94% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

ORIGINAL RESEARCH article

Front. Sustain., 01 February 2024

Sec. Modeling and Optimization for Decision Support

Volume 5 - 2024 | https://doi.org/10.3389/frsus.2024.1352572

Alok Bihari Singh1*

Alok Bihari Singh1* Vikrant Bhakar2

Vikrant Bhakar2 Gaurav Gaurav3

Gaurav Gaurav3 Chandni Khandelwal4,5

Chandni Khandelwal4,5 Prabir Sarkar2

Prabir Sarkar2 Harpreet Singh2

Harpreet Singh2 Govind Sharan Dangayach1

Govind Sharan Dangayach1Context: Assessing the sustainability of milk production in India (the largest milk producer country in the world) is essential to ensure that the dairy industry can meet the growing demands for dairy products while minimizing its negative impact on the environment, society, and the well-being of the people involved in the sector.

Objective: Current research is intended to compare the emissions associated with packed milk production in two contrasting states, Punjab (an Indian state with helpful agricultural resources and plenty of water) and Rajasthan (a state with a significant desert area) of India. The dairy industry has to undergo different production processes, including livestock, feed, farming, transportation, processing, packaging, and distribution. All of these production steps generate environmental impacts. This study aims to compare the environmental impacts of milk production in Punjab and Rajasthan by understanding the variation in the ecological effects due to the modifications adopted in dairy practices.

Methods: This study uses Umberto LCA+ with Ecoinvent v3.6 dataset as a Life cycle assessment (LCA) tool and data collected from milk producers and processing plants. The primary data was collected from farmers (milk producers) and dairy plants (processing plants), real-time observations, and inputs from the processing plant staff. The LCA analysis was performed, including parameters such as feed agriculture, milking, storage, transportation, processing, packaging, and distribution.

Results and conclusion: The analysis results indicate that milk production in Punjab is more environmentally efficient than in Rajasthan, and the feed required for cattle is a critical environmental impact-generating activity along with the selection of packaging material for processed milk.

Significance: The current article assesses the environmental implications of milk production. The study employs a comprehensive analysis to inform sustainable practices and reduce the ecological footprint of this crucial industry.

Milk is a commonly used material ingredient in the milk processing industry. However, its commercialization and processing into various milk products might vary significantly in terms of the exact technique followed, the environmental effect created, and the amount of output generated. As a result, it might be possible to develop a system in which one can learn about one effective milk production method from another. A comparative study of different commercial production methods employed by corporations in various states of India might uncover intriguing process-level changes that influence the environmental effect. The emphasis is on the variations in technology and systems utilized by different companies so that others may learn from them and enhance the system as a whole.

India is the largest milk-producing country in the world, followed by the USA, China, Pakistan, and Brazil (Gurtu et al., 2023). India’s share of global milk production is approximately 21.29%, with an annual production of 186.14 million tonnes in 2018 (Subbanna et al., 2021; Kashyap et al., 2023). Worldwide, 83% of the milk is produced from cows, 14% from buffalo, 2% by goats, 1% by sheep, and 0.3% by camels. Milk production in India has risen more than 200% since 1991. In 1991, per-capita milk availability in India was 178gm/day, with a total production of 55.6 million tonnes. India’s total milk production in 2018–19 was 187.7 million tonnes, with a per-capita availability of 394 gm/day (Milk Production in India | Nddb.Coop, 2022).

Milk is an essential part of life due to its nutritional value. According to Home | Food and Agriculture Organization of the United Nations (2023), milk fulfills 48% of the protein and 9% of calories required for a kid of 5–6 years of age with mild physical activity. On the other hand, milk production or dairy farming creates considerable environmental impact due to greenhouse gas emissions (Dairy | Industries | WWF, 2023). Livestock globally uses 70–80% of anthropogenic land and consumes approximately 35% of agricultural production (Kraham, 2017; Ghosh et al., 2020). Thus, livestock generates environmental pollution and climate change (Baldini et al., 2018). As a result, awareness of reducing emissions from livestock activities (GHGs and other pollutants) has increased, resulting in many studies focused on quantifying the environmental burden of dairy production (O’Brien et al., 2012; van der Werf et al., 2014). Global population growth and dietary changes (increased milk consumption) have enforced increased food production. In contrast, environmental threats of climate change, biodiversity, and land and freshwater degradation raised public concern about the ecological footprint (Albert et al., 2021). The primary emissions from the dairy sector are methane at 30–39%, nitrous oxide at 17–22%, carbon dioxide at 15% from energy, and CO2 from land-use changes at 14–38% (Weiss and Leip, 2012).

Because India is the largest milk-producing country in the world, assessing its environmental impact can lead to getting a clear picture of its mitigation strategies. The states of Rajasthan and Punjab, selected for the study, are among India’s top five milk-producing states (Milk Production in India | Nddb.Coop, 2022). The current research has also identified two cows’ milk-producing farms in both states from which farm-level data is collected. The study used a Life Cycle Assessment (LCA) methodology to conduct the analysis. Hotspot analysis, used along with LCA methodology, could help to achieve this objective. LCA assesses a system’s environmental impact, and hotspot identifies unit processes with a high probability of improvement with less resource allocation.

To set the foundation of the research, the current study briefly discusses the existing literature on milk production and its sustainability studies, followed by discussing the materials and method aspects of the study. The materials and Methods explicitly discuss the research methodology adopted for the study, including the steps of life cycle analysis. The outcomes are demonstrated and discussed thereafter, which provides a comparative analysis of milk production in both states (Punjab and Rajasthan), followed by offering clarity on the research approach and managerial implications. The conclusion of the analysis is presented by discussing its significant findings, the study’s limitations, and future research direction.

Milk is a necessary daily need and a vital product for human life, as no perfect substitute exists for milk and its products (Kaushik, 2020; Reyes-Jurado et al., 2023; Siddiqui et al., 2023). The demand for milk and its products is continuously increasing and, simultaneously, its environmental concerns (Yan et al., 2011; Autio et al., 2023; Dixon et al., 2023). According to Prof. Peter Alexander of the Global Academy of Agriculture and Food Security, 116 million tonnes of milk products are wasted globally, and almost half of it gets wasted even before it reaches stores (One in Six Pints of Milk Thrown Away Each Year, Study Shows | Milk | The Guardian, 2018). The Food and Agriculture Organization of the United Nations approximated that 4.4GtCO2 is generated annually due to food loss and waste generated (Home | Food and Agriculture Organization of the United Nations, 2023). The wastage of food or milk also includes the energy and raw material needed to produce it. Two folds of energy are required: nutritional energy and embodied energy to make the food (Pagani et al., 2020). To improve the efficiency of the food/milk supply chain, quantification of these energies and the potential environmental burden is crucial (Von Greyerz et al., 2023). According to March et al. (2019), food production efficiency can be improved by an association between agricultural management and global challenges. Particularly for milk and its products, the temperature is a critical parameter for improving the resource efficiency of the supply chain. The temperature conditions maintained to store the milk at various stages of its life cycle can significantly affect its rate of bacteria development and, consequently, its decomposition (Barabas, 1995). A study by Grochowska and Szczepaniak (2019) focused on the dairy sector due to its importance and high consumption of natural resources like water and energy, along with high losses and environmental emissions. It is observed from research studies that the assessment of food wastage in the supply chain is complex due to data availability in developing economies (Cakar et al., 2020).

Using techniques such as LCA can give definite answers to identify hotspots and make decisions on these conditional applications (Hauschild, 2015; Sihag et al., 2019; Cakar et al., 2020; Sharma et al., 2020). The hotspot analysis is utilized to filter large information sets for prioritization and identification of hotspots for further actions to be taken (New! Hotspots Analysis Methodological Framework and Guidance – Life Cycle Initiative, 2017). The use of LCA was initiated by Harold Smith at the World Energy Conference in 1963, followed by the Coca-Cola company in 1969 by comparing the beverage containers (Bjørn et al., 2018). Consoli (1993) defined LCA as a process to assess the environmental impacts associated with a process, product, or activity by estimating quantitative values of materials and energy used along with waste and emissions released to the natural environment (Hospido et al., 2003). Over time, LCA has been used for accounting for the environmental impacts generated by various products (Ibbotson et al., 2013; Bhakar et al., 2015), processes (Sangwan et al., 2014; Finkbeiner et al., 2015), etc. In the dairy sector also, various studies have been carried out to understand the environmental burdens of milk production and to incorporate the uncertainties in the ways of milk production (Cederberg and Mattsson, 2000; Hospido et al., 2003; Thomassen et al., 2008a,b; Yan et al., 2011).

A study by Poore and Nemecek (2018) reviewed 1,580 studies on food based on their environmental impact. In these studies, 28 are from milk production. These studies take into account several practices: organic and conventional. Parameters of milk processing and various assumptions have been made to visualize the hotspots of milk production. The food sector is complex, uses high resources, and resists changes through technological intervention.

Similarly, the dairy sector needs multiple inputs (such as land use, natural resources, and different operational practices) to produce essential products for human consumption and several other by-products and emissions (March et al., 2019). Assessing environmental impact using LCA is a way to avoid problem shifting, and it can deal with complexity. Researchers have studied other aspects too, i.e., preventing milk wastage; (Munsch-Alatossava et al., 2019) studied the use of N2 gas-flushing to avoid decay milk, and it is found that the milk can be maintained in the existing situation for more than usual. However, the scope of the current study is meant to provide a visualization of the hotspots in milk production and its supply chain. There are no correct estimations of the environmental impact of waste in India’s milk supply chain (India’s Solutions to Cut Milk Waste – Dairy Global, 2019). It is also observed that only very few studies in India have addressed the environmental aspects of milk production, out of which one published study is from Anand Gujrat for the accounting carbon footprint of milk production by small farmers (Garg et al., 2016). There is no comparative analysis of the environmental impacts of milk production provided by the research community in India. The comparative analysis helps to understand the variation in ecological impacts due to different climatic and cultural modifications adopted in dairy practices. The current study carried out a life cycle analysis for milk production in Punjab and Rajasthan, two states of India, to understand these various aspects discussed in the existing literature.

In current research, we have indeed introduced an innovative approach to conducting a life cycle assessment (LCA) of milk production processes. The novelty lies in the integration of Comparative Environmental Impact Analysis and Sustainability Evaluation of two different and largest milk producer states of India, the unique study of the Indian context comparing seven different impact assessment categories, which differentiates our study from existing literature. By elucidating the innovative components and providing a comprehensive rationale, we aim to showcase the scientific rigor and advancements embedded in our proposed method scheme. We are confident that these innovations contribute significantly to the field of environmental sustainability assessment in the context of milk production.

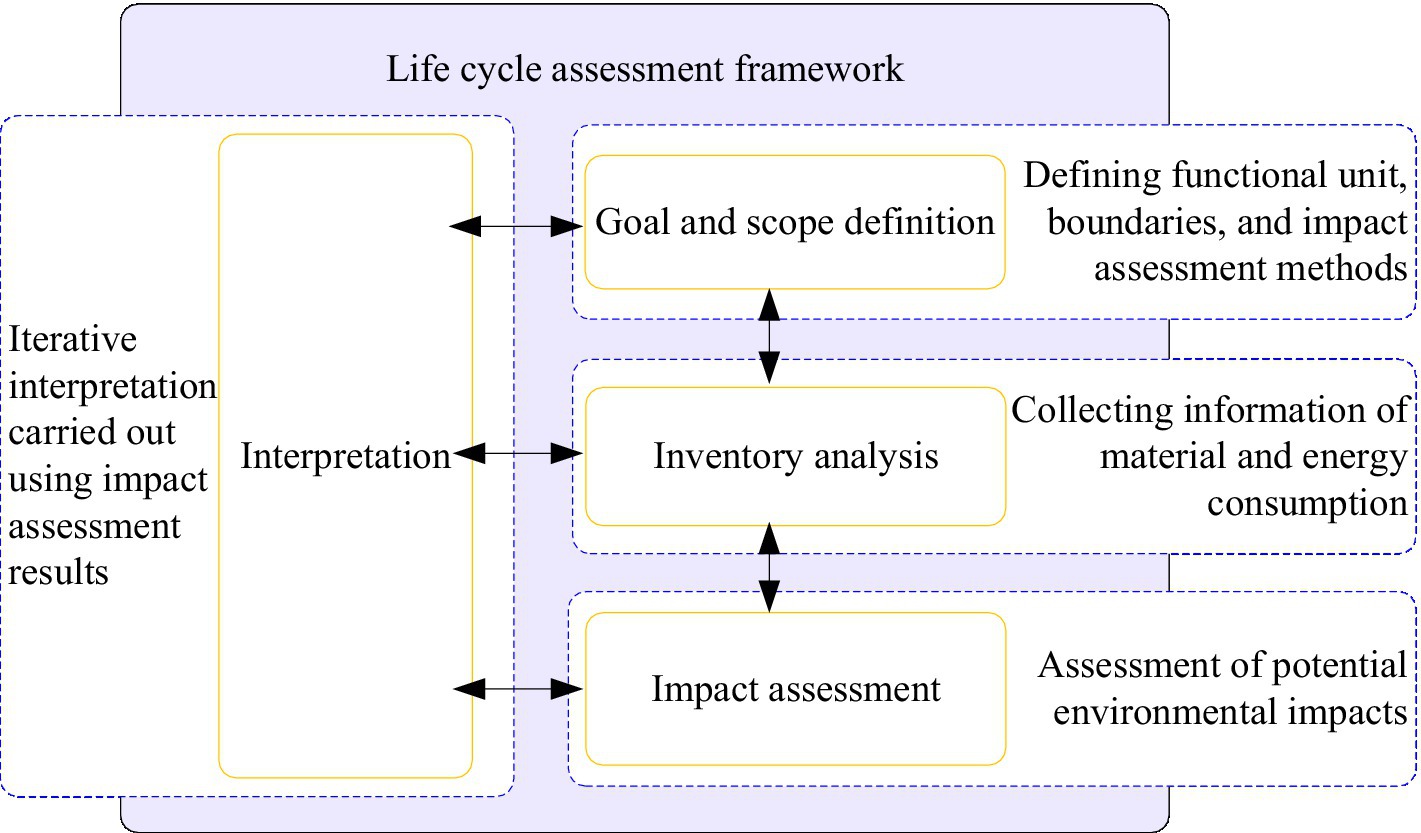

The environmental impact of milk production in the two states of Rajasthan and Punjab is analyzed using a simple LCA methodology. The method consists of four steps – goal and scope definition, inventory analysis, impact assessment, and interpretation, which are discussed in further detail later in this section. The data required for analysis are collected from both dairy farms and processing plants. The data collection includes feed needed for the cattle, water and energy requirements at the farm, raw and processed milk transportation, and material, energy, and water requirements at the milk processing plant. These inventory data are required to build a model of the material and energy flow for both states. The following subsection will discuss the details of the LCA methodology.

The methodology used to carry out the LCA is provided by the ISO 14040 series standards (International Organization for Standardization, 2006). This framework used to carry out the LCA includes four steps – goal and scope definition and inventory analysis (ISO 14041-issued in 1998), impact assessment (ISO14042 – issued at the end of 1999), and the last step was life cycle interpretation (ISO 14043 – published at the end of 1999). The system boundaries, the scope of the studies, and the functional unit are defined in the first step of goal and scope. In the second step, inventory analysis is carried out for the selected system under consideration. Inventory analysis is the most time-consuming step in LCA studies. The next step in LCA is impact assessment, which estimates the environmental impacts during different phases. There are two impact assessment methodologies: midpoint and endpoint assessment. The midpoint assessment evaluates some compounds’ ecological burdens in terms of equivalency. These environmental burdens expressed in different units of measurement are then further normalized and converted into damage categories to compare the environmental responsibility on a single scale. The last step in LCA analysis is the interpretation phase, an iterative phase. Interpretations are carried out based on the impacts assessed in the previous step. If the interpreted results fail to portray the desired view of the environmental impacts, then multiple interpretations are carried out. The commonly used LCA methodology suggested in ISO 14040 is shown in Figure 1.

Figure 1. Life cycle assessment framework (ISO 14040:1997 – Environmental Management — Life Cycle Assessment — Principles and Framework, 2006).

The objective of this study is to examine the total lifecycle of milk production and to identify the parameters responsible for environmental impacts. Above all, to compare the environmental impacts among the dairies of two states of Punjab (Pun) and Rajasthan (Raj). The functional unit chosen for the current study is 1 L of milk delivered to a retail outlet or end consumer. The description of the two milk processing plant companies in the two states is given below. It helps the reader to understand more about milk production in these companies.

a. Punjab State Cooperative Milk Producers Federation Limited (Milkfed): Milkfed was founded in 1973 to enhance the dairy farming and milk production in the state of Punjab. The primary objectives were to create a profitable milk market for dairy farmers and provide reasonable prices of milk to consumers. Presently, the co-operative company is operating with 11 milk unions, which are indulged in milk procurement, processing, and marketing activities in the state. Milkfed sells the milk and its products under the brand name of “Verka.” The Verka Mohali plant of the Milkfed was contacted, and multiple visits were carried out to understand the milk procurement and processing. The Mohali plant was registered in 1978 and started functioning in the year 1979. Currently, it procures milk from the entire Ropar or Rupnagar and Mohali district with an installed capacity of 5,00,000 liters and an annual turnover of 9.5 Billion INR. The plant has an association with 1,160 milk producer co-operative societies with an average collection of 3,62,000 liters of milk. In peak flushing season, it goes up to 5,20,000 liters per day. The Verka has a widespread reach to more than 3,60,000 farmers in the whole state of Punjab. The Mohali plant of Verka has an association with approximately 49,000 milk producers through 1,185 societies, and milk is collected and chilled at 300 Bulk milk cooler (BMC).

b. Rajasthan State Dairy Development Corporation (RSDDC): The RSDDC was initiated in the early seventies by the state Government of Rajasthan and registered in 1975. It became the nodal agency to implement operation flood in the state. Presently, the company has 21 milk unions, which are involved in milk procurement, processing, and marketing activities in the state. The RSDDC sells the milk and its products under the brand name of “Saras.”

The Saras Jaipur plant of the RSDDC was contacted, and multiple visits were carried out to understand the milk procurement and processing. The Saras Jaipur plant was established in 1975; it had increased its handling capacity from 1.5 lakh liters per day in 1981 to 5.0 lakh liter per day in 2019. The milk in the Jaipur plant is majorly procured from the Dausa and Jaipur district. The plant/union has 2,552 dairy co-operative societies with a total membership of 179,628 milk producers. Around 140 milk producers were contacted personally to understand the process.

The system boundary of the current study includes daily requirements of different feeds for the cows, fresh water for washing and drinking, energy, cleaning agents, biogas or biomass generated, methane emission from cows, energy, and freshwater required for milk processing and transportation. In short, the selected system boundary in this study covers a ‘cradle to gate’ approach, including extra transportation of processed milk to consumers. The organization system boundary of the study is shown in Figure 2. In contrast, the operating system boundary includes operations for 1 year. The yearly data on average resource consumption for a thousand liters of milk production for each state has been recorded. This strategy has been applied for a farm as well as for the processing unit.

The inventory analysis for the study has been carried out in various modes and steps. Carrying out the first step, a basic understanding of milk production has been gained by visiting multiple dairy farms in both states. After that, two large milk suppliers in both states providing milk to the state dairy cooperative processing industries were selected. Then, multiple visits were carried out at each of the chosen farms in both states. Real-time data has been collected through detailed discussions with the farmworkers and owners of the farms. Real-time observations and estimations were made for process-specific inputs at the farm level. It is observed that in both states, methane emission per cow due to enteric fermentation (in ruminant animals) is 35 gallons per day. The observations were based on the expert opinions of veterinary doctors and scientists of state agricultural universities in both states. It is assumed that at the retailer or consumer end, the milk is directly consumed after delivery and not stored longer. It is also believed that there is negligible or no transportation of milk between the retailer and the consumer. The sanitization solution used for cow cleaning is not included in the analysis.

Each state’s most significant state cooperative dairy organization was contacted to collect milk processing data. Multiple visits were made to their central plant in the state capitals to understand the milk processing. It is observed that besides the types of processed milk (toned, low-medium-full fat, milk powder, etc.), both the dairies have significant differences in demand for other milk products. Therefore, to establish a common basis for comparison, 1 liter of full cream milk (untoned milk) processed at each state has been considered as a functional unit. The differences exist due to different climatic conditions and food habits in both states. The inventory analysis developed by the above-stated method for both states is given in Table 1.

The impact assessment has been carried out using the ReCiPe method. Both midpoint and endpoint impact assessment has been used to evaluate the environmental burden of milk production in Punjab and Rajasthan. Seven impact categories have been selected for assessing the environmental impacts in the midpoint impact assessment. The selected seven impact categories are – Agricultural Land Occupation (ALO) – m2a, Climate Change (CC) – Kg CO2-Eq., Fossil Depletion Potential (FDP) -kg oil-Eq, Freshwater Eutrophication Potential (FEP) -kg P-Eq, Human Toxicity Potential (HTP) – kg 1,4-DCB-Eq, Ozone Depletion Potential (ODP) -kg CFC-11-Eq, and Water Depletion Potential (WDP) – m3. In the endpoint impact assessment, three categories were chosen for assessing the environmental impacts. The three selected categories are – Ecosystem quality – points, Human Health – points, and Resources – points.

The specific assessment results for each impact category in the Life Cycle Assessment (LCA) of the milk production process are calculated using impact assessment methods. The equations for each impact category are as follows:

Agricultural Land Occupation (ALO) – m2a:

Where:

ALOresult is the result for Agricultural Land Occupation.

ALOinventory is the inventory data for Agricultural Land Occupation (e.g., land area used in square meters per year).

ALOcharacterization is the characterization factor for Agricultural Land Occupation (unit: m2a per unit of impact).

Climate Change (CC) – Kg CO2-Eq:

Where:

CCresult is the result for Climate Change.

CCinventory is the inventory data for Climate Change (e.g., greenhouse gas emissions in kilograms of CO2-equivalents).

CCcharacterization is the characterization factor for Climate Change (unit: kg CO2-Eq per unit of impact).

Fossil Depletion Potential (FDP) – kg oil-Eq:

Where:

FDPresult is the result for Fossil Depletion Potential.

FDPinventory is the inventory data for Fossil Depletion Potential (e.g., fossil fuel consumption in kilograms of oil-equivalents).

FDPcharacterization is the characterization factor for Fossil Depletion Potential (unit: kg oil-Eq per unit of impact).

Freshwater Eutrophication Potential (FEP) – kg P-Eq:

Where:

FEPresult is the result for Freshwater Eutrophication Potential.

FEPinventory is the inventory data for Freshwater Eutrophication Potential (e.g., nutrient emissions in kilograms of phosphorus-equivalents).

FEPcharacterization is the characterization factor for Freshwater Eutrophication Potential (unit: kg P-Eq per unit of impact).

Human Toxicity Potential (HTP) – kg 1,4-DCB-Eq:

Where:

HTPresult is the result for Human Toxicity Potential.

HTPinventory is the inventory data for Human Toxicity Potential (e.g., toxic emissions in kilograms of 1,4-dichlorobenzene-equivalents).

HTPcharacterization is the characterization factor for Human Toxicity Potential (unit: kg 1,4-DCB-Eq per unit of impact).

Ozone Depletion Potential (ODP) – kg CFC-11-Eq:

Where:

ODPresult is the result for Ozone Depletion Potential.

ODPinventory is the inventory data for Ozone Depletion Potential (e.g., ozone-depleting substance emissions in kilograms of CFC-11-equivalents).

ODPcharacterization is the characterization factor for Ozone Depletion Potential (unit: kg CFC-11-Eq per unit of impact).

Water Depletion Potential (WDP) – m3:

Where:

WDPresult is the result for Water Depletion Potential.

WDPinventory is the inventory data for Water Depletion Potential (e.g., water consumption in cubic meters).

WDPcharacterization is the characterization factor for Water Depletion Potential (unit: m3 per unit of impact).

As described in the LCA framework, the results of the study are discussed in terms of impact assessment and their interpretation (as shown in Figure 1). Both midpoint and endpoint assessment results are developed in graphical and tabulated form to present with their relevant discussion. The units for midpoint categories are given after each category, whereas the endpoint categories have the same unit in points. As this is a comparative study of environmental impacts on milk production in Punjab and Rajasthan, all the results are prepared on a comparative basis. It is essential to mention that a direct comparison of different midpoint categories is not possible due to separate units of impact. However, the graphs can be plotted among two products or processes for absolute values in comparative analysis. Similarly, the values of inventory analysis in Rajasthan and Punjab are different; hence, an absolute comparison between midpoint results has been provided. As the endpoint environmental impacts are in a single unit, they can be plotted on absolute values of different categories, even without the case of two products or process comparison.

The midpoint assessment results are prepared using the selected seven categories. Figure 3 shows the comparative midpoint assessment results for milk production in Punjab (Pun) and Rajasthan (Raj). In Figure 3, results are visualized as per different inventory analysis materials. It is observed in the first place that dry feed has the highest impact, followed by concentrated feed, cleaning solution, green feed, packaging material, and LPG used in dairy and milking energy.

Therefore, Figure 3 carefully shows the impacts of the remaining materials/energy of inventory analysis. The results plotted without the abovementioned inventory items show that milk chilling at the farm, processed milk distribution, raw milk transportation, water pump energy, milk processing, and air conditioning energy have higher impacts. The energy required to run the feed-making plant has comparatively low impacts.

On the other hand, waste biomass at the farm and freshwater dairy plant has a negligible or meager impact in comparison to others, as shown in Figure 3. It is found that water pump energy required in Rajasthan has a high climate change impact when compared to Punjab. The key reason for the same will be the lower water table in Rajasthan compared to Punjab, whereas the milk chilling energy required has a high climate change impact in Punjab compared to Rajasthan. The values of the environmental impacts in various categories are shown in Table 2.

Figure 4 of the study shows the comparative analysis of the high-impacting inventory items beside dry feed. Figure 4 compares the environmental impacts of cleaning solution, green feed, concentrated feed, LPG used, packaging material, and milking energy for both Rajasthan and Punjab. It is observed that concentrated feed has the highest environmental impact, followed by packaging material, LPG used, milking energy, green feed, and cleaning solution. The impact in the agriculture land occupation category, the concentrated feed, and green feed produced in Punjab have more impact than in Rajasthan, as shown in Figure 4. At the same time, the climate change impact of LPG used in Punjab is significantly higher as compared to Rajasthan. The impact of climate change due to milking energy is reversed when compared to LPG used in Punjab and Rajasthan. The environmental impacts of green feed are on the higher side when compared to all the inventory items. Still, it’s the human toxicity potential that is having a negative impact in both Punjab and Rajasthan (as shown in Table 2). Figure 5 shows the environmental impacts of dry feed, which has the highest impact in the midpoint categories. Since its contribution to ecological burdens is higher, it has been plotted separately against the seven categories in a comparative manner.

The dry feed has a high impact in the agriculture land occupation category, followed by climate change, fossil depletion potential, human toxicity potential, and water depletion potential. In the rest of the two categories, there is a low impact. In all the above state categories, the dry feed used in Rajasthan has a slightly higher impact than in Punjab. In the agricultural land occupation category, dry feed’s impact on Rajasthan is relatively high.

Endpoint assessment is a top-down approach; it allows the expression of the environmental impacts of products and processes in single scores. The endpoint assessment is designed across three major damage categories: human health, resources, and ecosystem quality. Its methodology is described in three spheres – the techno sphere – the ecosphere – and the value sphere (Hofstetter et al., 2000; Bhakar et al., 2013). The LCA model is developed in the techno sphere, which results in inventory analysis. The modeling is carried out in the ecosphere to link the inventory analysis with the above-defined damage categories. Finally, the value sphere modeling is utilized to weigh these endpoints into single score indicators/values (Bhakar et al., 2013). The endpoint assessment results are plotted to show comparative environmental analysis in a single score environmental impact. It is observed that in the list of inventory analyses, LPG used, packaging material, green feed, dry feed, concentrated feed, and processed milk distribution have the highest environmental impacts over others. The values of endpoint assessment results are shown in Table 3.

These high-impacting parameters (i.e., materials/energy) are sweeping away the impacts of parameters with less impact. Therefore, these high-impacting materials/energies are plotted separately in Figures 6, 7. Similar to midpoint assessment results, in endpoint assessment, the highest environmental impacts are due to dry feed; after removing dry feed and other items – LPG used, packaging material, green feed, concentrated feed, and milking energy. The cleaning solution has high environmental impacts in the remaining inventory items, followed by milk chilling at the farm, raw milk transportation, processed milk distribution, water pump energy, air conditioning energy, milk processing energy, feed plant energy, diesel used at a dairy plant, etc. Punjab’s cleaning solution extensively impacts human health and resource categories. However, it is difficult to make a trade-off between the quantities required to clean efficiently and the hygiene level required for milk-carrying equipment/vessels. An in-depth study of the same may help in reducing environmental impacts significantly. Second, in the list, the energy required for milk chilling in Punjab also has a high effect on both human health and resources categories, as shown in Figure 6. The reason for the high impact may be due to the overcapacity of the chilling system equipped at the farm level in Punjab.

In the remaining high-impacting inventory items, dry feed used in Rajasthan has the highest impact on ecosystem quality and human health. Second in the row is concentrated feed, which creates a high environmental impact in the ecosystem quality category in both Punjab and Rajasthan, as shown in Figure 7. LPG used at a dairy plant in Punjab has a high impact on the resources category. The resource category’s impact due to milking energy and cleaning solutions stands in the third and fourth positions. Waste biomass and freshwater required at farms have a negligible effect on almost all the categories compared to others. The cleaning solution used in Punjab also has the highest impact on ecosystem quality compared to others, as shown in Figure 7.

LPG used at the dairy plant (processing) has the second-highest impact in the resources category; packaging material used in Punjab has the third-highest effect in the resources category. The concentrated feed has significantly impacted the ecosystem’s quality and stands in fifth place.

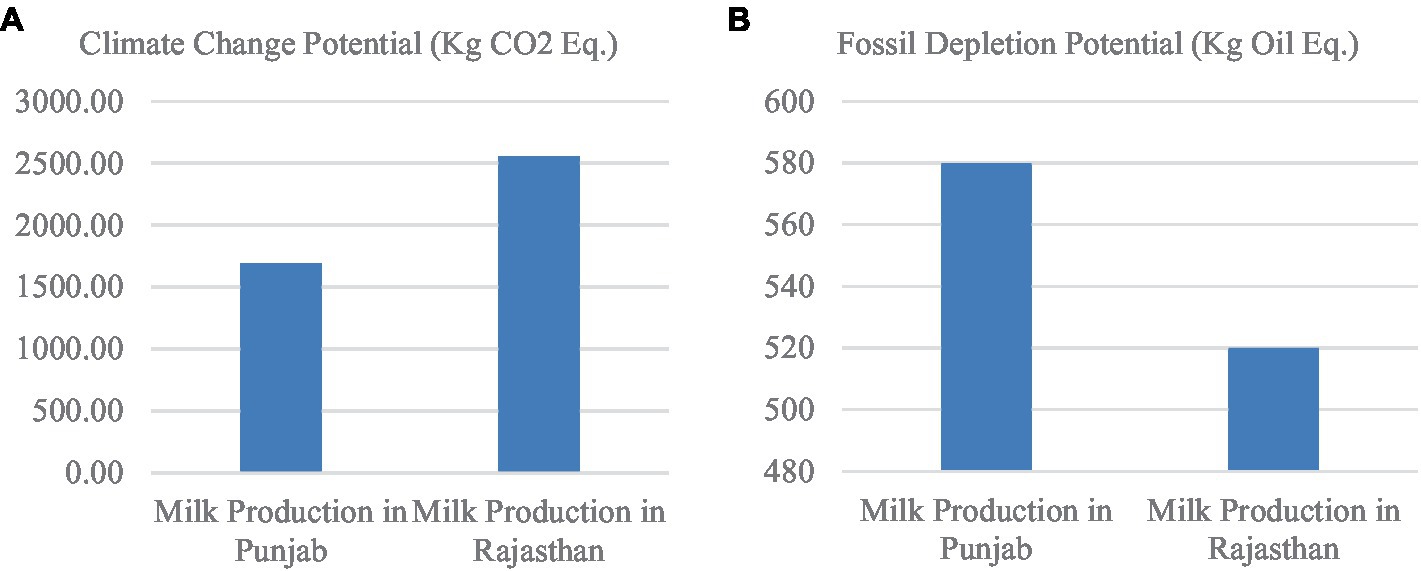

This section of the study provides a comparative analysis of the overall environmental impacts of milk production in Punjab and Rajasthan. Three midpoint assessment categories are selected to compare these widespread environmental impacts: climate change potential, fossil depletion potential, and agricultural land occupation. The graphical representations of these three categories are shown in Figures 8A,B and Figures 9A,B. Figure 8A shows the results of climate change potential, Figure 8B shows the comparative analysis of the fossil depletion potential category, and Figure 9A shows the results of agricultural land occupation. It is evident from the figures presented that milk production and its processing in Punjab generate less environmental impact in comparison to Rajasthan. However, milk production in Punjab has a higher fossil depletion potential than in Rajasthan. As shown in Figure 8A, 1,000 liters of milk production in Punjab generates 1,689 kg CO2 eq. Global warming potential, whereas Rajasthan’s milk production generates 2,550 kg CO2 eq. At the same time, the impact of fossil depletion is reversed in the case of Punjab.

Figure 8. Comparative analysis of milk production in Punjab and Rajasthan (A) climate change potential and (B) fossil depletion potential.

Figure 9. Comparative analysis of milk production in Punjab and Rajasthan (A) agricultural land occupation and (B) all the three categories together.

Similarly, regarding agricultural land occupation (ALO), milk production in Rajasthan needs more land to grow fodder crops and other raw materials. The ALO for milk production in Rajasthan is three times more as compared to Punjab, which is a major hotspot and needs in-depth analysis.

Figure 9B shows that the difference between the environmental impacts is small but significant. The milk production process in Rajasthan can be improved to make it more efficient.

The primary environmental impact categories found in this LCA of the milk production process are Agricultural Land Occupation, Climate Change, Fossil Depletion Potential, Freshwater Eutrophication Potential, Human Toxicity Potential, Ozone Depletion Potential, and Water Depletion Potential. According to the findings of current study and on the basis environmental impact categories selected, milk production in Punjab is more ecologically friendly than milk production in Rajasthan, and the feed required for cattle, together with the selection of packing material for processed milk, is a major environmental impact-generating activity. This study examined many phases of the milk production process to better understand the underlying causes of the detected environmental consequences. The results are further underlying that milk production in Punjab has a larger fossil depletion potential than milk production in Rajasthan, with 1,000 liters of milk production in Punjab generating 1,689 kg CO2 eq. global warming potential, whereas milk production in Rajasthan creates 2,550 kg CO2 eq. At the same time, in the case of Punjab, the impact of fossil depletion is reversed. Similarly, in terms of agricultural land occupancy (ALO), Rajasthan’s milk production requires greater land to cultivate fodder crops and other raw materials. Rajasthan has three times the ALO for milk production as Punjab, which is a key hotspot that requires in-depth investigation.

Current research is inherently aligned with the United Nations sustainable development goals (UN SDGs) through several key dimension. The goals of SDG2, SDG6, SDG12, SDG13, SDG14, SDG15 are attained either completely or up to some extents directly or indirectly from the implementation and results of the existing study.

Current study addresses the environmental sustainability of milk production, a crucial aspect of the broader food system. By identifying and mitigating environmental hotspots, this study contributes indirectly to ensuring sustainable food production systems, thus supporting the overarching goal of zero hunger.

The core focus of current research lies in evaluating the environmental impact of milk production, with an emphasis on identifying opportunities for sustainability improvements. By providing a comparative analysis and sustainability evaluation, this study directly contributes to SDG 12 by promoting responsible consumption and production practices.

The environmental impact analysis, particularly in the context of climate change (e.g., Climate Change impact category), addresses SDG 13. By understanding and quantifying greenhouse gas emissions associated with milk production, this study contributes valuable insights for stakeholders seeking to reduce the carbon footprint of the dairy industry.

The current investigation into the environmental effects of milk production extends to land use practices, directly aligning with SDG 15. By assessing impacts such as Agricultural Land Occupation, the study addresses the sustainability of land use in the context of milk production.

Through the evaluation of Water Depletion Potential and Freshwater Eutrophication Potential, this study contributes to discussions around water sustainability, aligning with SDG 6. By identifying areas for improvement, we indirectly support the goal of clean water and sanitation (Singh et al., 2023a).

While not a primary focus, current study indirectly contributes to SDG 14 by addressing aspects of environmental sustainability that can impact water ecosystems, especially in regions where milk production has localized environmental effects.

So, current research engages with multiple SDGs by directly addressing sustainable production practices, climate action, and responsible consumption, and acknowledge the interconnected nature of the SDGs, and serves as a valuable contribution to the broader discourse on achieving sustainability targets.

The Environmental Impacts of food products may vary more than 50 folds among different producers for the same product, which provides significant mitigating opportunities (Poore and Nemecek, 2018). However, these mitigation opportunities have trade-off limits in terms of both economic and environmental constraints. The best way to reduce the environmental impacts of food products, especially animal-based products (such as milk), is for the producer to monitor the impacts, choose best practices, and let the consumer know about the impacts. This study on the understanding of the environmental sustainability of milk production with two case studies from two different states of India is expected to contribute to the field of food LCA by suggesting a practical understanding of the environmental sustainability of milk production in various organizations. It is essential to mention here that the current research aims to assess environmental sustainability in general, and no allocation of dairy food supply chain by-products (such as meat) is performed. To assess the impacts, the study mainly addressed the operational boundaries (including energy and material as input milk and waste as output). Assessing the impacts of milk from varied animal sources or substitutes with different fat and protein content will vary; then, the goal and scope definition of the study will also need to be revisited. Contemporary research on the environmental sustainability of the general milk production process is scarce in the context of India. The results of this study are thus beneficial for managerial staff included in milk production, policymakers, and researchers. Here, the word manager represents the dairy farm managers and administrative staff of milk processing plants. Managers can identify hotspots as per the results of this study and can take necessary action to reduce the environmental burden. This paper has compared milk production in two different states of India so that respective state managers can learn the best practices of other states. The implication for policymakers is also crucial, as India is a developing country, and milk is a staple food. To satisfy the increasing demand for the ever-increasing population of India without compromising the needs of the future generation, it is essential to devise suitable policies for eco-efficient milk production. However, to meet the demand for milk, its other vegan substitutes can also be explored, such as soya milk, almond milk, pea milk, etc. Animal-based products always have a higher environmental impact as compared to their vegetable substitutes. The comprehensive inventory data of the Indian milk production dairy also forms a valuable dataset for academicians working in the field of LCA of dairy products to understand the LCA of Indian milk dairy better and incorporate the environmental perspectives in their future research. The processing plants can also improve their significant environmental impacting inventories (Gaurav et al., 2021, 2023a,b).

To address the identified environmental impacts, current study recommends in-depth investigation for key hotspots, which can depict the more elaborative reason behind it. For instance, implementing technology or process optimization, adopting sustainable sourcing practices for raw materials, and optimizing transportation logistics could contribute to significant reductions in specific impact categories (Singh et al., 2023b). Encouraging the adoption of sustainable practices, such as sustainable packaging, sustainable procurement, can not only mitigate the environmental impacts associated with milk production but also enhance the overall sustainability of the industry. The integration of circular economy principles and the use of renewable energy sources are key aspects to consider.

The research work carried out in this study has provided an initial visualization of hotspots in milk production in two states of India. A milk production comparison in two states in terms of processing and milk produced by cattle at the farm has been carried out. This study is an initial endeavor in this direction. Besides the direction to policymakers, the processing plants can also improve their significant environmental impacting inventories in milk production. Dry feed has been observed as the major hotspot in the milk production process in both states, followed by the impacts of different feeds required for cow food. The possible reason for this might be the pre-chain involved in the dry feed production from food grain harvesting. However, the pre-chain associated with the dry feed also delivers the food grains as a product. The milk production from every cattle does not remain constant year-round, but the daily feed requirement remains more or less consistent over the year. Second, everyday leftover feeds are removed, and fresh feeds are served to the cattle. These might be the potential reason for the high environmental impact due to various feeds. Partially closing the milk production loop by using waste biomass as an effective fertilizer for growing fodder crops can improve environmental performance significantly. Using renewable energy systems can also enhance milk production efficiency as the total energy requirement at the farm is also high and cumulatively makes a high impact. The roof of the sheds used for cow shelter can be utilized for a solar-powered system, and that much space is sufficient for meeting the daily energy requirement of a dairy plant. The use of renewable energy can also reduce dependency on fossil fuels. This study has several implications for managers of milk production, policymakers, and researchers. Managers can identify hotspots as per the results of this study and evolve techniques to reduce the environmental burden. This paper has compared the milk production in two states of India so that respective state managers can learn the best practices of other states. The implication for policymakers is also essential, as milk is a staple food, and its environmental impact study can guide the policymakers to devise eco-efficient policy for sustainable growth. This study only compared the milk production of two states, and future researchers can conduct a longitudinal study of all other dairy states. The study is limited to a large farm and processing plant in each of the states. The work can be extended to more plants and farms to understand the uncertainties in milk production practices. The milk processing companies can also compare and benchmark their environmental performance among competitors and other plants.

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

AS: Writing – original draft. VB: Conceptualization, Writing – review & editing. GG: Investigation, Writing – review & editing. CK: Supervision, Writing – review & editing. PS: Methodology, Writing – review & editing. HS: Validation, Writing – review & editing. GD: Conceptualization, Investigation, Writing – review & editing.

The author(s) declare financial support was received for the research, authorship, and/or publication of this article. This research was supported by IIT Ropar and MNIT Jaipur; DST, Government of India, for the Agriculture and Water Technology Development Hub (AWadh), Hub at the IIT Ropar in the framework of National Mission on Interdisciplinary Cyber-Physical Systems (NM – ICPS); Micro green roofing project supported by SERB, IMP/2018/000216 under IMPRINT 2 scheme, and TIGR2ESS project of DST-UKERI.

We acknowledge the help from the farmers and milk processing plants of Rajasthan and Punjab for allowing us to study the milk production process. The authors would also like to thank Rachit Kumar Sharma from IIT Ropar.

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Albert, J. S., Destouni, G., Duke-Sylvester, S. M., Magurran, A. E., Oberdorff, T., Reis, R. E., et al. (2021). Scientists’ warning to humanity on the freshwater biodiversity crisis. Ambio 50, 85–94. doi: 10.1007/s13280-020-01318-8

Autio, M., Sekki, S., Autio, J., Peltonen, K., and Niva, M. (2023). Towards de-dairyfication of the diet?—consumers downshifting milk, yet justifying their dairy pleasures. Front. Sustain. 4:975679. doi: 10.3389/frsus.2023.975679

Baldini, C., Bava, L., Zucali, M., and Guarino, M. (2018). Milk production life cycle assessment: a comparison between estimated and measured emission inventory for manure handling. Sci. Total Environ. 625, 209–219. doi: 10.1016/j.scitotenv.2017.12.261

Barabas, J. (1995). An alternative method of milk treatment. Rome: Revue Mondiale de Zootechnie (FAO); Revista Mundial de Zootecnia (FAO).

Bhakar, V., Sihag, N., Gieschen, R., Andrew, S., Herrmann, C., and Sangwan, K. S. (2015). Environmental impact analysis of a water supply system: study of an Indian university campus. Proc. CIRP 29, 468–473. doi: 10.1016/j.procir.2015.02.061

Bhakar, V., Uppala, V. V. K., Digalwar, A. K., and Sangwan, K. S. (2013). Life cycle assessment of smithy training processes. Proc. Eng. 64, 1267–1275. doi: 10.1016/j.proeng.2013.09.207

Bjørn, A., Owsianiak, M., Molin, C., and Hauschild, M. Z. (2018). “LCA history” in Life cycle assessment: theory and practice. eds. M. Z. hauschild, R. K. Rosenbaum, and S. I. Olsen (United States: Springer Publishing), 17–30.

Cakar, B., Aydin, S., Varank, G., and Ozcan, H. K. (2020). Assessment of environmental impact of FOOD waste in Turkey. J. Clean. Prod. 244:118846. doi: 10.1016/j.jclepro.2019.118846

Cederberg, C., and Mattsson, B. (2000). Life cycle assessment of milk production—a comparison of conventional and organic farming. J. Clean. Prod. 8, 49–60. doi: 10.1016/S0959-6526(99)00311-X

Consoli, F. (1993). Guidelines for life-cycle assessment. A code of practice. CiNii(Academic information search service.

Dairy | Industries | WWF (2023). Avaiable at: https://www.worldwildlife.org/industries/dairy (Accessed January 8, 2024, from

Dixon, K. A., Michelsen, M. K., and Carpenter, C. L. (2023). Modern diets and the health of our planet: an investigation into the environmental impacts of food choices. Nutrients 15:692. doi: 10.3390/nu15030692

Finkbeiner, M., Rethmeier, M., Chang, Y. J., Pittner, A., and Sproesser, G. (2015). Enviromental impacts of welding methods. Laser Mag. TRUMPF, 1–5.

Garg, M. R., Phondba, B. T., Sherasia, P. L., and Makkar, H. P. S. (2016). Carbon footprint of milk production under smallholder dairying in Anand district of Western India: a cradle-to-farm gate life cycle assessment. Anim. Prod. Sci. 56, 423–436. doi: 10.1071/AN15464

Gaurav, G., Bihari Singh, A., Mistry, S., Gupta, S., Dangayach, G. S., and Meena, M. L. (2021). Recent progress of scientific research on life cycle assessment. Mater. Today Proc. 47, 3161–3170. doi: 10.1016/J.MATPR.2021.06.208

Gaurav, G., Kumar, V., Bihari Singh, A., Gupta, S., Meena, M. L., Dangayach, G. S., et al. (2023a). Life cycle assessment of extraction of edible oil from mustard seeds: a case study of an oil industry. Mater. Today Proc. 1–6. doi: 10.1016/J.MATPR.2023.01.055

Gaurav, G., Singh, A. B., Khandelwal, C., Gupta, S., Kumar, S., Meena, M. L., et al. (2023b). Global development on LCA research: a bibliometric analysis from 2010 to 2021. Int. J. Soc. Ecol. Sustain. Dev. 14, 1–19. doi: 10.4018/IJSESD.327791

Ghosh, A., Misra, S., Bhattacharyya, R., Sarkar, A., Singh, A. K., Tyagi, V. C., et al. (2020). Agriculture, dairy and fishery farming practices and greenhouse gas emission footprint: a strategic appraisal for mitigation. Environ. Sci. Pollut. Res. 27, 10160–10184. doi: 10.1007/s11356-020-07949-4

Grochowska, R., and Szczepaniak, I. (2019). Sustainability business models in milk processing. Considerations based on the polish experience. J. Agribus. Rural Dev. 52, 111–122.

Gurtu, A., Salunke, P., and Debnath, T. K. (2023). Bird’s eye view of the global dairy industry: overview of milk-producing countries, dairy processes and cost comparison. Int. J. Agric. Resour. Gov. Ecol. 19, 22–40. doi: 10.1504/IJARGE.2023.133330

Hauschild, M. Z. (2015). Better – but is it good enough? On the need to consider both eco-efficiency and eco-effectiveness to gauge industrial sustainability. Proc. CIRP 29, 1–7. doi: 10.1016/j.procir.2015.02.126

Hofstetter, P., Baumgartner, T., and Scholz, R. W. (2000). Modelling the valuesphere and the ecosphere: integrating the decision makers’ perspectives into LCA. Int. J. Life Cycle Assess. 5, 161–175. doi: 10.1007/BF02978618

Home | Food and Agriculture Organization of the United Nations (2023). Available at: https://www.fao.org/home/en (Accessed January 8, 2024).

Hospido, A., Moreira, M. T., and Feijoo, G. (2003). Simplified life cycle assessment of Galician milk production. Int. Dairy J. 13, 783–796. doi: 10.1016/S0958-6946(03)00100-6

Ibbotson, S., Dettmer, T., Kara, S., and Herrmann, C. (2013). Eco-efficiency of disposable and reusable surgical instruments—a scissors case. Int. J. Life Cycle Assess. 18, 1137–1148. doi: 10.1007/s11367-013-0547-7

India’s Solutions to Cut Milk Waste – Dairy Global. (2019). Available at: https://www.dairyglobal.net/dairy/milking/indias-solutions-to-cut-milk-waste/ (Accessed January 8, 2024).

International Organization for Standardization (2006). Environmental management: life cycle assessment; principles and framework. Geneva, Switzerland: ISO.

ISO 14040:1997 – Environmental Management — Life Cycle Assessment — Principles and Framework (2006). Available at: https://www.iso.org/standard/23151.html (Accessed January 8, 2024)

Kashyap, A., Shukla, O. J., Jha, B. K., Ramtiyal, B., and Soni, G. (2023). Enhancing sustainable dairy industry growth through cold-supply-chain-integrated production forecasting. Sustain. For. 15:16102. doi: 10.3390/su152216102

Kaushik, H. (2020). A study on enablers and challenges in adoption of technology by north Indian dairy farms a systems approach.

Kraham, S. J. (2017). Environmental impacts of industrial livestock production. In G. Steier and K Patel. (eds) International farm animal, wildlife and food safety law. Springer, Cham.

March, M. D., Toma, L., Thompson, B., and Haskell, M. J. (2019). Food waste in primary production: Milk loss with mitigation potentials. Front. Nutr. 6:173. doi: 10.3389/fnut.2019.00173

Milk Production in India | Nddb.Coop (2022). Available at: https://www.nddb.coop/information/stats/milkprodindia (Accessed January 8, 2024).

Munsch-Alatossava, P., Ibarra, D., Youbi-Idrissi, M., and Alatossava, T. (2019). N2 gas-flushing prevents bacteria-promoted lipolysis and proteolysis and alleviates auto-oxidation in bovine raw milk during cold-storage. Front. Sustain. Food Syst. 3:41. doi: 10.3389/fsufs.2019.00041

New! Hotspots Analysis Methodological Framework and Guidance – Life Cycle Initiative (2017). Available at: https://www.lifecycleinitiative.org/new-hotspots-analysis-methodological-framework-and-guidance/ (Accessed January 8, 2024).

O’Brien, D., Shalloo, L., Patton, J., Buckley, F., Grainger, C., and Wallace, M. (2012). Evaluation of the effect of accounting method, IPCC v. LCA, on grass-based and confinement dairy systems’ greenhouse gas emissions. Animal 6, 1512–1527. doi: 10.1017/S1751731112000316

One in Six Pints of Milk Thrown Away Each Year, Study Shows | Milk | The Guardian (2018). Available at: https://www.theguardian.com/environment/2018/nov/28/one-in-six-pints-of-milk-thrown-away-each-year-study-shows (Accessed January 7, 2024).

Pagani, M., De Menna, F., Johnson, T. G., and Vittuari, M. (2020). Impacts and costs of embodied and nutritional energy of food losses in the US food system: farming and processing (part a). J. Clean. Prod. 244:118730. doi: 10.1016/j.jclepro.2019.118730

Poore, J., and Nemecek, T. (2018). Reducing food’s environmental impacts through producers and consumers. Science 360, 987–992. doi: 10.1126/science.aaq0216

Reyes-Jurado, F., Soto-Reyes, N., Dávila-Rodr’iguez, M., Lorenzo-Leal, A. C., Jiménez-Mungu’ia, M. T., Mani-López, E., et al. (2023). Plant-based milk alternatives: types, processes, benefits, and characteristics. Food Rev. Intl. 39, 2320–2351. doi: 10.1080/87559129.2021.1952421

Sangwan, K. S., Bhakar, V., Naik, S., and Andrat, S. N. (2014). Life cycle assessment of incandescent, fluorescent, compact fluorescent and light emitting diode lamps in an Indian scenario. Proc. Cirp 15, 467–472. doi: 10.1016/j.procir.2014.06.017

Sharma, R. K., Sodhi, G. P. S., Bhakar, V., Kaur, R., Pallakonda, S., Sarkar, P., et al. (2020). Sustainability in manufacturing processes: finding the environmental impacts of friction stir processing of pure magnesium. CIRP J. Manuf. Sci. Technol. 30, 25–35. doi: 10.1016/j.cirpj.2020.03.007

Siddiqui, S. A., Mehany, T., Schulte, H., Pandiselvam, R., Nagdalian, A. A., Golik, A. B., et al. (2023). Plant-based Milk – thoughts of researchers and industries on what should be called as ‘milk’. Food Rev. Intl. 10, 1–28. doi: 10.1080/87559129.2023.2228002

Sihag, N., Leiden, A., Bhakar, V., Thiede, S., Sangwan, K. S., and Herrmann, C. (2019). The influence of manufacturing plant site selection on environmental impact of machining processes. Proc. CIRP 80, 186–191. doi: 10.1016/j.procir.2019.01.023

Singh, A. B., Khandelwal, C., Sarkar, P., Dangayach, G. S., and Meena, M. L. (2023a). Achieving sustainable development in the hospitality industry: an evidence-based empirical study. Evergreen - Joint Journal of Novel Carbon Resource Sciences & Green Asia Strategy.

Singh, A. B., Khandelwal, C., Sarkar, P., Dangayach, G. S., and Meena, M. L. (2023b). Theoretical and methodological contribution of sustainable practices to the hospitality industry. Evergreen - Joint Journal of Novel Carbon Resource Sciences & Green Asia Strategy.

Subbanna, Y. B., Kumar, S., and Puttaraju, S. K. M. (2021). Forecasting buffalo milk production in India: time series approach. Buffalo Bull. 40, 335–343.

Thomassen, M. A., Dalgaard, R., Heijungs, R., and De Boer, I. (2008a). Attributional and consequential LCA of milk production. Int. J. Life Cycle Assess. 13, 339–349. doi: 10.1007/s11367-008-0007-y

Thomassen, M. A., van Calker, K. J., Smits, M. C. J., Iepema, G. L., and de Boer, I. J. M. (2008b). Life cycle assessment of conventional and organic milk production in the Netherlands. Agric. Syst. 96, 95–107. doi: 10.1016/j.agsy.2007.06.001

van der Werf, H. M. G., Garnett, T., Corson, M. S., Hayashi, K., Huisingh, D., and Cederberg, C. (2014). Towards eco-efficient agriculture and food systems: theory, praxis and future challenges. J. Clean. Prod. 73, 1–9.

Von Greyerz, K., Tidåker, P., Karlsson, J. O., and Röös, E. (2023). A large share of climate impacts of beef and dairy can be attributed to ecosystem services other than food production. J. Environ. Manag. 325:116400. doi: 10.1016/j.jenvman.2022.116400

Weiss, F., and Leip, A. (2012). Greenhouse gas emissions from the EU livestock sector: a life cycle assessment carried out with the CAPRI model. Agric. Ecosyst. Environ. 149, 124–134. doi: 10.1016/j.agee.2011.12.015

Keywords: Life cycle assessment, milk production system, milk LCA, environmental sustainability, milk handling and processing, hotspot identification

Citation: Singh AB, Bhakar V, Gaurav G, Khandelwal C, Sarkar P, Singh H and Dangayach GS (2024) Environmental sustainability of milk production: a comparative environmental impact analysis and sustainability evaluation. Front. Sustain. 5:1352572. doi: 10.3389/frsus.2024.1352572

Received: 08 December 2023; Accepted: 22 January 2024;

Published: 01 February 2024.

Edited by:

Yan Liu, Shantou University, ChinaReviewed by:

Zhou Chaoran, Changchun University of Science and Technology, ChinaCopyright © 2024 Singh, Bhakar, Gaurav, Khandelwal, Sarkar, Singh and Dangayach. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Alok Bihari Singh, bWVhYnNpbmdoQGdtYWlsLmNvbQ==

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.