95% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

ORIGINAL RESEARCH article

Front. Sustain. , 04 February 2021

Sec. Circular Economy

Volume 2 - 2021 | https://doi.org/10.3389/frsus.2021.644309

This article is part of the Research Topic What Is A Waste? A Potential Resource to Favor a Sustainable Transition. Evidence From the Practice. View all 7 articles

The pandemic that the world has been facing since Jan-2020 has promoted rapid changes in the form of consumption and service provision. In many countries, GDP forecasts have turned negative. But, if on the one hand, the prospects were negative, on the other, there were positive signs, including the adoption of recycling, remanufacturing, and reuse practices. Reusing raw materials in their production lines, companies and volunteers produced masks for mandatory use by the population of some countries such as Brazil. This brief period energized an economy that until then seemed to be dormant. In view of this scenario that took shape in the world, the present study aimed to assess how this pandemic affected sewing professionals' enterprises, contributing to an income generation and to a possible sustainable practice. The level of circularity was evaluated through a questionnaire and interviews as it was impossible to visit the ateliers. The survey of enterprise circularity was based on basic principles of circular economy from Ellen MacArthur Foundation. The questions were made considering some features, like level of knowledge about the theme The prospecting of the potential interviewers was carried out through a digital platform in the month of September-2020. Results obtained by fabric remnants mass balance indicated some level of circularity in the production mode of seamstresses during the pandemic. The challenge, however, is the high demand for masks allied to the search for customization by consumers. This represents the main obstacles to maintaining circularity in the production process.

From Feb-20, because of de pandemic caused by the spread of SARS-CoV-2, a hypothesis was raised stating that the crisis generated by the pandemic could accelerate circular economy practices (Corrêa and Corrêa, 2020). On that occasion, actions were observed in different parts of the world linked to the production of protective equipment (PPEs). Scarce due to high global demand, PPEs have become rare items even for use by health professionals. In order to go around the situation, companies, public sectors, and civil organizations have joined forces to manufacture PPEs from alternative materials. At first, masks and face shields were produced in large quantities in order to meet the primary needs of hospitals and health centers and subsequently be available—and not in rare cases, mandatory—to the population (Broom, 2020; Corbett, 2020; Elgin and Tozzi, 2020; Feng and Cheng, 2020; Ha, 2020; Lee, 2020; Parker-Pope, 2020; Subramanian, 2020).

Though to varying degrees, those examples have principles of circular economy. Considering the three pillars of circularity addressed by the Ellen MacArthur Foundation—preservation of natural capital, optimization of resource production, and process efficiency, many initiatives that have emerged and developed due to the pandemic seem to be at least based on the first two. This is because a lot of PPE production was based on alternative materials that were reused in the manufacturing process (Dela Cruz, 2020; Foy, 2020; Hitti, 2020; Reid and Hurst, 2020; Shokrani et al., 2020).

Contemporary society is structured in a linear production model of natural resource extraction, processing, use, and disposal. For the current system to be sustainable, disposed materials must return to the consumer in a useful form and within a reasonable time scale, when compared to human life span (<100 years) (Kümmerer and Clark, 2016). In order that this reintroduction into the productive cycle may occur, processes and technologies must be developed, improved, and applied. Many of them are based on the use of renewable resources, cleaner methods of energy conversion, and more efficient catalytic syntheses (Sheldon, 2016; Palkovits and Delidovich, 2017; Zhang et al., 2018; Payne et al., 2019; Catlow et al., 2020). This approach, in which reuse, recycling, recovery, and remanufacturing practices for waste reduction are privileged, is one of the bases of circular economy (Gregson et al., 2015; Kirchherr et al., 2017).

Based on observations made in a previous work (Corrêa and Corrêa, 2020), enterprises were selected that had started because of the demands for PPEs used to control the pandemic spread. The selection of organizations was based on geography and regional impact. In this sense, enterprises associated with the manufacture of non-disposable masks for use by the general population and with characteristics of a family business were analyzed. Having defined those criteria, it was possible to include in the present work entrepreneurial activities aimed at fighting Covid-19: civil organization initiatives.

One of the premises of circular economy, then, is the preservation and valorization of the natural capital and, therefore, minimizing waste. Thus, the concept permeates the entire production chain, from the product concept to its distribution and subsequent use. According to notes by the [Conselho Empresarial Brasileiro para o Desenvolvimento Sustentável, 2018], design is an important tool to achieve circular economy because, through it, durable products and services can be placed on the market using fewer resources. The production mode also matters for circular economy. Cleaner processes, with greater energy efficiency and water reuse, and new applications for by-products guarantee robustness to the activity from the point of view of circular economy (Kümmerer and Clark, 2016; Babitt et al., 2018).

In Brazil, the National Solid Waste Policy (Brasil, 2010) encourages circular economy practices, ensuring that products are reintegrated into the production chain with a resulting reduction in solid waste.

In the absence of a standard and consensual questionnaire for measuring practices related to circular economy, the present work adopted as references for the preparation of the questionnaire the basic principles necessary to establish circular economy, as listed by the Ellen MacArthur Foundation (2020). They are preservation and increase of the natural capital, optimization of resource production, and promotion of process efficiency. Judging by the production concept observed, the cases reported in the present work seem to be solidly based on the second principle. This is because a lot of PPE production was based on alternative materials that were reused in the manufacturing process (Dela Cruz, 2020; Foy, 2020; Hitti, 2020; Reid and Hurst, 2020; Shokrani et al., 2020). According to that principle, production is based on remanufacturing, reforming, and recycling so that products and services circulate in the production chain.

In the case of self-employed professionals, who are hardly unionized or registered as an individual micro entrepreneur (MEI), the collection of information regarding the number of seamstresses in the city of Curitiba-BR was carried out in official databases. However, the prospecting was carried out through a digital platform— “Mapa de Máscaras” (bWFwYWRlbWFzY2FyYXMuY29tLmJy), in the month of September-2020. It is a non-profit project, whose objective is to stimulate the local economy, giving visibility to he/she seamstresses who make reusable masks, according to information contained in that very site.

This platform was very important due to the lack of official information and to the still informal and unregulated nature of the seamstresses' activity (Bordin, 2019). Thus, the survey was carried out using the above-mentioned “Mapa de Máscaras” platform (bWFwYWRlbWFzY2FyYXMuY29tLmJy).

The survey was elaborated intending to check evidences of reuse of fabric in the process of manufacturing. It was used to investigate when the local professionals commenced producing face masks. This data was important to evaluate the level of knowledge of demand from the sewing professionals. Complementing the answers, interviews were made through messages (emails or mobile). And more data were obtained to identify some circularity at ateliers, as well the costs of manufacturing. The information about quantity of fabric reuse, raw material used and others were employed to material balance calculating. The data were included in a spreadsheet and treated.

The questionnaire consisting of five questions was sent to those professionals. All questions were oriented in such a way as to easily identify any indication of the application of circular economy in their business. The questions are presented in Table 1.

From the information collected from the above-mentioned site, 71 registered professionals were identified in Curitiba-Br. Figure 1 shows the areas where they work.

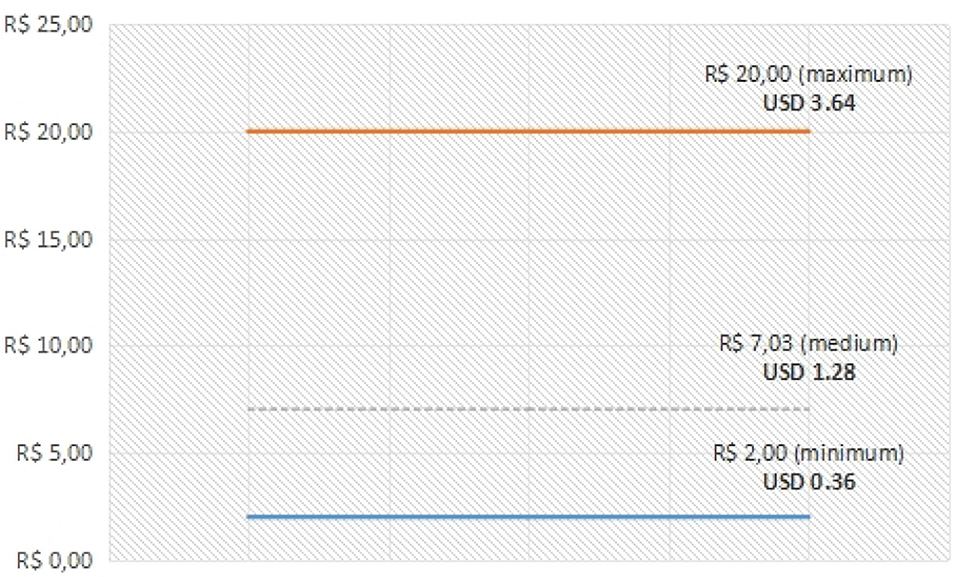

The questions were sent exclusively via the phone message application. The percentage of responses was 30%. Out of this group, 95% of the interviewed started to make masks in the outbreak of SARS-CoV-2 in Curitiba-Br. The others already produced masks for health professional and for other purposes. Figure 2 shows the minimum sales values practiced in the city, based on data obtained from that platform.

Figure 2. Variation in the minimum sale price practiced in Curitiba-Br, based on data collected from the “Mapa de Máscaras” platform.

The discrepancy between the values is basically due to two reasons: diversity in the supplies used—the prices of which are varied; and production of masks in different sizes—to fit adults and children. Another factor must be taken into account: the search for personalized masks, which required distinct prints and materials, and ended up being more costly. In this case, customization seems to be common among clothing customers who seek sewing services to readjust ready-made clothes, as pointed out by Novaes (2016). This consumer profile becomes the main barrier to the maintenance of a circular production process, since remnants of fabric cease to be used as a result of consumer demands.

As for the fabrics used for making masks, Figure 3 shows the most common types.

As for the use of fabrics, one observes that most of the reusable masks available are produced with cotton. This datum is in line with the recommendations of the Brazilian National Health Surveillance Agency (ANVISA-Br), which indicates the preferred use of fabrics containing cotton [Agência Nacional de Vigilância Sanitária, 2020]. Although the same Agency indicates the possibility of using synthetic Non-Woven Fabric (NWF), most masks produced are not made with this material, due to its allergic potential. This testifies the commitment of professional seamstresses to the safety of their customers.

Figure 4 shows the average prices of supplies, obtained from the site: centerfabril.com.br, in September-2020.

Although simple NWF has a lower value among the listed supplies, it is still the least used fabric by professional seamstresses. This choice is probably due to the ANVISA's recommendations, endorsing the seamstresses' commitment to the safety and quality of the product to be delivered, so much valued by customers and characteristics common to those professionals, as Novaes (2016) observed so well.

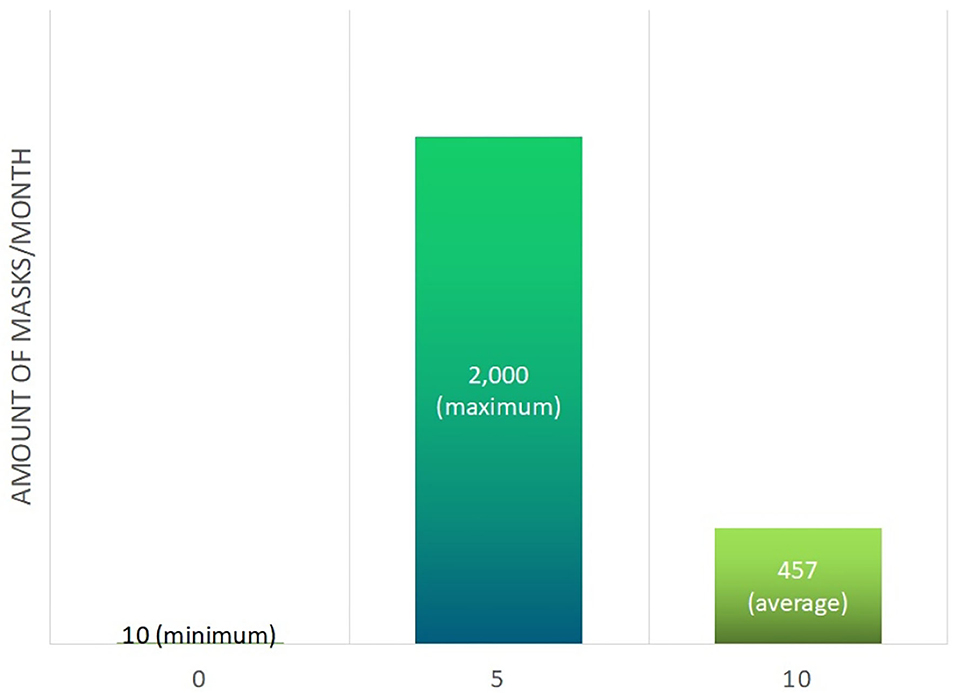

Figure 5 illustrates the monthly production capacity.

Figure 5. Monthly production capacity, with minimum and maximum values found, and the calculated average considering all seamstresses.

Comparing the extremes, one notices the heterogeneity in the production rhythm among professionals. In the universe of seamstresses evaluated, the lowest production capacity was 10 masks/month. The maximum production calculated was 2,000 masks/month. The average production capacity obtained considering the production by all professionals was 457 masks/month.

This great variation is probably due to the nature of the sewing craft of seamstresses, since this work niche is made up of professionals from various spectra—from those who depend exclusively on sewing and, therefore, need to produce in quantity, to those who resort to that craft to complement their income. There are also those, who produce only for personal satisfaction, as a hobby. In addition, there is the flexibility in the work environment, common among those professional. As highlighted by Novaes (2016) in her work addressing the historical evolution of seamstresses in Viçosa, Minas Gerais-Brazil, the tasks in a studio are performed according to the professionals' expectations, such as flexibility in the hourly load.

The disparity in production and confection among seamstresses, especially regarding the amount of fabric used, is probably due to the nature of the craft itself. When addressing the historical evolution of sewing professional in Viçosa (MG-Br), Novaes (2016) highlighted that, although linked to Market logistic, that craft does not necessarily aim at profiting. Despite having a double workday, professional in this segment work in their own studios for their personal satisfaction. Thus, as Novaes (2016) observed, each seamstress has his/her own work organization, which differentiates them, characterizing the dynamics and diversity of their craft. This information corroborates the results obtained in Curitiba-Br, which demonstrated the same specific character identified in the case study by Novaes (2016).

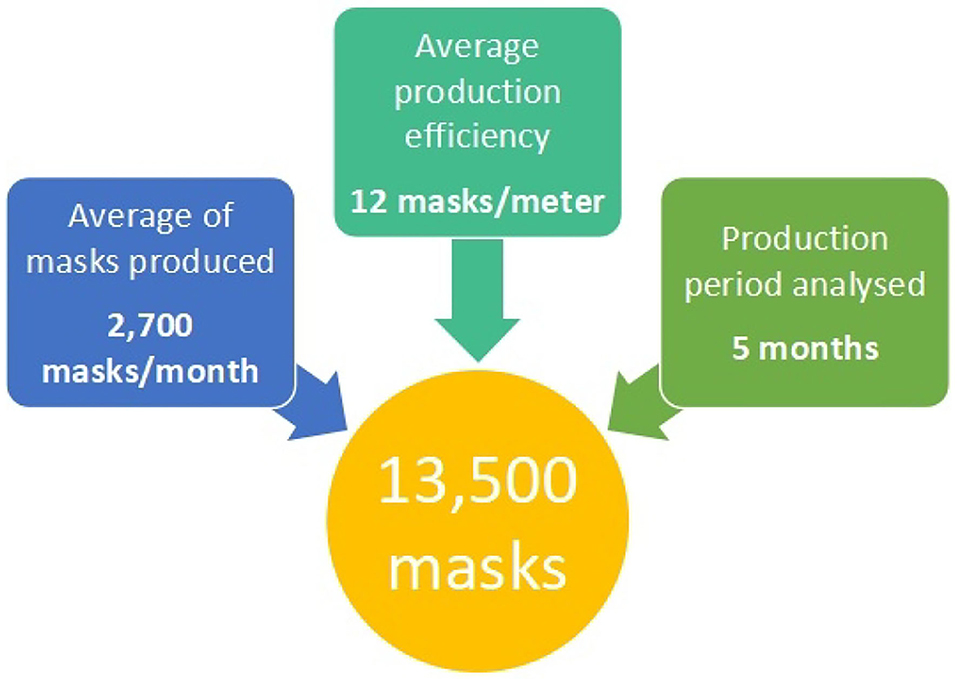

Based on the information collected from those professionals, it was possible to estimate the amount of remnants used in the production of masks and, therefore, the percentage reintroduced into the production process. According to the survey, 32% of seamstresses used remnants to make masks. However, only 50% of this universe controls the consumption of the fabric they use. Thus, calculations regarding the reuse of fabric were performed considering the analyzed percentage. Figure 6 shows the parameters for estimating the total number of masks produced with remnants.

Figure 6. Parameters used to calculate the estimated quantity of masks produced with remnants of fabric in Curitiba-Br.

Having as reference 100%-cotton white fabric, 0.75 m wide and weighing 173 g/m2, it is estimated that in the analyzed period about 150 kg of fabric were reused just for making masks. Projecting the values for the remaining 50% of the seamstresses that use remnants, it is estimated that an amount of up to 300 kg of fabrics were reincorporated into the production process.

Out of the total number of masks produced, including those that did not use remnants, almost 37% refer to the products that were designed based on reusable fabrics and, therefore, based on the concept of circular economy.

Although the estimates are encouraging, considering that more than 30% professionals were using remnants for making masks, some barriers to reuse practice still persist. The lack of control over spent materials and residues generated in the manufacturing process seems to be one of the reasons to discourage the use of remnants for making masks. The demand for customized materials, which require the acquisition of fabrics with a specific print, also hinders the full use of remnants, characterizing a social barrier, as pointed out by van Burel et al. (2016). Another limitation is due to the technical issue. Depending on the type of remnant generated in the studios, many of them do not have the minimum dimensions necessary to be used in making masks.

The current pandemic, despite its impact on health and human lives, has also contributed to the adoption of more sustainable practices. The making of remnant masks proves, at least in Curitiba-Br, to be promising for diversifying the products sold by sewing professionals. The use of remnants by a portion of seamstresses greatly contributes to a healthier environment, since the inclusion of fabric residues in the design of the masks allows their reinsertion in the production process. This reduces the need for new fabric, allowing the closure of the material cycle, at least partly. Although it was not within the scope of the present research, the seamstresses' initiatives can contribute to attracting, diversifying, and retaining new customers, especially those who strive for sustainable products. In this sense, the use of remnants for making reusable masks has shown interest on the part of consumers, whose share can be increased by the adoption of selling strategies directed to sustainability (Oliveira et al., 2019) by using, for example, principles of behavioral economics (Thaler, 2000; Mussi and Cassel, 2018).

The current Covid-19 pandemic crisis stimulated entrepreneurship among people in Curitiba-Brazil. The seamstresses segment was one of the first to readjust to the demands required by the population. The sewing professionals demonstrated a high capacity to understand the market demand, starting the production of masks in line with the evolution of the pandemic in that city. In a scenario of scarcity of disposable masks combined with the guidelines of the State and the Municipal Health Departments, these professionals made reusable masks to be used by the general population using cotton as their preferred fabric, according to guidelines of the ANVISA and the World Health Organization. This testifies the degree of commitment to customer safety.

Although many seamstresses use remnants of fabric to make their masks, this use was restricted to this type of production just in the first month of work. The high demand for masks together with the search for customization by consumers were the main obstacles to maintaining circularity in the production process, since remnants were not intended for the purpose of a clientele looking for exclusivity.

Despite the existing barrier to the use of masks made with remnants of fabric and the likely drop in sales due to a possible future reduction in the mandatory use, the current period can be an opportunity for diversifying customers, including attracting those whose consumption habit is guided by principles of environmental issues.

The raw data supporting the conclusions of this article will be made available by the authors, without undue reservation.

Material preparation, data collection, and analysis were performed by HC and DC. The first draft of the manuscript was written by HC. All authors contributed to the study conception, design, commented on previous versions of the manuscript, read, and approved the final manuscript.

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

The authors would like to thank all sewing professionals in Curitiba-Brazil for their initiative and excellent work in promoting health and sustainability.

Agência Nacional de Vigilância Sanitária (2020). Orientações gerais - máscaras faciais de uso não profissional. Brasília. Available online at: http://portal.anvisa.gov.br/documents/219201/4340788/NT+M%C3%A1scaras.pdf/bf430184-8550-42cb-a975-1d5e1c5a10f7 (accessed September 09, 2020).

Babitt, C., Gaustad, G., Fischer, A., Chen, W., and Liu, G. (2018). Closing the loop on circular economy research: From theory to practice and back again. Resour. Conserv. Recycl. 135, 1–2. doi: 10.1016/j.resconrec.2018.04.012

Bordin, E. Z. (2019). Ofício de costureira: Um estudo sobre educação e as posições ocupadas no mercado de trabalho da confecção de vestuário na região metropolitana de Porto Alegre. Programa de Pós-Graduação em Educação. Universidade Federal do Rio Grande do Sul. Available online at: https://lume.ufrgs.br/handle/10183/193385 (accessed September 09, 2020).

Brasil (2010). Lei 12,305/10. Política Nacional de Resíduos Sólidos. Available online at: http://www.planalto.gov.br/ccivil_03/_ato2007-2010/2010/lei/l12305.htm

Broom, D. (2020). Coronavirus: here's what you need to know about face masks. World Economic Forum. Available online at: https://www.weforum.org/agenda/2020/05/coronavirus-face-masks-rules-supply/ (accessed September 09, 2020).

Catlow, R., Davidson, M., Hutchings, G., and Mulholland, A. (2020). Science to enable the circular economy. Philos. Trans. A 378, 1–3. doi: 10.1098/rsta.2020.0060

Conselho Empresarial Brasileiro para o Desenvolvimento Sustentável (2018). 5 Perguntas Para Você Entender a Economia Circular. Available online at: https://cebds.org/publicacoes/5-perguntas-pra-voce-entender-economia-circular/#.X2iYIGhKjIU (accessed September 10, 2020).

Corbett, J. (2020). As coronavirus cases in US spike 40% in one day, medical workers plea for key supplies. Commom Dreams. Available online at: https://www.commondreams.org/news/2020/03/19/we-cannot-test-we-cannot-test-coronavirus-cases-us-spike-40-one-day-medical-workers (accessed April 08, 2020).

Corrêa, H. L., and Corrêa, D. G. (2020). Could the COVID-19 pandemic crisis stimulate circular economy practices? A brief reflection. Brazil. J. Health Rev. 3, 3820–3832. doi: 10.34119/bjhrv3n2-205

Dela Cruz, B. (2020). Palawan Eco-Artist transforms plastic bottles into face shields for healthcare workers. Good News Pilipinas. Available online at: https://www.goodnewspilipinas.com/palawan-eco-artist-jc-enon-transforms-plastic-bottles-into-face-shields-for-healthcare-workers/ (accessed April 08, 2020).

Elgin, B., and Tozzi, J. (2020). U.S. Hospital Workers Are Making Masks Protective Gear From Office Supplies Amid Equipment Shortage. Available online at: https://time.com/5805557/homemade-medical-face-mask-shortage/ (accessed April 08, 2020).

Ellen MacArthur Foundation (2020). What Is Circular Economy? Available online at: https://www.ellenmacarthurfoundation.org/circular-economy/concept (accessed September 10, 2020).

Feng, E., and Cheng, A. (2020). Covid-19 Has Caused a Shortage of Face Masks. But They'Re Surprisingly Hard to Make. NPR. Available online at: https://www.npr.org/sections/goatsandsoda/2020/03/16/814929294/covid-19-has-caused-a-shortage-of-face-masks-but-theyre-surprisingly-hard-to-make (accessed April 06, 2020).

Foy, K. (2020). Steady demand for PPE might encourage local businesses to start local production. MIT News. Available online at: https://news.mit.edu/2020/steady-demand-ppe-may-encourage-local-businesses-start-production-0616 (accessed September 22, 2020).

Gregson, N., Crang, M., Fuller, S., and Holmes, H. (2015). Interrogating the circular economy: the moral economy of resource recovery in E.U. Econ. Soc. 2, 218–243. doi: 10.1080/03085147.2015.1013353

Ha, K. O. (2020). The global mask shortage may get much worse. Bloomberg. Available online at: https://www.bloomberg.com/news/articles/2020-03-10/the-global-mask-shortage-may-be-about-to-get-much-worse (accessed August 06, 2020).

Hitti, N. (2020). MIT develops one-piece plastic face shields for coronavirus medics. Dezeen. Available online at: https://www.dezeen.com/2020/04/03/mit-covid-19-face-shields-design/ (accessed April 08, 2020).

Kirchherr, J., Reike, D., and Hekkert, M. (2017). Conceptualizing the circular economy: an analysis of 114 definitions. Resour. Conserv. Recycl. 127, 221–232. doi: 10.1016/j.resconrec.2017.09.005

Kümmerer, K., and Clark, J. (2016). Green and Sustainable Chemistry. Sustainability Science - An Introduction. Dordrecht: Springer.

Lee, B. (2020). Making an N95 mask for Covid-19 coronavirus? What you need to know. Forbes. Available online at: https://www.forbes.com/sites/brucelee/2020/03/29/making-an-n95-mask-for-covid-19-coronavirus-what-you-need-to-know/#6229aaa64989 (accessed April 08, 2020).

Mussi, F. B., and Cassel, K. A. (2018). O free rider e a sustentabilidade sob a ótica da economia comportamental. Pleiade 12, 48–56. Available online at: https://pleiade.uniamerica.br/index.php/pleiade/article/view/387/374

Novaes, C. A. (2016). Evolução Histórica do Ofício de Costureira e sua Configuração em Ateliês de Costura de Viçosa, MG. Dordrecht: Universidade Federal de Viçosa.

Oliveira, F. R., França, S. L. B., and Rangel, L. A. D. (2019). Principles of circular economy for the development of products in industrial clusters. Interações 20, 1179–1193. doi: 10.20435/inter.v20i4.1921

Palkovits, R., and Delidovich, I. (2017). Efficient utilization of renewable feedstocks: the role of catalysis and process design. Philos. Trans. A 376, 1–12. doi: 10.1098/rsta.2017.0064

Parker-Pope, T. (2020). What's the best material for a mask? The New York Times. Available online at: https://www.nytimes.com/article/coronavirus-homemade-mask-material-DIY-face-mask-ppe.html (accessed April 08, 2020).

Payne, J., McKeown, P., and Jones, M. (2019). A circular economy approach to plastic waste. Polym. Degr. 165, 170–181. doi: 10.1016/j.polymdegradstab.2019.05.014

Reid, V., and Hurst, T. (2020). When Desperation Breeds Creativity: How US Hospitals Are Approaching a PPE Shortage. Available online at: https://www.advisory.com/daily-briefing/2020/03/27/ppe-shortage (accessed September 22, 2020).

Sheldon, R. (2016). Green chemistry, catalysis and valorization of waste biomass. J. Mol. Catal. A Chem. 422, 3–12. doi: 10.1016/j.molcata.2016.01.013

Shokrani, A., Loukaides, E., Elias, E., and Lunt, A. (2020). Exploration of alternative supply chains and distributed manufacturing in response to Covid-19: a case study of medical face shields. Mater. Design 192:108749. doi: 10.1016/j.matdes.2020.108749

Subramanian, S. (2020). How the face mask became the worls's most coveted commodity. The Guardian. Available online at: https://www.theguardian.com/world/2020/apr/28/face-masks-coveted-commodity-coronavirus-pandemic (accessed September 09, 2020).

Thaler, R. (2000). From Homo economicus to Homo sapiens. J. Econ. Perspect. 14, 133–141. doi: 10.1257/jep.14.1.133

van Burel, N., Demmers, M., van der Heijden, R., and Witlox, F. (2016). Towards a circular economy: the role of Dutch logistics industries and governments. Sustainability 8, 1–17. doi: 10.3390/su8070647

Keywords: circular economy, COVID-19, entrepreneurship, sustainability, business

Citation: Corrêa HL and Corrêa DG (2021) The Covid-19 Pandemic—Opportunities for Circular Economy Practices Among Sewing Professionals in the City of Curitiba-Brazil. Front. Sustain. 2:644309. doi: 10.3389/frsus.2021.644309

Received: 20 December 2020; Accepted: 14 January 2021;

Published: 04 February 2021.

Edited by:

Idiano D'Adamo, Sapienza University of Rome, ItalyReviewed by:

Elkhan Richard Sadik-Zada, Ruhr University Bochum, GermanyCopyright © 2021 Corrêa and Corrêa. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Harrison Lourenço Corrêa, aGFycnkubG91LmNvcnJlYUBnbWFpbC5jb20=

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.