- 1National Engineering Laboratory for Exploration and Development of Low-Permeability Oil and Gas Fields, Xi’an, China

- 2Research Institute of Exploration and Development of PetroChina Changqing Oilfield Company, Xi’an, China

- 3Xi’an Changqing Chemical Group Co. Ltd., Xi’an, China

- 4Shaanxi Key Laboratory of Advanced Stimulation Technology for Oil and Gas Reservoirs, College of Petroleum Engineering, Xi’an Shiyou University, Xian, China

In this article, the characteristics of Chang 8 reservoir of Triassic Yanchang Formation in northern Shaanxi are studied by using polarizing microscope, field emission scanning electron microscope, image particle size, X-ray diffraction analysis of clay, and constant pressure mercury intrusion. The study shows that the target layer is in a relatively stable and uniform sinking burial period after deposition, and the lithology composition in the area is relatively complex, mainly composed of debris–feldspar sandstone and feldspar sandstone, with the characteristics of fine grain and high content of interstitial material. The porosity of the reservoir is generally between 4% and 12%, with an average of 8.05%. The permeability is generally between 0.03 × 10−3 and 0.5 × 10−3 μm2, with an average of 0.16 × 10−3 μm2. Strong compaction and well-developed cementation of calcareous, siliceous, and authigenic illite are important reasons for the formation of extra-low porosity and extra-low permeability reservoirs. But at the same time, because of the protective effect of chlorite film, some residual intergranular pores are preserved, which makes the some reservoirs with relatively good physical property, forming a local relatively high-porosity and high-permeability section of the “highway.”

1 Introduction

Triassic Yanchang Formation is rich in oil resources in northern Shaanxi. After more than 30 years of continuous exploration and development, the main oil reservoir Chang 6 has a high degree of exploration and development, and the next sustainable development is very difficult. In order to realize the development goal of steady and rising crude oil production in northern Shaanxi, it is urgent to find new replacement strata and consolidate the resource base of increasing oil storage and production. In recent years, with the deepening of oil and gas exploration in Yanchang Formation of Ordos Basin, new breakthroughs have been made in the exploration of Chang 8 in Wuqi, Zhijing, Ansai, and other areas in northern Shaanxi region of the basin, proving that there are rich oil resources. Previous studies on the sedimentary facies [1–3], accumulation mechanism [4–6], and other aspects of this area are more, but there are few studies on the characteristics of reservoir micropore structure, compact mechanism, and other aspects, which are limited to a few studies on the whole basin, and relatively few related to the northern Shaanxi area [7]. There are few research results on reservoir characteristics, pore structure characteristics, diagenetic evolution, and tight factors of Chang 8 in Wuqi, Zhijing, and Ansai Yanchang Formation in northern Shaanxi area. Therefore, it is necessary to further study the reservoir in this area.

2 Geological Setting

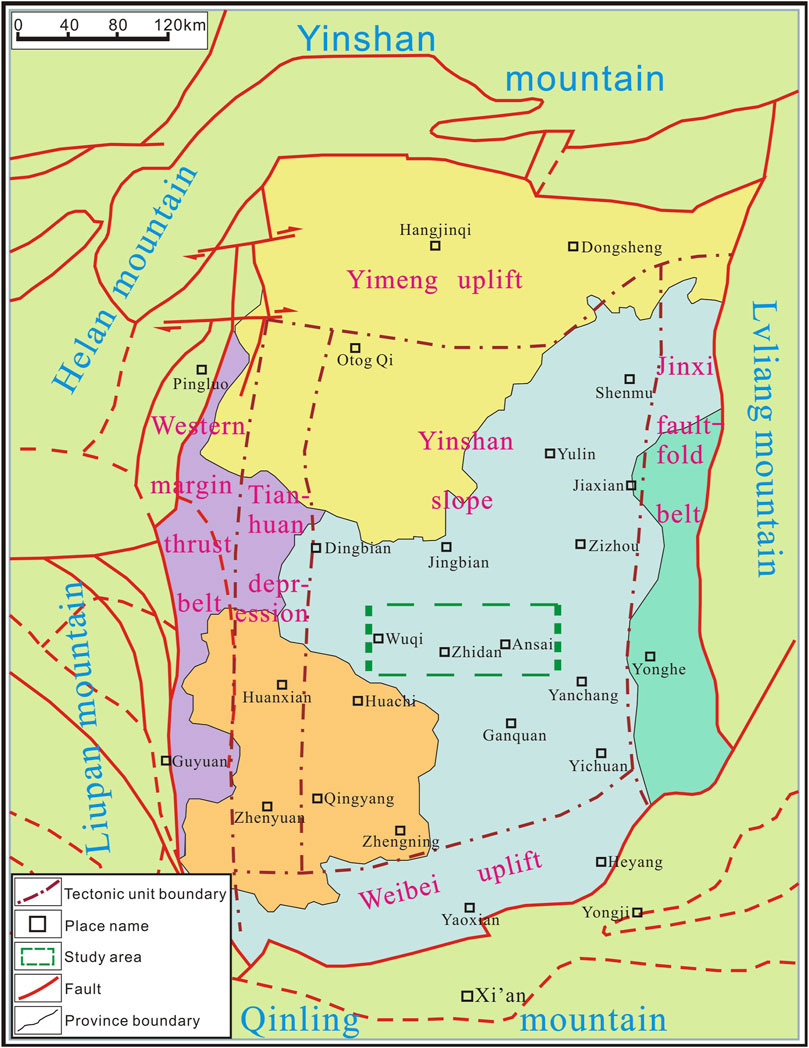

Ordos Basin is a multicycle composite craton basin with stable deposition, shifting depressions and obvious twists [8–10]. It has rich oil and gas resources, and the layers are horizontal with dip angle less than 1° [11, 12]. The present structure can be divided into six secondary structural units, including Yimeng uplift, Weibei uplift, Western margin thrust belt, Tianhuan depression, Yishan slope, and Jinxi fault-fold belt [13]. Because of the influence of Indosinian movement, the basin has developed a complete and typical continental clastic sedimentary system since the late Triassic. The Yanchang Formation of the Upper Triassic is a terrigenous clastic rock series of fluvial–lacustrine facies accumulated during the continuous depression and stable subsidence of the Ordos Basin [14–16].

The study area is located in the Yishan slope structural belt, from Wuqi in the west to Ansai in the east (Figure 1). It belongs to delta front deposition, close to Chang 7 high-quality source rock, and has developed sand body. It is an important replacement horizon for oil exploration in Changqing oilfield. In this article, we present study of petrology, pore structure, and diagenesis of Chang 8 reservoir in this area. We use these to point out the formation mechanism of tight reservoir, and provide geological basis for the next exploration.

3 Analytical Instruments

Samples of this study were analyzed at the National Engineering Laboratory for Exploration and Development of Low-Permeability Oil and Gas Fields, Xi’an, China. Rock thin sections were identified by polarizing microscope (LEICA 4500P) with a resolution of 0.27 μm and a grain size detection range of 3 to 5,000 μm; Image particle size analysis was conducted with an image analyzer (CIAS-V3.4), and the minimum measurement length was 0.0312 mm; X-ray diffractometer (D8 Focus) was used for clay mineral analysis with the power of 2.2 kW; the rotation range of 2θ was 2° to 168, and the minimum readable step size was 0.0001°. SEM analysis was performed using field emission scanning electron microscopy (Quanta 450 FEG) with a magnification of ×6∼300,000x and a resolution of 1.2 nm. Constant pressure-mercury injection test uses a high-pressure mercury injection instrument (9,520).

4 Petrological Characteristics of Reservoir

4.1 Rock Type

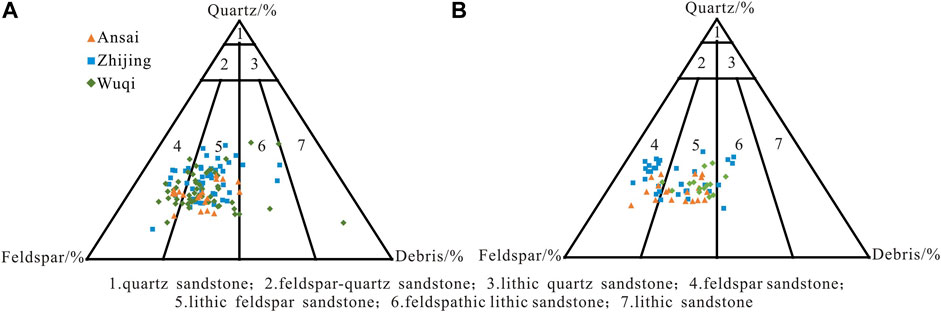

By analyzing the identification data of 185 Chang 8 sandstone casting thin sections from 100 wells in Wuqi–Zhijing–Ansai area, Ordos Basin, and according to the classification method of SY/T 5368-2016 Rock Thin Section Identification, the rock types are mainly ultrafine–fine-grained debris–feldspar sandstone and feldspar sandstone (Figure 2). It is different from Chang 8 reservoir in Jiyuan and Longdong area in petrological characteristics [7, 17, 18].

FIGURE 2. Triangle diagram of rock types of Chang 81 (A) and Chang 82 (B) sandstones in Wuqi–Zhijing–Ansai area.

4.2 Detrital Composition

According to the statistics of detrital content of Chang 8 reservoir in Wuqi–Zhijing–Ansai area (Table 1), the clastic content of Chang 8 reservoir is between 57.3% and 96.5%, with an average content of 85.9%, and the content of interstitial filling is relatively low. The detrital compositions are characterized by “two high and one low,” that is, high feldspar (feldspar > quartz > debris), high mica and other soft components, and low debris, which are the typical characteristics of Chang 8 reservoir in northern Shaanxi region different from other areas in the basin [7, 17, 18]. The main types of rock debris are metamorphic cuttings (8.4%) with the majority of phyllite and quartzite, followed by igneous cuttings (4.9%) with the majority of eruptive cuttings and very few sedimentary cuttings.

4.3 Characteristics of Interstitial Filling

Compared with Chang 8 reservoir in other areas of the basin, the Chang 8 reservoir in the study area has a high filling content with an average content of 13.0%, which is similar to Chang 81 in Longdong and Jiyuan area of the basin [7, 17, 18]. The filling content of Chang 81 is relatively high (14.5% on average), and that of Chang 82 is relatively low (11.5% on average). The main types of fillings are illite, chlorite, and carbonate (Table 2).

Chlorite is mainly distributed in thin films (Figures 3A, B). The authigenic illite is distributed as filamentous and bridging (Figure 3C). Felsic minerals fill the pores in the form of authigenic and secondary enlargement (Figure 3D). The ferrocalcite is patchy and coarse-giant crystal filling pores and metasomatism debris, whereas the carbonate minerals exist in the form of filling pores and metasomatism debris (Figures 3E, F).

FIGURE 3. Thin section and SEM images of Chang 8 interstitial filling in Wuqi–Zhijing–Ansai area. (A) Chlorite thin film on particle surface, Q59, 998.04 m; (B) chlorite thin film on the edge of the particles and adsorbed organic matter, X248, 2,063.40 m; (C) filamentous illite fills the pores, S268, 1,739.60 m; (D) authigenic quartz, Y55, 2,036.50 m; (E) ferrocalcite fills the pores and metasomates the particles, X311, 2,063.00 m; (F) ferrodolomite fills the pores, X416, 1,954.10 m.

5 Characteristics of Reservoir Pore Structure

5.1 Pore Type

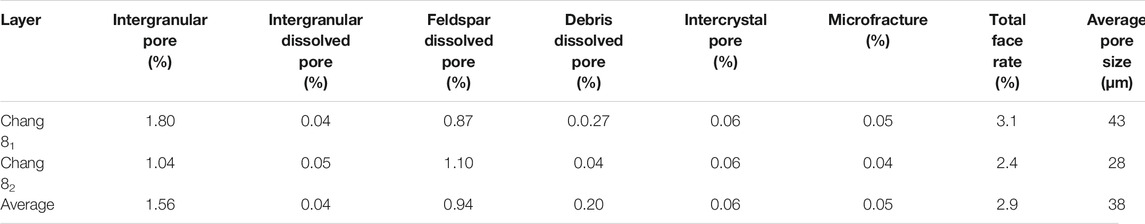

The pore types of Chang 8 sandstone in the study area are mainly residual intergranular pores and feldspar dissolved pores, with a few fractures. The reservoir is dominated by dissolved pores and intergranular pores, and the facial rate is between 2% and 3% (Table 3).

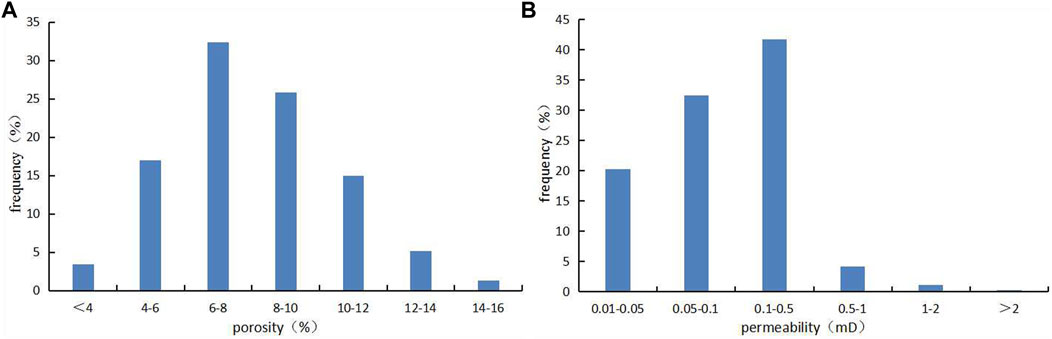

5.2 Physical Properties of Reservoir

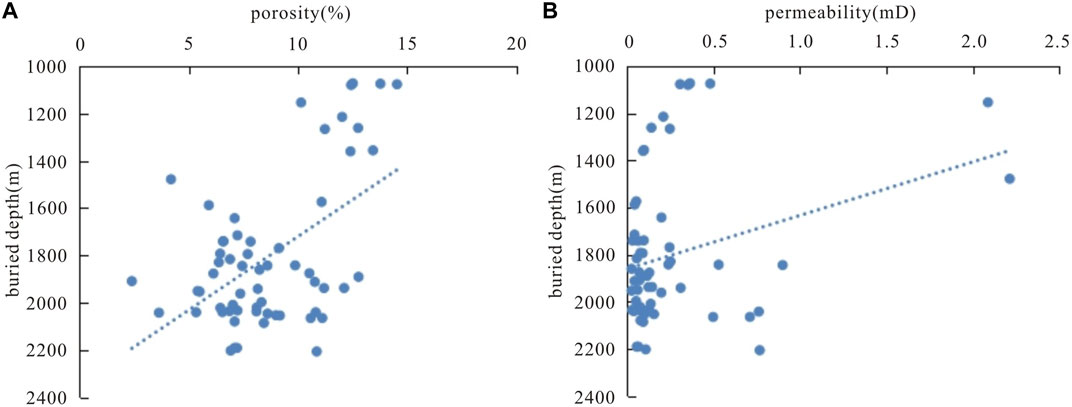

According to the statistics of 3,234 core analysis data from 66 wells in Chang 8 reservoir in the study area, the porosities of Chang 8 reservoir vary from 0.76% to 15.89%, mainly distributed between 6% and 10% (Figure 4A), with an average porosity of 8.05%. The permeabilities ranged from 0.03 × 10−3 to 6.0 × 10−3 μm2, mainly distributed between 0.1 × 10−3 and 0.5 × 10−3 μm2 (Figure 4B), with an average permeability of 0.16 × 10−3 μm2. The physical properties of Chang 81 and Chang 82 are basically the same, and the average porosity of Chang 81 (8.14%) is slightly higher than that of Chang 82 (7.87%). The average permeability of Chang 81 (0.16 mD) was slightly lower than that of Chang 82 (0.17 mD). The average porosity and permeability in Wuqi area are 7.74% and 0.16 × 10−3 μm2, respectively. The average porosity and permeability in Zhijing area are 7.54% and 0.16 × 10−3 μm2, respectively. The average porosity of Ansai area is 8.88%. The average permeability is 0.17 × 10−3 μm2 (Table 4). Wuqi, Zhijing, and Ansai areas have similar physical characteristics. According to the oil and gas industry standard “Oil and Gas Reservoir Evaluation Method” (SY/T 6285-2011), Chang 8 reservoir belongs to ultralow porosity and ultralow permeability reservoir in the study area.

FIGURE 4. Frequency distribution of porosity (A) and permeability (B) of Chang 8 reservoir in the study area.

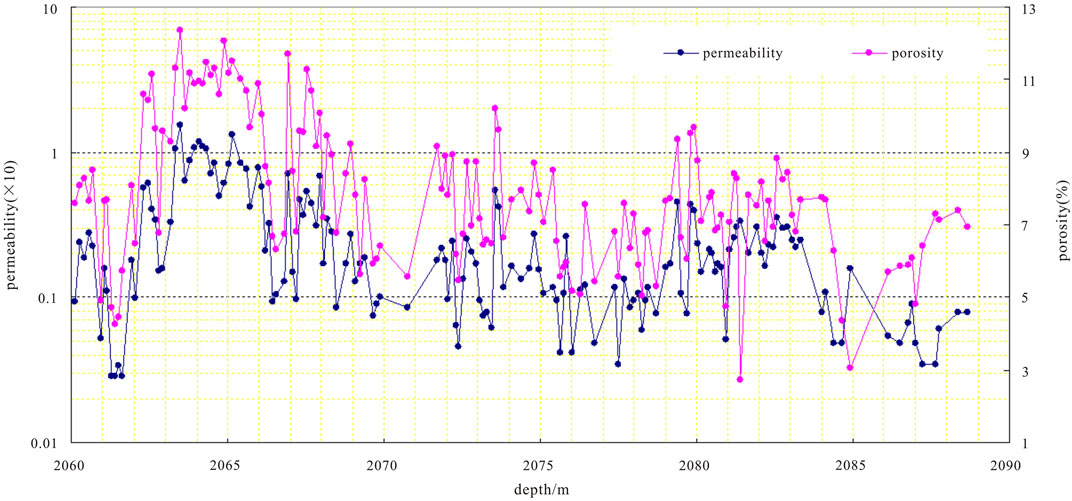

In the longitudinal direction, physical heterogeneity of the reservoir is strong. In the background of generally low permeability tight reservoir, residual intergranular pores are developed in local intervals (Figure 3B), showing the characteristics of relatively high porosity and high permeability. The highest permeability can reach above 2.4 × 10−3 μm2, forming a “highway” in the physical properties of local intervals of Chang 8 tight reservoir in the study area (Figure 5).

5.3 Pore Structure

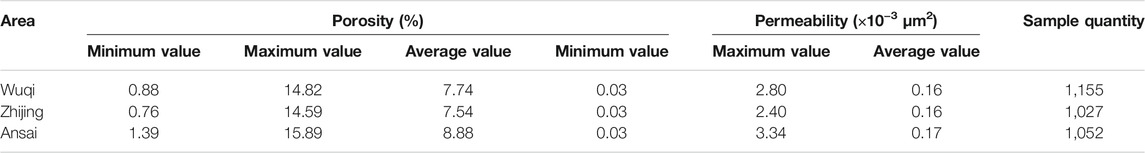

The mercury injection data of 50 samples in the study area show that the displacement pressure is between 0.11 and 3.54 MPa, with an average of 1.22 MPa. The median pressure ranged from 1.45 to 33.44 MPa, with an average of 11.07 MPa. The maximum connected pore-throat radius is between 0.21 and 6.67 μm, and the average median pore-throat radius is 0.07 μm (under the condition of 200 MPa mercury injection). The pore platform is well developed, with the platform segment reaching 70% to 80% (Figure 6). The bound pore throat is less than 30%, and some are even less than 10%, indicating that the reservoir of Chang 8 in the study area exhibits good reservoir properties.

FIGURE 6. Longitudinal variation characteristics of porosity and permeability of Chang 82 in 2,060- to 2,090-m section of X248 well.

6 Formation Mechanism of Low Permeability Tight Reservoir

6.1 Poor Sedimentary Basis, Burial Compaction of Long-term Stable Subsidence Is the Key Factor

Yingchang et al. (2011) showed that particle size and sorting had a great influence on the original porosity and permeability of sandstone reservoirs through simulation experiments and studied the effect of compaction on reservoir performance through simulation of overlying formation pressure. The results show that under the condition of mechanical compaction only, for the sandstone with the same source and the same sorting, the larger the particle size is, the smaller the pore reduction rate is during the compaction process, the more pores are preserved, and the permeability of the sandstone is better. For sandstone with similar grain size, the worse the sorting is, the larger the compaction porosity reduction rate is in the process of compaction, the less pores are preserved, and the lower the permeability of the sandstone. For sandstone of different lithofacies types in the slow compaction stage, the average pore reduction per 100 m is the smallest in the well-sorted medium sandstone facies; next came the well-sorted fine sandstone facies and well-sorted siltstone facies and then the medium-sorted coarse sandstone facies [19,20]. The average pore reduction per 100 m is the largest in the poor-sorted sandy gravel facies. Through the study of the image granularity data of 117 samples in the study area, it is shown that the Chang 81 and Chang 82 reservoirs in this area have relatively consistent structural characteristics. The grain size of sandstone is mainly fine sand and very fine sand, with a small amount of medium sand, silt, and suspended components such as argillaceous, and the sorting of sandstone is medium (Table 5). It belongs to the lithofacies type that is not conducive to pore preservation in the process of compaction. Moreover, after the deposition of Chang 8, the target layer is in a process of continuous and slow sinking, burial, and compaction [21]. Therefore, the fine particle size of Chang 8 reservoir, high content of soft components such as phyllites and mica (Table 1), long-term stable sinking, and burial and continuous compaction are the key factors leading to ultralow permeability and tight reservoir of Chang 8 in the study area. At the same time, the correlation diagrams of buried depth with porosity and permeability, respectively, also prove this viewpoint (Figure 7).

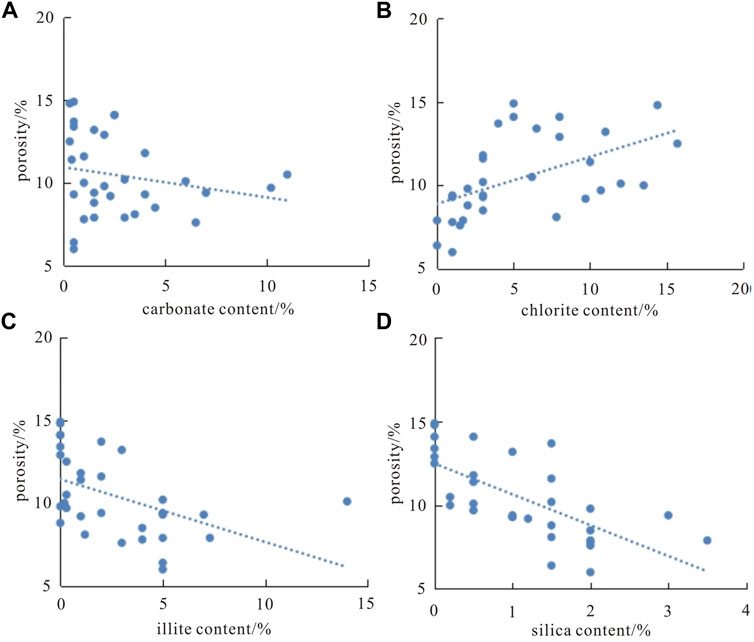

FIGURE 7. Relationship between porosity and carbonate content (A), chlorite content (B), illite concent (C), silica content (D) of Chang 8 reservoir in Wuqi-Zhijing-Ansai area.

6.2 Diagenetic Evolution Process Dominated by Destructive Diagenesis Is the Important Factor

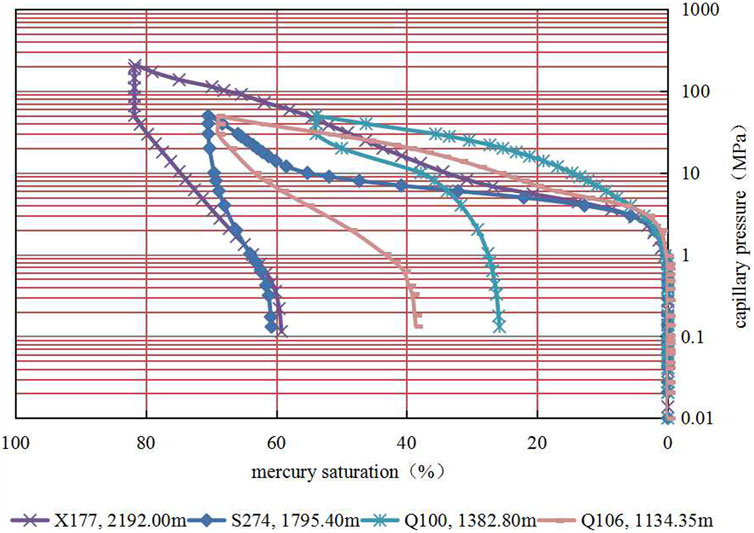

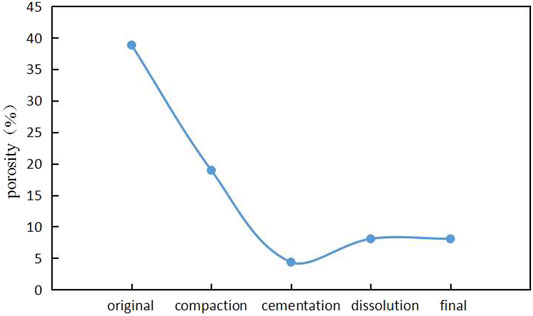

According to the data of casting thin sections and scanning electron microscope, the main diagenesis in this area is mainly destructive diagenesis, including compaction, cementation, and replacement, whereas constructive diagenesis such as dissolution is not developed. Chang 8 reservoir in the study area shows the characteristics of middle diagenesis stage A: (1) particles are mainly in point-line contact; (2) Ro is generally between 0.7% and 1.2%; (3) the clay minerals are mainly chlorite, next came illite; (4) the mixed-layer illite/smectite is ordered mixed layer, in which the proportion of smectite layer is 26% on average. The simulation of pore evolution process shows that the porosity lost by compaction and cementation accounts for more than 80% of the original porosity. Among them, cements such as carbonate, illite, and siliceous have a significant effect on porosity, which have an obvious negative correlation with the porosity (Figures 8A, C, D). The pore evolution process is as follows (Figure 9):

Original porosity 38.85% → (porosity lost by compaction 19.90%) → 18.95% → (porosity lost by cementation 14.10%) → 4.35% → (porosity increased by dissolution 3.20%) → 8.05% (final porosity).

Of course, the average contribution of dissolution to porosity is 15.78%, and chlorite film formed in the early diagenetic stage prevents the formation of minerals in the middle and late residual intergranular pores, which protects the reservoir to a certain extent (Figure 8B). These are the basic reasons for the formation of local relatively high-permeability sections.

7 Conclusion

1) Rock types of Chang 8 reservoir in Wuqi–Zhijing–Ansai area are mainly debris–feldspar sandstone and feldspar sandstone, which is different from Chang 8 reservoir in Jiyuan and Longdong areas. The reservoir space is dominated by dissolution pore–intergranular pore, and the reservoir is mainly characterized by low permeability tight reservoirs, but the reservoir capacity is relatively good with developed pore platform and high mercury injection saturation.

2) The tight reservoir of Chang 8 in northern Shaanxi province is caused by sedimentation and diagenesis. Fine particle size, high content of soft components and cements, and strong compaction are the main factors to form low porosity and low permeability reservoirs. However, because of the protective effect of early chlorite film on pores, the relatively “high-porosity and high-permeability” sweet spot area were formed locally.

Data Availability Statement

The original contributions presented in the study are included in the article/Supplementary Material further inquiries can be directed to the corresponding author.

Author Contributions

Conception and design of this study were mainly contributed by NL and JN. Data curation and investigationwere mainly contributed by XinW and XiaW. Drafting the manuscript was mainly contributed by XinW and JN. Writing-reviewing and editing were mainly contributed by NL and DR.

Funding

This work was supported by the National (Category A) Project of China (2016-6, 2016ZX05050), the Shaanxi Province Key Research and Development Plan (2021GY-140), the National Natural Science Foundation of China (51874240, 51934005 and, 52074226), the Open Fund of KeyLaboratory of Coal Resources Exploration and Comprehensive Utilization, Ministry of Natural and Resources (KF2021-3).

Conflict of Interest

The authors XinW, NL and JN were employed by the company Research Institute of Exploration and Development of PetroChina Changqing Oilfield Company. The author XiaW was employed by Xi'an Changqing Chemical Group Co.Ltd.

The remaining author declares that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s Note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

1. Li Y, Li W, Zhang Q. Atlas of Sedimentary Facies in Ordos Basin and its periphery[M]. Beijing: Geological Publishing House (2020).

2. Liu H, Li X, Wan Y, Lihua W, Liao J. Palaeogeographic and Sedimentological Characteristics of the Triassic Chang 8, Ordos Basin, China[J]. Acta Sedimentologica Sinica (2011) 29(6):1086–95.

3. Li S, Yao Y, Liu Z, Wang Y, Mou W, Yan C. Comparative Study of Underwater Distributary Channel Sandbodies in the Shallow-Water Delta from Chang 81 of Jiyuan and Northern Shaanxi Area[J]. Nat Gas Geosci (2015) 26(5):813–22.

4. Fu J, Deng X, Wang Q, Li J, Qiu J, Lewei H, et al. Compaction and Hydrocarbon Accumulation of Triassic Yanchang Formation Chang 8 Member, Ordos Basin, NW China: Evidence from Geochemistry and Fluid Inclusions[J]. Pet Exploration Develop (2017) 44(01):48–57. doi:10.1016/s1876-3804(17)30007-1

5. Chu M, Li S, Liu X, Deng X, Guo Z. Accumulation Mechanisms and Modes of Yanchang Formation Chang 8 Interval Hydrocarbons in Ordos Basin[J]. Acta Sedimentologica Sinica (2013) 31(04):683–92. doi:10.14027/j.cnki.cjxb.2013.04.012

6. Yao J, Xu L, Xing L, Luo A, Deng X, Duan Y, et al. Fluid Overpressure and Oil Migration in Chang 7 and Chang 8 Subsections of Yanchang Formation in Ordos Basin, China[J]. Nat Gas Geosci (2015) 26(12):2219–26. doi:10.11764/j.issn.1672-1926.2015.12.2219

7. Liu H, Yang Y, Wang F, Deng X, Liu Y, Nan J, et al. Micropore and Throat Characteristics and Origin of Tight sandstone Reservoirs: A Case Study of the Triassic Chang 6 and Chang 8 Members in Longdong Area, Ordos Basin, NW China. Pet Exploration Develop (2018) 45(02):223–34. doi:10.1016/s1876-3804(18)30027-2

9. Yang J. Tectonic Evolution and Oil-Gas Distribution in Ordos Basin[M]. Beijing: Petroleum Industry Press (2002).

10. Liu C. Geologic Characteristics and Petroleum Accumulation Conditions of Superimposed Basins[J]. Acta Petrolei Sinica (2007)(01) 1–7. doi:10.1016/S1872-5813(07)60034-6

11. Zhang K. Fault Block Structure and Resources in Ordos[M]. Xi'an: Shaanxi Science and Technology Press (1989).

12. Yang H. Deposition System and Oil Accumulation Research of Yanchang Formation in Triassic, Ordos Basin[D]. Chengdu: Chengdu University of Technology (2004).

13. Li K, Zhang D, Zhang S. Petroleum Geology of China (Vol. 12)[J], 199. Beijing: Petroleum Industry Press. p. 1.

14. Ye L. Sedimentary Formation of North China Platform[J]. Acta Petrologica Sinica (1984) 000(001):1–10.

15. Sun G, Liu J, Liu K, Yuan W. Evolution of a Major Mesozoic Continental Basin within Huabei Plate and its Geodynamic Setting[J]. Oil Gas Geology (1985)(03) 280–7. doi:10.11743/ogg19850309

16. Wu F, Li W, Li Y, Xi S. Delta Sediments and Evolution of the Yanchang Formation of Upper Triassic in Ordos Basin[J]. J Palaeogeogr (2004) 03:307–15. doi:10.1007/BF02873097

17. Chen C, Zhu Y, Chen X, Niu X, Zhou S, Wang X, et al. Sedimentation and Diagenesis of Chang 82 Reservoir in the Yanchang Formation in Jiyuan Region, Ordos Basin[J]. Oil Gas Geology (2013) 34(05):685–93. doi:10.11743/ogg20130516

18. Zhou Y, Xu L, Ji Y, Niu X, Che S, You Y, et al. Characteristics and Distributing Controlling Factors of Relatively High Permeability Reservoir: A Case Study from Chang82 Sandstones of Yanchang Formation in Longdong Area, Ordos Basin[J]. J China Univ Mining Tech (2017) 46(01):106–20. doi:10.13247/j.cnki.jcumt.000575

19. Jizhi 10Z, Chen S, Yan X, Lu J, Yang H, Liu C. Characteristics of the Chang 8 Tight sandstone Reservoirs and Their Genesis in Huaqing Area, Ordos Basin[J]. Oil Gas Geology (2013) 34(05):679–84. doi:10.11743/ogg20130515

20. Yingchang 11C, Xi K, Wang J, Yuan G, Tian Y. Preliminary Discussion of Simulation Experiments on the Mechanical Compaction and Physical Property Evolution of Sandstones[J]. Geoscience (2011) 25(06):1152–8. doi:10.1016/S1003-9953(10)60145-4

Keywords: Ordos Basin, Northern Shaanxi area, Chang 8 reservoir, low permeable dense, genesis mechanism

Citation: Wang X, Liu N, Nan J, Wang X and Ren D (2022) Characteristics and Genetic Mechanism of Chang Eight Low Permeability and Tight Reservoir of Triassic Yanchang Formation in Central-East Ordos Basin. Front. Phys. 9:801264. doi: 10.3389/fphy.2021.801264

Received: 25 October 2021; Accepted: 22 November 2021;

Published: 12 January 2022.

Edited by:

Qingxiang Meng, Hohai University, ChinaCopyright © 2022 Wang, Liu, Nan, Wang and Ren. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Na Liu, bGl1bjFfY3FAcGV0cm9jaGluYS5jb20uY24=

Xingying Wang

Xingying Wang Na Liu1,2*

Na Liu1,2* Dazhong Ren

Dazhong Ren