- 1Systems Engineering Department and Numérix Laboratory, École de Technologie Supérieure, Montreal, QC, Canada

- 2Interuniversity Research Centre on Enterprise Networks, Logistics and Transportation (CIRRELT), Montreal-Quebec City, QC, Canada

- 3Operations and Decision Systems Department, Faculty of Business Administration, Université Laval, Quebec City, QC, Canada

The growing interest in sustainability has pushed governments to elaborate new legislations and orientations and, in turn, has led companies and organizations to consider sustainability goals in their strategies, operations management, and decision-making processes. This is the case in natural resources supply chains, and particularly in forest products supply chains, where the row resource is publicly owned but exploited by private companies. While public owners are responsible for the sustainable management of the resource according to the three sustainability pillars, industrials tend to focus on the use of the allocated resources to maximize their utility, mainly from an economic perspective. The key question is how to rethink the whole public owners/industrials relationship to ensure consensual and satisfactory solutions for all the stakeholders. In this context, this paper reviews and analyzes sustainable supply chain planning approaches proposed in the forestry planning literature and, based on the model observed in the forestry sector in the province of Quebec, Canada, proposes and analyzes a new, performance-based approach to overcome its challenges and facilitate sustainability integration in the forestry planning processes.

1. Introduction

Sustainability has gained popularity and importance to become an essential concern for our society. This growing interest has pushed governments to elaborate new legislations and orientations and, in turn, has led companies to consider sustainability goals in their strategies and decision-making processes. However, this is not an easy task because, by definition, sustainability requires a balance between its three pillars (Elkington and Rowlands, 1999), and such balance depends on the perspective of each stakeholder (Boukherroub et al., 2018). Defining sustainability goals, setting performance indicators, prioritizing different sustainability aspects (Baumann, 2011; Boukherroub et al., 2015), and considering stakeholders' concerns are among the multiple challenges faced by decision-makers in the pursuit of sustainability. These issues are even more complex when observed across an entire supply chain, where the players at each link of the chain may not be perfectly aligned. This is the case, in natural resources supply chains, where the row resource is usually publicly owned but exploited by private companies. While public owners are concerned by the three sustainability pillars, industrials focus more on the use of the resources mainly from an economic perspective. The key question is then how to rethink public owners/private industrials relationship to ensure consensual solutions for all stakeholders and integrate sustainability aspects across the supply chain.

The forestry sector in the province of Quebec (Canada) is a good example illustrating those challenges. Sustainability issues are of high importance in this industry where 90% of the forests are publicly owned. It directly employs more than 184,000 people, is a source of income for local workers in 2,400 communities, contributes with $25.2 billion to nominal GDP, and supports more than 300 forest-reliant communities (NRCAN, 2022). Economic, environmental, and social benefits are expected from Canadian forests (employment opportunities, local economic development, outdoor activities, spiritual practices, wildlife habitat, carbon sequestration, etc.) (Boukherroub et al., 2018). Therefore, a rigorous and sustainable management of forest resources and forest products supply chains must be put in place. However, the literature analysis suggests that sustainability has not spread evenly across the upstream and the downstream forest supply chain. Sustainable Forest Management concept (SFM) appeared relatively early in the literature and has been applied widely in practice (Siry et al., 2018) while forest products supply chains (downstream part) received less interest from researchers and practitioners (Morali and Searcy, 2013; Boukherroub et al., 2016; Lähtinen et al., 2016; Santos et al., 2019).

The contributions of this paper are: (1) discuss major challenges related to sustainability integration into forest products supply chain management in the province of Quebec, particularly around the public owner/industrial interactions, and (2) propose an emerging approach to support sustainability integration in forestry and other natural resources supply chains. The remainder of the article is as follows: next section briefly presents relevant works in the literature-related to sustainable forest products supply chain management, and describes the challenges related to forestry management in the province of Quebec. Based on lessons learned from this context, Section 3 describes the proposed approach while Section 4 discusses implementation issues and further research avenues.

2. Current trends and issues in sustainable forest products supply chains

2.1. Sustainable forest products supply chain management in the literature

Forest products supply chains gradually transform wood fiber into consumer products such as pulp and paper, lumber, biofuels, among others (D'Amours et al., 2008). Decisions in this value chain range from land-use, regeneration, road building, harvesting, transportation, to production at manufacturing plants (Rönnqvist et al., 2015). D'Amours et al. (2008) distinguish two main research topics. The first one, referred to as forestry, focuses on forest management, harvesting and transportation while the second focuses on supply chain planning for manufactured products and sale markets. In forestry, the concept of sustainability can be traced to von Carlowitz (18th century), who introduced the notion of Nachhaltigkeit (sustainability) and advocated for a continued, stable and sustained use of forests (Schmithüsen, 2013). The idea of sustained use of renewable natural resources was incorporated and developed in forest science and has since been applied in forest management. Indeed, Sustainable Forest Management (SFM) is defined as “[a] dynamic and evolving concept [that] aims to maintain and enhance the economic, social and environmental values of all types of forests, for the benefit of present and future generations” (FAO, 2022). The Earth Rio Summit in 1992 contributed to SFM evolvement by including a chapter on forests in its agenda for sustainable development for the 21st century and by producing guidelines/means for protecting the world's forests. Criteria and indicators for measuring, monitoring, and reporting on progress toward SFM have been developed for different contexts at the global, regional, national, and local levels (Siry et al., 2018). Current forest management tools support the integration of different forest service outputs (e.g., carbon sequestration and old forest conservation), through the formulation of appropriate management objectives and constraints in various decision-support models (e.g., Garcia-Gonzalo et al., 2015; Marto et al., 2019; Eggers et al., 2020).

Sustainable forest products transportation and supply chain management is a relatively new research topic. Regarding performance assessment, studies published in the literature usually focus on production efficiency and economic performance of sawmills and paper mills at a regional, country or international level (e.g. Yin, 1999; Nyrud and Bergseng, 2002; Nyrud and Baardsen, 2003; Salehirad and Sowlati, 2005; Diaz-Balteiro et al., 2006). The study by Mikkila et al. (2005) in which the corporate social performance of pulp and paper companies is assessed is one of the rare exceptions. Santos et al. (2019) reviewed the literature on the assessment and optimization of sustainable forest product supply chains and found that, despite the growing number of contributions, few of them consider all three sustainability pillars. This confirms the conclusions of Boukherroub et al. (2016) who reviewed the literature on the integration of sustainability in supply chain optimization models (all sectors included). Morali and Searcy (2013) investigated how sustainability is integrated by Canadian companies (all sectors combined) in their supply chains by analyzing 100 corporate sustainable development reports and performing interviews with 18 experts. They found that although the majority of companies have a strategy or operational plans to address sustainability issues, their focus is on environmental and economic pillars. There is also a lack of indicators measuring companies' success related to sustainability initiatives and suppliers' sustainability performance. Lähtinen et al. (2016) analyzed corporate responsibility reports of 13 global forestry companies to evaluate how they address environmental issues related to biodiversity in reference to 30 environmental performance indicators of the Global Reporting Initiative (GRI) guidelines.

These studies confirm that sustainability has not spread evenly across the supply chain, with a rupture between the orientation of the upstream (SFM) and the downstream parts of the chain (Products supply chain). SFM is a concept that appeared relatively early in the literature and has been applied in practice at the global, regional, national, and local levels. In North America for instance, Siry et al. (2018) mentions that all public forests and many private forests have management plans developed in accordance with SFM principles and many forests are certified. The forest products supply chain has received less interest from researchers and practitioners. Most studies focus on bioenergy supply chains and rarely include social aspects. In practice, companies tend to focus on the supply chain's upstream activities (forest resources management) or manufacturing activities, but they lack environmental and social indicators regarding their sustainability initiatives. Two main conclusions could be made: (i) there is a “discontinuity” in integrating sustainability aspects across supply chains, and (ii) sustainability integration in the forestry sector is “unbalanced” in terms of importance paid to the three pillars.

2.2. Sustainable forest products supply chain management in Quebec

In the province of Quebec, more than 90% of the forests are publicly owned and managed by the Ministry of Natural Resources and Forests, hereinafter referred to as MRNF. The MRNF introduced a new forest regime in 2013 to promote SFM practices as well as integrated and participatory planning. MRNF also extended its responsibilities to ensure that forestry/harvest planning and postharvest activities, which were under the responsibility of forest companies, are made in compliance with SFM goals. Prior to the new regime implementation, there was a sharp separation of responsibilities (and decision-making) between the government (MRNF) and industrial companies.

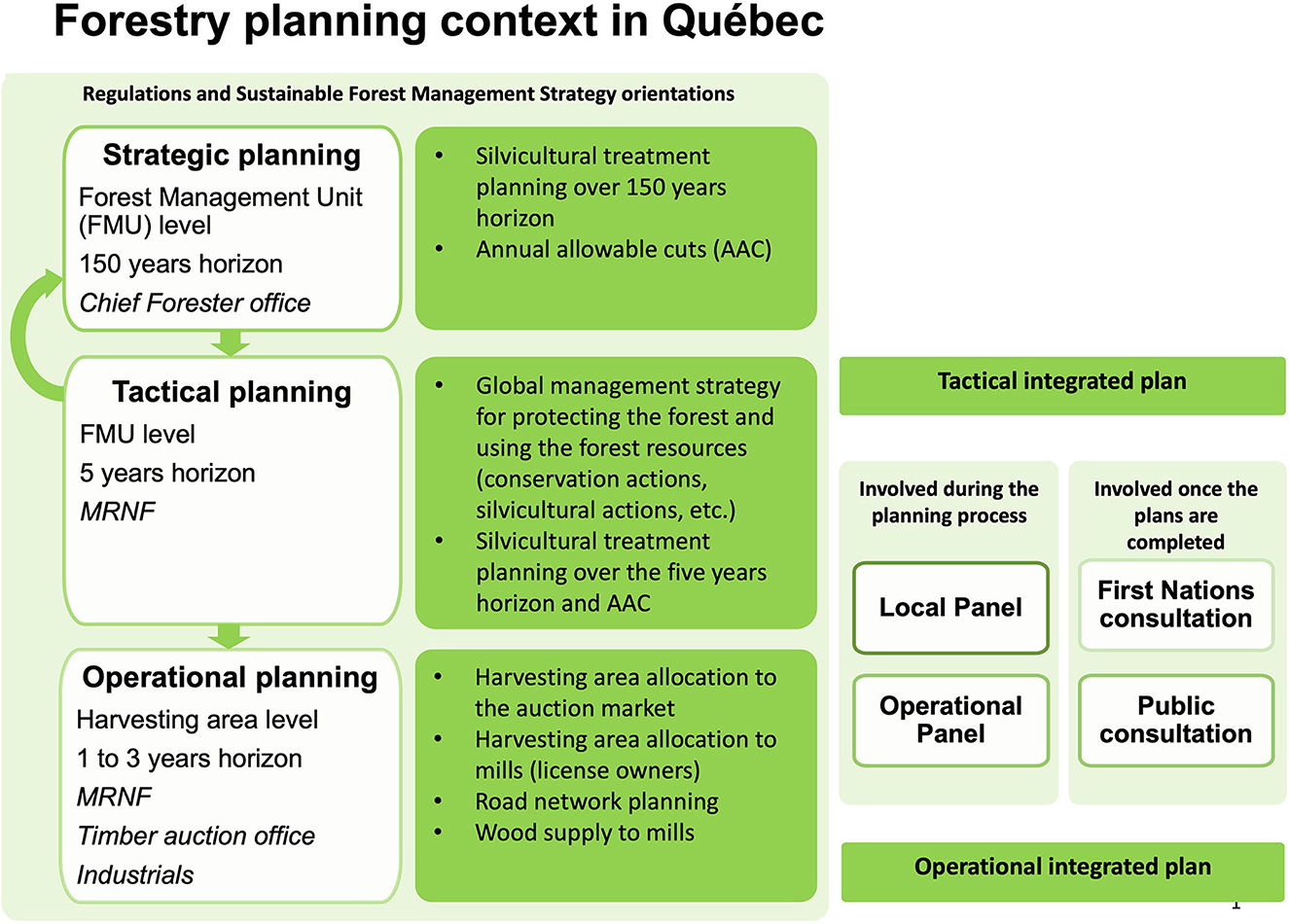

From a sustainability perspective, in the previous model public decision-makers focused on the management of forest viability and bearability (sustained use of forest resources), while private companies were concerned by the economic aspects (Azouzi and D'Amours, 2011) and, to some extent, perhaps in response to the labor shortages observed in the field, by social concerns. The new regime seeks to ensure that all forest users and stakeholders (forest companies, First Nations, outfitters, local communities, environmental organizations, etc.) participate in forest management and express their concerns. To this end, integrated planning and four participatory mechanisms—Local Panels, Operational Panels, First Nations and public consultations—have been introduced (Desrosiers et al., 2010; MRNF, 2013), giving forest companies and other stakeholders the opportunity to express and discuss their needs and concerns at different stages of the planning process. Figure 1 summarizes the main steps of the management process, outputs, and actors involved.

Figure 1. Description of public-owned forest management in Quebec (Boukherroub et al., 2018).

Three decision levels can be distinguished: strategic, tactical and operational. The forest management strategy is the basis for both the strategic and tactical plans. The strategy guides the strategic plan, which determines management activities and the volume of timber to be harvested annually to ensure a non-declining yield (i.e., Annual Allowable Cuts also called ACC) over a 150-year horizon divided into 30 periods of 5 years each (BFEC, 2013). The strategic plan is prepared by several governmental decision-makers (Bureau du Forestier en Chef, referred to as BFEC,1 and the MRNF) for all 71 Forest management units (FMU2) in Quebec. The decisions for the first period in the strategic plan are inputs for the elaboration of the tactical plan.

The tactical plan is established by MRNF for each FMU. It determines the allocation of forest resources for different uses (e.g., conservation areas and timber production areas), future developments of forest roads and other infrastructures as well as the sustainability goals for the FMUs for a 5-year period (MRNF, 2013, 2015). During its elaboration, the MRNF meets the members of a Local Panel (formed of representatives of First Nations, municipalities, forest companies, controlled zone operators, outfitting permit holders, etc.) to allow the stakeholders to express their concerns and take part in forest management and planning.

The operational plan, covering a 1 to 3-year horizon, uses the outputs of the tactical plan as constraints and decides the harvest areas that will be cut, their allocation to industrials (Licensed owners), wood volumes to harvest from each area, wood volumes to deliver to each mill, and forest road planning (MRNF, 2013, 2015). During the elaboration of an FMU operational plan, the MRNF confers with an Operational Panel which includes representatives of industrials to align their needs with the forest management strategy. Hearings are further organized to present the plans to First Nations and the general public.

Unfortunately, interviews conducted between 2012 and 2016 in different regions of the province of Quebec (see Boukherroub et al., 2018 for more details) revealed that the implementation of these new forest management and planning processes has raised many concerns among the stakeholders, mainly: (1) stakeholders' goals are inconsistent with each other, which leads to the difficulty of finding compromises and consensus, (2) economic objectives such as maximizing the wood volumes to allocate to industrials are not consistent with the SFM ecological goals, (3) forest road network planning, wildlife habitat, and landscapes are the most conflicting issues, and (4) there is a lack of plan impact analyses that makes difficult to foresee consequences of the proposed plans, particularly to non-experts (general public and representatives of First Nations).

3. An emergent approach to better integrate and align sustainability goals in forest products supply chain management

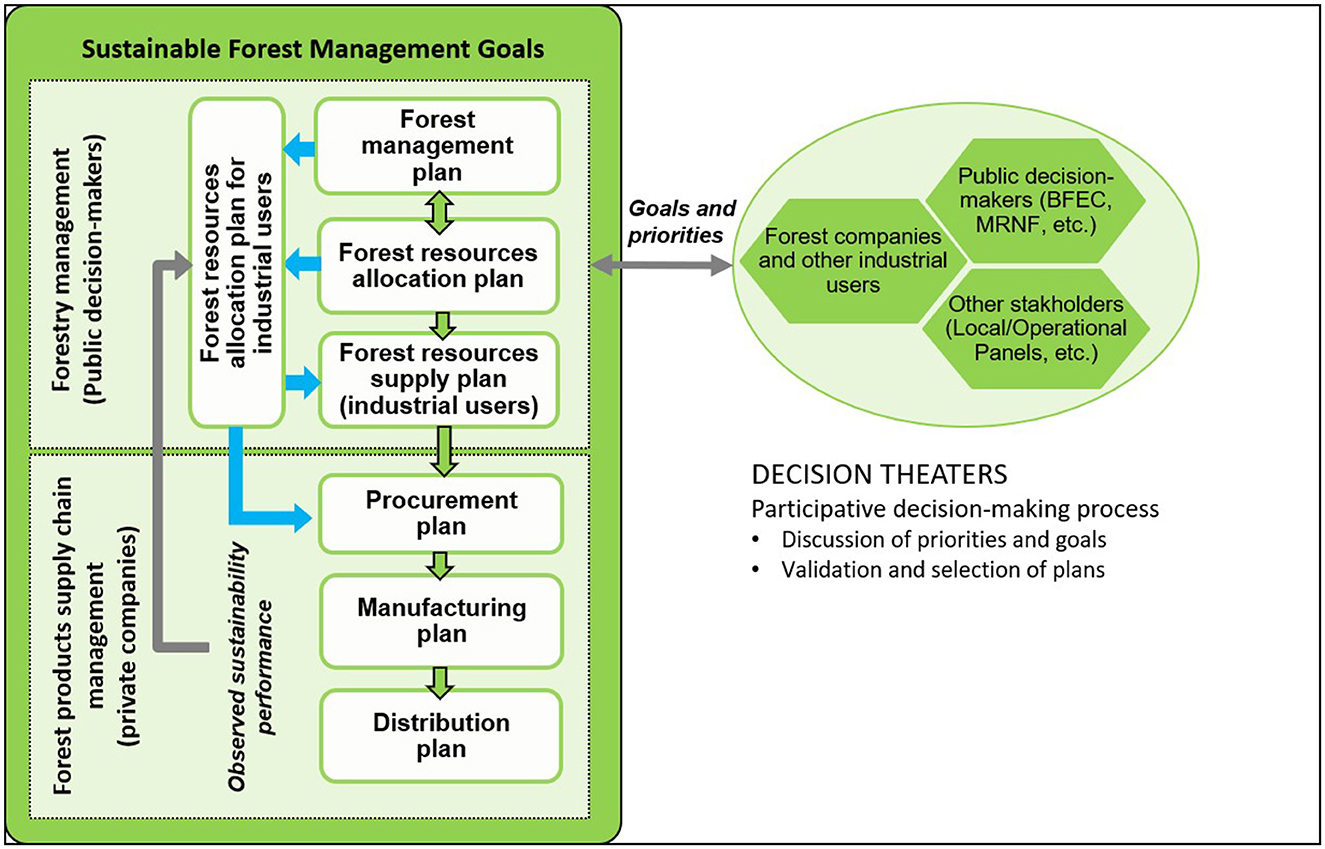

This section formalizes a proposal that seeks to overcome at least two of the concerns on the current forest products supply chain management model by improving two main aspects: better satisfaction of stakeholders' goals and better spread of sustainable objectives across the entire supply chain. Figure 2 illustrates the proposal.

Figure 2. The proposed model to improve stakeholders' satisfaction and sustainable objectives integration of Forest management and Forest products supply chain.

Concerning supply chain integration, the proposal extends the scope of the model to integrate forest management and the industrial supply chain in a closed-loop, performance-based approach where the allocation of forest resources to companies will be related not only to their demands, but to their observed sustainable performance. In this model, guidelines and a set of sustainable performance evaluation criteria should be elaborated by public decision-makers considering all the stakeholders' perspectives (i.e., their expectations regarding sustainability benefits that should be generated through forest resources transformation). Industrials' wood volume requests should be evaluated with respect to the organizations' past sustainable performance and to the organizations' commercial plan and strategy (e.g., what the organizations intend to do with the allocated resource) in such a way that organizations generating higher value (measured with respect to the three sustainability aspects) will be rewarded with higher volumes or volumes that better fit their requirements.

In contrast to the current approach, the closed-loop one enables “pushing” sustainability objectives and responsibilities to industrials, that have no choice but to improve their overall performance to compete for the resource. The wood allocation process described in Boukherroub et al. (2017) supports this closed-loop approach. It is based on a three-step method: (1) sustainability allocation criteria specification, (2) multicriteria performance evaluation, and (3) value maximization and wood allocation. They explored several scenarios to support the wood allocation decisions. One scenario considers solely the economic performance, reflecting the current practice, while another one grants equal weights to the economic, environmental, and social dimensions of performance. The solutions generated in the two scenarios were very different with respect to the ranking of the players (and therefore, the volumes of the wood to allocate to them). The economic value maximization scenario tends to concentrate volume on the most cost-efficient companies independently of how they perform well in other sustainability performances. Furthermore, this might progressively weaken competition provoking more “sustainable companies” to close in the long-term. On the other hand, the sustainability-maximization-based model rewards companies achieving higher sustainable scores (independently of their size) with more wood in order to encourage a better use of the resource and more sustainable practices.

As per the stakeholders' satisfaction, in the new proposal public decision-makers are still responsible for the elaboration of the forest management plans since they own the technical skills required to perform such specific and complex tasks. However, stakeholders must be consulted, and their needs and priorities taken into consideration during the elaboration of plans in a more efficient way. Although participative decision-making approaches have been observed in different contexts such as environmental management (Antunes et al., 2006), waste management (Hornsby et al., 2017), urban planning (Salter et al., 2009), and even natural resources management (Langsdale et al., 2013), their development and implementation in forest management raises, despite their evident advantages, important challenges, some of which were also observed in the case studied here. For instance, participatory processes must provide the right information to all the stakeholders, and at the right time. However, considering the variety and the complexity of data related to forest planning is a major challenge.

The proposed closed-loop model seeks to enable all stakeholders, not only to express their concerns, but to take part in forest management decisions by introducing an innovative participative planning and decision-making approach based on the use of recent technology developments. More precisely, the proposed approach aims to take advantage of data visualization and (semi-)immersive technological environments such as the concept of “Decision Theater” described in Boukherroub et al. (2018), which could support more efficiently both decision-makers and stakeholders infinding compromises and reaching consensus. In this regard, Têtu (2014) mentions that due to recent technologies, tools supporting forest management planning that enable data visualization and plan impacts analyses from different perspectives are becoming widespread.

4. Discussion

Although forest companies have not yet well-integrated the concept of sustainability performance in their operations and strategy, governmental requirements toward forest companies that procure timber from public forests can have a major impact on industrial behavior and practices regarding more sustainability integration in their supply chains. The implementation of the proposed closed-loop performance-and-technology-based approach might help public decision-makers to push sustainability objectives downstream in the forest supply chain. However, the proposed approach raises several challenges.

First, governmental decision-makers must develop and implement scoreboard systems and performance indicators that effectively reflect governmental sustainability policy and vision. The literature devoted to supply chain performance assessment under a sustainable perspective is still consolidating. However, recent works (see for instance Santos et al., 2021) provide integrated systems of sustainability performance analysis of the supply chain. Inspired by the literature on multi-criteria performance measurement, Boukherroub et al. (2015) designed a method that links sustainability performance criteria to the decisions of the supply chain, which allowed them to set coherent performance indicators. By linking this method to a multi-objective optimization model, the economic, environmental, and social performances were all coherently integrated in this decision support tool.

Secondly, the application of a sustainability performance-based allocation process would require communicating the selected performance criteria as well as the adopted methodology to forest companies. These criteria should be known well in advance before applying such a process on a regular basis (most of the companies did not develop sustainability indicators). The implementation of a performance-based allocation process will certainly impact the whole network of industry sourcing wood from public forests. To mitigate potential undesirable impacts, the performance-based allocation process should be implemented progressively in such a way that the companies' efforts toward more sustainable objectives and practices might be appreciated over time rather than evaluated at static instants. Indeed, how to consider the evolvement of companies' sustainability performance over time, and how to determine dynamically allocations over several time-periods are open questions that require additional research and the development of quantitative models and thorough simulations.

Finally, additional multidisciplinary research is needed to develop integrated approaches combining methods, models, and tools coming from complementary disciplines (e.g., performance evaluation, decision-making sciences, Operations Research, computer science, and data visualization and analytics) that might support and enhance participative decision-making processes.

Data availability statement

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding authors.

Author contributions

TB and AR contributed equally to the conceptualization, analysis, investigation, validation, and writing—original draft, review, and editing. All authors contributed to the article and approved the submitted version.

Funding

This research was supported by the Natural Sciences and Engineering Research Council of Canada (NSERC) grant 2018-04555.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher's note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Footnotes

1. ^An independent entity from MRNF.

2. ^A forest area, which supplies mills having supply agreements in the FMU territory.

References

Antunes, P., Santos, R., and Videira, N. (2006). Participatory decision making for sustainable development - the use of mediated modelling techniques. Land Use 23, 44–52. doi: 10.1016/j.landusepol.2004.08.014

Azouzi, R., and D'Amours, S. (2011). Information and knowledge sharing in the collaborative design of planning systems within the forest products industry: survey, framework and roadmap. J. Sci. Technol. Forest Prod. Process. 1, 6–14.

Baumann, E. (2011). Modèles D'évaluation des Performances Économique, Environnementale et Sociale dans les Chaînes Logistiques [Ph.D. thesis]. France: Institut National des Sciences Appliquées de Lyon.

BFEC (2013). Manual for Determining Allowable Cuts (2013-2018) (Manuel de Determination des Possibilités Forestières (2013-2018)). Roberval, QC: Government of Quebec, 247 (In Latvian).

Boukherroub, T., D'amours, S., and Rönnqvist, M. (2018). Sustainable forest management using decision theaters: rethinking participatory planning. J. Clean. Prod. 179, 567–580. doi: 10.1016/j.jclepro.2018.01.084

Boukherroub, T., LeBel, L., and Ruiz, A. (2017). A framework for sustainable forest resource allocation: a Canadian case study. Omega 66, 224–235. doi: 10.1016/j.omega.2015.10.011

Boukherroub, T., Ruiz, A., Fondrevelle, J., Guinet, A., and Ouhimmou, M. (2016). Intégration de la performance durable dans les modèles de conception et de planification des chaînes logistiques : un état de l'art. J. Eur. Syst. Autom. 49, 237–270. doi: 10.3166/jesa.49.233-270

Boukherroub, T., Ruiz, A., Guinet, A., and Fondrevelle, J. (2015). An integrated approach for sustainable supply chain planning. Comput. Oper. Res. 54, 180–194. doi: 10.1016/j.cor.2014.09.002

D'Amours, S., Rönnqvist, M., and Weintraub, A. (2008). Using operational research for supply chain planning in the forest products industry. Inf. Syst. Oper. Res. 46, 265–281. doi: 10.3138/infor.46.4.265

Desrosiers, R., Lefebvre, S., Munoz, P., Paquet, J., and Géographe, M. (2010). Guide for Integrated Management of Resources and Territory; its Application in the Elaboration of Integrated Forest Management (Guide sur la gestion intégrée des ressources et du territoire: son application dans l'élaboration des plans d'aménagement forestier intégré). MFFP, 18 (In Latvian). Available online at: http://www.mrnf.gouv.qc.ca/publications/forets/amenagement/guide-GIRT.pdf

Diaz-Balteiro, L., Casimiro Herruzo, A., Martinez, M., and Gonzàlez-Pachòn, J. (2006). An analysis of productive efficiency and innovation activity using DEA: an application to Spain's wood-based industry. For. Policy Econ. 8, 762–773. doi: 10.1016/j.forpol.2005.06.004

Eggers, J., Melin, Y., Lundström, J., Bergström, D., and Öhman, K. (2020). Management strategies for wood fuel harvesting-Trade-offs with biodiversity and forest ecosystem services. Sustainability 12, 4089. doi: 10.3390/su12104089

Elkington, J., and Rowlands, I. H. (1999). Cannibals with forks: the triple bottom line of 21st century business. Altern. J. 25, 42.

FAO (2022). Food and Agriculture Organization on the United Nations. https://www.fao.org/forestry/sfm/85084/en/ (accessed November 7, 2022).

Garcia-Gonzalo, J., Bushenkov, V., McDill, M. E., and Borges, J. G. (2015). A decision support system for assessing trade-offs between ecosystem management goals: an application in Portugal. Forests 6, 65–87. doi: 10.3390/f6010065

Hornsby, C., Ripa, M., Vassillo, C., and Ulgiati, S. (2017). A roadmap towards integrated assessment and participatory strategies in support of decision-making processes. The case of urban waste management. J. Clean. Prod. 142, 157–172. doi: 10.1016/j.jclepro.2016.06.189

Lähtinen, K., Guan, Y., Li, N., and Toppinen, A. (2016). Biodiversity and ecosystem services in supply chain management in the global forest industry. Ecosyst. Serv. 21, 130–140. doi: 10.1016/j.ecoser.2016.07.006

Langsdale, S., Beall, A., Bourget, E., Hagen, E., Kudlas, S., Palmer, R., et al. (2013). Collaborative modeling for decision support in water resources: principles and best practices. J. Am. Water Resour. Assoc. 49, 629–638. doi: 10.1111/jawr.12065

Marto, M., Reynolds, K. M., Borges, J. G., Bushenkov, V. A., Marques, S., Marques, M., et al. (2019). Web-based forest resources management decision support system. Forests 10, 1079. doi: 10.3390/f10121079

Mikkila, M., Kolehmainen, O., and Pukkala, T. (2005). Multi-attribute assessment of acceptability of operations in the pulp and paper industries. For. Policy Econ. 7, 227–243. doi: 10.1016/S1389-9341(03)00062-5

Morali, O., and Searcy, C. (2013). A review of sustainable supply chain management practices in Canada. J. Bus. Ethics 117, 635–658. doi: 10.1007/s10551-012-1539-4

MRNF (2013). Manual of Forestry Planning 2013-2018 (Version 5, 1.) ([Manuel de Planification Forestière 2013-2018 (version 5.1)]). Roberval, QC: Government of Quebec, 242 (In Latvian).

MRNF (2015). Integrated Tactical Forest Management Plan. Mauricie and Centre-du-Quebec regions. Management Unité 026-51 (Plan D'aménagement Forestier Intégré e Tactique 2013-2018 : Région de la Mauricie et du Centre-du-Québec. Unité D'aménagement 026-51) (In Latvian). Available online at: http://www.mffp.gouv.qc.ca/forets/consultation/consultation-amenagement.jsp

NRCAN (2022). Natural Resources Canada (Government of Canada). Available online at: https://www.nrcan.gc.ca/our-naturalresources/forests/13497 (accessed November 7, 2022).

Nyrud, A. Q., and Baardsen, S. (2003). Production efficiency and productivity growth in Norwegian sawmilling. J. For. Sci. 49, 89–97. doi: 10.1093/forestscience/49.1.89

Nyrud, A. Q., and Bergseng, E. R. (2002). Production efficiency and size in Norwegian sawmilling. Scand. J. For. Res. 17, 566–575. doi: 10.1080/02827580260417224

Rönnqvist, M., D'Amours, S., Weintraub, A., Jofre, A., Gunn, E., Haight, R. G., Romero, C., et al. (2015). Operations research challenges in forestry: 33 open problems. Ann. Oper. Res. 232, 11–40. doi: 10.1007/s10479-015-1907-4

Salehirad, N., and Sowlati, T. (2005). Performance analysis of primary wood producers in British Columbia using data envelopment analysis. Can. J. For. Res. 35, 285–294. doi: 10.1139/x04-154

Salter, J. D., Campbell, C., Journeay, M., and Sheppard, S. R. (2009). The digital workshop: exploring the use of interactive and immersive visualisation tools in participatory planning. J. Environ. Manage. 90, 2090–2101. doi: 10.1016/j.jenvman.2007.08.023

Santos, A., Carvalho, A., Barbosa-Póvoa, A. P., Marques, A., and Amorim, P. (2019). Assessment and optimization of sustainable forest wood supply chains-A systematic literature review. For. Policy Econ. 105, 112–135. doi: 10.1016/j.forpol.2019.05.026

Santos, D. A., Quelhas, O. L. G., Gomes, C. F. S., and Filho, J. R. F. (2021). Theoretical proposal for an integrated sustainability performance measurement system in the supply chain. Front. Sustain. 2, 720763. doi: 10.3389/frsus.2021.720763

Schmithüsen, F. J. (2013). Three Hundred Years of Applied Sustainability in Forestry. Working papers/Forest Policy and Forest Economics Department of Forest Sciences. doi: 10.3929/ethz-a-009955604

Siry, J. P., Cubbage, F. W., Potter, K. M., and McGinley, K. (2018). Current perspectives on sustainable forest management: North America. Curr. For. Rep. 4, 138–149. doi: 10.1007/s40725-018-0079-2

Têtu, P. (2014). Workshops on How to Improve the Implementation of the New Forest Regime, 50. Quebec. [Chantiers sur les améliorations à apporter à la mise en œuvre du régime forestier.] (In Latvian).

Keywords: sustainability, supply chain management, Sustainable Forest Management, forestry, decision-making, participative decision-making

Citation: Boukherroub T and Ruiz A (2023) Embracing sustainability in public-owned forest resources management: Lessons learned and perspectives. Front. Sustain. 3:1096356. doi: 10.3389/frsus.2022.1096356

Received: 12 November 2022; Accepted: 29 December 2022;

Published: 13 January 2023.

Edited by:

Maxim A. Dulebenets, Florida Agricultural and Mechanical University, United StatesReviewed by:

Lazarus Chapungu, University of South Africa, South AfricaCopyright © 2023 Boukherroub and Ruiz. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Angel Ruiz,  YW5nZWwucnVpekBmc2EudWxhdmFsLmNh

YW5nZWwucnVpekBmc2EudWxhdmFsLmNh

Tasseda Boukherroub

Tasseda Boukherroub Angel Ruiz

Angel Ruiz