- 1Department of Gaseous Electronics (F6), Jožef Stefan Institute, Ljubljana, Slovenia

- 2Jožef Stefan International Postgraduate School, Ljubljana, Slovenia

Supercapacitors (SCs) are considered one of the front-runner energy storage devices for future electronic and automobile device applications. Even though their high-power densities, fast charge/discharge, and long cycling stabilities make them promising for future applications, their charge-discharge takes place below 1 Hz, a major issue for using them as capacitors for line filtering applications. Therefore, developing ultrafast electrochemical supercapacitors with alternating current (AC) line filtering functions has gained research attention to replace conventional aluminum electrolytic capacitors (AEC). Most available SCs possess resistive features rather than capacitive at 120 Hz because of the electrode geometry and configurations, which is a bottleneck in the research of line-filtering SCs. Addressing this challenge could be possible by developing novel electrode materials using hybrid nanostructures to meet the critical requirements for line filtering functions. This mini-review focuses on the advancement and challenges of carbon nanostructure-based electrode materials for AC line filtering applications and the future directions of this growing research area.

1 Introduction

Ultra-high-power performance, long-term stability, and compact size of supercapacitors (SCs) make them an efficient alternative for addressing the rising demand for portable and miniaturized electronic devices (Miller and Simon, 2008; Simon and Gogotsi, 2020). However, due to the microporous materials in the electrode configurations, the charge-discharge mechanism limits up to 1 Hz (Toupin et al., 2005; Miller et al., 2010). Such poor performance of available SCs limits their commercial use, considering the large-scale requirement of direct current (DC) supply. The constant production of DC voltage is attained by converting alternating current (AC) using a rectifier to get a unidirectional output. Nevertheless, the output should be further smoothed for a stable DC voltage, which can be achieved by the AC line filters (ALF). In order to satisfy the large-scale power demand, the ALF has been installed in a capacitor, which demonstrates high capacitance at high-frequencies (100–200 Hz).

Currently, aluminum electrolytic capacitors (AEC), a polarized asymmetric dielectric capacitor, have been widely used to achieve sufficient ALF performance (Both, 2015; Park and Kim, 2021; Tang et al., 2022). Even though AEC can respond at higher frequencies (>10 kHz), the energy density and capacitance have been reported to be much lower (∼2–5 orders of magnitude) than the SCs. Besides, the bulky size and rigid shape of AECs are considered incompatible with designing portable miniaturized electronic devices (Tang et al., 2022). In addition, bridging the large performance gap between the supercapacitors and AECs regarding capacitance density and frequency response could benefit compact circuit designs. Even though AECs can respond at high frequencies, bulky size is required to provide capacitance in microfarads (Both, 2015; Yoo et al., 2015). Such a scenario leads to the development of advanced capacitors to replace AECs that can respond at higher frequencies with higher capacitance for better ALF performance. Owing to their high energy performance and small-scale dimensions, SCs have gained interest in being used as a promising ALF tool despite their unsatisfactory capacitive responses at high frequencies (Park and Kim, 2021; Ma et al., 2024). According to US/EU standards, the ALF capacitors for a 60/50 Hz line filtering should respond at 120/100 Hz with minimal energy loss (Li et al., 2019; Santhosh et al., 2023). The unsatisfactory high-frequency responses of SCs are attributed to the high equivalent series resistance (ESR) and the microporous structure of the active electrode materials. Therefore, numerous efforts have been made to develop novel electrode materials with minimum ESR and structural connectivity (Zhang et al., 2023).

The efforts to develop novel electrodes for ALF applications have significantly increased since Miller et al. used vertically oriented graphene nanosheet (VOGN) as an advanced electrode material for filtering capacitors in 2010 (Miller et al., 2010). Later, various electrode structures, including carbon, metal, polymer-based, and hybrid nanostructures, have been reported to meet the electrode criteria for ALF (Fan et al., 2021; Kumar Mariappan et al., 2021; Tang et al., 2022; Zhang et al., 2023). Several studies reported that mesoporosity and open structure features of carbon-based nanostructures could be the most promising electrode materials for ALF with improved frequency response (Zhang et al., 2020; Feng et al., 2021). Therefore, this mini-review summarizes the critical features of electrode materials and the advancement of carbon-based nanostructures as efficient electrode materials for filtering electrochemical capacitors (FECs).

2 Mechanism and measurement of FECs

In line filtering, the circuit comprises a rectifier bridge using diodes and FECs. The high-frequency AC signal is converted to a constant signal by the rectifier bridge and smoothed by the FECs. In a capacitor filtering process, a capacitor acts as a reservoir of charge and maintains the stability of the device by adjusting the fluctuation in the voltage (Fan et al., 2017; Zhao et al., 2020; Ma et al., 2024). If the voltage in the circuit is less than the capacitor voltage, the capacitor releases the charge, while in a higher voltage scenario, the capacitor absorbs the charge to maintain the voltage balance. However, if the capacitor is in a circuit with a frequency range higher than the response range, the capacitor could have difficulties maintaining the charge storage balance, which eventually loses the filtering function and acts as a resistive device (Zhao et al., 2020; Tang et al., 2022; Ma et al., 2024). Such an effect could lead to the appearance of ripple voltage, which can be eliminated by achieving higher capacitance. Therefore, to minimize the voltage loss during the FEC performance, the series RLC equivalent circuit model has been widely used, in which R, L and C represent resistance, inductance, and capacitance, respectively (Wu et al., 2019; Feng et al., 2021). These values are directly influenced by the mass loading of the active materials, in which L increases, C decreases with the high-frequency performance, and R remains constant (Feng et al., 2021). Therefore, different electrochemical capacitor models compared to AECs, such as electrical double-layer capacitors (EDLC) and pseudocapacitors, have been explored. Such models have higher specific capacitance but require higher time to respond at higher frequencies due to the ion transfer and surface reaction process. Therefore, it is necessary to monitor the changes in the capacitance response along with the changes in the frequency range. In order to achieve high filtering performances, the capacitors should respond with very high capacitive features and demand the typical triangular galvanostatic charge-discharge and rectangular cyclic voltammetry curve (Mathis et al., 2019).

Electrochemical impedance spectroscopy (EIS), which measures the variation in impedance with sinusoidal frequency, could be the key method for evaluating the filtering capability of an SC (Taberna et al., 2003). The Nyquist plot of the EIS of an SC consists of three regions, including a high-frequency semi-circle (due to the charge transfer resistance at the electrode/electrolyte interface), which could be formed due to the presence of an insulated layer on the current collector or due the pseudocapacitive effect (Gamby et al., 2001; Shuai et al., 2017; dos Santos et al., 2023); intermediate region Warburg impedance (rapid diffusion of ions), towards the higher frequency, the evolution of knee point (knee frequency fk) could be visible, followed by the characteristic 45° slope region (Fan et al., 2017). This region reveals the distributed capacitance and resistance in the electrode material. The almost tilted/vertical line at a low frequency can be attributed to a constant phase element (CPE) with an ideality factor. In addition, the frequency response is mainly expressed by the time constant and impedance phase, in which the relationship between the phase angle of impedance to the frequency is expressed as a Bode diagram (Zhao et al., 2020). A bode diagram also presents three regions: capacitive (low-frequency), diffusion (intermediate), and induction (high-frequency) behaviors. The gradual transition from the diffusion region to the capacitive region increases the phase angle in the Bode plot, and a near-optimal stable phase angle value is approximately 90°. In general, the phase angle at 120 Hz is described as one of the key indicators for investigating the ALF performance. The specific capacitance of FEC could be evaluated by the following equation, Equation 1 (Zhao et al., 2020; Santhosh et al., 2023):

Creal is the real component of capacitance, f is frequency (Hz), and Z″ (Ω) is the imaginary part of the impedance (Kyeremateng et al., 2016). The time constant (RC) could be obtained by the equation, Equation 2:

C is the specific capacitance, and Z′ is the resistance derived from the real part of the impedance. The minimum time constant for FECs is approximately 8.3 m at 120 Hz, and a phase angle close to 90° gives better filtering performance with minimal heat loss (Zhang P. et al., 2018). Apart from this, to have higher FEC performance, a minimum of ESR is critical (ideally in the order of milli ohms). To achieve the minimum ESR values, it is important to reduce the electrolyte resistance, electrode resistance and contact resistance between the electrode and the current collector.

3 Key factors and nanostructure design

The RC value of an SC is generally 1s, which is much higher than the minimum requirement needed for ALF applications (Zhang Z. et al., 2018; Zhao et al., 2020). The high RC value of conventional SCs could be attributed to the complex pore structures of the active electrode material, which limit the ion diffusion speed and increase the charge transfer resistance. Apart from RC, the relaxation time constant (τ0) and the cut-off frequency are also critical parameters. The first is the minimum time required to discharge the energy from SC with more than 50% efficiency. The cut-off frequency is when the impedance phase angle reaches −45°, which determines the characteristic of SC between the capacitive and the resistive behavior (Fan et al., 2017). Lower τ0 corresponds to higher rate performance of the SC and excellent capacitive behavior at the high-frequency regime. The high-rate performance and stability of SC are the keys to developing electronic devices with maximum damage and long-term running time.

Considering the ALF performance of an SC is significantly influenced by the employed electrode materials, most of the research focused on developing novel electrode materials by considering the following key aspects (Fan et al., 2017; Zhao et al., 2020; Santhosh et al., 2023):

• Highly conductive active material with high interconnectivity, surface area, and minimum internal resistance by designing electrodes with hierarchical morphology.

• Direct contact between the current collector and active material to keep the contact resistance as minimal as possible by directly growing structures on the current collector.

• Active material with controlled thickness avoids the porous effect during the charge transfer. The optimum thickness for the ALF applications is ∼1–10 μm.

• Well-connected nanostructures with large-size pores to avoid the micro/inner pore effect to achieve fast ion diffusion on the surface.

To satisfy these conditions, various nanostructures directly grown on the current collector with different structural orientations and hierarchical morphologies, including carbon, metal oxides, polymers, and their hybrids, were reported. Due to the low cost, fast production techniques, electrochemical inertness, and various available allotrope forms, carbon-based nanostructures are front runners in FEC applications.

4 Carbon-based electrodes

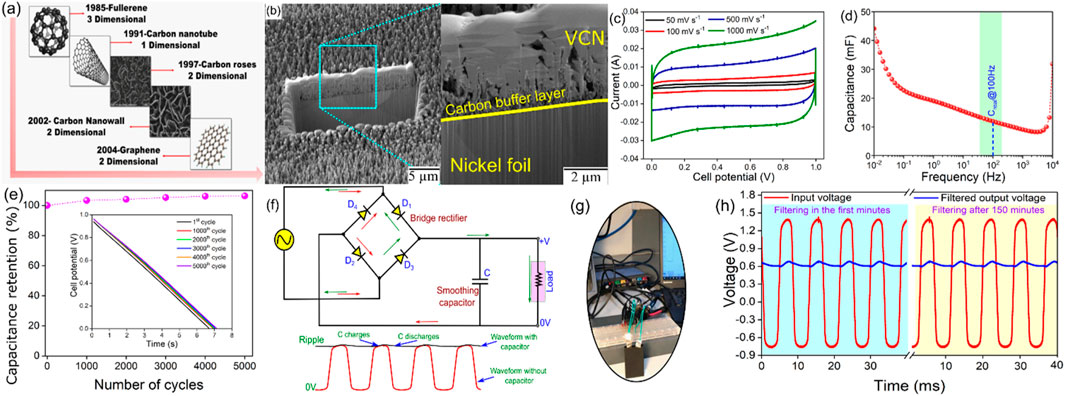

Carbon exists in both crystalline and amorphous forms with different allotropes, including graphene, carbon nanotubes, and carbon black, which offer large specific areas and high electrical conductivity (Santhosh et al., 2018; Kothandam et al., 2023; Sammed et al., 2023). The excellent structural, chemical and electrical characteristics of carbon and its allotropes offer a large scope for ALF applications (Feng et al., 2021; Bundaleska et al., 2024). Carbon nanostructure-based research has gained much interest in the last few decades due to its structural diversity and surface tailorability. The invention of fullerene enthused nanocarbon research and its potential applications (Rao et al., 1996; Prassides, 1997). Such research attention guided the invention of various structures, including carbon nanotubes (CNTs), which were discovered as multi-walled and single-walled (Rao et al., 1996; Purohit et al., 2014). More recently, a two-dimensional single-layered form of carbon atoms with a hexagonal lattice was discovered, known as graphene. Later, advanced carbon structures with sp2 and sp3 hybridisations were developed with structural designs of diamond, few-layer graphene, defected graphene, vertical graphene and graphitic nanoribbons (Geim, 2009; Olabi et al., 2021; Bhatt et al., 2022). Based on the dimension (0D, 1D, 2D or 3D) and orientation of the structure to the substrate (horizontal or vertical), the properties of the carbon nanostructures could be varied and tailored for specified applications. A milestone study in carbon research during the invention of different structural designs is presented in Figure 1A.

Figure 1. (A) milestones in carbon nanostructure research [Reproduced with permission from ref (Santhosh et al., 2018) (B) surface morphology and cross-section image of NCNF electrodes; Electrochemical results on a device made with 10 pairs of NCNF electrodes: (C) CV at different scan rates; (D) capacitance vs. frequency; (E) stability results up to 5,000 cycles at 4 mA; (F) Schematic illustration of set-up for AC/DC conversion and (G) electrochemical device made of 10 pairs of NVCN electrodes assembled to filter AC signal (H) long-term filter output profile (in blue, applied voltage 2 V peak to peak, frequency 100 Hz). Reproduced with permission from ref (Santhosh et al., 2023); copyright 2023, Elsevier.

Carbon with different allotropes, including graphene, carbon nanotubes, and carbon black, offers large specific areas and high electrical conductivity, have enormous potential for ALF applications. Besides, the easy tailorability of carbon into different orientations, including vertical and hierarchical, with different dimensions, also attracts the ALF research areas. However, their micropore structures diminish their potential to respond at high frequencies and limits below 1 Hz. To boost the capacitance and the ion diffusion rate, the current research mainly focuses on designing the hierarchical structure of graphene, carbon nanotubes, carbon nanofiber, and their derivatives to reduce the volume and increase energy density.

Miller et al. initiated interest in carbon-based materials for FEC in 2010, using VOGN produced by plasma-enhanced chemical vapour deposition (PECVD) as an electrode material (Miller et al., 2010). Following this, several FEC designs were developed using carbon-based electrode structures, device configurations, and integrated systems. The timeline of major developments of FECs includes vertical graphene (Miller et al., 2010), 3D graphene-based microsupercapacitor (Lin et al., 2013), reduced GO-based femtosecond microsupercapacitor (Li et al., 2016), and circuit integrable microsupercapacitor (Ye et al., 2018; Xu et al., 2019). To minimize the ionic transfer distance and internal resistances, various advanced techniques, including inkjet printing (Kossyrev, 2012), PECVD (Cai et al., 2014; Lim et al., 2016; Santhosh et al., 2023), chemical vapour deposition (CVD) (Han et al., 2022; Chen et al., 2024b), vacuum filtration (Yoo et al., 2015; Kang et al., 2016), photolithography (Lin et al., 2013), electrochemical reduction (Chi et al., 2017), electrodeposition and wet chemistry (Zhou et al., 2016) techniques have been employed for the carbon electrode FEC fabrications. All these design strategies were targeted to ensure rapid frequency response by providing high conductivity of the electrode materials and direct contact between the current collector and electrode materials to minimize the contact resistance.

Thus, the structural design of electrodes was classified as follows: (i) Oriented structures with open edges to promote rapid charge transfer by providing sufficient active sites and exposed edges for direct accessibility of ions in the electrolyte. Such an approach resulted in developing vertically oriented graphene and carbon nanotube-based structures for FECs (Miller et al., 2010; Yan et al., 2020; Lin et al., 2021; Santhosh et al., 2023). (ii) Porous electrode materials with hierarchical morphologies were targeted to provide rapid ionic transport. Even though such porous materials possess slightly larger resistance, the abundant active sites promote high specific capacitance with rapid frequency response (Cheng et al., 2019; Gao et al., 2020). (iii) Electrodes with fiber network architecture ensure minimal resistance and unidirectional electronic transport. The interconnected networked electrodes could facilitate ionic transport and permeation owing to their open boundary structures (Pu et al., 2018; Gao et al., 2019; Zhai et al., 2020). Apart from the structure design, the thickness of the active material also plays a critical role in the FEC device, considering the thickness could influence the ionic transport pathway, accessible active sites, and vertical electronic transport (Zhang Z. et al., 2018). An order of magnitude of cut-off frequency could be enhanced by decreasing the thickness of the material, and thus, extremely thin electrodes are mainly suitable for FECs, which are also suitable for FECs in miniaturized circuit designs.

The advancement in carbon-based electrodes in FECs started with using VOGN, in which the vertical orientation of VOGN with interspacing contributes to more electroactive sites at the edges and minimizes the charge transfer impedance (Miller et al., 2010). Additionally, the growth of VOGN directly on the current collector reduces the contact resistance and facilitates the charge transfer pathways to enhance the frequency response. The FEC fabricated using VOGN exhibited a phase angle of −82° at 120 Hz with a capacitance of 175 µF. Similarly, Islam et al. demonstrated the edge-oriented graphene grown on cellulose paper as an effective electrode for FECs with a promising capacitance performance of 1,070 µF and phase angle −80.5° at 120 Hz (Islam et al., 2019). The porous graphene films prepared by in situ carbothermal reduction strategies proposed by Zhang et al. demonstrated that the porous structure enhances the surface area to boost the ion diffusion significantly (Zhang Z. et al., 2018). As a result, the prepared FEC delivered a capacitance of 360 µF with a phase angle of −82.3° at 120 Hz. Like graphene-based electrodes, several researchers reported the potential of reduced graphene oxide (rGO) as an electrode for FECs. A 3D interpenetrating structure proposed by Sheng et al. demonstrated the electrochemically reduced GO as an FEC electrode with a capacitance of 283 µF and phase angle −83° at 120 Hz (Sheng et al., 2012). In another report, Zhao et al. demonstrated the rGO fibers as FEC electrodes with an internal resistance of 1.78 Ω and high-frequency response with a specific capacitance of 264 µF and phase angle −81.1° at 120 Hz (Zhao et al., 2019).

Following the growing interest in graphene structures for FECs, carbon nanotubes (CNTs) have also been considered a prime candidate for use as an FEC electrode. In one of the reports, Kang et al. demonstrated CNT-based FEC using an ionic electrolyte and investigated the effect of thickness during ALF (Kang et al., 2016). While investigating different thicknesses of CNT electrodes at 300 nm and 50 nm, the phase angle increased from 70.6° to 82.7°, while the capacitance reduced to 43 from 233 μF at 120 Hz. Such results enlighten the observation that the area density and thickness of the material are directly connected to the frequency response. To overcome this issue, in one of the works, Lin et al. demonstrated the design of hybrid graphene-CNT-based electrodes for FEC and achieved a phase angle and capacitance of −82.3° and 230 μF, respectively, at 120 Hz (Lin et al., 2013). To design lightweight FECs and develop miniaturizing electronic devices, Santhosh et al. reported the growth of nitrogen-doped vertical carbon nanotube (VCN) and nanoforest (NCNF) directly on nickel foil as electrode material using plasma deposition techniques. At 100 Hz (according to EU standards), the FEC composed of a pair of NCNF (2.5 × 3.5 cm2) displays a phase angle of −80° and a superior capacitance of 1,145 μF (Santhosh et al., 2023). In addition, to analyze the industrial potential of such devices, the authors fabricated a prototype consisting of 10 pairs of NCNF electrodes, which demonstrated an ESR of 5.8 mΩ and a high capacitance value of 12 mF. Besides, the fabricated prototype enables constant filtering of AC waveform into stable DC voltage for a long time by providing the same filtering capability without changing ripple voltage over 3 h. The surface morphology and electrochemical performance of the reported NCNF for FECs are presented in Figures 1B–H.

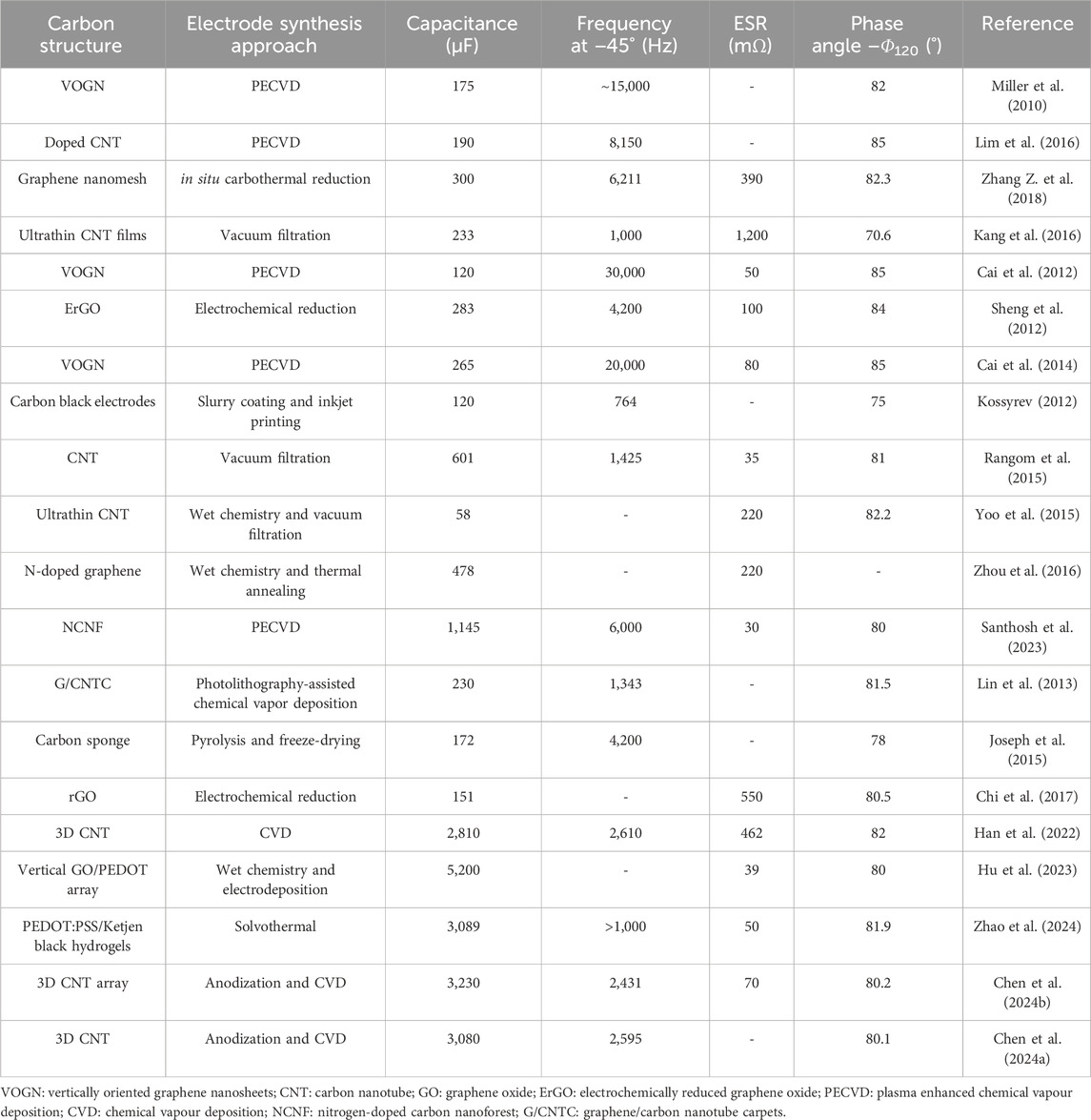

Besides CNTs and graphene structures, other carbon forms, including carbon onions, carbon fibers, carbon black, and activated carbon, were also reported for FEC applications (Zhang et al., 2020; Zhang et al., 2022; Ma et al., 2024). Table 1 summarizes the various carbon-based nanostructures and their FEC performances. The pioneering research in carbon-based FEC delivered a specific capacitance of 175 μF at 120 Hz. The latest research on carbon-based electrodes reported by Hu et al. delivered a higher capacitance of 5,200 µF with a similar phase angle at 120 Hz (Hu et al., 2023). The 3D nanoarrays of nanotubes have also been reported with capacitance above 3,000 µF (Zhao et al., 2024) and also reported for use in integrated circuit designs (Laszczyk et al., 2015).

Table 1. Summary of various carbon nanostructures reported for high-frequency applications and their FEC performances.

The advancement of carbon-based FECs, besides the electrode developments, is their implementation in different applications. Switching circuit power supplies is one of the fields where FECs are widely used. Hu et al. demonstrated the potential of GO-based FECs for filtering applications in printed circuit board-based switch circuits (Hu et al., 2023). Similarly, N. M. Santhosh et al. demonstrated the ability of a FEC prototype fabricated based on the NCNF electrodes for efficient line filtering (Santhosh et al., 2023). Both devices are compact and have demonstrated superior performance compared to conventional AECs. Another focused area of FEC application is voltage stabilization by introducing FEC in parallel at the output end of the rectifier. The DC output is smoothed by reducing the AC ripple factor, which ensures a stable and smooth DC output. Wang et al. demonstrated a compact hybrid aqueous-based FEC for the effective AC-DC conversion (Wang et al., 2023). The research reported that by introducing the FEC, voltage stabilization is enhanced, as observed from the LED placed in the circuit. The LED remained continuously bright without any fading. Apart from the line filtering performances, FECs have been explored in the field of fluctuating energy harvesting devices. Placing FECs into the circuit can improve the smoothing of fluctuating energy, which could be applied to electronic devices. Wu et al. propose the potential of high-performing FEC fabricated using hierarchically 3D fibrous electrodes (based on ErGO) in series with triboelectric nanogenerators to constantly harvest the human motion energy during continuous contact with human skin (Wu et al., 2023). The unstable AC signal successfully smoothed into a gradual voltage rise with the human body movement and achieved a DC output once the body movement ended. Nevertheless, circuit design and electronic devices still need an all-in-one-chip rectifying circuit to decrease device volume further. Therefore, there are still several areas that need to be optimized for further advancements in FEC research.

5 Conclusion and future perspectives

With the rapid progress of portable and miniaturized devices, research attention is significantly increasing towards developing advanced ALF supercapacitors to replace the AECs. Thus, the research focuses on optimizing electrode materials, tailoring electrical properties, fine-tuning pore structures, and establishing feasible synthesis methods to achieve ultrahigh frequency response with excellent rate capability, energy density, and long-term filtering stability. To overcome the drawbacks of the conventional electrodes for SCs in ALFs, researchers have switched the focus to developing novel carbon-based electrodes with open boundaries and channels to enhance capacitance and frequency response simultaneously. However, the capacitance response of carbon-based electrodes is still not sufficient to use them in large-scale applications. Therefore, establishing fast fabrication methods to design novel carbon electrodes with high ALF capabilities is still a potential area of research.

Even though the future of carbon electrodes for FECs has significant potential, several challenges need to be addressed, including scaling up production. Most currently reported direct growth of carbon nanostructures for FECs are based on CVD or PECVD at low pressure, which are comparatively energy-consuming techniques. Therefore, designing electrodes at a large scale and low cost is critical for upscaling the electrodes for practical applications. Apart from this, electrode-electrolyte combinations need to be optimized to achieve higher performance in FECs. One of the most efficient approaches to improving the frequency response is to design a bicontinuous electrode structure. This advanced design of carbon electrodes ensures higher electrical conductivity by a continuous carbon structure and pore structure filled with electrolytes for fast charge transfer in high frequencies. In addition, the formulation of nanostructured electrolytes could also contribute to improved performance by developing ion-gel-based electrolytes (Park and Kim, 2021). Designing bicontinuous electrodes and electrolytes could contribute to minimizing the ESR and improving the thermal stability of the FEC by reducing heat dissipation.

In this perspective, the future of carbon-based electrodes for ALFs need to cover several aspects to make breakthroughs: (i) homogeneity and thickness of electrodes play a crucial role. The thicker electrodes give higher capacitance, but the porous structure hinders the frequency response. Also, the non-homogenous electrode fabrication may limit the charge transfer to lower the performance significantly; (ii) ultralow contact and internal resistance: developing electrodes with low ESR and minimal resistance between the current collector is critical for the fast response and high capacitance in ALFs. Therefore, electrodes with enhanced conductivity by post-treatments and interconnected morphologies are the future of ALFs; iii) structural design with improved density: electrode materials with 3D networks and vertical morphologies could enhance the charge storage and increased density. In addition, the continuous pore and active material connection would facilitate the fast ion diffusion to enhance the frequency response; (iv) hybrid design with pseudocapacitive materials: designing electrodes with multifunctional properties, including EDLC and pseudocapacitors. One example is combining vertical carbon-based electrodes with metal oxides or sulfides, which could contribute to high capacitance and structural stability with high-frequency responses. In addition, combining carbon-based materials with a polymeric matrix benefits the design of free-standing, flexible electrodes for FECs. (v) Self-discharge and output voltage limitation: the intrinsic properties of SCs lead to self-discharging, and most of the developed FECs are operated under 10V. This could result from parasitic faradaic reactions and ohmic leakage and should be overcome by ensuring good electronic insulation between the electrodes and optimizing the electrolyte combination.

Furthermore, integrating FECs with different energy harvesting devices, such as nanogenerators, could lead to the innovation of multipurpose electronic devices in the future. In addition, with solid electrolytes, FECs can be used in flexible electronics, an important direction for the next-generation electronic devices. Considering that the bulk part of a circuit system is occupied by the conventional AEC-based filtering capacitor, replacing them with miniaturized SCs has an inevitable future and is a vital branch of future SC research. Developing advanced electrode materials and optimizing electrolyte combinations would achieve superior ALF performances for practical applications.

Author contributions

NS: Conceptualization, Investigation, Writing–original draft, Writing–review and editing. UC: Conceptualization, Funding acquisition, Validation, Writing–review and editing.

Funding

The author(s) declare that financial support was received for the research, authorship, and/or publication of this article. NMS and UC acknowledge the Slovenian Research Agency (ARIS) for the program P1-0417, research grants J2-50074 and Z2-4467 (post-doctoral grant) and M-ERA. NET 3 project ANGSTROM funded in Joint Translational Call 2023 (The project is funded by Ministrstvo za visoko solstvo, znanost in inovacije – MVZI, Slovenia).

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

The author(s) declared that they were an editorial board member of Frontiers, at the time of submission. This had no impact on the peer review process and the final decision.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Bhatt, M. D., Kim, H., and Kim, G. (2022). Various defects in graphene: a review. RSC Adv. 12, 21520–21547. doi:10.1039/D2RA01436J

Both, J. (2015). The modern era of aluminum electrolytic capacitors. IEEE Electr. Insul. Mag. 31, 24–34. doi:10.1109/MEI.2015.7126071

Bundaleska, N., Felizardo, E., Santhosh, N. M., Upadhyay, K. K., Bundaleski, N., Teodoro, O. M. N. D., et al. (2024). Plasma-enabled growth of vertically oriented carbon nanostructures for AC line filtering capacitors. Appl. Surf. Sci. 676, 161002. doi:10.1016/J.APSUSC.2024.161002

Cai, M., Outlaw, R. A., Butler, S. M., and Miller, J. R. (2012). A high density of vertically-oriented graphenes for use in electric double layer capacitors. Carbon N. Y. 50, 5481–5488. doi:10.1016/j.carbon.2012.07.035

Cai, M., Outlaw, R. A., Quinlan, R. A., Premathilake, D., Butler, S. M., and Miller, J. R. (2014). Fast response, vertically oriented graphene nanosheet electric double layer capacitors synthesized from C 2 H 2. ACS Nano 8, 5873–5882. doi:10.1021/nn5009319

Chen, G., Han, F., Lin, D., Zhang, S., Pan, Q., Shao, C., et al. (2024a). Three-dimensional multi-layer carbon tube electrodes for AC line-filtering capacitors. Joule 8, 1080–1091. doi:10.1016/J.JOULE.2024.01.026

Chen, G., Han, F., Ma, H., Li, P., Zhou, Z., Wang, P., et al. (2024b). High density 3D carbon tube nanoarray electrode boosting the capacitance of filter capacitor. Nanomicro Lett. 16, 235–313. doi:10.1007/s40820-024-01458-6

Cheng, T., Wu, Y.-W., Chen, Y.-L., Zhang, Y.-Z., Lai, W.-Y., Huang Cheng, W. T., et al. (2019). Inkjet-printed high-performance flexible micro-supercapacitors with porous nanofiber-like electrode structures. Small 15, 1901830. doi:10.1002/SMLL.201901830

Chi, F., Li, C., Zhou, Q., Zhang, M., Chen, J., Yu, X., et al. (2017). Graphene-based organic electrochemical capacitors for AC line filtering. Adv. Energy Mater 7, 1700591. doi:10.1002/AENM.201700591

dos Santos, J. P. A., Cesar Rufino, F., Yutaka Ota, J. I., Fernandes, R. C., Vicentini, R., Pagan, C. J. B., et al. (2023). Best practices for electrochemical characterization of supercapacitors. J. Energy Chem. 80, 265–283. doi:10.1016/J.JECHEM.2022.12.034

Fan, Y. F., Yi, Z. L., Song, G., Wang, Z. F., Chen, C. J., Xie, L. J., et al. (2021). Self-standing graphitized hybrid Nanocarbon electrodes towards high-frequency supercapacitors. Carbon N. Y. 185, 630–640. doi:10.1016/J.CARBON.2021.09.059

Fan, Z., Islam, N., and Bayne, S. B. (2017). Towards kilohertz electrochemical capacitors for filtering and pulse energy harvesting. Nano Energy 39, 306–320. doi:10.1016/j.nanoen.2017.06.048

Feng, X., Shi, X., Ning, J., Wang, D., Zhang, J., Hao, Y., et al. (2021). Recent advances in micro-supercapacitors for AC line-filtering performance: from fundamental models to emerging applications. eScience 1, 124–140. doi:10.1016/J.ESCI.2021.11.005

Gamby, J., Taberna, P. L., Simon, P., Fauvarque, J. F., and Chesneau, M. (2001). Studies and characterisations of various activated carbons used for carbon/carbon supercapacitors. J. Power Sources 101, 109–116. doi:10.1016/S0378-7753(01)00707-8

Gao, K., Wang, S., Liu, W., Yue, Y., Rao, J., Su, J., et al. (2019). All fiber based electrochemical capacitor towards wearable AC line filters with outstanding rate capability. Chem. Electro Chem. 6, 1450–1457. doi:10.1002/CELC.201801593

Gao, Y., Zheng, S., Fu, H., Ma, J., Xu, X., Guan, L., et al. (2020). Three-dimensional nitrogen doped hierarchically porous carbon aerogels with ultrahigh specific surface area for high-performance supercapacitors and flexible micro-supercapacitors. Carbon N. Y. 168, 701–709. doi:10.1016/J.CARBON.2020.06.063

Geim, A. K. (2009). Graphene: status and prospects. Science 324, 1530–1534. doi:10.1126/science.1158877

Han, F., Qian, O., Meng, G., Lin, D., Chen, G., Zhang, S., et al. (2022). Structurally integrated 3D carbon tube grid-based high-performance filter capacitor. Science 377, 1004–1007. doi:10.1126/science.abh4380

Hu, Y., Wu, M., Chi, F., Lai, G., Li, P., He, W., et al. (2023). Ultralow-resistance electrochemical capacitor for integrable line filtering. Nature 624, 74–79. doi:10.1038/s41586-023-06712-2

Islam, N., Hoque, M. N. F., Li, W., Wang, S., Warzywoda, J., and Fan, Z. (2019). Vertically edge-oriented graphene on plasma pyrolyzed cellulose fibers and demonstration of kilohertz high-frequency filtering electrical double layer capacitors. Carbon N. Y. 141, 523–530. doi:10.1016/J.CARBON.2018.10.012

Joseph, J., Paravannoor, A., Nair, S. V., Han, Z. J., Ostrikov, K., and Balakrishnan, A. (2015). Supercapacitors based on camphor-derived meso/macroporous carbon sponge electrodes with ultrafast frequency response for ac line-filtering. J. Mater Chem. A Mater 3, 14105–14108. doi:10.1039/C5TA03012A

Kang, Y. J., Yoo, Y., and Kim, W. (2016). 3-V solid-state flexible supercapacitors with ionic-liquid-based polymer gel electrolyte for AC line filtering. ACS Appl. Mater Interfaces 8, 13909–13917. doi:10.1021/ACSAMI.6B02690

Kossyrev, P. (2012). Carbon black supercapacitors employing thin electrodes. J. Power Sources 201, 347–352. doi:10.1016/j.jpowsour.2011.10.106

Kothandam, G., Singh, G., Guan, X., Lee, J. M., Ramadass, K., Joseph, S., et al. (2023). Recent advances in carbon-based electrodes for energy storage and conversion. Adv. Sci. 10, 2301045. doi:10.1002/ADVS.202301045

Kumar Mariappan, V., Krishnamoorthy, K., Manoharan, S., Pazhamalai, P., Kim, S.-J., Mariappan, V. K., et al. (2021). Electrospun polymer-derived carbyne supercapacitor for alternating current line filtering. Small 17, 2102971. doi:10.1002/SMLL.202102971

Kyeremateng, N. A., Brousse, T., and Pech, D. (2016). Microsupercapacitors as miniaturized energy-storage components for on-chip electronics. Nat. Nanotechnol. 12 (1), 7–15. doi:10.1038/nnano.2016.196

Laszczyk, K. U., Kobashi, K., Sakurai, S., Sekiguchi, A., Futaba, D. N., Yamada, T., et al. (2015). Lithographically integrated microsupercapacitors for compact, high performance, and designable energy circuits. Adv. Energy Mater 5, 1500741. doi:10.1002/AENM.201500741

Li, R. Z., Peng, R., Kihm, K. D., Bai, S., Bridges, D., Tumuluri, U., et al. (2016). High-rate in-plane micro-supercapacitors scribed onto photo paper using in situ femtolaser-reduced graphene oxide/Au nanoparticle microelectrodes. Energy Environ. Sci. 9, 1458–1467. doi:10.1039/C5EE03637B

Li, W., Islam, N., Ren, G., Li, S., and Fan, Z. (2019). AC-filtering supercapacitors based on edge oriented vertical graphene and cross-linked carbon nanofiber. Materials 12, 604. doi:10.3390/MA12040604

Lim, J., Maiti, U. N., Kim, N. Y., Narayan, R., Lee, W. J., Choi, D. S., et al. (2016). Dopant-specific unzipping of carbon nanotubes for intact crystalline graphene nanostructures. Nat. Commun. 7, 10364. doi:10.1038/NCOMMS10364

Lin, J., Zhang, C., Yan, Z., Zhu, Y., Peng, Z., Hauge, R. H., et al. (2013). 3-dimensional graphene carbon nanotube carpet-based microsupercapacitors with high electrochemical performance. Nano Lett. 13, 72–78. doi:10.1021/NL3034976

Lin, S., Tang, J., Zhang, K., Suzuki, T. S., Wei, Q., Mukaida, M., et al. (2021). High-rate supercapacitor using magnetically aligned graphene. J. Power Sources 482, 228995. doi:10.1016/J.JPOWSOUR.2020.228995

Ma, X., Sha, J., Chen, B., Shi, C., Ma, L., Wang, H., et al. (2024). Recent progress on the materials and structure of supercapacitors for AC line filtering applications. J. Mat. Chem. A 12, 17817–17834. doi:10.1039/d4ta03370a

Mathis, T. S., Kurra, N., Wang, X., Pinto, D., Simon, P., and Gogotsi, Y. (2019). Energy storage data reporting in perspective—guidelines for interpreting the performance of electrochemical energy storage systems. Adv. Energy Mater 9, 1902007. doi:10.1002/AENM.201902007

Miller, J. R., Outlaw, R. A., and Holloway, B. C. (2010). Graphene double-layer capacitor with ac line-filtering performance. Science 329, 1637–1639. doi:10.1126/science.1194372

Miller, J. R., and Simon, P. (2008). Electrochemical capacitors for energy management. Science 321, 651–652. doi:10.1126/science.1158736

Olabi, A. G., Abdelkareem, M. A., Wilberforce, T., and Sayed, E. T. (2021). Application of graphene in energy storage device – a review. Renew. Sustain. Energy Rev. 135, 110026. doi:10.1016/J.RSER.2020.110026

Park, J., and Kim, W. (2021). History and perspectives on ultrafast supercapacitors for AC line filtering. Adv. Energy Mater 11, 2003306. doi:10.1002/AENM.202003306

Prassides, K. (1997). Fullerenes. Curr. Opin. Solid State Mater Sci. 2, 433–439. doi:10.1016/S1359-0286(97)80085-X

Pu, J., Wang, X., Xu, R., Xu, S., and Komvopoulos, K. (2018). Highly flexible, foldable, and rollable microsupercapacitors on an ultrathin polyimide substrate with high power density. Microsystems and Nanoeng. 4, 16–11. doi:10.1038/s41378-018-0016-3

Purohit, R., Purohit, K., Rana, S., Rana, R. S., and Patel, V. (2014). Carbon nanotubes and their growth methods. Procedia Mater. Sci. 6, 716–728. doi:10.1016/J.MSPRO.2014.07.088

Rangom, Y., Tang, X. S., and Nazar, L. F. (2015). Carbon nanotube-based supercapacitors with excellent ac line filtering and rate capability via improved interfacial impedance. ACS Nano 9, 7248–7255. doi:10.1021/acsnano.5b02075

Rao, C. N. R., Sen, R., and Govindaraj, A. (1996). Fullerenes and carbon nanotubes. Curr. Opin. Solid State Mater Sci. 1, 279–284. doi:10.1016/S1359-0286(96)80095-7

Sammed, K. A., Farid, A., Mustafa, S., Kumar, A., Tabish, M., Khan, A. A., et al. (2023). Developing next-generation supercapacitor electrodes by coordination chemistry-based advanced functional carbon nanostructures: progress, Current challenges and prospects. Fuel Process. Technol. 250, 107896. doi:10.1016/J.FUPROC.2023.107896

Santhosh, N. M., Filipič, G., Tatarova, E., Baranov, O., Kondo, H., Sekine, M., et al. (2018). Oriented carbon nanostructures by Plasma processing: recent advances and future challenges. Micromachines (Basel) 9, 565. doi:10.3390/mi9110565

Santhosh, N. M., Upadhyay, K. K., Filipič, G., Zavašnik, J., de Fátima Montemor, M., and Cvelbar, U. (2023). Widening the limit of capacitance at high frequency for AC line-filtering applications using aqueous carbon-based supercapacitors. Carbon 203, 686–694. doi:10.1016/J.CARBON.2022.12.026

Sheng, K., Sun, Y., Li, C., Yuan, W., and Shi, G. (2012). Ultrahigh-rate supercapacitors based on eletrochemically reduced graphene oxide for ac line-filtering. Sci. Rep. 2, 247. doi:10.1038/srep00247

Shuai, X., Bo, Z., Kong, J., Yan, J., and Cen, K. (2017). Wettability of vertically-oriented graphenes with different intersheet distances. RSC Adv. 7, 2667–2675. doi:10.1039/C6RA27428E

Simon, P., and Gogotsi, Y. (2020). Perspectives for electrochemical capacitors and related devices. Nat. Mater. 19, 1151–1163. doi:10.1038/s41563-020-0747-z

Taberna, P. L., Simon, P., and Fauvarque, J. F. (2003). Electrochemical characteristics and impedance spectroscopy studies of carbon-carbon supercapacitors. J. Electrochem Soc. 150, A292. doi:10.1149/1.1543948

Tang, H., Tian, Y., Wu, Z., Zeng, Y., Wang, Y., Hou, Y., et al. (2022). AC line filter electrochemical capacitors: materials, morphology, and configuration. Energy Environ. Mater. 5, 1060–1083. doi:10.1002/EEM2.12285

Toupin, M., Bélanger, D., Hill, I. R., and Quinn, D. (2005). Performance of experimental carbon blacks in aqueous supercapacitors. J. Power Sources 140, 203–210. doi:10.1016/j.jpowsour.2004.08.014

Wang, L., Zhao, L., Song, M., Xie, L., Wang, X., Li, X., et al. (2023). Alternatingly stacked thin film electrodes-based compact aqueous hybrid electrochemical capacitors for hundred-volts AC line filtering. J. Energy Chem. 78, 158–168. doi:10.1016/J.JECHEM.2022.11.055

Wu, M., Chi, F., Geng, H., Ma, H., Zhang, M., Gao, T., et al. (2019). Arbitrary waveform AC line filtering applicable to hundreds of volts based on aqueous electrochemical capacitors. Nat. Commun. 10, 2855. doi:10.1038/s41467-019-10886-7

Wu, M., Sun, K., He, J., Huang, Q., Zhan, W., Lu, Z., et al. (2023). Hierarchically 3D fibrous electrode for high-performance flexible AC-line filtering in fluctuating energy harvesters. Adv. Funct. Mater 33, 2305039. doi:10.1002/ADFM.202305039

Xu, S., Liu, W., Hu, B., and Wang, X. (2019). Circuit-integratable high-frequency micro supercapacitors with filter/oscillator demonstrations. Nano Energy 58, 803–810. doi:10.1016/J.NANOEN.2019.01.079

Yan, J., Li, S., Lan, B., Wu, Y., See Lee, P., Yan, J., et al. (2020). Rational design of nanostructured electrode materials toward multifunctional supercapacitors. Adv. Funct. Mater 30, 1902564. doi:10.1002/ADFM.201902564

Ye, J., Tan, H., Wu, S., Ni, K., Pan, F., Liu, J., et al. (2018). Direct laser writing of graphene made from chemical vapor deposition for flexible, integratable micro-supercapacitors with ultrahigh power output. Adv. Mater. 30, 1801384. doi:10.1002/ADMA.201801384

Yoo, Y., Kim, S., Kim, B., and Kim, W. (2015). 2.5 V compact supercapacitors based on ultrathin carbon nanotube films for AC line filtering. J. Mater Chem. A Mater 3, 11801–11806. doi:10.1039/C5TA02073E

Zhai, S., Enis Karahan, H., Wang, C., Pei, Z., Wei, L., Chen, Y., et al. (2020). 1D supercapacitors for emerging electronics: current status and future directions. Adv. Mater. 32, 1902387. doi:10.1002/ADMA.201902387

Zhang, C., Du, H., Ma, K., and Yuan, Z. (2020). Ultrahigh-rate supercapacitor based on carbon nano-onion/graphene hybrid structure toward compact alternating current filter. Adv. Energy Mater 10, 2002132. doi:10.1002/AENM.202002132

Zhang, M., Dong, K., Saeedi Garakani, S., Khorsand Kheirabad, A., Manke, I., Wu, M., et al. (2022). Bridged carbon fabric membrane with boosted performance in AC line-filtering capacitors. Adv. Sci. 9, 2105072. doi:10.1002/ADVS.202105072

Zhang, P., Wang, F., Yu, M., Zhuang, X., and Feng, X. (2018). Two-dimensional materials for miniaturized energy storage devices: from individual devices to smart integrated systems. Chem. Soc. Rev. 47, 7426–7451. doi:10.1039/C8CS00561C

Zhang, S., Li, B., Cui, C., Qian, W., and Jin, Y. (2023). The progress and comprehensive analysis of supercapacitors for alternating current line filtering: a review. Batter Supercaps 6. doi:10.1002/BATT.202200566

Zhang, Z., Liu, M., Tian, X., Xu, P., Fu, C., Wang, S., et al. (2018). Scalable fabrication of ultrathin free-standing graphene nanomesh films for flexible ultrafast electrochemical capacitors with AC line-filtering performance. Nano Energy 50, 182–191. doi:10.1016/J.NANOEN.2018.05.030

Zhao, D., Jiang, K., Li, J., Zhu, X., Ke, C., Han, S., et al. (2020). Supercapacitors with alternating current line-filtering performance. BMC Mater 2, 3. doi:10.1186/s42833-020-0009-z

Zhao, J., Zhang, Y., Yan, J., Zhao, X., Xie, J., Luo, X., et al. (2019). Fiber-shaped electrochemical capacitors based on plasma-engraved graphene fibers with oxygen vacancies for alternating current line filtering performance. ACS Appl. Energy Mater 2, 993–999. doi:10.1021/ACSAEM.8B02060

Zhao, M., Qin, Y., Wang, X., Wang, L., Jin, Q., Song, M., et al. (2024). PEDOT:PSS/Ketjenblack holey nanosheets with ultrahigh areal capacitance for kHz AC line-filtering micro-supercapacitors. Adv. Funct. Mater 34, 2313495. doi:10.1002/ADFM.202313495

Keywords: carbon nanostructures, electrochemical capacitors, AC line-filtering, high-frequency response, filtering capacitors

Citation: M. Santhosh N and Cvelbar U (2024) Carbon nanostructures for high-frequency line-filtering supercapacitors. Front. Nanotechnol. 6:1463972. doi: 10.3389/fnano.2024.1463972

Received: 12 July 2024; Accepted: 16 October 2024;

Published: 28 October 2024.

Edited by:

Subrata Ghosh, Polytechnic University of Milan, ItalyReviewed by:

Guowen Meng, Chinese Academy of Sciences (CAS), ChinaCopyright © 2024 M. Santhosh and Cvelbar. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Uros Cvelbar, dXJvcy5jdmVsYmFyQGlqcy5zaQ==

Neelakandan M. Santhosh

Neelakandan M. Santhosh Uros Cvelbar

Uros Cvelbar