- Beijing Explorer Software Co., LTD, Beijing, China

Strength and durability of concrete are critical performance indicators for the safety and service life of building structures. These properties are significantly influenced by the material proportions and their microstructure. Traditional methods for designing concrete mix ratios have certain limitations when dealing with complex multivariable relationships. Therefore, intelligent mix optimization techniques have become a key focus of current research. This paper presents an optimization approach for mortar mix design based on a multi-output neural network model with a multi-head attention mechanism, combined with the genetic algorithm. Firstly, a neural network model based on the multi-head attention mechanism is developed to establish a nonlinear mapping relationship between material proportions and performance. The genetic algorithm is then applied to optimize the model’s predictions, yielding the optimal mix design. Finally, by converting the optimized mix design data into element ion ratios parameters, the correlation between these microscopic factors and cementitious materials durability is analyzed. Results show that the neural network model effectively captures complex nonlinear relationships, with the predicted strength and durability closely aligning with experimental data. The mix ratio optimized by the genetic algorithm significantly improves the strength and durability of the mortar. Furthermore, the study of ion content provides new theoretical support for enhancing concrete durability. This research not only offers an innovative solution for the intelligent optimization of concrete mix design but also lays a theoretical foundation for concrete material design and performance enhancement.

1 Introduction

As one of the most widely used construction materials, strength and durability of concrete directly influence the safety and long-term performance of building structures. With the development of construction industry, particularly in the context of increasingly high requirements for the service life and safety of buildings, the strength and durability of concrete have become core indicators for evaluating its performance [1]. Optimizing concrete mix ratios to enhance its performance, especially its durability, has become a research hotspot. The strength and durability of concrete not only depend on the proportions of cement, aggregates, and water, but are also influenced by various factors such as microstructure, phase assemblage, and porosity [2–6]. Therefore, the scientific design and optimization of concrete material proportions under multiple variable factors have become key issues in current research. Traditional concrete mix design typically relies on classical empirical formulas and experimental data, adjusting the proportions of cement, sand, aggregates, and water to meet requirements [7, 8]. However, traditional methods have certain limitations, as they fail to fully account for the complex nonlinear relationships between concrete performance and microstructure, which cannot accurately predict the optimal mix ratio within a short period. Consequently, with advances in data processing technologies, intelligent optimization methods have emerged as effective tools for optimizing concrete mix design [9, 10].

In recent years, data-driven optimization methods have been widely applied in concrete mix design. Neural networks, as a common machine learning approach, possess strong nonlinear mapping capabilities, enabling them to effectively capture the complex relationships between concrete mix ratios and performance [11, 12]. Deep learning methods, such as multi-head attention mechanisms, convolutional neural networks (CNN), and long short-term memory networks (LSTM), can extract features from multidimensional data, thereby enabling more accurate performance prediction [13–15].

Moreover, optimization methods, such as genetic algorithms (GA), are often combined with neural networks to further enhance the optimization of concrete mix designs [11]. The attention mechanism, widely used in deep learning, especially the multi-head attention mechanism, has demonstrated exceptional performance in handling complex multidimensional data. The multi-head attention mechanism enables simultaneous attention to different parts of the input data through multiple distinct “attention heads”, allowing for multi-angle modeling of different features. This mechanism has been successfully applied in natural language processing and can be gradually extended to other fields, particularly in concrete mix optimization [16, 17]. In concrete mix optimization research, neural network models using multi-head attention mechanisms can effectively capture the nonlinear relationships between material proportions and concrete performance. Compared to traditional neural network models, models incorporating multi-head attention mechanisms can better identify key features and improve prediction accuracy when handling complex data. By optimizing the material mix data, the model can provide more precise predictions for concrete strength and durability, thereby achieving optimal mix ratios.

Genetic algorithms in concrete mix optimization can conduct a global search in complex parameter spaces, avoiding the potential pitfalls of traditional optimization methods that may fall into local optima. Through genetic algorithms, global optimization of material proportions can be performed, leading to the discovery of the best mix designs and significantly enhancing concrete performance [11]. In concrete mix optimization, genetic algorithms can be integrated with multi-head attention mechanism models to optimize the mix design parameters based on the model’s predictions through evolutionary algorithms. This combined approach not only improves the precision of the optimization but also significantly reduces the time and cost of experimental testing.

In addition to material proportions, the microstructure of concrete also plays a crucial role in its strength and durability. Factors such as the pore structure and ion content directly influence the durability of concrete [6, 18–20]. Excessive porosity can lead to a decrease in the concrete’s impermeability, thereby reducing its durability, whereas an optimized pore structure contributes to the long-term stability of concrete during service [21]. Moreover, the content of ions in concrete has a significant impact on its durability, particularly chloride ions and sulfate ions, which notably affect the corrosion resistance and chemical durability of concrete [22, 23]. Therefore, in-depth studies on the relationship between element ion ratios, pore structure, and concrete durability are essential for improving its long-term performance.

Despite numerous studies focusing on the optimization of concrete mix ratios and enhancing durability, existing optimization methods still face several challenges. First, the composition and performance of concrete are influenced by a variety of factors, particularly environmental conditions and variations in raw materials, which limit the applicability of current optimization models. Secondly, current intelligent optimization methods often rely on large amounts of experimental data for training, and the process of obtaining and processing experimental data remains an expensive and time-consuming task [24–26].

Since mortar can be treated as a small size for concrete, to simplify the system for better investigation, this paper presents an optimization approach for mortar mix designs based on a neural network model with a multi-head attention mechanism, combined with a genetic algorithm. It also provides an in-depth analysis of the significant impact of element ion content on mortar durability. The optimized mix ratios are expected to enhance the strength and durability of mortar, offering a novel intelligent optimization approach for mix design and providing a theoretical basis for improving concrete durability.

2 Methodology

2.1 Data collection and preprocessing

2.1.1 Data collection

The experimental data in this study were obtained through specific experiments and relevant literature [6, 27], with the primary aim of investigating the effects of different materials on the strength and chloride ion diffusion. The materials selected for the experiments included cement, fly ash (FA), limestone powder (LT), granulated blast furnace slag (Slag), and various types of calcined clay (CC). To explore the influence of material proportions on mortar performance, mortar mixtures of different types of raw materials were prepared. The corresponding strength and chloride ion diffusion coefficients were compared.

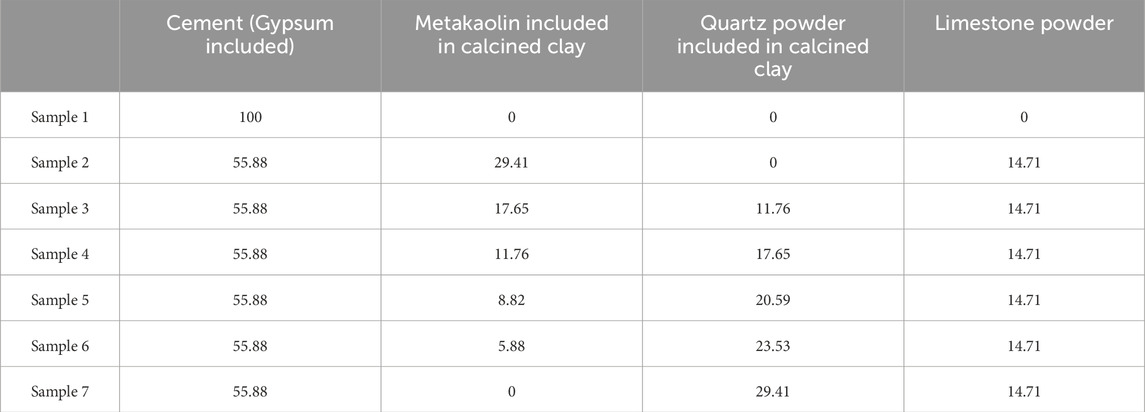

(1) Mix design

Based on the material mix designs, multiple cement mortar samples were prepared by incorporating different amounts of cement, FA, LP, Slag, CC, and other substances. Some of the mix ratios are shown in Table 1, with 300 g of standard sand included. The water to solid ratio is fixed as 0.5.

(2) Compressive strength

Compressive strength was measured on mortar samples after 90 days of moist curing, following the procedure outlined in EN 196. Three specimens were tested for each curing period to ensure reliable results.

(3) Chloride diffusion coefficient test

Chloride profile analysis was conducted on cylindrical mortar samples with a diameter of 11 cm and a height of 10 cm, which were cured for 28 days in moist conditions. After curing, the samples were cut into two-halves, and all surfaces were sealed with epoxy resin, except for the saw-cut face. The samples were then submerged in a 0.5 M NaCl solution at 23 °C. After 1 year of exposure, the specimens were removed from the solution. The chloride content profiles were measured by drilling, followed by nitric acid dissolution and AgNO3 titration according to the ASTM C1152 method. The collected data was subsequently used to calculate the apparent diffusion coefficient of the mortars, in accordance with ASTM C1556.

2.1.2 Data preprocessing

After data collection was completed, all experimental data need to be preprocessed for subsequent training and analysis of the neural network model. The preprocessing steps included the following.

(1) Data normalization

Since the content of various substances and experimental results (such as compressive strength and chloride ion diffusion coefficient) had different numerical scales, data normalization was applied to improve the convergence speed of the neural network model. This process mapped the value range of all variables to the same scale (typically from 0 to 1). The normalization formula is as follows in Equation 1:

where

(2) Missing data handling

If missing data occurs during certain experimental processes, the mean imputation method was used to fill in the missing values, ensuring data integrity and preventing potential impacts on subsequent model analysis.

(3) Dataset splitting

To train the neural network model, the experimental data were randomly divided into training, validation, and test sets. The training set was used for model fitting, the validation set was used for hyperparameter tuning, and the test set was employed to evaluate the model’s generalization ability. The data was split with 70% allocated to the training set, 15% to the validation set, and 15% to the test set.

(4) Outlier removal:

Through preliminary statistical analysis of the data, outliers were identified and removed using the Z-score method, ensuring that extreme values did not affect the model’s performance. This step helps improve the robustness and accuracy of the model.

These preprocessing steps ensure that all experimental data are effectively prepared for training and analysis of the neural network model, thereby laying a solid data foundation for subsequent research.

2.1.3 Data fitting and augmentation

Due to the limited number of mortar sample data obtained in the actual experiments (only 20 sets), and to meet the large-scale dataset requirements for neural network training while enhancing the model’s predictive capability, this study employed data fitting and augmentation techniques. By fitting the existing experimental data, additional sample data can be generated, thereby expanding the size of the training set.

(1) Determining the basis for data fitting

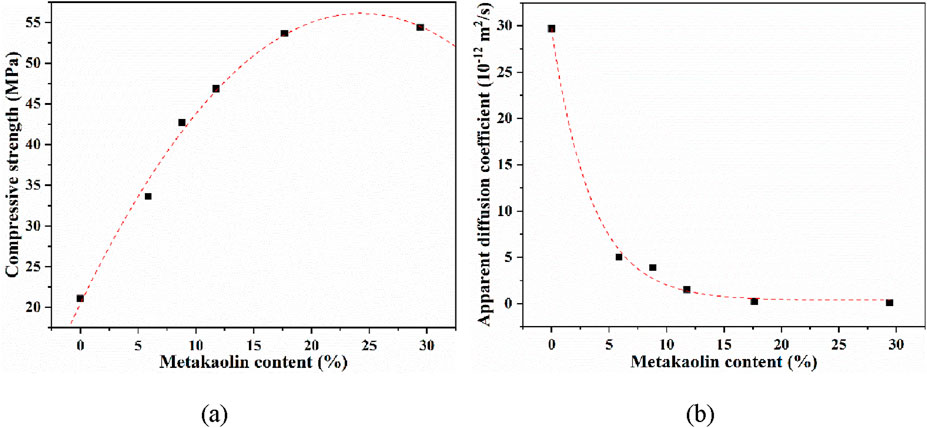

In this study, the experimental data cover the effects of different material mix ratios (including cement, FA, LT, Slag, and CC) on the compressive strength and chloride ion diffusion coefficient of mortar. Since the influence of similar mix combinations on mortar performance exhibits certain regularities, materials under specific mix designs demonstrate relatively stable trends in terms of strength and durability. For example, as shown in Figure 1 below, the impact of calcined clay with different kaolinite content on performance is presented, where the calcined clay content is fixed at 29.41%. It can be observed that the effect of varying kaolinite content on strength and chloride ion diffusion coefficient follows a consistent pattern, which can also be verified in the literature [28]. Therefore, by dividing the data into different subsets and fitting curves, the data can be expanded.

(2) Piecewise fitting and extension

Figure 1. The effect of different types of calcined clay (with various metakaolin content) on compressive strength (A) and chloride ion diffusion coefficient (B).

The data from each subset were fitted to capture the regular relationships between the mix designs and mortar performance. The fitting methods employed include polynomial regression, support vector regression (SVR), and other techniques capable of handling complex nonlinear relationships. Each fitting model is tailored to a specific mix combination or performance indicator, generating a corresponding fitting curve. Besides, the fitting should be reasonable or consistent with some previous study. Based on these curves, hundreds of new data points can be generated within the known range of mix ratios, at specified intervals. This approach effectively expands the data across different regions.

(3) Quality control and data validation

To ensure the validity of the fitted data, the quality of each fitting model was rigorously evaluated. First, the accuracy of the fit was verified using cross-validation and residual analysis to prevent overfitting or excessive fitting errors. Secondly, the generated extended data points must conform to actual physical laws and the distribution of experimental data. For instance, strength and durability should not exhibit significant deviations. Moreover, the generated data must align with the patterns observed in the behavior of the actual materials.

(4) Integration of the extended dataset

After expanding multiple fitting curves, a total of 1,500 new data points were generated. These data, combined with the original experimental data, formed a larger and more diverse dataset, providing sufficient samples for subsequent neural network model training. Throughout this process, the quality of the extended data was carefully ensured to guarantee the effectiveness of the final model training.

Through data fitting and augmentation, this study successfully overcame the issue of limited experimental data and provided ample training data for the neural network model. This approach not only ensured data diversity but also enabled the model to better learn the complex relationships between material mix designs and mortar performance, thereby enhancing prediction accuracy and the model’s generalization capability.

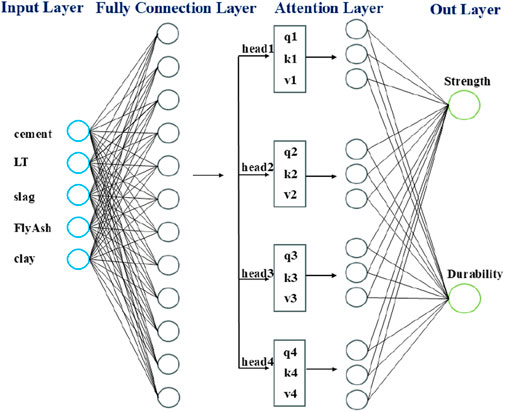

2.2 Neural network architecture design

The neural network architecture in this study consists of several components, including the input layer, fully connected layer, multi-head attention layer, and output layer. The input layer receives feature vectors representing five kinds of materials, corresponding to cement, FA, LT, Slag, and CC. These input data are mapped to a 12-dimensional feature space through a fully connected layer, with the goal of transforming the original material mix ratios into high-dimensional representations that the model can learn, thereby enhancing the network’s feature expression capability.

After mapping the input data to the 12-dimensional feature space, the data are passed through a multi-head attention mechanism, which divides them into four attention heads. Each attention head independently processes a subset of features, capturing interaction effects from different perspectives. Finally, the outputs of the four attention heads are concatenated and passed through the output layer to generate predictions for mortar strength or durability.

2.2.1 Design of the 12 embedding dimensions and their physical significance

Although the 12 embedding dimensions in the neural network do not directly correspond to physical properties, each dimension represents a latent feature that reflects the influence of different material mix designs on mortar performance. Through the weights learned during the training process, these dimensions can be automatically adjusted, ultimately forming a feature space capable of accurately predicting mortar strength and durability. Specifically, these 12 dimensions correspond to the key chemical and physical characteristics of the materials, as follows:

(1) Chemical composition of raw materials: The content of different elements in raw materials significantly impacts the hydration reactions, strength development, and durability performance of cement-based materials.

(2) Particle size distribution of raw materials: The particle size of raw materials, which is related to their specific surface area, plays a crucial role in the hydration rate of cement, the workability of mortar, and its final strength.

(3) Phase composition of raw materials: The phase composition of raw materials is essential for the hydration reactions of cement and its interactions with other components.

(4) Reaction rates of materials: Various reactions, such as hydration and pozzolanic reactions, are critical to the long-term strength and durability of mortar.

(5) Synergistic effects of reactions: The interactions and effects between different reactions further influence the performance over time.

(6) Properties of hydration products: The characteristics of hydration products directly affect the performance at the micro- and nano-scale, which then extend to the meso- and macro-scales, influencing the final mortar performance.

(7) Pore size distribution of the hardened specimen: This describes the distribution of pore structures in mortar, which impacts its density and compressive strength.

(8) Porosity: This refers to the pore content in mortar, which further affects its density and compressive strength.

(9) Pore tortuosity: The tortuosity of pores directly influences the movement of ions within the pores, subsequently affecting durability and other performance aspects.

(10) Ionic concentration in pore solution: The ionic concentration in the pore solution can affect the double electric layer on the pore surface, influencing the transport of external corrosive ions.

(11) Ionic coupling effects in pore solution: The interactions between ions in the pore solution further affect the transport of external penetrating ions.

(12) Other important factors: Other factors not directly addressed, but which may influence the performance of cement-based materials.

These embedding dimensions represent the key physical and chemical properties of the mortar components, providing the neural network with rich feature information. Through the multi-head attention mechanism, the model allocates these 12 dimensions into 4 attention heads, with each head independently learning specific feature combinations and their complex interactions. This allows the model to achieve accurate predictions of mortar performance.

2.2.2 Multi-head attention mechanism and feature allocation

After passing through the fully connected layer, the 12-dimensional feature vector enters the multi-head attention layer, where the 12 dimensions are allocated to four attention heads. Each head focuses on a different subset of features and independently computes the relationships between them, thereby capturing more complex interaction effects among the materials. The following outlines the design and function of each head.

Head 1: Considering the impact of raw materials’ physical properties and microstructure

This head focuses on the influence of the physical properties and microstructure of raw materials in cement-based materials on their mechanical properties and durability, particularly the physical properties of cement and supplementary cementitious materials (SCMs), as well as their microstructural characteristics. The particle size, mineral composition of cement, and the microstructure of SCMs such as CC, FA, and Slag directly affect the hydration reactions, pore structure, and overall performance of cement-based materials. Through this head, the network is able to capture the interactions between the physical properties and microstructure of the raw materials and assess their contribution to the strength, durability, and long-term stability of cement-based materials. This research helps optimize material design and enhances the performance of cement-based materials under varying environmental conditions.

Head 2: Considering the synergistic reactions of raw materials and the impact of hydration products

This head focuses on the synergistic reactions of raw materials and the influence of hydration products on the performance of cement-based materials, particularly the reaction processes between cement, SCMs (such as CC, FA, and Slag), and water. These synergistic reactions not only facilitate the formation of cement hydration products but also improve the microstructure and mechanical properties of cement-based materials. Through the interactions between cement and SCMs, denser hydration products are generated, thereby enhancing the strength and durability of mortar. Through this head, the network is able to capture the synergistic effects between cement and SCMs, and deeply analyze their contributions to the long-term performance and stability of cement-based materials. This research provides theoretical support for optimizing material mix designs and improving the overall performance of cement-based materials.

Head 3: Considering the influence of hardened paste pore structure distribution and characteristics

This head focuses on the impact of the pore structure distribution and characteristics of hardened specimen in cement-based materials on their performance. The pore structure of hardened paste is a crucial factor affecting the strength and durability of cement-based materials. The size, morphology, and distribution of pores directly influence the compressive strength and durability of these materials. Smaller pores enhance the density, reduce the penetration of moisture and corrosive ions, and thus improve the long-term performance of the material, whereas larger pores may lead to reduced strength and durability. This head aims to explore the characteristics of the hardened specimen pore structure and its specific effects on the performance of cement-based materials, helping the model to better understand the role of pore structure in the mechanics and durability of cement-based materials.

Head 4: Considering the impact of pore solution ion information

This head focuses on the influence of ion information in the pore solution of cement-based materials on their performance. The type, concentration, and distribution of ions in the pore solution significantly affect the strength, durability, and corrosion resistance of cement-based materials. Variations in the concentrations of ions such as calcium, sulfate, and chloride can impact the hydration process of cement and the stability of its microstructure, thereby affecting the material’s mechanical properties and durability. For instance, the presence of chloride ions may accelerate the corrosion of reinforcing steel, reducing the long-term stability of the material, while the concentration of calcium ions is closely related to the extent of cement hydration, influencing strength development. This head aims to analyze the characteristics of ion information in the pore solution, helping the model gain a deeper understanding of the role these ions play in cement-based materials and their overall impact on performance.

2.2.3 Neural network architecture diagram

To better understand the model architecture, Figure 2 illustrates the detailed structure of the neural network. The input layer consists of five nodes, each corresponding to one of the five material components (i.e., cement, FA, LT, Slag, and CC). These input data are first mapped to a 12-dimensional feature space through a fully connected layer. Then, the features are processed by a multi-head attention mechanism, which splits them into four attention heads. Each head receives 4-dimensional data and performs independent attention calculations. Finally, the outputs from the individual heads are merged and passed through the output layer to generate the final predictions for strength or durability.

2.3 Mathematical formulation of the model

2.3.1 Multi-head attention mechanism

The multi-head attention mechanism captures the complex relationships between mortar mix parameters and performance by concurrently computing multiple attention heads. The main steps and formulas are as follows:

(1) Computing the Query, Key, and Value matrices

For the input matrix X, the Query (Q), Key (K), and Value (V) matrices are obtained through linear transformations as follows in Equations 2–4:

Where WQ 、WK和 WV are the learned weight matrices.

(2) Computing the attention weights

For each attention head, the dot product of the Query and Key is calculated, followed by a scaling operation, as shown in Equation 5:

Where

(3) Concatenation and linear transformation

The outputs of all attention heads are concatenated and then passed through a linear transformation (Equation 6):

The output of each attention

Where

2.3.2 Multi-output neural network

Based on the output of the multi-head attention mechanism, a multi-output neural network is constructed to simultaneously predict the strength and durability of mortar.

Two independent linear transformations of Equations 8, 9 are applied to the final output Fn of the feed forward neural network to separately predict the mortar strength

where

2.4 Model architecture

In order to explore the influence of cement, FA, LT, Slag, and CC on the strength and durability of mortar, a neural network incorporating the multi-head attention mechanism is introduced. The network architecture is designed to capture the complex relationships between the mix design factors, thereby enabling more accurate prediction of the performance indicators of mortar.

2.4.1 Overview of the network architecture

The multi-head attention mechanism neural network mainly consists of the following components:

(1) Input layer

The input layer is responsible for receiving the numerical features of the mix ratio components. The proportions of each component are normalized to the range [0, 1] to ensure the stability and convergence of the model.

(2) Embedding layer

To enhance the network’s ability to represent input features, each mix design component is transformed into a higher-dimensional dense vector through the embedding layer. The output of this layer is a high-dimensional feature vector that captures more comprehensive interaction information between the mix components.

(3) Multi-head attention mechanism.

In this layer, the model applies the multi-head attention mechanism to perform weighted processing of the input features. Specifically, multiple attention heads are used to compute the weighted representation of each input feature in parallel, capturing different relationships between the mix components. Each attention head calculates attention scores using an independent attention weight matrix and combines the scores to obtain the weighted feature representations. Finally, the outputs of all attention heads are concatenated and fused through a linear transformation layer.

(4) Feedforward neural network

The output of the multi-head attention mechanism is passed into a feedforward neural network, which consists of several fully connected layers. These layers include activation functions (such as ReLU) and regularization techniques (such as Dropout) to enhance the model’s generalization ability. The feedforward network further performs nonlinear mappings on the features extracted by the multi-head attention mechanism to capture complex patterns.

(5) Output layer

The output layer consists of two branches, each predicting the strength and durability of mortar, respectively. These branches generate the final prediction results through independent fully connected layers and activation functions. The prediction of strength and durability is performed as a regression task, where the output of each branch is a continuous value representing the predicted performance of the mortar.

(6) Loss function and optimization

Mean Squared Error (MSE) is used as the loss function to measure the difference between the model’s predicted values and the true values. The network parameters are optimized through the backpropagation algorithm and an optimizer (such as Adam) to minimize the loss function, thereby improving the model’s prediction accuracy.

2.4.2 Model training and validation

During the training process, the training set is used to adjust the network parameters, the validation set is employed to tune hyperparameters and prevent overfitting, while the test set is utilized to evaluate the final performance of the model. Cross-validation is applied to ensure the robustness and generalization capability of the model. Through the aforementioned architecture and training strategy, it is expected that the model can fully leverage the advantages of the multi-head attention mechanism to accurately capture the impact of mix ratio factors on the strength and durability of mortar, thereby providing a scientific basis for mortar mix optimization in practical applications.

3 Results and discussion

3.1 Model prediction results

3.1.1 Strength prediction results

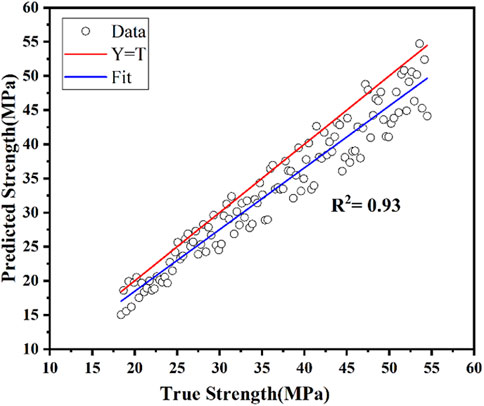

Figure 3 presents a comparison between the actual strength values and the model’s predicted values for a subset of samples. As shown in the figure, the predicted compressive strength values exhibit a good fit with the actual experimental data. The model’s prediction error is relatively small, with the prediction error for most samples falling within 10%, indicating that the model effectively captures the mapping relationship between the material mix ratio and compressive strength. This suggests that the model demonstrates high robustness when handling different mix ratios.

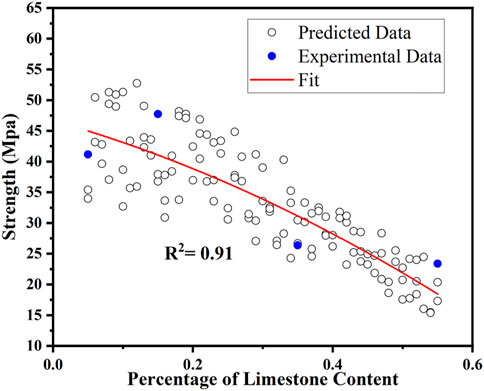

Furthermore, a deeper analysis was conducted on the effect of limestone powder content on compressive strength. The curve depicting the change in strength of cement mortar with varying limestone content, fitted based on experimental data, is shown in Figure 4. The blue data points represent the strength values from the real experiment, while the hollow dots are from the predicted data. It can be observed that the data points in the figure closely match the predicted results, and the overall trend shows a decrease in compressive strength as the limestone powder content increases. Although results from the literature indicate that a small amount of limestone powder can effectively enhance mortar strength, excessive limestone powder may weaken the strength of mortar, there are also studies confirming that strength gradually decreases with increasing limestone content [29–31]. Therefore, this trend is closely related to the physical and chemical properties of limestone powder, such as particle size and purity. Overall, the strength values calculated by the model are relatively accurate.

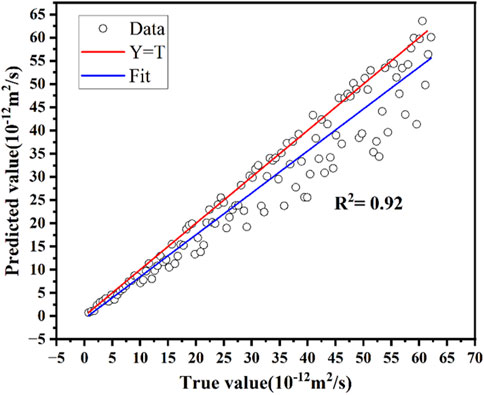

3.1.2 Durability prediction results

In terms of durability, the model also demonstrates high prediction accuracy, as shown in Figure 5. The prediction of durability indicators, represented by the chloride ion diffusion coefficient, shows a good fit with the actual experimental results. Based on the experimental data for the chloride ion diffusion coefficient, the multi-head attention mechanism effectively focuses on key mix ratio features related to durability, thereby improving the accuracy of durability predictions. The results indicate that the model’s prediction error for the chloride ion diffusion coefficient is also controlled within approximately 10%.

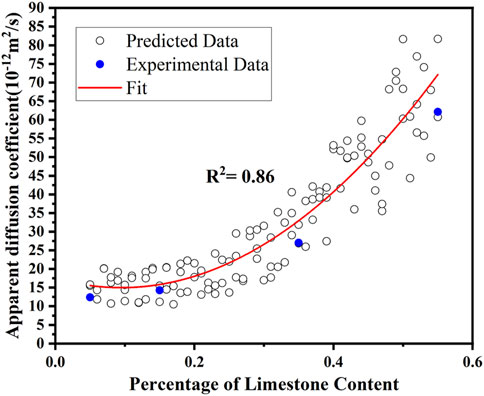

The model’s accuracy is further validated by the variation in limestone powder content. The curve depicting the change in mortar block durability with varying limestone content, fitted based on experimental data, is shown below in Figure 6. The blue data points represent the chloride diffusion coefficient values from the experiment, while other points are data calculated by the model for the given mix ratios. From the figure, it can be observed that as the limestone powder content increases, the chloride ion diffusion coefficient first remains stable and then gradually increases. This indicates that a small amount of limestone powder does not affect the system’s resistance to chloride ion penetration. However, when the content is higher, it significantly reduces the system’s chloride ion resistance. It results from the filler effect and the dilution effect of limestone. When the content of limestone is low, the filler effect is beneficial for the microstructure refinement, while when the content is too high, the lacking of the cement would lead to the porous pore structure. This result is consistent with findings in the literature [32, 33], confirming the accuracy of the chloride ion diffusion coefficient values calculated by the model.

3.2 Results analysis and discussion

The experimental results demonstrate that the multi-head attention mechanism neural network model effectively captures the complex relationships between mix designs and mortar performance. Through a comprehensive analysis of the mix ratios and the results for strength and durability, it is evident that the incorporation of high-activity mineral admixtures such as FA, Slag, and CC significantly impacts the long-term compressive strength, with mixes containing relatively high slag content notably enhancing the compressive strength of mortar. Additionally, in terms of durability, the introduction of CC and FA significantly improves the chloride ion resistance, especially in high-admixture mixes, where the mortar exhibits excellent resistance to chloride ion penetration. The multi-output neural network model employed in this study can simultaneously predict both strength and multiple durability indicators, providing an effective approach for comprehensive optimization of mortar mix ratios. The model’s high prediction accuracy offers valuable support for material mix optimization and demonstrates its broad potential for application in the field of materials science.

4 Obtaining the optimal mix design

Compared to strength, durability indicators are considered more critical. Therefore, the criteria for determining the optimal mix ratio are set as follows: a compressive strength greater than 45 MPa (for mortar with a water to solid ratio of 0.5), and as low a chloride ion diffusion coefficient as possible. Next, the pre-trained model is further utilized, and a genetic algorithm is employed to identify the optimal mix ratio.

4.1 Genetic algorithm optimization process

The genetic algorithm is an optimization technique based on the principles of natural selection and genetics, suitable for complex search spaces. Its core processes include selection, crossover, and mutation. The following are the main steps and relevant formulas.

(1) Initialization of the population

At generation t, the population P(t) is initialized, where each individual xi corresponds to a different mix ratio. The representation of each mix ratio is as follows in Equations 10, 11:

These mix ratios satisfy the total quantity constraint in Equation 12:

(2) Fitness function

The fitness function is used to evaluate the quality of each individual. The fitness functions for strength S and chloride ion resistance D are defined as follows in Equation 13:

In this way, the fitness function ensures that the strength requirement is met while optimizing the system’s chloride ion resistance.

(3) Selection operation

The roulette wheel selection strategy is used to select individuals from the current population, where the selection probability

(4) Crossover operation

The selected individuals undergo single-point crossover to generate new individuals. A crossover point c is randomly selected, and the new individuals generated from the crossover of two individuals

At the same time, to increase the diversity of the population, individual genes are mutated with a mutation rate µ in each generation as follows in Equation 16:

Where Ɛ is the random perturbation value.

4.2 Termination condition

The genetic algorithm continues to iterate until one of the following termination conditions is met.

(1) The predefined maximum number of generations

(2) The optimal fitness value of the population shows no significant change over several consecutive generations.

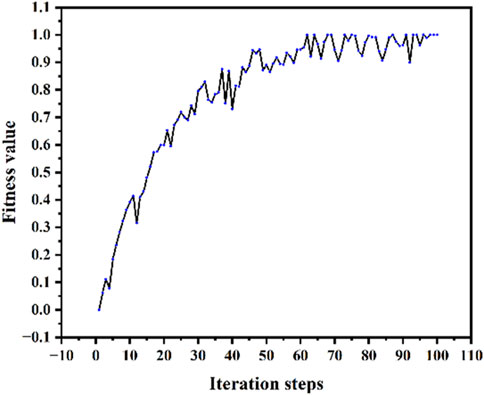

Through steps such as population initialization, fitness evaluation, selection, crossover, and mutation, the genetic algorithm continuously generates new mix ratio solutions. As the number of iterations increases, the algorithm gradually converges to the optimal mix ratio. Figure 7 illustrates the fitness variation process of the genetic algorithm, showing that as the number of iterations increases, the fitness value gradually improves, indicating that the chloride ion diffusion coefficient decreases and the strength requirement of greater than 45 MPa is met.

4.3 Results and analysis

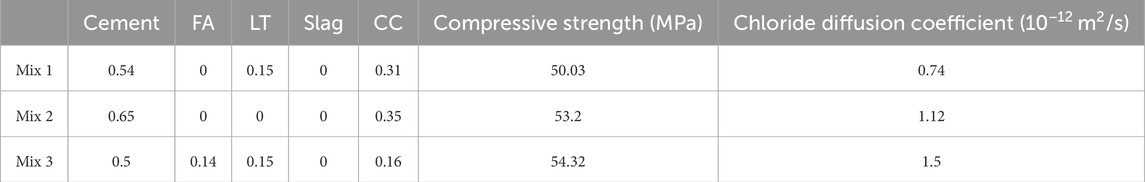

After several generations of evolution, the genetic algorithm identified the mix ratios that satisfy the strength requirement and are optimal in terms of durability.

Table 2 lists several typical mix ratios along with their corresponding strength and durability results.

Through the optimization process of the genetic algorithm, a mix ratio that satisfies the strength requirement and optimizes durability was successfully identified. The genetic algorithm effectively avoids local optima and reasonably balances the two key indicators, strength and durability, through the fitness function. The final optimized result demonstrated good practical application value in the experiments.

5 Preliminary exploration of factors affecting durability

Research indicates that the incorporation of materials such as CC, Slag, and FA significantly enhances the durability of mortar. Through the analysis of raw material composition, it was found that these materials contain higher levels of ions such as potassium (K), sodium (Na), and titanium (Ti). It is hypothesized that these ions play a crucial role in improving the durability of the mortar structure. To further validate this, the data will be converted into elemental content form for more in-depth investigation.

5.1 Data conversion and processing

Based on the optimized material mix ratio data (such as cement, FA, LT, Slag, and CC), we further analyzed their chemical compositions and converted these mix ratio data into corresponding elemental content ratios. The specific method involves using the chemical composition of the admixtures (provided by laboratory chemical analysis or literature data) and converting mass fractions and molar fractions (element content divided by the water added) to calculate the ion content of each material in the mixed system. These ion contents are used as inputs for the model, enabling further analysis of their impact on mortar durability.

5.2 Neural network model construction and training

Since the previous section utilized a neural network model based on the multi-head attention mechanism to explore the mapping relationship between material mix ratios and mortar performance, this study adopts a similar neural network architecture to further analyze the impact of ion content ratios on mortar durability.

5.2.1 Overview of the model architecture

In this phase of the study, the basic architecture of the model remains consistent with the previous sections, continuing to use the multi-head attention mechanism to capture the complex nonlinear relationships between input variables and durability. The model inputs include ion content ratios (e.g., K, Na, Ti, etc.), while the outputs are mortar performance indicators (e.g., compressive strength, chloride ion diffusion coefficient, etc.).

5.2.2 Model training and validation

To avoid redundancy, the training process of the model follows the same procedure as described earlier, utilizing the same optimization method (Adam optimizer) and loss function (Mean Squared Error, MSE). The dataset is similarly divided into standard training, validation, and test sets. During training, multiple iterations are performed to adjust the model parameters, ensuring that the model’s performance is stable and converges well across different datasets.

5.3 Results and analysis

5.3.1 Model prediction performance

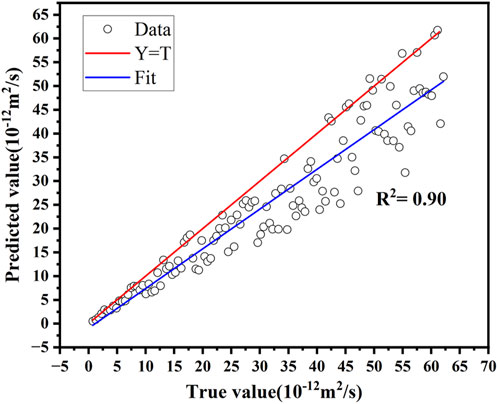

As shown in Figure 8, after training, the model performs well on the test set, accurately predicting the impact of ion content and pore structure on mortar durability. Specifically, the predicted chloride ion diffusion coefficient shows minimal error compared to the experimental data, with the model achieving a low Mean Squared Error (MSE) and a coefficient of determination (R2) of 0.90. By comparing the model’s predictions with the actual experimental results, it is evident that the neural network model successfully captures the complex nonlinear mapping relationships and can effectively predict the contribution of different elemental contents to durability.

5.3.2 Impact of ion content on durability

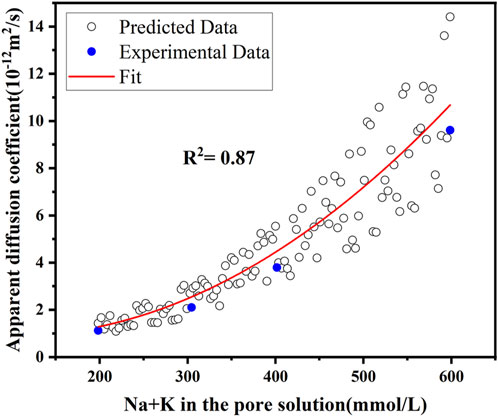

The study found that as the concentrations of Na and K ions increase, the chloride ion diffusion coefficient of the mortar samples also shows an increasing trend, as shown in Figure 9.

Figure 9. The relationship between sodium and potassium ion content in pore solution and chloride ion diffusion coefficient.

Through exploratory research, the impact of ion content ratios on mortar durability has been validated. The model results show that ions such as potassium (K) and sodium (Na) play a significant role in enhancing durability. This study not only provides a theoretical basis for ion regulation in material science but also offers valuable insights for optimizing mortar mix designs in practical engineering applications.

Future research could further investigate the influence of other elements (e.g., magnesium, aluminum) on mortar durability and optimize the model by incorporating more experimental data. With more comprehensive data and more sophisticated model architectures, we hope to further improve the predictive accuracy of the model, thereby contributing to the performance optimization and innovation of mortar materials.

6 Conclusion

In this study, mortar mix optimization was carried out by introducing a neural network model and genetic algorithm optimization. The following conclusions were drawn.

(1) By examining the materials used in the mix, such as cement, fly ash, limestone powder, slag, and calcined clay, it was demonstrated that the material composition has a significant impact on mortar durability.

(2) Composition analysis showed that the content of ions such as potassium (K) and sodium (Na) plays an important role in the durability of mortar. The neural network model successfully captured the nonlinear relationship between these ion contents and durability.

(3) The multi-head attention mechanism in the neural network model effectively captured the complex influence of mix composition and ion content on mortar durability. The model exhibited high predictive accuracy. This result proves the significant application potential of artificial intelligence methods in the field of materials science.

(4) The optimal material mix, derived through genetic algorithm optimization, improved mortar durability. This approach, combining intelligent algorithms, provides new insights for future mortar material optimization.

Overall, this study, through artificial intelligence technologies, deeply analyzed the influence of material composition and ion content on mortar durability. By optimizing the model, effective measures to improve durability were successfully proposed. This provides a theoretical foundation and technical support for the development and optimization of future mortar materials, promoting the integration of materials science and engineering practices.

Data availability statement

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

Author contributions

CJ: Conceptualization, Data curation, Investigation, Methodology, Resources, Software, Validation, Visualization, Writing–original draft, Writing–review and editing.

Funding

The author(s) declare that no financial support was received for the research, authorship, and/or publication of this article.

Acknowledgments

The help from Yuting Yang from Shandong University of Science and Technology with AI model discussion are highly appreciated.

Conflict of interest

Author CJ was employed by Beijing Explorer Software Co., LTD.

Generative AI statement

The author(s) declare that no Generative AI was used in the creation of this manuscript.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

1. Wang D, Shi C, Wu Z, Xiao J, Huang Z, Fang Z. A review on ultra high performance concrete: Part II. Hydration, microstructure and properties. Constr Build Mater (2015) 96:368–77. doi:10.1016/j.conbuildmat.2015.08.095

2. Thomas J, Thaickavil NN, Wilson PM. Strength and durability of concrete containing recycled concrete aggregates. J Building Eng (2018) 19:349–65. doi:10.1016/j.jobe.2018.05.007

3. Nguyen DH, Boutouil M, Sebaibi N, Baraud F, Leleyter L. Durability of pervious concrete using crushed seashells. Constr Build Mater (2017) 135:137–50. doi:10.1016/j.conbuildmat.2016.12.219

4. Lu Z, gang Feng Z, Yao D, Li X, Ji H. Freeze-thaw resistance of Ultra-High performance concrete: dependence on concrete composition. Constr Build Mater (2021) 293:123523. doi:10.1016/j.conbuildmat.2021.123523

5. Liu Y, Jin B, Huo J, Li Z. Effect of microstructure evolution on mechanical behaviour of concrete after high temperatures. Mag Concrete Res (2018) 70:770–84. doi:10.1680/jmacr.17.00197

6. Sui S, Georget F, Maraghechi H, Sun W, Scrivener K. Towards a generic approach to durability: factors affecting chloride transport in binary and ternary cementitious materials. Cem Concr Res (2019) 124:105783. doi:10.1016/j.cemconres.2019.105783

7. Yu R, Spiesz P, Brouwers HJH. Mix design and properties assessment of ultra-high performance fibre reinforced concrete (UHPFRC). Cem Concr Res (2014) 56:29–39. doi:10.1016/j.cemconres.2013.11.002

8. Panda B, Tan MJ. Experimental study on mix proportion and fresh properties of fly ash based geopolymer for 3D concrete printing. Ceram Int (2018) 44:10258–65. doi:10.1016/j.ceramint.2018.03.031

9. Zandifaez P, Asadi Shamsabadi E, Akbar Nezhad A, Zhou H, Dias-da-Costa D. AI-Assisted optimisation of green concrete mixes incorporating recycled concrete aggregates. Constr Build Mater (2023) 391:131851. doi:10.1016/j.conbuildmat.2023.131851

10. DeRousseau MA, Kasprzyk JR, Srubar WV. Computational design optimization of concrete mixtures: a review. Cem Concr Res (2018) 109:42–53. doi:10.1016/j.cemconres.2018.04.007

11. Shariati M, Mafipour MS, Mehrabi P, Ahmadi M, Wakil K, Trung NT, et al. Prediction of concrete strength in presence of furnace slag and fly ash using Hybrid ANN-GA (Artificial Neural Network-Genetic Algorithm). Smart Struct Syst (2020) 25. doi:10.12989/sss.2020.25.2.183

12. Chithra S, Kumar SRRS, Chinnaraju K, Alfin Ashmita F. A comparative study on the compressive strength prediction models for High Performance Concrete containing nano silica and copper slag using regression analysis and Artificial Neural Networks. Constr Build Mater (2016) 114:528–35. doi:10.1016/j.conbuildmat.2016.03.214

13. Shen Y, Tang B, Li B, Tan Q, Wu Y. Remaining useful life prediction of rolling bearing based on multi-head attention embedded Bi-LSTM network. Measurement (Lond) (2022) 202:111803. doi:10.1016/j.measurement.2022.111803

14. Li K, Pan L, Guo X, Wang YF. Hybrid random aggregation model and Bayesian optimization-based convolutional neural network for estimating the concrete compressive strength. Computer-Aided Civil Infrastructure Eng (2024) 39:559–74. doi:10.1111/mice.13096

15. Jin L, Zhang Y, Liu P, Fan T, Wu T, Wu Q. Carbon-footprint based concrete proportion design using LSTM and MOPSO algorithms. Mater Today Commun (2024) 38:107837. doi:10.1016/j.mtcomm.2023.107837

16. An Y, Xia X, Chen X, Wu FX, Wang J. Chinese clinical named entity recognition via multi-head self-attention based BiLSTM-CRF. Artif Intell Med (2022) 127:102282. doi:10.1016/j.artmed.2022.102282

17. Wu J, Hu R, Xiao Z, Chen J, Liu J. Vision Transformer-based recognition of diabetic retinopathy grade. Med Phys (2021) 48:7850–63. doi:10.1002/mp.15312

18. Jiang C, Fan K, Wu F, Chen D. Experimental study on the mechanical properties and microstructure of chopped basalt fibre reinforced concrete. Mater Des (2014) 58:187–93. doi:10.1016/j.matdes.2014.01.056

19. Thomas C, Setién J, Polanco JA, Alaejos P, Sánchez De Juan M. Durability of recycled aggregate concrete. Constr Build Mater (2013) 40:1054–65. doi:10.1016/j.conbuildmat.2012.11.106

20. Provis JL, Myers RJ, White CE, Rose V, Van Deventer JSJ. X-ray microtomography shows pore structure and tortuosity in alkali-activated binders. Cem Concr Res (2012) 42:855–64. doi:10.1016/j.cemconres.2012.03.004

21. Shaikh FUA, Supit SWM. Mechanical and durability properties of high volume fly ash (HVFA) concrete containing calcium carbonate (CaCO3) nanoparticles. Constr Build Mater (2014) 70:309–21. doi:10.1016/j.conbuildmat.2014.07.099

22. Xiao J, Qiang C, Nanni A, Zhang K. Use of sea-sand and seawater in concrete construction: current status and future opportunities. Constr Build Mater (2017) 155:1101–1111. doi:10.1016/j.conbuildmat.2017.08.130

23. Maes M, De Belie N. Resistance of concrete and mortar against combined attack of chloride and sodium sulphate. Cem Concr Compos (2014) 53:59–72. doi:10.1016/j.cemconcomp.2014.06.013

24. Chen N, Zhao S, Gao Z, Wang D, Liu P, Oeser M, et al. Virtual mix design: prediction of compressive strength of concrete with industrial wastes using deep data augmentation. Constr Build Mater (2022) 323:126580. doi:10.1016/j.conbuildmat.2022.126580

25. Hoang ND. Machine learning-based estimation of the compressive strength of self-compacting concrete: a multi-dataset study. Mathematics (2022) 10:3771. doi:10.3390/math10203771

26. Chen H, Yang J, Chen X. A convolution-based deep learning approach for estimating compressive strength of fiber reinforced concrete at elevated temperatures. Constr Build Mater (2021) 313:125437. doi:10.1016/j.conbuildmat.2021.125437

27. Sui S, Shan Y, Li S, Geng Y, Wang F, Liu Z, et al. Investigation on chloride migration behavior of metakaolin-quartz-limestone blended cementitious materials with electrochemical impedance spectroscopy method. Case Stud Construction Mater (2024) 20:e03064. doi:10.1016/j.cscm.2024.e03064

28. Maraghechi H, Avet F, Wong H, Kamyab H, Scrivener K. Performance of Limestone Calcined Clay Cement (LC3) with various kaolinite contents with respect to chloride transport. Mater Struct (2018) 51:125. doi:10.1617/s11527-018-1255-3

29. Ramezanianpour AA, Ghiasvand E, Nickseresht I, Mahdikhani M, Moodi F. Influence of various amounts of limestone powder on performance of Portland limestone cement concretes. Cem Concr Compos (2009) 31:715–20. doi:10.1016/j.cemconcomp.2009.08.003

30. Diab AM, Abd Elmoaty AEM, Aly AA. Long term study of mechanical properties, durability and environmental impact of limestone cement concrete. Alexandria Eng J (2016) 55:1465–82. doi:10.1016/j.aej.2016.01.031

31. Fanghui H, Qiang W, Mutian L, Yingjun M. Early hydration properties of composite binder containing limestone powder with different finenesses. J Therm Anal Calorim (2016) 123:1141–51. doi:10.1007/s10973-015-5088-9

32. Ghafoori N, Spitek R, Najimi M. Influence of limestone size and content on transport properties of self-consolidating concrete. Constr Build Mater (2016) 127:588–95. doi:10.1016/j.conbuildmat.2016.10.051

Keywords: durability, neural network model, genetic algorithm, mix design optimization, multi-head attention mechanism

Citation: Jiang C (2025) Research on the optimization of mortar mix proportion based on neural network models and genetic algorithm. Front. Phys. 13:1557999. doi: 10.3389/fphy.2025.1557999

Received: 09 January 2025; Accepted: 13 February 2025;

Published: 05 March 2025.

Edited by:

Wenxiang Xu, Hohai University, ChinaReviewed by:

Fengjuan Wang, Southeast University, ChinaAng Liu, Qingdao University of Technology, China

Copyright © 2025 Jiang. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Chunyu Jiang, MTUwNjQwOTIzMDFAMTYzLmNvbQ==

Chunyu Jiang

Chunyu Jiang