94% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

ORIGINAL RESEARCH article

Front. Phys., 11 April 2025

Sec. Fluid Dynamics

Volume 13 - 2025 | https://doi.org/10.3389/fphy.2025.1533252

This article is part of the Research TopicDynamics of Complex FluidsView all 7 articles

The study of stochastic non-Newtonian fluid flows in porous media has significant applications in engineering and scientific fields, particularly in geophysical transport, biomedical flows, and industrial filtration systems. This research develops a high-order numerical scheme to solve deterministic and stochastic partial differential equations governing the Darcy–Forchheimer flow of Williamson fluid over a stationary sheet. This study aims to formulate and validate a computationally efficient two-stage method that accurately captures the effects of non-Newtonian behavior, porous media resistance, and stochastic perturbations. The proposed two-stage numerical method integrates a modified time integrator with a second-stage Runge-Kutta scheme, ensuring second-order accuracy in time for deterministic problems. The Euler-Maruyama approach handles Wiener processes for stochastic models, providing robust performance under random fluctuations. A compact sixth-order spatial discretization scheme enhances solution accuracy while maintaining computational efficiency. Numerical experiments, including Stokes’ first problem, demonstrate the superior accuracy and reliability of the proposed method compared to existing second-order Runge-Kutta schemes. The results confirm that the technique effectively captures complex interactions between deterministic and stochastic effects while significantly improving computational efficiency. This study advances numerical techniques for stochastic fluid dynamics, providing a practical framework for modeling and analyzing non-Newtonian fluid flows in porous media with real-world applications in engineering, geophysics, and industrial systems.

In recent years, the investigation of non-Newtonian fluids has gained considerable interest owing to its complex behaviour, which is crucial in numerous engineering and commercial applications, including petroleum extraction, polymer processing, and biological systems. The Williamson fluid is a non-Newtonian fluid distinguished by its shear-thinning characteristics. The flow characteristics of Williamson fluids, particularly when affected by stochastic factors, pose distinct challenges in modelling and computation because of the nonlinear structure of their governing equations. Numerical strategies are essential for achieving approximate solutions when analytical methods are impractical.

We formulate a resilient two-stage predictor-corrector methodology to tackle the flow’s stochastic characteristics. The predictor phase calculates the solution at an intermediate temporal level, yielding a preliminary estimate, while the corrector phase enhances this solution at the following temporal level. This method facilitates precise time-stepping for the stochastic differential equations that dictate the flow of Williamson fluid, rendering it appropriate for managing the system’s intrinsic uncertainties and unpredictable variations.

Here are the main points of this work:

1. We developed a two-stage numerical scheme for solving deterministic and stochastic partial differential equations with second-order temporal and sixth-order spatial accuracy.

2. We Integrated a compact sixth-order scheme for spatial discretization, enabling efficient handling of spatial gradients in the Darcy–Forchheimer model.

3. In the context of Williamson fluid flow, a thorough examination of the interplay between concentration and temperature gradients, magnetic fields, and the effects of porous media.

4. Comparative analysis of the proposed scheme with the existing second-order Runge-Kutta method, demonstrating superior accuracy in solving the Stokes first problem for the Williamson fluid.

Non-Newtonian fluids exhibit distinct rheological characteristics, defined by their shear-thinning or shear-thickening behaviour. The characteristics mentioned above confer benefits in domains such as fluid transport, mixing, and heat transfer, thereby enhancing the efficiency and performance of various processes. Consequently, these fluids play an essential role in shaping and advancing the domain of modern engineering and industrial methodologies. Recently, a growing body of research has focused on a range of non-Newtonian models, encompassing the viscoelastic system [1], Maxwell system [2], Casson system [3], power-law system [4], Carreau system [5], and Eyring-Powell system [6].

The Williamson model, a significant element in emulsion sheet manufacture, exemplifies one category of such models. This notion is applied in various contexts, including plasma flow, photographic film production, and the understanding of hemodynamics. The shear-thinning properties of the Williamson [7] model in non-Newtonian fluids are well-known. He stressed how this model is crucial for differentiating plastic flow from viscous flow. In addition, he found that this model is just as important in bioengineering, especially for evaluating hemodialysis applications and mass and heat transport in blood arteries. Due to its significance, numerous scholars have dedicated their time and resources to investigating the dynamics of Williamson fluid flow across various conditions, demonstrating the research community’s deep interest and commitment to comprehensively understanding this fluid type. Owing to their importance, these fluids are essential in numerous vital technical and industrial domains. The homotopy analysis method can be used for quantitative analysis [8], in stagnation point flow [9], chemical reactions on a stretching cylinder [10], in porous media [11], with the effects of viscous dissipation and slip velocity [12], with thermal radiation and chemical reaction influences [13], under multiple slip boundary conditions [14], and in nanofluid scenarios with magnetic field effects [15].

According to Williamson, the Williamson fluid model is one of the simplest non-Newtonian models that attempts to capture the behaviour of viscoelastic shear-thinning [16]. A chemical process was used by Krishnamurthy et al. [17] to demonstrate the flow of thermally radiative Williamson fluid on a stretched sheet. Their findings demonstrated a decrease in fluid temperature attributable to the existence of the Williamson parameter. Khan et al. [18] illustrated the effects of slip flow of Williamson nanofluid within a porous media. The surface drag force diminishes as the Williamson fluid parameter increases. Hayat et al. [19] examined a Williamson fluid’s 2D unsteady radiative flow on a porous stretched surface. As the Williamson parameter increases, the fluid velocity decreases. In their investigation of Williamson fluid flow across a stretching sheet, Nadeem et al. [20] discovered that the skin friction coefficient decreases as the Williamson parameter increases. Apply the Keller box method to investigate the MHD flow of Williamson fluid across a stretching sheet, as demonstrated by Salahuddin et al. [21]. Their results suggest that the Williamson fluid parameter decreases fluid velocity. Refs. [22, 23] contain only a few substantial analyses of this subject matter.

Many industrial processes include fluids passing through porous media. Its few uses include drying wood, storing nuclear waste, processing food, refining oil, facilitating drainage, and watering crops. Darcy’s principle analyses flow behaviour under low porosity and small velocity conditions. The Darcy principle didn't work when the Reynolds number amount was more than 1. Forchheimer [24] included the square velocity element in the momentum equation to get around this restriction. Then, for operations involving higher Reynolds numbers, this is referred to as the Forchheimer number. The Darcy–Forchheimer flow of a viscous fluid across a plate was examined by Mukhopadhyay et al. [25] using numerical analysis. The researchers found that lowering the permeability parameter made the fluid colder. The 3D Williamson nanomaterial flow over a Darcy–Forchheimer porous media is shown by Hayat et al. [26]. As the Forchheimer number increases, the surface shear stress decreases. Khan et al. [27] visualized the Darcy–Forchheimer flow of a viscous fluid undergoing heterogeneous-homogeneous chemical processes. The availability of the Darcy number causes a noticeable reduction in the fluid speed, as their data demonstrate. An analysis of the hybrid nanofluid’s Darcy–Forchheimer and slip flow on a revolving disc is carried out by Haider et al. [28]. They demonstrated that a greater estimate of Forchheimer enhances the fluid temperature. Sadiq et al. [29] identified a steady 3D Darcy–Forchheimer flow of carbon nanotubes on a spinning disc in Refs. [30–33], you can find a compilation of significant research on these topics.

A viscous fluid that cannot be compressed and is incompressible is described by the Navier-Stokes equation. Despite the notion that the Navier-Stokes equation is intrinsically deterministic, the fact that certain solutions behave randomly may lead to fresh insights regarding the beginning of turbulence. However, from a purely mathematical point of view, whether solutions to the equation presented above exist and whether they are smooth is still largely unsolved. In the following paragraphs, we will discuss several approaches to analyzing the solutions to the above equation, including a random component.

One famous example of a deterministic equation that conceals unpredictability is the famous Schrödinger equation. Any quantum physics experiment will show some degree of blatant randomness, even though it is not based on mathematical probability theory. Notwithstanding this inexplicable dilemma, Quantum Theory has yielded an impressive suite of control tools, notably the inversion of solutions to classical equations of motion that are (in principle) differentiable and instead display uncertainty. Simulating “dry water” (Von Neumann) only adds another layer of complexity to the already complicated Euler equation.

There seems to be no proof currently that it does not produce singularities [34]. There are other ways to generate randomness, although errors in the initial conditions could also be a source of uncertainty. This calls for applying statistical approaches, such as tracking the evolution of a probability measure in conjunction with the pertinent physical beginning data. See, for instance [35, 36], for examples of how this fits into the statistical approach to turbulence that began in the 19th century. A variety of stochastic diffusion-based Langevin dynamics may account for both equilibrium and non-equilibrium dynamics, as well as Kraichnan’s model in turbulent advection [37]. Nevertheless, the chosen numerical model may include uncertainty (see [38, 39] for further information on this subject in climate modelling).

A popular method for dealing with stochasticity is introducing stochastic partial differential equations by applying random forces to the Navier-Stokes equation. After the revolutionary mathematical work, a deluge of material covers the subject [40]. Even though turbulence usually introduces stochasticity at the Eulerian level, models of the Langevin type that include smooth Lagrangian trajectories and stochastic velocities have been evaluated [41]. D.D. Holm more recently used Lie transfer to introduce stochastic advection [42]. Stochastic partial differential equations describe the resultant motion, and the approach is also Eulerian.

This space cannot accommodate any stochastic methods related to fluid dynamics. A limited number of subjects and their corresponding references have been chosen. It is important to note that several fascinating formulas exist for probabilistic representations. This is a recognized practice in stochastic analysis. A potential application lies in fluid dynamics, where it may be utilized to depict the anticipated values of functionals of stochastic processes as solutions to partial differential equations. Three distinct methodologies are presented: one employs a probabilistic model of the vorticity field, another utilizes branching processes alongside the Fourier transform, and the third implements Lagrangian diffusion processes. For additional information, go to [43–45] accordingly.

This study offers two numerical schemes that can be used to discretize partial differential equations. The scheme is constructed using Taylor series expansion and then implemented to solve the flow problem. The non-Newtonian, incompressible, laminar fluid flow is considered over the flat plate. The governing equations are reduced to dimensionless partial ones rather than ordinary ones. Then, these dimensionless equations are solved using the proposed scheme.

The proposed scheme is applicable for solving stochastic differential equations; however, a scheme for the deterministic model must be constructed before its construction. The scheme is a bifurcated predictor-corrector framework. The predictor scheme determines the answer at a specified time level, whereas the corrector scheme identifies the solution at the subsequent time level. To propose a scheme, consider the following differential equations.

where

Step 1: Predictor Stage:

Using an explicit exponential integration approach, the predictor stage approximates the solution at an intermediate time step.

The symbol

Step 2: Corrector Stage:

The corrector stage refines the predicted solution by incorporating further corrections derived using the Taylor series expansion. The corrector stage can be expressed as:

The Taylor series method will determine the parameter in Equation 3.

It is obtained using predictor stage (Equation 2) in Equation 3.

The Taylor series expansion for

By inserting the Taylor series expansion (Equation 5) into Equation 4 as

By equating the terms

Upon solving Equation 7, the solution can be written as

These coefficients from Equation 8 are then used in the corrector equation to improve the accuracy of the final solution.

The semi-discretized scheme for Equation 1 is written as

Equations 9, 10 are used for time discretization for Equation 1. To discretize space, the variable compact scheme is employed. The compact scheme for Equation 1 can be written as Equations 11, 12

Where

Where

This compact discretization method ensures higher-order spatial accuracy while maintaining computational efficiency. Better resolution of gradients and boundary layer effects.

The primary objective of this project is to develop a framework for stochastic partial differential equations. To accomplish this, consider the subsequent stochastic partial differential equation.

Where

The first stage or predictor stage of the proposed scheme for Equation 14 is the same as the first stage of the deterministic model (1). The second stage for stochastic differential Equation 14 can be written as

Where

The predictor stage provides a first estimate of the solution, incorporating explicit nonlinear effects. The corrector stage refines the solution using a higher-order correction term, ensuring improved accuracy.

The stochastic term

The Von Neumann stability analysis, or Fourier series analysis, is used to assess the stability of finite difference schemes. Using this stability analysis, the difference equation is transformed into trigonometric equations. Further stability conditions are imposed into the trigonometric equations. The analysis provides the exact condition for linear partial differential equations and estimates the actual stability condition for nonlinear partial differential equations. To apply this analysis, consider the following transformations

Where

Applying transformations (Equation 16) and (Equation 17) into the predictor stage of the proposed scheme (Equation 11) yields

Re-write Equation 18 as

Where

Incorporating transformation (Equations 16, 17) into the second corrector stage of the scheme (Equation 15) gives using

By using the first stage (Equation 19) in the second stage (Equation 20) it yields

Re-write Equation 21 as

Where

The amplification factor can be expressed as

By using the expected value of the square of the amplification factor, Equation 23 is written as

If

The scheme will remain stable in the mean square sense if it meets conditions (Equation 25); otherwise, the solution will be unstable.

Theorem 1. The proposed time and compact scheme in space are consistent in the mean square sense.

Proof: Let

Where

By subtracting Equation 27 from Equation 26 and then applying the absolute value of the square of difference it yields

Re-write Equation 28 as

Now consider the inequality

The use of inequality (Equation 30) in inequality (Equation 29) yields

Upon applying the

Thus, the proposed scheme in time and compact spatial discretization is consistent in the mean square sense proved by Equation 32.

Here, we provide a comparative summary highlighting the stability criteria of our proposed scheme versus alternative methods. Below, we outline a summary of Table 1 comparing the stability characteristics of the proposed method against existing numerical schemes.

The Von Neumann stability analysis is applied to derive the stability condition. The stochastic nature of the problem requires the scheme to be stable in the mean-square sense. The derived stability condition is:

Table 1 effectively compares the stability criteria, stochastic effects, accuracy, and efficiency of the proposed method versus alternative approaches. The proposed scheme ensures stability in stochastic problems and offers superior accuracy and computational efficiency.

Examine a laminar, unstable, incompressible Williamson fluid above a fixed plate. The fluid flow is propelled by temperature and concentration gradients. Let

Here is the explanation of each equation used in problem formulation:

Momentum (Velocity) Equation 33:

Energy (Heat Transfer) Equation 34:

Concentration (Mass Diffusion) Equation 35:

Subject to initial and boundary conditions

Let

where

The governing Equations 33–36 are reduce to Equations 38–40

subject to the dimensionless initial and boundary conditions

Where in Equation 41

The dimensionless local Nusselt and Sherwood numbers are given as Equation 42

These describe the rate of heat and mass transfer at the surface.

The stochastic model is written as Equations 43–45

Subject to the same initial and boundary conditions for the deterministic model.

We present a detailed simulation study with the following objectives:

The proposed computational approach is validated for both deterministic and stochastic models. For deterministic problems, the method exhibits second-order accuracy, while it demonstrates improved accuracy for stochastic differential equations compared to the conventional Euler-Maruyama method. The Euler-Maruyama scheme is an adaptation of the classical Euler method that incorporates the Wiener process term, efficiently managed in our approach through a two-stage process. The first phase involves modifying the exponential integrator, while the second phase employs the Runge-Kutta method. The results confirm that the scheme effectively captures deterministic and stochastic effects, ensuring numerical stability in the mean-square sense for stochastic diffusion equations.

The stability of the proposed scheme is verified for the scalar stochastic diffusion equation. Unlike traditional approaches, the scheme preserves consistency in the mean and does not require linearization to address nonlinear differential equations. The explicit nature of the scheme ensures efficient computation by solving the differential equations in two distinct phases: the first stage excludes the Wiener process, while the second stage incorporates it. Numerical simulations confirm the scheme’s robustness in handling nonlinear Darcy–Forchheimer flows and effectively capturing oscillatory boundary conditions.

Figure 2 illustrates the impact of the Weissenberg number

Figure 3 illustrates the impact of the magnetic field parameter

Figure 4 illustrates the effect of the Forchheimer number

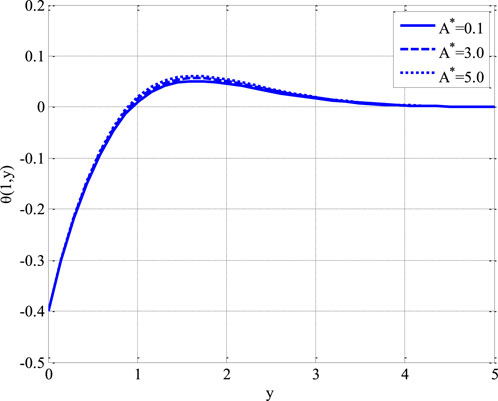

Figure 5 illustrates the effect of the coefficient of the space-dependent term in the heat source

Figure 5. Effect of coefficient of space dependent term in heat source on temperature profile using

Figure 6 illustrates the effect of the reaction rate parameter

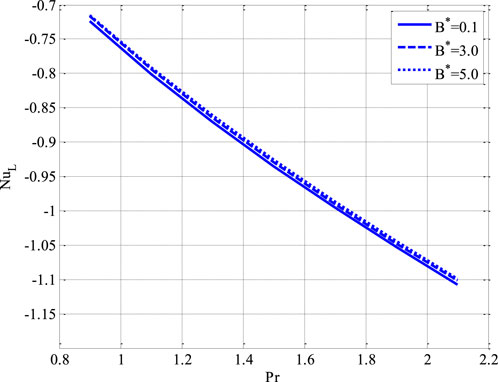

Figure 6 illustrates the effect of the Prandtl number

Figure 7. Effect of Prandtl number and coefficient of temperature-dependent term of heat source on local Nusselt number using

Figure 8 illustrates the effect of the Schmidt number

Figure 9 presents a contour plot representing the velocity distribution in a non-Newtonian Williamson fluid flow through a porous medium under various physical effects. The parameters used in the simulation are:

Figure 10 presents a contour plot illustrating the temperature distribution in a non-Newtonian Williamson fluid flow through a porous medium under various physical parameters. The simulation is conducted with the following parameter values:

Figure 11 presents a contour plot illustrating the concentration distribution in a non-Newtonian Williamson fluid flowing through a porous medium. The concentration field is influenced by various physical parameters, which are set as follows:

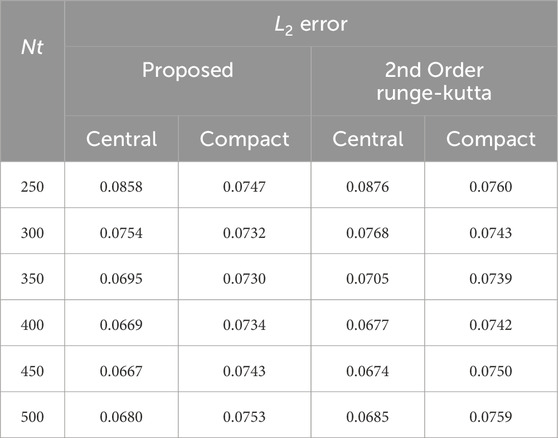

Table 2 presents a comparative analysis of the proposed numerical scheme and the existing second-order Runge-Kutta (RK2) method for solving Stokes’ first problem. For comparison purposes, the corrector stage of the proposed scheme is replaced with the following stage.

Table 2. Comparison of proposed and existing second-order runge-kutta method for Stokes’ first problem using

The comparison is performed based on

These results validate the effectiveness of the two-stage computational method developed in this study, demonstrating its superior numerical performance in solving stochastic Darcy–Forchheimer non-Newtonian flows.

This research introduces an innovative computational method for addressing deterministic and stochastic partial differential equations, specifically emphasizing the stochastic Darcy–Forchheimer flow of Williamson fluid over a stationary surface. The suggested two-stage approach integrates a modified time integrator with a second-stage Runge-Kutta algorithm, attaining second-order temporal precision for deterministic models. A sixth-order compact approach is utilized to tackle spatial discretization difficulties, providing great accuracy and processing efficiency. The strategy employs the Euler-Maruyama method to manage Wiener processes in stochastic models, facilitating flexibility to fluctuations in fluid flow dynamics. A numerical scheme has been proposed for solving stochastic time-dependent partial differential equations. The scheme was explicit, and it was comprised of two stages. The compact scheme was chosen to discretize space variable(s). The stability and consistency in the mean square sense of the scheme were presented. The scheme did not require any other scheme to get a solution to the problem. The proposed scheme is implemented in a dimensionless stochastic model of Williamson fluid dynamics, integrating essential physical phenomena such as Darcy–Forchheimer drag and the shear-thinning characteristics of the fluid. Numerical studies on the Stokes first issue indicate that the suggested technique surpasses current second-order Runge-Kutta methods in accuracy, especially in describing the complex relationship between deterministic and stochastic factors affecting the flow. The concluding points can be expressed as.

1. The modification of the proposed scheme performed better than the existing second-order Runge-Kutta method.

2. The compact sixth-order spatial discretization enhances solution accuracy without introducing excessive computational overhead, making it well-suited for high-resolution simulations.

3. Velocity profile declined on average due to the increase in Weissenberg’s number.

4. The velocity profile had dual behaviour on average due to the rising Forchheimer number.

5. The concentration profile declined by raising the reaction rate parameter.

6. The comparative analysis highlights the superior performance of the proposed scheme, offering a reliable alternative to existing methods for solving similar problems.

Finally, a computationally efficient and highly accurate method for non-Newtonian fluids in porous media is introduced, expanding the current state-of-the-art in stochastic fluid dynamics numerical techniques. This paradigm could be further developed in future studies to examine various types of non-Newtonian fluids and more complicated flow configurations, including three-dimensional geometries or transient boundary conditions. Furthermore, there is still room for improvement in the scheme’s optimization for real-time applications and large-scale simulations.

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

MA: Methodology, Software, Supervision, Validation, Visualization, Writing–original draft, Writing–review and editing. KA: Funding acquisition, Investigation, Project administration, Resources, Writing–original draft, Writing–review and editing. YN: Conceptualization, Data curation, Methodology, Validation, Writing–original draft, Writing–review and editing.

The author(s) declare that financial support was received for the research, authorship, and/or publication of this article.

The authors would like to acknowledge the support of Prince Sultan University for paying the Article Processing Charges (APC) of this publication.

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

The author(s) declare that no Generative AI was used in the creation of this manuscript.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

1. Cortell R. Similarity solutions for flow and heat transfer of a viscoelastic fluid over a stretching sheet. Int J Nonlinear Mech (1994) 29:155–61. doi:10.1016/0020-7462(94)90034-5

2. Mahmoud MAM. The effects of variable fluid properties on MHD Maxwell fluids over a stretching surface in the presence of heat generation/absorption. Chem Eng Comm (2011) 198:131–46. doi:10.1080/00986445.2010.500148

3. Pramanik S. Casson fluid flow and heat transfer past an exponentially porous stretching surface in the presence of thermal radiation. Ain Shams Eng J (2014) 5:205–12. doi:10.1016/j.asej.2013.05.003

4. Ahmed F, Iqba M. MHD power-law fluid flow and heat transfer analysis through Darcy Brinkman porous media in the annular sector. Int J Mech Sci. (2017) 130:508–17. doi:10.1016/j.ijmecsci.2017.05.042

5. Megahed AM. Carreau fluid flow due to nonlinearly stretching sheet with thermal radiation, heat flux, and variable conductivity. Appl Math Mech (2019) 40:1615–24. doi:10.1007/s10483-019-2534-6

6. Bilal M, Ashbar S. Flow and heat transfer analysis of Eyring-Powell fluid over stratified sheet with mixed convection. J Egypt Math Soc (2020) 28:40. doi:10.1186/s42787-020-00103-6

7. Williamson RV. The flow of pseudoplastic materials. Ind Eng Chem Res. (1929) 21:1108–11. doi:10.1021/ie50239a035

8. Nadeem S, Hussain ST, Lee C. Flow of a Williamson fluid over a stretching sheet. Braz J Chem Eng (2013) 30:619–25. doi:10.1590/s0104-66322013000300019

9. Khan NA, Khan HA. A boundary layer flows of non-Newtonian Williamson fluid. Nonlinear Eng (2014) 3:107–15. doi:10.1515/nleng-2014-0002

10. Malik M, Salahuddin T, Hussain A, Bilal S, Awais M. Homogeneous heterogeneous reactions in Williamson fluid model over a stretching cylinder by using Keller box method. AIP Adv (2015) 5:107227. doi:10.1063/1.4934937

11. Khudair WS, Al-Khafajy DGS. Influence of heat transfer on magnetohydrodynamics oscillatory flow for Williamson fluid through a porous medium. Iraqi J Sci (2018) 59:389–97. doi:10.24996/ijs.2018.59.1B.18

12. Megahed AM. Steady flow of MHD Williamson fluid due to a continuously moving surface with viscous dissipation and slip velocity. Int J Mod Phys C. (2020) 31:2050019. doi:10.1142/s0129183120500199

13. Humane PP, Patil VS, Patil AB. Chemical reaction and thermal radiation effects on magnetohydrodynamics flow of Casson-Williamson nanofluid over a porous stretching surface. Proc Instit Mech Eng E J Process Mech Eng (2021) 235(6):2008–18. doi:10.1177/09544089211025376

14. Humane PP, Patil VS, Rajput GR, Shamshuddin M. Dynamics of multiple slip boundaries effect on MHD Casson-Williamson double-diffusive nanofluid flow past an inclined magnetic stretching sheet. Proc Instit Mech Eng Part E J Process Mech Eng (2022) 236(5):1906–26. doi:10.1177/09544089221078153

15. Patil VS, Humane PP, Patil AB. MHD Williamson nanofluid flow past a permeable stretching sheet with thermal radiation and chemical reaction. Int J Model Simulat (2023) 43(3):185–99. doi:10.1080/02286203.2022.2062166

16. Williamson RV. The flow of pseudoplastic materials. Ind Eng Chem Res (1929) 21(11):1108–11. doi:10.1021/ie50239a035

17. Krishnamurthy MR, Prasannakumara BC, Gireesha BJ, Gorla RSR. Effect of chemical reaction on MHD boundary layer flow and melting heat transfer of Williamson nanofluid in porous medium. Eng Sci Technol Int J (2016) 19(1):53–61. doi:10.1016/j.jestch.2015.06.010

18. Khan MI, Alzahrani F, Hobiny A, Ali Z. Modeling of Cattaneo-Christov double diffusions (CCDD) in Williamson nanomaterial slip flow subject to porous medium. J Mater Res Technology (2020) 9(3):6172–7. doi:10.1016/j.jmrt.2020.04.019

19. Hayat T, Shafiq A, Alsaedi A. Hydromagnetic boundary layer flow of Williamson fluid in the presence of thermal radiation and Ohmic dissipation. Alexandria Eng J (2016) 55(3):2229–40. doi:10.1016/j.aej.2016.06.004

20. Nadeem S, Hussain ST, Lee C. Flow of a Williamson fluid over a stretching sheet. Braz J Chem Eng (2013) 30(3):619–25. doi:10.1590/s0104-66322013000300019

21. Salahuddin T, Malik MY, Arif H, Bilal S, Awais M. MHD flow of Cattanneo-Christov heat flux model for Williamson fluid over a stretching sheet with variable thickness: using numerical approach. J Magnetism Magn Mater (2016) 401(1):991–7. doi:10.1016/j.jmmm.2015.11.022

22. Mohanty D, Mahanta G, Shaw S, Sibanda P. Thermal and irreversibility analysis on Cattaneo–Christov heat flux-based unsteady hybrid nanofluid flow over a spinning sphere with interfacial nanolayer mechanism. J Therm Anal Calorim (2023) 148(21):12269–84. doi:10.1007/s10973-023-12464-y

23. Kumar NN, Sastry DRVSRK, Shaw S. Irreversibility analysis of an unsteady micropolar CNT-blood nanofluid flow through a squeezing channel with activation energy-Application in drug delivery. Computer Methods Programs Biomed (2022) 226:107156. doi:10.1016/j.cmpb.2022.107156

25. Mukhopadhyay S, De PR, Bhattacharyya K, Layek GC. Forced convective flow and heat transfer over a porous plate in a Darcy-Forchheimer porous medium in presence of radiation. Meccanica (2011) 47(1):153–61. doi:10.1007/s11012-011-9423-3

26. Hayat T, Aziz A, Muhammad T, Alsaedi A. Darcy–Forchheimer three-dimensional flow of Williamson nanofluid over a convectively heated nonlinear stretching surface. Commun Theor Phys (2017) 68(3):387–94. doi:10.1088/0253-6102/68/3/387

27. Khan MI, Hayat T, Alsaedi A. Numerical analysis for Darcy-Forchheimer flow in presence of homogeneous-heterogeneous reactions. Results Phys (2017) 7:2644–50. doi:10.1016/j.rinp.2017.07.030

28. Haider F, Hayat T, Alsaedi A. Flow of hybrid nanofluid through Darcy-Forchheimer porous space with variable characteristics. Alexandria Eng J (2021) 60(3):3047–56. doi:10.1016/j.aej.2021.01.021

29. Sadiq MA, Haider F, Hayat T, Alsaedi A. Partial slip in Darcy-Forchheimer carbon nanotubes flow by rotating disk. Int Commun Heat Mass Transfer (2020) 116. doi:10.1016/j.icheatmasstransfer.2020.104641

30. Mohanty D, Mahanta G, Shaw S. Analysis of irreversibility for 3-D MHD convective Darcy–Forchheimer Casson hybrid nanofluid flow due to a rotating disk with Cattaneo–Christov heat flux, Joule heating, and nonlinear thermal radiation. Numer Heat Transfer, B: Fundamentals (2023) 84(2):115–42. doi:10.1080/10407790.2023.2189644

31. Nayak MK, Shaw S, Ijaz Khan M, Pandey VS, Nazeer M. Flow and thermal analysis on Darcy-Forchheimer flow of copper-water nanofluid due to a rotating disk: a static and dynamic approach. J Mater Res Technology (2020) 9(4):7387–408. doi:10.1016/j.jmrt.2020.04.074

32. Mohanty D, Mahanta G, Chamkha AJ, Shaw S. Numerical analysis of interfacial nanolayer thickness on Darcy-Forchheimer Casson hybrid nanofluid flow over a moving needle with Cattaneo-Christov dual flux. Numer Heat Transfer, A: Appl (2023) 1–25. doi:10.1080/10407782.2023.2263906

33. Umavathi JC, Ojjela O, Vajravelu K. Numerical analysis of natural convective flow and heat transfer of nanofluids in a vertical rectangular duct using Darcy-Forchheimer-Brinkman model. Int J Therm Sci (2017) 111:511–24. doi:10.1016/j.ijthermalsci.2016.10.002

34. Nadeem S, Ishtiaq B, Alzabut J, Ghazwani HA. Entropy generation for exact irreversibility analysis in the MHD channel flow of Williamson fluid with combined convective-radiative boundary conditions. Heliyon (2024) 10(4):e26432. doi:10.1016/j.heliyon.2024.e26432

35. Marchioro C, Pulvirenti M. Vortex methods in two-dimensional fluid mechanics. In: Lecture notes in physics. Berlin, Germany: Springer (1984).

36. Vishik MI, Komechi AI, Fursikov AI. Some mathematical problems of statistical hydrodynamics. Russ Math Surv (1979) 34:149–234. doi:10.1070/rm1979v034n05abeh003906

37. Gawedzki K. Soluble models of turbulent transport. In: S Nazarenko, and O Zaboronski, editors. Non-equilibrium statistical mechanics and turbulence. Cambridge, UK: Cambridge Uniersity Press (2008). p. 47–107.

38. Khan AA, Zafar S, Khan A, Abdeljawad T. Tangent hyperbolic nanofluid flow through a vertical cone: unraveling thermal conductivity and Darcy–Forchheimer effects. Mod Phys Lett B (2024) 39:2450398. doi:10.1142/s0217984924503986

39. Fatima N, Kousar N, Ur Rehman K, Shatanawi W. Computational analysis of heat and mass transfer in magnetized Darcy-forchheimer hybrid nanofluid flow with porous medium and slip effects. CMES-Computer Model Eng and Sci (2023) 137(3):2311–30. doi:10.32604/cmes.2023.026994

40. Bensoussan A, Teman R. Équations stochastiques du type Navier–Stokes. J Funct Anal (1973) 13:195–222. doi:10.1016/0022-1236(73)90045-1

41. Pope SB. On the relationship between stochastic Lagrangian models of turbulence and second-moment closures. Phys Fluids (1994) 6:973–85. doi:10.1063/1.868329

42. Holm DD. Variational principles for stochastic fluid dynamics. Proc R Soc A (2015) 471:20140963. doi:10.1098/rspa.2014.0963

43. Bharathi V, Prakash J. Zeta potential and activation energy effects in an EMHD non-Newtonian nanofluid flow over a wedge with Darcy-Forchheimer porous medium. Numer Heat Transfer, Part A: Appl (2024) 1–28. doi:10.1080/10407782.2024.2316212

44. Prakash J, Tripathi D, Bég OA. Computation of EMHD ternary hybrid non-Newtonian nanofluid over a wedge embedded in a Darcy-Forchheimer porous medium with zeta potential and wall suction/injection effects. Int J Ambient Energ (2023) 44(1):2155–69. doi:10.1080/01430750.2023.2224339

45. Lund LA, Fadhel MA, Prakash J, Dhange M, Verma A, Ramesh K. Duality and stability analysis of radiatively magnetized rotating CNTs/C2 H6 O2 + H2 O nanofluid flow over a stretching/shrinking surface. Int J Appl Comput Mathematics (2024) 10(1):25. doi:10.1007/s40819-023-01661-w

46. Ahmed OS, Eldabe NT, Abou-zeid MY, El-kalaawy OH, Moawad SM. Numerical treatment and global error estimation for thermal electro-osmosis effect on non-Newtonian nanofluid flow with time periodic variations. Scientific Rep (2023) 13:14788. doi:10.1038/s41598-023-41579-3

Keywords: stochastic scheme, stability, consistency, Williamson fluid, Darcy Forchheimer flow, porous media, Stokes first problem

Citation: Arif MS, Abodayeh K and Nawaz Y (2025) A two-stage computational approach for stochastic Darcy-forchheimer non-newtonian flows. Front. Phys. 13:1533252. doi: 10.3389/fphy.2025.1533252

Received: 23 November 2024; Accepted: 05 March 2025;

Published: 11 April 2025.

Edited by:

Francisco Vega Reyes, University of Extremadura, SpainReviewed by:

Prakash Jayavel, Avvaiyar Government College for Women, IndiaCopyright © 2025 Arif, Abodayeh and Nawaz. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Muhammad Shoaib Arif, c2hvYWliLmFyaWZAbWFpbC5hdS5lZHUucGs=

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.