95% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

ORIGINAL RESEARCH article

Front. Space Technol. , 27 March 2025

Sec. Advanced Space Engineering

Volume 6 - 2025 | https://doi.org/10.3389/frspt.2025.1550526

This article is part of the Research Topic Next generation of materials for space applications View all 5 articles

This study investigates the potential of Microbially Induced Calcium Carbonate Precipitation (MICP) as a repair technique for consolidated (sintered) bricks made from Lunar Highland Simulant-1 (LHS-1), aiming to extend their functional lifespan in extra-terrestrial conditions. Sintered bricks (compressive strength

The prospect of human settlement on the Moon, the closest celestial body to Earth, rich in material resources, has grabbed the interest of many researchers (Crawford et al., 2016). Insights into the lunar structure through the Apollo and Soviet Luna missions and the presence of water in the form of ice by Chandrayaan-1 has fueled research in this direction (Goswami and Annadurai, 2009). While these missions have laid the foundation for lunar exploration by understanding its structure and conditions, scientists are now interested in the prospect of a long-term stay on the moon through the construction of infrastructure. With the launch of the Artemis series of missions, the National Aeronautics and Space Administration (NASA) aims to return people to the moon and establish long-term settlements (Creech et al., 2022). The success of Artemis Phase I and Chandrayaan-3’s historic touchdown at the southernmost point on the moon has taken us a step closer to achieving the same (Kanu et al., 2024). China has also successfully executed several phases of the Chang’e (CE) mission to acquire samples from the far side of the Moon and use probes to detect ice at the South Pole (Lin et al., 2024). However, to make these lunar explorations sustainable and feasible, one needs to exploit the local resources present on the Moon, termed in situ resource utilization (ISRU) (Sanders and Larson, 2011).

One bountiful local resource on the moon is the unconsolidated and fine-grained lunar regolith covering the lunar surface and the underlying bedrock (Lucey et al., 2006; McKay et al., 1991). This regolith, rich in

Although sintered bricks have a good compressive strength, they need to withstand the extreme environmental conditions of the moon. The lack of heat insulation due to the absence of an atmosphere makes the surface temperatures on the moon vary greatly between 224°F on a lunar day and

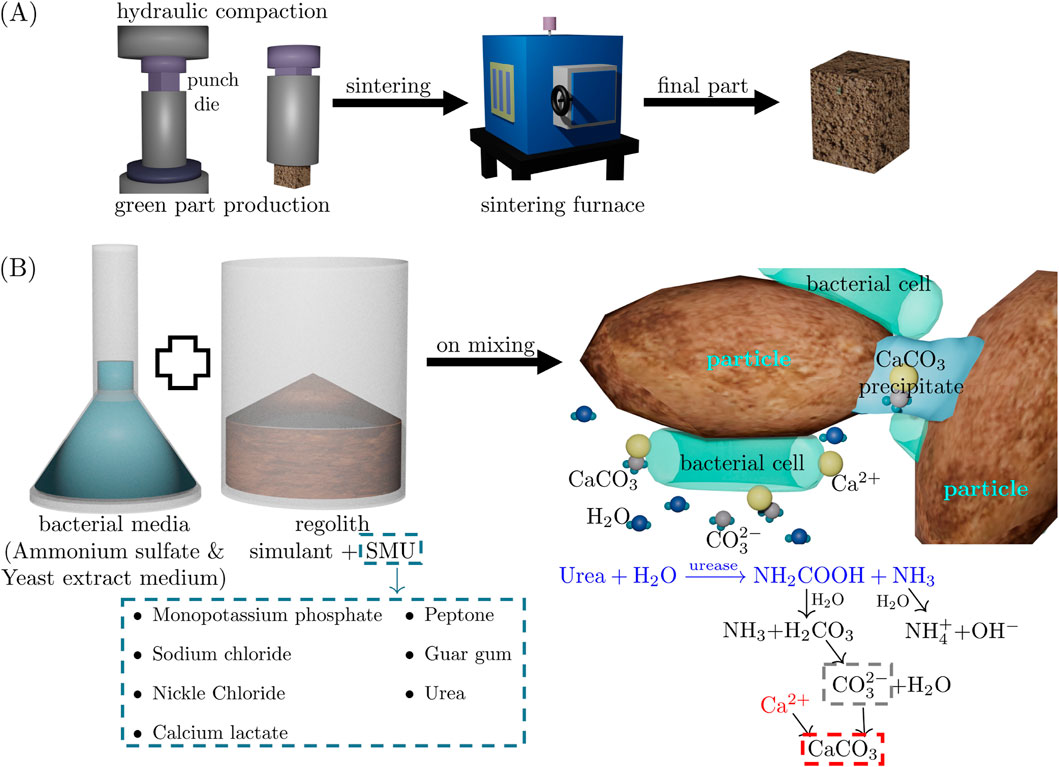

Biomineralization through Microbially Induced Calcium Carbonate Precipitation (MICP) is a particularly promising area of research, which utilizes microorganisms to produce calcium carbonate as a binding agent in construction materials (Dhami et al., 2013; Dikshit et al., 2023; Zhu and Dittrich, 2016). This process relies on certain microbial metabolic activities, such as urea hydrolysis, iron and sulfite reduction, methane oxidation, photosynthesis, and the carbonic anhydrase pathway (Jain et al., 2021; Mwandira et al., 2023), which facilitate the precipitation of calcium carbonate from soluble calcium sources (De Muynck et al., 2008; Zhang et al., 2023). Among these, ureolysis by certain urease-producing bacteria, including Bacillus sphaericus, Bacillus megaterium, Bacillus cereus and Sporosarcina pasteurii has been extensively explored (Kho et al., 2024; Wang et al., 2012). These bacteria can hydrolyze the urea present in their extracellular environment, converting it to carbonate and ammonia. When calcium ions are present in the surrounding media, they get deposited on the negatively charged surface of these bacteria and react with the carbonate ions, thus forming calcium carbonate precipitates (Mwandira et al., 2023; Wu et al., 2021) (Figure 2B). Previous studies from our lab have used MICP for consolidating lunar and martian soil simulants to make ’space bricks’ with a significant structural strength (Dikshit et al., 2021; Dikshit et al., 2022). Recognized as a sustainable alternative to traditional cement-based options, MICP addresses environmental concerns by reducing carbon emissions and enhancing sustainability (Zhang et al., 2023; Wiktor and Jonkers, 2016). It is an energy-efficient method and can be proposed as a cost-effective solution for construction challenges both on Earth and in space (Haouzi and Courcelles, 2018; Gebru et al., 2021). The ingredients required for bacterial growth and bio-cementation are substantially lesser than those used in traditional binders like cement. Water is vital in ureolysis and will be necessary for subsequent binder-based consolidation. Recent research focuses on extracting water from the lunar surface (Yanwei et al., 2024; Metzger et al., 2021; Kleinhenz and Paz, 2020; Sowers and Dreyer, 2019). Researchers are also attempting to produce plants in the lunar regolith, which may lead to future extraction of guar gum powder on the lunar surface (Hosamani et al., 2024; Duri et al., 2022; Caporale et al., 2023), and this will reduce resource dependency on Earth.

MICP’s effectiveness in repairing both natural and simulated cracks in terrestrial brick materials has been previously demonstrated (Ortega-Villamagua et al., 2020; Hermawan et al., 2023; Wiktor and Jonkers, 2011), significantly improving their mechanical properties such as compressive strength and water resistance. These studies indicate that MICP-treated consolidates exhibit higher failure loads than untreated specimens, underscoring its potential as a sustainable repair technique—particularly relevant in extraterrestrial settings where resource availability is limited. In addition, we have previously demonstrated that supplementing the soil with biopolymers such as guar gum and xanthan gum can significantly improve the strength of the final construction materials formed (Dikshit et al., 2022) due to their effective binding activities (Gupta et al., 2025; Sujatha and Saisree, 2019; Chang et al., 2015). The calcium carbonate produced through MICP serves as both a filler and a cementing agent, effectively decreasing porosity and durability by filling voids, repairing cracks, and thus enhancing the mechanical properties of construction materials (Mu et al., 2021). Although there is extensive research on using MICP for consolidation and making self-healing terrestrial bricks, its healing ability in lunar bricks has not yet been explored.

The present work studies the possibility of using MICP-based slurry (via ureolysis pathway) to repair fractures in sintered bricks made from lunar soil simulant. Our findings show a significant increase in the compressive strength of the fractured lunar bricks upon filling the cracks with MICP-based slurry. Further, the interfacial bonding between the filler and brick and the crack propagation patterns are also evaluated to gain insights into the binding efficacy. We propose that MICP can serve as a sustainable solution for enhancing the practical utility of lunar bricks for long-term human settlement in extraterrestrial habitats.

The Lunar Highland Simulant (LHS-1), which accurately replicates the lunar regolith, was procured from Exolith Lab (Space Resource Technologies), Florida, USA (Isachenkov et al., 2022). LHS-1 comprises 75% anorthosite, 24% glass-rich basalt, and a small percentage of olivine, pyroxene, and ilmenite. The size of grain particles of LHS-1 ranges from 0.4

In this investigation, we employed a sintering method for brick fabrication, as detailed in our previous work (Gupta et al., 2024a; Gupta et al., 2024b).

As demonstrated in the previous work (Dikshit et al., 2022), 1% (w/w) guar gum (GG) powder was added as a binder to LHS-1. Subsequently, 15 mL of DI (de-ionized) water was thoroughly mixed with every 100 g of LHS-1 to form the mixture. This mixture was then die-cast with a load of 10 tonnes in a prismatic cavity with a square cross-section of 15 mm sides to form cubical samples with side 15 mm (density of LHS-1 is 2.2 g/cc, this implies that

Figure 2. Schematic representation of the manufacturing process. Panel (A) illustrates the die compaction of guar gum (GG) mixed with Lunar Highland Simulant (LHS-1), which is hydraulically compacted at a load of 10 tons, followed by sintering in a muffle furnace for 4 h at

Sporosarcina pasteurii (Miquel) Yoon et al. ATCC®11859™ obtained from American Type Culture Collection (ATCC) was revived using NH4-YE medium containing 1 g/L ammonium sulfate and 2 g/L yeast extract in 0.13 M tris buffer (pH = 9) as recommended by ATCC. Synthetic media containing 1 g/L glucose, 1 g/L peptone, 5 g/L sodium chloride, 2 g/L monopotassium phosphate was added in 100 g of Lunar highland simulant (LHS-1) and supplemented with 1% guar gum (GG). The contents were mixed thoroughly and autoclaved at 121°C and 15 psi pressure for 30 min 3% urea, 10 mM

The integrity of the consolidated bricks was assessed by measuring the unconfined compressive strength (UCS) according to ASTM C109 standards under quasi-static conditions on a Universal Testing Machine (UTM) (Instron 5,697), employing a load cell capacity of 30 kN. The specimen dimensions were kept smaller than ASTM standards because of practical constraints. Compression tests were carried out for the control samples (sintered samples without holes and notches), and GMBs (with holes and notches), and the samples were repaired using MICP (as filler material). Cubical samples of dimension 15 mm

Furthermore, Digital Image Correlation (DIC) was performed on the samples to monitor crack propagation during tensile testing and repairing-based analysis, using the Ncorr software package (Blaber et al., 2015), with MATLAB version 2021a. Image sequences for the DIC analysis were obtained using a Digital Single-Lens Reflex (DSLR) camera (Nikon-D850) at a frame rate of 30 frames per second.

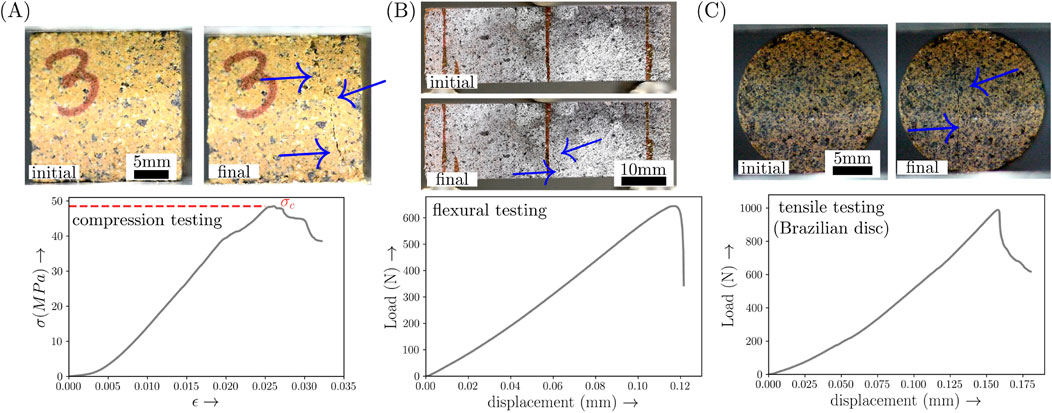

The mechanical properties of the bricks determine their strength and ability to withstand loads and stresses in construction applications. The tensile strength of the sintered bricks was measured indirectly from the Brazilian disc test, with the maximum load converted into tensile strength using

In addition to quantitative measurements, the failure modes and crack patterns observed during testing are illustrated in Figure 3. The blue arrows in the figure indicate primary crack propagation paths, highlighting the typical behavior of the bricks under applied loads. This information can help develop methods to engineer or steer crack paths.

Figure 3. Failure modes of bricks under different loading conditions: (A) compressive loading, (B) three-point loading (flexural test), and (C) tensile loading (Brazilian disc configuration).

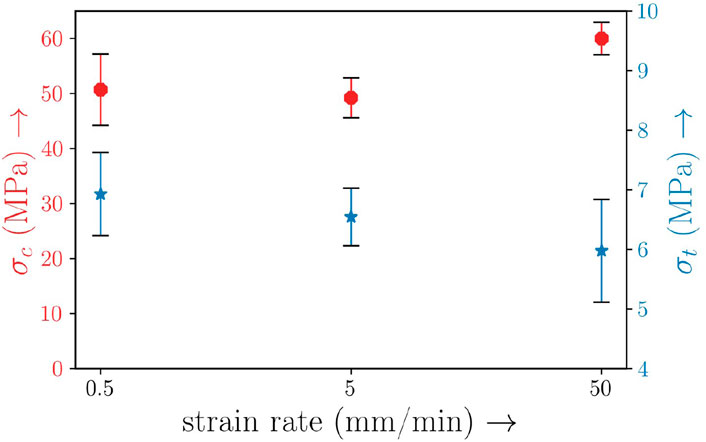

The tests conducted at three different loading rates: 0.5, 5, and 50 mm/min showed no significant change in either compressive or tensile strength with these loading rates. As shown in Figure 4, both compressive and tensile strength values remained relatively consistent across the different loading rates tested.

Figure 4. Compressive (blue) and tensile (red) strength of the sintered bricks under various strain rates (0.5, 5, and 50 mm/min). Strength values are averaged over four specimens, with standard deviation represented as error bars.

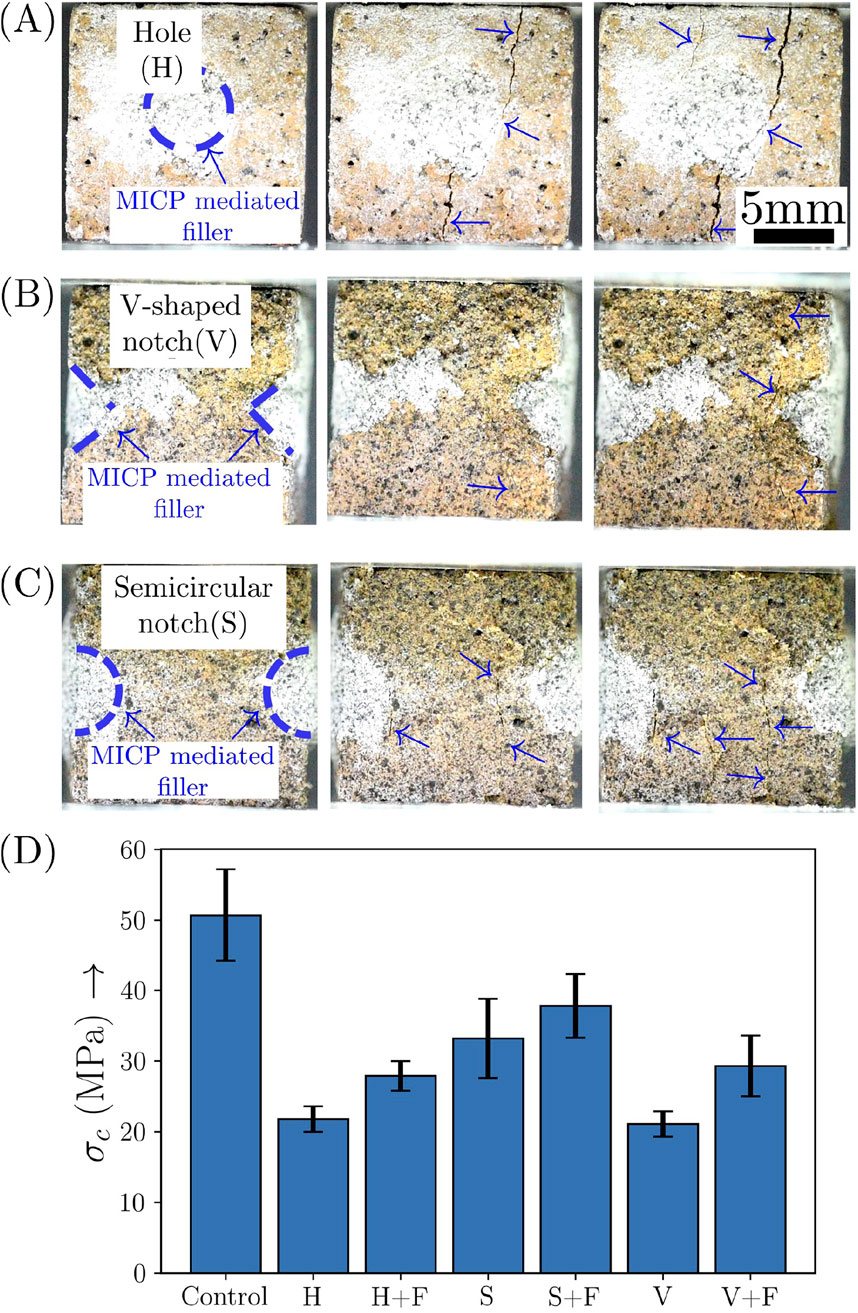

These results were used as a baseline to evaluate GMBs, which simulated damage. Compression tests on the GMBs revealed a significant reduction in strength. Figure 6D summarizes the results obtained from these tests. These results confirm that the GMBs that simulate damaged bricks are considerably weaker than the unaltered solid bricks, indicating the need for repair for prolonged use.

Using lunar bricks for extraterrestrial construction requires them to withstand the impacts of meteors and other threats in these extreme environments. As a result, repairing them to restore their structural integrity and strength becomes crucial for building sustainable structures for long-term settlement. In this context, we used a MICP-based approach to repair the intentionally fractured bricks as described in Section 2.3. The details of these investigations are presented in this section.

MICP exploits the natural processes of microorganisms to facilitate the precipitation of calcium carbonate, which can fill the damaged areas within the bricks. Sporosarcina pasteurii is a microbe very well known for its ability to precipitate calcium carbonate (

With the aim of restoring the brick strength, the MICP-based slurry was filled into the central hole, the V-shaped and semi-circular notches. Previous studies from our lab have reported that MICP-based bricks made using LHS-1 show a compressive strength of

Figure 6. Failure patterns and crack paths in GMBs repaired with MICP-based slurry. Panels (A–C) illustrate the repaired GMBs with holes (H), V-shaped notches (V), and semi-circular notches (S). The three side-by-side frames represent initial loading conditions, intermediate stages showing crack propagation, and final failure stages. Panel (D) presents compressive strength measurements for bricks with and without filler conditions, averaged over four specimens with standard deviation indicated as error bars.

The observed increase in strength can be attributed to the mechanism of MICP, which facilitates calcium carbonate precipitation within the holes and notches. This process not only fills cavities but also reinforces the surrounding material through additional bonding. Indeed, previous studies have demonstrated that MICP effectively enhances mechanical properties by sealing cracks and reducing porosity, thereby improving overall durability (De Muynck et al., 2008; Zhang et al., 2023; Mu et al., 2021).

Further, to understand crack initiation and failure mechanisms in these bricks, videos were recorded during the strength tests. The image series showed that upon application of the MICP-mediated filler to the GMBs with a central hole and V-shaped notch, the cracks propagated through both the filler material interface and into the surrounding brick material rather than the interface between the two, as can be seen in Figures 6A, B. This indicates a strong interfacial bonding, increasing the overall strength of the bricks upon repair. Conversely, for semi-circular notches, initial cracks appeared near the notch; however, significant failure occurred at the center as loading increased (Figure 6C).

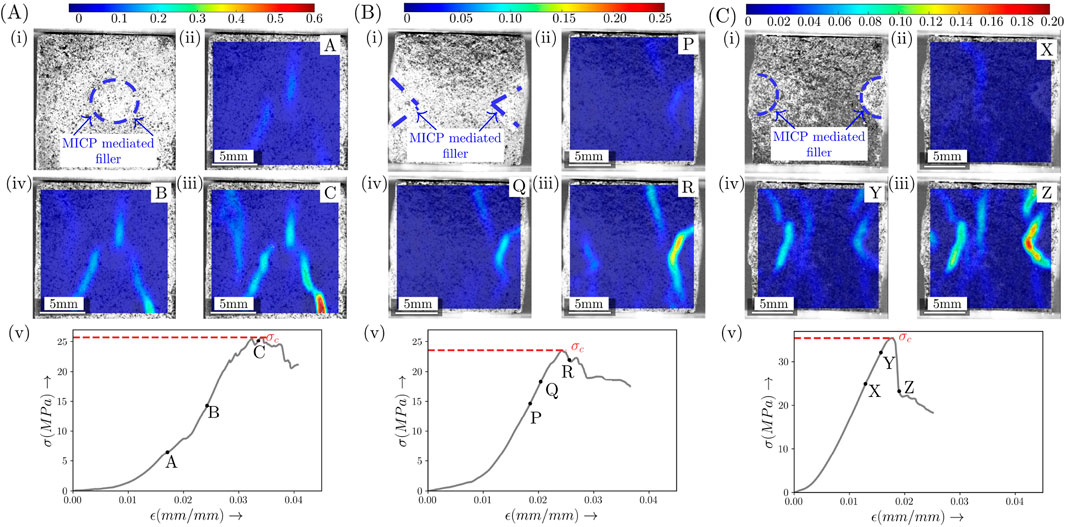

To identify the crack propagation path and to corroborate our observations, we performed Digital Image Correlation (DIC) analysis on the samples from the image sequences that we generated through the recorded videos. The results are presented in Figure 7, which show the crack initiation and propagation patterns within the repaired bricks. Cracks were initiated at locations of high-stress concentration for both fillers at central holes and V-shaped notches on the sides of bricks; however, for semi-circular notches at the sides, initial cracks appeared within the bulk material itself.

Figure 7. DIC analysis of the repaired GMBs. Panels (A–C) depict MICP filling in circular holes (H), V-shaped notches (V), and semi-circular notches (S) cavities of sintered brick specimens, respectively, under loading conditions. The (i) panels show brick under loading while (ii), (iii), and (iv) show the DIC color contours strains in x-direction

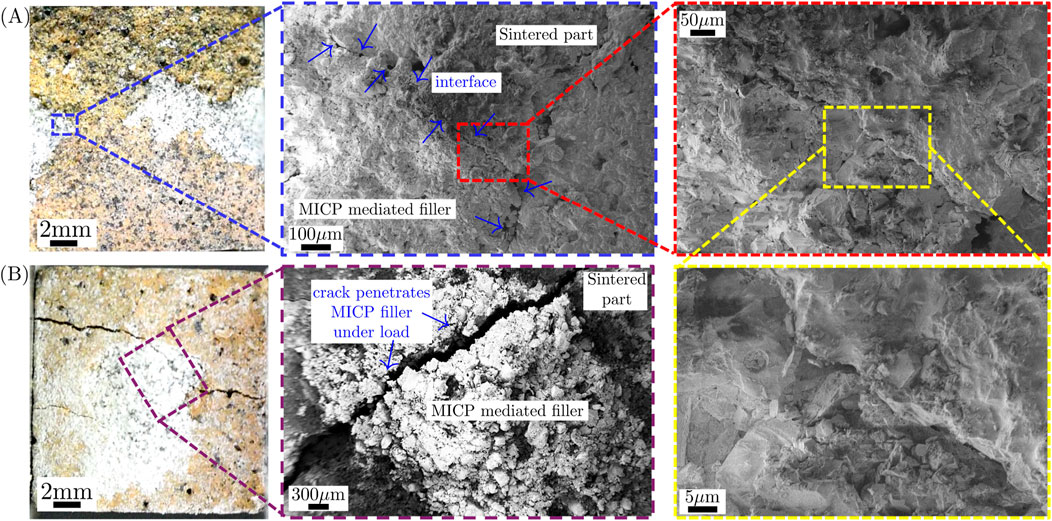

Additionally, to better understand how the filler influences the overall material performance, the interfacial bonding between the MICP filler and the sintered specimen was investigated through Scanning Electron Microscopy (SEM) analysis. As shown in Figure 8A, there is evidence of robust interfacial bonding, with insets highlighting detailed views of the interface. To support this, Figure 8B reveals instances where cracks penetrate and extend through the MICP interface. MICP can, therefore, serve as a viable solution for enhancing the durability and lifespan of these construction materials. However, instances of crack propagation through the repaired regions suggest the need for continued investigation into optimizing repair strategies to enhance the durability and performance of MICP-treated materials.

Figure 8. Interfacial bonding of MICP-mediated slurry with sintered parts. Panel (A) illustrates the bonding characteristics, with insets providing a magnified view of the interface. Panel (B) depicts instances where cracks penetrate and traverse the MICP interface. The first big brick image shown in both panels was taken with a DSLR camera and kept to show the location from where SEM micrographs were obtained.

This study highlights the potential of MICP as an effective method for repairing sintered bricks in extraterrestrial construction applications. The mechanical testing demonstrated that the formation of holes and notches in the bricks significantly reduced their compressive strength. However, the subsequent application of MICP-mediated slurry led to a notable strength recovery. This enhancement can be attributed to the precipitation of calcium carbonate, which not only fills the cavities but also reinforces the surrounding material through improved interfacial bonding. Research carried out with the consolidation of terrestrial soils via MICP by Dhami et al. (2016) shows the dependence of the strength on the grain size, and the larger grains show poor strength. In our previous work (Kumar et al., 2020), we characterized calcite precipitation using various calcium sources, such as calcium lactate, calcium acetate, calcium chloride, and calcium nitrate, among which calcium lactate showed the highest calcite precipitation, followed by calcium chloride. We have also demonstrated the effect of varying the composition of urea, pH, temperature, and biopolymer content on the precipitation and, subsequently, on the compressive strength of the consolidates. Additionally, we demonstrated that using admixtures like guar gum and nickel chloride supplements enhances the binding properties and reduces the porosity (measured using micro-CT), which is one of the major parameters in governing the compressive strength of consolidate (Dawara et al., 2022). As opposed to this, the control filler samples without the bacteria and guar gum could only fill the cavities but not reinforce the strength.

However, the increased strength observed in the repaired bricks did not reach the levels of the unfractured bricks, indicating that MICP-based slurry can effectively extend the functional lifespan of damaged structures but not restore their strength. This is particularly relevant in construction applications where maintaining structural integrity is crucial. The ability to repair rather than replace damaged components aligns with sustainable practices, thereby reducing waste and minimizing resource consumption.

Additionally, SEM analysis provided valuable insights into the bonding mechanisms between the MICP filler and the sintered brick substrate. The strong interfacial bonding observed suggests that MICP can facilitate durable repairs. Nevertheless, instances of crack propagation through the MICP interface underscore the need for further investigation. Understanding these failure mechanisms is essential for optimizing repair strategies and enhancing overall material performance. At the same time, certain limitations of MICP through the ureolysis pathway, such as the release of ammonia, raising environmental concerns, and the sensitivity of the process to temperature, pH, aeration, and nutrient availability, leading to variability in compressive strength need to be addressed for the successful implementation of the process for space brick repair. One solution could be to co-culture with ammonia utilizing microbes to mitigate the ammonia released.

Future studies should consider the long-term durability of MICP repairs under varying environmental conditions, including moisture exposure, high strain rate loading, vacuum, radiation exposure, and temperature fluctuations. In our recent trials, we have exposed that consolidated material to different temperatures ranging from

This study demonstrates the feasibility and effectiveness of using MICP to repair sintered lunar bricks. The systematic approach employed revealed that while initial damage significantly compromised the bricks’ mechanical properties, subsequent repair using MICP-based slurry resulted in a meaningful recovery of their compressive strength (about 28%–55%).

The findings highlight the potential of MICP as a sustainable solution for extending the service life of construction materials, aligning with contemporary efforts to enhance material resilience and reduce environmental impact. The strong interfacial bonding observed through SEM analysis further supports the viability of this method; however, challenges related to crack propagation through repaired areas warrant additional research.

Overall, this investigation contributes valuable insights into innovative repair techniques for extraterrestrial construction materials, emphasizing the importance of integrating biological processes. Future work should focus on optimizing MICP applications and exploring their effectiveness across diverse environmental conditions to realize their full potential in practical applications.

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

NG: Data curation, Investigation, Methodology, Writing–original draft. RK: Data curation, Investigation, Methodology, Writing–original draft. AN: Data curation, Investigation, Methodology, Writing–original draft. KV: Conceptualization, Funding acquisition, Investigation, Project administration, Resources, Supervision, Writing–original draft. AK: Conceptualization, Funding acquisition, Investigation, Project administration, Resources, Supervision, Writing–original draft.

The author(s) declare that financial support was received for the research and/or publication of this article. The authors acknowledge financial support from the Department of Science and Technology, Govt. of India, under the Advanced Manufacturing Technologies program (AK for DST/TDT/AM/2022/345(G), and KV for DST/TDT/AM/2022/280(G)) for carrying out this work.

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

The author(s) declare that no Generative AI was used in the creation of this manuscript.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Blaber, J., Adair, B., and Antoniou, A. (2015). Ncorr: open-source 2D digital image correlation matlab software. Exp. Mech. 55 (6), 1105–1122. doi:10.1007/s11340-015-0009-1

Caporale, A. G., Palladino, M., De Pascale, S., Duri, L. G., Rouphael, Y., and Adamo, P. (2023). How to make the Lunar and Martian soils suitable for food production-assessing the changes after manure addition and implications for plant growth. J. Environ. Manag. 325, 116455. doi:10.1016/j.jenvman.2022.116455

Castelein, S. M., Aarts, T. F., Schleppi, J., Hendrikx, R., Böttger, A. J., Benz, D., et al. (2021). Iron can be microbially extracted from Lunar and Martian regolith simulants and 3D printed into tough structural materials. Plos one 16 (4), e0249962. doi:10.1371/journal.pone.0249962

Chang, I., Im, J., Prasidhi, A. K., and Cho, G. C. (2015). Effects of Xanthan gum biopolymer on soil strengthening. Constr. Build. Mater. 74, 65–72. doi:10.1016/j.conbuildmat.2014.10.026

Crawford, I., Elvis, M., and Carpenter, J. (2016). Using extraterrestrial resources for science. Astronomy & Geophys. 57 (4), 4.32–4.36. doi:10.1093/astrogeo/atw150

Creech, S., Guidi, J., and Elburn, D. (2022). “Artemis: an overview of NASA’s activities to return humans to the Moon,” in 2022 ieee aerospace conference (aero) (IEEE), 1–7.

Dawara, V., Gupta, N., Dey, A., Kumar, A., and Viswanathan, K. (2022). Pore–microcrack interaction governs failure in bioconsolidated space bricks. Ceram. Int. 48 (23), 35874–35882. doi:10.1016/j.ceramint.2022.09.013

De Muynck, W., Debrouwer, D., De Belie, N., and Verstraete, W. (2008). Bacterial carbonate precipitation improves the durability of cementitious materials. Cem. Concr. Res. 38 (7), 1005–1014. doi:10.1016/j.cemconres.2008.03.005

Dhami, N. K., Reddy, M. S., and Mukherjee, A. (2013). Biomineralization of calcium carbonates and their engineered applications: a review. Front. Microbiol. 4, 314. doi:10.3389/fmicb.2013.00314

Dhami, N. K., Reddy, M. S., and Mukherjee, A. (2016). Significant indicators for biomineralisation in sand of varying grain sizes. Constr. Build. Mater. 104, 198–207. doi:10.1016/j.conbuildmat.2015.12.023

Dikshit, R., Dey, A., Gupta, N., Varma, S. C., Venugopal, I., Viswanathan, K., et al. (2021). Space bricks: from LSS to machinable structures via MICP. Ceram. Int. 47 (10), 14892–14898. doi:10.1016/j.ceramint.2020.07.309

Dikshit, R., Gupta, N., Dey, A., Viswanathan, K., and Kumar, A. (2022). Microbial induced calcite precipitation can consolidate martian and lunar regolith simulants. Plos one 17 (4), e0266415. doi:10.1371/journal.pone.0266415

Dikshit, R., Gupta, N., and Kumar, A. (2023). Microbial endeavours towards extra-terrestrial settlements. J. Indian Inst. Sci. 103 (3), 839–855. doi:10.1007/s41745-023-00383-8

Dry, C. (1994). Matrix cracking repair and filling using active and passive modes for smart timed release of chemicals from fibers into cement matrices. Smart Mater. Struct. 3 (2), 118–123. doi:10.1088/0964-1726/3/2/006

Duri, L. G., Caporale, A. G., Rouphael, Y., Vingiani, S., Palladino, M., De Pascale, S., et al. (2022). The potential for lunar and martian regolith simulants to sustain plant growth: a multidisciplinary overview. Front. Astronomy Space Sci. 8, 747821. doi:10.3389/fspas.2021.747821

Farries, K. W., Visintin, P., Smith, S. T., and van Eyk, P. (2021). Sintered or melted regolith for lunar construction: state-of-the-art review and future research directions. Constr. Build. Mater. 296, 123627. doi:10.1016/j.conbuildmat.2021.123627

Gebru, K. A., Kidanemariam, T. G., and Gebretinsae, H. K. (2021). Bio-cement production using microbially induced calcite precipitation (MICP) method: a review. Chem. Eng. Sci. 238, 116610. doi:10.1016/j.ces.2021.116610

Ghosh, T., Bhaduri, S., Montemagno, C., and Kumar, A. (2019). Sporosarcina pasteurii can form nanoscale calcium carbonate crystals on cell surface. PloS one 14 (1), e0210339. doi:10.1371/journal.pone.0210339

Goswami, J., and Annadurai, M. (2009). Chandrayaan-1: India’s first planetary science mission to the Moon. Curr. Sci., 486–491. Available online at: https://www.jstor.org/stable/24105456

Gupta, N., Dawara, V., Kumar, A., and Viswanathan, K. (2024a). Synthetic space bricks from lunar and martian regolith via sintering. Adv. Space Res. 74, 3902–3915. doi:10.1016/j.asr.2024.06.045

Gupta, N., Dawara, V., Kumar, A., and Viswanathan, K. (2024b). Liquid state sintering enhances consolidation in basalt-rich lunar regolith. Adv. Space Res. 74, 1693–1705. doi:10.1016/j.asr.2024.05.024

Gupta, N., Kumar, A., and Viswanathan, K. (2025). Biopolymers can be used for consolidation of lunar and Martian regoliths. bioRxiv, 2025–2101. doi:10.1101/2025.01.03.631200

Haouzi, F. Z., and Courcelles, B. (2018). Major applications of MICP sand treatment at multi-scale levels: a review. Geo Edmont. Available online at: https://www.researchgate.net/publication/327844198_Major_applications_of_MICP_sand_treatment_at_multi-scale_levels_A_review

Harrell, M. J., Schroeder, G. S., and Daire, S. A.Lunar environment, overview (2021). Handbook of life support systems for spacecraft and extraterrestrial habitats, 1–23.

Hermawan, H., Wiktor, V., Serna, P., and Gruyaert, E. (2023). “Experimental investigation on the novel self-healing properties of concrete mixed with commercial bacteria-based healing agent and crystalline admixtures,” in International RILEM Conference on Synergising expertise towards sustainability and robustness of CBMs and concrete structures (Springer), 841–852.

Hosamani, R., Swamy, B. K., Sathasivam, M., Dsouza, A., and Ashiq, M. (2024). Cocopeat supplementation negates lunar soil simulant-induced baneful phenotypic and biochemical changes in crop seedlings. Acta Astronaut. 220, 416–426. doi:10.1016/j.actaastro.2024.05.001

Isachenkov, M., Chugunov, S., Landsman, Z., Akhatov, I., Metke, A., Tikhonov, A., et al. (2022). Characterization of novel lunar highland and mare simulants for ISRU research applications. Icarus 376, 114873. doi:10.1016/j.icarus.2021.114873

Jain, S., Fang, C., and Achal, V. (2021). A critical review on microbial carbonate precipitation via denitrification process in building materials. Bioengineered 12 (1), 7529–7551. doi:10.1080/21655979.2021.1979862

Kanu, N. J., Gupta, E., and Verma, G. C. (2024). An insight into India’s Moon mission–Chandrayan-3: the first nation to land on the southernmost polar region of the Moon. Planet. Space Sci. 242, 105864. doi:10.1016/j.pss.2024.105864

Kho, Y. S., Wong, K. S., Pauzi, N. N. M., Joo, M. S., and Hadibarata, T. (2024). Self-healing concrete utilizing ureolysis mechanism of microbially induced calcite precipitation (MICP): a review. Iran. J. Sci. Technol., 1–22. doi:10.1007/s40996-024-01660-x

Kleinhenz, J. E., and Paz, A. (2020). Case studies for lunar isru systems utilizing polar water. ASCEND, 4042. doi:10.2514/6.2020-4042

König, B. (1977). Investigations of primary and secondary impact structures on the Moon and laboratory experiments to study the ejecta of secondary particles. Hampton, VA: NASA.

Kumar, A., Dikshit, R., Gupta, N., Jain, A., Dey, A., Nandi, A., et al. (2020). “Bacterial growth induced biocementation technology,” in Space-Brick’-A proposal for experiment at microgravity and planetary environments Cold Spring Harbor, New York (BioRxiv), 2020–2101.

Lin, Y., Yang, W., Zhang, H., Hui, H., Hu, S., Xiao, L., et al. (2024). Return to the moon: new perspectives on lunar exploration. Sci. Bull. 69, 2136–2148. doi:10.1016/j.scib.2024.04.051

Lucey, P., Korotev, R. L., Gillis, J. J., Taylor, L. A., Lawrence, D., Campbell, B. A., et al. (2006). Understanding the lunar surface and space-Moon interactions. Rev. mineralogy Geochem. 60 (1), 83–219. doi:10.2138/rmg.2006.60.2

Ma, L., Pang, A. P., Luo, Y., Lu, X., and Lin, F. (2020). Beneficial factors for biomineralization by ureolytic bacterium Sporosarcina pasteurii. Microb. cell factories 19, 12. doi:10.1186/s12934-020-1281-z

McKay, D. S., Heiken, G., Basu, A., Blanford, G., Simon, S., Reedy, R., et al. (1991). The lunar regolith. Lunar Sourceb. 567, 285–356. Available online at: https://www.lpi.usra.edu/publications/books/lunar_sourcebook/

Metzger, P. T., Sapkota, D., Fox, J., and Bennett, N. (2021). Aqua factorem: Ultra low energy lunar water extraction.

Meurisse, A., Beltzung, J., Kolbe, M., Cowley, A., and Sperl, M. (2017). Influence of mineral composition on sintering lunar regolith. J. Aerosp. Eng. 30 (4), 04017014. doi:10.1061/(asce)as.1943-5525.0000721

Mu, B., Gui, Z., Lu, F., Petropoulos, E., and Yu, Y. (2021). Microbial-induced carbonate precipitation improves physical and structural properties of nanjing ancient city walls. Materials 14 (19), 5665. doi:10.3390/ma14195665

Mwandira, W., Mavroulidou, M., Gunn, M. J., Purchase, D., Garelick, H., and Garelick, J. (2023). Concurrent carbon capture and biocementation through the carbonic anhydrase (CA) activity of microorganisms-a review and outlook. Environ. Process. 10 (4), 56. doi:10.1007/s40710-023-00667-2

Ortega-Villamagua, E., Gudiño-Gomezjurado, M., and Palma-Cando, A. (2020). Microbiologically induced carbonate precipitation in the restoration and conservation of cultural heritage materials. Molecules 25 (23), 5499. doi:10.3390/molecules25235499

Papike, J., Simon, S., and Laul, J. (1982). The lunar regolith: chemistry, mineralogy, and petrology. Rev. Geophys. 20 (4), 761–826. doi:10.1029/rg020i004p00761

Phuah, X. L., Wang, H., Zhang, B., Cho, J., Zhang, X., and Wang, H. (2020). Ceramic material processing towards future space habitat: electric current-assisted sintering of lunar regolith simulant. Materials 13 (18), 4128. doi:10.3390/ma13184128

Roberts, A. D., Whittall, D., Breitling, R., Takano, E., Blaker, J. J., Hay, S., et al. (2021). Blood, sweat, and tears: extraterrestrial regolith biocomposites with in vivo binders. Mater. Today Bio 12, 100136. doi:10.1016/j.mtbio.2021.100136

Roedel, H., Lepech, M., and Loftus, D. (2014). Protein-regolith composites for space construction. Earth Space 2014, 291–300. doi:10.1061/9780784479179.033

Sanders, G. B., and Larson, W. E. (2011). Integration of in-situ resource utilization into lunar/Mars exploration through field analogs. Adv. Space Res. 47 (1), 20–29. doi:10.1016/j.asr.2010.08.020

Sowers, G. F., and Dreyer, C. B. (2019). Ice mining in lunar permanently shadowed regions. New Space 7 (4), 235–244. doi:10.1089/space.2019.0002

Sujatha, E. R., and Saisree, S. (2019). Geotechnical behaviour of guar gum-treated soil. Soils Found. 59 (6), 2155–2166. doi:10.1016/j.sandf.2019.11.012

Taylor, S. L., Jakus, A. E., Koube, K. D., Ibeh, A. J., Geisendorfer, N. R., Shah, R. N., et al. (2018). Sintering of micro-trusses created by extrusion-3D-printing of lunar regolith inks. Acta Astronaut. 143, 1–8. doi:10.1016/j.actaastro.2017.11.005

Toklu, Y. C., and Akpinar, P. (2022). Lunar soils, simulants and lunar construction materials: an overview. Adv. Space Res. 70 (3), 762–779. doi:10.1016/j.asr.2022.05.017

Toutanji, H., Glenn-Loper, B., and Schrayshuen, B. (2005). “Strength and durability performance of waterless lunar concrete,” in 43rd AIAA aerospace sciences meeting and exhibit, 1436.

Van Tittelboom, K., Wang, J., Araújo, M., Snoeck, D., Gruyaert, E., Debbaut, B., et al. (2016). Comparison of different approaches for self-healing concrete in a large-scale lab test. Constr. Build. Mater. 107, 125–137. doi:10.1016/j.conbuildmat.2015.12.186

Wang, J., Van Tittelboom, K., De Belie, N., and Verstraete, W. (2012). Use of silica gel or polyurethane immobilized bacteria for self-healing concrete. Constr. Build. Mater. 26 (1), 532–540. doi:10.1016/j.conbuildmat.2011.06.054

Wang, Y., Wang, Z., Ali, A., Su, J., Huang, T., Hou, C., et al. (2024). Microbial-induced calcium precipitation: bibliometric analysis, reaction mechanisms, mineralization types, and perspectives. Chemosphere 362, 142762. doi:10.1016/j.chemosphere.2024.142762

Wiktor, V., and Jonkers, H. (2016). Bacteria-based concrete: from concept to market. Smart Mater. Struct. 25 (8), 084006. doi:10.1088/0964-1726/25/8/084006

Wiktor, V., and Jonkers, H. M. (2011). Quantification of crack-healing in novel bacteria-based self-healing concrete. Cem. Concr. Compos. 33 (7), 763–770. doi:10.1016/j.cemconcomp.2011.03.012

Wu, Y., Li, H., and Li, Y. (2021). Biomineralization induced by cells of Sporosarcina pasteurii: mechanisms, applications and challenges. Microorganisms 9 (11), 2396. doi:10.3390/microorganisms9112396

Yang, Y., Lepech, M. D., Yang, E. H., and Li, V. C. (2009). Autogenous healing of engineered cementitious composites under wet–dry cycles. Cem. Concr. Res. 39 (5), 382–390. doi:10.1016/j.cemconres.2009.01.013

Yanwei, W., Jiafeng, H., and Guoguang, W. (2024). Evalution of water in lunar interior and water ice on lunar surface. Geol. J. China Univ. 30 (02), 165. doi:10.16108/j.issn1006-7493.2023013

Zhang, K., Tang, C. S., Jiang, N. J., Pan, X. H., Liu, B., Wang, Y. J., et al. (2023). Microbial-induced carbonate precipitation (MICP) technology: a review on the fundamentals and engineering applications. Environ. Earth Sci. 82 (9), 229. doi:10.1007/s12665-023-10899-y

Keywords: biocementation process, lunar regolith simulant, space bricks, lunar habitation, repairing

Citation: Gupta N, Kulkarni R, Naik AR, Viswanathan K and Kumar A (2025) Bacterial bio-cementation can repair space bricks. Front. Space Technol. 6:1550526. doi: 10.3389/frspt.2025.1550526

Received: 23 December 2024; Accepted: 06 March 2025;

Published: 27 March 2025.

Edited by:

Antonio Mattia Grande, Polytechnic University of Milan, ItalyReviewed by:

Nicanor Cimpoesu, Gheorghe Asachi Technical University of Iași, RomaniaCopyright © 2025 Gupta, Kulkarni, Naik, Viswanathan and Kumar. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Aloke Kumar, YWxva2VrdW1hckBpaXNjLmFjLmlu

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.