94% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

BRIEF RESEARCH REPORT article

Front. Phys., 23 March 2022

Sec. Interdisciplinary Physics

Volume 10 - 2022 | https://doi.org/10.3389/fphy.2022.856062

This article is part of the Research TopicMicroscopic Structure Effect on the Macroscopic Property of GeomaterialsView all 63 articles

Zi-jie Hong1,2

Zi-jie Hong1,2 Jian-ping Zuo2,3*

Jian-ping Zuo2,3*The effect of nano-clay (NC) on hydration and microstructure of grouting materials was investigated under different erosion conditions. Six different contents of NC specimens were prepared. This study investigated the effect of NC on the mechanical properties and microstructure of grouting materials under chloride ion erosion and standard curing conditions (SCCs), using ultrasonic pulse velocity (UPV), uniaxial compressive strength (UCS), Fourier transform infrared spectroscopy (FT-IR), and scanning electron microscopy (SEM). The experimental results demonstrated that the nano-core effect can promote the formation of the core reaction of grouting materials and accelerate the hydration process. With the NC increase, the hydration products of ettringite (AFt) and calcium silicate hydrate (C-S-H) also increases. Under chloride ion erosion, it was obtained that when NC was less than 2%, the UCS and UPV were improved. As the NC content is 2%, the hydration reaction is the most appropriate. However, under high humidity conditions, as the NC content is 1%, the amount and density of AFt increased and the formation of C-S-H gel enhanced. The hydration reaction inhibited, and the mechanical properties of grouting materials decreased when NC was further increased. It indicated that the complex underground engineering environment affected the hydration mechanism of nano-grouting materials.

There is an increasing demand for underground engineering in China, such as coal mines, subway repair, and tunnel reinforcement. Therefore, cement grouting materials are widely used in underground engineering to ensure the overall stability of the project [1, 2]. However, due to the complex conditions of the underground engineering, the existing cement grouting materials suffer several issues, such as low bearing capacity and easy craking. Efforts have been made to overcome these shortcomings. Nanomaterials are unique in that they have many different chemical and physical properties, such as small size, surface, and quantum effects, compared with traditional materials [3, 4]. Therefore, compared with ordinary material particles, nanomaterial particles have higher catalytic activity and chemical activity. With the development of nanotechnology, more and more nanomaterials have partially replaced cement and have been widely used in the modification of concrete materials, such as nano-clay [5], nano-graphene [6, 7], nano-TiO2 [8], nano-SiO2 [9], and carbon nanotubes (CNT) [10].

Liu et al. [11] showed that with an additional 1% nanoCaCO3, the strength was improved by 111 and 108% at 7 and 28 days by the cement mortar. Essawy et al. [12] showed that the strength of a cement specimen increased by 5% after adding 5 wt% nano TiO2. However, Hassan et al. [13] found that the compressive strength of 2% nano-TiO2 changed a little, even presented a decreasing trend. Nazari et al. [14] studied the influence of nano-Al2O3 on the compressive strength of concrete under different curing conditions, and the results showed that under saturated lime water and water curing conditions, the maximum dosage of nano-Al2O3 was 2 and 1%, respectively.

The aforementioned analysis indicated that the properties of nanomaterials were unstable and needed to be further discussed [15–17]. Very few authors focused on the NC to increase the performance of grouting materials in complex environments, such as, ion erosion, and soaking water. In addition, the grouting material with small particle size required for small-scale damage caused by underground stress has not been reported. Therefore, the systematic research of the influence of NC on grouting materials with small particle sizes in complex underground engineering environments is the most important step.

This work aims to study the properties of nano-grouting reinforcement materials under different erosion conditions. Different erosion conditions and six different contents of NC samples were prepared, and the hydration mechanism of NC has been studied. The main preliminary results were obtained by microstructure experiments.

The experimental materials used were sulphoaluminate cement clinker (CSA) and anhydrite, purchased from Shandong Cement Co., Ltd. and Xian Anhydrite Plant, respectively. The composition of sulphoaluminate cement clinker was tested by XRF to be 11.51% SiO2, 43.59% CaO, 2.10% Fe2O3, 29.96% Al2O3, 8.06% SO3 and 2.12% MgO. And the composition of anhydrite was tested by XRF to be 3.50% SiO2, 49.80% CaO, 0.51% Fe2O3, 1.13% Al2O3, 41.23% SO3 and 3.16% MgO. At the same time, compound admixture and nano-clay materials were also added to the grouting reinforcement materials. Nano-clay was purchased from Hebei Trading Co., LTD. Nano-clay was classified as nano-clay with a powdery appearance and white color. The composition of the nano-clay was tested by XRF to be 75.95% SiO2, 2.19% CaO, 1.70% Fe2O3, 4.31% Al2O3, 41.23% SO3, 0.68% MgO, and 0.76 Na2O.

The mixed proportion (CSA cement clinker:anhydrite:compound additives is 80, 20, and 3%) was fixed. The content of NC was added at 0, 1, 2, 3, 5, and 7 wt% for a fixed W/C of 1.0. The specimens were 50*100 mm (diameter*height), the specimens were solidified and placed in a solution of chloride ions, the chloride ion solution was prepared with NaCl, and 5% chloride ion solution was prepared according to the test requirements, and other parts of specimens were cured under standard curing conditions. The compressive strength and ultrasonic pulse velocity were tested using the system of GCTS RTR-1000 rapid triaxial rock testing. The FT-IR was measured by using a Nicolet iS10 FT-IR spectrometer, and the range was from 400 to 4,000 cm−1. SEM analysis was carried out using a Hitachi SU8010 Japan system.

The measurement UPV was used to test the wave velocities of specimen P wave and S waves, and the coupling agent was honey. Then the wave velocities were measured under different corrosion times. The wave velocities at every angle were taken as the average of three measurements.

The compressive strength of the specimens was tested by using a GCTS RTR-1000 Rapid Triaxial Rock Testing System. The compressive strength was tested at various curing times of 7 d, 28 d, and 60 d, respectively. For each test, a mean value of three pastes was used.

The mineral composition and hydration products of grout materials were analyzed by Fourier transform infrared spectroscopy (FT-IR). The Nicolet iS10 FT-IR spectrometer was used to collect the test results, with a measurement range of 400–4,000 cm−1.

The microstructure of hydration products was studied by scanning electron microscopy (SEM). SEM uses the Hitachi SU8020 test system, in which the working voltage of the SEM method was set as 15 kV and the working distance 12.5 mm.

The curves of ultrasonic pulse velocity (UPV) and uniaxial compressive strength (UCS) under different ion erosions were evaluated. As shown in Table 1, it indicates that the influence of NC on the cement material is greatly affected by the different curing environments. Under chloride ion erosion, the UCS increased obviously with the additional NC. Without the NC content, the UCS was 6.43 MPa during chloride ion erosion for 7 d. When the NC content reached 1 and 2%, the UCS was 8.64 and 7.69 MPa, with the NC content increasing to 7% and the UCS decreasing to 6.14 MPa.

The results showed that NC inhibited the hydration products. Because of the small size effect and large surface energy of NC, it has the ability to accelerate the hydration reaction, but it weakens the properties of cement materials. The possible reason is that NC can play a better role only under certain conditions, at RTC, and NC inhibits the formation of hydrated calcium aluminate (C-A-H) and further reduces the formation of ettringite (AFt). In addition, at the beginning of hydration reaction, the large surface of the nanoparticles cannot be fully developed, resulting in the formation of the crystal nucleus centered on the nanoparticles; the development of calcium silicate hydrate (C-S-H) is not enough, which leads to the decrease in the ratio of crystal to adhesive, and the structure of the cement matrix becomes loose.

However, at the SCC, without the NC content, the UCS was 5.86 MPa, compared with RTC, and the change rate of UCS was not obvious. When the NC content reached 1 and 2%, the UCS increased to 8.50 and 6.86 MPa, respectively, and the UCS was improved by 1.45 and 1.17 times compared with 0% NC. When the NC content was more than 2%, the UCS presented a downward trend, and the UCS had little change, and the curve change was also basically the same. The aforementioned analysis indicated that the additional NC can promote the NC to play an important role under SCC; however, once the content of the NC exceeds 2%, the promoting effect will be obviously weakened.

Moreover, from the P-wave velocity, it is clear that P-wave velocity and strength presented a positive correlation. It is also observed that the P-wave velocity falling point advanced at the stress peak point, especially the phenomenon was more obvious under the SCC. It shows that P-wave velocity can effectively identify stress damage and ultimate stress.

It can be explained that SCC is more suitable for NC properties, especially when the NC content is less than 2%, NC can promote the formation of AFt and C-S-H gels. The curing environment stimulates the high activity of nanoparticles; thus, the NC promotes hydration and forms a dense microstructure, and the pore structure has been obviously improved. The large surface of the nanoparticles has also been fully developed, and the crystal core centered on NC is formed, which can make the loose gel product become the network structure with nanoparticles as the core. Therefore, the particle gradation of cement-based material is improved, the compactness is increased, and the P-wave velocity is also increased. However, as the content of NC increases, the spacing between particles decreases, the growth space of hydrated products is blocked, and the production of AFt and C-S-H decreases, so the properties of cement material weakened.

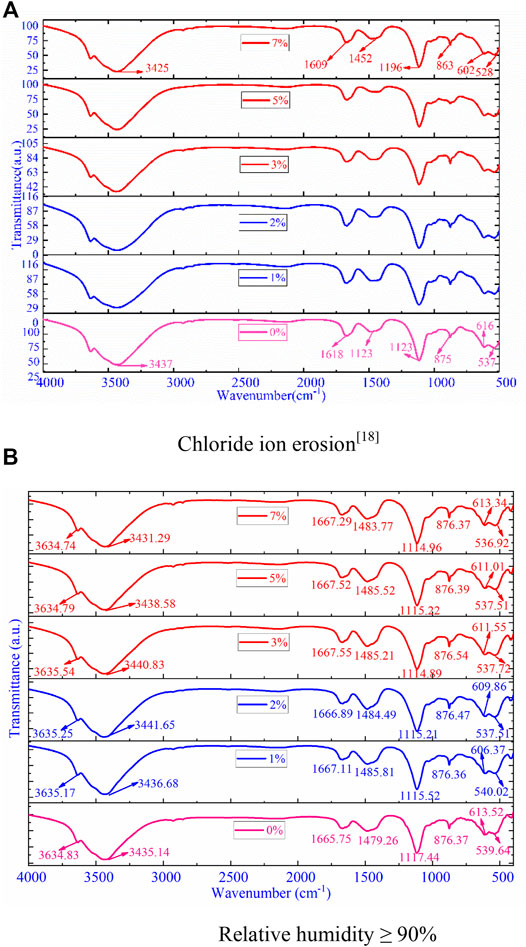

Figure 1 shows the FT-IR spectra under different erosion environments of NC grouting materials. A similar trend in the vibration band demonstrates that no new phase is generated. Due to the stretching vibrations of SO42-, (CO3)2−, and -OH in the hydration products, the main absorption band presents 500 cm−1 to 3,600 cm−1 spectral wavenumbers. Figure 1A shows the chloride ion erosion. It is observed that the absorption band presents a large fluctuation at approximately 1,000 cm-1, indicating that the C-S-H gel was found in the pastes [19]. As NC is less than 2%, the absorption bands are strong at approximately 1,120 cm−1; the main reason is the production of AFt, which contains a large amount of SO42-, and the peak occurs in the 2% NC. However, when the relative humidity is 90% (Figure 1B), the peak occurs in the 1% NC. With more NC, the hydration process decreases, and the peak value of the absorption band is weakened.

FIGURE 1. FT-IR spectra curves with different erosion environments of grouting materials for 7d. (A) Chloride ion erosion[18]. (B) Relative humidity ≥90%.

The main reason is that the crystal core centered on NC was formed, which can make the loose gel product become the network structure with nanoparticles as the core; this accelerated the formation of AFt and C-S-H gel. When the nano-grouting material was soaked in chloride ion erosion, due to the complex erosion conditions, more NC (NC = 2.0%) was needed to give full play to its nano-effect. However, as more NC was added, the nano-core effect decreased, the hydration process was limited, and the peak weakened. It showed calcite with a double energy band at 1,483 and 1667 cm−1 of (CO3]2-. The strongest vibration occurred at 3,430 cm−1 and 3,634 cm−1, and it is presented by the O-H [18] bond of CH. The existence of the substances produced in the hydration process was verified by FT-IR analysis, which provided the basis for SEM analysis.

Figure 2 shows the SEM micrographs of the chloride ion solution for 7d. It is clearly observed that NC promoted the formation of AFt and C-S-H hydration products and improved the corrosion resistance of grouting materials. It can be seen from Fig. (a) and (b) that AFt is wrapped by CH and cannot develop well, and it shows that when the NC content is small, the hydration of grouting materials cannot be well stimulated. As the NC content increased, especially when the NC content is 2%, during the hydration process of grouting materials, more AFt was formed, CH was consumed, and C-S-H gel was increased. The hydration reaction of grouting material reflects the mechanical properties. The mechanical properties of grouting materials can be improved with the increase in the ettringite content and the increase in C-S-H production. Therefore, the mechanical properties of grouting materials improved. However, as NC was more than 2%, for example, if the NC content was 3%, the AFt became coarse and rod-shaped, abs the amount and density of AFt decreased obviously; meanwhile, CH consumption was reduced, C-S-H gel formation was blocked, and the hydration products had larger pores. It showed that more NC (more than 2%) inhibits the hydration process of grouting material.

Figure 3 shows a SEM micrograph for humidity curing 7d under different NC contents. As the NC is more than 1%, as shown in images (c) and (d), it is noticed that the hydration products of AFt and C-S-H were inhibited, the amount and the density of AFt decreased, and the morphology became finer and shorter compared to those less than 1% NC. Meanwhile, the C-S-H gels were limited; the C-S-H gel with a granular and short fibrous shape did not overlap between the gels. Especially, as the NC is more than 2%, the flake CH obviously increased, the AFt showed a concentrated development, the “coarse-rod flowers state” disappeared, and the AFt was wrapped in flake products. Because C-S-H gels can fill pores in cement, less C-S-H gels were found, and as a result, the microstructural compactness dropped. It indicated that too much NC (more than 1%) inhibited the hydration process, and the hydration products were also restricted. The distribution of microstructure was bound to affect the mechanical properties of the cement grouting material.

The hydration process and products of grouting material affected the mechanical properties; the amount and density of AFt and the filling effect of C-S-H gel determined the mechanical properties of grouting material. When the grouting material was in the chloride ion erosion environment, NC was 2%, hydration reaction was adequate, and mechanical properties and erosion resistance were the best. When the grouting material was in a high humidity condition, NC was 1%, and the hydration process and mechanical properties were the best. This was consistent with the results of the FT-IR analysis.

The study investigated the effect of NC on hydration and microstructure of grouting materials under different ion erosions. The conclusions were drawn as follows: that under the chloride ion erosion, as NC was less than 2%, the UCS and UPV improved; NC accelerated the hydration process, resulting in the hydration products of AFt and C-S-H well developed; however, the hydration effect of NC varied greatly under different environments. The density and the morphology of AFt were increased, CH was exhausted, the C-S-H was formed during the hydration reaction, and the microstructural compactness was improved. Under chloride ion erosion and high humidity conditions, NC hydration reaction was the best when NC is 2 and 1%, respectively. However, with the increase in NC, the nano-core effect was inhibited, the morphology of AFt became thinner and shorter, and the C-S-H gel was restricted. In the future, facing the complex underground environment, the research and development of grouting materials with better adaptability will play an important role in China’s underground engineering.

The original contributions presented in the study are included in the article/Supplementary Material, further inquiries can be directed to the corresponding author.

ZH wrote the manuscript, and JZ revised the manuscript.

This study was financially supported by the Outstanding Young Scientist of Beijing (BJJWZYJH01201911413037), the Science and Technology Project of Henan Province (222102320004), the Fund Project for Improving Young Teachers’ Scientific Research Ability of the School of Civil Engineering, Henan Polytechnic University, and the Doctoral Fund of Henan Polytechnic University.

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors, and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

1. Shen S-L, Wang Z-F, Horpibulsuk S, Kim Y-H. Jet Grouting with a Newly Developed Technology: The Twin-Jet Method. Eng Geology (2013) 152:87–95. doi:10.1016/j.enggeo.2012.10.018

2. Zhu C, He MC, Zhang XH, Tao ZG, Yin Q, Li LF. Nonlinear Mechanical Model of Constant Resistance and Large Deformation Bolt and Influence Parameters Analysis of Constant Resistance Behavior. Rock Soil Mech (2021) 42(7):1911–24.

3. Hong Z-j., Zuo J-p., Liu C, Zhang Z-s. Hydration and Microstructure of Nano-clay Cement Material in Ion Erosion Solution. Mater Lett (2019) 252:27–30. doi:10.1016/j.matlet.2019.05.085

4. Langaroudi MAM, Mohammadi Y. Effect of Nano-clay on Workability, Mechanical, and Durability Properties of Self-Consolidating concrete Containing mineral Admixtures. Construction Building Mater (2018) 191:619–34. doi:10.1016/j.conbuildmat.2018.10.044

5. Kawashima S, Kim JH, Corr DJ, Shah SP. Study of the Mechanisms Underlying the Fresh-State Response of Cementitious Materials Modified with Nanoclays. Construction Building Mater (2012) 36:749–57. doi:10.1016/j.conbuildmat.2012.06.057

6. Nazari A, Riahi S. RETRACTED: Al2O3 Nanoparticles in concrete and Different Curing media. Energy and Buildings (2011) 43(6):1480–8. doi:10.1016/j.enbuild.2011.02.018

7. Gao MZ, Xie J, Gao YN, Wang W, Li C, Yang B, et al. Mechanical Behavior of Coal under Different Mining Rates: A Case Study from Laboratory Experiments to Field Testing[J]. Int J Mining Sci Technol (2021) 31(2021):825–41. doi:10.1016/j.ijmst.2021.06.007

8. Maravelaki-Kalaitzaki P, Agioutantis Z, Lionakis E, Stavroulaki M, Perdikatsis V. Physico-chemical and Mechanical Characterization of Hydraulic Mortars Containing Nano-Titania for Restoration Applications. Cement and Concrete Composites (2013) 36(36):33–41. doi:10.1016/j.cemconcomp.2012.07.002

9. Li ZH, Wang HF, He S, Lu Y, Wang M. Investigations on the Preparation and Mechanical Properties of the Nano-Alumina Reinforced Cement Composite[J]. Mater Lett (2006) 60:356–9. doi:10.1016/j.matlet.2005.08.061

10. Yakovlev GJ, Keriene J, Gailius A. Cement Based Foam concrete Reinforced by Carbon Nanotubes[J]. Mater Sci (2006) 12(2):147–51.

11. Liu X, Chen L, Liu A, Wang X. Effect of Nano-CaCO3 on Properties of Cement Paste. Energ Proced (2012) 16:991–6. doi:10.1016/j.egypro.2012.01.158

12. Essawy AA, Abd El. Aleem S, Aleem S. Physico-mechanical Properties, Potent Adsorptive and Photocatalytic Efficacies of Sulfate Resisting Cement Blends Containing Micro Silica and Nano-TiO2. Construction Building Mater (2014) 52:1–8. doi:10.1016/j.conbuildmat.2013.11.026

13. Noorvand H, Abang Ali AA, Demirboga R, Farzadnia N, Noorvand H. Incorporation of Nano TiO2 in Black rice Husk Ash Mortars. Construction Building Mater (2013) 47:1350–61. doi:10.1016/j.conbuildmat.2013.06.066

14. Nazari A, Riahi S. Improvement Compressive Strength of concrete in Different Curing media by Al2O3 Nanoparticles. Mater Sci Eng A (2011) 528(3):1183–91. doi:10.1016/j.msea.2010.09.098

15. Zhu C, He M-c., Jiang B, Qin X-z., Yin Q, Zhou Y. Numerical Investigation on the Fatigue Failure Characteristics of Water-Bearing sandstone under Cyclic Loading. J Mt Sci (2021) 18(12):3348–65. doi:10.1007/s11629-021-6914-0

16. Li G, Hu Y, Tian S-m., weibin M, Huang H-l. Analysis of Deformation Control Mechanism of Prestressed Anchor on Jointed Soft Rock in Large Cross-Section Tunnel. Bull Eng Geol Environ (2021) 80:9089–103. doi:10.1007/s10064-021-02470-5

17. Gao MZ, Hao HC, Xue SN, Tong L, Pengfei C, Yanan G, et al. Discing Behavior and Mechanism of Cores Extracted from Songke-2 Well at Depths below 4,500 M. Int J Rock Mech Mining Sci (2022) 149:104976. doi:10.1016/j.ijrmms.2021.104976

18. Hong Z-j., Zuo J-p., Zhang Z-s., Liu C, Liu L, Liu H-y. Effects of Nano-clay on the Mechanical and Microstructural Properties of Cement-Based Grouting Material in Sodium Chloride Solution. Construction Building Mater (2020) 245:118420. doi:10.1016/j.conbuildmat.2020.118420

Keywords: corrosion, ultrasonic pulse velocity, NC, hydration reaction, microstructure

Citation: Hong Z and Zuo J (2022) Effects of Different Ion Erosion on the Hydration Mechanism and Microstructure of Nano-Clay Single-Liquid Grouting Material. Front. Phys. 10:856062. doi: 10.3389/fphy.2022.856062

Received: 16 January 2022; Accepted: 23 February 2022;

Published: 23 March 2022.

Edited by:

Qingxiang Meng, Hohai University, ChinaCopyright © 2022 Hong and Zuo. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Jian-ping Zuo, empwQGN1bXRiLmVkdS5jbg==

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.