- 1School of Mechanical and Electrical Engineering, Xi’an University of Architecture and Technology, Xian, China

- 2Engineering Research Center of Development and Management for Low to Ultra-Low Permeability Oil and Gas Reservoirs in West China, Ministry of Education, Xi’an Shiyou University, Xian, China

A digital core obtained without damage and contact can provide intuitive and quantitative analysis data for sandstone pore structure analysis. However, pore analysis results based on digital cores are quite different from experimental results due to limitations of scanning resolution, quality, pore extraction method, and experimental errors. In this research, the influence of pore geometry on pore analysis is studied from pore angles and pore resolution. First, sharp angles are extracted by image processing, and the influence of angles on pore radius distribution is analyzed. Then, by up–down sampling, high- and low-resolution digital cores are reconstructed, and the effects of resolution on pore connectivity and throat structure are discussed.

Introduction

The digital core obtained by CT scanning technology can provide visual and quantitative data for pore structure characterization without damage and contact [1, 2]. However, many experiments have shown that pore analysis results extracted from digital cores are often deviated from the experimental results [3–5]. On the one hand, they are affected by the accuracy of pore extraction and the resolution limitation of scanning. On the other hand, there are errors in the experimental measurement method because of the microstructure inside the pores [6–8]. Therefore, analyzing the influence of pore geometry on pore analysis in a digital core is helpful to guide designing and developing experiments, application of digital core technology, and understanding the mechanism of pore microstructures on seepage [9, 10].

This study analyzes two sandstones with size 655 × 655 × 655 um3, in the Ordos area. The digital cores are obtained by CT scanning technology with 1.0-um physical resolution. Combined with image processing to extract the pore structure, the influence of pore geometry is analyzed by simulation from two aspects:

1) Influence of pore angles

The pore shape of sandstone is complex and irregular, which reflects a large difference in pore size from a macroscopic view. From a microscopic view, the pores with the same size have different pore angles. These angles are ignored in both experimental tests and simulation, and every pore and throat are replaced by an ideal model. This also leads to error values in the experiment. In this study, the pore angles are extracted based on image processing, and the variation characteristics are analyzed.

2) Influence of digital core resolution

Scanning resolution and scanning field of view are contradictory. Under the same image resolution, higher scan resolution leads to a smaller field of view. Although higher resolution can obtain more detailed information, only a partial core can be collected due to the small field of view. Conversely, the resolution has to be reduced in order to obtain an overall scanning image from the core sample. Meanwhile, resolution variation will affect the pore morphology. In this study, digital cores with different resolutions are reconstructed from the same scanning results to analyze their influence on porosity and connectivity.

Influence of Pore Angles

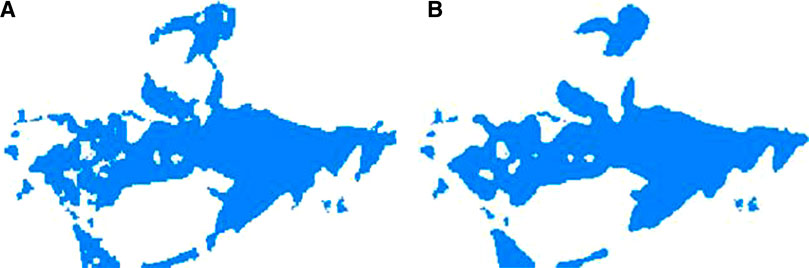

Based on the image processing method (Eq. 1) and logical operation, the pore angles are removed and the edge is smoothed. The effect comparison is shown in Figure 1. In Eq. 1, we set

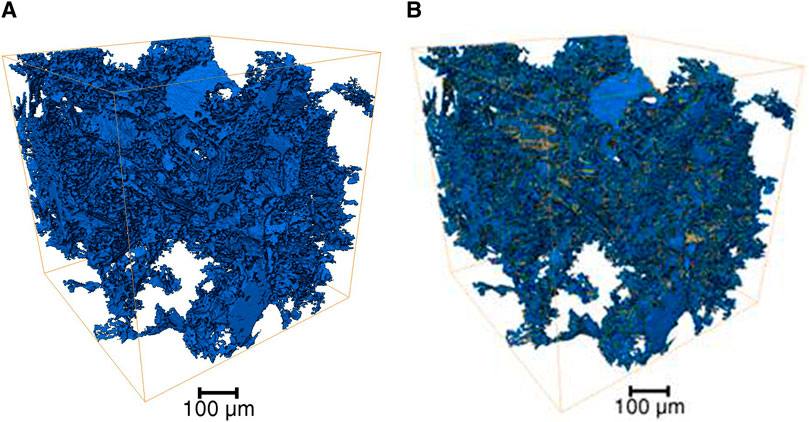

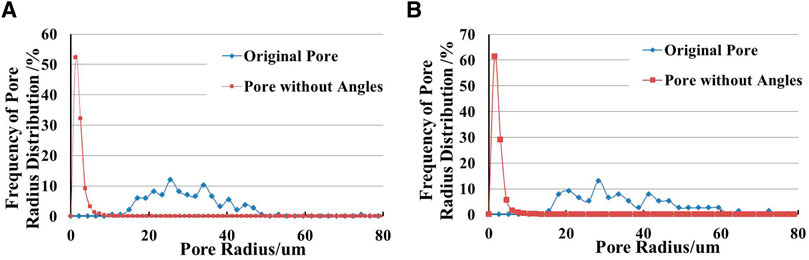

In Figure 1B, pores and edge are smoother and the ideal pore network model is closer to it. However, removing pore angles affects the porosity as single holes are relatively reduced and some small pores are directly smoothed out in the 2D slice. Therefore, combined with a logical operation, small pores are retained. The comparison in 3D is shown in Figure 2. The influence of pore angles on radius is shown in Figure 3.

In Figure 3, each sample has a large difference in pore radius distribution. The original pore size decreases and the large pores are divided into smaller ones with angles removed, which results in an increasing number of small pores. What needs to be considered here is that the overall porosity decreases after the pore angles are removed. The porosity of sample 1 changes from 8.9% to 7.5%, and that of sample 2 changes from 5.7% to 4.9%. The permeability of sample 1 changes from 0.1162 to 0.1069 μm2, and that of sample 2 changes from 0.1177 to 0.1230 μm2. The change in sample 2 indicates that angles in pores can reduce permeability. While in sample 1, porosity and permeability decrease by 1.4% and 0.0093 μm2, respectively, which illustrates there are more angles in it and the structure is more complex than the structure of sample 2. The degree of variation can also be used to evaluate the complexity of the pore structure.

Influence of Digital Core Resolution

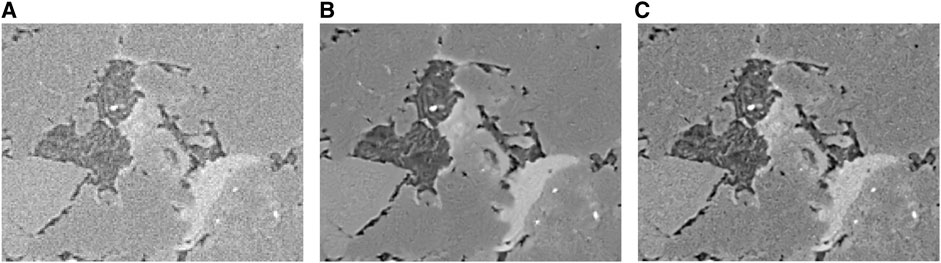

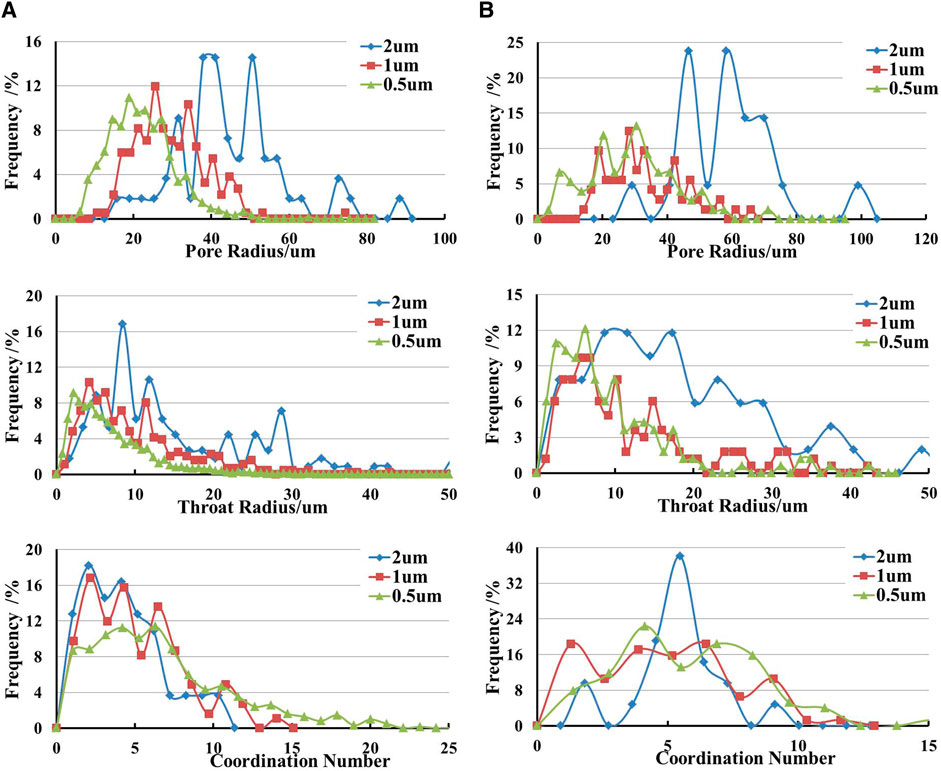

Based on the principle of the same physical size, digital cores with high and low resolutions are established by using up–down sampling methods for each sample. In Figure 4, parts of sample 1 are shown. Figure 4A shows a 0.50-um size sample with high resolution by up-sampling. Figure 4B shows a 2.0-um size sample with low resolution by down-sampling. The pore size, throat size, and coordination number distribution of the two samples are shown in Figure 5.

FIGURE 4. Sample parts with different resolutions. (A) Low resolution. (B) Original. (C) High resolution.

FIGURE 5. Distribution of pore and throat radius and coordination number under different physical sizes. (A) Sample 1. (B) Sample 2.

In Figure 5, the pore radius and throat radius distribution of the two samples have a significant deviation to the left in the core with 0.5 um. It indicates that, due to improvement of physical resolution, more details could be observed, and pores with small size would increase. Pores that cannot be observed at a low physical resolution will be observed at a high resolution. On the contrary, the distribution deviates to the right at high physical resolution. The trend of coordination numbers is opposite. It indicates that the connectivity is enhanced due to an increase in recognizable pores. The resolution analysis can provide predictable results of pore distribution at different pore scales which is useful for analyzing the pore structure in the core.

Conclusion

In this study, the influence of pore geometry on pore characteristics based on a digital core is introduced. The influence of pore angles and physical resolution on pore distribution, throat distribution, and coordination number characteristics are analyzed. It also concludes that the existence of pore angles greatly affects the variation of pore size distribution, which is the reason for the obvious difference between experimental measurement and digital core analysis results. Meanwhile, we analyzed the throat, pore size, and coordination number in the same physical size with different resolutions, which can predict pore characteristics of the whole core at different resolutions, which makes the analysis results more objective. This article proposes a new method for pore analysis based on a digital core.

Data Availability Statement

The raw data supporting the conclusion of this article will be made available by the authors, without undue reservation.

Author Contributions

XL: conceptualization, methodology, investigation, writing—original draft, and visualization. DR: validation, formal analysis, resources, writing—review and editing.

Funding

This study was supported by the Open Funds of Engineering Research Center of Development and Management for Low to Ultra-Low Permeability Oil and Gas Reservoirs in West China (no. KFJJ-XB-2020-3); the Young Science and Technology Talents Foundation of Shaanxi Province (2019KJXX-054); the Shaanxi Province Key Research and Development Plan (2021GY-140), the National Natural Science Foundation of China (51874240, 51934005, and 52074226); the Open Fund of Key Laboratory of Coal Resources Exploration and Comprehensive Utilization, Ministry of Natural Resources (KF2021-3); the Open Fund of Shaanxi Key Laboratory of Advanced Stimulation Technology for Oil and Gas Reservoirs (20JS120); Doctoral Research Initiation Fund (no. 6040300529); and Youth Foundation of Xi’an University of Architecture and Technology (no. 60405170 45).

Conflict of Interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s Note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors, and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

1. Münch B, Holzer L. Contradicting Geometrical Concepts in Pore Size Analysis Attained with Electron Microscopy and Mercury Intrusion[J]. J Am Ceram Soc (2010) 91(12):4059–67. doi:10.1111/j.1551-2916.2008.02736.x

2. Lei Q. Quantitative Study of Different Patterns of Microscale Residual Water and Their Effect on Gas Permeability through Digital Core Analysis. J Pet Sci Eng (2020) 196:108053. doi:10.1016/j.petrol.2020.108053

3. Hasnan HK, Sheppard A, Amir Hassan MH, Knackstedt M, Abdullah WH. Digital Core Analysis: Improved Connectivity and Permeability Characterization of Thin sandstone Layers in Heterolithic Rocks. Mar Pet Geology (2020) 120:104549. doi:10.1016/j.marpetgeo.2020.104549

4. Wang H, Rezaee R, Saeedi A. Evaporation Process and Pore Size Distribution in Tight Sandstones: A Study Using NMR and MICP. Proced Earth Planet Sci (2015) 15:767–73. doi:10.1016/j.proeps.2015.08.124

5. Fe A, Pl B, Th C. Digital Sand Core Physics: Predicting Physical Properties of Sand Cores by Simulations on Digital Microstructures - ScienceDirect. Int J Sol Structures (2020) 188–189:155–68. doi:10.1016/j.ijsolstr.2019.09.014

6. Li Z, Liu S, Ren W, Fang J, Zhu Q, Dun Z. Multiscale Laboratory Study and Numerical Analysis of Water-Weakening Effect on Shale. Adv Mater Sci Eng (2020) 2020:5263431. doi:10.1155/2020/5263431

7. Wlab E, Sc C, Yang GD. Evaluating Seepage Radius of Tight Oil Reservoir Using Digital Core Modeling Approach. J Pet Sci Eng (2019) 178:609–15. doi:10.1016/j.petrol.2019.03.072

8. An S. The Microscale Analysis of Reverse Displacement Based on Digital Core. J Nat Gas Sci Eng (2016) S1875510016309143. doi:10.1016/j.jngse.2016.12.014

9. Wang H, Kou Z, Bagdonas DA, PhillipsPhillips EHW, Alvarado V, Johnson AC, et al. Multiscale Petrophysical Characterization and Flow Unit Classification of the Minnelusa Eolian Sandstones. J Hydrol (2022) 607:127466. doi:10.1016/j.jhydrol.2022.127466

Keywords: digital core, sandstone, pore structure, pore radius distribution, pore analysis

Citation: Liu X and Ren D (2022) Influence of Pore Geometry on Sandstone Pore Analysis Based on a Digital Core. Front. Phys. 10:838954. doi: 10.3389/fphy.2022.838954

Received: 18 December 2021; Accepted: 07 March 2022;

Published: 05 May 2022.

Edited by:

Qingxiang Meng, Hohai University, ChinaCopyright © 2022 Liu and Ren. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Dazhong Ren, ZHpyZW5AeHN5dS5lZHUuY24=

Xuechao Liu

Xuechao Liu Dazhong Ren

Dazhong Ren