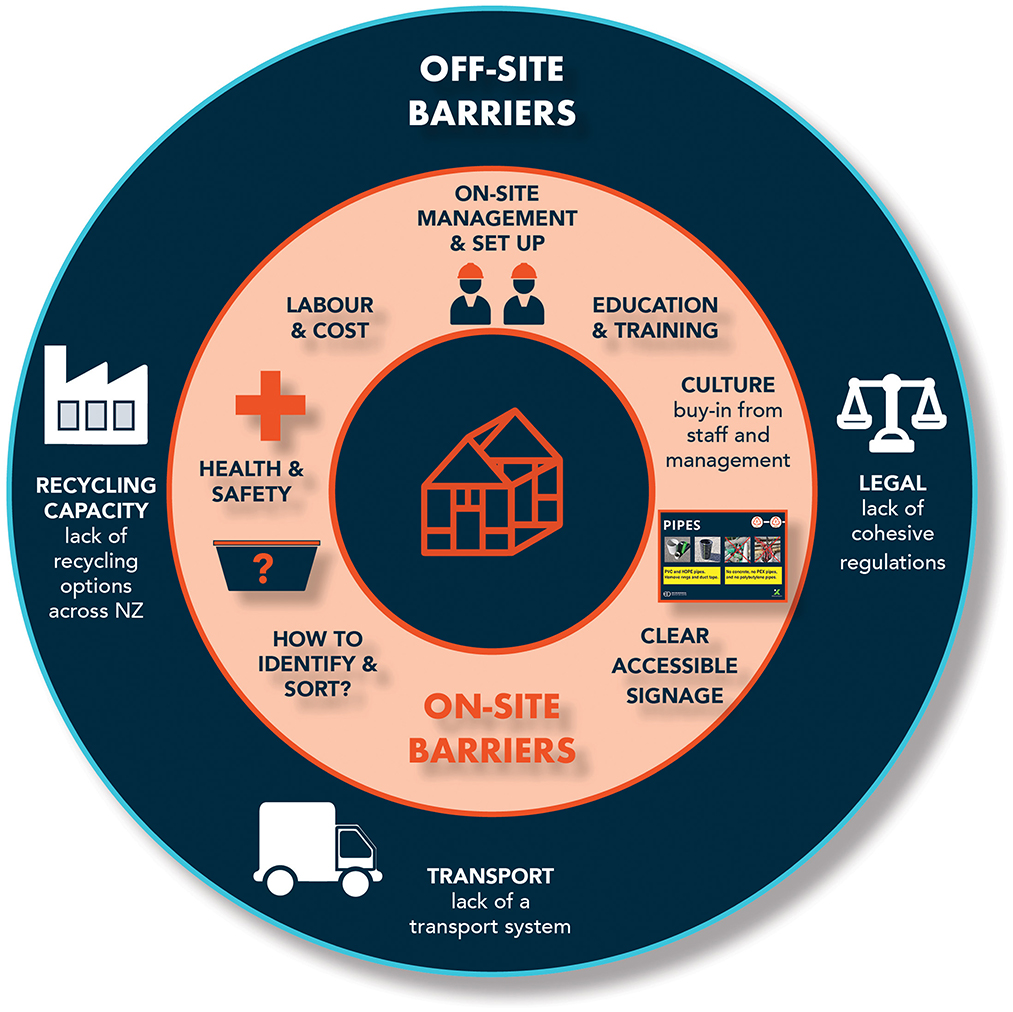

Ferriz-Papi et al. (2024) note the lack of cohesive regulation as a key barrier. In NZ, sending plastic waste to landfills is currently more cost-effective and straightforward than recycling it. Municipal landfill costs in NZ are currently $60 NZD per ton (Ministry for the Environment, 2022), compared to £103.70 per ton (or $220 NZD) in the UK (HM Revenue and Customs, 2023). Landfill levies tend to coincide with higher recycling rates; for example, the UK has a recorded recycling rate of 93% (Department for Environment, Food & Rural Affairs, 2024), while NZ has just 28% (Berry et al., 2022). This is especially relevant for plastic due to its low mass and high volume. This regulatory mechanism could easily be changed, but the question remains whether NZ has adequate facilities to meet the resulting recycling demand. Are there cost-effective, low-carbon transport options? What are the recycling options for the regions? How do you identify and sort the plastic? Where can you find resources to train and educate staff? These questions underline a complex and overwhelming issue for an industry already navigating a tough economic environment (Figure 1). Despite these many barriers, there is a growing awareness within the industry and a strong desire to do the right thing for the environment and future generations. Recent on-site trials have shown it is possible to address these questions; the results, in terms of reducing plastic waste, have been extremely promising and achievable (Low et al., 2024).

Additionally, there is growing recognition within the construction industry that building materials are valuable resources. This shift in mindset is fostering a collaborative effort between government agencies, industry, technology, and communities to drive behavioral change and improve environmental outcomes. One example is a project funded by NZ's Ministry for the Environment, in 2022, through the Plastics Innovation Fund. This $11.5 million initiative focuses on recycling plastic pipe off-cuts, which have traditionally been sent to landfill due to a lack of recycling facilities for construction waste. This project provides a blueprint of how to establish and fund a successful recycling operation. It includes investments in infrastructure to sort, wash and shred PVC and HDPE plastics, as well as developing a collection network in partnership with a major waste supplier. Additionally, the project conducts research to develop practical on-site solutions for construction sites and raises awareness through a hub of educational resources. The project addresses every step in the process to ensure a seamless circular solution. It underscores the value of collaboration in the NZ construction sector and the potential for the industry to work with global suppliers. This approach supports innovative local waste management initiatives, including supplier stewardship schemes, collaboration with local construction retailers and reverse logistics.

2.2 On-site factors

Over the last 4 years, several studies have sought to improve understanding and awareness of on-site plastic C&D waste in NZ. Hernandez et al. (2023) and Low et al. (2024) conducted plastic waste audits at various construction sites in Auckland to identify and measure the plastic waste stream. Low et al. (2020) identified considerable barriers to reducing, reusing and recycling plastic waste streams, including health and safety considerations, material contamination (such as soil, food, concrete, and non-plastic items) and the need for education and training for on-site waste management. To test these barriers, Berry et al. (2022) conducted a “foundations to completion” plastic waste audit on a new secondary school in Auckland, NZ, to trial separating and sorting waste. Several on-site barriers were identified; in this case, contractors could only recycle 21% by mass of all plastics generated (including all PVC pipework and polystyrene). Berry et al. (2022) concluded that this outcome was partly a reflection of the lack of staff training and site visits (due to COVID-19), the lack of a recycling culture on-site, and the lack of engagement from subcontractors. Berry noted that an essential factor was using dedicated reusable bags for sorting rather than co-mingled skip bins, which encourage poor waste management practices. Another barrier was the lack of clear and appropriate signage on-site (including images of waste types).

Low et al.'s (2024) study found that by implementing on-site plastic waste separation, training and appropriate signage, an Auckland residential construction site was able to divert 66.4% (wt.) of plastic waste from landfill through reuse and recycling. In this case study, the cost of sustainable waste management (separating all waste types) was ~2.3-fold more expensive than “traditional” waste management (using commingled landfill bins). Plastic waste management itself accounted for about 0.11% of the total project costs. However, these costs are specific to this site and will differ based on location, available transportation, recycling operators, and site size. The site owner did not find the increased cost for sustainable waste management to be unreasonable, and the additional cost passed onto each homebuyer was ~0.16% of the house's selling price.

Insights from informal discussions with on-site managers during case studies (PIF-funded projects) support the research findings (Berry et al., 2022). Signage with imagery is identified as a critical factor in overcoming language barriers for non-English speakers, and for quick identification of waste types. Other printed information such as posters, signage, and images were preferred, as online information is less accessible due to limited internet and phone access on construction sites. Education and training are essential and best kept simple and easy, with roles and responsibilities for waste management being outlined alongside health and safety protocols. While these case studies took place in NZ, many of the findings (factors to drive on-site separation of waste) can be implemented on any site.

Alhawamdeh et al. (2024) investigated why contractors fail to segregate construction waste. They identified key factors such as management effort, site space limitations, labor, cost, and interference with day-to-day construction activities. Effective waste management requires commitment across all organizational levels, starting with involving the site management early in the project; this ensures they are engaged and will encourage the site team to carry out proper waste segregation. In addition, having a designated person for waste management is another key strategy. This role involves overseeing everyday waste sorting, communicating with both the site team and waste operators and finding solutions for any issues in the process. Successful plastic waste management on any site involves several steps: correctly identifying and sorting plastic waste, ensuring waste is clean, providing staff training, locating recycling operators, arranging waste transport, timely pickups, and maintaining quality control (Figure 1). Simplifying these processes and providing an educational hub of information is vital to support this change. Whilst the current recycling landscape can be overwhelming and confusing, there is a definite shift toward a culture of sustainability in the construction industry. This is often driven by a younger, more environmentally-conscious generation, which creates a valuable opportunity to improve sustainable waste practices in the industry.

3 Conclusion

The path toward effective plastic waste recycling in the New Zealand construction industry has many off-site and on-site challenges. External barriers include regulatory constraints, insufficient funding and infrastructure, entrenched industry norms and culture, and a lack of training and awareness.

However, the tide is turning. Collaborative initiatives, such as the Plastic Innovation Fund project, demonstrate the potential for successful recycling operations through coordinated efforts involving government, industry, and academia. The increasing awareness, urgency, and commitment to sustainable practices in the construction industry, especially among the younger generation, are promising signs for the future.

New Zealand must improve its plastic waste minimization and management to align with global standards and contribute to a more circular economy. Recent plastic waste trials have produced very promising results, but a concerted, ongoing effort from the industry is needed. Site managers need information and tools to set up and consistently use an on-site sorting area. Site workers will require education and training that is accessible and meaningful, with delegated responsibility for someone to ensure waste is properly sorted and clean. Additionally, ongoing feedback mechanisms and encouragement for site staff are crucial. This effort needs to be supported with updated online resources that clearly outline the process, lists of recyclers, and drop-off and transport options.

The construction industry is increasingly recognizing the need for changes in waste management. New Zealand must seize this opportunity to address regulatory gaps, invest in necessary infrastructure, and adopt innovative localized approaches. By fostering a culture of sustainability and collaboration, the construction industry can lead the way in reducing plastic waste and ensuring long-term environmental sustainability.

Author contributions

PT: Writing – original draft, Writing – review & editing. JL: Writing – review & editing. T-AB: Writing – review & editing.

Funding

The author(s) declare financial support was received for the research, authorship, and/or publication of this article. Funding for this research initiative comes from the Plastics Innovation Fund (PIF), through the Ministry for the Environment.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher's note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Alhawamdeh, M., Ferriz-Papi, J. A., and Lee, A. (2024). Examining the drivers to support improved construction and demolition waste management for a circular economy: a comprehensive review using a systematic approach. Sustainability 16:6014. doi: 10.3390/su16146014

Andrews, D. (2015). The circular economy, design thinking and education for sustainability. Local Econ. 30, 305–315. doi: 10.1177/0269094215578226

Berry, T.-A., Low, J. K., Wallis, S. L., Kestle, L., Day, A., and Hernandez, G. (2022). Determining the feasibility of a circular economy for plastic waste from the construction sector in New Zealand. IOP Conf. Ser. Earth Environ. Sci. 1122:e012002. doi: 10.1088/1755-1315/1122/1/012002

Climate Change Commission NZ (He Pou a Rangi). (2024). At a glance: Monitoring emissions reduction (2024). Available at: https://www.climatecommission.govt.nz/ (accessed December 31, 2024).

Department for Environment, Food & Rural Affairs. (2024). UK statistics on waste. GOV.UK. Available at: https://www.gov.uk/government/statistics/uk-waste-data/uk-statistics-on-waste

Ferriz-Papi, J., Lee, A., and Alhawamdeh, M. (2024). Examining the challenges for circular economy implementation in construction and demolition waste management: a comprehensive review using systematic methods. Buildings 14:1237. doi: 10.3390/buildings14051237

Hernandez, G., Low, J., Nand, A., Bu, A., Wallis, S. L., Kestle, L., et al. (2023). Quantifying and managing plastic waste generated from building construction in Auckland, New Zealand. Waste Manag. Res. J. Int. Solid Wast. Publ. Cleans. Assoc. 41, 205–213. doi: 10.1177/0734242X221105425

HM Revenue and Customs (2023). Increases to Landfill Tax Rates From 1 April 2024. Available at: https://www.gov.uk/government/publications/landfill-tax-rates-for-2024-to-2025/increases-to-landfill-tax-rates (accessed April 01, 2024).

Level (2020). Minimising Waste - Construction and Demolition Produce Large Amounts of Waste. Available at: https://www.level.org.nz/material-use/minimising-waste/ (accessed July 22, 2024).

Low, J. K., Hernandez, G., and Berry, T.-A. (2024). Plastic waste characterisation to maximise landfill diversion from a New Zealand residential construction site. Front. Sustainabil. 5:1455480. doi: 10.3389/frsus.2024.1455480

Low, J. K., Wallis, S. L., Hernandez, G., Cerqueira, I. S., Steinhorn, G., and Berry, T.-A. (2020). Encouraging circular waste economies for the New Zealand construction industry: opportunities and barriers. Front. Sustain. Cit. 2, 1–7. doi: 10.3389/frsc.2020.00035

Ministry for the Environment (2007). Targets in the New Zealand Waste Strategy: 2006 Review of Progress (ME 802). Ministry for the Environment. Available at: https://~environment.govt.nz/publications/targets-in-the-new-zealand-waste-strategy-2006-review-of-progress/ (accessed February 3, 2023).

Ministry for the Environment (2022). Waste Disposal Levy Expansion. Available at: https://environment.govt.nz/what-government-is-doing/areas-of-work/waste/waste-disposal-levy/expansion/ (accessed July 22, 2024).

Ministry of Business Innovation and Employment. (2024). Building and Construction Sector Trends—Annual Report 2023. Available at: https://www.mbie.govt.nz/building-and-energy/building/building-system-insights-programme/sector-trends-reporting/building-and-construction-sector-trends-annual-report/2023/emerging-trends-in-building-design-technologies-and-materials (accessed October 11, 2024).

Office of the Prime Minister's Chief Science Advisor (2023). Changing Our Relationship With Plastics. Available at: https://www.pmcsa.ac.nz/topics/rethinking-plastics/changing-our-relationship-with-plastics/ (accessed September 30, 2024).

Osmani, M., Glass, J., and Price, A. (2008). Architects' perspectives on construction waste reduction by design. Waste Manag. 28, 1147–1158. doi: 10.1016/j.wasman.2007.05.011

Poon, C., Yu, A. T., and Ng, L. (2003). Comparison of low-waste building technologies adopted in public and private housing projects in Hong Kong. Eng. Construct. Archit. Manag. 10, 88–98. doi: 10.1108/09699980310466578

Keywords: barriers, opportunities, plastics, recycling, construction waste management, New Zealand

Citation: Thomson P, Low JK and Berry T-A (2025) Addressing barriers and unveiling opportunities for plastic waste recycling in the New Zealand construction industry. Front. Sustain. 5:1487972. doi: 10.3389/frsus.2024.1487972

Received: 03 September 2024; Accepted: 23 December 2024;

Published: 08 January 2025.

Edited by:

T. A. Kurniawan, Xiamen University, ChinaReviewed by:

Guohao Wang, China Electric Power Research Institute (CEPRI), ChinaCopyright © 2025 Thomson, Low and Berry. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Joanne K. Low, am9hbm5lQGVudmlyb25tZW50YWwtaW5ub3ZhdGlvbi5ueg==

Penelope Thomson

Penelope Thomson Joanne K. Low

Joanne K. Low Terri-Ann Berry

Terri-Ann Berry