95% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

ORIGINAL RESEARCH article

Front. Sustain. , 22 April 2024

Sec. Sustainable Supply Chain Management

Volume 5 - 2024 | https://doi.org/10.3389/frsus.2024.1387907

This article is part of the Research Topic Circular Economy in Sustainable Supply Chain Management: Practices and Strategies in the Manufacturing Industry View all articles

Introduction: Onion is a significant vegetable crop in Ethiopia, serving as a source of income for smallholder farmers. However, various challenges in the production and post-harvest handling processes impede a consistent supply and marketing of the crop. This study focused on a comprehensive analysis of the onion supply chain, ranging from production to post-harvest handling, to address the existing production and marketing processes. The research initiative was undertaken to map the onion supply chain from farmers to consumers, intending to establish an improved marketing system in northwest Ethiopia.

Methods: The study area covered three onion-producing districts of the Amhara Region. Data collection involved interviews, observations, and market assessments using a structured questionnaire. Sampling followed a multistage technique. The analysis included descriptive statistics and food system analysis to map the supply chain and estimate marketing margins.

Results and Discussion: Post-harvest loss in onion production presents a major obstacle in the farming sector, impacting its growth. The study identified six alternative channels for onion marketing where different actors are involved throughout the supply chain. Key stakeholders include farmers, local collectors, brokers, transporters, wholesalers, retailers, and consumers. Packaging and sorting activities are implemented at different supply chain stages to minimize post-harvest losses. Farm-level activities, including curing, sorting, grading, and ventilating, are crucial for reducing losses. The perishable nature of onion bulbs and the existing production and handling challenges exacerbate post-harvest losses. Efforts to address this challenge demand a comprehensive approach, integrating interventions across the value chain, from improved cultivars and storage infrastructure to enhanced market access strategies. Hence, stakeholders and governmental organizations are urged to promote onion value-addition technologies, including the establishment of processing industries. Such endeavors promote collaborative efforts across the onion supply chain, ensuring sustainable benefits for producers and traders.

Ethiopia’s diversified agro-climatic conditions are suitable for producing a variety of vegetable crops produced through commercial as well as small-scale farms both as a source of income as well as food (Dawit et al., 2004; Lemma et al., 2006). Onion (Allium cepa) is considered one of the second most important vegetable crops in Ethiopia, produced on a small scale and large scale for home consumption and exporting (Lemma and Shimelis, 2003).

Among vegetable crops, onion takes an economically important place. The area covered under onion is increasing from time to time, mainly due to its high profitability per unit area (Lemma and Shimelis, 2003).

In Ethiopian agriculture, onions play a pivotal role as a lucrative cash crop (Adugna, 2021), cultivated across various regions for both local consumption and export. Beyond meeting domestic demands, onions significantly contribute to the national economy, with products like bulbs and cut flowers being exported globally (Lemma and Shimelis, 2003). The market report from ETFRUIT (2005) reveals an annual onion sales estimate of 2.0 million Birr, underscoring Ethiopia’s substantial potential for economic gains from onion cultivation.

Onion stands as a pivotal cash crop for farmers in northwestern Ethiopia, driving economic prosperity (Getu and Ibrahim, 2018). The dynamism of marketing, shaped by year-round consumer demand, influences the diversification pace (CSA, 2016/2017). To elevate production and productivity across supply chains, a conducive environment is essential for efficient marketing distribution, as emphasized by the (MOA, 2020).

The supply chain paradigm is vital for advancing sustainable onion production, providing valuable insights for policymakers, practitioners, donors, and academics (Masamha et al., 2018). Onions, prone to post-harvest losses due to elevated moisture content, encounter challenges throughout the production cycle. Quantitative losses, attributed to factors like mechanical damage, diseases, pests, bruising, and shriveling, alongside qualitative losses impacting acceptability and edibility, hinder seamless market supply (Kitinoja and Kader, 2002).

Ethiopia’s seasonal onion production (October to March) affects shelf life, posing challenges for year-round market demand (Pessu et al., 2011). The onion supply chain, crucial for market planning and distribution (Carvalho et al., 2012), requires effective strategies to ensure consistent and sustainable supply. Comprehensive approaches are needed to address post-harvest challenges and enhance onion production and utilization.

Evidences revealed that substantial constraints in Ethiopia’s onion production and marketing industry, including as access to quality inputs, agronomic practices, extension services, disease management, and market dynamics (AgroBIG, 2016; Abebe, 2018). Despite onions being a vital source of income, issues such as inadequate storage, improper handling and transportation networks, pricing inefficiencies, and market coordination gaps continue to impede sector expansion. Addressing these multifaceted challenges is crucial to improving productivity, livelihoods, and overall economic resilience in Ethiopia’s onion supply chain. This study, which focuses on the production and post-harvest processes in Northwest Ethiopia, attempts to identify areas for improvement and offer interventions to increase the efficiency and resilience of the onion supply chain. By examining production methods, and market dynamics, the study hopes to provide actionable insights for strengthening the onion supply chain and promoting sustainable farming practices in the region. We expect that this analysis can give valuable insights for decision makers, scholars, and industry stakeholders who want to strengthen the onion supply chain and boost regional economic development.

This paper examines into the onion production and post-harvest processes in Northwest Ethiopia to find areas for improvement and offer strategic interventions that can improve the supply chain’s overall efficiency and sustainability. It underscores the significance of onion supply chain analysis as a pivotal strategy for addressing existing challenges throughout the chain. Previous research in the study area primarily focused on onion production and marketing, lacking comprehensive insights into the overall mapping of onion supply chain actors. Despite the strategic importance of onion production for income generation, there is a scarcity of evidence on market nature, value addition at each segment, and the roles of various actors. To bridge this gap, our study aims to thoroughly investigate the onion supply chain, mapping actors, understanding their roles, and exploring linkages.

This research strives to answer key questions: Who are the actors in the onion supply chain, what roles do they play, what are the constraints in onion production and marketing, and what factors drive onion production, marketing, and post-harvest losses? As the first of its kind in Northwest Ethiopia, this study comprehensively analyzes the onion supply chain, providing valuable insights from production to post-harvest handling.

Managerial benefit of this study: the study strives to provide useful insights to transform resource management and sustainability in onion supply chains. It can enhance resource usage, reduce waste, and promote circular resource management paradigms by conducting thorough analysis. This helps to improve both environmental stewardship and economic viability by deliberately examining post-harvest systems, identifying sources of waste and implementing effective recovery plans. With a thorough understanding of the onion supply chain can streamline operations, increase efficiency, and reduce environmental impact through proactive planning and collaborative efforts. Likewise, this study promotes the use of sustainable methods such as organic farming and energy-efficient processing, hence accelerating environmental consciousness across the food chain. Moreover, these comprehensive studies can provide decision makers with insights into their vulnerabilities to external shocks, allowing them to strengthen resilience through diverse strategies and climate-resilient practices. Collaboration among stakeholders develops a culture of transparency and responsibility, resulting in superior sustainability outcomes throughout the onion supply chain. This multidimensional strategy not only promises real benefits, but it also establishes firms as leaders in sustainable supply chain management, with far-reaching consequences for industry standards and environmental conservation efforts. Ultimately, the findings seek to enhance the commercialization of onion production and improve the income of onion producers in the region.

The article contains five sections. The first section provides background information about the study, stating the problem, research gaps, and research objectives (introduction). The second section deals with the methodology, which includes study area description, methods of data collection, and statistical methods for data analysis to achieve study objectives. The fourth section explains the major findings of the study. The fifth section outlines the major findings of the study and provides suggestions and future research areas.

As can be seen the summarized content of Table A1. Since the 1980s, the importance of supply chains has steadily increased as companies in various industries realize the benefits of establishing collaborative relationships both within and outside of their own organizations (Gallo et al., 2019).

According to Van der Vorst et al. (2007) and FAO (2007), a supply chain encompasses the end-to-end processes from production to consumption, involving multiple organizations to fulfill customer demands. It manages the flow of materials, information, funds, and products, covering product development, marketing, operations, sales, and customer service. Supply chain mapping visually represents its structure to comprehend functionality and complexity. The food supply chain scrutinizes production, storage, transportation, trading, processing, and retailing, influenced by external factors like transportation and regulatory bodies. Business services, providing inputs and assistance, interact with the food supply system, shaping its dynamics (Van Berkum et al., 2018). Understanding these intricacies is essential for effective management and optimization of supply chain processes.

Mila et al. (2022) assert that supply chain analysis systematically elucidates the movement of goods and services from origin to destination, facilitating effective production management for quality control and enhanced year-round market access.

Stakeholders in supply chain management play a crucial role for various reasons, including sharing information, collecting, packing, distributing, selling, processing, buying, and consuming produce (Minnens et al., 2019; Adamashvili et al., 2021). Their involvement is integral for enhancing sustainability performance (Tsoulfas et al., 2019). Future studies aiming at impactful interventions should prioritize understanding the stakeholders, their interactions, and interrelations (WCDI, 2021). From onion producers to final consumers, various chain actors, directly or indirectly, contribute to the overall supply chain dynamics.

• Input Suppliers: Provide agricultural inputs (seeds, compost, fertilizer, pesticides) from various sources, including government, individuals, and growers (Hailu et al., 2017; Getahun et al., 2018).

• Producers/Farmers: Undertake field operations, from preparation to post-harvest. Major value chain contributors, managing inputs, cultivation, and marketing (Abebe, 2018).

• Local Collectors: Middlemen/wholesalers facilitating onion distribution for specific wholesalers and retailers (Getu and Ibrahim, 2018).

• Brokers/Middlemen: Intermediaries between farmers and wholesalers, providing market information (Daniels and Fors, 2015).

• Wholesalers: Purchase and supply large volumes of locally produced or imported onions to retailers and consumers (Getahun et al., 2018).

• Retailers: Sell onions and other items in public markets, acting as the final link between producers and consumers (Daniels and Fors, 2015).

• Consumers: Household, cafes, restaurants, and hotels purchasing onions directly from producers, retailers, or wholesalers.

• Chain Supporters: Entities providing diverse support, funds, and research collaboration, including research institutes, universities, credit unions, governmental and non-governmental organizations (SNV), infrastructure, and private companies.

• Influencer Actors (Enabling Environment): Policies, regulatory frameworks, financial sectors, trade and market development offices, business support services, land administration, and environmental protection offices shaping the overall onion supply chain (WCDI, 2021).

• Extension Services: Extension workers and research centers providing technical advice and improved onion varieties (WCDI, 2021).

• Influencer Actors (Policies and Regulatory Frameworks): Policies and regulations in financial sectors, trade, and market development, impacting the onion supply chain (WCDI, 2021).

Previous Studies: Past research has primarily focused on onion production and marketing, with limited emphasis on post-harvest and comprehensive value chain analysis. Governance Impact Relations between actors in the supply chain are influenced by governance within each step (Daniels and Fors, 2015). Likewise, factors affecting supply: previous studies identified factors such as price per kilogram, household and land size, post-harvest value addition, and market information affecting onion supply volume (Asale et al., 2016; Mossie et al., 2020).

Onion production in the Amhara Region, Ethiopia faces challenges despite a labor-intensive approach, with over 50% of the population capable of engaging in cultivation (BoFED, 2003). Sustainable strategies encompass good management, cultural practices, new variety development, and improved production input access. However, obstacles like low soil fertility, inadequate post-harvest technologies, improper agronomic practices, inappropriate fertilizer use, pests, diseases, and costly production inputs contribute to Ethiopia’s low and unstable onion yields (Lemma and Shimelis, 2003; Bekele et al., 2006; Kumilachew et al., 2014), preventing farmers from maximizing the benefits of onion cultivation.

Mila et al. (2022) highlighted a lack of research and market information, while Gebremedhin et al. (2009) observed that insufficient access to improved inputs and limited land holdings result in inadequate production to meet household consumption needs. Getu and Ibrahim (2018) noted the crucial role of fertilizers and pesticides in boosting onion productivity in the Amhara region. However, challenges such as high costs and improper access lead to suboptimal fertilizer use by most farmers, impacting crop yield.

Haile et al. (2016) found that the primary constraint in onion production in the Masha district is the lack of pesticides. Alemayehu et al. (2015) noted fertilizer availability mainly for main-season crops, insufficient for irrigated onion production. Diseases and insect pests are significant challenges in Amhara Region’s onion production. Agumas (2019) identified constraints in the Fogera district, highlighting suboptimal fertilizer application rates due to untimely supply and insufficient capital for purchasing the recommended amount.

While Ethiopian agricultural cooperatives historically focused on input marketing, recent shifts include their involvement in imports since 1970’s. These cooperatives serve as crucial foundations, supporting smallholder farmers with necessary inputs and mitigating market risks (Woldu et al., 2013). Despite smallholders contributing 95% of Ethiopia’s agricultural output, they face challenges such as restricted market access and low productivity (Gebremedhin et al., 2009; Ahmed and Mesfin, 2017), underscoring the need for improved support structures and market integration for enhanced agricultural sustainability and productivity.

Ethiopian cooperatives initially played a crucial role in fertilizer distribution, supplying 56% in 2010 (Matsumoto and Yamano, 2010). By 2008, cooperative unions dominated imports, reaching a 75% market share in 2007/2008 (IFPRI, 2012). However, to achieve economies of scale, the government centralized fertilizer imports through a single entity in 2008, annually selecting the importer, limiting cooperatives to distribution (World Bank, 2011; Abebaw and Haile, 2013).

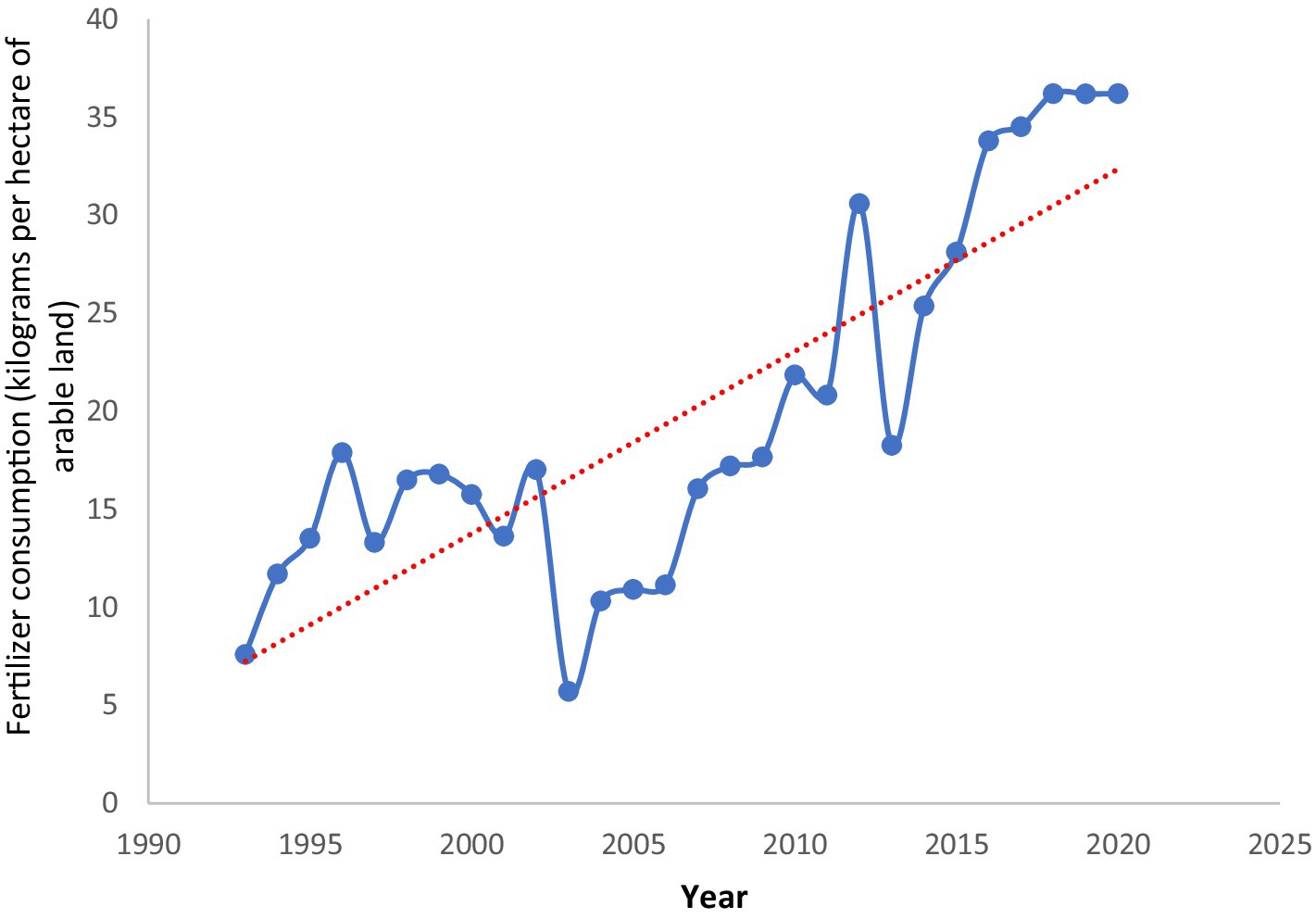

The entire chemical fertilizer, and pesticide demand in Ethiopia is met only by importing. In addition, high cost, long lead time, little involvement of farmers in demand estimation, and the mismatch between quantity supplied and demanded are the major ones for accessibility of fertilizers. Due to this, farmers do not access the required amount of time. As illustrated in Figure 1 (From 1993 to 2022), farmer fertilizer consumption trend in kilograms per hectare of arable land increases significantly. In 1993, 7.6 kg fertilizers were enough for 1 hectare. However, in 2022, 36.2 kg of fertilizer was required per hectare (World Bank, 2022). The increase in the amount of fertilizer applied might be due to the decreasing rate of soil fertility. Moreover, recently, the significant rise in the price of fertilizers and pesticides has posed a great challenge for farmers.

Figure 1. Fertilizer consumption trend in kilograms per hectare of arable land in Ethiopia (1993–2022). Source; World Bank (2022).

Marketing channels are routes through which agricultural products move from producer to consumer. The length of the channel varies from commodity to commodity, depending on the quantity to be moved, the form of consumer demand, and the degree of regional specialization in production (Kohls and Uhl, 1985; Adnan et al., 2014). According to Kohls and Uhl (1985), the marketing channels start at the farmgate and end at the consumer’s front door. Some of the products are processed on their way to the end users while other products reach them without undergoing any form of change. According to Emana et al. (2017), a significant proportion of onion harvest is meant for sale in various towns within Ethiopia, implying that production of the crop is commercially driven and access to the market is crucial to improve household income. In Ethiopia, there are increasing numbers of onion marketing channels where farmers are selling their products directly to consumers or through a middleman.

Getu and Ibrahim (2018) identified six types of onion marketing channels in the Amhara region in Ethiopia. They were channel one is the producer to consumer, channel two is the producer to retailer to consumer, channel three is the producer to the collector to the wholesaler to retailer to consumer, channel four is producer/broker to collector/broker to wholesaler to retailer to consumer, channel five is the producer to processor to retailer to consumer and channel six is the producer to the collector to wholesaler to the exporter. They also indicated that of the total onion produced, 10–15% of produce was sold by farmers directly to consumers and that farmers that are able to sell directly to the consumer are getting better profit margins.

Emana et al. (2017) identified around five marketing channels for onion in the Bora and Dugda districts of Oromia Regional State, Ethiopia. Farmers can sell the product to village collectors, wholesalers, retailers, cooperatives. Consumer sales to wholesalers, however, are the main market channel used, accounting for 95% of the onion sold by the producers. Village collectors and cooperatives buy very small proportions (1–2%) of the produce. Some farmers, especially women, also sell small quantities of onion on the open market to consumers. Six market channels of onion were also identified by Hailu et al. (2017) in the Ejere district, Oromia national regional state of Ethiopia. They are (1) Producer–Consumer (2) Producer–Rural Collector–Wholesaler–Central Retailer–Consumer (3) Producer–District Retailers–Consumer (4) Producer–Wholesaler–Central Retailer–Consumer (5) Producer–Wholesaler–Processor–Consumer and (6) Producer–Wholesaler–District Retailer–Consumer.

Elevated onion production costs, as discussed by Agumas (2019), diminish the likelihood of farmers bringing more products to the market. Our principal hypothesis posits that production costs, encompassing agricultural inputs like fertilizers, pesticides, and fuel costs, exert a negative influence on onion production.

Derege (2010) highlights the nuanced impact of fertilizer usage on crop yields, emphasizing the potential for diminished yields or crop failure with improper application. We posit that judicious use of chemical fertilizers can positively influence onion production, enhancing farmer efficiency. Additionally, our hypothesis suggests a positive correlation between household size and onion production, as family members contribute valuable labor to onion cultivation activities (Abedullah et al., 2009).

Yeshiwas et al. (2023) contend that experienced farmers exhibit enhanced management skills, likely contributing to improved production processes. Consequently, we posit that as farming experience, their proficiency in farming and yield enhancement may increase. Furthermore, transportation methods, market access, and price information are anticipated to exert positive or negative influences on onion production decisions. Our hypothesis suggests that longer transportation routes may adversely affect onion production, as an extended canal length is likely to diminish returns to producers.

The purpose of this study was to analyze the supply chain and to bring an improved marketing system of onions in Northwest Ethiopia.

The study encompassed three pivotal onion-producing districts in northwest Amhara: Mecha, Fogera, and Bahir Dar Zuria. Fogera, part of the Amhara Regional State, is located at 11°58′ N latitude and 37°41′ E longitude, with Woreta as its capital. Mecha, in the West Gojjam Administrative Zone, lies 515 km north of Addis Ababa, and its capital, Merawi, connects the main road between Addis Ababa and Bahir Dar. Bahir Dar Zuria is situated around Bahir Dar town, with a mean altitude of 1800 m above sea level and an annual mean rainfall of 750 mm, experiencing temperatures ranging from 10 to 38°C.

Primary data were gathered through personal interviews, direct field and market observation, covering socio-demographics, constraints in farmers’ onion production, marketing, harvesting, transportation, post-harvest handling, losses, and interactions with respective actors.

This study employed a structured questionnaire for key informant interviews, direct field observations, and market assessments, following the methodology outlined by Elahi et al. (2022). The questionnaire incorporated both open and close-ended questions, with the latter being coded for ease of analysis. Open-ended questions encouraged respondents to freely express their ideas. Prior to interviews, respondents were informed about the study’s purpose, granted the right to skip uncomfortable questions, and allowed to replace them with alternative willing respondents (Elahi et al., 2021). Secondary data were gathered through document analysis and systematic literature reviews.

The interview questionnaire, initially prepared in English, was translated into Amharic, the national language, to overcome language barriers. It covered household socio-demographics, onion cultivation methods, raw material access, harvesting, post-harvest handling, distribution methods, and market information access. Utilizing a multistage sampling technique (Elahi et al., 2021, 2022; Abbas et al., 2022), two kebeles known for significant onion production were selected, with randomly chosen onion-producing households. Bahir Dar City, Woreta City, and Merawi City were specifically chosen for wholesalers, retailers, and consumer chains due to their reputation for large-scale onion trade (Getu and Ibrahim, 2018). This comprehensive methodology ensured representative data collection across various stages of the onion supply chain.

To determine the household sample size, Yamane’s (1967) sampling formula was used with his 7% accuracy; as.

where n is the required sample size, N is the target population size (total number of onion-producing households), and e is the precision level (7%). A precision of 7% is required to minimize sample size. Consequently, the representative sample proportional sample as indicated Equation 1 interviewed. Thus, a total of 197 respondents representing onion farmers, 15 wholesalers, 30 local collector, 50 retailers and 20 consumers were surveyed. Additionally, interviews with key informants were conducted.

The initial value chain mapping involved discussions with actors during the first survey, and the final map incorporated ideas from key informant interviews and group discussions. Interlinkages among various actors’ activities in the onion supply chain were observed. Open-ended question data underwent narrative analysis and thematic coding for a comprehensive understanding of supply chain dynamics.

Data analysis utilized SPSS 16.0 for statistical analysis and Microsoft Excel for graph creation. Descriptive statistics, including frequency, mean, and percentage, were employed. Formal interviews and key informant discussions identified onion market channels. Food system analysis (Van Berkum et al., 2018) mapped the actual supply chain and its linkages.

In addition to that the marketing margins and net margins of main market actors were estimated using the following equations.

• Gross marketing margin = Sales price − Purchase price (i).

• Net marketing margin = Gross margin − Marketing cost (ii).

• Producer share (%) = Farm price/Retail price × 100.

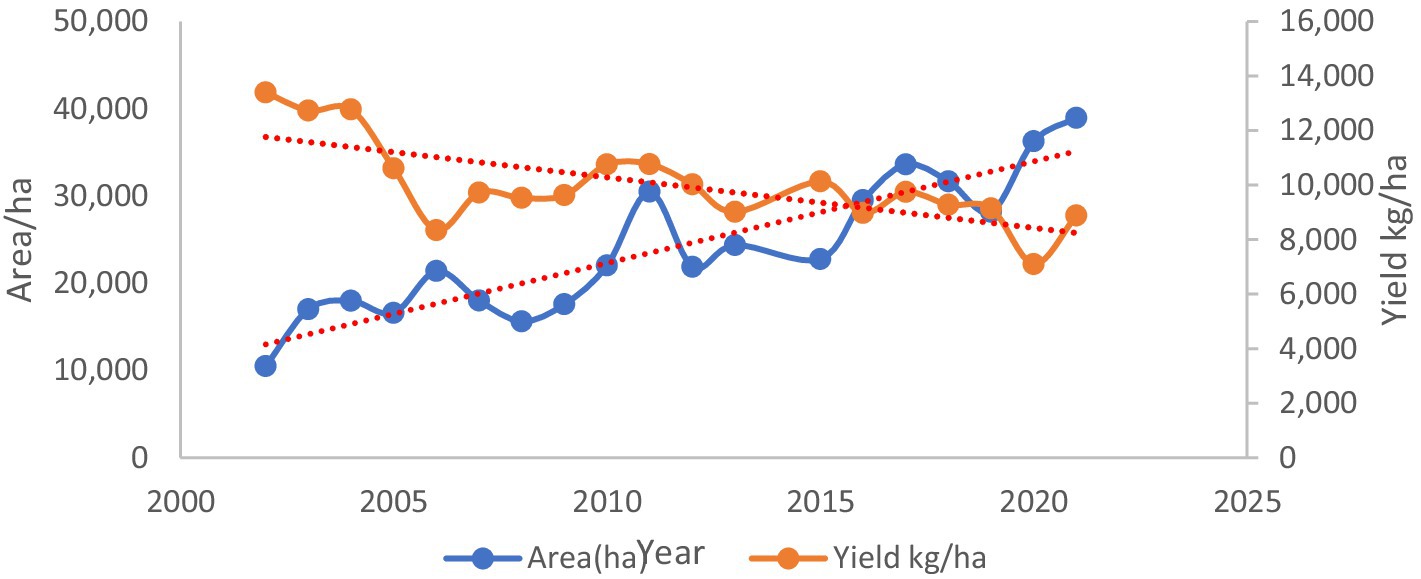

The survey findings indicate an average onion yield of 16 tons/ha in the study area, surpassing the Amhara National Regional State’s reported yield of 11.67 tons/ha (2016/17). However, this falls short of the global average of 19.7 t/ha (Habtamu, 2017). Figure 2 depicts onion production (2002–2022) in area per hectare and yield in kilograms per hectare. While the area under cultivation shows an increasing trend since 2020, onion productivity is declining. Factors limiting productivity include fluctuations in cultivation area and inadequate storage facilities, leading to significant post-harvest losses. The surge in onion cultivation since 2020 suggests heightened production potential and robust consumer demand.

Figure 2. Onion production trend (2002–2021). Source; CSA (2022).

Despite a surplus of onions in the country for two to three months, prices during harvest season remained low at 1–3 Ethiopian Birr per kilogram due to storage and handling challenges. Conversely, during off-season scarcity, prices sharply rose, reaching 30–55 birr per kilogram, as highlighted by respondents. This study provides valuable insights into the onion supply chain dynamics, emphasizing the need for improved storage infrastructure and handling practices to mitigate losses and stabilize prices.

This study reveals diverse transportation methods employed by onion traders, ranging from open trucks at the farm level to various means when delivering to markets. Farmers predominantly use open trucks for on-farm sales and carts with manpower for market deliveries. Market price challenges are universal among onion producers. The majority of wholesalers (86.7%) use open FSR trucks, while 13.3% use Isuzu open trucks (Table 1), with differences in load capacity. Retailers use hand carts (36.7%), wheelbarrows (30%), animal-powered carts (23.3%), and motor-driven carts (13.3%) for onion transportation. These findings underscore the varied transport strategies within the onion supply chain.

Efficient transportation services are essential for fruits and vegetables to transport the products as quickly as possible or with little damage (Rehman et al., 2007; Tesfaye, 2015). Yeshiwas and Tadele (2021) found 55% of respondents in Debre Markos, Ethiopia, use hand-drawn Gehry for transport. Abera et al. (2020) noted that 60.6% of tomato producers in Shewa, Ethiopia, rely on animal packing carts, while 39.4% use trucks for transportation to local markets.

As illustrated in Supplementary Data Sheet 2, value addition, such as packaging, was universally adopted in the onion supply chain, except for some activities like curing, sorting, grading, and ventilating, particularly at the producer level. The perishable nature of onions leads to post-harvest losses due to deterioration, rotting, sprouting, and weight loss during transportation and storage. Wholesalers exhibited suboptimal practices in sorting, grading, and ventilating (Table 2). Implementing timely harvesting, curing, sorting, grading, packaging, and efficient transportation can enhance storage life and post-harvest quality, ensuring sustained benefits for onion producers and traders. Similar value-adding activities have proven effective for tomatoes in Ethiopian districts (Bure, Jabitehinan and North Mecha), boosting shelf life and returns (Wosene and Gobie, 2022).

Therefore, stakeholders and concerned sectors through the application of interventions such as creating awareness at different levels (leaders, extension workers, and farmers), developing national post-harvest management policies/strategies, enhancing infrastructure, and promoting agro-processing and value addition at different scales can encourage all actors in the onion supply chain to the sustainable benefit of onion producers and traders.

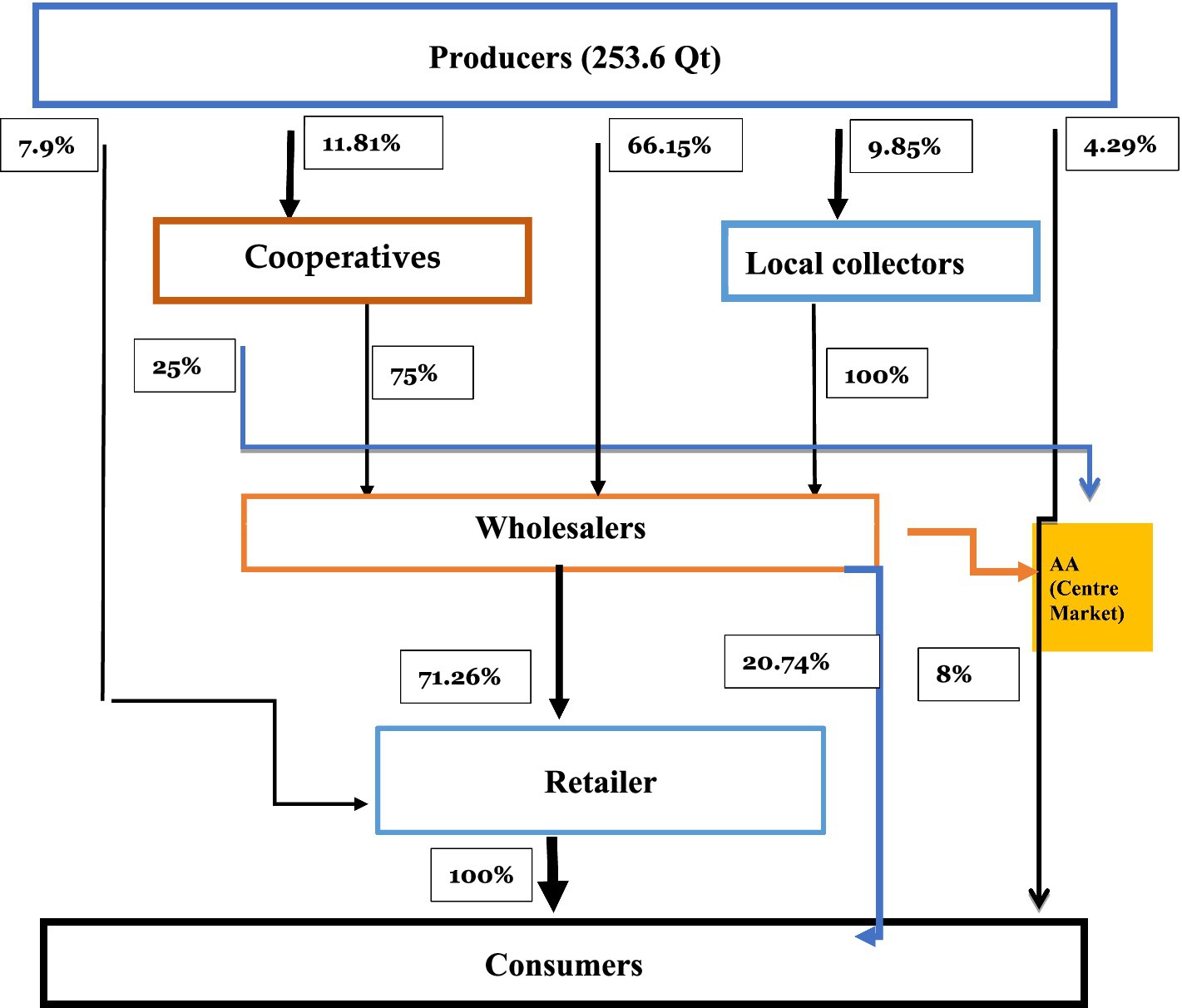

Marketing of Onion were sketched based on the direction of flow and volume of onion yield transacted. The present study identifies six alternative channels for onion marketing. The estimated quantity of onion supplied to the market by the sampled households in the year 2022 was about 253.6 quintals. From Figure 3, many market channels can be outlined. However, six main marketing channels are identified from the production point to the final consumer through different intermediaries.

Figure 3. Onion supply chain and volume share of flows. Source: Own sketch from 2022 survey results.

Channel I: Producers–consumers.

Channel II: Producer–local collector–wholesaler.

Channel III: Producer–wholesaler–consumer.

Channel IV: Producer–wholesaler–retailer.

Channel V: Producers–cooperative–wholesalers–transfer (Center Market AA).

Channel VI: Producers–wholesalers–retailer–consumers.

The amount of onion transacted in these market channels was not the same. The result indicates that the producers sold the majority of their produce (66.15%) to wholesalers, followed by marketing cooperatives (11.81%). The remaining produce was sold to local collectors (9.85%), retailers (7.9%), and consumers (4.29%) (Figure 3).

The producers sell their onions directly to the consumer at the nearest market and farmgate price. In this channel, the producers directly sell to consumers on the market day in the study area and onion producers are more benefited by getting better prices and consumers have the chance to get a fresh onion. However, a small volume of onion (4.29%) is transacted through this channel (Figure 3).

The market size for shorter channels is small and cannot absorb all onions produced due to the lack of modern market infrastructure. Retailing is time-consuming for producers, especially for those who have more produce. Hence, farmers can use holidays and market days for retailing.

The producer sold their onions to the local collectors (9.85%) and local collectors who sold their 100% onions to the wholesalers. The producers sold 66.15% of onion to wholesalers and then wholesalers sold 71.26% of onion and 20.7% to retailers and to consumers such as households, cafes, restaurants, and which have the capacity to purchase five kilograms and above of onions (Figure 3).

Producers sold their produce to wholesaler without the involvement of brokers and wholesaler resale to consumer. It represented 66.15% of total onion marketed during the survey period. This channel is the most important channel in which the largest volume of onion was transacted in the study area.

The producer sold 66.15% of onions to the wholesaler, wholesalers sold 71.26% of onions to the retailer.

The producer sold 11.81% of onions to the marketing cooperatives and cooperatives, sold 75% of onions to wholesalers in different parts of the country, and transfer to center market (Addis Ababa).

Producers were selling their produce to wholesalers, and wholesalers were sold to retailers who sold the produce to the consumer. It is the longest chain in terms of market participants (Figure 3). As the number of actors between producers and consumers increases, the profit margin of the producer will decrease.

The findings showed that the highest profit margin is obtained by producers and collectors followed by retailers and wholesalers. The maximum operational cost is incurred by wholesalers followed by collectors. The distribution of profit margins in the onion supply chain reveals that producers receive the highest share at 38.38%, followed by collectors at 25.79%, and retailers at 18.11%. Additionally, a notable portion of the margin, 17.72%, is allocated to wholesalers in the chain. This breakdown underscores the significant contribution of producers to the profitability of the supply chain, highlighting their pivotal role in the onion market (Table 3).

A supply chain, as delineated by Felea and Albăstroiu (2013) and Chopra and Meindl (2010), is a complex network of organizations, activities, and resources facilitating the movement of products from suppliers to customers. The current map’s significance lies in designing a research framework, identifying barriers across the supply chain. A meticulous two-stage process was employed to develop the final value chain map for onion production. This approach is pivotal for comprehensively addressing challenges and optimizing the onion supply chain from farmers to consumers.

The main chain actors were found to be farmers, local collectors, brokers, transporters, wholesalers, retailers, and consumers. The way the chain actors of onion commodities are related is illustrated in Figure 4, which indicates the different actors and activities performed by chain actors and the activities interlinked by them. The supply chain map of onion includes input suppliers, onion producers, packaging, handling, transportation, distribution by traders (retailers, wholesalers, local collectors), and consumption. It also indicates inputs for onion production from suppliers to onion producers. The product is a flow from producer to consumer through different supply chain actors. Along the supply chain, each chain actors add value to the product. In addition, there is also a flow of information from chain actors on the price.

In the study area, there are union supply chain supporters such as the financial sector (credit unions), input suppliers (private sector unions, local markets, seed companies), and service providers (BoA, NGOs, extension office). The survey results indicated that there are challenges to alleviating the low income of onion producers. Among the challenges, lack of harvesting and post-harvest handling technologies, lack of market power for small-scale onion producers, lack of value addition and diversification, and shortage of inputs were identified as key challenges.

Input suppliers–there were different input suppliers involved directly or indirectly in the onion supply chain in the study area. Input suppliers in the study area provide chemical fertilizers (Urea and NPS/B), onion seeds, herbicides, pesticides, and fuel. As illustrated in Table 2, in the study area, the major sources of fertilizers (93.9%) are local markets and cooperatives together. However, 6.1% of respondents indicated that cooperatives alone are the source of their fertilizers such as Urea and NPS/B. All respondents (100%) purchased herbicides and pesticides from the local market. The result of the present findings identified the existence of problems related to timely and adequately input supply including the high price of fertilizers and fuel and the quality of pesticides and insecticides (sometimes farmers had the possibility to purchase expired pesticides and insecticides).

Producers/farmers–Small-scale farmers are the major actors who perform farm input preparation on their farms or procurement of inputs from other sources, undertake post-harvest handling activities, and marketing of their onions. The major value chain functions performed by farmers are land preparation, raising seedlings, transplanting, irrigating, fertilizer application, weeding, cultivation, disease management (Powdery mildew), insect management (onion thrips), harvesting, implementing post-harvest handling activities, and marketing. Major value-addition activities performed by onion production are illustrated in Table 2.

Local collectors–in the study area, local collectors are a type of middleman/wholesaler who plays a major role in the distribution of onions for certain wholesalers and retailers. They are aware of the area with surplus onion production area, purchase from the farmers on the farm, and resell with wholesalers, retailers, and consumers.

Brokers/middlemen–are between farmers and wholesalers; they provide market information and price between farmers and wholesalers. They identify potential producers and facilitate onion bulb transactions and link the producers to wholesalers. They collected sample bulbs from the farm and gave them to wholesalers to evaluate the quality of the bulbs and to convince purchasing. In addition, they set selling prices between wholesalers and retailers for onions as far as possible. They provide quick and readily information regarding onion marketing systems. As farmers explained that sometimes they go beyond facilitation, they tend to control the selling power of producers and fix selling prices.

Wholesalers–are individuals that purchase onions produced by local collectors and farmers in large volumes and supply them to retailers and consumers. They are equipped with storage space for produce, better financial capacity, and communication access to traders. Almost all wholesalers have an unstandardized house in the market, either self-owned or rental basis. They store the product, usually for a maximum of 7 days. Value-addition activities performed by wholesalers are packaging, transporting, ventilating, and storing. Major wholesalers are located in Merawi town, Bahir Dar city, Wereta town, Kudmi rural town, Andassa, and Sabatamit town. Therefore, 66.15% of onion produced from producers alone was handled by wholesalers (Figure 4).

Retailers–They are supply chain actors who sell onions in small quantities. The value-addition activities performed by retailers are buying onions, transporting, sorting, grading, displaying, and selling to consumers.

Marketing cooperatives–they are legal organizations established to collect onion bulbs from member farmers and supply them to wholesalers, hotels, and transport in Addis Ababa. They have criteria to purchase onions. Attractive color, marketable size, and sorted onions are ranked first to purchase. The value addition practices applied by them are spread on the bed and packaging and storage. In this regard, 11.81% of onion bulbs are handled by marketing cooperatives of farmers (Figure 4).

Consumers–they are chain actors who purchase onions directly from producers, retailers, and wholesalers, but most of the consumers buy from retailers. The rural and urban households, cafes, restaurants, and hotels were identified as onion consumers in the study area. They are those purchasing the products for consumption and final users of these commodities. Consumers purchase. Consumers directly purchasing onion from producers was 4.29% of the total transacted (Figure 4).

Chain supporters: Involved directly or indirectly in the onion supply chain. They provide different services including financial services, technology dissemination, infrastructure, and market information. In the study area, there are many institutional supporters available in the study area. Among them, the district agricultural office (to provide extension services, facilitate input, access, and technical support), research centers (improving production technologies of onions), and NGOs (supplying onion seeds and providing training) support onion production (Figure 4).

Chain influencers (Enabling environment): In the study area, the chain influencers are regulatory frameworks and policymakers, revenue authority, trade and industry office, land administration, environmental protection office, and irrigation development office to intervene in onion marketing (Figure 4).

This study investigates the onion supply chain from farmers to consumers. The significance of the current map in designing a research framework lies in identifying key points that may impede proper information flow within the entire supply chain. A supply chain encompasses organizations, people, activities, information, and resources facilitating the movement of products or services from suppliers to customers. it involves all parties directly or indirectly fulfilling customer requests.

Likewise, packaging and sorting activities were applied along the supply chain to reduce post-harvest losses. Thus, all actors in the supply chain packaging as a value addition were applied. At the producer level, mandatory activities such as curing, sorting, grading, and ventilating were applied by average respondents. In addition, sorting, grading, and ventilating practices were not well applied by wholesalers, retailers, and producers at the required level.

Study shows varied onion transportation methods, from open trucks at farms to diverse means for market deliveries. Price challenges persist. Moreover, market channels were sketched based on the direction of flow and volume of onion yield transacted. The present study identifies six alternative channels for onion marketing. Onion transactions vary across market channels. Producers predominantly sell to wholesalers (66.15%), followed by marketing cooperatives (11.81%), with the remainder distributed among local collectors, retailers, and consumers.

Cultivated area increased post-2020, yet onion productivity declines due to fluctuating cultivation and inadequate storage, leading to significant post-harvest losses. Horticultural crop production, particularly onions, demands substantial labor. Effective strategies, such as sound management, cultural practices, new variety development, and accessible production inputs, are crucial for enhancing onion productivity. Despite high potential, local farmers face challenges including soil fertility issues, insufficient post-harvest technologies, suboptimal agronomic practices, improper fertilizer application, and pest pressures, contributing to low and inconsistent yields. Targeted interventions are essential for improving onion production, emphasizing the necessity for region-specific solutions.

Based on the findings, considering the perishability nature of the crop and the existing problems aggravate onion loss after harvest it is recommended to prioritize interventions that enhance onion value addition, including establishing processing industries to mitigate post-harvest losses. Stakeholders and governmental organizations should support onion producers and traders with continuous capacity building, improved extension services, infrastructure enhancement, and better input access for sustainable benefits. Meaningful policy interventions, informed by the identified supply chain dynamics, should be developed and implemented. Additionally, incorporating spatial and temporal data in future studies can provide a more comprehensive understanding for informed decision-making in onion production and handling.

The original contributions presented in the study are included in the article/Supplementary material, further inquiries can be directed to the corresponding author/s.

Ethical approval was not required for the study involving human participants in accordance with the local legislation and institutional requirements. Written informed consent to participate in this study was not required from the participants in accordance with the national legislation and the institutional requirements.

YY: Conceptualization, Data curation, Formal analysis, Investigation, Methodology, Resources, Software, Validation, Visualization, Writing – original draft, Writing – review & editing. MA: Conceptualization, Formal Analysis, Investigation, Methodology, Supervision, Validation, Visualization, Writing – review & editing. EA: Conceptualization, Formal Analysis, Investigation, Methodology, Supervision, Validation, Visualization, Writing – review & editing.

The author(s) declare that no financial support was received for the research, authorship, and/or publication of this article.

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

The Supplementary material for this article can be found online at: https://www.frontiersin.org/articles/10.3389/frsus.2024.1387907/full#supplementary-material

Abbas, A., Zhao, C., Waseem, M., and Ahmad, R. (2022). Analysis of energy input–output of farms and assessment of greenhouse gas emissions: a case study of cotton growers. Front. Environ. Sci. 9:826838. doi: 10.3389/fenvs.2021.826838

Abebaw, D., and Haile, M. G. (2013). The impact of cooperatives on agricultural technology adoption: empirical evidence from Ethiopia. Food Policy 38, 82–91. doi: 10.1016/j.foodpol.2012.10.003

Abebe, A. (2018). Review on onion value chain analysis in Ethiopia. Nutr. Food Sci. Int. J. 6:555698. doi: 10.19080/NFSIJ.2018.06.555698

Abedullah, A., Mahmood, N., and Kouser, S. (2009). The role of agricultural credit in growth of crop production sector in Faisalabad in Pakistan. Faisalabad, Pakistan: Research Report; University of Agriculture.

Abera, G., Ibrahim, A. M., Forsido, S. F., and Kuyu, C. G. (2020). Assessment on post-harvest losses of tomato (Lycopersicon esculentem mill.) in selected districts of east Shewa zone of Ethiopia using a commodity system analysis methodology. Heliyon 6:e03749. doi: 10.1016/j.heliyon.2020.e03749

Adamashvili, N., State, R., Tricase, C., and Fiore, M. (2021). Blockchain-based wine supply chain for the industry advancement. Sustain. For. 13:13070. doi: 10.3390/su132313070

Adnan, K. M., Rahman, M. M., and Sarker, S. A. (2014). Marketing channels and post-harvest practices of onion: a case of Bogra and Joypurhat District in Bangladesh. Univers. J. Agric. Res. 2, 61–66. doi: 10.13189/ujar.2014.020205

Adugna, D. (2021). Marketing analysis of onion in the case of Fentalle Woreda, east Shewa zone, Oromia National Regional State, Ethiopia. Asian J. Plant Sci. Res. 11, 65–72. Available at: https://www.imedpub.com/articles-pdfs/marketing-analysis-of-onion-in-the-case-of-fentalle-woreda-east-shewa-zone-oromia-national-regional-state-ethiopia.pdf

AgroBIG. (2016). Onion value chain analysis. Agro Big programme for agribusiness induced growth in the Amhara region. Available at: https://www.agrobig.org/documents/1.1_Value_Chain_Analysis_ONION_Update_Aug_2016.pdf

Agumas, Y. (2019). Determinants of onion production in Fogera District, South Gondar ZoneMSc thesis. Gonder, Ethiopia: Gonder Univeristy.

Ahmed, M. H., and Mesfin, H. M. (2017). The impact of agricultural cooperatives membership on the wellbeing of smallholder farmers: empirical evidence from eastern Ethiopia. Agric. Food Econ. 5, 1–20. doi: 10.1186/s40100-017-0075-z

Alemayehu, M., Tesfa, F., Bizuayehu, S., and Ayele, B. (2015). Amhara region horticultural development strategy 2015–2019.Bahir Dar Univerity, Ethiopia. Available at: https://agrobig.org/documents/

Asale, A., Yhanes, D., and Buke, T. (2016). Onion market chain analysis in Humbo District of Wolaita zone, southern Ethiopia. Int. J. Sci. Res. Eng. Technol. 2, 7–8. Available at: https://ijsret.com/paper/IJSRET_V2I1-80.PDF

Bekele, E., Azerefegne, F., and Abate, T. (2006) Facilitating the implementation and adoption of integrated Pest management (IPM) in Ethiopia. In: Planning workshop, 13–15 October 2003, Melkassa agricultural research center, EARO. Jointly organized by the Association for Advancement of IPM (ASAI) and the Ethiopian agricultural research organization (EARO). DCG; Miljøhuset: Oslo, Norway.

BoFED. (2003). (Bureau of Finance and Economic Development). Development indicators of Amhara region; office of finance development, Bahir Dar, Ethiopia. Ethiopia: BoFED.

Carvalho, H., Cruz-Machado, V., and Tavares, J. G. (2012). A mapping framework for assessing supply chain resilience. Int. J. Logist. Syst. Manag. 12, 354–373. doi: 10.1504/IJLSM.2012.047606

Chopra, S., and Meindl, P. (2010). Supply chain management; prentice-hall, London, UK: Pearson Education.

CSA. (2016/2017). Agricultural sample survey 2016/2017 (2009 E.C), volume I report on area and production of major crops (private peasant holdings, Meher season). Ababa, Ethiopia: Central Statistical Agency (CSA) Addis.

CSA. (2022). Agricultural sample survey 2021/2022 (2014 E.C), volume I report on area and production of major crops (private peasant holdings, Meher season). Addis Ababa, Ethiopia: Central Statistical Agency (CSA).

Daniels, H., and Fors, S. (2015). Supply and Value Chain Analysis of onions in Ethiopia; SLU, Swedish Unuversity of Agricultural Science, Uppsala. Available at: https://stud.epsilon.slu.se/

Dawit, A., Abera, D., Lemma, D., and Chemdo, A. (2004). Domestic vegetable seed production and marketing; research report no. 5. EARO: Addiss Ababa, Ethiopia.

Derege, A. E. (2010). Analysis of factors affecting the technical efficiency of coffee producers in Jimma zone: A stochastic frontier analysis. M. Sc Thesis. Ethiopia: Addis Ababa University, p. 110.

Elahi, E., Khalid, Z., and Zhang, Z. (2022). Understanding farmers’ intention and willingness to install renewable energy technology: a solution to reduce the environmental emissions of agriculture. Appl. Energy 309:118459. doi: 10.1016/j.apenergy.2021.118459

Elahi, E., Zhang, H., Lirong, X., Khalid, Z., and Xu, H. (2021). Understanding cognitive and socio-psychological factors determining farmers’ intentions to use improved grassland: implications of land use policy for sustainable pasture production. Land Use Policy 102:105250. doi: 10.1016/j.landusepol.2020.105250

Emana, B., Afari-Sefa, V., Kebede, D., Nenguwo, N., Ayana, A., and Mohammed, H. (2017). Assessment of postharvest losses and marketing of onion in Ethiopia. Int. J. Postharvest Technol. Innov. 5, 300–319. doi: 10.1504/IJPTI.2017.092466

ETFRUIT. (2005). Ethiopian fruit and vegetable marketing Enterprise, Annual Report. Ethiopia: Office of Agriculture, Addis Abeba, pp. 46–58.

Felea, M., and Albăstroiu, I. (2013). Defining the concept of supply chain management and its relevance to romanian academics and practitioners. Amfiteatru Econ. J. 15:74. Available at: https://Defining_the_Concept_of_Supply_Chain_Management_an.pdf

Gallo, C., Faccilongo, N., Contò, F., and Adamashvili, N. (2019). Blockchain: a tool for supply chain certification. EFITA, Springer Nature: Berlin/Heidelberg, Germany.

Gebremedhin, B., Jaleta, M., and Hoekstra, D. (2009). Smallholders, institutional services, and commercial transformation in Ethiopia. Agric. Econ. 40, 773–787. doi: 10.1111/j.1574-0862.2009.00414.x

Getahun, W., Tesfaye, A., Mamo, T., and Ferede, S. (2018). Apple value chain analysis in the central highlands of Ethiopia. Int. J. Agric. Innov. Res. 7, 2319–1473.

Getu, K., and Ibrahim, A. (2018). Onion value chain analysis in north Mecha, Bahir dar zuria, Fogera and Dera Woredas of amhara national regional state. Programme for Agribusiness Induced Growth in the Amhara region (AgroBIG).

Habtamu, G. M. (2017). Onion (Allium cepa L.) yield improvement progress in Ethiopia: a review. Inter J Agri Biosci 6, 265–271.

Haile, B., Babege, T., and Hailu, A. (2016). Constraints in production of onion (Allium cepa L.) in Masha District, Southwest Ethiopia. Glob. J. Agric. Sci. 4, 314–321.

Hailu, A., Zemedu, L., and Getnet, K. (2017). Value chain analysis of onion: the case of Ejere district, west Shoa zone, Oromia national regional state of Ethiopia. Afr. J. Agric. Econ. Rural. Dev. 5, 512–524. Available at: http://www.internationalscholarsjournals.org

IFPRI. (2012). Fertilizer in Ethiopia: Policies, value chain, and profitability; international food and policy research institute press : Ethiopia: Addis-Ababa.

Kitinoja, L., and Kader, A. A. (2002). Small-scale postharvest handling practices: A manual for horticultural crops; University of California, Davis, postharvest technology research and information center, Davis, CA.

Kohls, R. L., and Uhl, J. N. (1985). In Marketing of Agricultural Products. United States of America: Macmillan Publishing Company.

Kumilachew, A., Mengistu, K., and Fekadu, G. (2014). Risks in vegetables production from the perspective of smallholder armers: the case of Kombolcha Woreda, Oromia region, Ethiopia. Agric. For. Fish. 3, 1–5. doi: 10.11648/j.aff.s.2014030601.11

Lemma, D., Shimeles, A., Selamawit, K., and Chimdo, A. (2006). The vegetable seed sector in Ethiopia: current status and future prospects. In: Proceedings of the inaugural and third National Horticultural Workshop, EHSS, Ethiopia, Addis Ababa, Ethiopa-19-20 May Volume I, pp. 103–109.

Lemma, D., and Shimelis, A. (2003). Research experience in onion production; research report no 55; Ethiopia Agricultural Research Organizational: Addis Ababa, Ethiopia. Available at: http://publication.eiar.gov.et:8080/xmlui/bitstream/handle (Accessed on November, 20, 2021).

Masamha, B., Thebe, V., and Uzokwe, V. N. (2018). Mapping cassava food value chains in Tanzania’s smallholder farming sector: the implications of intra-household gender dynamics. J. Rural. Stud. 58, 82–92. doi: 10.1016/j.jrurstud.2017.12.011

Matsumoto, T., and Yamano, T. (2010). The impacts of fertilizer credit on crop production and income in Ethiopia (no. 10–23). Tokyo, Japan: National Graduate Institute for Policy Studies, GRIPS.

Mila, F. A., Nahar, A., Amin, M. R., Culas, R. J., and Ahmed, A. (2022). Empirical assessment of onion supply chain constraints in Bangladesh: a pre-covid to covid situation. J. Agric. Food Res. 10:100418. doi: 10.1016/j.jafr.2022.100418

Minnens, F., Lucas Luijckx, N., and Verbeke, W. (2019). Food supply chain stakeholders’ perspectives on sharing information to detect and prevent food integrity issues. Food Secur. 8:225. doi: 10.3390/foods8060225

MoA. (2020). Plant variety release, protection and seed quality control directorate crop variety Register Issue No. 23 June, 2020; Addis Ministry of Agriculture: Ababa, Ethiopia.

Mossie, H., Berhanie, Z., and Alemayehu, G. (2020). Econometric analysis of onion marketed supply in Northwest Ethiopia. Cogent Food Agric. 6:1733329. doi: 10.1080/23311932.2020.1733329

Pessu, P., Agoda, S., Isong, I., and Ikotun, I. (2011). The concepts and problems of postharvest food losses in perishable crops. Afr. J. Food Sci. 5, 603–613. Available at: http://www.academicjournals.org/AJFS

Rehman, M. U., Khan, N., and Jan, I. (2007). Post-harvest losses in tomato crop: a case of Peshawar valley. Sarhad J. Agric. 23, 1280–1284. Available at: https://www.aup.edu.pk/sj_pdf/POST%20HARVEST%20LOSSES%20IN%20TOMATO%20CROP.pdf

Tesfaye, S. (2015). Assessment of postharvest loss for perishable produce from wholesalers to consumers. A case study of et-fruit distribution company in Addis Ababa, Ethiopia. Master’s thesis. Uppsala, Sweden: Swedish University of Agricultural Sciences.

Tsoulfas, G. T., Marinagi, C., Trivellas, P., and Reklitis, P. (2019). Sustainable Agri-food supply chains in Greece: the role of stakeholders. In: Proceedings of the 2nd international conference on management, Economics and Finance, Rotterdam, the Netherlands, pp. 15–17.

Van Berkum, S., Dengerink, J., and Ruben, R. (2018). The food systems approach: Sustainable solutions for a sufficient supply of healthy food (No. 2018-064). Wageningen Economic Research: The Netherlands.

Van der Vorst, J. G., Da Silva, C., and Trienekens, J. H. (2007). Agro-industrial supply chain management: Concepts and applications. Rome: FAO.

WCDI. (2021). Value Chain Mapping. Horticulture Sector Development for Emerging Markets. Training Manual. Wageingen Center for Devlopment Innovation. Available at: www.wur.eu/cdi (Accessed on May 25, 2021).

Woldu, T., Tadesse, F., and Waller, M. K. (2013). Women’s participation in agricultural cooperatives in Ethiopia (no. 57); International food policy research institute (IFPRI): Addis Abeba, Ethiopia.

World Bank. (2011). Ethiopia: Fertilizer support project performance assessment report; report no. 62834. Washington, DC: The World Bank.

World Bank. (2022). Available at: https://data.worldbank.org/indicator/AG.CON.FERT.ZS?locations=ET (Accessed on January 27, 2023).

Wosene, G., and Gobie, W. (2022). Value chain analysis of tomato: the case of bure, Jabitehinan and north Mecha districts of Amhara regional state, Ethiopia. J. Agric. Food Res. 7:100272. doi: 10.1016/j.jafr.2022.100272

Yeshiwas, Y., Alemayehu, M., and Adgo, E. (2023). The rise and fall of onion production; its multiple constraints on pre-harvest and post-harvest management issues along the supply chain in northwest Ethiopia. Heliyon, 9. doi: 10.1016/j.heliyon.2023.e15905

Yeshiwas, Y., and Tadele, E. (2021). An investigation into major causes for postharvest losses of horticultural crops and their handling practice in Debre markos, North-Western Ethiopia. Adv. Agric. 2021:1985303. doi: 10.1155/2021/1985303

Keywords: onion supply chain, Mapping, Market channel, Smallholder farmers, Production challenges, Market prices, post-harvest handling, post-harvest losses

Citation: Yeshiwas Y, Alemayehu M and Adgo E (2024) Strategic mapping of onion supply chains: a comprehensive analysis of production and post-harvest processes in Northwest Ethiopia. Front. Sustain. 5:1387907. doi: 10.3389/frsus.2024.1387907

Received: 18 February 2024; Accepted: 02 April 2024;

Published: 22 April 2024.

Edited by:

Bikash Koli Dey, Hongik University, Republic of KoreaReviewed by:

Arne Nygaard, Campus Kristiania, NorwayCopyright © 2024 Yeshiwas, Alemayehu and Adgo. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Yebirzaf Yeshiwas, eWViaXJ6YWZ5QGdtYWlsLmNvbQ==

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.