- 1Department of Chemical Engineering, University of Cape Town, Cape Town, South Africa

- 2World Wide Fund for Nature (WWF) South Africa, Bridge House, Cape Town, South Africa

An estimated 15,000–40,000 tons of plastic waste leaks into the oceans from South Africa annually. This has put the management of plastic products in the spotlight. In South Africa, life cycle management (LCM) is not a term that is commonly used however some companies have adopted LCM tools and concepts including cleaner production, sustainable procurement and design for recycling. Interviews with key value chain actors were conducted in 2017 and 2018–2019, on the influence of plastic leakage on plastic product life cycle management. In 2017, actors largely did not view themselves as responsible for plastic leakage, mostly putting blame on consumers. During the second interview period, a shift was observed wherein the actors recognized the role of product design in plastic leakage and started taking a more active role in its mitigation from the perspective of extended producer responsibility. The drivers for addressing marine pollution mirrored those for the adoption of LCM tools, including maintaining a competitive advantage and meeting investor and consumer expectations. In 2020, the South African Plastic Pact was developed and launched, which aims to create a circular economy for plastic packaging. As of October 2021, the majority of interviewed value chain actors are members. Ultimately the increasing concern surrounding plastic pollution has directly influenced value chain actors' perspectives and actions.

Introduction

The growing concern surrounding plastic pollution has resulted in global concerted efforts for its mitigation. Although it is a global problem, an understanding of regional contexts has been recognized as a matter of key importance in its mitigation (UNEP, 2020). South Africa has been identified as one of the 20 most important national contributors to marine plastic pollution, with an estimated amount of 15,000–40,000 tons of plastic waste possibly reaching the oceans annually (Verster and Bouwman, 2020). Beach surveys conducted in South Africa have found that the majority of plastic is associated with food and beverages, including beverage bottles, snack packets, polystyrene and drinking straws (Lamprecht, 2013; Chitaka and von Blottnitz, 2019; Ryan, 2020; Weideman et al., 2020). Recent years have seen concerted efforts to address this challenge and marine pollution was declared a priority area in life cycle management (LCM) in the Medellin Declaration on Marine Litter in Life Cycle Assessment and Management (Sonnemann and Valdivia, 2017).

Life cycle management is a concept centered on the incorporation of sustainable development principles into modern business practice (Sonnemann et al., 2015). It can be considered a business management approach that aims to minimize the environmental and socio-economic burdens associated with an organization's products or services from a life cycle perspective (Hunkeler et al., 2004; UNEP/SETAC, 2007; Sonnemann et al., 2015; Bey, 2018; Nilsson-Lindén et al., 2019). More practically, it provides a toolkit for business sustainability, built on the tenets of life cycle thinking.

Multinational fast-moving consumer goods companies are increasingly employing LCM tools and concepts in their business operations to varying extents (UNEP/SETAC, 2009; Adams et al., 2015; Stewart et al., 2018). There are a number of key drivers for an organization to implement a life cycle approach including business strategy, market requirements, regulations and legislations as well as international agreements (Hunkeler et al., 2004; UNEP/SETAC, 2007; Sonnemann et al., 2015). Mapping value chains and developing criteria for product enhancement and value creation may enable organizations to gain a competitive advantage (UNEP/SETAC, 2007; Sonnemann et al., 2015). In addition, the implementation of LCM may contribute to an improved public perception. Government regulations and legislation surrounding environmental impacts may force organizations to employ a life-cycle based approach to ensure compliance.

This paper explores the extent to which enhanced knowledge of plastic leakage has influenced approaches to plastic product LCM in South Africa. This includes investigating the extent to which a life cycle management approach has been adopted by companies operating in South Africa. In addition, the challenges, barriers and drivers for the development of interventions and/or strategies are explored.

Methods

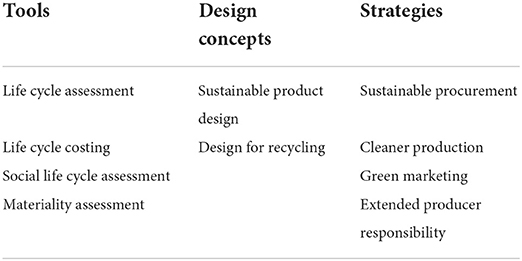

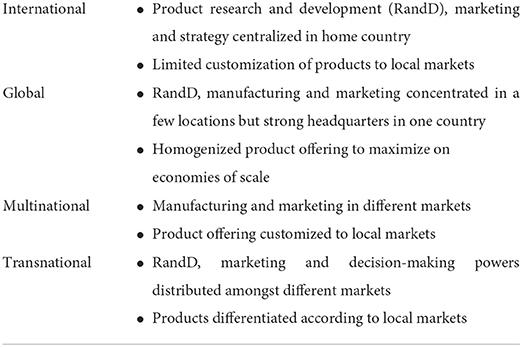

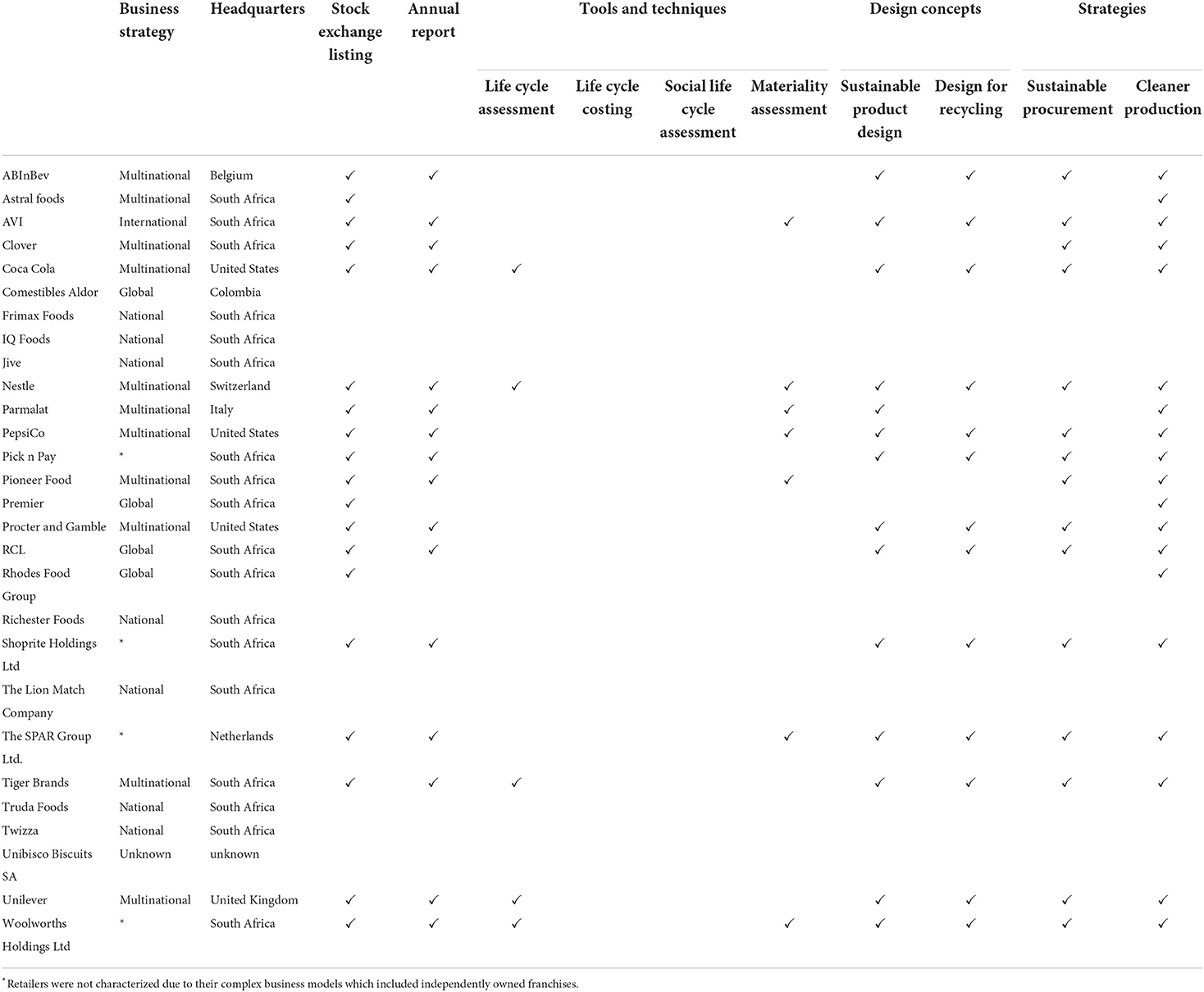

Approaches to plastic product LCM were investigated using a combination of primary and secondary data sources available in 2019. More specifically, the application of any LCM tools, design concepts and strategies (shown in Table 1) employed by Fast-Moving Consumer Goods (FMCG) companies operating in South Africa were explored using secondary data sources, including annual reports, websites and media releases. Furthermore, companies which operated in multiple countries were characterized according to their business strategies (described in Table 2) as well as whether they were listed on any stock exchanges.

Table 2. Company business strategies (Bartlett and Ghoshal, 1998; Hill, 2013).

Primary data was sourced via semi-structured interviews with key actors along the plastics value chain, with a focus on the fast-moving consumer goods sector. The interviews explored current approaches to plastic product LCM including product design. In addition, value chain actors' depth of knowledge regarding the extent of plastic pollution and how this has influenced their practices was explored. The interviews also investigated the key factors that influence the development of strategies and interventions to address plastic pollution.

Stakeholder identification

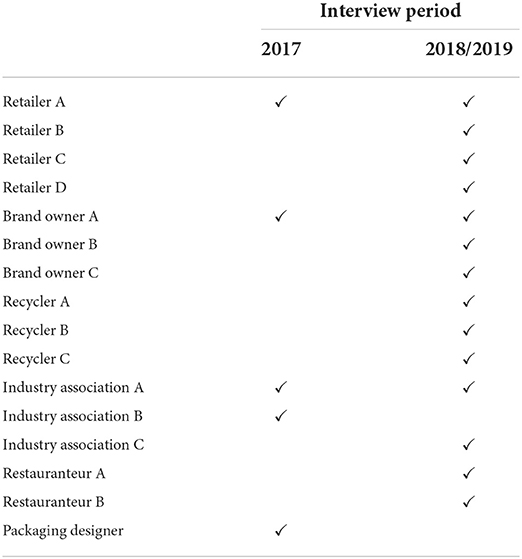

A total of 16 stakeholders were interviewed including industry associations who can speak with authority regarding relevant industry perceptions and product designers with intimate knowledge on the design decision-making process (Table 3). Brand owners and retailers (who all had in-house brands, i.e., brands owned by the retailers) were also engaged as they play a pivotal role in bringing products to market. Formal recyclers, who process plastic waste, were engaged as key players in waste diversion and processing. All value chain actors were directly involved in value chains for items that were identified as major contributors to marine pollution. Furthermore, their market share was also taken into consideration. Accessibility to value chain actors was a limitation as not all identified actors were willing to participate in the research.

Interview protocol and analysis

An initial set of interviews was conducted in March 2017, followed by more extensive interviews from November 2018 to March 2019. The two sets of interviews enabled a comparison of stakeholder perspectives as the conversation surrounding plastic pollution evolved.

Semi-structured interviews were conducted using a series of open-ended questions based on the aims of the research. This allowed for the interviewer to ask probing questions to elicit further information and explore different avenues which arise. Furthermore, the interview protocol also allowed for the interviewer to move back and forth between questions based on the participant's responses.

The relative influence of different factors influencing packaging design were explored via a short exercise conducted during the interview. The exercise required interviewees to rank the importance of different packaging design criteria with 1 being the most important.

Interviews were conducted face-to-face or via electronic communication, including online platforms, e-mail and telephonically, depending participant preference. They were on average 1-h long during which audio recordings were made and later transcribed.

A hybrid thematic approach was taken for interview analysis whereby a combination of a priori and grounded theory approaches were employed. A priori analysis is a deductive approach whereby themes are identified during the interview structuring phase based on the aims of the research (Miles et al., 2014). In this case, specific themes were identified based on the research questions. Grounded theory is an inductive approach to interview analysis, focused on the exploration of new theory or phenomena that arises from data (Corbin and Strauss, 2012). The use of a hybrid approach allowed for a more in-depth analysis of the key themes based on the research questions (a priori) through the identification of additional themes that emerged from the interviews. The interview analysis was conducting using NVivo 12 qualitative data analysis software.

To ensure that the research complied with ethical practices, it was reviewed by the University of Cape Town Engineering and Built Environment Ethics in Research Committee prior to data collection. To maintain anonymity no direct reference to the participants is made with identities presented in an anonymized form.

Results and discussion

Approaches to life cycle management in South Africa

Multinational companies operating in South Africa were found to adopt a number of LCM concepts across their departments, shown in Table 4. They applied different life cycle concepts to the respective life cycle stages. Sustainable procurement was practiced for materials sourcing, which often took a socio-economic perspective. Many companies employed cleaner production principles with a focus on reductions in energy and water consumption as well as carbon emissions and waste production. However, this is often based on a gate-to-gate assessment of the manufacturing facilities directly owned by the company and does not necessarily extend to suppliers. Life cycle assessments (LCA), i.e., environmental assessments of products or processes from cradle-to-grave, are not commonly conducted; when they are it is usually for new products or to support significant product improvements. Furthermore, no evidence was found of any of the surveyed companies having employed life cycle costing (LCC) or social life cycle assessment (SLCA), which investigate the economic and social aspects of a product or process, respectively.

Table 4. LCM concepts, strategies, tools, and techniques employed by companies in South Africa in 2019.

When it comes to packaging design, sustainable product design traditionally took the form of packaging reduction and light-weighting. To a lesser extent, some companies (Coca-Cola, Nestle, PepsiCo, Tiger Brands and Unilever) were exploring the use of compostable or plant-based material alternatives to plastic. Recent years have seen increasing emphasis on design for recycling and integration of recycled content, particularly for plastic packaging. As expected, these companies often practice green marketing based on the application of the aforementioned concepts.

When this analysis was conducted in 2019, extended producer responsibility (EPR), a policy approach in which producers are held responsible for their products throughout their entire life cycle, was yet to be legislated in South Africa. However, some companies practiced EPR through voluntary membership of producer responsibility organizations (PROs) particularly in the packaging industry.

Unlike large multinationals, locally based South African companies which do not have investments in other countries, and are not listed on any stock exchanges, often do not employ any LCM concepts. Their public communications are centered around product marketing, via a company website and various social media platforms. It is also noteworthy that these brands were identified as the major contributors to marine litter during beach surveys conducted in Cape Town by Chitaka and von Blottnitz (2019). For example, Unibisco Biscuits SA which was observed to be a major contributor of biscuit packaging, Richester Foods and Comestibles Aldor for lollipop wrappers, as well as Truda Foods and Frimax Foods when it came to snack packets.

Influence of leakage on approaches to plastic product life cycle management in South Africa

Value chain actor perspectives of plastic pollution

Value chain actor perspectives of plastic pollution were explored in order to gain insights on their understanding of the issue.

Causes of plastic pollution

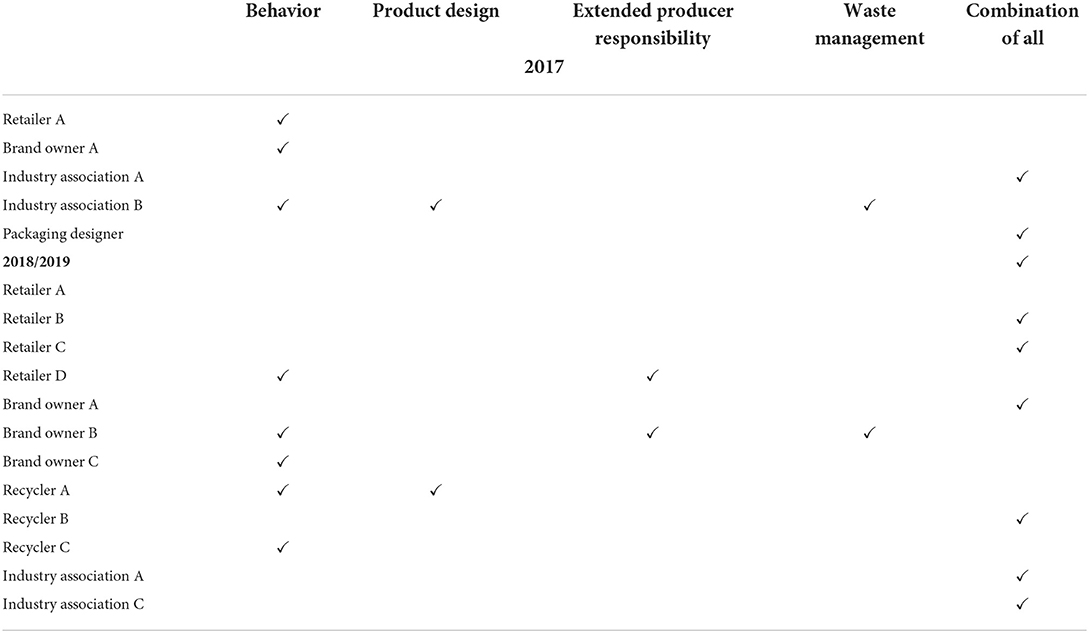

As shown in Table 5, there were differing perspectives on the causes of plastic pollution, including consumer behavior, ineffective solid waste management infrastructure and practices and poor extended producer responsibility practices. Product design was also deemed as a contributing factor, in that the characteristics of the product and the intrinsic value at end-of-life influence the likelihood of escaping the value chain.

Many of the stakeholders viewed pollution causes as a complex combination of some or all factors, albeit to varying extents. Whilst they cited consumer behavior as an integral element, they believed that it was no longer adequate to view the problem from this singular perspective and instead address the multifaceted nature of the problem. All of the retailers and brand owners acknowledged they held some responsibility for the products they put on the market, both from a product design perspective and the fate of the product waste.

Although Brand Owner C acknowledged the responsibility of brand owners for their products, they viewed plastic pollution as a purely behavioral issue. This may be attributed to the fact that the value chain actor is an active participant in voluntary EPR programs and thus viewed themselves as responsible brand owners.

Whilst Recycler B attributed pollution to a combination of issues, they viewed brand owners and retailers as largely responsible, with consumers being used as a convenient scapegoat. In their opinion, brand owners and retailers need to take more responsibility for the nature of the products they put on the market and play a more active role in their management at end-of-life. Recycler B qualified this using the case of PET bottles, which have built up a relatively high recycling rate, that they attributed to the active engagement of brand owners in supporting the recycling sector.

All the recyclers emphasized the importance of product design in the fate of products at end-of-life. This is to be expected as they represent one of the options for waste treatment, thus they are familiar with the different design characteristics that may influence how that product is treated including likelihood of collection for recycling.

Perceptions of the extent of the problem

Interviewees presented a limited understanding of the extent of the plastic pollution problem. The majority were either unwilling or unable to provide an estimate of how large they believed the problem was, readily admitting their limited knowledge. Interviewees were aware that research that had been conducted in this regard, but the level of engagement with such work varied. Retailer B and Industry Associations A and C both demonstrated active engagement with this work, expressing their skepticism surrounding current knowledge. Retailer B also highlighted the limited information available regarding plastic flows within the South Africa, which was also expressed by Brand Owner A. Whilst Retailer D and Brand Owner A were willing to hazard a guess, these were mostly based on anecdotes and their own personal experiences with litter.

Stakeholder plastic pollution strategies and initiatives

Although the majority of interviewees viewed plastic pollution causes to be multifaceted, in 2017 value chain actors generally did not view themselves as playing a significant role in its mitigation; instead they put the onus on consumers when it came to addressing it. Furthermore, they did not view themselves as responsible for the fate of products at their end-of-life. Thus, the approaches of their employers were focused on consumer education and awareness raising campaigns. In addition, value chain actors supported recycling initiatives but did not view them as having a significant impact.

As plastic pollution received increasing attention between the two sets of interviews, a shift was observed in value chain actor approaches to plastic product LCM. Retailers and brand owners now increasingly viewed their role in mitigating plastic pollution from an EPR perspective, recognizing the role of product design in plastic pollution and taking greater responsibility for the fate of their products at end-of-life. Through growing appreciation of EPR, upstream value chain actors are increasingly supporting end-of-life activities that would facilitate proper disposal of their products. This is commonly done through supporting recycling initiatives either directly or through membership of voluntary PROs which have been found to play a significant role in growing the recycling landscape (Godfrey and Oelofse, 2017).

Value chain actors are also changing their product design approaches to facilitate their activities at end-of-life. Whilst South Africa has traditionally promoted design for recycling (Godfrey and Oelofse, 2017), it has gained in popularity in recent years with more companies deeming it necessary for survival. Thus, value chain actors are increasingly integrating design for recycling and/or circularity into packaging design strategies. However, Retailer A did not believe that the focus on recycling would solve the plastic pollution problem and would instead require a suite of approaches including plastic reduction and elimination. A similar sentiment was expressed by the Packaging Designer, who believed that whilst a focus on design for recycling would enable a circular economy it would not necessarily reduce littering.

Material substitution is an additional approach being implemented, one example being the substitution of plastic straws with paper or polylactide (PLA) alternatives. Furthermore, value chain actors are now reviewing the effectiveness of their consumer education initiatives, in supporting their EPR activities.

Recyclers viewed themselves as integral to waste diversion. They considered themselves a “tool” to be utilized but, the onus was on retailers and brand owners to ensure that products were designed with end-of-life in mind.

Key drivers for intervention development

As expected, value chain actors cited a desire to maintain a competitive advantage as a key driver. Retailer A highlighted that consumers would commonly refer to competitor practices when lodging complaints. Thus, retailers and brand owners keep abreast of their competitors' practices. In addition, they take note of practices of their counterparts in developed markets viewing them as predictors of future local market expectations.

Brand Owner A and Retailer D highlighted the increasing consideration of a company's sustainability efforts by investors. Thus, responding to the concern surrounding plastic pollution is seen to be imperative to a company's image. Furthermore, Retailer B noted that interventions are more readily approved by company executives for products that were in the public spotlight. For example, the rising unpopularity of straws—which have readily available material alternatives—presented a relatively easy opportunity for retailers to be viewed as environmentally responsible through material substitution.

Consumer pressure is a major driving force for intervention development, as evidenced by the shift in stakeholder approaches from 2017 to 2019. Increasing concern surrounding plastic marine pollution has led to societal pressure being placed on stakeholders to take a more proactive role. This often takes the form of campaigns led by consumers or environmental groups, one example being the campaign by WWF South Africa which advocated against the use of single-use plastics with a particular focus on items they considered to be the “worst offenders” including straws and cotton bud sticks (WWF-SA Notten, 2018).

Job creation is viewed as the major driver for the development of strategies, particularly those with a focus on recycling. In South Africa, informal waste collectors play a vital role in waste diversion. In 2018, the recycling industry provided 7,892 formal jobs whilst 58,470 people were indirectly employed including informal collectors (Plastics SA, 2019). Thus, an increase in recyclable waste would likely result in more job opportunities.

Some value chain actors view international legislation, particularly in Europe, as a precursor to similar legislations being enacted locally, and choose to comply pre-emptively. For multinational companies, compliance with legislation may be integrated into global strategies. South African based companies which export to foreign markets are also driven by compliance in their target market. In addition, they are driven by global agreements including the New Plastics Economy Global Commitment (Ellen MacArthur Foundation, 2018), which had the additional benefit of increasing the organization's image in society, portraying them as “good corporate citizens”. In some export markets there are existing or emerging national Plastics Pacts, which are the “implementation” of the New Plastics Economy Global Commitment, with local and multinational companies committed to the national targets of these Plastics Pacts. These national targets are internalized in the companies, resulting in guidelines being set up and sent to suppliers of plastic packaging.

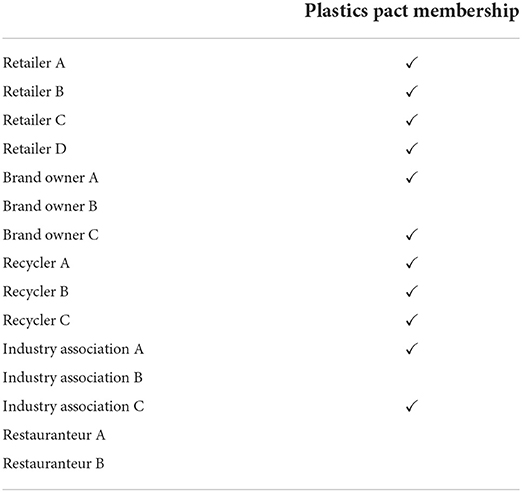

Since the interviews took place, in October 2020, a national Plastics Pact was developed and launched in South Africa, which forms part of the international Plastics Pact network under the Ellen MacArthur Foundation. WWF South Africa together with partners the South African Plastic Recycling Organization (SAPRO), WRAP and the Ellen MacArthur Foundation conducted extensive stakeholder engagement during 2019 with the industry and government. The acknowledgment that not one organization can address the complexity of the plastic pollution problem resulted in a number of stakeholders across the plastic packaging value chain supporting the concept of this multi-stakeholder pre-competitive platform and agreeing to ambitious 2025 targets. As it stands the majority of interviewed stakeholders are members of this Plastics Pact as shown in Table 6.

Challenges and barriers to intervention development

Many of the challenges and barriers identified during the interviews are related to packaging design, including functionality and technical requirements. Of particular concern is food packaging, whereby designers are faced with the challenge of finding alternative designs that would meet food safety requirements. Retailers without production facilities for their in-house brands are constrained by the technological capabilities of their suppliers.

As expected, cost is a major barrier to the design of product interventions, including material substitution and complete redesign. Interviewees pointed out that plastic was a favored material due to its relatively low cost, thus material substitution would inevitably be associated with increased costs. They also highlighted the higher costs associated with new alternative products due to their novelty. Value chain actors have varying capacities to absorb this extra cost. For example, Retailer A indicated that their company has funds set aside to absorb additional sustainability related costs whereas Retailer D indicated that these costs would be passed onto the consumer. Industry Association B also highlighted the socio-economic implications of designing out all small format items that have been identified as problematic as some provide an affordable option to populations who cannot afford to buy in high volumes. Thus, a product redesign would need to take this into consideration.

A lack of suitable solid waste management infrastructure to manage and process waste is viewed as a challenge to the efficacy of any design interventions implemented. Whilst value chain actors are emphasizing design for recycling, interviewees often cited the potentially limited recycling infrastructure available in the country. In addition, the lack of solid waste services to separate and collect recyclables present an additional challenge. However, the interviewed recyclers all expressed confidence in their abilities to meet the additional required capacity. The lack of suitable infrastructure to process alternative materials, specifically biodegradable and/or compostable materials, was also cited as a deterrent for their adoption. Interviewees raised concerns of potential contamination of recycling streams by such materials which would impact the quality of plastic products downstream.

Retailers highlighted consumer misinformation as a challenge they face in trying to meet consumer desires. According to interviewees, some consumers demonstrate a limited understanding of the function of packaging (i.e., food safety and preservation) and the broader environmental impacts associated with alternative materials. One retailer gave the example of a consumer attacking them on their use of plastic packaging whilst simultaneously praising them for the quality of the food contained within. Retailers also highlighted the increasing popularity of alternative products in popular media which results in consumers advocating for such items without a complete understanding of the material properties.

Differing stakeholder priorities across the value chain present an additional level of complexity to strategy development. Retailer A highlighted the threat that initiatives aiming to reduce or eliminate plastic presents to their upstream suppliers, as this would effectively reduce their business throughput. Recycler B accused producers of being unwilling to adopt sustainable practices, including incorporation of recycled content or exclusion of additives that decreased recyclability, due to a desire to cut costs. They also expressed their exasperation at retailers for seemingly not exerting enough pressure on their suppliers. Furthermore, there was some contention amongst stakeholders regarding their different roles. Retailers were commonly viewed as having the most power as the interface between suppliers and consumers. Brand Owner A viewed themselves as subject to the principles adopted by retailers as they are reliant upon them for product distribution. Whereas, Retailer B described the relationship between retailers and brand owners as “co-dependent”. As a result, there is reportedly some acrimony amongst stakeholders across the value chain resulting in multiple parallel initiatives.

The broader environmental impacts associated with interventions are considered to a much lesser extent with only two interviewees highlighting the potential for trade-offs; Retailer D and Recycler A highlighted that the focus on mitigating plastic pollution could result in interventions that resulted in greater damages in other ecological spheres such as climate change. In addition, some interviewees were concerned about the potential impacts of bio-based plastics on food security as they are often made from food crops.

Discussion

Adoption of LCM concepts, tools, and techniques in South Africa

LCM is not a term that is commonly used in South Africa, however there are a number of related techniques applied by FMCG companies and retailers operating locally. The extent to which LCM concepts are being adopted can be linked to a company's characteristics, including its business footprint and whether it is publicly traded. Multinational companies were found to adopt many LCM concepts including cleaner production principles, with a focus on water and energy consumption, carbon emissions and waste generation. This is to be expected as larger companies are deemed to be subject to greater public scrutiny and are thus under more pressure to behave sustainably (Chih et al., 2010; Lourenço and Branco, 2013). Furthermore, ranking institutions are placing increasing emphasis companies' approaches to environmental and social sustainability as an indicator of overall performance, increasing its importance amongst investors (UNEP/SETAC, 2006). Hence companies listed on major stock exchanges are found to make greater efforts toward their corporate sustainability (Chih et al., 2010). Multinationals are also driven to employ an LCM based approach due to market requirements as well as regulations and legislation in the countries in which they operate (Hunkeler et al., 2004; UNEP/SETAC, 2007; Sonnemann et al., 2015). In comparison, locally based South African companies that are not publicly listed, often do not employ any LCM concepts. Furthermore, their communication is often limited to product sales. This may be attributed to their relatively smaller business footprint.

In November 2021, Extended Producer Responsibility Regulations were enacted in South Africa for specific product classes including plastic packaging. Notably, the Regulations include LCM concepts which producers will have to adopt. For example, the Regulations stipulate that product life cycle assessments must be conducted within 5 years of the enactment of the regulations (DEFF, 2021). In addition, producers are required to implement cleaner production measures including design for recycling. This regulatory prescription of LCM tools should lead to their wider adoption not only by multinationals but also by smaller, locally based South African companies.

Key drivers and challenges for pollution mitigation strategy development

Key drivers for strategy and intervention development closely mirror those for adopting LCM based concepts and strategies including maintaining a competitive advantage, compliance with regulations and legislation, meeting investor expectations and meeting consumer expectations (Hunkeler et al., 2004; UNEP/SETAC, 2007; Sonnemann et al., 2015). Retailers and brand owners not only keep abreast of their competitors' practices, but also look toward their counterparts in developed markets for guidance. This may be attributed to institutional normative pressure, which is a key driver for environmental policy development, whereby companies will look toward what others are doing as an indication of their “moral” and “social” obligations (Ramus and Montiel, 2005). As a result, a company may not only copy another's policies but may also be more willing to endorse industry wide initiatives if they view their counterparts doing the same. At the time of the interviews the only legislation aimed at mitigating plastic pollution was the Plastic Bag Regulations which included the prohibition of certain bags (DEAT, 2002). As such, value chain actors view European legislation as a precursor (including the EU agreement on single-use plastics (European Parliament, 2018), choosing to comply pre-emptively. In addition, they are driven by global agreements including the New Plastics Economy Global Commitment (Ellen MacArthur Foundation, 2018), which was further exemplified by their membership of the South African Plastics Pact. This has the additional benefit of increasing a company's image in society, portraying them as “good corporate citizens”. This is in line with a suggestion by Stafford and Jones (2019) that the visibility associated with plastic pollution creates an opportunity for “environmental branding” of corporations. With the local implementation of EPR Regulations for plastics and packaging in May 2021 (DEFF, 2020, 2021), value chain actors will be forced to take a more active role in the fate of their products to meet the specified targets for collection and recycling.

Many of the challenges associated with intervention development are related to the packaging design criteria. A fundamental barrier is the design of alternative products that could effectively protect and preserve the contents. Cost is a major constraint to product redesign as plastic is an attractive option due to its relatively low cost in comparison with other options. Furthermore, interviewees reported that new alternative products are associated with higher costs due to the novelty. The extent to which cost affects value chain actors differs according to their ability to absorb this extra cost.

A lack of suitable infrastructure is also a consideration for value chain actors as it would directly impact the effectiveness of their interventions. In particular, the state of solid waste management practices and infrastructure is of concern with regards to their ability to collect the waste and divert it to the appropriate waste treatment. According to Stats SA (2021), 37.3% of South African households in 2020 did not have access to waste removal services. Furthermore, source separation is not a prevalent practice in South Africa (Godfrey and Oelofse, 2017). The lack of suitable infrastructure is also a deterrent for the adoption of compostable materials due to the limited availability of industrial composting facilities in South Africa (DST, 2014).

Stafford and Jones (2019) highlight the potential for a single-minded focus on marine pollution to lead to a side-lining of other environmental threats. This was demonstrated during the interviews whereby the broader environmental impacts associated with the interventions are considered to a much lesser extents with only two interviewees highlighting the potential for trade-offs. Of particular concern were the potential impacts on climate change as previous studies comparing plastic and paper often found plastic to be the favorable option (James and Grant, 2005; Sevitz et al., 2012; Kimmel et al., 2014). However, the converse was found in a study comparing different straw materials whereby paper was found to be the favorable option (Chitaka et al., 2020), suggesting that this trade-off may be potentially negated in the South African context.

Consumer perception appears to be both a key driver and a challenge to strategy development. Value chain actors are under increasing societal pressure to develop strategies to address plastic pollution. However, retailers highlighted consumer misinformation as a challenge they face in trying to meet consumer desires. According to interviewees, some consumers demonstrate a limited understanding of the function of packaging as well as the broader environmental impacts associated with alternative materials. This has led to consumers advocating for alternative materials based on a shallow understanding of the implications. This is in line with a study conducted in 2014, whereby Scott and Vigar-Ellis (2014) found that South African consumers had an incomplete understanding of what environmentally friendly packaging is, or the benefits it provided to themselves or the environment. In addition, some consumers relied on their “common sense” to evaluate whether packaging is environmentally friendly based on the material employed (Scott and Vigar-Ellis, 2014). A similar finding was made by Lindh et al. (2016) and Steenis et al. (2017) who found that Swedish and Dutch consumers, respectively, based their perception of environmental impacts on the packaging material used leading to the belief that plastic and metal were least sustainable. Furthermore, Steenis et al. (2017) found that consumers perceived products that were deemed most environmentally sustainable from an LCA perspective as the least sustainable. This suggests that consumer perceptions have the potential to contradict their desire for sustainability (Lindh et al., 2016; Steenis et al., 2017).

Differing stakeholder priorities across the value chain present an additional level of complexity to strategy development. In particular, value chain actors reported plastic converters felt threatened by the rhetoric surrounding plastic pollution as it was commonly associated with the reduction of plastic products. Furthermore, there was some acrimony between value chain actors surrounding stakeholder roles and responsibilities in mitigating plastic pollution.

Conclusions

Whilst life cycle management is not a term that is widely used in South Africa, the evidence assembled here has shown that many large companies including multinationals have adopted LCM tools and concepts. The extent to which these concepts are adopted is linked to a company's characteristics including footprint and whether it is publicly traded. Thus, smaller companies have to date been less likely to adopt LCM concepts.

The growing concern surrounding plastic leakage has directly influenced value chain actors' practices, with some companies taking a more active role in plastic pollution mitigation. From 2017 to the next interview period in 2018–2019, a shift was observed in value chain actors' perceptions of their roles in plastic pollution mitigation. Initially, they distanced themselves from the issue then later they played a more active role in plastic pollution mitigation.

The drivers for the development of strategies to address plastic pollution mirror those for adopting LCM based concepts including maintaining a competitive advantage, compliance with regulations and legislation, and meeting investor and consumer expectations. Aligned with these LCM concepts, some industry stakeholders who acknowledge the systemic challenges of plastic leakage have welcomed the establishment of the SA Plastics Pact as a credible response to transition to a circular plastics economy. However, consumer expectations present a challenge due to some ill-founded consumer perceptions of sustainability. Cost is also a major challenge for stakeholders due to the relatively higher costs associated with material alternatives to plastic. The broader environmental impacts associated with intervention development were considered to a lesser extent, increasing the potential of trade-offs being made unwittingly.

This paper has demonstrated the factors influencing decision-making of value chain actors in a developing country when faced with an environmental challenge. It presented the challenges and limitations that need to be mitigated to ensure efficient and effective progress toward addressing issues such as pollution. In addition, the identified drivers can be leveraged to hasten progress.

Data availability statement

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

Ethics statement

The studies involving human participants were reviewed and approved by University of Cape Town Engineering and Built Environment Ethics in Research Committee. The patients/participants provided their written informed consent to participate in this study.

Author contributions

TC: substantial contributions to the conception or design of the work, the acquisition, analysis, or interpretation of data for the work, and drafting the work or revising it critically for important intellectual content. LdK: the acquisition and interpretation of data for the work. HvB: conception of the work, supervision, and provide approval for publication of the content. All authors contributed to the article and approved the submitted version.

Funding

This work was based on the research supported in part by the National Research Foundation of South Africa (Grant Number: 116431).

Acknowledgments

The authors would like to thank the interviewees for their participation and Kirsten Barnes for her comments on a draft of the paper.

Conflict of interest

Author LdK was employed by WWF South Africa.

The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher's note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Adams, A., Schenker, U., and Loerincik, Y. (2015). “Life cycle management as a way to operationalize the creating shared value concept in the food and beverage industry: a case study,” in Life Cycle Management, eds G. Sonnemann and M. Margni (Dordrecht: Springer Open), 341–348.

Bartlett, C. A., and Ghoshal, S. (1998). Managing Across Borders: The Transnational Solution. Boston, MA: Harvard Business School Press. doi: 10.5465/amr.1991.4279037

Bey, N. (2018). “Life cycle management,” in Life Cycle Assessment: Theory and Practice, eds M. Z. Hauschild, R. K. Rosenbaum, and S. I. Olsen (Cham: Springer International Publishing), 519–544.

Chih, H. L., Chih, H. H., and Chen, T. Y. (2010). On the determinants of corporate social responsibility: international evidence on the financial industry. J. Bus. Ethics. 93, 115–135. doi: 10.1007/s10551-009-0186-x

Chitaka, T. Y., Russo, V., and von Blottnitz, H. (2020). In pursuit of environmentally friendly straws: a comparative life cycle assessment of five straw material options in South Africa. Int. J. Life Cycle Assess. 25, 1818–1832. doi: 10.1007/s11367-020-01786-w

Chitaka, T. Y., and von Blottnitz, H. (2019). Accumulation and characteristics of plastic debris along five beaches in Cape Town. Marine Poll. Bull. 138, 451–457. doi: 10.1016/j.marpolbul.2018.11.065

Corbin, J. M., and Strauss, A. (2012). “Introduction,” in Basics of Qualitative Research: Techniques and Procedures for Developing Grounded Theory, 3rd Edn (Thousand Oaks, CA: SAGE Publications Inc.), 1–18.

DEAT (2002). Regulations Under Section 24(d) of the Environmental Conservation Act (Act No. 73 of 1989) - Plastic Carrier Bags and Plastic Flat Bags. Pretoria: Government Gazette, 24839.

DEFF (2020). National Environmental Management: Waste Act (59/2008): Regulations Regarding Extended Producer Responsibility. Government Gazette 43879. Available online at: http://www.greengazette.co.za/pages/national-gazette-37230-of-17-january-2014-vol-583_20140117-GGN-37230-003 (accessed November 10, 2020).

DEFF (2021). Amendements to the Regulations and Notices Regarding Extended Producer Responsibility, 2020. Government Gazette, 44539. Available online at: http://www.greengazette.co.za/pages/national-gazette-37230-of-17-january-2014-vol-583_20140117-GGN-37230-003 (accessed May 7, 2021).

DST (2014). A National Waste Research, Development and Innovation Roadmap for South Africa: Phase 2 Waste RDI Roadmap. Pretoria: Department of Science and Technology. Available online at: http://www.wasteroadmap.co.za/download/trends_in_waste_management.pdf (accessed September 19, 2020).

Ellen MacArthur Foundation (2018). A Vision of a Circular Economy for Plastic. Ellen MacArthur Foundation. Available online at: https://www.newplasticseconomy.org/assets/doc/npec-vision.pdf (accessed January 6, 2019).

European Parliament (2018). Plastic Oceans: MEPs Back EU Ban on Throwaway Plastics by 2021. [Press Release]. Available online at: http://www.europarl.europa.eu/news/en/press-room/20181018IPR16524/plastic-oceans-meps-back-eu-ban-on-throwaway-plastics-by-2021 (accessed October 10, 2018).

Godfrey, L., and Oelofse, S. (2017). Historical review of waste management and recycling in South Africa. Resources. 6, 57. doi: 10.3390/resources6040057

Hill, C. W. L. (2013). International Business: Competing in the Global Marketplace, 9th Edn. New York, NY: McGraw-Hill/Irwin. doi: 10.1017/CBO9780511750410

Hunkeler, D., Saur, K., Stranddorf, H., Rebitzer, G., Finkbeiner, M., Schmidt, W.-P., et al. (2004). Life Cycle Management. Pensacola, FL: SETAC Press.

James, K., and Grant, T. (2005). “LCA of degradable plastic bags,” in Proceedings of the 4th Australian LCA Conference, Sydney, 1–17.

Kimmel, R. M., Cooksey, K. D., Littman, A., Ally, S., and Lebanon, T. N. (2014). Life Cycle Assessment of Grocery Bags in Common Use in the United States. Clemson, SC: Clemson University Press.

Lamprecht, A. (2013). The abundance, distribution and accumulation of plastic debris in Table Bay, Cape Town, South Africa (MSc thesis). Department of Biological Sciences, University of Cape Town, Cape Town, South Africa.

Lindh, H., Olsson, A., and Williams, H. (2016). Consumer perceptions of food packaging: contributing to or counteracting environmentally sustainable development? Pack. Technol. Sci. 29, 3–23. doi: 10.1002/pts.2184

Lourenço, I. C., and Branco, M. C. (2013). Determinants of corporate sustainability performance in emerging markets: the Brazilian case. J. Clean. Prod. 57, 134–141. doi: 10.1016/j.jclepro.2013.06.013

Miles, M. B., Huberman, A. M., and Saldaña, J. (2014). Qualitative Data Analysis: A Methods Sourcebook. 3rd Edn. Thousand Oaks, CA: SAGE Publications.

Nilsson-Lindén, H., Rosén, M., and Baumann, H. (2019). Product chain collaboration for sustainability: a business case for life cycle management. Bus. Strat. Environ. 28, 1619–1631. doi: 10.1002/bse.2388

Plastics SA. (2019). Available online at: https://www.plasticsinfo.co.za/wp-content/uploads/2019/08/Plastics-Recycling-in-SA-July-2018-Executive-Summary-final.pdf (accessed September 25, 2019).

Ramus, C. A., and Montiel, I. (2005). When are corporate environmental policies a form of greenwashing? Bus. Soc. 44, 377–414. doi: 10.1177/0007650305278120

Ryan, P. G. (2020). The transport and fate of marine plastics in South Africa and adjacent oceans. South Afr. J. Sci. 116, 1–9. doi: 10.17159/sajs.2020/7677

Scott, L., and Vigar-Ellis, D. (2014). Consumer understanding, perceptions and behaviours with regard to environmentally friendly packaging in a developing nation. Int. J. Cons. Stud. 38, 642–649. doi: 10.1111/ijcs.12136

Sevitz, J., Brent, A. C., and Fourie, A. B. (2012). An environmental comparison of plastic and paper consumer carrier bags in South Africa: implications for the local manufacturing industry. South Afr. J. Indust. Eng. 14, 67–82. doi: 10.7166/14-1-299

Sonnemann, G., Gemechu, E. D., Remmen, A., Frydendal, J., and Jensen, A. A. (2015). Life cycle management: implementing sustainability in business practice. Life Cycle Manag. 7–21. doi: 10.1007/978-94-017-7221-1_2

Sonnemann, G., and Valdivia, S. (2017). Medellin declaration on marine litter in life cycle assessment and management. Int. J. Life Cycle Assess. 22, 1637–1639. doi: 10.1007/s11367-017-1382-z

Stafford, R., and Jones, P. J. S. (2019). Ocean plastic pollution: a convenient but distracting truth? Marine Policy. 103, 187–191. doi: 10.1016/j.marpol.2019.02.003

Stats SA (2021). General Household Survey 2020. Pretoria: Department: Statistics South Africa. Available online at: http://www.ncbi.nlm.nih.gov/pubmed/11469378 (accessed December 16, 2021).

Steenis, N. D., van Herpen, E., van der Lans, I. A., Ligthart, T. N., and van Trijp, H. C. M. (2017). Consumer response to packaging design: the role of packaging materials and graphics in sustainability perceptions and product evaluations. J. Clean. Prod. 162, 286–298. doi: 10.1016/j.jclepro.2017.06.036

Stewart, R., Fantke, P., Bjørn, A., Owsianiak, M., Molin, C., Hauschild, M. Z., et al. (2018). Life cycle assessment in corporate sustainability reporting: global, regional, sectoral, and company-level trends. Bus. Strat. Environ. 27, 1751–1764. doi: 10.1002/bse,.2241

UNEP (2020). National Guidance for Plastic Pollution Hotspotting and Shaping Action - Introduction Report. Nairobi: United Nations Environment Programme.

UNEP/SETAC (2006). Background Report for a UNEP Guide to Life Cycle Management - a bridge to sustainable products. A. A. Jensen and A. Remmen, eds (Paris: UNEP/SETAC Life Cycle Initiative).

UNEP/SETAC (2007). Life Cycle Management. A Business Guide to Sustainability. Paris: UNEP/SETAC Life Cycle Initiative.

UNEP/SETAC (2009). Life Cycle Management: How Business Uses it to Decrease Footprint, Create Opportunities and Make Value Chains More Sustainable. United Nations Environment Programme.

Verster, C., and Bouwman, H. (2020). Land-based sources and pathways of marine plastics in a South African context. South Afr. J. Sci. 116, 1–9. doi: 10.17159/sajs.2020/7700

Weideman, E. A., Perold, V., Arnold, G., and Ryan, P. G. (2020). Quantifying changes in litter loads in urban stormwater run-off from Cape Town, South Africa, over the last two decades. Sci. Total Environ. 724, 138310. doi: 10.1016/j.scitotenv.2020.138310

WWF-SA, and Notten, P.J. (2018). Stop Using Single-Use Plastics. Available online at: https://www.wwf.org.za/plastic_files.cfm?26062/plastic-file-02 (accessed October 20, 2018).

Keywords: extended producer responsibility, life cycle management, plastic leakage, plastic pollution, plastic

Citation: Chitaka TY, de Kock L and von Blottnitz H (2022) Evolution of value chain and governance actor responses to the plastic leakage problem in South Africa. Front. Sustain. 3:993011. doi: 10.3389/frsus.2022.993011

Received: 13 July 2022; Accepted: 12 August 2022;

Published: 29 August 2022.

Edited by:

Britta Denise Hardesty, Commonwealth Scientific and Industrial Research Organisation (CSIRO), AustraliaReviewed by:

Maria Angela Butturi, University of Modena and Reggio Emilia, ItalyAnupam Khajuria, United Nations Centre for Regional Development, Japan

Copyright © 2022 Chitaka, de Kock and von Blottnitz. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Takunda Yeukai Chitaka, Y2hpdGFrYXR5QGdtYWlsLmNvbQ==

Takunda Yeukai Chitaka

Takunda Yeukai Chitaka Lorren de Kock2

Lorren de Kock2