- UCL Plastic Waste Innovation Hub, University College London, London, United Kingdom

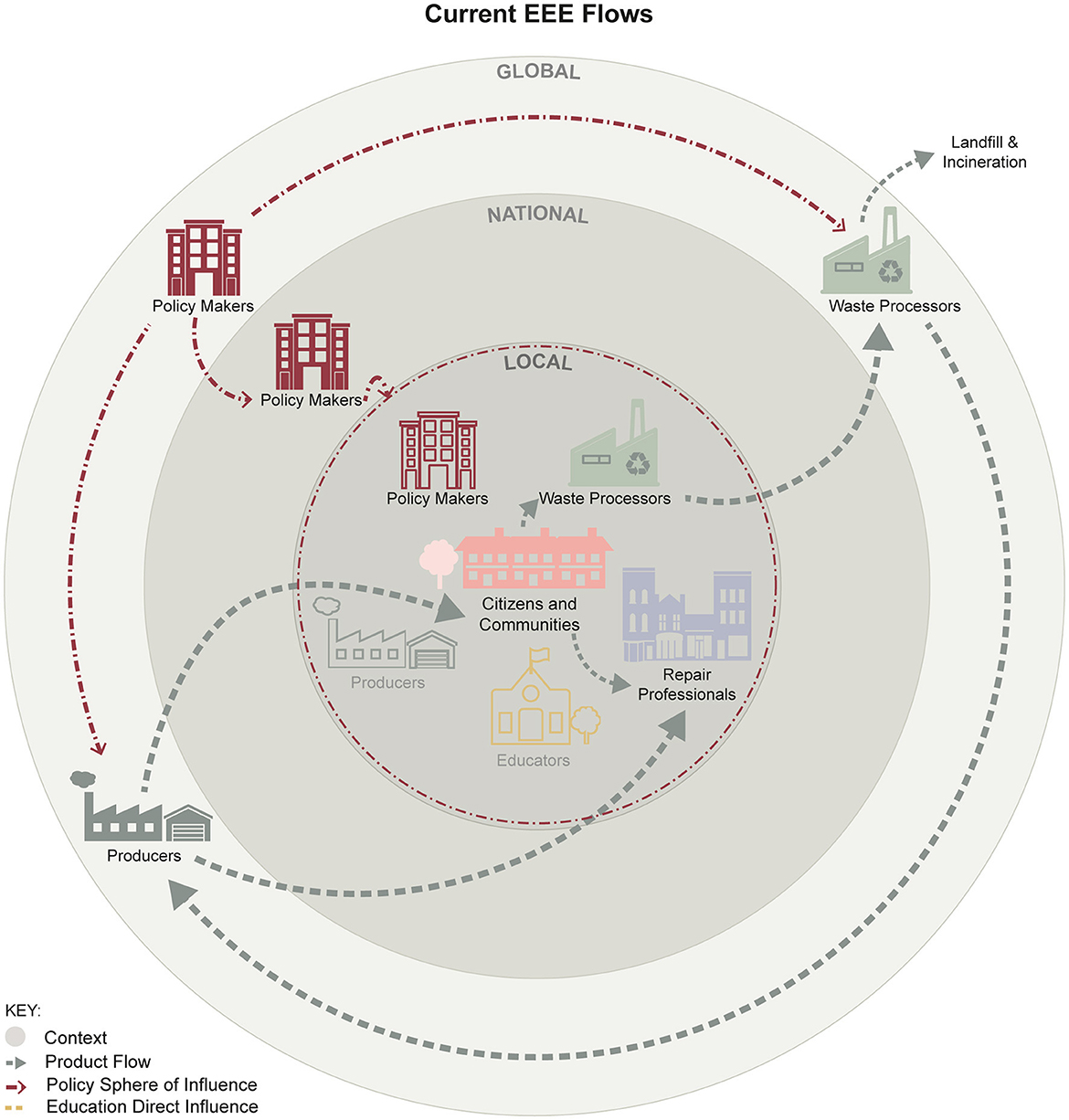

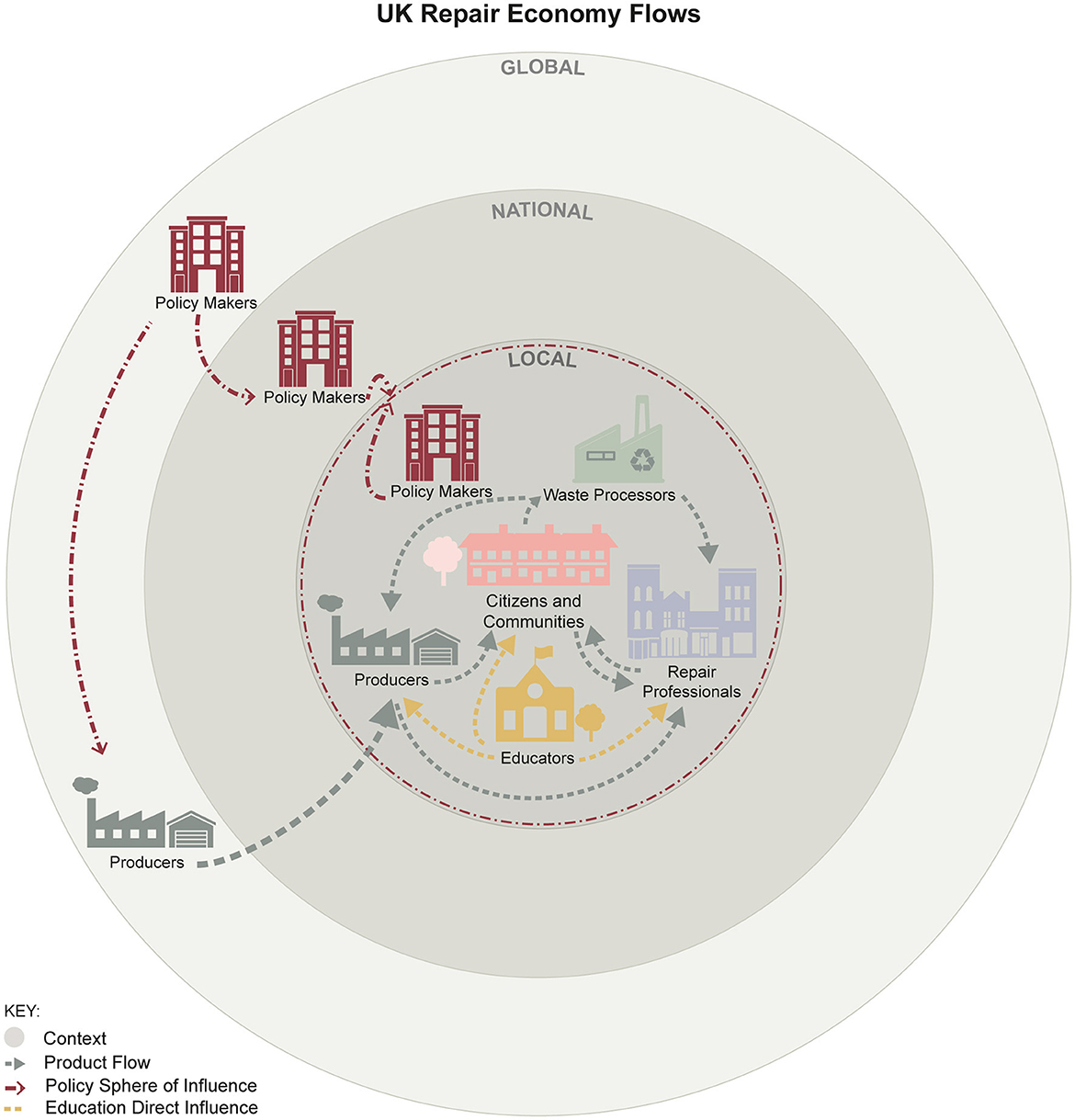

The UK has a growing problem in the fast and unsustainable accumulation of Waste Electrical and Electronic Equipment, causing a wide range of negative environmental and social impacts. The UK repair economy, by its nature, is a complex system involving an interplay of legislative (i.e., policy, law, regulation), social (i.e., education, health, wellbeing), economic (i.e., fiscal, business models, supply chains) and environmental aspects (i.e., materials and energy use, greenhouse gas emissions), and stakeholders (i.e., citizens, educators, repair professionals, producers, waste processors, policymakers) at a range of scales (i.e., local, national, and global). Growing a successful UK repair economy can help tackle many negative environmental and social impacts including reducing electronic waste, material consumption, mitigating supply chain risk, and regional inequality. To do this, the needs and interactions of stakeholders at local, national and global level should be supported via coordinated policy and regulation initiatives. This article takes a systems approach to understanding the UK repair economy, identifying key policy and regulatory aspects and opportunities for action and development across global, national, and local contexts to help it grow.

1 Introduction

In the past, repair was an affordable and accessible activity (Perzanowski, 2022). In pre-21st century Britain, electrical and electronic products were relatively simple and availability of relevant repair skills and access to repair services was more common and affordable. Technological and societal changes through industrial and digital eras have led to electronic product and software complexity, planned obsolescence1 (European Parliament, 2016; Bisschop et al., 2022), and increasing technical, regulatory and fiscal barriers to electronics repair. The relative convenience and affordability of buying new electronics rather than repairing them and the role of fashion and advertising have also contributed to an increase in consumption behaviors (Hernandez et al., 2020). These factors have led to the electronics market becoming a significant source of emissions and causing adverse environmental and social effects, due to the rise in new electronics production, shortening product lifespans (Bakker et al., 2014; Prakash et al., 2016) and increasing volumes of electronic waste (Green Alliance, 2018a).

This paper acknowledges the wide range of product categories covered by the Electrical and Electronic Equipment (EEE) definition (WEEE and EEE as defined by HM Government, 2023a), and the respective differences with regards to waste processes, warranties and design repair potential which must be considered for any future policy interventions. Repair is defined as ‘the mending or reconditioning of human-made goods to restore their form or function' (Perzanowski, 2022), activities that extends a product's lifespan (including maintenance) (Hernandez et al., 2020), and forms part of preparing for re-use activities in the waste hierarchy framework (DEFRA, 2011).

Currently the waste management recycling sector comprises approximately 1% of UK's total GPD at around £24.9 billion pounds, encompassing activities such as waste collection, processing, recycling of materials, and energy-from-waste processes (Statista, 2022b). The electronics repair sector is comparatively smaller and currently difficult to accurately calculate as it forms part of the broader category of repair and installation of machinery or equipment, which accounts for around 1–2% of UK GDP with a value added increase of around 1.1% in 2024 (Statista, 2024).

In the UK and elsewhere there is increasing market demand for longer lasting, repairable, refurbished and remanufactured electronic products (Green Alliance, 2018b, 2015a) including phones (GfK, 2024) and laptops (Transparency Market Research, 2023), and globally the estimated growth rate in repaired and refurbished electronics markets is 12.1% from $85.42 billion in 2021 to $272.91 billion in 2031 (Trojan Electronics, 2023).

Growing the UK repair economy for appliances and electronics can effectively address environmental, social and economic issues on a range of scales (global, national, and local) by: (1.1) Reducing electronic waste globally and the associated negative environmental and social impacts; (1.2) Slowing material loops by reducing demand for new products and extending product lifespans; (1.3) Mitigating supply chain risks for the critical minerals used in electronic products and technologies that reduce digital exclusion and facilitate the green economy (i.e., laptops, electric vehicles, photo voltaics); (1.4) Provide regional equality and social benefits through jobs creation, community network strengthening and wellbeing (see Figure 1).

Figure 1. Illustration summarizing the benefits of growing a UK Repair Economy as discussed in this paper.

1.1 Reducing electronic waste

Globally, electronics and appliances are a growing part of contemporary life. In the UK the consumer electronics market is estimated at US$32.9bn and household appliances US$10.07bn, with smartphones and telephony equipment comprising the largest consumer electronics market and major appliances (i.e., washing machines, ovens, refrigerators) comprising the largest appliances market segment (Statista, 2023a,b).

Electronic waste is one of the fastest growing waste streams globally, comprising 53.6 million metric tons in 2019, and projected to grow to 74.7 million metric tons (UNITAR, 2020; World Health Organization, 2021). In the UK the current Electrical and Electronic Equipment (EEE) market is largely a linear one. 55% of EEE items placed on the market go to landfill, incineration or are dumped overseas (House Of Commons Environmental Audit Committee, 2020) instead of utilizing circular routes such as reuse, repair, remanufacture, or recycling. It is forecasted that the UK will generate the highest amount of WEEE per capita globally by 2024 (Green Alliance, 2020a; House Of Commons Environmental Audit Committee, 2020; Statista, 2022a).

This in-turn is causing significant harm to the environment and to human health. One study suggests that only 17.4% of the 53.6 million tons of e-waste produced globally in 2019 was processed in regulated waste management or recycling systems, with the remainder either disposed of in illegal landfills or recycled by informal and unregulated worker communities (World Health Organization, 2021). Unregulated e-waste recycling practices have significant associated health and environmental impacts. Dismantling activities, like heating or burning release particulate matter and other toxic emissions including heavy metals, dioxins, furans, carcinogenic chemical compounds and flame retardants into air, soil, dust, water and food. Unregulated landfilling of e-waste causes leaching of hazardous substances and contamination of aquifers and surface water. Children, pregnant women and developing fetuses are disproportionately affected, with health hazards including impaired neurodevelopment, negative birth outcomes, respiratory and thyroid impairment, and an increased risk of chronic disease, including cancer and cardiovascular disease (World Health Organization, 2021). To reduce WEEE and minimize environmental and health risks associated with sorting and recycling, re-use should be considered as a priority in both policy and corporate strategy.

1.2 Slowing material loops

The UK consumes circa 1.7 million tons of EEE every year (House Of Commons Environmental Audit Committee, 2020), and according to the UN, the UK generates the second highest amount of WEEE per person at 23.9 kg (Global E-waste Monitor, 2020). The production of new EEE requires the use of vast quantities of Critical Raw Materials and at the current high rate of consumption and discard, a vast majority of these materials are lost if WEEE is exported for dumping, sent to landfill, incinerated or shredded (Green Alliance, 2020a). These currently lost materials are critical for the transition to Net Zero to enable grid electrification, manufacturing of electric cars, wind turbines, solar panels, healthcare, aerospace etc. By reducing consumption of new EEE, extending product lifespans and repair, we can slow down the need for material extraction for EEE, enabling climate mitigation and adaptation technologies to develop at faster rates. According to Green Alliance, UK manufacturers currently spend five times more on resource inputs than labor, therefore reducing consumption could also benefit the manufacturing sector through increased profits estimated at £10 billion (UK Parliament, 2020).

DEFRA analysis in 2011 put Electronic Equipment and Machinery as the fifth most carbon emitting sector in the UK when measured by consumption of products (Sustainability Research Institute, 2011). The bulk of environmental impacts (i.e., greenhouse gas emissions, water use, eco-toxicity) of electronic devices like smart phones or laptops come from their production phase, through the ore mining, material extraction and processing. If current trends for the consumption of goods, including electronics, continue, greenhouse gas emissions from resource extraction and processing will increase by 43 per cent from 2015 to 2060. Thus, to reduce global warming from electronics production it is important to decarbonise provision. An effective way to do this is to slow consumption rates, extend product lifespans and slow demand for new products by supporting alternative measures such as product reuse, repair and remanufacturing (Green Alliance, 2020a).

In Europe, to boost the transformation to a circular economy and slow material loops, different circular business models are being deployed and scaled-up across sectors, including the electrical appliances sector. The models include pay-per-use, product lease, subscription and shared-access, which embed repair services as part of the model. Life cycle Assessments of the models are showing that in material use benefits, the circular business models perform significantly better than a regular ownership model (Sigüenza et al., 2021).

1.3 Mitigating supply chain risk

Several critical minerals including lithium, nickel, and cobalt, are essential to a wide range of electronic products (i.e., batteries, smartphones, laptops, Electric Vehicles) (HM Government, 2022a). Global supply chains for these materials are vulnerable to social, geopolitical, and technical disruptions, highlighted by the disruption to electronic components during the Covid-19 pandemic (Althaf and Babbitt, 2021). In the UK the demand for lithium for the manufacture of electronic products such as electric vehicle batteries exceeds supply from other countries (UK lithium imports were 1,975 tons in 2020) and from primary UK production, with overall demand projected to increase significantly (UK Critical Minerals, 2022, 2023). Supply chain pressures are likely to increase in the face of increasing manufacture and use of digital and “green” technologies which will rely on sourcing large quantities of critical minerals and creating resilient supply chains (Skidmore, 2023). Relying on domestic raw material extraction through mining or recycling will be insufficient to meet demands. Recycling activities are also not keeping pace with the global growth rate of electronic waste (UNITAR, 2020). Recycling alone, although an important circular economy activity and part of increasing UK supply chain resilience, will not meet growth in consumption demands in the UK, and requires significant energy use and is itself a source of emissions (Green Alliance, 2020b). Instead, other circular economy activities such as reduction and reuse (including repair and remanufacture), will be essential to meet demand (HM Government, 2022a) and ensure secure supplies of materials and components for new and reused, repaired and remanufactured products. In circular economy frameworks, repairing products is generally regarded a higher priority activity over recycling as it extends product lifespans and reduces the overall environmental and social impacts and emissions associated with raw material extraction, and manufacturing of new products (DEFRA, 2011; Skidmore, 2023).

1.4 Regional equality

Growing a repair economy in the UK, combined with reducing energy usage and resource efficiency measures, could benefit the wider UK economy by: reducing environmental impacts; greater economic stability through increased resource security and new business; and addressing “structural unemployment” (the mismatch between job vacancies and where people live) through creating new employment opportunities (including around 472,000 new jobs by 2035) across the UK (Green Alliance, 2015b). For instance regional decline in manufacturing industries due to automation and offshoring in the Midlands, Wales and Yorkshire and the Humber (Green Alliance, 2021) can be mitigated by diversifying repair services on offer and providing more accessible local services can lower costs for consumers and provide local jobs where people live.

Using a traditional literature review method this paper takes a systems approach (HM Government, 2023h) to analyzing the policy and regulation, the social and cultural barriers, and the growth opportunities of the UK repair economy in the global, national, and local contexts. The analysis recognizes that the repair economy is a complex system with interconnected stakeholders and legislative frameworks (see Figure 2) and highlights the strategic importance of supporting a wide range of actions including local repair services to strengthen the UK repair economy.

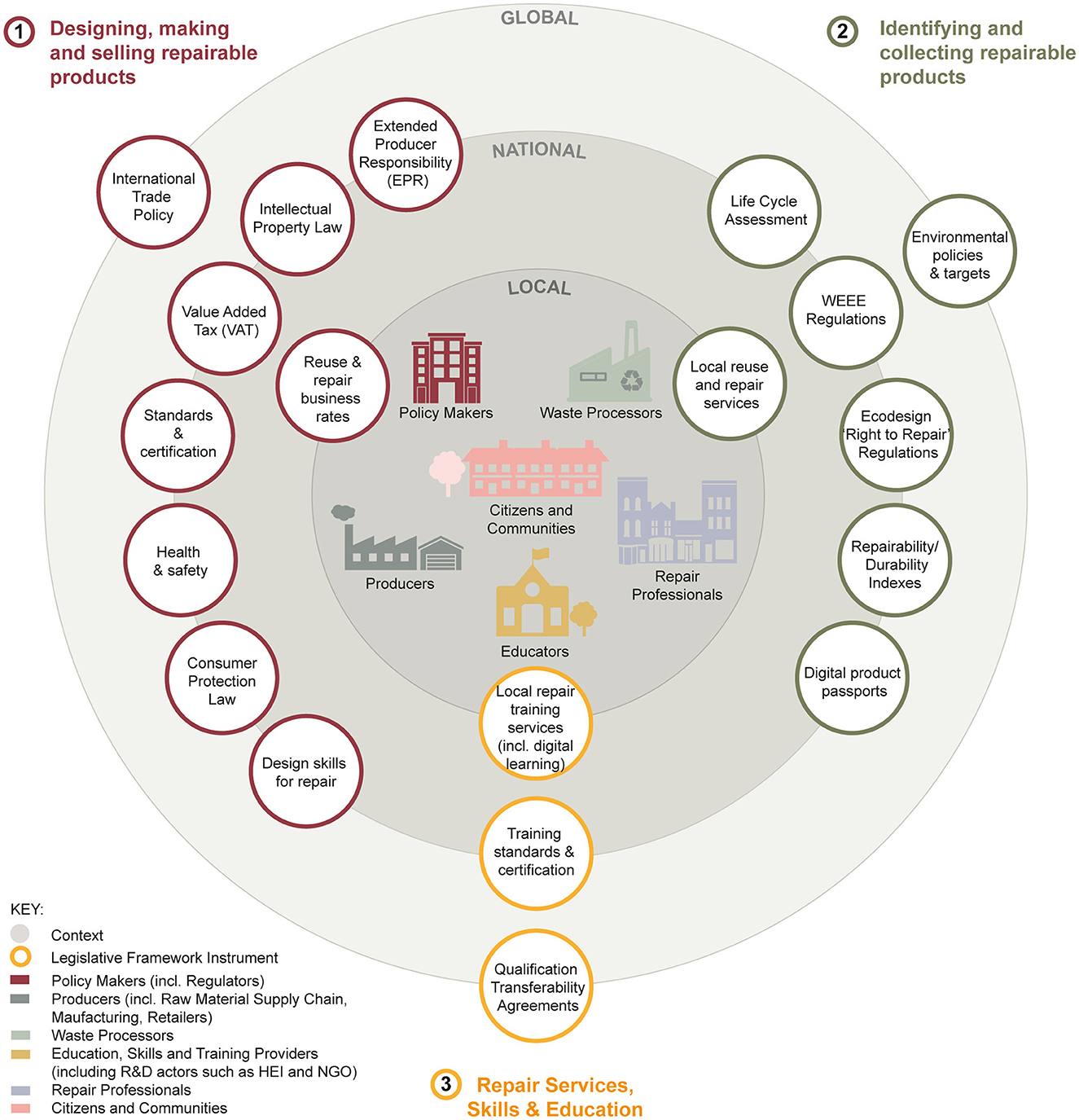

Figure 2. Illustration describing the global, national and local context relationships between policy and policy instruments in (1) Design, making and selling repairable products. (2) Identifying and collecting repairable products. (3) Repair services, skills and education.

This paper acknowledges wider definitions of a repair economy (Rinkinen and Shove, 2023) alongside existing policy and regulation aimed at tackling the barriers to repair (“Material Efficiency”, “Ecodesign” and “Right to Repair”). Additionally, the paper builds upon existing work done to assess and highlight technical and policy barriers to repair in the EU (European Commission, 2022a,b), and in the UK (Green Alliance, 2023), by taking a systems approach to the framing and discussion of the interactions of key stakeholders and policies in the UK repair system under the themes of:

“Designing, making and selling repairable products” (Trade policies, Extended Producer Responsibility, Intellectual Property Law, Warranties, VAT, Standards and Certification, Health & Safety, Consumer Protection Law, Design skills for repair, Business rates),

“Identifying and collecting repairable products for reuse and repair” (Environmental policies and targets, Life Cycle Assessment, WEEE Regulations, Ecodesign “Right to Repair” Regulations, Repairability/Durability Indexes, Local reuse and repair services), and

“Repair services, skills and education” (Skills and education policies, Training standards & certification, local repair training services, Business Models, Green Public Procurement).

The following discussions highlight the issues with the current global EEE/WEEE economy (Figure 3) and highlight further regulatory and policy measures that could support national and local repair economy growth, creating economic, environmental and social benefits (see Figure 4).

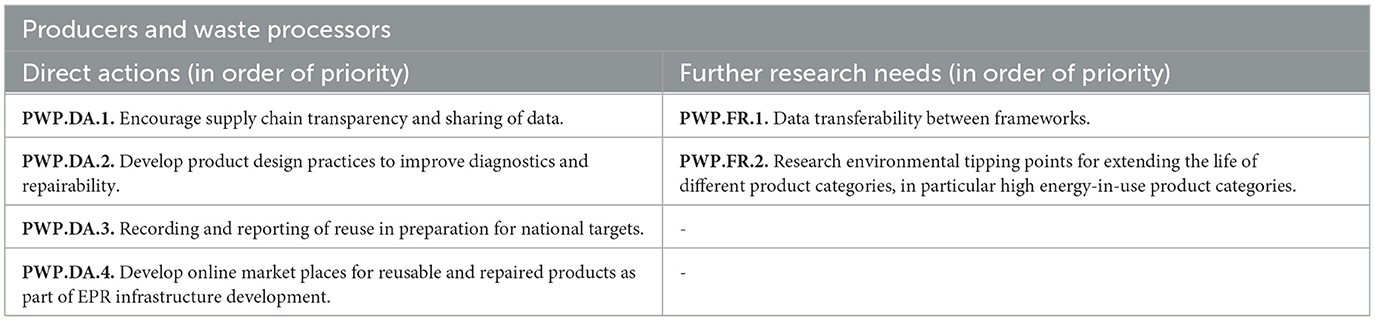

2 Designing, making, and selling repairable products

See Figure 5.

Figure 5. Table summarizing reviewed topics under the theme of “designing, making and selling repairable products”.

2.1 Global context

Continuing with “business as usual” production and consumption behaviors will cause significant ecological harm. Significant changes to electronic product design and manufacturing supply chain behaviors are needed to mitigate negative environmental, social, and economic impacts (Dasgupta, 2021). This is particularly relevant to electronics production and trade due to its global reach.

International organizations play an important role in the overarching industry regulation, facilitation and environmental target setting for national electronics imports and exports. The UK is an active member and has decision-making influence as part of the World Trade Organization (WTO), World Customs Organization (WCO), International Chamber of Commerce (ICC), United Nations Conference on Trade and Development (UNCTAD), International Maritime Organization (IMCO), International Air Transport Association (IATA), International Organization for Standardization (ISO), and the United Nations Commission on International Trade Law (UNCITRAL). In these organizations decisions on subjects like trade targets and regulations are made by the entire membership and typically by consensus.

Overall changes in trade practices and policies can help support more sustainable supply chain behaviors, including increasing imports/exports of remanufactured products and decreasing imports/exports of new products, thereby overall reducing the associated impacts of primary production. These trade measures include supply chain transparency, border adjustment taxes, regional trade agreements, aid expenditure, environmental taxes, and subsidies (Dasgupta, 2021).

Greater supply chain transparency is needed globally to support this change, requiring the sharing of information relating to manufactured, repaired, and remanufactured electronics. This information should be verifiable and underpinned by the enforcement of harmonized international standards relating to assessment, data collection and data sharing (Dasgupta, 2021; UNITAR, 2022). In addition to this, agreeing national threshold targets for the import and export of second hand, repaired or remanufactured electronics and spare parts could help to facilitate markets for these products.

Novel technologies such as geospatial data and blockchain, and other methods such as certification schemes could help to facilitate better supply chain transparency and increase more sustainable manufacturing and remanufacturing business practices. However, strong national and local governance, regulation and enforcement is needed to make these schemes effective (Dasgupta, 2021).

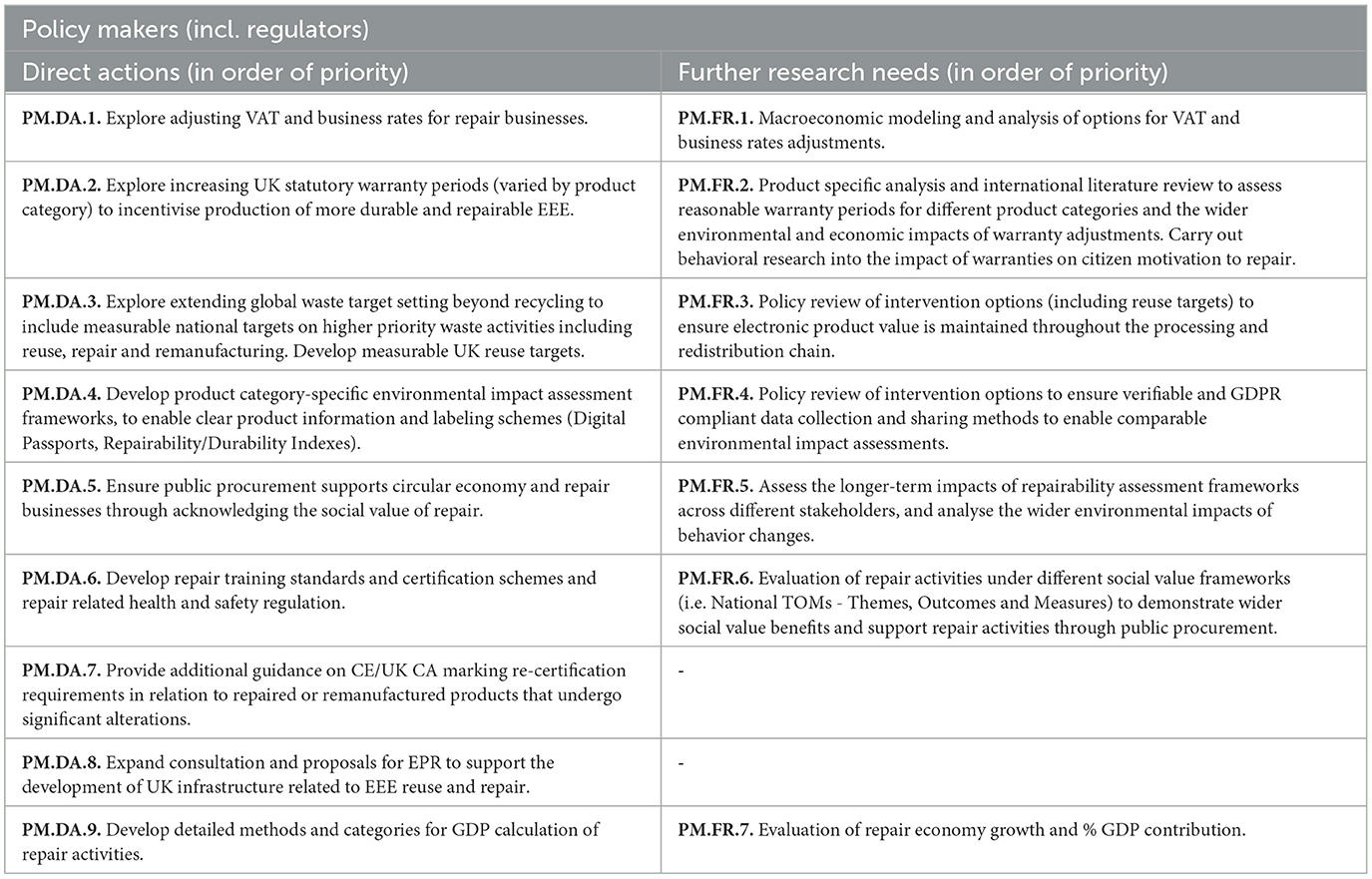

2.2 National context

There are several areas of the UK legislative and regulatory framework impacting the making, selling and repair of electronic products in the UK. Manufacturers and retailers who sell electronics, and the citizens who buy them, have certain rights and obligations under the UK Consumer Rights Act 2015. UK Conformity Assessment marking and certification requirements cover the minimum health and safety test requirements for electronic products being sold in the UK. The rate and scope of Value Added Tax (VAT) on electronic products (including spare parts) and repair services affects repair affordability, which is a significant barrier to increased repair rates. Additionally it is currently difficult to accurately calculate the % GDP value of the electronics repair sector in the UK due to lack of data collection. Together these national regulations and policies have a major influence on product purchasing and repair behaviors.

2.2.1 Gross domestic productivity (GDP)

The electronics repair sector forms part of the broader category of repair and installation of machinery or equipment, which encompasses a range of activities including the repair and maintenance of various types of machinery and equipment, installation services, and related activities across different industries. This category accounts for around 1–2% of UK GDP with a value added increase of around 1.1% in 2024 (Statista, 2024). Globally the estimated growth rate in repaired and refurbished electronics markets is 12.1% from $85.42 billion in 2021 to $272.91 billion in 2031 (Trojan Electronics, 2023). Although there is increasing demand for repaired and remanufactured products in the UK (Green Alliance, 2018b; Transparency Market Research, 2023; GfK, 2024) there is currently a lack of data collection methods and categories specific to electronics repair activities to evaluate their economic impacts. Until repair activities and their GDP impacts are reported and calculated more rigorously by governments the goal to increase repair and correlate it with other environmental goals such as waste and resource management or emissions reduction will be hard to achieve.

2.2.2 Value added tax (VAT)

HM Revenue and Customs administers the rate and scope of VAT on goods and services sold within the UK. Currently VAT is charged at 20% on goods and services, including the sale of electronic products, spare parts, and maintenance and repair service labor. Businesses selling products or services have to register for VAT if their VAT taxable turnover is more than £85,000 (HM Government, 2011). Imported goods are normally VAT chargeable at the same domestic rate, whereas goods exported outside the UK are zero-rated, instead subject to conditions such as national export tariffs and taxes.

VAT and other general consumption taxes are commonly regarded as regressive and common responses to this problem aim to redistribute social and economic impacts by excluding certain products or services from full taxation (De La Feria and Walpole, 2020). Removing VAT on repair and remanufacturing related goods and services could be a significant driver to make repairing products more affordable whilst expanding the range of new materials and products to which VAT is applied could help maintain tax revenues and support more circular business models and citizen behaviors (Green Alliance, 2023). Reducing VAT on repair and remanufacturing related goods and services in the UK could also strengthen national and local economies by creating greater demand for high skilled repair and remanufacturing professionals and distributing education and job opportunities across the UK (Green Alliance, 2021).

However, a recent example of product VAT exemption that has not yet resulted in redistributed social and economic impact is the abolishment of VAT on sanitary products, or the so-called “tampon tax”, by UK Government in 2021 (HM Government, 2021a). So far, without market or regulatory incentive there is little evidence of retailers passing this cost saving on to UK citizens (Financial Times, 2022), suggesting that additional measures are needed to drive behavioral change across industries and citizens. Although it is suggested that simplified VAT rate structures can reduce legal difficulties and economic distortions, there is currently a lack of evidence to conclude that VAT reduction or removal alone has the social and distributional effects it aims to achieve. Other aspects such as a product's price sensitivity, political pressure, market competition and regulation are also likely to have an impact and should be considered (De La Feria and Walpole, 2020).

2.2.3 Standards and certification

Standards are documents, “established by consensus and approved by a recognized body, that provides, for common and repeated use, rules, guidelines or characteristics for activities or their results, aimed at the achievement of the optimum degree of order in a given context” (International Standards Organisation, 2004). Several standards have been developed by the European Committee for Standardization CEN and CENELEC and other national standards institutes (BSI) in response to circular economy and material efficiency initiatives that cover the reuse, repair, and remanufacture of electronic products. Key areas covered include; terminology; durability; upgradability, ability to repair, facilitate re-use; ability to remanufacture; recyclability, recoverability, RRR index, recycling, use of recycled materials; documentation and/or marking relating to material efficiency of the product, and critical raw material (CRM) declaration (Cormenier et al., 2018). The continued development and adoption of harmonized repair related standards globally and nationally can help coordinate repair economy regulation and support growth, ensuring minimum technical and environmental performance and health and safety standards are achieved (European Commission, 2022a). BS 8887-220:2010 “Design for manufacture, assembly, disassembly and end-of-life processing (MADE)” specifies the requirements for the process of remanufacture. The standard lists the steps needed to change a use product into an as-new product, with at least equivalent performance and warranty of a comparable new replacement product (British Standards Institute, 2010).

The European Standardization bodies CEN and CENELEC published CSN EN 45554: 2020 (BS EN 45554 in the UK) “General methods for the assessment of the ability to repair, reuse and upgrade energy-related products” which defines the criteria to determine how easy it is to repair, reuse or upgrade products such as household appliances and consumer electronics. The standard sets out the methodology for assessment criteria including availability of spare parts and repair information, and a method to aggregate relevant criteria into one repairability score. The standard includes CSN EN 45552 “General method for the assessment of the durability of energy-related products” and CSN EN 45553 “General method for the assessment of the ability to remanufacture energy-related products.”

Several standards exist setting out the general safety requirements for different electrical product categories. These include BS EN 60335-1:2012+A15:2021 which covers household and similar electrical appliances; BS EN 60950-1:2006+A2:2013 covers information technology equipment, and BS EN 61010-1:2010+A1:2019 covers electrical equipment for measurement, control, and laboratory use; BS EN 60950-1:2006+A2:2013 sets out different requirements for operators, lay people and for service people to reduce risks of fire, electric shock or injury. British Standards are not mandatory, and manufacturers can follow alternative guidance such as Directive 2014/35/EU to demonstrate the safety of their products.

BS EN 50614:2020 “Requirements for the preparing for re-use of waste electrical and electronic equipment” covers the process of preparing electrical products for reuse (British Standards Institute, 2020) and supersedes the previous PAS141:2011 “Reuse of used and waste electrical and electronic equipment”. The standard covers the processes that preparing for reuse operators need to carry out to ensure that electronics defined as Waste Electrical and Electronic Equipment (WEEE) are suitable for reuse, have been competently tested and are safe to use, and are functioning and fit for purpose. This standard is intended to be read in conjunction with EN50625 “Collection, logistics and treatment requirements for WEEE” series documents covering quantifying re-use, recycling and recovery rates. This standard does not cover activities connected with used or second-hand products defined as Electrical and Electronic Equipment (EEE) and does not cover assessment of repairer skills, competencies or safety.

2.2.4 Product health and safety conformity (UK CA)

Right to repair movements and other sustainability initiatives are calling for products to be designed to be repairable and longer lasting. Uncertainty exists in the UK and EU regarding both electronic product's health and safety regulation conformity and liability for defects arising from product repair (Van Gool, 2021).

The UK Conformity Assessment (CA) Certification was introduced in 2021 with the aim to replace the equivalent EU Conformité Européene (CE) Certification for products being placed on the market in Great Britain (England, Wales and Scotland). In 2023, the UK government announced the intention to introduce legislation to extend the recognition of the CE marking for placing most goods on the market in Great Britain indefinitely. The UK CA marking applies to most products including appliances and electrical equipment for which the CE marking can also be used (HM Government, 2023a). The general principles of the CE mark are contained in Regulation (EC) No 765/2008 which sets the requirements for accreditation and market surveillance relating to the marketing of products (European Union, 2008). Other Directives, Regulations or EU Commission initiatives exist that are closely related to CE/CA Marking and product compliance including the General Product Safety Directive, the Low Voltage Directive (LVD), the WEEE Directive, and the Batteries and Accumulators (and Waste Batteries and Accumulators) Directive, the Medical Devices Directive (CE Marking Association, 2014).

Both the CE and UK CA marking procedures are of self-assessment unless the relevant directives specifically state that a Notified Body (EU) or an Approved Body (UK) must be involved in the assessment of the products. The assessment involves product testing and a conformity assessment procedure subject to Standards and risk assessment. Commonly, electronic product repair, refurbishment or remanufacturing may require replacement or alteration of one or more component parts. In some cases where electronic products or machinery have been substantially changed or rebuilt this may constitute a new product or machine. It is then subject to the conformity assessment, marking and labeling requirements of the Supply of Machinery (Safety) Regulations 2008, and certification fees, even if originally compliant and marked when first placed on the market. Examples include fitting a computer control to a previously manual machine or the replacement of a machine which forms part of an assembly of machines. Examples that do not require re-certification include; originally compliant and CE/UKCA marked products that are refurbished and where parts are replaced with new similar versions; refurbishment of machinery products using disassembly and a rebuild to original specification using replacement parts (which may be newer designs); repainting a machine, undertaking servicing and routine maintenance; changing motors or replacing parts such as guards with essentially identical new ones; the replacement of original safety critical parts with newer better ones (Health and Safety Executive, 2023; HM Government, 2023b). Further clarification of CE/UKCA requirements for different electronic products that have undergone substantial alterations and component replacement during repair, refurbishment or remanufacturing is needed to ensure compliance and product safety.

2.2.5 Consumer protection law—Health and safety

To widen participation in the repair economy legal and regulatory mechanisms must be designed to support the safety of stakeholders in different product repair scenarios (manufacturers, independent repairers, household repairers) and to reasonably assign liability between parties if damage or harm is caused when carrying out a repair or caused by a repaired product. The ability of product safety regulation to protect citizens from harm depends on the extent to which it can keep pace with evolving product markets such as repair or other circular behaviors (National Audit Office, 2021). Concern has been raised that the unintended consequences of increased product lifespans due to repair may mean products are more likely to develop faults or be bought second hand, which may leave citizens more vulnerable to health and safety risks and increase manufacturer or repairer liability (National Audit Office, 2021; Pinsent Masons, 2021).

In the UK, the main sources of product liability and safety law are the Consumer Protection Act 1987, the General Product Safety Regulations 2005, and the Consumer Rights Act 2015 (derived from EU Directive 85/374/EEC Product Liability Directive). Other relevant Regulations include the Consumer Protection from Unfair Trading Regulations 2008 and the Consumer Contracts (Information, Cancellation and Additional Charges) Regulations 2013. These Acts ensure that manufacturers, distributors, suppliers, retailers, and others who make products available to the public are held responsible for damage or injuries products may cause. The rights of citizens set out under these Acts are not exclusive of other rights, therefore people who suffer damage as a result of defective products may also have rights under common law principles of tort and contract (Thomson Reuters, 2020; ICLG, 2023).

The Office for Produce Safety Standards (OPSS) is a UK Government national regulator and is part of the UK's product safety regime reforms. The role of this body is to address national product safety issues, including strengthening high-profile recall processes for home appliances, provide new support for local authority regulators, and develop new product and safety databases. The OPSS faces challenges in ensuring product safety in relation to growing the UK electronics repair economy. These include addressing gaps in regulators' powers over products and spare parts sold online, coordination of local and national regulation of repair related activities, and availability of adequate tools and data collection on the safety and performance of repaired electronic products (National Audit Office, 2021).

There is little evidence that repaired electronics present higher health and safety risk to citizens than new products. This is due to a lack of empirical data available on the health and safety performance of repaired electronic products, in the UK and elsewhere (Radovnikovic et al., 2020). It is critical to understand these risks (if any), without which real and perceived issues of health and safety will remain a significant barrier to growing the repair economy. Additionally, concern has been raised that wider participation from independent or household repairers in electronic product repair may increase the risk of personal or third-party damage or injury due to a lack of health and safety and skills training, standards and certification. Several repair training schemes exist or are in development that could help to address this concern.

2.3 Consumer protection law—Guarantees (warranties)

Under the Consumer Rights Act 2015 all products must be of satisfactory quality, fit for purpose and as described. Consumers have the right to claim repair or replacement of faulty goods under the Act if the product they have purchased fails to meet any one of the above criteria under a 6 year breach of contract period. Rights vary according to when a claim is made from date of purchase (up to 30 days, between 30 days to 6 months, and 6 months to 6 years) (HM Government, 2015). Subsections (14) and (15) of the Act provide that if the breach e.g., a fault, arises in the first 6 months from delivery it is presumed to have been present at the time of delivery unless the trader proves otherwise, making it easier for consumers to exercise their right to repair or replacement. However, after the 6 month period and up to 6 years after purchase the burden is on the consumer to prove that the fault existed at time of purchase (HM Government, 2015).

In many cases, retailers, manufacturers or third parties may offer commercial guarantees (express warranties) as standard or as an additional cost to the citizen which cover repairs outside of the implied 6 months period.

Second hand goods such as repaired or refurbished products bought from retailers are also covered by the Consumer Rights Act 2015 (and the Consumer Contracts Regulations 2013 if purchased from an online retailer). Under the Act retailers are required to notify a customer about any product faults or problems. If goods are purchased from a private seller (as opposed to a retailer) the goods must be as described, for example second-hand goods should not be described as new, but there is no obligation for a seller to disclose any faults (Which?, 2021). Further development of this Act may help facilitate the sale of repaired second hand goods in private markets whilst providing buyers with reasonable rights and protections against faulty products.

In comparison, EU law stipulates a minimum 2 year legal guarantee whereas several countries require even longer legal guarantee periods, including 3 years in Sweden, and up to 5 years in Iceland and Norway, and 6 years in Ireland. The Netherlands uses a method of calculating minimum legal warranty periods using the expected average life of the product, its price, the type of shop it was purchased from and producer information to determine the duration of the warranty (European Consumer Centre France, 2022; Perzanowski, 2022). Extending electronic product warranties in the UK in relation to expected product lifespan or other metrics could support higher repair rates by extending the period of manufacturer and retailer repair obligations for defective products and change manufacturer behaviors toward the design, making and selling of more durable products (European Commission, 2023). However, it should be noted that extending warranties would mostly impact retailers of electronics goods who are not in control of the design aspects of products and yet are liable for the costs of the warranty. Thus to have the desired effect any change in the law should apply to the brands and manufacturers of EEE goods sold in the UK.

Additionally, the right to elect replacement or repair under legal guarantees often means citizens and producers would choose the relative convenience of replacement over repair. Further development of this law to incentivise choosing repair by making sellers internalize the cost of replacing faulty goods could help (Perzanowski, 2022) as well as raising public awareness of the positive environmental impacts of repairing products.

2.4 Intellectual Property (IP) Law

Intellectual Property (IP) Law remains a significant barrier to growing the repair economy. Whilst IP Law is important to ensure a product is not illegally copied, reproduced or sold, in many cases it has been interpreted and used in a way that limits the ability to repair a product or to replace parts. IP Law covers several areas including copyright, designs, patents, and trademarks, and trade secrets (HM Government, 2020). Commonly identified manufacturer activities and interpretations of IP Law include limiting the repair of electronic products include restricting access to product manuals, parts numbering, software restrictions and locks, and planned obsolescence (European Commission, 2022a; Perzanowski, 2022).

In the UK the Intellectual Property Office (IPO) is the official government body responsible for intellectual property (IP) rights including patents, designs, trademarks and copyright (HM Government, 2023e). Currently there is a lack of harmonization in the application of IP Law across the EU, UK and elsewhere causing uncertainty in electronic product repair rights across businesses operating in the global markets (European Commission, 2022a). Better clarity and harmonization of IP Law is needed in the UK and elsewhere to increase confidence in repair businesses operations whilst ensuring reasonable IP protections, and to support repair economy growth.

2.5 Extended Producer Responsibility (EPR)

In this paper Extended Producer Responsibility (EPR) is defined as “an environmental policy approach in which a producer's responsibility for a product is extended to the post-consumer stage of the product's lifecycle” (OECD, 2016). In the UK, The Environment Act 2021 sets the framework for new and enhanced EPR regime with reference to certain product groups including electronic products. The EPR framework is intended to build on existing regulations such as (but not exclusive to) the Waste Electrical and Electronic Equipment (WEEE) Regulations 2013. The reforms of the WEEE Regulations with regards to EPR are under development and discussed further in “Identifying and collecting repairable products for reuse” section of this paper.

A UK Government consultation on EPR for the “Maximizing Resources, Minimizing Waste” programme highlights areas for EPR development, including for electronic products. These include EPR fee calculations and product sustainability assessment frameworks, how EPR funds will be used to develop UK's waste infrastructure (including reuse, repair and remanufacturing), safe repair of used products, the need for measurable reuse and repair targets, clarity on timelines and producer obligations, and the support of “recommerce” platforms to encourage greater use of repaired, remanufacture and reclaimed products. Clarity on categorization of EEE for reuse vs. WEEE for recycling and disposal, the need to support EPR changes with product specific design standards and requirements, and the need to provide better information for citizens on sustainable products and behaviors with labeling and education are also issues that need consideration (DEFRA, 2023).

2.6 Design skills for repairable products

The design of a product directly influences the way a product is managed throughout a product's life cycle and value chain, across production and use systems (Dindarian et al., 2012). Creating electronic products with circular attributes (i.e., durability, repairability, remanufacturing, recycling) requires new proficiencies in design and engineering practices, including design skills in sharing platforms, products as services (including remanufacture), product life extension (including repair, refurbishment, and upgrade), material recovery, and circular supplies (De Los Rios and Charnley, 2017). In this way, sustainability and circularity requires designers and engineers to operate on two levels: product and system (Bak-Andersen, 2021). Adding new areas of knowledge to design curricula, including design for durability, disassembly, repair and remanufacture, and a better awareness of the social and technical systems in which these practices occur, could support industries to move toward circular design and manufacturing practices (Hernandez et al., 2020; Bak-Andersen, 2021). Organizations like the Design Council and Ellen MacArthur Foundation have created a range of resources for students, teachers, and professionals to help incorporate circular economy design principles into education practices (Ellen MacArthur Foundation, 2020; Design Council, 2023).

2.7 Local context

Business rates have a significant impact on the operating costs and viability of businesses making and selling new or repaired electronic products.

2.7.1 Business rates

Business rates are charged on most non-domestic properties, including shops, factories and warehouses, and are calculated according to the “rateable value” of a business and its premises. Certain businesses are eligible for business rate relief, including startups, small businesses, or businesses located in designated “Enterprise Zones” (HM Government, 2023c). Current criticism of the UK's Business Rates tax rates and scope are that high street “bricks-and-mortar” shop tax rates are excessive and disproportionate (2.3% of total retail sales) when compared with online retailers that commonly use low-cost warehouses away from high streets or town centers (0.6% of online traders' sales) (Centre For Retail Research, 2020). This is largely seen as problematic and a disproportionate cause of “high street collapse” in town centers across many regions, including a loss of local investment and employment in communities (Greenhalgh et al., 2019). A possible policy option is to design business rates alongside other sustainable business finance initiatives, to incentivise more sustainable businesses like reuse and repair shops and services in local settings and support more circular business and citizen behaviors through rate relief or other exemptions (House of Commons Treasury Committee, 2019). Given that repair and reuse are essentially local activities, and that WEEE waste collection and costs are also local—there are significant advantages for local communities of a stronger repair economy. This would then impact national and global WEEE production and flows as shown in Figure 2.

3 Identifying and collecting repairable products for reuse and repair

See Figure 6.

Figure 6. Table summarizing reviewed topics under the theme of “Identifying and collecting repairable products for reuse and repair”.

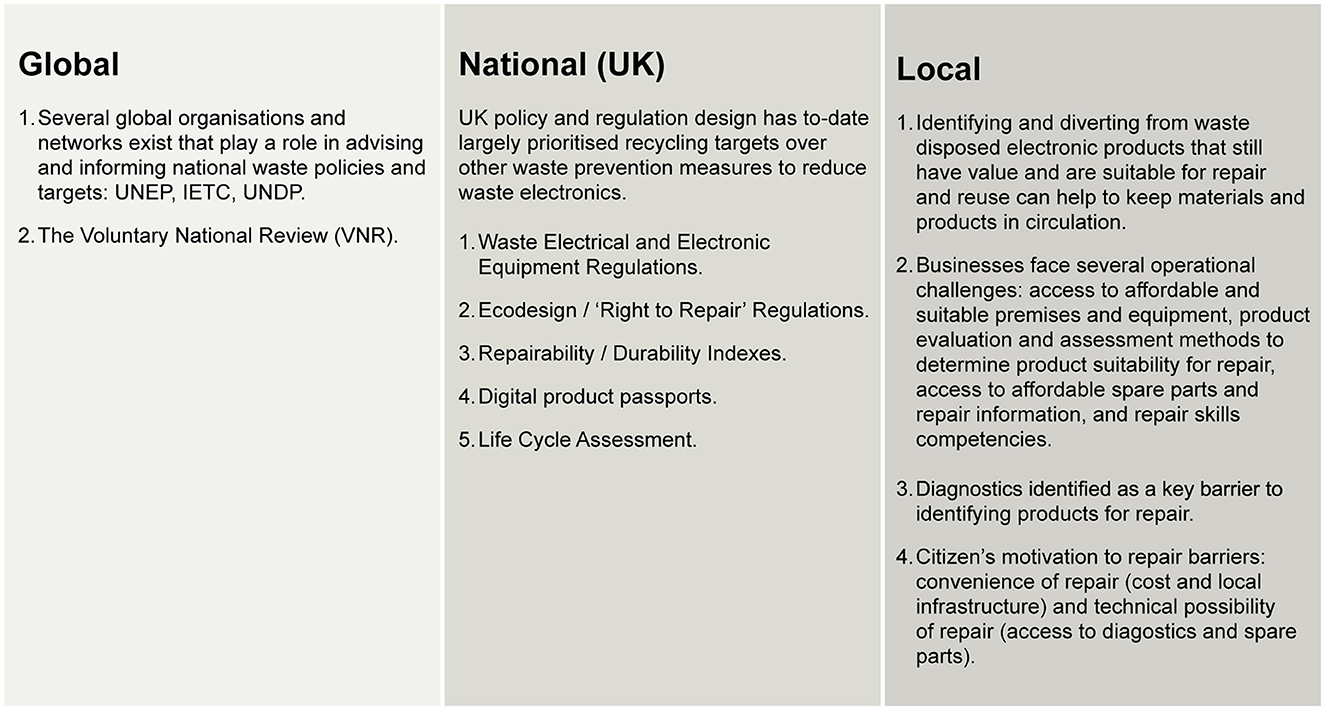

3.1 Global context

Several global organizations and networks exist that play a role in advising and informing national waste policies and targets. The UK is an active member of the United Nations Environment Programme (UNEP) and the International Environmental Technology Center (IETC), and the United Nations Development Programme (UNDP). UNEP and the IETC supports national and local governments and other stakeholders to develop strategies and policies for better management of wastes including electronic waste (UNEP, 2019). As a UNEP member state, the UK has a role in approving the programme of work and budget, and is also a financial contributor to UNEP's core funds. Other international organizations that have a role in national waste policies and targets, of which the UK is not part of, include the International Environmental Partnership (IEP), and International E-Waste Management Network (IEMN), which are active across Asia-Pacific regions, the Americas, and Africa (IEMN, 2021).

Several multilateral environmental agreements and international conventions exist aimed at regulating the transport of electronic waste. These include the voluntary United Nations Sustainable Development Goals (SDGs), the (UNEP, 1989), and the (UNEP, 2001). At European level, the EU Commission is responsible for EU-wide waste recovery and recycling targets, including batteries and WEEE. Member states are required to share data on these waste streams in order for the EU Commission to monitor member state's compliance with Directive targets.

The Voluntary National Review (VNR) is a process by which UN member countries assess and present national progress in implementing the SDGs. Currently there is a lack of standardization in content and reporting, making it difficult to compare progress across members. Agreements such as the Basel Convention do not specifically cover second hand or repaired electronic products, and differences in national application of regulations cause delays and cost increases for importers and exporters of second hand and repaired electronics (Milovantseva and Fitzpatrick, 2015). New agreements for these products could be added to management frameworks to help regulate the circulation of second hand and repaired electronic products globally, including developing harmonized standards and classification methods for their durability, availability, and safety performance (Milovantseva and Fitzpatrick, 2015; Liu et al., 2023). New global and national targets for reuse and repaired electronic products could help increase market stability and supply and demand for repaired electronics. Greater data transparency and sharing across countries would be needed to monitor progress.

3.2 National context

UK policy and regulation design has to-date largely prioritized recycling targets over other waste prevention measures to reduce waste electronics. This is problematic due to the associated impacts and emissions of electronics recycling, intensified by the projected increase in overall global consumption rates, calling for an increase in other waste prevention measures including reuse and repair (Green Alliance, 2019).

3.2.1 Waste electrical and electronic equipment regulations

Identifying electronic products that have higher “waste hierarchy” potential such as reuse, repair or remanufacturing and diverting them away from waste electronic collection and processing such as recycling or landfill/incineration can help retain product value and reduce environmental impacts (Cole et al., 2017).

In the UK the Waste Electrical and Electronic Equipment (WEEE) Regulations 2013 aim to achieve reduction in waste electronic products being sent to landfill or incineration using alternative measures including recovery, reuse and recycling of products and components. Under the Regulations electronics producers (marketing over 5 tons in the UK) are obligated to join a Producer Compliance Scheme (PCS) under Extended Producer Responsibilities (EPR), and contribute to the financing of collection, treatment, recovery and disposal of household WEEE. Distributors must offer free WEEE take back schemes, accept WEEE for free from customers supplied with like-for-like products, keep WEEE records, and provide customers with written information on the service provided and what they should do with their WEEE. Retailers with a sales area of EEE >400 sqm must also accept small WEEE (<25 cm) for free from private household customers at their retail site or nearby without the requirement to buy a new product (HM Government, 2014, 2021b, 2023d). Additionally, preparation for reuse guidelines as part of WEEE Regulations include recovery operations by approved authorized treatment facilities (AATF) such as checking, grading, cleaning or repairing products or components (HM Government, 2019).

In a recent consultation, UK Government has proposed reforming the WEEE regulations through extending producer responsibilities: for financing kerbside collection of small households EEE; for internet sellers to provide free of charge waste collection on delivery service on a like-for-like basis; for online market places to make financial contributions to WEEE management; for retailers to offer take-back of unwanted equipment without the need for new purchase; and to introduce a new Scheme Administrator (for Producer Compliance Schemes); and to measure performance of future WEEE EPR (DEFRA, 2023).

However, the UK's WEEE collection, processing and preparation for reuse system continues to face several challenges. Studies suggest that a common issue faced by organizations involved in diverting electronics for repair and reuse markets from waste streams is the poor condition of donated or disposed electronic products (Cole et al., 2017). This includes damage (i.e., scratches, dents, water damage) incurred during the storage and transport of products thereby reducing value and potential for reuse or repair. Diverting products as far upstream in the WEEE collection process as possible could help to mitigate this damage and yield higher reuse and repair rates (Johnson et al., 2020). Having mandatory reuse targets for producers, alongside encouraging collection upstream through increased collection responsibilities (as planned under latest consultation) can stimulate circular business models and the circular economy.

Another issue is the lack of standard methods for grading the condition of different electronic products across the electronics supply chain which can cause citizen mistrust, high return rates and decrease product value (Fixably, 2023). Organizations like CTIA are developing methods that could form the basis for industry wide grading standards (CTIA, 2018).

Other issues to be addressed include method discrepancies in calculating WEEE using weight as opposed to number of units, and low citizen awareness and uptake of correct waste electronics disposal practices (i.e., signage, labeling and communication) (Ongondo and Williams, 2012; Johnson et al., 2020).

3.2.2 Ecodesign/“Right to Repair” regulations

A measure that has been introduced in the UK and other countries to reduce WEEE waste and reduce CO2 emissions are Ecodesign Regulations, also referred to as “Right to Repair” Regulations (Green Alliance, 2020a; House of Commons Library, 2021; Möslinger et al., 2022).

UK “Right to Repair” regulations came into force in July 2021 as part of the Ecodesign for Energy-Related Products and Energy Information Regulations 2021 (SI 2021 No. 745) (House of Commons Library, 2021; UK Parliament, 2021). These Regulations apply to Great Britain, with Northern Ireland subject to EU Ecodesign requirements under the Northern Ireland Protocol (House of Commons Library, 2021). These Regulations aim to increase producer responsibility, reduce energy usage and electrical waste, and enable citizens to identify more energy efficient products (House of Commons Library, 2021). They also increase the responsibilities of electronics manufacturers to provide spare parts and technical repair information and aim to increase consumer product lifespans by up to ten years by giving professional repairers access to spare parts and technical information from July 2021 (manufacturers have a grace period of up to 2 years to make parts available). Rights to access spare parts and maintenance information should enable citizens to repair appliances when they break and continue to use them even when their statutory rights to have them repaired or replaced under Consumer Rights Act 2015 have expired (House of Commons Library, 2021).

Currently the UK's “Right to Repair” Regulations do not cover the full range of electrical and electronic equipment (EEE) goods contributing to WEEE waste. It only covers dishwashers, washing machines, washer-dryers, refrigeration appliances as well as televisions and electronic displays. Several organizations are calling for UK Government to go further and cover more electronics and appliances within scope, in particular laptops and smartphones (House of Commons Library, 2021) and to better regulate the cost and accessibility of spare parts (House of Commons Library, 2021). The Regulations also do not include a requirement to publish information about the repairability of products based on an agreed repairability assessment framework.

Although Ecodesign standards and labeling initiatives have been successful in improving the energy efficiency of household electronics and appliances (Green Alliance, 2020a), both electronics markets and electronic waste volumes continue to grow rapidly suggesting additional measures are needed to prevent the wider impacts of electronic product consumption and waste.

3.2.3 Repairability/Durability Indexes

Several countries have implemented (or are planning to implement) a mandatory “repairability index” under “Right to Repair” Regulations. Repairability indexes give customers information at the point of sale about the ease and cost of repair (European Commission, 2020; Lindice de réparabilité, 2020; Ministère de la Transition écologique et de la Cohésion des territoires, 2020; La Moncloa, 2021). A repairability index is intended to act in a similar way to energy efficiency ratings, providing information to help citizens make more informed purchasing decisions, and to provide a level playing field to drive manufacturer design and innovation toward more repairable and longer lasting products (Dangal et al., 2022). The UK does not currently have a repairability index as part of its Ecodesign “Right to Repair” regulations but it was one of the agreed outcomes of a Royal Academy of Engineering roundtable that such a measure would have support across the sector (UCL Plastic Waste Innovation Hub, 2021). A citizen science study called the Big Repair Project shows evidence that UK citizens are largely in favor of implementing a UK repair assessment framework (UCL Plastic Waste Innovation Hub, 2022a).

Over the last few years several countries and organizations have developed tools and standards for evaluating and communicating the repairability of EEE products. These include the France Repairability Index, EN 45554, and the Austrian Durability Label (ONR 192 102:2014). Other frameworks in development include the EU Durability Score and Spain Repairability Index (UCL Plastic Waste Innovation Hub, 2022b).

A prevalent example is France's Repairability Index which covers smartphones, laptops, televisions, porthole washing machines, lawnmowers, top washing machines, dishwashers, vacuum cleaners, and high-pressure cleaners (Lindice de réparabilité, 2020; Ministère de la Transition écologique et de la Cohésion des territoires, 2020). The index calculation method assesses five criteria; (1) Documentation; (2) Disassembly; (3) Availability of spare parts; (4) Price of spare parts; (5) Product-specific aspects (such as software aspects of smartphones or laptops). Sellers are obligated to display the index near the product at point of sale and online next to the price of the product. Manufacturers are free to find additional ways of displaying the index, such as displaying the index on product packaging or adding a QR code information link. Additionally, manufacturers must communicate, free of charge, the rating and the details of the repairability index rating to any person who requests it within 15 days (Right to Repair, 2021).

The France Repairability Index has several challenges. The index scores are self-declared by manufacturers and France's market surveillance authorities have limited capacity to monitor compliance. Also, the price of spare parts fluctuates over time and location. Although the French repair index includes an assessment criteria for spare parts pricing, the prices declared are the expected prices at the time of compiling the score and as such may fluctuate after assessment has been carried out (Right to Repair, 2021). A price of spare parts assessment model and methodology should be examined further (BEUC, 2022). There is also a call to address shortcomings on methodology, display to consumers, and additional durability information including a ‘guaranteed lifespan' label, informing citizens of the minimum lifetime guaranteed of a product. Citizen expectations and repair experiences should also be monitored to assess any potential repair index revisions needed (HOP, 2022).

Although the UK Government has not implemented its own index, many electronic product manufacturers that sell into the UK, EU and other markets globally have chosen to meet France Repairability Index obligations across markets generally. Initial studies suggest that repair indexes are changing manufacturer and citizen behaviors, including raising awareness of the importance of electronics repair, and improving the availability of repair information (HOP, 2022).

3.2.4 Digital product passports

Digital product passports (DPP) are a tool for collecting and sharing a range of product data including material or chemical composition and environmental impacts throughout the entire product life cycle, and are regarded as an important measure needed to support circular product supply chain management and decision making, including for reuse and repair (Foldager Jensen et al., 2023). As part of Extended Producer Responsibility the European Commission are introducing a Digital Product Passport (DPP) initiative, with the aim to implement legislation covering product categories including consumer electronics and batteries by 2026. Elements of DPPs will include a unique product identifier (UID), a QR code data carrier, compliance documentation, and information related to the manufacturer or person placing the product on the market. DPPs could make it easier to repair and recycle products, facilitating the tracking substances of concern and maintenance and repair activities across the supply chain (European Commission, 2022a).

The UK does not have a DPP initiative yet but will likely need to prioritize development of this regulation in view of the forthcoming EU DPP initiative, requiring significant changes to information and data flows for most products in the EU and UK (World Business Council for Sustainable Development, 2023a).

There are several key challenges to the successful development of DPPs for the UK. Policymakers face the challenge of balancing mandatory data requirements for digital product passports requiring data transparency and protecting Intellectual Property Rights permitting actors to withhold critical data. Additionally, certain product data is more readily available including product manuals, whereas collecting data related to environmental performance and circularity will require prioritization. In particular, data needs and standard data assessment and collection methodologies should be further defined to ensure data consistency in the categories of (1) Usage and maintenance, (2) Product identification, (3) Product and materials, (4) Guidelines and manuals, (5) Supply chain and reverse logistics, (6) Environmental data, (7) Compliance (Foldager Jensen et al., 2023).

Organizations like the World Business Council for Sustainable Development have created tools to illustrate information flows for DPPs under different actor scenarios in electronic product supply chains (World Business Council for Sustainable Development, 2023a,b). In addition to DPPs there are several other voluntary initiatives that exist that share similar aims to improve the availability of product information. These include Environmental Product Declarations (EPDs), Greenhouse Gas Protocol, Science Based Targets Initiative (SBTI), European Battery Alliance (EBA), Global Battery Alliance (GBA), Industrial Deep Decarbonisation Initiative (IDDI), Partnership for Carbon Transparency (PACT). DPPs could provide a platform to synthesize information across these initiatives [University of Cambridge Institute for Sustainability Leadership (CISL) the Wuppertal Institute, 2022].

3.2.5 Life cycle assessment

Repair of electronic products has been identified as an important strategy for reducing CO2 emissions (Bovea et al., 2020). Understanding the social and environmental impacts of electronic products across the whole product life cycle (including material extraction, manufacture, in-use, and end-of-life) is useful to determine the best circular pathways and end-of-life options for products (including reuse, repair, remanufacture, and recycling) and to inform policy development (environmental targets and regulation) and stakeholder behaviors (including product design, purchasing, and use).

In many cases, extending the lifespan of appliances and electronics through repair is the best option environmentally. Bovea et al. (2020) conducted life cycle assessments on nine common categories of domestic appliances and demonstrated that in most cases repair is preferential to replacement, unless the appliance is near the end of its expected lifespan. There are a few types of failures, such as with the Printed Circuit Boards (PCB) of vacuum cleaners, hand blenders and heaters, and the replacement of motors, where replacement is a better environmental choice than repair. This type of assessment has the potential to help citizens assess their product failure against the average lifespan of the product, which for the nine categories examined, ranges from 6 to 8 years (Bovea et al., 2018).

Other LCA studies highlight that there are different optimal lifespans for electronic products, 3.4–30 years for microwaves, 2.7–26.2 years for dishwashers, and 4.6–33.9 years for washing machines. This is due to the balancing of embodied and environmental impacts from production and end-of-life phases with energy performance of certain high energy-in-use product categories (Devoldere et al., 2006; den Hollander and Bakker, 2012; Alejandre et al., 2022). This suggests that for high energy-in-use products like major appliance, energy performance is a significant contributing factor to overall environmental impacts and should be considered alongside other factors like age of product to determine whether repair or replacement is the better option at the point of product failure. Other studies suggest many products' energy efficiency performance in-use is improving, with the relative importance of embodied impacts from production and end-of-life disposal increasing (Cooper and Gutowski, 2017; Cheung et al., 2018).

Several assessment frameworks are in development. They are aimed at helping different repair pathway stakeholders (i.e., citizens, repair professionals) make informed decisions about whether repair or replacement of an electronic product is the best option environmentally (Bovea et al., 2016a,b; Bracquené et al., 2019; Tech-Takeback, 2023). Similarly, Life Cycle Costing (LCC) frameworks have also been developed to ascertain the financial impact of repair and reuse on annual product ownership costs (Brusselaers et al., 2019). Further research and design development is needed to validate and standardize these framework methods and calculations for different product categories in a UK context.

3.3 Local context

Identifying and diverting from waste disposed electronic products that still have value and are suitable for repair and reuse can help to keep materials and products in circulation. This can help to reduce the negative environmental impacts associated with making new products or end-of life pathways such as landfill or incineration. There are several different examples of hybrid electronics collection, reuse or resale business models being carried out by local authorities, businesses, and other organizations in the UK. Figure 2 illustrates the impact of the grow of these local repair ecosystems and their impact of changing WEEE flow in a national and global context.

3.3.1 Local reuse and repair services

Although a minority, there is increasing UK market demand for secondhand refurbished, repaired or remanufactured electronics in the UK, including general electronic items like mobile phones, laptops and monitors, and other product categories such as “white goods” and “household appliances” (Office for Product Safety and Standards, 2021b).

SUEZ and the Greater Manchester Combined Authority (GMCA) and other Greater Manchester local authorities have created a Renew Hub and shops with the aim of reclaiming the value of household items including electronics through repair. Items are donated and collected in containers at recycling centers then delivered to the Hub, refurbished, and distributed and sold through Renew shops, or online via eBay. The Hub also provides premises for a range of partner organizations, providing a range of services and employment including white goods and electrical repairs and repair training courses and apprenticeships (SUEZ, 2021). SUEZ also operate a number of bespoke electronic waste collection services for households and businesses. Restart Project's Fixing Factory initiatives in London are community repair hubs offering collection of donated second hand electronics as well as repair services and repair skills training for local residents (Fixing Factory, 2023). Tech-Takeback operate a waste electricals collection service for households and businesses in Brighton and Hove in conjunction with a high street shop selling repaired electronics as well as repair services and repair skills training (Tech-Takeback, 2023).

These businesses and other initiatives face several operational challenges. These include access to affordable and suitable premises and equipment, product evaluation and assessment methods to determine product suitability for repair, access to affordable spare parts and repair information, and repair skills competencies. Further research into business and funding models in conjunction with local services provision is needed to help inform national and local policies to support reuse and repair initiatives in local authorities.

An existing barrier to identifying repairable household appliances is the lack of reliable, accessible and affordable fault diagnostics for owners (Roskladka et al., 2023). Research has shown that diagnostics are often hindered by the product's design where access to and visibility of components are blocked, making fault isolation challenging. User manuals commonly lack relevant explanations, for instance when symptoms are different from error codes (Pozo Arcos et al., 2020). This is creating a significant technical and economic barrier for owners where professional diagnostics with specialist equipment and/or involving disassembly are required before the viability and cost of repair can be ascertained.

The success of policy initiatives (Right to Repair Regulations, WEEE regulations, EPRs) depends to a significant degree on the citizen's motivation to repair—if a product fails, it is the owner's choice what to do with it. Recent study findings reveal that convenience of repair (in particular, the costs of repair services and limitations in repair infrastructure) and the technical possibility of repair (lack of spare parts and diagnostics) are the most significant barriers affecting consumers' choice to repair or replace (Roskladka et al., 2023). Further research is needed to understand citizen barriers and motivations to repair and to inform the development of localized repair infrastructures and services.

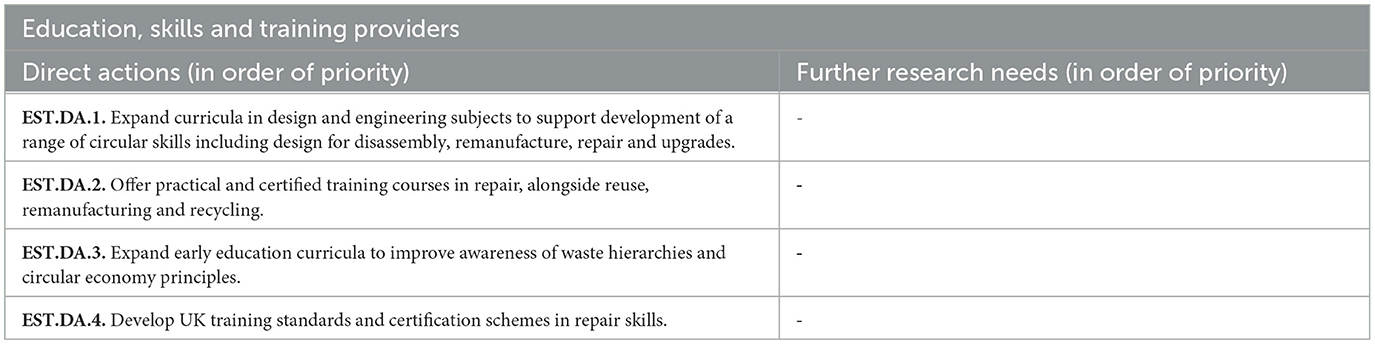

4 Repair services, skills, and education

See Figure 7.

Figure 7. Table summarizing reviewed topics under the theme of “Repair services, skills and education”.

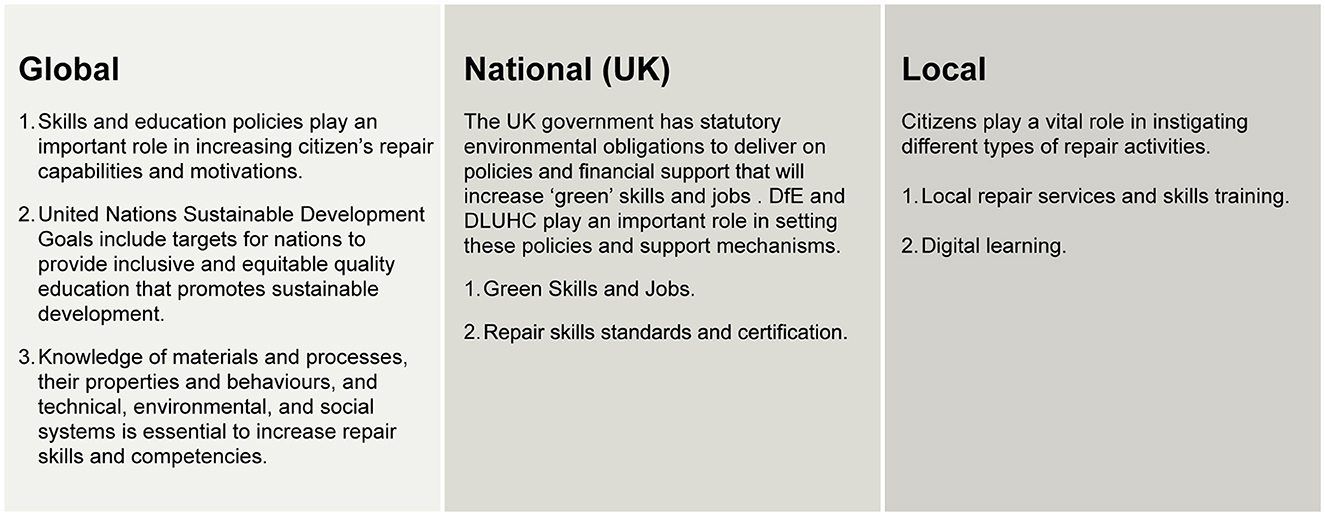

4.1 Global context

For citizens and other stakeholders to participate in the repair economy they need the capability, opportunity and motivation to do so (Public Health England, 2019). Skills and education policies play an important role in increasing repair capabilities (i.e., knowledge, physical and mental skills) and increasing repair related motivations (i.e., desires, emotions, habits) through better awareness of the environmental and social importance of repair. This can help increase education and employment opportunities in repair related training and businesses and support repair economy growth.

Globally, the United Nations Sustainable Development Goals include targets for nations to provide inclusive and equitable quality education including; equal access to affordable technical, vocational and higher education; increasing the number of people with relevant skills for financial success; ensuring learners acquire the knowledge and skills needed to promote sustainable development (United Nations, 2015). Provision and access to repair services and skills varies globally with reuse and repair services forming a relatively large part of “informal sector” economies in several countries of the Global South (UK Foreign, Commonwealth and Development Office, 2022). For example, in Kenya the repair and reuse sector accounts for 1.5% of its economy (£1.12 billion GBP) (Munro et al., 2022).

Knowledge of materials and processes, their properties and behaviors, and technical, environmental, and social systems is essential to increase repair skills and competencies and to enable more people to repair things safely and successfully (Hernandez et al., 2020; Bak-Andersen, 2021). Increasing fair access to skills and knowledge related to materials, products and repair through national frameworks, targets and policies will be vital to support national and local repair economy development.

4.2 National level

The UK government has statutory environmental obligations in delivering the government's 25 Year Environment Plan and Net Zero Strategy, which include obligations under the Climate Change Act (2008) and the Environment Act (2021) to deliver on policies and financial support that will increase “green” skills and jobs (including those related to repair) across the UK (HM Government, 2022b).

4.2.1 “Green” skills and jobs

The Department for Education (DfE) and the Department for Leveling Up, Housing and Communities (DLUHC) play an important role in setting the policies and financial support for sustainable or “green” education and employment services in the UK.

The DfE is responsible for children's services and education, including early years, schools, higher and further education policy, apprenticeships, and wider skills in England. In 2022 the DfE published commitments to improve education sector sustainability, including to promote learning about environmental sustainability, climate change and the circular economy (HM Government, 2022b). This includes education funding opportunities to address skills gaps in local communities including the Local Skills Improvement Fund. This funding is available to further education providers with the aim of renovating facilities and equipment, upskilling teachers, delivering new courses related to sustainability skills (i.e., green construction) to address the changing needs of local employers (HM Government, 2023f).

The Department for Leveling Up, Housing and Communities has responsibilities including local area investment, growth and jobs creation, and community group support. The Department is responsible for managing different funding streams to local government, including local body core funding, Towns Fund, Leveling Up fund, and the UK Shared Prosperity fund (HM Government, 2023g).

The National Audit Office is currently carrying out a study into whether these funds have clear aims and objectives, have been distributed in line with their objectives, and how these funds are being monitored and evaluated (National Audit Office, 2023).

UK government launched a Green Jobs Taskforce in 2020 to address challenges of long-term planning and coordination of “green” skills and education provision with “green” industry growth. Recommendations include better assessment of supply and demand of skills mix needed (i.e. skills and knowledge of materials and processes), a public campaign to raise awareness of the benefits of circular behaviors (including repair), increased investment in “green” businesses and employment in local communities (i.e., repair cafes and hubs), tax deductions for training, local skills plans linking businesses and higher accounting for local contexts, and creation of a UK wide body and framework to align development of skills and education and business and employment opportunities across policy and industry (HM Government, 2021c; Green Alliance, 2022).

In the context of the increasing demand for electrical engineering skills to facilitate the UK's Environment Plan and Net Zero Strategy, industry is reporting “a critical shortage” of certified engineers (mechanical and electrical) and welders, also projecting that 20% of the existing workforce will retire this decade (Energy and Utility Skills Partnership, 2020). Skills in the retired population can be harnessed in the repair economy, however skills shortages can become a significant barrier to growing the repair economy and action should be taken to promote engineering skills across the education framework through secondary, higher education and apprenticeships (Royal Academy of Engineering, 2023).

4.2.2 Repair skills standards and certification

Electronic product repair activities can vary in their complexity and may require a range of skills and tools to undertake them safely and successfully. Concern from industry stakeholders and statutory safety authorities on product repair safety has been raised. In response, repairer competency training and certification schemes have been developed. EEEsafe is a voluntary training and certification scheme covering “white goods” appliance repair competencies in the UK including equipment, skills and insurance (EEEsafe, 2023). The Cellular Telephone Industries Association (CTIA) runs a technician certification programme in the United States covering technician training and certification for the repair of wireless devices (CTIA, 2023). These schemes are voluntary and limited in product scope, with further potential for development. Additionally, the following standard is under development 61/6511/NP, PNW TS 61-6511 ED1 “Household and similar electrical appliances—repair, refurbishment, and remanufacturing of an appliance and subsequent safety testing—General safety requirements” (British Standards Institute, 2022). This standard is intended to be supplementary to additional requirements on the safe use of electronic products specified by national health and safety authorities and UK CA/EU CE safety conformity.

4.3 Local context

Citizens play a vital role in instigating different types of repair activities, either choosing to repair products themselves or using a third-party repairer, usually a manufacturer repair service or an independent repairer. In general, citizens are more likely to use third-party repair services but many prefer to tackle a range of types of repair themselves. If choosing to repair products themselves, commonly identified barriers include lack of skills and knowledge, access to repair information and tools. If citizens choose to repair products using third party repair services, commonly identified barriers include cost uncertainty of repair services and inconvenience (UCL Plastic Waste Innovation Hub, 2022a; Office for Product Safety and Standards, 2023). A significant impact of a stronger repair economy could result in a significant reduction of the production of WEEE waste by extending the lifespan of EEE. It would require an increase in local repair skills and repair businesses, as illustrated in Figure 2.

4.3.1 Local repair services and skills training

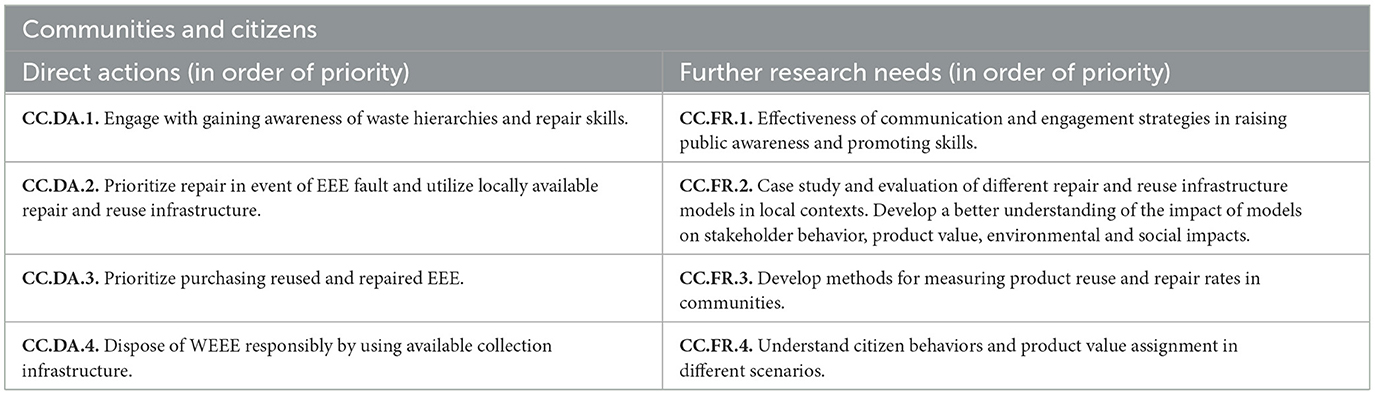

In the UK several initiatives, services, organizations and businesses exist that aim to widen participation, education and awareness in electronics repair in a variety of scenarios. An example is the One World Living Action Plan, one of seven London-wide local authority climate programmes committed to “Act ambitiously to meet the climate challenge that science sets out and find political and practical solutions to delivering carbon reductions that also secure the wellbeing of Londoners” (London Councils, 2022). As part of this programme the London Borough of Hammersmith and Fulham are developing and implementing actions to increase electrical product lifespans and increase circular behaviors including reuse and repair within the borough. These include establishing a network of repair and reuse hubs, providing space and funding for repair cafes, and extending and maintaining a Repair Directory (Restart, 2022). Other actions include awareness raising campaigns, exploring options for a London repair standard, and reviewing council IT procurement and policies to slow down electronic replacement cycles (London Councils, 2022).