- 1Department of Advanced Robotics, Istituto Italiano di Tecnologia, Genova, Italy

- 2Surgical Robotics Laboratory, Department of Biomechanical Engineering, MIRA – Institute for Biomedical Technology and Technical Medicine, University of Twente, Enschede, Netherlands

- 3Department of Information Engineering and Mathematics, University of Siena, Siena, Italy

- 4Department of Biomedical Engineering, University of Groningen and University Medical Center Groningen, Groningen, Netherlands

Microrobotics systems are showing promising results in several applications and scenarios, such as targeted drug delivery and screening, biopsy, environmental control, surgery, and assembly. While most of the systems presented in the literature consider autonomous techniques, there is a growing interest in human-in-the-loop approaches. For reasons of responsibility, safety, and public acceptance, it is in fact beneficial to provide a human with intuitive and effective means for directly controlling these microrobotic systems. In this respect, haptic feedback is widely believed to be a valuable tool in human-in-the-loop teleoperation systems. This article presents a review of the literature on haptic feedback systems for microrobotics, categorizing it according to the type of haptic technology employed. In particular, we considered both tethered and untethered systems, including applications of micropositioning, microassembly, minimally invasive surgery, delivery of objects, micromanipulation, and injection of cells. One of the main challenges for an effective implementation is stability control. In fact, the high scaling factors introduced to match variables in the macro and the micro worlds may introduce instabilities. Another challenge lies in the measurement of position and force signals in the remote environment. The integration of microsized sensors may significantly increase the complexity and cost of tools fabrication. To overcome the lack of force-sensing, vision seems a promising solution. Finally, although the literature on haptic feedback for untethered microrobotics is still quite small, we foreseen a great development of this field of research, thanks to its flexible applications in biomedical engineering scenarios.

1. Introduction

The field of microrobotics has been progressing fast since the last decade, and its applications have shown promising results in several robotic tasks at the microscale, such as controlled positioning (Solovev et al., 2009; Woods and Constandinou, 2011; Khalil et al., 2014a,b), pick up and delivery of objects, cells, and molecules (Solovev et al., 2010; Balasubramanian et al., 2011; Sanchez et al., 2011; Zhang et al., 2012), biopsy (Gultepe et al., 2013), and drilling into soft tissue (Matteucci et al., 2008; Solovev et al., 2012; Soler et al., 2013; Xi et al., 2013).

For reasons of responsibility, safety, and public acceptance, it is beneficial to provide a human operator with intuitive and effective means for directly controlling these microrobots (Troccaz and Delnondedieu, 1996; Jakopec et al., 2003; Bolopion and Régnier, 2013). In this condition, the operator should receive enough information about the controlled microrobot and the remote environment. Haptic feedback is one piece of this information flow. Its benefits typically include increased manipulation accuracy and decreased completion time, peak and mean force applied to the remote environment (Massimino and Sheridan, 1994; Wagner et al., 2002; Okamura, 2004; Pacchierotti, 2015; Pacchierotti et al., 2015b,c, 2016).

2. Literature Review

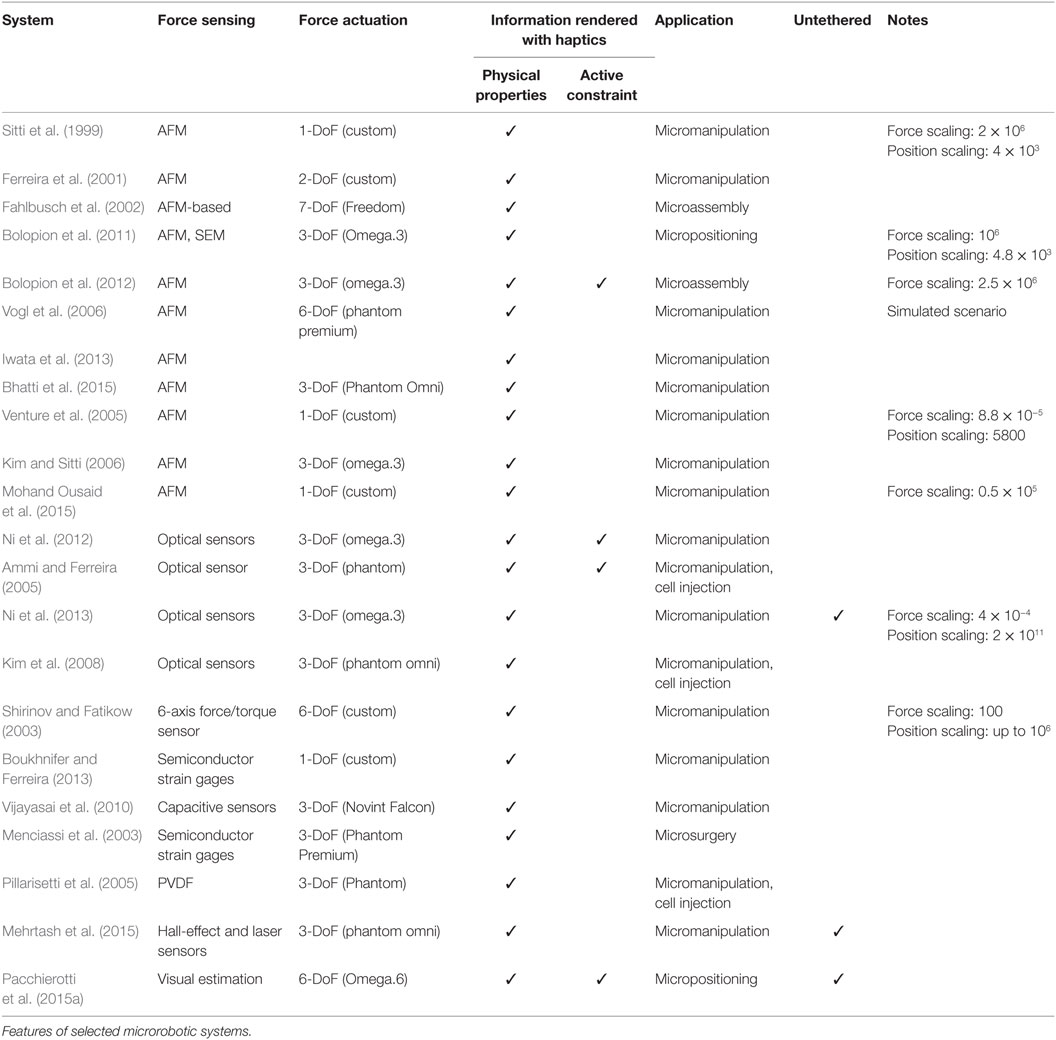

This article reviews the literature on haptic feedback systems for microrobotics, categorizing it according to the type of haptic sensing technique employed. Table 1 summarizes the features of the considered microrobotic systems.

2.1. Atomic Force Microscopy

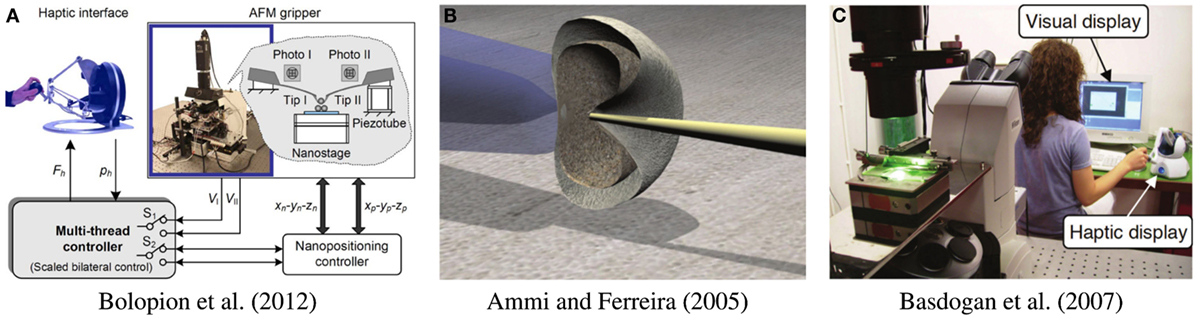

Atomic force microscopy (AFM) is a high-resolution type of scanning probe microscopy with a resolution of fractions of a nanometer. An AFM probe has usually a sharp tip on the free-swinging end of a cantilever that is protruding from a holder. The cantilever deflection due to the interaction between the tip and the surface gives information about the mechanical properties of the environment (Binnig et al., 1986). One of the first examples of haptic-enabled microrobotic system employed a scanning tunneling microscope coupled with a 6-degrees-of-freedom (6-DoF) haptic interface (Hollis et al., 1990; Bolopion and Régnier, 2013). The vertical movement of the haptic device end-effector replicates one of the microscope tip, so that users can feel the topology of the environment. Few years later, Sitti et al. (1999) presented a teleoperated microscale haptic system composed of a 1-DoF haptic device and an AFM cantilever tip. They addressed the problem of modeling the contact forces at the microscale and designed a scaled bilateral teleoperation controller for reliable contact force feedback. Using a Phantom Premium haptic device, the same group extended these results to 2-D and 3-D tele-micromanipulation scenarios (Sitti et al., 2003). In the same years, Ferreira et al. (2001) presented a teleoperated micromanipulator considering both a piezoelectric microgripper and an AFM operating under an optical microscope. The registered forces are provided to the human operator through a two-finger planar haptic device. Fahlbusch et al. (2002) focused more on the study of suitable force sensing techniques for nanohandling robotics. They used an AFM wheatstone bridge-based sensor for the measurement of gripping forces, and a haptic interface to allow the operator to feel and control these forces. Later on, Bolopion et al. (2011) described a haptic-enabled system for the remote handling of microscale objects. The micromanipulation setup is composed of an AFM manipulator integrated in a scanning electron microscope (SEM). The master teleoperation system is composed of an Omega.3 haptic interface and a virtual reality room (Grange et al., 2001). The system was validated in an approach-retract teleoperation experiment between Paris, France, and Oldenburg, Germany. The same group presented a teleoperated system with haptic feedback for 3-D AFM-based manipulation (Bolopion et al., 2012; see Figure 1A). It uses two independent AFM probes to collaboratively grasp and position microscale objects with known shape equations. Haptic feedback is based on dynamic-mode AFM data. It is used to provide information on the measured interaction forces and assist the user in improving dexterity and avoiding collisions. An AFM, together with a haptic interface and an augmented reality system has been also used by Vogl et al. (2006) for applications of micropositioning and sensing. Later on, also Iwata et al. (2013) described an AFM-based manipulator. It can be coupled with a SEM and provides haptic feedback through a Phantom Desktop interface, which is also in charge of controlling the cantilever-based probe of the micromanipulator. More recently, Bhatti et al. (2015) developed a custom haptic interface able to provide force feedback about the interaction forces sensed by an AFM. Interaction forces are characterized by estimating the forces sensed by the cantilever tip using geometric deformation principles.

Figure 1. Three teleoperation systems for the telemanipulation of microsized objects with haptic feedback. (A) AFM gripper-based teleoperation system. (B) 3-D reconstructed cell deformations based on visual tracking data. (C) Optical tweezers. All pictures are adapted with permission.

Microscale teleoperation with haptic feedback requires scaling gains in the order of 104–107, depending on the application. These high gains impose a trade-off between stability and transparency. Venture et al. (2005) were one of the first groups to consider stability issues in remote micromanipulation systems with force feedback. They implemented a passivity-based position–position coupling scheme that ensures unconditional stability. Stability issues have been also addressed by Kim and Sitti (2006), who introduced a scaled virtual coupling concept and derived the relationship between performance, stability, and scaling factors of velocity (or position) and force.

2.2. Visual Sensing

Kim et al. (2001) developed a 3-D visuo-haptic teleoperated micromanipulation system. A 6-DoF Phantom Premium haptic interface provides the necessary force feedback and controls the positioning of the micromanipulator in the remote environment. The micromanipulator is equipped with a 2-DoF gripper, and multiple CCD cameras are used for position sensing. Similarly, Ni et al. (2012) presented a vision-based microrobotic system combining an asynchronous Address Event Representation silicon retina and a frame-based camera. The temporal precision of the asynchronous silicon retina is used to provide haptic feedback using an Omega.3 haptic device, while the camera is used to retrieve the position of the object to be manipulated. The same group also presented a haptic feedback teleoperation system for optical tweezers (OT) that attains high frequency (Ni et al., 2013). It is composed of laser OT and an Omega.3 haptic interface. The force is estimated using a trap stiffness model that measures the relative position of the object with respect to the laser spot. The human operator controls the OT using the master haptic interface, and the pico-newton forces detected by a vision system are provided to the operator through the same haptic device. Ni et al. (2014) recently extended this approach to multi-trap OT. Mehrtash et al. (2012) developed a haptic-enabled virtual reality interface for a magnetic-haptic micromanipulation platform. It is composed of a magnetic untethered microrobotic station and a Phantom Omni haptic interface. The difference between the actual and commanded position of the microrobot is used to provide force feedback to the human operator. Later on, the same authors also addressed the problem of estimating forces in real environments using a combination of Hall-effect and laser sensors (Mehrtash and Khamesee, 2013; Mehrtash et al., 2015). It uses the produced magnetic flux information and the real position of the microrobot to estimate the forces applied by the robot to the environment. More recently, Pacchierotti et al. (2015a) presented a haptic teleoperation system that enables a human operator to control the positioning of self-propelled catalytic microrobots. A particle-filter-based tracking algorithm tracks, at runtime, the position of the microsized agents in the remote environment. A 6-DoF Omega haptic interface then provides the human operator with haptic feedback about the interaction between the controlled microrobot and the environment, as well as enabling the operator to control the target position of the microrobot. Finally, a wireless magnetic control system regulates the orientation of the microrobot to reach the target point.

2.3. Strain Gages/Piezoresistive Sensors

Shirinov and Fatikow (2003) developed a 4-DoF haptic interface for the remote control of microrobotic cells, which are realized on the basis of a SEM. Two microrobots equipped with piezoelectric actuators operate in the cell, and a 6-axis force/torque sensor is in charge of registering the forces to be filtered, amplified, and finally provided to the human user through the haptic interface. Probst et al. (2009) presented a 6-DoF system for the assembly of 3-D bio-microrobotic devices out of individual 2.5-D microelectromechanical systems (MEMS) components. A gripper exchange mechanism allows reaching for parts, and a microfabricated platform provides a structured working area. The human operator controls the microgripper through a Phantom Omni haptic interface, which is also able to provide force feedback about the interaction of the microgripper with the remote environment. More recently, Boukhnifer and Ferreira (2013) used a passivity-based approach for the bilateral control and robust fault tolerant control of a two-fingered microgripper system with haptic feedback. The considered haptic interface is a custom 1-DoF haptic feedback system driven by a DC motor.

Vlachos et al. (2007) presented a haptic telemanipulation system composed of a 2-DoF slave robot driven by two centripetal force vibration micromotors and a custom 5-DoF haptic interface. Since the sensed forces have the form of impulses, the system first filters the forces, it magnifies them, and then provides them to the human operator through the custom haptic interface. The same group recently devised a shared-control steering approach for this manipulation system that uses visual servoing techniques to help the operator in completing various micromanipulation tasks (Vlachos and Papadopoulos, 2014). Sieber et al. (2008) developed a haptic platform for bilateral micromanipulation of cells with 3-D force feedback. It is composed of a MEMS-based silicon triaxial force sensor, customized to act as a sensing probe. The sensor is mounted on a nanomanipulator with 3-DoF, and a Phantom Premium device is in charge of providing the sensed force to the operator. Horan et al. (2009) proposed another system to provide the human operator with intuitive means for controlling a micromanipulator during intracellular injection. A Phantom Omni haptic device controls the position of a micropipette in the remote environment. The authors also investigated the importance of proper position and force scaling. More recently, Seifabadi et al. (2013) presented a 1-DoF macro–micro teleoperation system with haptic feedback. A micromotion piezo actuator is used as the slave robot, and a servo DC motor actuates the master handle. Force sensors are placed at both ends for haptic feedback, and a microscope system is used for real-time visual feedback. A sliding mode-based impedance controller ensures position tracking, while an impedance force controller is used at the master side to ascertain force tracking.

Salcudean et al. (1995) started to investigate the role of haptic feedback for minimally invasive surgery applications at the microscale by developing a macro–micro manipulator with a micro-motion wrist identical to the haptic-enabled master. By using a combination of position and rate control, the system requires small operator hand motions to provide low mechanical impedance, high motion resolution, and force feedback over a substantial volume. Later on, Menciassi et al. (2003) presented a set of robotic haptic-enabled microinstruments for minimally invasive surgery. At the operating table, a microgripper, instrumented with semiconductor strain gages as force sensors, is in charge of manipulating tissue samples. A fiber optic microscope monitor allows the operator to visualize the sample and the microgripper position. Finally, a Phantom haptic interface enables the human operator to control the position of the microgripper and feels the pulse in the considered microvessels. The same group leaded the collaborative project “ARAKNES”1 on the advancement of technologies for the surgical treatment of morbid obesity and gastroesophageal reflux. Within the same project, Santos-Carreras et al. (2010) developed a bimanual haptic-enabled workstation to teleoperate surgical microrobots in the abdominal cavity of the patient. More recently, Payne et al. (2012) presented a hand-held device capable of amplifying micromanipulation forces during minimal invasive surgical tasks. The device uses a three-phase linear motor capable of generating forces that allow amplification factors up to 15 times.

2.4. Capacitive Sensors

Vijayasai et al. (2010) uses a MEMS microgripper as an end-effector and a force sense circuit to measure the gripping force. Force feedback is then provided to the operator using a Novint Falcon, which is also employed to control the position of the microgripper. The same system has been also employed in a chess piece pick-and-place game at the microscale (Vijayasai et al., 2012).

2.5. Electrostatic Active Sensors

Mohand Ousaid et al. (2014) proposed a modular micro teleoperation system using custom passive components. The stability of the teleoperation loop is guaranteed as the serial connection of passive systems yield a passive system. The slave probe is equipped with a force sensor, which uses electrostatic energy. The sensed force is scaled up and provided to the human operator through a custom 1-DoF haptic interface (Mohand Ousaid et al., 2012). The authors tested the proposed system in microscale force sensing scenarios, such as feeling capillary forces while penetrating a water droplet (Mohand Ousaid et al., 2015). The same group participates in the collaborative project “REMIQUA,”2 which aims at developing modular and versatile systems for microassembly and quality inspection.

2.6. Piezoelectric Sensors

Ammi and Ferreira (2005) presented a bio-inspired cell micromanipulation system. Stereoscopic visual information is provided to the operator through a 3-D reconstruction method using vision-based tracking of the environment deformations (see Figure 1B). A Phantom haptic device provides haptic feedback. Results show that the stability of the cell punction is improved when adding haptic feedback about cellular forces and the viscosity of the medium. Similarly, Pillarisetti et al. (2005) developed a haptic system capable of measuring cell injection forces and providing a suitable feedback to the user through a Phantom Premium device. All subjects were able to correctly detect the puncturing of the membrane through the haptic interface.

2.7. Physical Models

Kim et al. (2008) presented a haptic rendering technique in which interaction forces between the slave instrument, driven by a Phantom Omni haptic device, and a deformable cell are estimated in real time based on a physical model of the object. The system was evaluated in micromanipulation experiments using zebrafish embryos. Asgari et al. (2011) used a 3-D particle-based model to simulate the deformation of a cell membrane and cellular forces during microrobotic cell injection. The model is based on the kinematic and dynamic of spring–damper multi-particle joints taking into account viscoelastic fluidic properties. It simulates indentation haptic feedback as well as cell visual deformation. The model was validated using experimental data of zebrafish embryo microinjections. A simulator for cell injection has been also presented by Ladjal et al. (2011, 2013). It is composed of a computer-generated mesh of the cell, a needle, a collision detection algorithm, a physical-based model of deformable cell modeling, and a haptic interaction controller. The authors devised two models based either on an explicit linear finite element model or on a non-linear finite element Saint Venant–Kirchhoff material. The operator is able to see the 3-D shape of the cell and interact with it using a Phantom Desktop haptic device.

2.8. Active Constraints

Haptic feedback is not only useful to render the mechanical properties of the remote environment, but it can also be used to provide the human operator with navigation information. Ghanbari et al. (2010) investigated the use of haptic active constraints for cell injection. The active constraints assist the human operator when performing intracellular injection by limiting the micropipette tip’s motion to a conical volume as well as recommending the desired path for optimal injection. The same group recently extended this approach to volumetric active constraints (Ghanbari et al., 2014) and to multi-point interaction (Ang et al., 2015). Similarly, Faroque et al. (2015) used haptic constraints to assist an operator performing real-time cell injection. As the operator commands the micropipette to approach the cell, a conical potential field encourages her/him to follow an optimized trajectory toward the penetration point on the cell membrane. To prevent the operator from overshooting the deposition location, a planar active constraint is also used. Kim et al. (2012) described a shared-control framework for microinjection, in which a micromanipulator is controlled by the shared-motion commands of both the human operator and an autonomous controller. While the controller retains cells and glass pipettes within a desired path or space, the operator can concentrate on the injection task. A Phantom desktop haptic interface controls the motion of the pipette and provides the operator with haptic guidance.

Regarding untethered microrobotics, Basdogan et al. (2007) demonstrated the manipulation of polymer microspheres floating in water using OT (see Figure 1C). Trapped microspheres are steered using the end-effector of a haptic device that is virtually coupled to an XYZ piezo-scanner controlling the movements of the fluid bed. To ease the manipulation, the system computes a collision-free path for the particle and then provides the user with guidance through the haptic interface to keep him/her on this path.

Author Contributions

CP and SS searched in the literature for relevant works and wrote the paper. SM and DP wrote the paper.

Conflict of Interest Statement

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Funding

This project (ROBOTAR) has received funding from the European Research Council (ERC) under the European Union’s Horizon 2020 Research and Innovation programme (Grant Agreement #638428). The research has also received funding from the European Union’s FP7/2007-2013 (Grant Agreement #601165 of project “WEARHAP”).

Footnotes

References

Ammi, M., and Ferreira, A. (2005). “Realistic visual and haptic rendering for biological-cell injection,” in Proc. IEEE International Conference on Robotics and Automation (Barcelona), 918–923.

Ang, Q.-Z., Horan, B., Abdi, H., and Nahavandi, S. (2015). Multipoint haptic guidance for micrograsping systems. IEEE Syst. J. 9, 1388–1395. doi: 10.1109/JSYST.2014.2314737

Asgari, M., Ghanbari, A., and Nahavandi, S. (2011). “3d particle-based cell modelling for haptic microrobotic cell injection,” in Proc. International Conference on Mechatronics Technology: Precision Mechatronics for Advanced Manufacturing, Service, and Medical Sectors (Melbourne), 1–6.

Balasubramanian, S., Kagan, D., Hu, C. M., Campuzano, S., Lobo-Castañon, M. J., Lim, N., et al. (2011). Micromachine-enabled capture and isolation of cancer cells in complex media. Angew. Chem. Int. Ed. 50, 4161–4164. doi:10.1002/anie.201102193

Basdogan, C., Kiraz, A., Bukusoglu, I., Varol, A., and Doganay, S. (2007). Haptic guidance for improved task performance in steering microparticles with optical tweezers. Opt. Express 15, 11616–11621. doi:10.1364/OE.15.011616

Bhatti, A., Khan, B., Nahavandi, S., Hanoun, S., and Gao, D. (2015). “Intuitive haptics interface with accurate force estimation and reflection at nanoscale,” in Advances in Global Optimization (Springer International Publishing), 507–514.

Binnig, G., Quate, C. F., and Gerber, C. (1986). Atomic force microscope. Phys. Rev. Lett. 56, 930. doi:10.1103/PhysRevLett.56.930

Bolopion, A., and Régnier, S. (2013). A review of haptic feedback teleoperation systems for micromanipulation and microassembly. IEEE Trans. Autom. Sci. Eng. 10, 496–502. doi:10.1109/TASE.2013.2245122

Bolopion, A., Stolle, C., Tunnell, R., Haliyo, S., Régnier, S., and Fatikow, S. (2011). “Remote microscale teleoperation through virtual reality and haptic feedback,” in Proc. IEEE/RSJ International Conference on Intelligent Robots and Systems (San Francisco), 894–900.

Bolopion, A., Xie, H., Haliyo, D. S., and Régnier, S. (2012). Haptic teleoperation for 3-d microassembly of spherical objects. IEEE/ASME Trans. Mechatron. 17, 116–127. doi:10.1109/TMECH.2010.2090892

Boukhnifer, M., and Ferreira, A. (2013). Fault tolerant control of a teleoperated piezoelectric microgripper. Asian J. Control 15, 888–900. doi:10.1002/asjc.593

Fahlbusch, S., Shirinov, A., and Fatikow, S. (2002). “Afm-based micro force sensor and haptic interface for a nanohandling robot,” in Proc. IEEE/RSJ International Conference on Intelligent Robots and Systems, Vol. 2. (Lausanne), 1772–1777.

Faroque, S., Horan, B., Adam, H., Pangestu, M., and Thomas, S. (2015). “Haptic virtual reality training environment for micro-robotic cell injection,” in Haptic Interaction, Vol. 277. (Springer), 245–249.

Ferreira, A., Cassier, C., Haddab, Y., Rougeot, P., and Chaillet, N. (2001). “Development of a teleoperated micromanipulation system with visual and haptic feedback,” in Intelligent Systems and Advanced Manufacturing, 112–123.

Ghanbari, A., Abdi, H., Horan, B., Nahavandi, S., Chen, X., and Wang, W. (2010). “Haptic guidance for microrobotic intracellular injection,” in Proc. IEEE RAS and EMBS International Conference on Biomedical Robotics and Biomechatronics (Tokyo), 162–167.

Ghanbari, A., Horan, B., Nahavandi, S., Chen, X., and Wang, W. (2014). Haptic microrobotic cell injection system. IEEE Syst. J. 8, 371–383. doi:10.1109/JSYST.2012.2206440

Grange, S., Conti, F., Helmer, P., Rouiller, P., and Baur, C. (2001). “Delta haptic device as a nanomanipulator,” in Intelligent Systems and Advanced Manufacturing, 100–111.

Gultepe, E., Randhawa, J. S., Kadam, S., Yamanaka, S., Selaru, F. M., Shin, E. J., et al. (2013). Biopsy with thermally-responsive untethered microtools. Adv. Mater. Weinheim 25, 514–519. doi:10.1002/adma.201203348

Hollis, R., Salcudean, S., and Abraham, D. (1990). “Toward a tele-nanorobotic manipulation system with atomic scale force feedback and motion resolution,” in Proc. IEEE Micro Electro Mechanical Systems (Napa Valley), 115–119.

Horan, B., Ghanbari, A., Nahavandi, S., Chen, X., and Wang, W. (2009). “Towards haptic microrobotic intracellular injection,” in Proc. ASME 2009 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference (San Diego), 135–142.

Iwata, F., Mizuguchi, Y., Ko, H., and Ushiki, T. (2013). A compact nano manipulator based on an atomic force microscope coupling with a scanning electron microscope or an inverted optical microscope. J. MicroBio Rob. 8, 25–32. doi:10.1007/s12213-013-0063-7

Jakopec, M., Rodriguez Baena, F., Harris, S. J., Gomes, P., Cobb, J., and Davies, B. L. (2003). The hands-on orthopaedic robot acrobot: early clinical trials of total knee replacement surgery. IEEE Trans. Rob. Autom. 19, 902–911. doi:10.1109/TRA.2003.817510

Khalil, I. S. M., Magdanz, V., Sanchez, S., Schmidt, O. G., and Misra, S. (2014a). The control of self-propelled microjets inside a microchannel with time-varying flow rates. IEEE Trans. Robot. 30, 49–58. doi:10.1109/TRO.2013.2281557

Khalil, I. S. M., Magdanz, V., Sanchez, S., Schmidt, O. G., and Misra, S. (2014b). Wireless magnetic-based closed-loop control of self-propelled microjets. PLoS ONE 9:e83053. doi:10.1371/journal.pone.0083053

Kim, D.-N., Kim, K., Kim, K.-Y., and Cha, S.-M. (2001). “Dexterous teleoperation for micro parts handling based on haptic/visual interface,” in Proc. IEEE Micromechatronics and Human Science (Kawasaki), 211–217.

Kim, J., Ladjal, H., Folio, D., Ferreira, A., and Kim, J. (2012). Evaluation of telerobotic shared control strategy for efficient single-cell manipulation. IEEE Trans. Autom. Sci. Eng. 9, 402–406. doi:10.1109/TASE.2011.2174357

Kim, J., Sharifi, F. J., and Kim, J. (2008). “A physically-based haptic rendering for telemanipulation with visual information: macro and micro applications,” in Proc. IEEE/RSJ International Conference on Intelligent Robots and Systems (Nice), 3489–3494.

Kim, S.-G., and Sitti, M. (2006). Task-based and stable telenanomanipulation in a nanoscale virtual environment. IEEE Trans. Autom. Sci. Eng. 3, 240–247. doi:10.1109/TASE.2006.876909

Ladjal, H., Hanus, J.-L., and Ferreira, A. (2011). “Microrobotic simulator for assisted biological cell injection,” in Proc. IEEE/RSJ International Conference on Intelligent Robots and Systems (San Francisco), 1315–1320.

Ladjal, H., Hanus, J.-L., and Ferreira, A. (2013). Micro-to-nano biomechanical modeling for assisted biological cell injection. IEEE Trans. Biomed. Eng. 60, 2461–2471. doi:10.1109/TBME.2013.2258155

Massimino, M. J., and Sheridan, T. B. (1994). Teleoperator performance with varying force and visual feedback. Hum. Factors 36, 145–157.

Matteucci, M., Casella, M., Bedoni, M., Donetti, E., Fanetti, M., De Angelis, F., et al. (2008). A compact and disposable transdermal drug delivery system. Microelectron. Eng. 85, 1066–1073. doi:10.1016/j.mee.2007.12.067

Mehrtash, M., and Khamesee, M. B. (2013). Micro-domain force estimation using hall-effect sensors for a magnetic microrobotic station. J. Adv. Mech. Des. Syst. Manuf. 7, 2–14. doi:10.1299/jamdsm.7.2

Mehrtash, M., Khamesee, M. B., Tarao, S., Tsuda, N., and Chang, J.-Y. (2012). Human-assisted virtual reality for a magnetic-haptic micromanipulation platform. Microsyst. Technol. 18, 1407–1415. doi:10.1007/s00542-012-1560-7

Mehrtash, M., Zhang, X., and Khamesee, M. (2015). Bilateral magnetic micromanipulation using off-board force sensor. IEEE/ASME Trans. Mechatron. 20, 3223–3231. doi:10.1109/TMECH.2015.2417116

Menciassi, A., Eisinberg, A., Carrozza, M. C., and Dario, P. (2003). Force sensing microinstrument for measuring tissue properties and pulse in microsurgery. IEEE/ASME Trans. Mechatron. 8, 10–17. doi:10.1109/TMECH.2003.809153

Mohand Ousaid, A., Bolopion, A., Haliyo, S., Régnier, S., Hayward, V. (2014). “Stability and transparency analysis of a teleoperation chain for microscale interaction,” in Proc. IEEE International Conference on Robotics and Automation (ICRA) (Hong Kong: IEEE), 5946–5951.

Mohand Ousaid, A., Haliyo, D., Regnier, S., and Hayward, V. (2015). A stable and transparent microscale force feedback teleoperation system. IEEE/ASME Trans. Mechatron. 20, 2593–2603. doi:10.1109/TMECH.2015.2423092

Mohand Ousaid, A., Millet, G., Régnier, S., Haliyo, S., and Hayward, V. (2012). Haptic interface transparency achieved through viscous coupling. Int. J. Rob. Res. 31, 319–329. doi:10.1177/0278364911430421

Ni, Z., Bolopion, A., Agnus, J., Benosman, R., and Régnier, S. (2012). Asynchronous event-based visual shape tracking for stable haptic feedback in microrobotics. IEEE Trans. Robot. 28, 1081–1089. doi:10.1109/TRO.2012.2198930

Ni, Z., Pacoret, C., Benosman, R., and Régnier, S. (2013). “2d high speed force feedback teleoperation of optical tweezers,” in Proc. IEEE International Conference on Robotics and Automation (Karlsruhe), 1700–1705.

Ni, Z., Yin, M., Pacoret, C., Benosman, R., and Régnier, S. (2014). “First high speed simultaneous force feedback for multi-trap optical tweezers,” in Advanced Intelligent Mechatronics (AIM), 2014 IEEE/ASME International Conference on (Besançon), 7–12.

Okamura, A. M. (2004). Methods for haptic feedback in teleoperated robot-assisted surgery. Ind. Rob. 31, 499–508. doi:10.1108/01439910410566362

Pacchierotti, C. (2015). “Cutaneous haptic feedback in robotic teleoperation,” in Springer Series on Touch and Haptic Systems (Springer International Publishing).

Pacchierotti, C., Magdanz, V., Medina-Sanchez, M., Schmidt, O. G., Prattichizzo, D., and Misra, S. (2015a). Intuitive control of self-propelled microjets with haptic feedback. J. MicroBio Rob. 10, 37–53. doi:10.1007/s12213-015-0082-7

Pacchierotti, C., Meli, L., Chinello, F., Malvezzi, M., and Prattichizzo, D. (2015b). Cutaneous haptic feedback to ensure the stability of robotic teleoperation systems. Int. J. Rob. Res. 34, 1773–1787. doi:10.1177/0278364915603135

Pacchierotti, C., Tirmizi, A., Bianchini, G., and Prattichizzo, D. (2015c). Enhancing the performance of passive teleoperation systems via cutaneous feedback. IEEE Trans. Haptics 8, 397–409. doi:10.1109/TOH.2015.2457927

Pacchierotti, C., Prattichizzo, D., and Kuchenbecker, K. J. (2016). Cutaneous feedback of fingertip deformation and vibration for palpation in robotic surgery. IEEE Trans. Biomed. Eng. 63, 278–287. doi:10.1109/TBME.2015.2455932

Payne, C. J., Latt, W. T., and Yang, G.-Z. (2012). “A new hand-held force-amplifying device for micromanipulation,” in Proc. IEEE International Conference on Robotics and Automation (St. Paul), 1583–1588.

Pillarisetti, A., Anjum, W., Desai, J. P., Friedman, G., and Brooks, A. D. (2005). “Force feedback interface for cell injection,” in Proc. World Haptics (Pisa), 391–400.

Probst, M., Hürzeler, C., Borer, R., and Nelson, B. J. (2009). A microassembly system for the flexible assembly of hybrid robotic mems devices. Int. J. Optomechatronics 3, 69–90. doi:10.1080/15599610902894592

Salcudean, S. E., Wong, N., and Hollis, R. L. (1995). Design and control of a force-reflecting teleoperation system with magnetically levitated master and wrist. IEEE Trans. Rob. Autom. 11, 844–858. doi:10.1109/70.478431

Sanchez, S., Solovev, A. A., Schulze, S., and Schmidt, O. G. (2011). Controlled manipulation of multiple cells using catalytic microbots. Chem. Commun. 47, 698–700. doi:10.1039/c0cc04126b

Santos-Carreras, L., Leuenberger, K., Beira, R., and Bleuler, H. (2010). “Araknes haptic interface: user-centered design approach,” in pHealth (Berlin), 2010.

Seifabadi, R., Rezaei, S. M., Ghidary, S. S., and Zareinejad, M. (2013). A teleoperation system for micro positioning with haptic feedback. Int. J. Control Autom. Syst. 11, 768–775. doi:10.1007/s12555-012-0139-5

Shirinov, A., and Fatikow, S. (2003). “Haptic interface for a microrobot cell,” in Proc. EuroHaptics (Dublin), 6–9.

Sieber, A., Valdastri, P., Houston, K., Eder, C., Tonet, O., Menciassi, A., et al. (2008). A novel haptic platform for real time bilateral biomanipulation with a mems sensor for triaxial force feedback. Sens. Actuators A Phys. 142, 19–27. doi:10.1016/j.sna.2007.03.018

Sitti, M., Aruk, B., Shintani, H., and Hashimoto, H. (2003). Scaled teleoperation system for nano-scale interaction and manipulation. Adv. Robot. 17, 275–291. doi:10.1163/156855303764018503

Sitti, M., Horighuchi, S., and Hashimoto, H. (1999). “Tele-touch feedback of surfaces at the micro/nano scale: modeling and experiments,” in Proc. IEEE/RSJ International Conference on Intelligent Robots and Systems, Vol. 2 (Kyongju), 882–888.

Soler, L., Magdanz, V., Fomin, V. M., Sanchez, S. O., and Schmidt, O. G. (2013). Self-propelled micromotors for cleaning polluted water. ACS Nano 7, 9611–9620. doi:10.1021/nn405075d

Solovev, A. A., Mei, Y., Urena, E. B., Huang, G., and Schmidt, O. G. (2009). Catalytic microtubular jet engines self-propelled by accumulated gas bubbles. Small 5, 1688–1692. doi:10.1002/smll.200900021

Solovev, A. A., Sanchez, S., Pumera, M., Mei, Y. F., and Schmidt, O. G. (2010). Magnetic control of tubular catalytic microbots for the transport, assembly, and delivery of micro-objects. Adv. Funct. Mater. 20, 2430–2435. doi:10.1002/adfm.201090064

Solovev, A. A., Xi, W., Gracias, D. H., Harazim, S. M., Deneke, S. M., Sanchez, S., et al. (2012). Self-propelled nanotools. ACS Nano 6, 1751–1756. doi:10.1021/nn204762w

Troccaz, J., and Delnondedieu, Y. (1996). Semi-active guiding systems in surgery. a two-dof prototype of the passive arm with dynamic constraints (PADyC). Mechatronics 6, 399–421. doi:10.1016/0957-4158(96)00003-7

Venture, G., Haliyo, D. S., Régnier, S., and Micaelli, A. (2005). “Force-feedback micromanipulation with unconditionally stable coupling,” in Proc. International Conference on IEEE/RSJ Intelligent Robots and Systems (Edmonton), 1923–1928.

Vijayasai, A. P., Sivakumar, G., Mulsow, M., Lacouture, S., Holness, A., and Dallas, T. E. (2010). Haptic controlled three-axis mems gripper system. Rev. Sci. Instrum. 81, 105114. doi:10.1063/1.3499243

Vijayasai, A. P., Sivakumar, G., Mulsow, M., Lacouture, S., Holness, A., Dallas, T. E., et al. (2012). Haptic controlled three degree-of-freedom microgripper system for assembly of detachable surface-micromachined mems. Sens. Actuators A Phys. 179, 328–336. doi:10.1016/j.sna.2012.03.035

Vlachos, K., and Papadopoulos, E. (2014). “Design and experimental validation of a hybrid micro tele-manipulation system,” in 8th Hellenic Conference on Artificial Intelligence (Ioannina: Springer International Publishing), 164–177.

Vlachos, K., Vartholomeos, P., and Papadopoulos, E. (2007). “A haptic tele-manipulation environment for a vibration-driven micromechatronic device,” in Proc. IEEE/ASME International Conference on Advanced Intelligent Mechatronics (Zurich), 1–6.

Vogl, W., Ma, B. K.-L., and Sitti, M. (2006). Augmented reality user interface for an atomic force microscope-based nanorobotic system. IEEE Trans. Nanotechnol. 5, 397–406. doi:10.1109/TNANO.2006.877421

Wagner, C. R., Howe, R. D., and Stylopoulos, N. (2002). “The role of force feedback in surgery: analysis of blunt dissection,” in Proc. International Symposium on Haptic Interfaces for Virtual Environment and Teleoperator Systems (Orlando), 354–355.

Woods, S. P., and Constandinou, T. G. (2011). “Towards a micropositioning system for targeted drug delivery in wireless capsule endoscopy,” in Proc. International Conference of the IEEE Engineering in Medicine and Biology Society (Boston), 7372–7375.

Xi, W., Solovev, A. A., Ananth, A. N., Gracias, D. H., Sanchez, S., and Schmidt, O. G. (2013). Rolled-up magnetic microdrillers: towards remotely controlled minimally invasive surgery. Nanoscale 5, 1294–1297. doi:10.1039/c2nr32798h

Keywords: haptics, microrobotics, robotics, teleoperation, micromanipulation, micropositioning, microsurgery

Citation: Pacchierotti C, Scheggi S, Prattichizzo D and Misra S (2016) Haptic Feedback for Microrobotics Applications: A Review. Front. Robot. AI 3:53. doi: 10.3389/frobt.2016.00053

Received: 26 April 2016; Accepted: 16 August 2016;

Published: 31 August 2016

Edited by:

Juan Wachs, Purdue University, USAReviewed by:

Arianna Menciassi, Sant’Anna School of Advanced Studies, ItalyHuan Tan, GE Global Research, USA

Copyright: © 2016 Pacchierotti, Scheggi, Prattichizzo and Misra. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) or licensor are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Claudio Pacchierotti, Y2xhdWRpby5wYWNjaGllcm90dGlAaWl0Lml0

Claudio Pacchierotti

Claudio Pacchierotti Stefano Scheggi

Stefano Scheggi Domenico Prattichizzo

Domenico Prattichizzo Sarthak Misra

Sarthak Misra