- 1Department of Civil Engineering, Jamia Millia Islamia, New Delhi, India

- 2Department of Civil Engineering, Baba Ghulam Shah Badshah (BGSB) University, Rajouri, Jammu and Kashmir, India

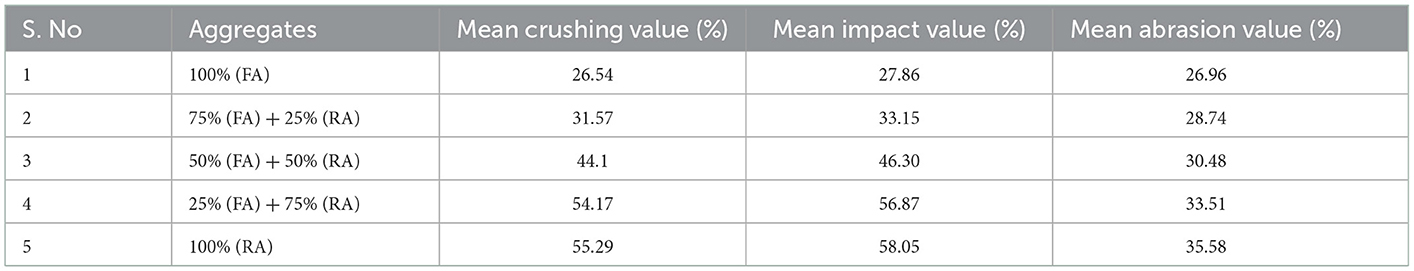

Recycled concrete aggregate, waste rock, crushed stone aggregate, reclaimed asphalt pavement, crushed clay brick, fine recycled glass, and gravel are some of the things that are left behind when concrete buildings are torn down. These things are a big problem for many countries around the world. More and more people want to find smart ways to use the waste that these substances make. To protect the environment and natural resources and to keep damage to the environment to a minimum, it is important to deal with this issue locally. Several studies have shown that old concrete is strong and can be used as a green material. This will make construction cheaper in the long run. Thus, the goal of this research was to find out how well demolished concrete waste works and what its engineering properties are so that it could be used in the base and sub-base of road pavements. The old concrete waste aggregates were used to replace the new or fresh aggregates in a range from 0% to 100% by weight. When demolished concrete waste aggregates were used instead of new aggregates, the water absorption went up from 1.58 to 4.65%. This shows that the water-cement ratio got better. The crushing value went up from 26.54 to 55.29%, the impact value went up from 27.86 to 58.05%, and the abrasion value went up from 26.96 to 35.58%. Based on the results of this study, the sub-base of roads can be made from a mix of 50% recycled aggregates and 50% new aggregates. Reusing concrete waste from buildings that have been torn down as a sub-base material will help reach social, economic, and environmental sustainability.

1. Introduction

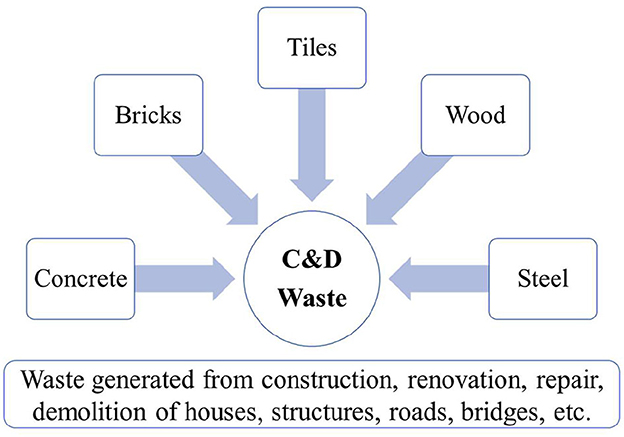

Normally, demolished concrete waste materials are solid waste materials produced by construction and demolition (C&D) or by industrial and commercial activities. These materials include building materials and products like bricks, concrete, timber, steel, reclaimed asphalt, fiber, etc. The major components of C&D waste are shown in Figure 1. Even though several benefits of using aggregates of recycled concrete in pavements have been proposed in the past, their implementation is still not widespread (Park, 2003). However, the apprehension about the environment made governments establish laws to use waste materials so that the environment can be protected, and the principles of sustainable development can be promoted.

The transportation department of the United Kingdom has already incorporated the application of recycled concrete into the specification for highway works. Japan has ordered a regulation to advance the utilization of reused concrete for development as it necessitates that a business substance under the class of development will attempt to keep up with the capacity requested by the work and to utilize recyclable assets to the actual and financially conceivable degree. Thinking about the pounding of the waste at the worksite, the area of reuse, and getting ready for the dynamic utilization of the space, a business will advance the utilization of recyclable assets (Poon, 1997). The carbon footprint will also be reduced by recycling the demolished concrete waste as compared to the traditional use of the materials. C&D waste can be used sustainably for asphalt applications, reducing the need for virgin materials (Arulrajah et al., 2013; Parihar et al., 2019). As compared to new aggregates, the selling rate of recycled material will be reduced if dumping charges are increased for C&D waste. In Korea, C&D waste is widely used in pavement construction.

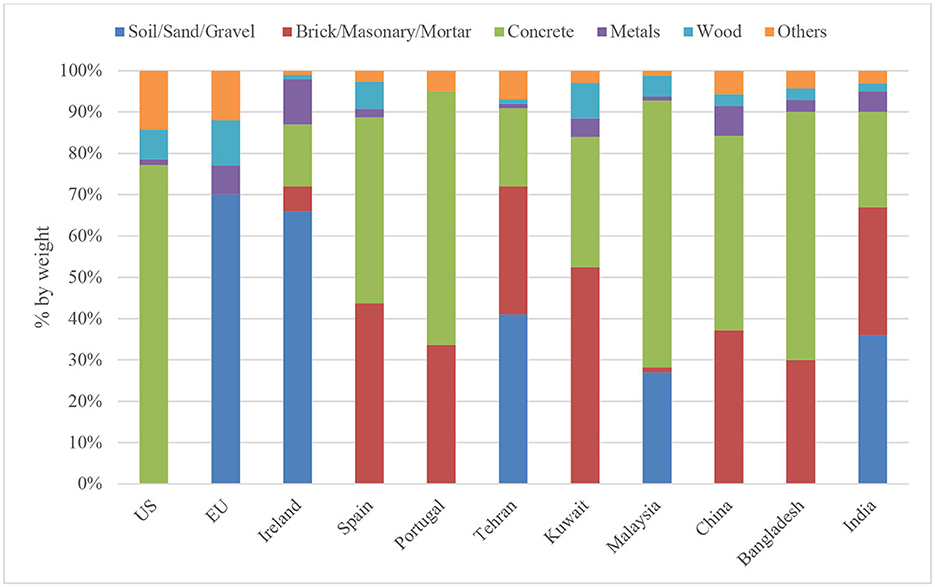

The demolition and restoration sites produce a large amount of construction waste, which gets dumped into landfills. The economic value of C&D waste materials becomes expensive when they get mixed with rubble, stone, and soil, which makes recycling problematic (Joshi and Ahmed, 2016). This C&D waste is considered only as a filling material at sites. Reusing C&D waste is an advanced methodology for forestalling ecological contamination by lessening loads of waste and by diminishing the utilization of regular materials. Figure 2 depicts the composition of typical C&D waste in India and worldwide. The greater part of the C&D waste is inert even though it is enormous in volume, which permits it to be crushed and reused in construction. Demolition waste that contains discarded solutions, half-used paint pots, chemicals, and solvents is most likely to be dangerous.

1.1. C&D materials

The various types of C&D materials used are discussed below:

1.1.1. Use of demolished concrete

In the United States and European countries, the quantity of concrete demolished every year is about 50–60 million tons, respectively (Kawano, 2003; Robinson et al., 2004). At present, only a very meager quantity of demolished concrete is recycled in these countries. However, in India, C&D waste is not used as a stabilizing material in road construction. Reusing demolished concrete to produce recycled concrete is of utmost importance in India as it is presently only dumped off as fill. Recycling demolished concrete is a necessity for developing countries like India as it does sustain the resources and promotes economic use of such C&D waste (Chandra, 2005). There are certain limitations to using recycled concrete in the construction of structures as the data available at present is insufficient to prove whether recycled concrete can be effectively used, but research work indicates that using recycled concrete for pavement construction is beneficial. Some countries have developed technologies and specifications for recycling C&D wastes (Poon et al., 2002; Shui et al., 2008).

The primary function of the sub-base is structural support, it reduces the break-in of fines from the subgrade in the structure of pavement and it also makes drainage efficient. The sub-base must be even and uniform to support the structures above it. The thickness of the sub-base should be sufficiently increased to resist the load coming on it (Khatib, 2005; Khater, 2011). Coarse or fine recycled concrete aggregates or recycled mortar produced from C&D waste can be utilized partly in road base materials or the construction of new structures. A gravel base as per design is laid over the subgrade, whereas a cover layer is given for weaker subgrade, i.e., California Bearing Ratio (CBR) = 2 in gravel roads. Based on the CBR value, the thickness of the gravel base can be altered into a sub-base of the pavement. One study in Hong Kong finds that the optimum moisture content got increased and the maximum dry density got decreased when the concrete aggregates were replaced by clay brick aggregates, which is mainly due to the low density and greater water absorption of bricks (Poon and Chan, 2006). Another study showed that the mechanical resistance showed improvement when sand (5%), cement (10%), and brick (6%) were added to recycled concrete aggregate (Chidiroglou et al., 2008). Experimental research work conducted on crushed concrete aggregates by Chidiroglou et al., 2008 suggested that different demolition waste materials are produced, which have different properties, and the results of the research would not be consistent with other wastes. The recycled aggregates were studied for physical characteristics, which showed that the greater the size of the aggregate, the less cement mortar will attach to its surface. The study concluded that there will be a greater amount of deformation when the porosity is high in recycled concrete aggregates (Melbouci, 2009).

In 2006, Poon and Chan gave careful attention to the utilization of crushed concrete and found that it can be used in the sub-base of roads when mixed with fine aggregates of variable sizes. They found out that the density of recycled aggregates does not change and showed flatter moisture density curves have greater tolerance. The recycled aggregates also showed an insignificant change in volume after four days of soaking in water, and their hydraulic conductivity was also greater than virgin aggregates (Poon and Chan, 2006). An experimental study conducted in 2004 by Sivakumar et al. (2004) indicated that due to cyclic loading, the resistance due to friction got reduced for C&D waste and shear strength was also suitable for its use in soil stability (Sivakumar et al., 2004). Another study found that when the clay slurry is mixed with recycled concrete, the internal angle of friction gets reduced from 39° to 32° (Mckelvey et al., 2002). Permanent deformation was compared between a dense graded aggregate, reclaimed asphalt pavement, and recycled concrete aggregate, and it was observed that the recycled concrete showed the lowest permanent deformation under cyclic loading (Bennert et al., 2000). In another study, the resilient modulus and permanent deformation were studied for recycled concrete, and it was concluded that recycled concrete aggregate was suitable for unbound base courses (Gabr and Cameron, 2012).

1.1.2. Use of crushed brick

While numerous studies have looked at the use of crushed brick in concrete mix (Chang et al., 2011; Zheng et al., 2011), concrete tiles and blocks (Jankovic et al., 2012; Li et al., 2012; López Gayarre et al., 2013), or new bricks (Liu et al., 2012), there has been less research on the use of crushed brick in road subbase applications. An experimental study on the particle size distribution, water absorption, flakiness index, particle density, compaction characteristics, aggregate impact, and aggregate crushing value of crushed brick concluded that crushed brick and crushed concrete had very different engineering properties (Chidiroglou et al., 2008). In 2006 Poon and Chan (2006) looked at the use of crushed brick aggregates in unbound subbase layers in Hong Kong 2006, and the authors found that they performed poorly under shear in CBR tests than recycled concrete aggregates. Gregory et al. conducted a study on brick recycling and reuse in the United Kingdom (2004). To attain better economic and environmental performance, their study examined the UK's current brick recycling capabilities and suggested new brick recycling technology (Gregory et al., 2004). The geotechnical characteristics of crushed brick used as a pavement subbase have been discussed by Aatheesan et al. (2010) and Arulrajah et al. (2011, 2012b). The performance of crushed bricks in comparison to other C&D materials and the effects of their use on the environment have not been reported before.

1.1.3. Use of waste rock

To use sandstone and shale aggregates in unbound forest roads, Rodgers et al. (2009) investigated their behavior under cyclic stress. According to test results, shale showed weak resistance to deformation and rutting while sandstone had very strong resistance (Rodgers et al., 2009). Through a variety of static and repetitive load triaxial experiments, Jitsangiam and Nikraz (2009) investigated the mechanical behavior of treated crushed rock used in road base layers. Research on the use of marble and andesite quarry wastes in asphalt pavements was done by Akbulut and Gürer in 2007. According to test results, these waste aggregates physical characteristics were within predetermined limits, which suggests that they could be used as aggregates in asphalt pavement binder layers for light to medium traffic areas (Akbulut and Gürer, 2007). In Mckelvey et al. (2002) utilized 40 mm homogenous crushed recycled rock (quarry waste) in ground improvement projects. Slurry negatively affects the shear strength and settlement potential of quarry waste aggregates, according to test data. In Nunes et al. (1996) in the UK conducted research on the use of secondary materials for paving and conducted a number of experiments, such as repeated load triaxial testing on mine-rock waste and slate waste. In their respective studies, Arulrajah et al. examined the geotechnical characteristics of waste rock used as a subbase for pavements. The performance of waste rock in comparison to other C&D materials and the environmental effects of its use, however, has not yet been reported (Arulrajah et al., 2012a).

1.1.4. Reclaimed asphalt pavement

Although there have not been many studies using cement-stabilized reclaimed asphalt pavement in this field, their use in road construction, including base and subbase layers, has been limited due to a lack of laboratory and field performance data. As a substitute for base layers, Taha et al. conducted a laboratory study of cement-stabilized reclaimed asphalt pavement and reclaimed asphalt pavement-virgin aggregate blends. According to test results, adding virgin aggregate and cement to recycled asphalt pavement generally increases its strength, moisture content, and maximum dry density. According to test results, only when stabilized with cement may pure reclaimed asphalt pavement aggregate be used as a typical base material. When stabilized with cement as opposed to when combined with virgin aggregate, reclaimed asphalt pavement aggregate has a greater potential to serve as a structural component in road pavements (Taha et al., 2002).

Hoyos et al. (2011) tested materials made from recycled asphalt pavement that had been coated with various amounts of Portland cement and alkali-resistant glass fibers. The potential of cement-fiber-treated recycled asphalt pavement as a structurally sound substitute for nonbonded materials in the base and subbase layers of road pavements was demonstrated by test results (Hoyos et al., 2011). In a study to determine if adding cement improves the robust qualities of reclaimed asphalt pavement aggregates, Puppala et al. conducted a series of repeated load triaxial tests. Reclaimed asphalt pavement's performance in comparison to other C&D materials and the environmental effects of its use, however, has not yet been reported (Puppala et al., 2011).

1.1.5. Use of fine recycled glass

The use of recycled broken glass as an alternative to sand and gravel in asphalt aggregate and concrete mixtures has been studied extensively (Meyer, 2001; Landris, 2007; Taha and Nounu, 2008). Recycled glass has also been proposed for use in pavements, embankment fills, and backfill material (Wartman et al., 2004; Senadheera et al., 2005; Landris, 2007). However, the primary obstacles to recycled glass's sustainable use in road repair applications are a lack of knowledge about its geotechnical properties and potential environmental dangers (Disfani et al., 2011).

Rubble from buildings that are demolished due to disasters contains furnishings, organic matter, and fragmented building components that are difficult to segregate. If buildings are demolished intentionally, it is possible to selectively demolish them, which makes it conceivable to reuse most of the structure's materials and parts and reuse a large portion of the rubble that was utilized in building them. Investigations were carried out on the composition of C&D waste in the Netherlands before the demolition of a building, and it was found that wood (20%), steel (90%), and other metals (100%) can be removed (Zhang et al., 2020). Low-income communities in developing countries generally use components and materials that are salvaged from demolished buildings for new construction work and renovation projects. Due to the recent global economic crisis, materials that were not considered worthy of being reused a few years ago are now sold in the market. For example, measures are adopted to enable the use of steel reinforcement from demolished buildings as building material instead of recycling it back into steel. Demolition contractors have now started giving significance to appropriate storage and segregation as they have become conscious of the practicality of recuperating C&D waste in construction work (Khalaf and DeVenny, 2004).

The increasing rate of industrial development can cause the exhaustion of resources and may also lead to an increase in C&D waste. In Australia, appreciable efforts are made to use recycled crushed aggregate for road pavements because of the unavailability of landfills and the rising cost of dumping. However, very limited information is available regarding the performance of non-standard materials like recycled crushed aggregate, particularly under the application of traffic loading, which makes the usage of such materials difficult. The inconstancy of this material may also affect the dependability of future expectations (Nataatmadja and Tan, 2001). The primary goal of this study was to make use of C&D waste, which is currently being discarded at various locations and landfills in India, and determine whether it might be used to build the sub-base for road pavement. The main objective was to determine the engineering characteristics as per Indian Standards by replacing the new or fresh aggregates with the C&D waste aggregates hereafter called recycled aggregates in terms of percentage by weight from 0 to 100%. The issue can be somewhat mitigated by using recycled aggregates in the sub-base for new construction projects.

2. Methodology

For experimental work, the engineering properties were analyzed for the recycled aggregates. For this, the concrete waste was acquired and then crushed. The crushed recycled aggregates were segregated and mixed with sand to match it with a mix of virgin aggregate and crushed stone aggregates. The tests were conducted by replacing the fresh aggregates (FA) with recycled aggregates (RA) in terms of percentage by weight, as 0, 25, 50, 75, and 100% replacement. In the control specimen, the fresh aggregates were not replaced with the recycled aggregates, i.e., 100% (FA), the second specimen contains 75% (FA) + 25% (RA), the third specimen contains 50% (FA) + 50% (RA), the fourth specimen contains 25% (FA) + 75% (RA), and the fifth specimen contains 100% (RA). Then the engineering properties like water absorption, sieve analyses, aggregates crushing value test, aggregate impact value test, and Los Angeles abrasion test were investigated for these specimens and compared with requirements stated by the Indian Road Congress (IRC) and Ministry of Road Transport and Highways (MORTH) regarding the usage of these materials as a sub-base material. The experiments were conducted as per the Bureau of Indian Standards (BIS).

3. Results and discussion

Various experiments were conducted to find the engineering properties of the specimens for their usage in road sub-base and the results obtained are discussed below:

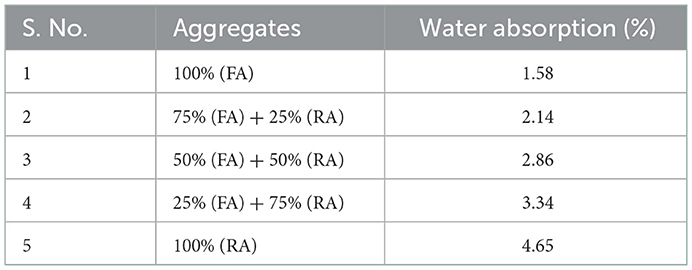

3.1. Water absorption

For an aggregate, water absorption is acknowledged as a proportion of its porosity. For road surfaces, the coarse aggregates normally have a 0.1 to 2.0% water absorption value. For the bituminous surface dressing, the aggregates should have a water absorption value of up to 1% as per the Indian Road Congress (IRC) and the Ministry of Road Transport and Highways (MORTH) (MoRTH, 2013). For the base course in bituminous macadam roads, the coarse aggregates should have a water absorption value of up to 2.0% as per MORTH. The water absorption by the aggregates with different percentages of replacement is shown in Table 1. From the results, it was observed that at full replacement with recycled aggregates, the water absorption value was the highest, i.e., 4.65%. This means that recycled aggregate has a greater capacity for water absorption than virgin aggregate. This can be due to mortar present in recycled aggregates as its capacity to absorb water is high. The water was absorbed into the pores present in the mortar, which caused a high absorption of water by the recycled aggregates.

3.2. Sieve analysis

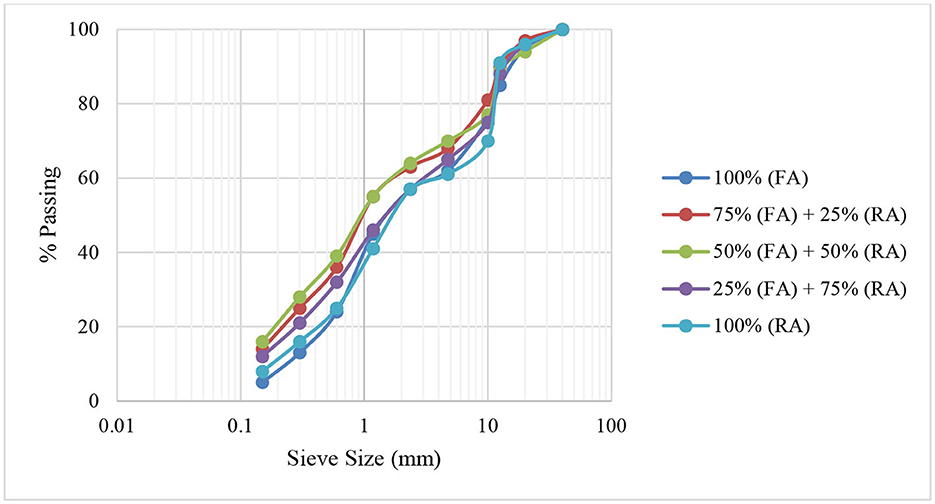

To determine the particle size distribution, a sieve test was performed by using different sizes of sieves in accordance with the BIS code (IS 2720: Part 4, 1985). The soils are divided into four groups based on particle size. The coarse fraction of soil and rock particles of size between 80 mm and 4.75 mm is called gravel. The next size between 4.75 mm and 0.075 mm is called sand. A particle size smaller than 0.075 mm is called fine-grained soil, which consists of silt (0.075 mm to 0.002 mm) and clay (0.002 mm). The weight of the material retained on each sieve is weighed and is expressed in terms of a percentage of the total weight of the sample. The recycled aggregate was passed through the sieves and the amount of aggregate segregated in accordance with its size was retained on the different sieves, which were recorded as shown in Figure 3.

Figure 3. Recycled aggregate particle size-distribution curves at different percentages of replacement.

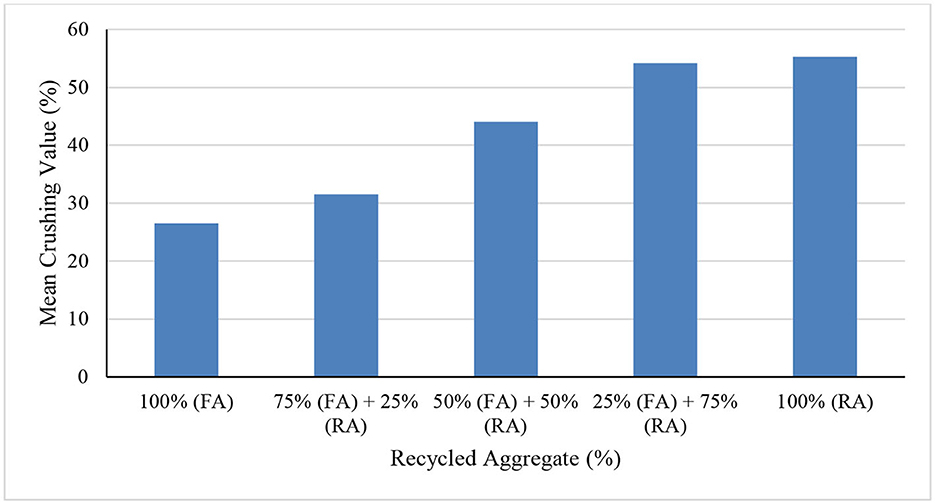

3.3. Aggregate crushing value test

Coarse aggregates used in pavement should resist crushing under rollers during compaction as well as due to heavy vehicular loads. The performance and stability of the pavement will be adversely impacted if weak aggregates are used in the pavement. The aggregate crushing value was determined to find the strength of coarse recycled aggregates. For the sub-base of roads, the aggregates used should be strong and not get crushed under vehicular load. The pavement structure will be weak if the aggregate is weak, which makes the test essential. Figure 4 depicts the aggregate crushing value with various percentages of replaced recycled aggregates. It was observed that the mean crushing value increased as the percentage of replacement of recycled aggregates increased. For cement concrete pavement surfaces, the coarse aggregates should have a crushing value of up to 30% and 45% for other than wearing surfaces as per IRC and BIS [IRC, 2011; IS: 2386 (Part IV), 2016]. For flexible and bituminous pavement, no aggregate crushing value is given for coarse aggregates by IRC or MORTH. Only 50% replacement of recycled C&D aggregates was permitted in the impacts test. Therefore, it can be used in the sub-base of the road.

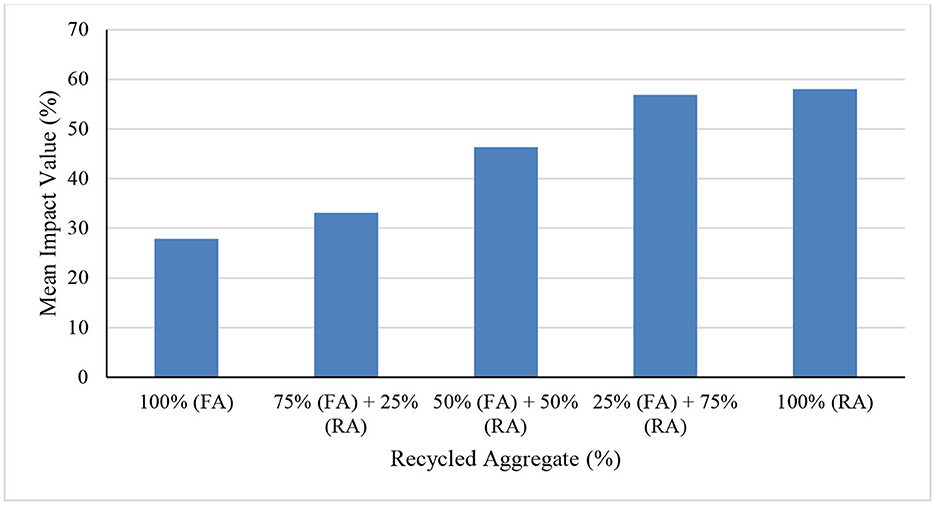

3.4. Aggregate impact test

The toughness of recycled aggregates was evaluated by performing an impact test. The aggregates used in the sub-base of roads get crushed due to vehicular movement or sudden impact load. Therefore, they should be strong enough to bear the impact load. For coarse aggregates, the maximum permissible aggregate impact value as specified by IRC and MORTH is 50% for using them in the sub-base and base course of the road [27, 30]. For aggregates or stones used in the sub-base of roads, they should resist fracture under impact loading. The aggregate impact value shows its capacity to resist impact loading. The aggregates' impact value is shown in Figure 5 with different % of replaced recycled aggregates. Only 50% of replaced recycled C&D aggregates were permitted in the impacts test, which means that the sub-base of the road made up of a mix of 50% of recycled aggregates and 50% of fresh aggregates can only be compacted by a roller.

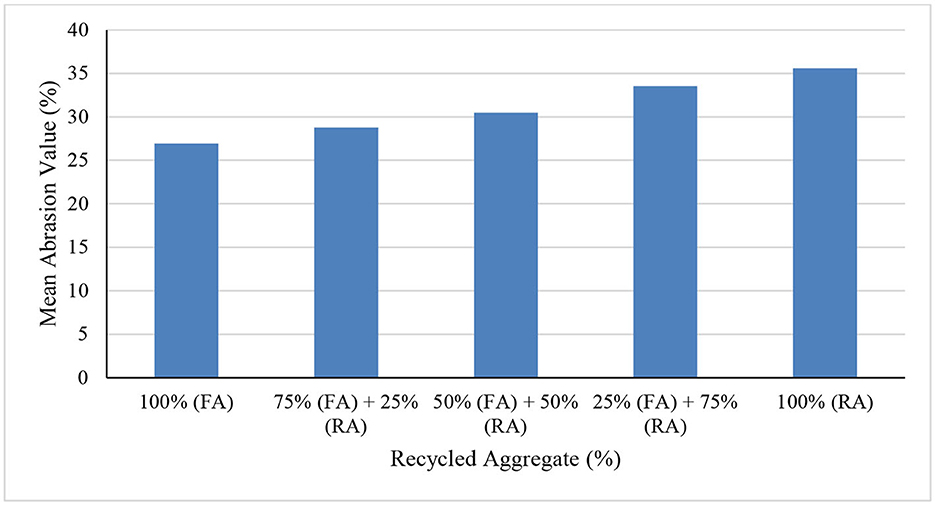

3.5. Los Angeles abrasion test

Due to the traffic movement, wearing action takes place on the surface of the aggregates used in the top layer of the pavements. Therefore, the aggregates should be strong enough to resist wear and abrasion due to traffic load. The IRC and MORTH have specified only the Los Angeles abrasion test concerning the requirement for abrasion resistance [27, 30]. Due to the rubbing of different aggregates, the surface of aggregates gets worn. This wear in terms of percentage is found out by the Los Angeles abrasion test. In this test, steel balls are used to find out the percentage of wear between aggregates and steel balls. IRC and MORTH have specified the maximum permissible Los Angeles abrasion value of coarse aggregates as 40% for use in the sub-base and base course of the road. Figure 6 depicts the aggregate abrasion value with various percentages of replaced recycled aggregates. A maximum of 100% of recycled C&D aggregates were permitted in the abrasion test, which means that the sub-base of the road made up of up to 100% of recycled aggregates can only be compacted by a roller. The summary of the results is shown in Table 2.

Table 2. Crushing value, impact value, and abrasion value of C&D waste at different percentages of replacement.

The challenge with such non-standard materials is the dearth of knowledge on how well they operate, particularly when subjected to wheel loads. Additionally, the material's unpredictability may have an impact on how accurately their future in-service performance is predicted. Therefore, it is important to research C&D waste's long-term performance when traffic is heavy and after numerous cycles of loading how much it will deteriorate. As a result, specific applications should only be made after taking the restrictions into account.

4. Conclusion

For sustainability in construction, it is very important to reuse the C&D waste material. The aim was to determine the feasibility of using construction and demolition waste as sub-base material on roads. Various standard tests were carried out on recycled aggregate, such as water absorption, sieve analysis, impact value, crushing value, and abrasion value tests. The results of the testing showed that even while the C&D waste comprises other waste such as rubble, dust, trash, etc., it can still be utilized as a sub-base material for building roads. The absorption of water increased from 1.58 (for 0% RA) to 4.65% (for 100% RA), which means that the requirement of water is greater, i.e., more water is required when used in the sub-base. The higher percentage of recycled aggregate leads to an increase in the crushing value of the aggregates. The physical requirements of coarse aggregates for water-bound macadam for sub-base are Los Angeles Abrasion value (40%), Aggregate Impact Value (50% max), and Aggregate Crushing Value (45%). Based on the results, the fresh aggregates can be optimally replaced with 50% of construction and demolition waste as the results obtained for 50% replacement with C&D waste were below the permissible limits given by IRC and MORTH. The experimental data suggest that demolished waste materials can be used for the construction of sub-bases of roads, which will make it possible to reduce the cost of road construction. Natural resources are finite and will eventually run out. Unnecessary waste of natural resources needs to be limited and controlled in order to conserve them. The reuse of demolished concrete will help in improving environmental conditions by reducing the load on stone mines; reducing air pollution, which is caused by manufacturing aggregates at stone crushers; and reducing vehicular pollution, in which aggregates are transported from crushers to construction sites. C&D waste can be reduced by creating and following a proper waste management plan throughout the course of the project. The responsible authority should provide a minimum required share of recycled aggregate for usage on roads after investigating its geotechnical perceptions in long-term performance. C&D waste is not waste, but rather a suitable material that can be used in the sub-base of road construction in and around cities. Recycling must be promoted through education and information. Most of the materials used in building and demolition can be recycled or used again with an integrated resource management strategy, helping to save more natural resources for future generations.

Data availability statement

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding authors.

Author contributions

All authors listed have made a substantial, direct, and intellectual contribution to the work and approved it for publication.

Acknowledgments

The authors are very thankful and acknowledge the administration of Jamia Millia Islamia, New Delhi and BGSBU, Jammu & Kashmir for their kind assistance, guidance, and technical support.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher's note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Abbreviations

BIS, Bureau of Indian Standard; CBR, California Bearing Ratio; C&D, Construction and Demolition; FA, Fresh Aggregates; IRC, Indian Road Congress; MORTH, Ministry of Road Transport and Highways; RA, Recycled Aggregates.

References

Aatheesan, T., Arulrajah, A., Bo, M. W., Vuong, B., and Wilson, J. (2010). Crushed brick blends with crushed rock for pavement systems. Proc. Inst. Civ. Eng. Waste Resour. Manag. 163, 29–35. doi: 10.1680/warm.2010.163.1.29

Akbulut, H., and Gürer, C. (2007). Use of aggregates produced from marble quarry waste in asphalt pavements. Build. Environ. 42, 1921–1930. doi: 10.1016/j.buildenv.2006.03.012

Arulrajah, A., Ali, M. M. Y., Piratheepan, J., and Bo, M. W. (2012a). Geotechnical properties of waste excavation rock in pavement subbase applications. J. Mater. Civ. Eng. 24, 924–932. doi: 10.1061/(ASCE)MT.1943-5533.0000419

Arulrajah, A., Piratheepan, J., Aatheesan, T., and Bo, M. W. (2011). Geotechnical properties of recycled crushed brick in pavement applications. J. Mater. Civ. Eng. 23, 1444–1452. doi: 10.1061/(ASCE)MT.1943-5533.0000319

Arulrajah, A., Piratheepan, J., Bo, M. W., and Sivakugan, N. (2012b). Geotechnical characteristics of recycled crushed brick blends for pavement sub-base applications. Can. Geotech. J. 49, 796–811. doi: 10.1139/t2012-041

Arulrajah, A., Piratheepan, J., Disfani, M. M., and Bo, M. W. (2013). Geotechnical and geoenvironmental properties of recycled construction and demolition materials in pavement subbase applications. J. Mater. Civ. Eng. 25, 1077–1088. doi: 10.1061/(ASCE)MT.1943-5533.0000652

Bennert, T., Papp, J., Maher, A., and Gucunski, N. (2000). Utilization of construction and demolition debris under traffic-type loading in base and subbase applications. Transp. Res. Rec. 2, 33–39. doi: 10.3141/1714-05

Chandra, S. (2005). Implications of using recycled construction and demolition waste as aggregate in concrete. Int. Conf. Sustain. Waste Manag. Recycl. 27, 738–741.

Chang, C. Y., Huang, R., Lee, P. C., and Weng, T. L. (2011). Application of a weighted grey-taguchi method for optimizing recycled aggregate concrete mixtures. Cem. Concr. Compos. 33, 1038–1049. doi: 10.1016/j.cemconcomp.2011.06.005

Chidiroglou, I., Goodwin, A. K., Laycock, E., and O'Flaherty, F. (2008). Physical properties of demolition waste material. Proc. Inst. Civ. Eng. Constr. Mater. 161, 97–103. doi: 10.1680/coma.2008.161.3.97

Disfani, M. M., Arulrajah, A., Bo, M. W., and Hankour, R. (2011). Recycled crushed glass in road work applications. Waste Manag. 31, 2341–2351. doi: 10.1016/j.wasman.2011.07.003

Gabr, A. R., and Cameron, D. A. (2012). Properties of recycled concrete aggregate for unbound pavement construction. J. Mater. Civ. Eng. 24, 754–764. doi: 10.1061/(ASCE)MT.1943-5533.0000447

Gregory, R. J., Hughes, T. G., and Kwan, A. S. K. (2004). Brick recycling and reuse. Proc. Inst. Civ. Eng. Eng. Sustain. 157, 155–161. doi: 10.1680/ensu.2004.157.3.155

Hoyos, L. R., Puppala, A. J., and Ordonez, C. A. (2011). Characterization of cement-fiber-treated reclaimed asphalt pavement aggregates: preliminary investigation. J. Mater. Civ. Eng. 23, 977–989. doi: 10.1061/(ASCE)MT.1943-5533.0000267

IRC (2011). Standard Specifications and Code of Practice for Construction of Concrete Roads. New York, NY.

IS : 2386 (Part IV) (2016). Methods of test for Aggregates for Concrete, part 4 : Mechanical Properties. Bur. Indian Stand. New Delhi.

IS 2720: Part 4 (1985). Indian Standard, Methods of Test for Soils, Part 4: Grain Size Analysis. Bur. Indian Stand. New Delhi.

Jankovic, K., Nikolic, D., and Bojovic, D. (2012). Concrete paving blocks and flags made with crushed brick as aggregate. Constr. Build. Mater. 28, 659–663. doi: 10.1016/j.conbuildmat.2011.10.036

Jitsangiam, P., and Nikraz, H. (2009). Mechanical behaviours of hydrated cement treated crushed rock base as a road base material in Western Australia. Int. J. Pavement Eng. 10, 39–47. doi: 10.1080/10298430802342682

Joshi, R., and Ahmed, S. (2016). Status and challenges of municipal solid waste management in India: a review. Cogent Environ. Sci. 2, 1139434. doi: 10.1080/23311843.2016.1139434

Kawano, H. (2003). “The state of using by-products in concrete in Japan and outline of JIS,” in Proceedings of the 1st FIB Congress on Recycling (Osaka), 245–253.

Khalaf, F. M., and DeVenny, A. S. (2004). Recycling of demolished masonry rubble as coarse aggregate in concrete: review. J. Mater. Civ. Eng. 16, 331–340. doi: 10.1061/(ASCE)0899-1561(2004)16:4(331)

Khater, H. M. (2011). Utilization of demolished concrete, grog, hydrated lime and cement kiln dust in building materials. J. Mech. Eng. Res. 3, 279–285.

Khatib, J. M. (2005). Properties of concrete incorporating fine recycled aggregate. Cem. Concr. Res. 35, 763–769. doi: 10.1016/j.cemconres.2004.06.017

Landris, T. (2007). Recycled glass and dredged materials engineer research and development center vicksburg ms geotechnical and structures lab. Materials 1, 12.

Li, F., Chen, J., Zhao, X., and Hou, N. (2012). Experiment research on the use of recycled brick aggregate in concrete tiles. Adv. Mater. Res. 377, 1912–1915. doi: 10.4028/www.scientific.net/AMR.374-377.1912

Liu, H. J., Li, P. X., Cao, S. G., and Zhao, F. Q. (2012). Preparation of high-performance brick from construction and demolition waste. Adv. Mater. Res. 392, 180–183. doi: 10.4028/www.scientific.net/AMR.391-392.180

López Gayarre, F., López-Colina, C., Serrano, M. A., and López-Martínez, A. (2013). Manufacture of concrete kerbs and floor blocks with recycled aggregate from CandDW. Constr. Build. Mater. 40, 1193–1199. doi: 10.1016/j.conbuildmat.2011.11.040

Mckelvey, D., Sivakumar, V., Bell, A., and Mclaverty, G. (2002). Shear strength of recycled construction materials intended for use in vibro ground improvement. Proc. Inst. Civ. Eng. Gr. Improv. 6, 59–68. doi: 10.1680/grim.2002.6.2.59

Melbouci, B. (2009). Compaction and shearing behaviour study of recycled aggregates. Constr. Build. Mater. 23, 2723–2730. doi: 10.1016/j.conbuildmat.2009.03.004

Meyer, C. (2001). “Recycled glass - from waste material to valuable resource,” in Recycling and Reuse of Glass Cullet, 1–10.

MoRTH (2013). Specifications for road bridge works 5th revision. Minist. Road Transp. Highw. 1, 1–883.

Nataatmadja, A., and Tan, Y. L. (2001). Resilient response of recycled concrete road aggregates. J. Transp. Eng. 127, 450–453. doi: 10.1061/(ASCE)0733-947X(2001)127:5(450)

Nunes, M. C. M., Bridges, M. G., and Dawson, A. R. (1996). Assessment of secondary materials for pavement construction: technical and environmental aspects. Waste Manag. 16, 87–96. doi: 10.1016/S0956-053X(96)00030-X

Parihar, R. S., Ahmed, S., Baredar, P., Sharma, A., and Kiran, T. R. (2019). MSWM in Bhopal city: a critical analysis and a roadmap for its sustainable management. Proc. Inst. Civ. Eng. Munic. Eng. 172, 83–95. doi: 10.1680/jmuen.17.00011

Park, T. (2003). Application of construction and building debris as base and subbase materials in rigid pavement. J. Transp. Eng. 129, 558–563. doi: 10.1061/(ASCE)0733-947X(2003)129:5(558)

Poon, C. S. (1997). Management and recycling of demolition waste in Hong Kong. Waste Manag. Res. J. Sustain. Circ. Econ. 15, 561–572. doi: 10.1177/0734242X9701500602

Poon, C. S., and Chan, D. (2006). Feasible use of recycled concrete aggregates and crushed clay brick as unbound road sub-base. Constr. Build. Mater. 20, 578–585. doi: 10.1016/j.conbuildmat.2005.01.045

Poon, C. S., Kou, S. C., and Lam, L. (2002). Use of recycled aggregates in molded concrete bricks and blocks. Constr. Build. Mater. 16, 281–289. doi: 10.1016/S0950-0618(02)00019-3

Puppala, A. J., Hoyos, L. R., and Potturi, A. K. (2011). Resilient moduli response of moderately cement-treated reclaimed asphalt pavement aggregates. J. Mater. Civ. Eng. 23, 990–998. doi: 10.1061/(ASCE)MT.1943-5533.0000268

Robinson, G. R., Menzie, W. D., and Hyun, H. (2004). Recycling of construction debris as aggregate in the Mid-Atlantic Region, USA. Resour. Conserv. Recycl. 42, 275–294. doi: 10.1016/j.resconrec.2004.04.006

Rodgers, M., Hayes, G., and Healy, M. G. (2009). Cyclic loading tests on sandstone and limestone shale aggregates used in unbound forest roads. Constr. Build. Mater. 23, 2421–2427. doi: 10.1016/j.conbuildmat.2008.10.007

Senadheera, S., Nash, P., and Rana, A. (2005). Characterization of the Behavior of Granular Road Material Containing Glass Cullet. Lubbock, TX: Texas Tech University.

Shui, Z., Xuan, D., Wan, H., and Cao, B. (2008). Rehydration reactivity of recycled mortar from concrete waste experienced to thermal treatment. Constr. Build. Mater. 22, 1723–1729. doi: 10.1016/j.conbuildmat.2007.05.012

Sivakumar, V., McKinley, J. D., and Ferguson, D. (2004). Reuse of construction waste: performance under repeated loading. Proc. Inst. Civ. Eng. Geotech. Eng. 157, 91–96. doi: 10.1680/geng.2004.157.2.91

Taha, B., and Nounu, G. (2008). Properties of concrete contains mixed colour waste recycled glass as sand and cement replacement. Constr. Build. Mater. 22, 713–720. doi: 10.1016/j.conbuildmat.2007.01.019

Taha, R., Al-Harthy, A., Al-Shamsi, K., and Al-Zubeidi, M. (2002). Cement stabilization of reclaimed asphalt pavement aggregate for road bases and subbases. J. Mater. Civ. Eng. 14, 239–245. doi: 10.1061/(ASCE)0899-1561(2002)14:3(239)

Wartman, J., Grubb, D. G., and Nasim, A. S. M. (2004). Select Engineering characteristics of crushed glass. J. Mater. Civ. Eng. 16, 526–539. doi: 10.1061/(ASCE)0899-1561(2004)16:6(526)

Zhang, C., Hu, M., Yang, X., Miranda-Xicotencatl, B., Sprecher, B., Maio, D., et al. (2020). Upgrading construction and demolition waste management from downcycling to recycling in the Netherlands. J. Clean. Prod. 266, 121718. doi: 10.1016/j.jclepro.2020.121718

Keywords: construction and demolition waste, recycled concrete aggregates, sub-base, waste management, sustainable materials

Citation: Mazhar MA, Alam P, Ahmed S, Khan MS and Adam FA (2023) Sustainable usage of demolished concrete waste as a sub-base material in road pavement. Front. Sustain. 4:1060878. doi: 10.3389/frsus.2023.1060878

Received: 03 October 2022; Accepted: 02 January 2023;

Published: 26 January 2023.

Edited by:

Afzal Husain Khan, Jazan University, Saudi ArabiaReviewed by:

Osama Dawoud, University of Istinye, TürkiyeAneel Manan, COMSATS University Islamabad, Abbottabad Campus, Pakistan

Copyright © 2023 Mazhar, Alam, Ahmed, Khan and Adam. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Mohd. Aamir Mazhar,  Z2YuYW1hemhhckBqbWkuYWMuaW4=; Pervez Alam,

Z2YuYW1hemhhckBqbWkuYWMuaW4=; Pervez Alam,  cGVydmV6am1pQGdtYWlsLmNvbQ==

cGVydmV6am1pQGdtYWlsLmNvbQ==

Mohd. Aamir Mazhar

Mohd. Aamir Mazhar Pervez Alam

Pervez Alam Sirajuddin Ahmed

Sirajuddin Ahmed Mohammed Sharib Khan1

Mohammed Sharib Khan1