- 1Jiangsu Key Laboratory of Atmospheric Environment Monitoring and Pollution Control, School of Environmental Science and Engineering, Nanjing University of Information Science and Technology, Nanjing, China

- 2State Key Laboratory of Environmental Criteria and Risk Assessment, Chinese Research Academy of Environmental Sciences, Beijing, China

- 3Kweichow Moutai Distillery Co., Ltd., Renhuai, China

- 4Chishui River Middle Basin, Watershed Ecosystem, Observation and Research Station of Guizhou Province, Guiyang, China

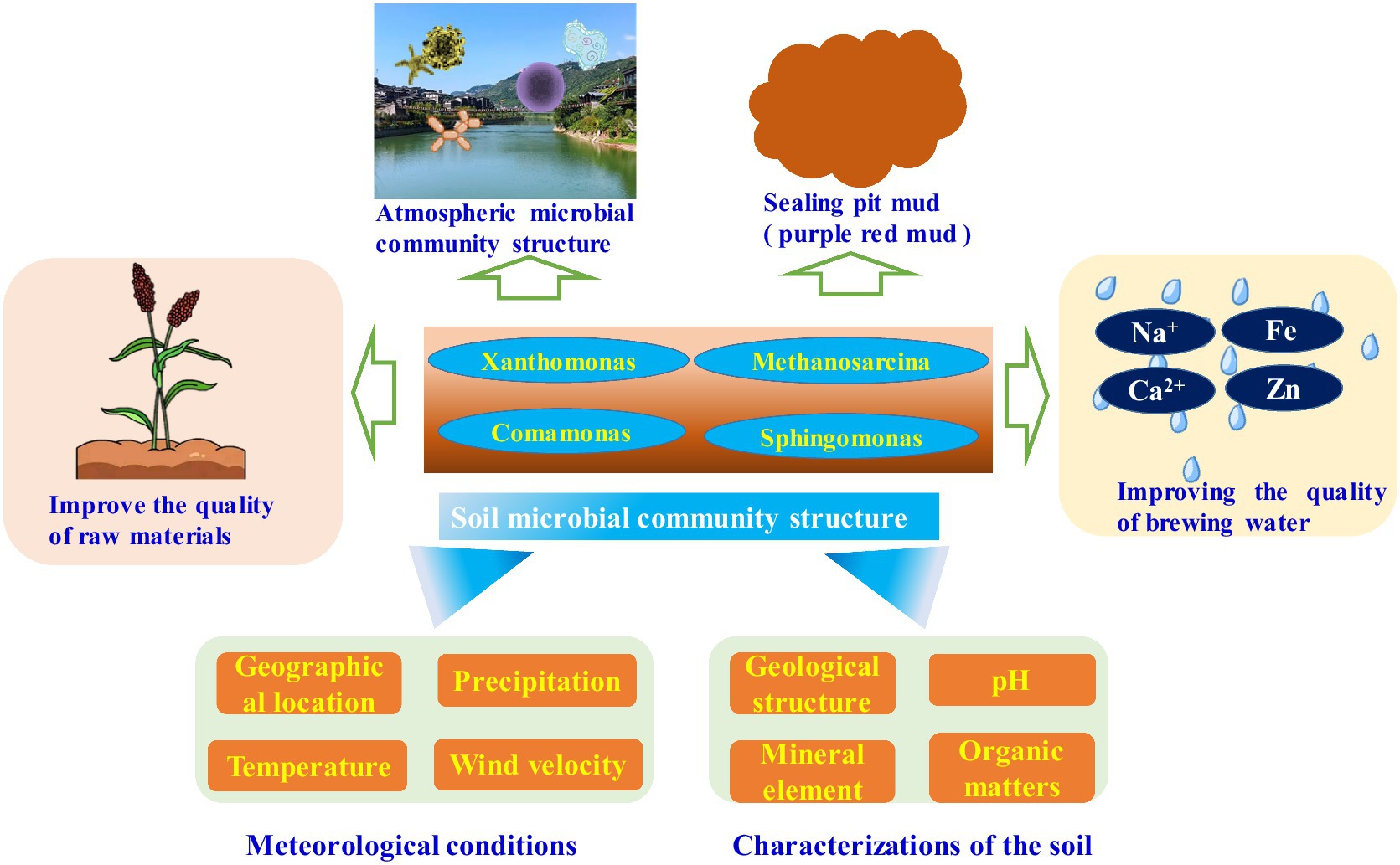

Chinese baijiu as one of the famous distilled liquor in which fermented in open environments, with various microorganisms (i.e., bacteria, fungi, and yeast) involved in their brewing process, and created corresponding unique flavor. However, the sources of environmentally enriched microbial communities associated with liquor fermentation are still being characterized yet. Given the dependence of microbial growth and reproduction on environmental ecology, it is important to understand the correlation between baijiu fermentation microbial community and surrounding environmental ecology (i.e., temperature, humidity, wind, and precipitation). This study systematically overviewed the sources of microorganisms in the Jiang-flavor-Baijiu fermentation system. The results showed that microorganisms in baijiu brewing (i.e., mold, lactic acid bacteria, and yeast) mainly originated from surrounding environmental matrices, including the air (i.e., Yeast, Streptomyces and Bacillus), soil (i.e., Xanthomonas, Methanococcus and Comamonas) and water (i.e., Flavobacterium, Acinetobacter, and Pseudomonas) via atmospheric transport, raw material transfer and surface runoff. In addition, the unique baijiu fermentation microbial community diversity depends on local geology and meteorological conditions, highlighting that the structural stability and diversity of the microorganisms in the Baijiu brewing process dominated by local environmental ecology. We also explored the regional environmental conditions on the microbial community and found that the unique Jiang-flavor-Baijiu fermentation microbial community diversity depends on local geology and meteorological conditions. The Jiang-flavor-Baijiu workshop is located in the basin of the middle-and low latitude mountainous areas, with sufficient solar irradiation and rainfall, high air humidity, and low wind speed that favor the growth and propagation of Baijiu fermentation microorganisms. Therefore, the obtained conclusions provide new insights unraveling the key factor controlling the unique flavor of Chinese Baijiu, where protecting the ecology of baijiu brewing-regions is fundamental for maintaining the long-term quality of baijiu.

1 Introduction

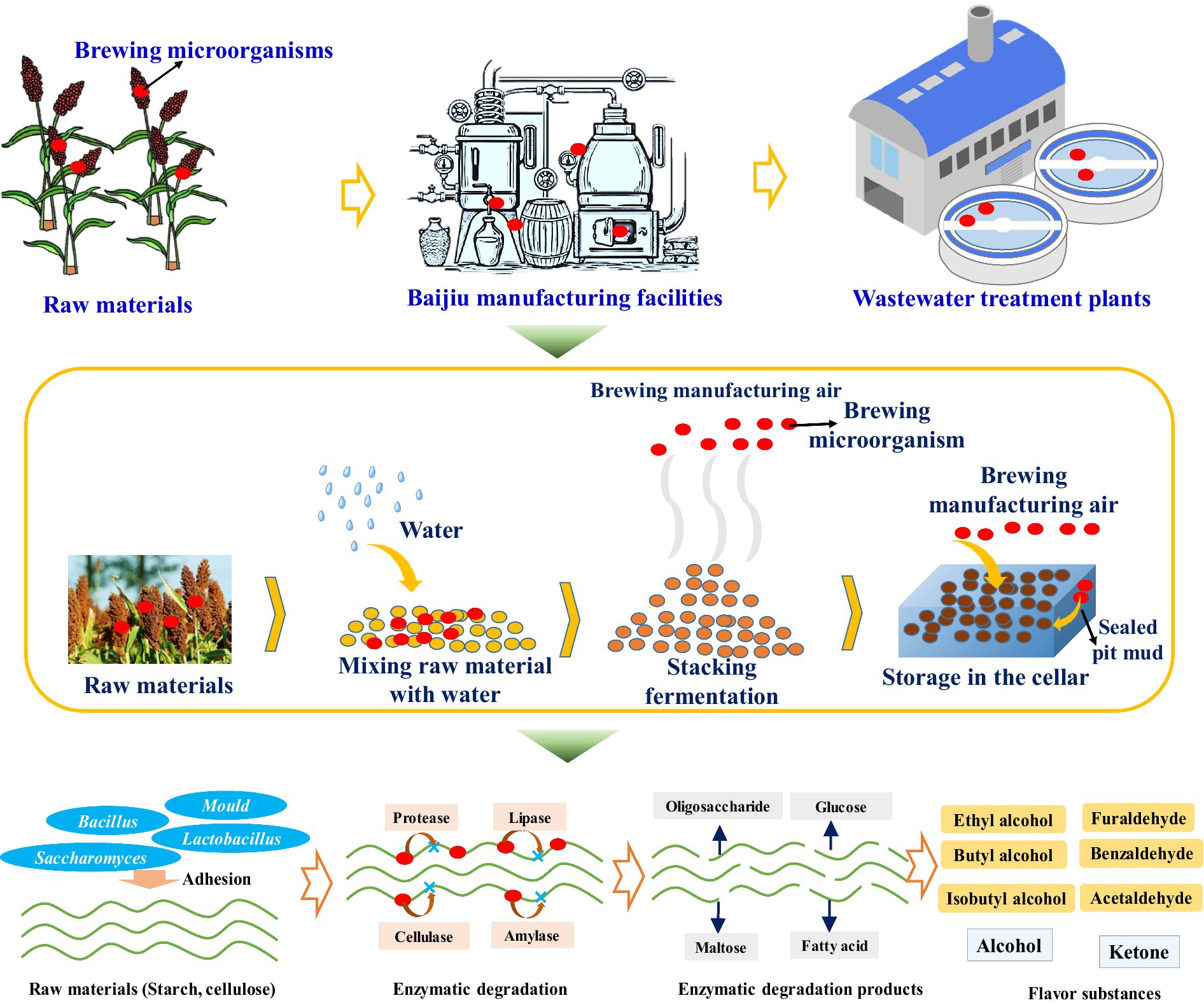

Chinese Jiang-flavor Baijiu, a kind of fermented beverage (approximately 40–60% alcohol by volume) obtained by solid-state fermentation distillation with a mixture of various microorganisms and enzymes as starter, which popular around the world owing to its unique flavor (Zhou et al., 2024; Zhu et al., 2024). Jiang-flavor-Baijiu is produced by the fermentation of raw grains (sorghum and wheat) to carboxylic acids, alcohols, aldehydes, and esters through several stages: Daqu-making, heap fermentation (on the ground), and pit fermentation (in sealed mud pits) (Liu and Sun, 2018; Tu et al., 2022). Studies revealed that highly complex microbial community of fermenters are important determinants of Baijiu flavor and quality (Dai et al., 2019; Zhang et al., 2022), as the flavor components (e.g., alcohols, aldehydes, carboxylic acids and esters) are microbial (e.g., yeast, mold, lactic acid bacteria, and Bacillus) fermentation products (Tu et al., 2022; Xu et al., 2021; Xu et al., 2022). Zygosaccharomyces produce 2-ethylhexanol, decanoic acid, dodecanol, lauric acid, octanoic acid, 2-nonanol, acetophenone, ethyl caprylate, 4-tert-butylphenol and other complex trace flavor components during baijiu brewing (Zhuang et al., 2017). Pichia anomala produces acetic acid, octanoic acid, lactic acid, phenylethyl alcohol, 2,3-butanediol, ethyl myristate, and 2-furanethanol during fermentation, all of which contributes to the flavor of Baijiu (Kong et al., 2014). These Baijiu fermentation associated microorganisms predominate several fermentation processes, such as Daqu (Wang P. et al., 2017; Zheng et al., 2014), raw materials (Du et al., 2019; Wang Q. et al., 2021), and fermented grains (Ao et al., 2020; Beecroft et al., 2012). However, the sources of Baijiu fermentation microorganisms remain unclear, particularly regarding their origins within the fermentation facilities (fermentation conditions and specific raw materials) (Pang et al., 2018; Wang et al., 2022b; Zheng et al., 2014). Given the adaptability of different microorganisms to environmental conditions such as temperature, wind, precipitation, and humidity, it is important to understand how highly variations in the environment influence the structure and stability of Baijiu fermentation microbial populations (Dai et al., 2019; Du et al., 2019; Zhu et al., 2015). Maintaining a stable microbial fermentation community structure is closely related to the stability of Baijiu flavor; therefore, it is important to understand the correlation between the environmental ecology of Baijiu-making region and fermentation associated raw materials and processing (Li et al., 2016).

Environmental factors that impact the Jiang-flavor-Baijiu fermentation microbial communities include temperature, humidity, wind, precipitation, geography, and sunlight irradiation, which located on the Renhuai, Guizhou province China (106°22′ E, 27°51′ N) (Knights et al., 2011). Jiang-flavor-Baijiu fermentation workshops are surrounding by abundant mountains and are considered as a typical basin area. The unique basin environment crates a relative slow air velocity in the Baijiu manufacturing region (wind speed: 1.3–1.35 m/s, the maximum and minimum wind speed is only 0.05 m/s), thereby stabilizing the Baijiu fermentation microbial community structure. The stability of the microbial community structure in the Baijiu fermentation area aids in maintaining the stability of Baijiu quality. The region in which Jiang-flavor-Baijiu manufactured has a subtropical climate with warm winter and hot summers (annual average temperature is 17.7°C), year-round humidity (annual precipitation is 800 ~ 1,000 mm), and plenty of sunshine irradiation (annual duration is 1,400 h), which provides a suitable habitat for the growth and reproduction of fermentation microbes (Wu et al., 2014). The Jiang-flavor-Baijiu region also has a unique geological structure and climatic conditions, with unique regional soil, water, and air quality that directly influence the dominant microbial community (Li et al., 2017). The mechanism by which these environmental factors influence the Jiang-flavor Baijiu fermentation microbial community structure has not been clarified.

When interpreting the Baijiu “flavor code,” the following issues need to be considered: (i) clarifying the ecological characteristics necessary for a high-quality Baijiu manufacturing workshop (i.e., temperature, climate, humidity, precipitation, and topography); (ii) establishing the correlation between the ecological characteristics of Baijiu fermentation and microbial community structure; and (iii) exploring the mechanisms by which Baijiu fermentation microbiota from the surrounding environment (soil, air, or water) enter the fermentation process. This review systematically summarizes the sources of environmentally enriched microbial communities and the ecological conditions influencing the Jiang-flavor-Baijiu fermentation microbial communities during solid state fermentation. The findings described here will provide insights into the intricate relationship between the environmental ecology and the composition (or stability) of the Jiang-flavor-Baijiu fermentation microbial community structure. At the same time, we advocate more efforts to be conducted to protect the ecological environment quality of baijiu-making areas, maintain the stability of baijiu-making microbial community structure, so as to ensure and enhance the flavor of liquor.

2 Characterizing the influence of microbial diversity on Paijiu quality and flavor

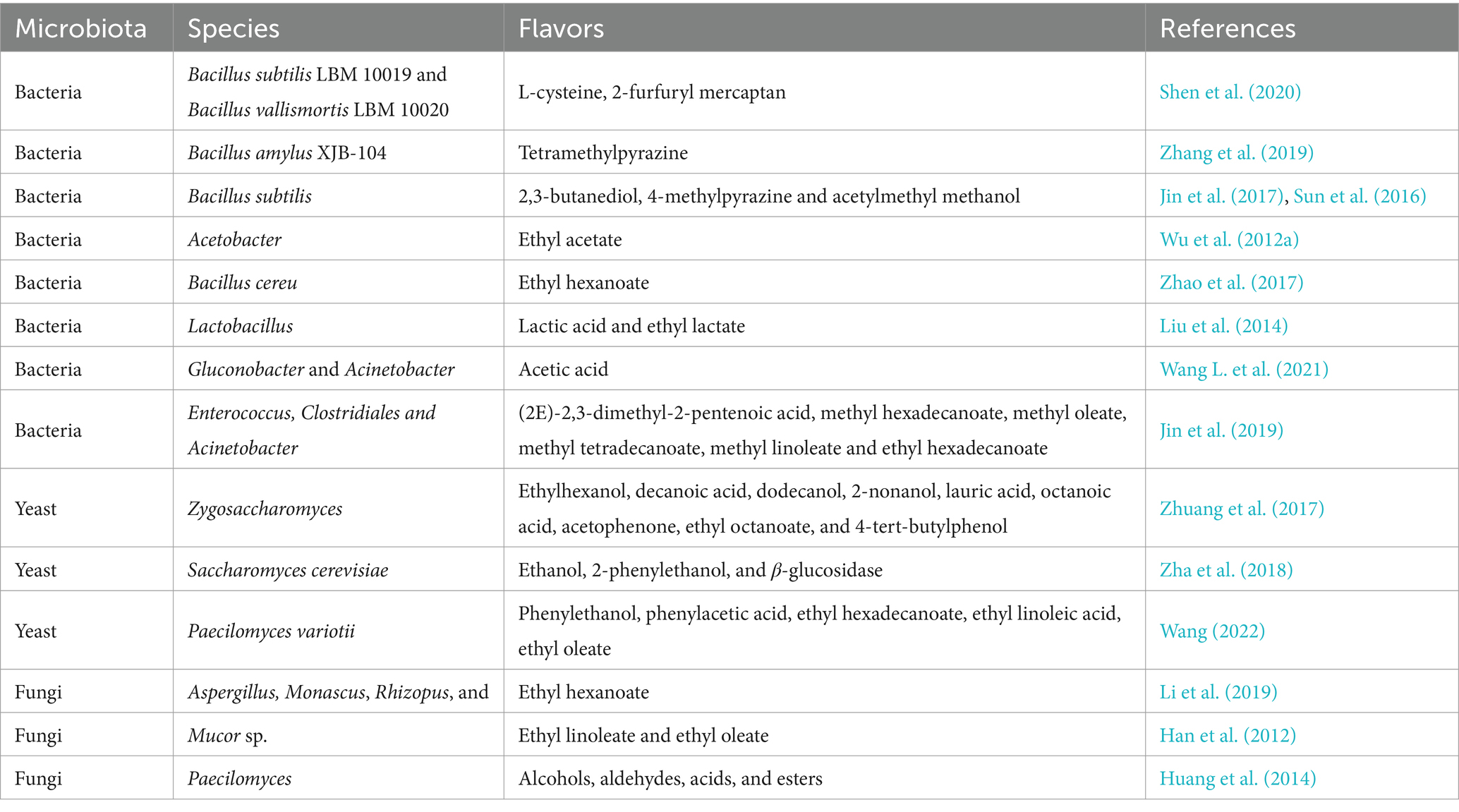

It is important to clarify the relationship between environmental parameters, fermentation microbial community structure, and Baijiu flavor and quality to optimize processes and screen the most efficient fermentation microbiota. We reviewed current knowledge on the impact of fermentation microbiota on Baijiu quality and flavor, by performing a literature search for articles published in the past 20 years (2002–2022) on the literature database Web of Science, with the keywords “Baijiu, microorganisms.” Between January 2002 and March 2023, a total of 4,718 papers were published, 3,732 (65.19%) of which were published in the past 10 years, reflecting a substantial increase in research interest in the microorganisms associated with Baijiu flavor and quality (Figure 1A).

Figure 1. (A) Statistics of the number of published literatures on liquor microbiota from 2002 to 2022; (B) 2002–2022 Jiang-flavored baijiu microbial impact study published literature over the years statistics; (C) Research Progress of Microorganism in Jiang-flavored baijiu Brewing VOSviewer (1.6.16) Analysis (Different radius of the ball in the figure represents the keyword frequency, the greater the radius of the ball, the higher the keyword frequency).

The general research areas into the effects of microbiota on Jiang-flavor-Baijiu quality and flavor were searched in the Web of Science database using “Jiang-flavor Baijiu, microbiota.” Between January 2002 and March 2023, 53 publications addressed the effect of fermentation microbiota on Jiang-flavor-Baijiu, 60.37% of which were published in the past 5 years, reflecting increased interest (Figure 1B). Subsequently, VOS viewer 1.6.16 was used to visualize the prevailing research on the influence of Baijiu fermentation microbiota on flavor. A total of 280 keywords were sorted by the frequency; 53 keywords that appeared at least twice were selected. Prior studies of the microbial effects on Baijiu flavor have focused on the effects of Daqu and solid-state fermentation on microbial community structure, while the environmental factors driving the spatial–temporal variations in microbial community structure during stacking fermentation remain unknown (Figure 1C).

3 Microbial communities in Jiang-flavor-baijiu fermentation systems and their impact on baijiu quality

3.1 Occurrence of Jiang-flavor-baijiu fermentation of microbes in raw material, high-temperature Daqu, and fermented grains

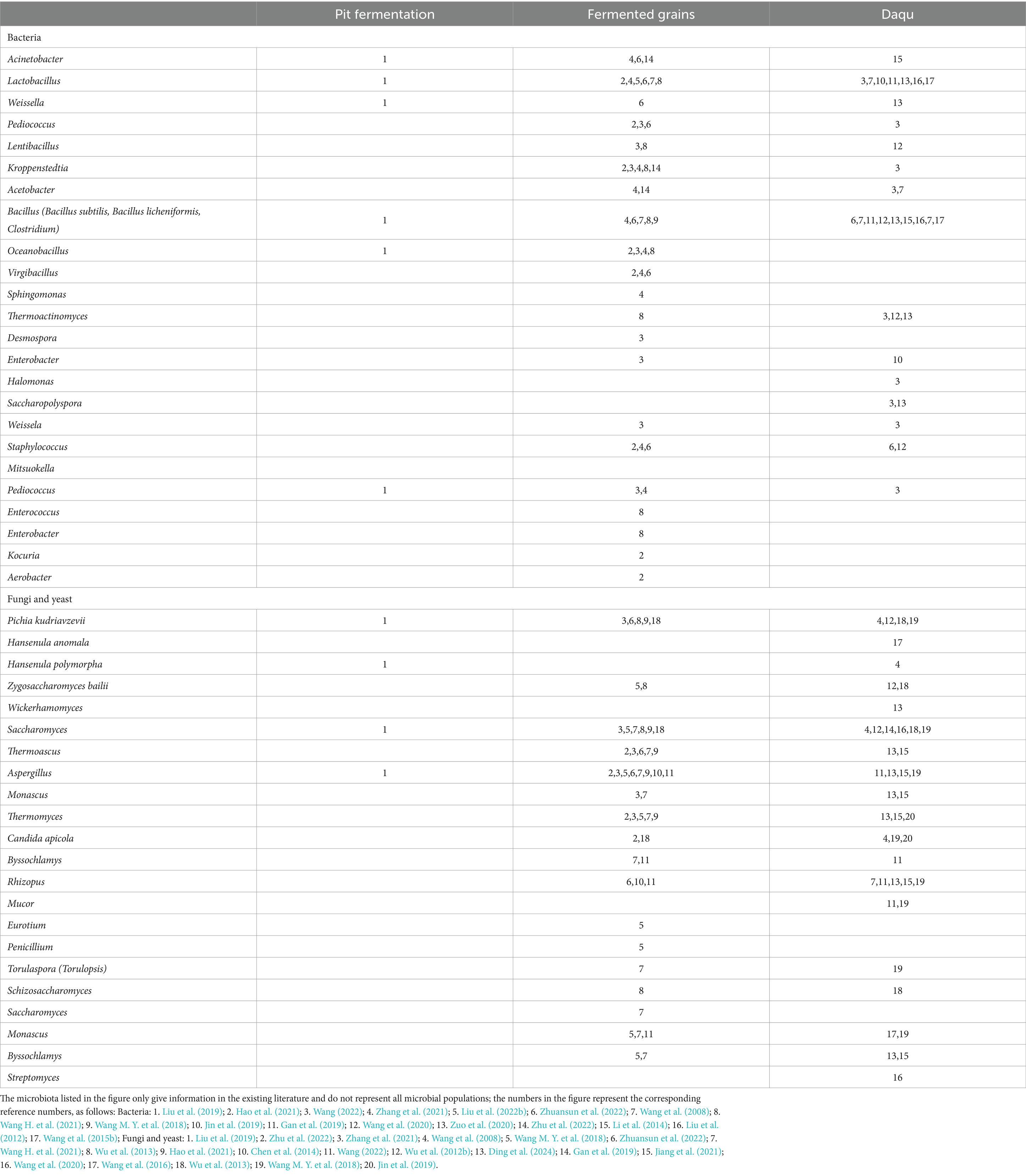

During fermentation of Jiang-flavor-Baijiu, several complex microbial communities (i.e., bacteria, yeasts, and molds) are readily involved and mainly residue in the raw material (sorghum), heap fermented grains, Daqu, and pit mud (Figure 2) (Yang et al., 2020a,b). In terms of heap fermentation, microbiota become enriched on the surface of the raw materials and produce Baijiu-flavor precursors such as alcohols, carboxylic acids, and esters (Tang et al., 2021). The core communities in the fermented grain liquor starters include lactic acid bacteria and Bacillus (Bacillus amyloliquefaciens, Bacillus licheniformis and Lactobacillus sp.), as well as yeast (Saccharomyces cerevisiae, Candida, Hansenula polymorpha, Hansenula anomala, and Pichia pastoris), Aspergillus (Aspergillus, Monascus, Aspergillus flavus, Monascus purpureus, Aspergillus niger, Aspergillus nidulans, and Aspergillus fumigatus), Thermomyces, Rhizopus, and Mucor (Mucor plentus, Mucor pusillus, Mucor racemosus, and Mucor racemosus) (Fan et al., 2006) (see Figure 3).

Figure 3. Soil microbial community structure in Jiang-flavor liquor brewing area and its effect on liquor flavor.

High-temperature Daqu is a typical starter for Jiang-flavor-Baijiu as the saccharification and fermentation starter (Wu et al., 2023). The microbial community structure of Daqu is important for developing quality and flavor as the primary microbial and enzyme source (Zuo et al., 2020). The microbiota such as Aspergillus, Thermoactinomyces, Lentibacillus, Bacillus, Kroppenstedtia, Staphylococcus, and Saccharopolyspora in Daqu decompose macromolecular substances in fermented grains, providing aroma substances or precursors of aroma substances that determine the flavor of Baijiu (Wang et al., 2020). Daqu can be categorized as low-temperature Daqu (peak temperature < 50°C), medium-temperature Daqu (peak temperature range in 50–60°C), and high-temperature Daqu (peak temperature > 60°C) (Jin et al., 2020). Given the adaptability of Baijiu fermentation microbiota to temperature, microbial community structure in Baijiu Daqu varies with temperature category. For example, bacteria rather than fungi predominate in Jiang-flavor-Baijiu Daqu, such as Thermoactinomyces, Saccharopolyspora, Streptomyces, Brevibacterium, Staphylococcus, Lentibacillus, Kroppenstedtia and Bacillus (Wang et al., 2020). These microbes are adapted to high temperatures and represent the unique diversity of Jiang-flavor Baijiu.

In the fermented grains, the fungi Ascomycota, Zygomycota, Chytridiomycota, and Basidiomycota are most prevalent; Ascomycota accounts for 94% at the phylum level. At the genus level, Aspergillus, Emericella, Candida, Monascus, Pichia, Wallemia, Trichosporon, and Wickerhamomyces are the primary contributors (Table 1). The predominant fungi in Baijiu fermented grains are Aspergillus (2.70–50.02%) and Monascus (15.08–52.47%). Bacteria and fungi residue in raw material, Daqu, and fermented grains secrete enzymes (glucoamylase, liquefying enzyme, and protease) that decompose starch, protein, and other macromolecular substances into flavor substances (Wang et al., 2008; Wang M. Y. et al., 2018; Yang et al., 2019). Thus, the microbial community structure in Baijiu fermentation is an important determinant of Baijiu quality and flavor. The correlation between Baijiu fermentation microbial community and their quality is subsequently reviewed.

Table 1. Different stages of brewing process (sand making, stacking fermentation and koji making) dominant microbial populations (bacteria, yeast, and fungi).

3.2 Microbe mediated Jiang-flavor-baijiu fermentation and formation of flavor compounds

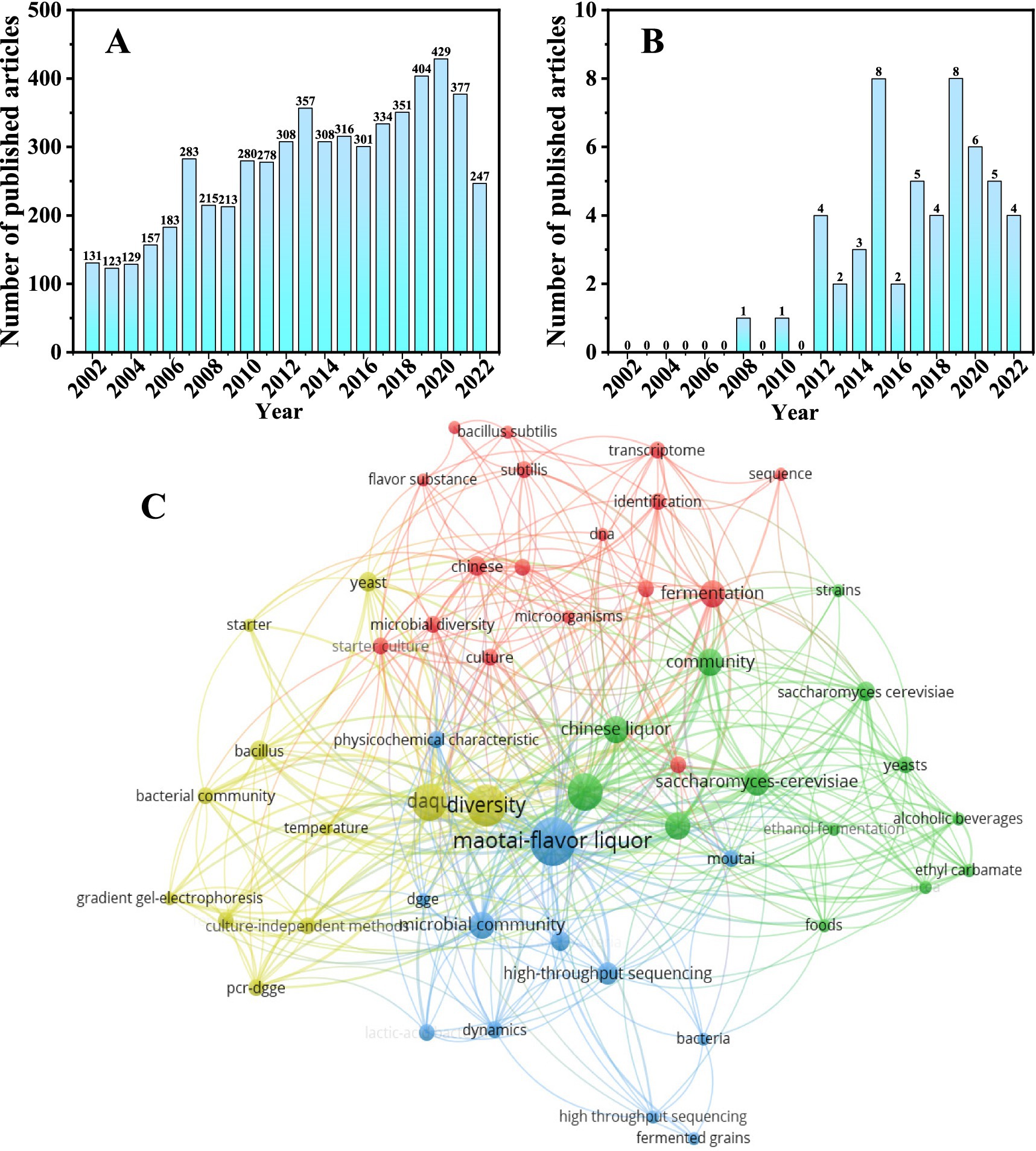

Owing the difference in fermentation raw materials and technical procedure, the microbial community structure and metabolism procedure of Jiang-flavor-Baijiu are varied in comparison with other types of Chinese Baijiu (i.e., Laobaigan-flavored baijiu, Fuyu-flavored baijiu, and Feng-flavored baijiu), which vary in their decomposition of starch, cellulose, and polysaccharides from raw materials (Wang X. et al., 2017; Wang X. D. et al., 2017; Wang Z. et al., 2018). For example, Lactobacillus promotes the Maillard reaction and produces lactic acid-related organic acids and diacetyl via sugar fermentation (Yang et al., 2020b). Pichia anomala, a saccharomycete, generates acetic acid, octanoic acid, lactic acid, phenylethyl alcohol, 2,3-butanediol, ethyl tetradecanoate, and 2-furanethanol (Kong et al., 2014). Saccharomyces cerevisiae produces β-glucosidase during fermentation process and further promotes the release of monoterpenes from glycoside precursors (Zha et al., 2018). Thus, many flavor substances are detected in Baijiu, which contribute to distinctive scent and flavor profiles (Table 2). Jiang-flavor-Baijiu has a complex characteristic scent generated by esters (ethyl acetate, ethyl butyrate, ethyl caproate, ethyl caprylate, and ethyl lactate), alcohols (isobutanol, butanol, isoamyl alcohol, phenylethyl alcohol, and furfuryl alcohol), carboxylic acids (acetic, propionic, butyric, and caproic acids), ketones (3-hydroxy-2-butanone, furfural, benzaldehyde, and phenylacetaldehyde), and phenols (guaiacol and tetra-ethyl guaiacol) (Niu et al., 2017). These substances usually have special aromas, such as fruity short-chain fatty acid esters; floral aromatic compounds; nutty pyrazines; cellar bottom: medium- and short chain fatty acids (Li et al., 2017). Baijiu flavor substances are produced by fermentation microbiota via enzyme degradation and microbial interactions. Understanding the mechanisms of these processes is important to unravel how Baijiu flavor profiles develop.

Enzymatic degradation and production of Baijiu flavor substances are mediated by secreted enzymes, including lipase, amylase (α-amylase, β-amylase, saccharifying amylase and γ-amylase), cellulase, esterification enzymes, pectinase, and tannase. During solid-state fermentation (Li et al., 2019). These enzymes accelerate the conversion of starch, cellulose, protein and fat to smaller molecular weight flavor substances such as glucose, fructose, fatty acids, and esters (Zhu et al., 2022). In sorghum, α-amylase in amylase reacts amylopectin to produce dextrin, maltose, and glucose, and with amylose to produce oligosaccharides, maltose and glucose (Li et al., 2019). Cellulase (produced by Bacillus subtilis, Trichoderma, Aspergillus and Penicillium) hydrolyzes lignin and cellulose; protease hydrolyzes protein into amino acids, the precursor of other Baijiu flavor substances; and the amino acids also provide nutrients to support the growth of microbes in the community. Lipase decomposes fat in raw materials into glycerol, fatty acids, monoglycerides and diglycerides (Li et al., 2019).

In addition to enzymatic degradation, complex microbial interactions also contribute to the formation of flavor substances in Baijiu fermentation (Meng et al., 2015). Mutualism, parasitism, antagonism, predation, and competition among Baijiu-making microbiota inhibit some populations and induce others, influencing the population structure in different Baijiu manufactories and generating different flavor profiles. For instance, populations that include Aspergillus oryzae XJ10 and Saccharomyces cerevisiae produce more esters, aldehydes, ketones, and ethyl acetate than either species alone, indicating that Aspergillus oryzae XJ10 and Saccharomyces cerevisiae produce a synergistic effect and unique fermentation product (Chen et al., 2014). Other microbes, in the Baijiu fermentation system can interfere with the growth of some fermenting populations. For instance, Saccharomyces cerevisiae CCTCCM2014463 inhibits the growth of Zygosaccharomyces bailii CGMCC4745, but has no significant effect on Bacillus licheniformis CGMCC3962 and Lactobacillus buchneri (Xu et al., 2018). Similarly, Saccharomyces cerevisiae is also able to impact the growth of Lactobacillus bread when co-existence with each other, the presence of Saccharomyces cerevisiae in fermentation system is available to produces ethanol and inhibits the growth and reproduction of Lactobacillus bread and lactic acid accumulation (Liu et al., 2022a).

4 Input of Jiang-flavor-baijiu fermentation microbes from the surrounding environmental matrices

Regarding the source of Jiang-flavor-Baijiu fermentation microbes, many efforts demonstrated that Baijiu fermentation microbe residue in the fermented grain samples, high-temperature Daqu, and sealed mud pits are readily input from the production workshop of Jiang-flavor-Baijiu (Hao et al., 2021; Wang M. Y. et al., 2018). For instance, it was reported that the predominant fungi (Monascus ruber and Hanseniaspora varoom) responsible for Jiang-flavor-Baijiu fermentation, the predominant bacteria (e.g., Weissella cibaria, Weissella cibaria, and Microbacterium testaceum) were originated from atmospheric, water, or soil of Daqu, outside the Baijiu manufacturing workshop (Wang et al., 2016). Tracking the source of Chinese Jiang-flavor-Baijiu fermentation microbes is important elucidating their unique flavor as microbial metabolism. Herein, we systematically overviewed the sources of Jiang-flavor-Baijiu fermentation microbiota from surrounding environmental matrices.

4.1 Soil transportation of baijiu fermentation microorganisms

The unique soil types of Jiang-flavor-Baijiu production workshops include red soil (purplish red mudstone, purplish red rock and soil and mixed purplish red clay) and yellowish brown soil (yellowish brown sandstone and clay) (Li et al., 2017). These soils contain abundant minerals and trace elements that support microbial growth and reproduction. A recent study showed that the content of rare-earth elements (REE) (i.e., Samarium (Sm), Europium (Eu), Erbia (Er), and Cerium (Ce)) in the surface soil Jiang-flavor-Baijiu producing area (287.1 μg/g) was than that in soil (186.8 μg/g) and crust (207 μg/g) for other areas of mainland China (Jiang et al., 2023). The rich mineral elements in the soil can improve the quality of Baijiu: by increasing the mineral content of the water, composing sealed mud pits and cultivating high-quality raw materials. Soil minerals support Baijiu fermentation microbiota and improve the quality of water, sealed mud pits, and raw materials, thus indirectly improving Baijiu quality.

The sealed mud pits are considered as the ideal habitat of fermentation microbiota. Under sealed fermentation conditions, different microbiota in the sealed mud pits continue to metabolize and affect Baijiu flavor (Li et al., 2023). During Jiang-flavor-Baijiu fermentation, the purple red mud was extensively utilized as sealed pit mud due to its specific signatures, including low sand content, strong viscosity, and well sealing performance. In addition, the purple red mud is of moderate in acid and alkali, rich in a variety of beneficial components (organic matter content ~1%), and rich in mineral nutrients (SiO2: 52–74.7% (average 60.1%); Fe2O3: 5.28–7.43% (average 6.51%); Al2O3: 11.7–17.6% (average 15.6%)) (Liu and Tan, 2011). This will facilitate for Baijiu fermentation microbial growth and community succession, indicating that soil quality is an important determinant of high-quality Jiang-flavor-Baijiu fermentation. A recent study investigated the microbial community structure in fresh red soil, sealed mud pits used for 1 month and sealed mud pits used for 12 months near the producing area of Jiang-flavor-Baijiu, and discovered abundant microbiota residue (Wang et al., 2015a). The abundance of microbial populations was greater in fresh soil used for sealed mud pits (81 families) than in sealed mud pits used for 1 month (77 families) and 12 months (47 families), suggesting the number of microbial species decreased with increasing age of Maotai red soil as sealed mud pits (Wang et al., 2015a). In addition, there are 12 families of microbiota were detected in fresh soil and in sealed mud pits used for 1 and 12 months (Wang et al., 2015a). During the long-term domestication of microbiota in cellars, the content of high-efficiency fermentation microbiota continues to increase, an important determinant of improved Baijiu quality. Hence, in red and yellow soil surrounding the Jiang-flavor-Baijiu manufacturing workshop can be used as sealed mud pits and transfer abundant Baijiu fermentation process, influencing the Baijiu flavor over the long-term.

High-quality red and yellow soil surrounding the Baijiu manufacturing workshop yields high-quality raw materials essential to the Baijiu fermentation microbial community and flavor because these materials support the energy and habitat for microbial growth. The diverse content of amylopectin and amylose in sorghum from different Baijiu-producing areas generates differences in water absorption and gelatinization capacities during the manufacture of Baijiu and koji, affecting saccharification efficiency and other differences in the community structure of Baijiu-making microbiota. In addition, differences in starch content and structure in different types of sorghum will also lead to a variety in the composition and structure of amino acids after enzymatic hydrolysis, thereby affecting the content and composition of flavor substances (alcohols, aldehydes, carboxylic acids and esters) (Ding et al., 2024; Ma et al., 2022). Hongyingzi sorghum used in Jiang-flavor-Baijiu brewing is a unique, organic waxy sorghum characterized by its small grain, thick skin and full grain. The total starch content of Hongyingzi sorghum is >65%, and amylopectin accounted for 88–93% of the total starch content, giving it characteristics of small grain, thick skin, full and solid, and able to withstand nine rounds of cooking. In contrast, the Hongyingzi sorghum in which mainly produced in Renhuai, Guizhou, China (105°–106 °E and 27°–28° N latitude) are planted with mid-subtropical monsoon climate conditions (average annual temperature of 18°C). This further induced the Hongyingzi sorghum became a symbol as the raw material of the unique flavor Jiang-flavor-Baijiu.

4.2 Aquatic transport of baijiu fermentation microorganisms

The water for Jiang-flavor-Baijiu fermentation comes from the Chishui River Basin, which has an intact natural ecology and exiguous industrial and anthropogenic activity. In addition, the Chishui River contains many trace elements beneficial to human health that are also discovered in red soil, leading to the high-quality Jiang-flavor brew water being moderate in acidity and rich in minerals and trace elements (Li et al., 2017). The basic Chishui River water quality parameters are as follows: pH: 6.5–8.5, total hardness: 2–7 mmol/L, nitrate nitrogen: <0.2 mg/L, free chlorine residual: < 0.1 mg/L, consistent with high-quality brew water requirements (pH: 8.1, total hardness: 6.2 mmol/L, nitrate nitrogen: 0.5 mg/L, free chlorine residual: < 0.3 mg/L) (Li et al., 2017). Previous effort has focused on the microbial community structure in the Chishui River, and discovered substantial fermentation microbiota residue (Jin et al., 2009), thereby unravel the preliminary fermentation microbiota in environmental media is necessary to improve the quality of Baijiu. Jiang-flavor-Baijiu fermentation microorganisms Actinobacteria, Bacteroidetes, Proteobacteria, and Firmicutes have been detected year-round in the Chishui River using 16S rRNA gene sequencing analysis. Proteobacteria was the dominant species, followed by Firmicutes, Actinobacteria, and Bacteroidetes (Tan et al., 2014). The microbial community structure in the Chishui River and water intake sites at Baijiu manufactories also revealed the presence of Baijiu fermentation microbiota, including 55 phyla, 167 classes, 415 orders, 706 families, and 1,431 genera. Pseudomonas (16.99%) and Massilia (12.45%) were the dominant species (Lv et al., 2021).

However, during long-term Baijiu manufacturing activities, the discharge of wastewater will influence nearby water quality despite wastewater treatment efforts, affecting water quality (pH), chemical oxygen demand (COD), and ammonia nitrogen (NH3-N) and possibly influencing the brewing microbial community structure. Using COD and NH3-N as example, a recent study discovered that the quality of the water intake at Maotai Distillery is significantly different from that of the upstream/downstream water intake, with COD concentration 7.22 ± 0.01 mg/L in the water body at the intake section of the distillery less than the upstream 8.62 ± 0.07 mg/L and downstream concentrations 8.36 ± 0.05 mg/L. The NH3-N concentration 0.51 ± 0.02 mg/L in the Baijiu water intake is greater than upstream 0.28 ± 0.01 mg/L and downstream concentrations 0.33 ± 0.01 mg/L (Lv et al., 2021). This is due to the fact that continuous Jiang-flavor-Baijiu making activities inevitable discharge varied organic contaminants (fertilizers and natural manure) into the water, accelerating oxygen the consumption and the formation of NH3-N, leading to the COD and NH3-N in the Baijiu making water intake section higher than that of the upstream river. Simultaneously, the COD and NH3-N associated contaminants produced by Baijiu making areas are readily to be degraded and diluted during the surface runoff, resulting the COD and NH3-N concentration Baijiu making water intake section higher than that of the downstream river consequently (Lv et al., 2021). Redundancy analysis showed that the concentration of CODMn, COD, and DO in the water of Jiang-flavor-Baijiu fermentation areas also determined the diversity of microbial community structure. Taking DO as an example, unclassified_Comamonadaceae, Sphingorhabdus, Flavobacterium, and Pseudarcicella were significantly positively correlated with DO (p < 0.05), while unclassified_Micrococcaceae and Pedobacter were significantly negatively correlated with DO (p < 0.05), verifying that water quality is an important determinant of the structure and function of bacterial communities in the ecosystem surrounding Baijiu brewing areas (Lv et al., 2021).

There were significant differences in the microbial community structure in the water body of the Baijiu brewing area and upstream/downstream water of the water intake, with Pseudomonas (15.33%) and Acinetobacter (14.99%) being the dominant species. Acinetobacter (22.21%) and Flavobacterium (16.84%) were the dominant microbiota upstream of the water intake, while Pseudomonas and Massili were the dominant microbiota downstream of the water intake (Lv et al., 2021). We conclude that long-term Baijiu-making activities have led to a significant difference in water quality between Baijiu regions and waters upstream and downstream of the manufactory intakes. This difference drives the specific distribution of microbial community structure in Baijiu regions. The intake water is rich in minerals that have an important impact on Baijiu flavor. The content of sodium (21,000 μg/L), magnesium (67,000 μg/L), chlorine (27,000 μg/L), manganese (14.47 μg/L), and iron (164.4 μg/L) in the water of Jiang-flavor Baijiu is much higher than that of Luzhou Laojiao (sodium: 12783 μg/L, magnesium 5,886 μg/L, chlorine 22,776 μg/L, manganese 3.77 μg/L, and iron 37.9 μg/L) and Wenjun Distillery (sodium 8,065 μg/L, magnesium 5,103 μg/L, chlorine 10,773 μg/L, manganese 2.1 μg/L, and iron 23.9 μg/L), indicating that there are abundant mineral elements in the water of Jiang-flavor-Baijiu (Wang et al., 2022a). These inorganic salt ions improve the formation of flavor substances and improve the quality of Baijiu during fermentation.

4.3 Atmospheric transport of baijiu fermentation microorganisms

As with water, microbiota in the air are also an important source of microbiota in Jiang-flavor-Baijiu. A recent study explored the dominant microorganism species in the air around the Jiang-flavor Baijiu brewing area and found a relativity stable microbial community structure that varied with the seasons, such as Acinetobacter, Arthrobacter, Aspergillus, Bacillus, Brevibacterium, Cedecea, Pichia, and Rhodoceccus (Wang et al., 2022a). This variability may be due to the unique geographical location of the Jiang-flavor-Baijiu brewing area, which is surrounding by mountains. The airflow is slow (wind speed 1.3–1.35 m/s), the annual average temperature fluctuates little (the average temperature from 1961 to 2018 was 15.1°C, SD (standard deviation) 0.34°C), and the annual average precipitation fluctuates stably (average precipitation from 1961 to 2018 was 1018.6 mm, SD 10 mm), resulting in a stable microbial community structure in the area and reduced influence of external environment (Wang et al., 2022a). The primary bacteria in the air of Jiang-flavor-Baijiu brewing areas are Streptomyces, Acinetobacter, Staphylococcus, Bacillus, Brevibacterium, Brevibacterium, Kocuria, and Pseudomonas. The dominant fungi are Aspergillus, Cladosporium, and Pteris. Thus, fermentation microbiota residue in the Jiang-flavor Baijiu brewing area originated from surrounding environment, highlighting the critical impact of brewing microbial community structure on the flavor of Jiang-flavor Baijiu. For example, For example, Zhou et al. (2024) discovered that bacterial communities of phyla Actinobacteriota, Firmicutes, and Proteobacteri, as well as fungal communities of Ascomycota and Basidiomycota were predominant airborne microbiomes residue in the Jiang-flavor Baijiu core production areas, whereas the Saccharomonospora, Thermoactinomyces, Bacillus, Oceanobacillus, and Methylobacterium contributing were demonstrated as core functional flora to the Baijiu producing according to the Random Forest analysis (Zhou et al., 2024). Relative Bacillus amounts in the air surrounding the Baijiu-making workshop, koji-making workshop, and outdoor air surrounding the workshop were also assessed in the Daqu, sealed pit mud, and fermented grains (accumulated fermented grains and pit fermented grains), including B. licheniformis, B. amyloliquefaciens, B. subtilis, Paenibacillus lactis, Bacillus lentus, Paenibacillus sp., and Staphylococcus lentus. Fermentation microbiota in the Daqu, pit mud and fermented grains exhibited obvious homology with the microbial community structure of surrounding air, indicating that air exposure is an important contributor to Baijiu-fermentation microbiota.

5 Environmental driving factors controlling the Jiang-flavor baijiu fermentation microbial diversity

5.1 Effect of natural geographical and meteorological conditions on the fermentation microbial community structure

To bridge the knowledge gap unraveling the role of environmental factors (monsoon climate, temperature, wind speed, humidity, and precipitation) on shaping microbiomes during Jiang-flavor-Baijiu brewing, correlations between environmental factors and microbial community structure indicators (ACE index and Chao index) were thus established (Wang et al., 2022b), which favoring to understood the bacterial diversity and community dynamics during Jiang-flavor-Baijiu open fermentation process. For instance, Beecroft et al. (2012) developed the microbial communities surrounding the Jiang-flavor manufacturing workshops (indoor dust, windows, sills, and wall surfaces) using high throughput sequencing analysis (Beecroft et al., 2012). They discovered 33 bacterial classes (Gammaproteobacteria, Bacilli, Sphingobacteriia, Alphaproteobacteria, Actinobacteria, Flavobacteriia, and Betaproteobacteria), 153 bacterial families (Enterobacteriaceae, Sphingobacteriaceae, Bacillaceae, Flavobacteriaceae, Thermoactinomycetaceae, Planococcaceae), and 396 bacterial genera (Sphingobacterium, Enterobacter, Pantoea, Acinetobacter, Oceanobacillus, and Pseudomonas) (Beecroft et al., 2012). The bacterial community structure was significantly correlated with the surrounding environment (temperature, sunlight, humidity, atmospheric pressure, and precipitation) (Wang et al., 2022b). The unique natural environmental factors and their influence on Baijiu fermentation microbial communities were systematically reviewed.

Temperature is important in microbial dynamics and diversity during fermentation, especially in the Daqu making (Garcia et al., 2023; Simon et al., 2020; Walker et al., 2018; Zhang et al., 2023). Alphaproteobacteria, Acetobaqcteraceae, Sphingomonadaceae, Caulobacteraceae, and Brevundimonas were positively correlated with the fermentation temperature, with p values were 0.350, 0.488, 0.283, 0.290, and 0.284, respectively. In contrast, Bacillaceae (p = 0.489), Bacillus (p = 0.387), Oceanobacillus (p = 0.419), Thermoactinomycetaceae (p = 0.284), and Kroppenstedtia (p = 0.347) exhibited a negative correlation with fermentation temperature (significance defined as p < 0.5) (Beecroft et al., 2012). These results highlighted the important role of temperature in the domestication and screening of microbial community structures during fermentation. Jiang-flavor Baijiu manufacturing facilities are located in the Guizhou province, southwest China, which is a subtropical climate with high temperature and humidity that facilitate microbial growth. The temperature of Jiang-flavor-Baijiu manufacturing workshop is reported as in the range of 2.7°C–40.6°C, with an annual average temperature of 17.4°C, which provides a suitable habitat for the growth and reproduction of fermentation microbiota (Li et al., 2017).

A seasonal subtropical climate brings precipitation (annual precipitation from 1961–2018: 1018.6 ± 10 mm), resulting in a relatively high air humidity to the Jiang-flavor Baijiu making regions, and influencing the Baijiu brew microbial growth and propagation (Li et al., 2017). The abundance of Gammaproteobacteria (p = 0.342), Enterobacteriaceae (p = 0.376), Escherichia-Shigella (p = 0.366), and Pantoea (p = 0.367) were positively correlated with humidity, while Rhodospirillales (p = 0.363), Acetobacteraceae (p = 0.298), and Actinobacteria (p = 0.359) were negatively correlated with humidity (Wang et al., 2022b). Bacillaceae, Lentibacillus, Thermoactinomycetaceae, and Lactobacillaceae were also reported to correlate significantly with precipitation. Thus, humidity and regional precipitation significantly affect Baijiu fermentation microbial diversity. Microbial respiration and growth decrease with decreasing air humidity and temperature (Cruz-Paredes et al., 2021).

Moreover, the geology of Jiang-flavor-Baijiu regions creates unique wind speed and direction conditions that drive seasonal variations in the type and abundance of Baijiu brew microbial species and Baijiu quality (Tan et al., 2014). Microbes in air influence Baijiu manufacturing and a steady wind direction and speed facilitate consistent transfer of microbes from the air to the fermentation raw material, especially during open static fermentation of Jiang-flavor Baijiu. Wang et al. (2022b) characterized the variations of wind speed in a Jiang-flavor manufacturing workshop (Chishui River basin, China) from 1961- to 2018, and discovered that the multi-year wind speed variation is 1.33 m/s, with the wind speed increasing at 0.014 m s−1 every 10 years (Wang et al., 2022a). The Jiang-flavor-Baijiu manufacturing workshop is located in a closed basin area (103°36′–109°35’N, 24°37′–29°13′E) surrounding by mountains, and has low wind velocities. This unique topography favors stability in the Baijiu brew microbial community structure and facilitates stable flavor and quality in the product (Jiang et al., 2009). The Jiang-flavor-Baijiu manufacturing workshops are located in low-latitude mountainous areas and are subject to subtropical monsoons. The climate is warm and humid, with sufficient rainfall to support the growth of fermentation microbiota. In addition, the Jiang-flavor-Baijiu factories are located in a basin that is relatively closed, supporting long-term stability in the wine-making microbial community structure and essential to the high quality of Jiang-flavor-Baijiu. Thereby, from the perspective of environmental microorganisms, we can conclude that long-term Baijiu making activities and regional suitable climatic conditions will lead to a relatively stable microbial community structure in the water, air and soil surrounding the Baijiu producing area, resulting the quality of Baijiu produced by new distilleries is not as good as that produced by old distilleries. This is assigned to the close correlation among the regional geological structure (location, wind, humidity, and water quality), Baijiu brewing microbial community structure, composition of microbial metabolites, and liquor flavor. These also highlighted the fact protecting the ecology of Jiang-flavor-Baijiu plays essential role in maintaining the stability of Baijiu fermentation microbial community and their special flavors.

5.2 Environmental factors controlling microbial succession within fermentation system

Environmental factors driving the microbial community structure are also varied within the Baijiu fermentation system. For instance, Yang et al. (2023) developed the changes of microbial community structure succession during 1–6 rounds of Jiang-flavor-Baijiu stacking process and discovered that, with the continuous progress of the stacking process, the dominant bacterial genera are readily to be replaced from Lactobacillus to Acetobacter, while the fungal genus are readily to be replaced from Pichia to Candida (Yang et al., 2023). With the Jiang-flavor-Baijiu fermentation transfer from the stacking heap fermentation to pit fermentation, microorganisms also changed consequently according to the high-throughput sequencing analysis. The abundance of Pichia decreased whereas the abundance of Saccharomyces began to increase and act as one of the dominant fungal species within the fermentation system. Meanwhile, in comparison with stacking heap fermentation, the bacterial species of Lactobacillus and Saccharomyces increased continuously, and Lactobacillus contributing >80% to total bacterial abundance during pit fermentation process (Hao et al., 2021). Environmental driving factors controlling the successive changes of microbial communities during Jiang-flavor-Baijiu brewing are responsible to the multiple constituents of temperature, moisture, sugar content, ethanol, acidity, lactic acid (Yang et al., 2023). Specifically, lactic acid, ethanol, acidity, and temperature were found to positively correlated with Lactobacillus and Saccharomyces; acetic acid was demonstrated to negatively controlled the abundance of Virgibacillus and Bacillus; and water was reported to negatively controlled the abundance of Virgibacillus, Bacillus, Oceanobacillus, taphylococcus, and Kocuria simultaneously (Hao et al., 2021). These highlighted a comprehensive environmental factors for natural meteorological and Baijiu fermentation system on the specific Baijiu brewing microbial succession.

6 Conclusions and perspective

Jiang-flavor-Baijiu is one of the most complex and typical Chinese liquor in which produced through traditional open brewing. Nevertheless, the source of the Jiang-flavor-Baijiu fermentation microbial community current still unclear, hindering the subsequent knowledge for the procedure of microbial metabolism and the formation of specific flavor substances in Baijiu liquor. This study systematically overviewed the microbial sources in various stages of Maotai flavor Baijiu. The obtained results revealed that microbes residue in the Jiang-flavor-Baijiu fermentation system are prone to be originated from the surrounding environmental matrices, with the relationships between Baijiu fermented microbial diversity and surrounding meteorological and geographical conditions (temperature, humidity, solar irradiation, precipitation) has been widely demonstrated according to the current knowledge. Specifically, environmental microorganisms in the air, water, and soil of Baijiu producing area are readily enter into the Baijiu manufacturing plants via air flow, sealed mud pits, or water intake. This will further interfere the microbial community structure in such as raw materials, Daqu-making, stacking fermentation, distillation, and pit fermentation in sequential, and ultimately shaping the special flavor of liquor. These results offer a comprehensive understanding elaborating the source of microbes among various stages of Maotai flavor Baijiu brewing. In contrast, the obtained results also highlighted that: protecting the regional ecological environment quality of Jiang-flavor-Baijiu producing area is helpful to maintain the stability of the Baijiu fermentation microbial community structure during the brewing process, and maintains the quality and unique flavor of the liquor.

Further research should explore the correlations and interactions between environmental conditions and Jiang-flavor-Baijiu fermentation microorganism communities. Regular monitoring of water, air, and soil qualities surrounding the Jiang-flavor-Baijiu making area will support efforts to maintain Baijiu quality and flavor. It is also important to establish a system of environmental protection measures to maintain the stability of the fermentation microbial community and eliminate potential point source and non-point source pollution in brewing areas. Finally, it is necessary to explore the spatiotemporal diversity of microbial community dynamics and environment factors in Jiang-flavor Baijiu fermentation.

Author contributions

XWu: Conceptualization, Visualization, Writing – original draft, Writing – review & editing. XZ: Conceptualization, Supervision, Writing – review & editing. LW: Investigation, Writing – review & editing. BC: Investigation, Writing – review & editing. FL: Investigation, Writing – review & editing. ZT: Writing – review & editing. FW: Visualization, Writing – original draft, Writing – review & editing.

Funding

The author(s) declare that financial support was received for the research, authorship, and/or publication of this article. This research was financially supported National Key Research and Development Program of China (2022YFC3203500) by the Kweichow Moutai Distillery Co., Ltd.

Conflict of interest

LW, PX, BC, and FL were employed by Kweichow Moutai Distillery Co., Ltd.

The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Ao, T., Ran, Y., Chen, Y., Li, R., Luo, Y., Liu, X., et al. (2020). Effect of viscosity on process stability and microbial community composition during anaerobic mesophilic digestion of Maotai-flavored distiller's grains. Bioresour. Technol. 297:122460. doi: 10.1016/j.biortech.2019.122460

Beecroft, N. J., Zhao, F., Varcoe, J. R., Slade, R. C. T., Thumser, A. E., and Avignone-Rossa, C. (2012). Dynamic changes in the microbial community composition in microbial fuel cells fed with sucrose. Appl. Microbiol. Biotechnol. 93, 423–437. doi: 10.1007/s00253-011-3590-y

Chen, B., Wu, Q., and Xu, Y. (2014). Filamentous fungal diversity and community structure associated with the solid state fermentation of Chinese Maotai-flavor liquor. Int. J. Food Microbiol. 179, 80–84. doi: 10.1016/j.ijfoodmicro.2014.03.011

Cruz-Paredes, C., Tájmel, D., and Rousk, J. (2021). Can moisture affect temperature dependences of microbial growth and respiration? Soil. Boil. Biochem. 156:108223. doi: 10.1016/j.soilbio.2021.108223

Dai, Y. J., Tian, Z. Q., Meng, W. N., Li, C. Y., and Li, Z. J. (2019). Changes in microbial diversity, physicochemical characteristics, and flavor substances during Maotai-flavored liquor fermentation and their correlations. J. Biobased Mat. Bioenergy 13, 290–307. doi: 10.1166/jbmb.2019.1866

Ding, Y. Q., Wang, Y. L., Xu, J. X., Jiang, F., Li, W. Z., Zhang, Q. L., et al. (2024). A telomere-to-telomere genome assembly of Hongyingzi, a sorghum cultivar used for Chinese baijiu production. Crop J. 12, 635–640. doi: 10.1016/j.cj.2024.02.011

Du, H., Wang, X., Zhang, Y., and Xu, Y. (2019). Exploring the impacts of raw materials and environments on the microbiota in Chinese Daqu starter. Int. J. Food Microbiol. 297, 32–40. doi: 10.1016/j.ijfoodmicro.2019.02.020

Fan, X. G., Wang, H. Y., Cui, T. B., Chen, A. J., Han, P., Jiang, H. J., et al. (2006). Researching development of Maotai microorganisms. Liquor-Making Sci. Technol. 10, 75–77. doi: 10.13746/j.njkj.2006.10.055

Gan, S. H., Yang, F., Sahu, S. K., Luo, R. Y., and Liu, H. (2019). Deciphering the composition and functional profile of the microbial communities in Chinese Moutai liquor starters. Front. Microbiol. 10, 1540–1553. doi: 10.3389/fmicb.2019.01540

Garcia, F. C., Clegg, T., O'Neill, D. B., Warfield, R., Pawar, S., and Yvon-Durocher, G. (2023). The temperature dependence of microbial community respiration is amplified by changes in species interactions. Nat. Microbiol. 8, 272–283. doi: 10.1038/s41564-022-01283-w

Han, Y., Wang, H. Y., Lin, L., Wang, L., Yang, D. Y., and Lv, Y. H. (2012). Investigation on the metabolites by solid fermentation of a mucor strain liquor making. Sci. Technol. 3, 34–39. doi: 10.13746/j.njkj.2012.03.016

Hao, F., Tan, Y. W., Lv, X. B., Chen, L. Q., Yang, F., Wang, H. Y., et al. (2021). Microbial community succession and its environment driving factors during initial fermentation of Maotai-flavor Baijiu. Front. Microbiol. 12, 1–8. doi: 10.3389/fmicb.2021.669201

Huang, Y., Wu, Q., and Xu, Y. (2014). Isolation and identification of a black aspergillus strain and the effect of its novel protease on the aroma of Moutai-flavoured liquor. J. Inst. Brew. 120, 268–276. doi: 10.1002/jib.135

Jiang, Q. E., Chen, W. H., Sun, J. Y., and Liu, Y. (2021). Research progress on microorganism of sauce-flavor Baijiu Daqu. China Brewing 40, 1–5. doi: 10.11882/j.issn.0254-5071.2021.12.001

Jiang, T., Chen, W., Xiao, T. F., Ning, Z. P., and Jia, Y. L. (2023). Concentration and spatial distribution characters of the rare-earth elements in soils in Maotai, Guizhou Province. Earth Environ. 41, 281–287. doi: 10.14050/j.cnki.1672-9250.2013.03.017

Jiang, Y., Luo, Y., Zhao, Z. C., and Tao, S. W. (2009). Changes in wind speed over China during 1956–2004. Theor. Appl. Climatol. 99, 421–430. doi: 10.1007/s00704-009-0512-7

Jin, X. Y., Cai, Y. K., Chen, P., Guo, T. T., Chen, M. B., and Fang, S. L. (2020). Overview of the research on brewing microorganisms of Chinese liquor. Liquor Making 47, 16–21.

Jin, Y., Li, D. Y., Ai, M., Tang, Q. X., Huang, J., Ding, X. F., et al. (2019). Correlation between volatile profiles and microbial communities: a metabonomic approach to study Jiang-flavor liquor Daqu. Food Res. Int. 121, 422–432. doi: 10.1016/j.foodres.2019.03.021

Jin, X. L., Li, S. M., and Zhang, C. Y. (2009). Situation and evaluation of soil fertility of the raw materials base for producing Moutai wine. Guizhou Agric. Sci. 37, 103–106.

Jin, G., Zhu, Y., and Xu, Y. (2017). Mystery behind Chinese liquor fermentation. Trends Food Sci. Technol. 63, 18–28. doi: 10.1016/j.tifs.2017.02.016

Knights, D., Kuczynski, J., Charlson, E. S., Zaneveld, J., and Kelley, S. T. (2011). Bayesian community-wide culture-independent microbial source tracking. Nat. Methods 8, 761–763. doi: 10.1038/nmeth.1650

Kong, Y., Wu, Q., Zhang, Y., and Xu, Y. (2014). In situ analysis of metabolic characteristics reveals the key yeast in the spontaneous and solid-state fermentation process of Chinese light-style liquor [J]. Appl. Environ. Microbiol. 80, 3667–3676. doi: 10.1128/AEM.04219-13

Li, L., Fan, M., Xu, Y., Zhang, L., Qian, Y., Tang, Y., et al. (2023). Comparative analysis of volatile flavor compounds in strongly flavored baijiu under two different pit cap sealing processes. Food Secur. 12:2579. doi: 10.3390/foods12132579

Li, H., Lian, B., Ding, Y. H., Nie, C. C., and Zhang, Q. M. (2014). Bacterial diversity in the central black component of Maotai Daqu and its flavor analysis. Ann. Microbiol. 64, 1659–1669. doi: 10.1007/s13213-014-0809-z

Li, P., Lin, W., Liu, X., Wang, X., and Luo, L. (2016). Environmental factors affecting microbiota dynamics during traditional solid-state fermentation of Chinese Daqu starter. Front. Microbiol. 7:1237. doi: 10.3389/fmicb.2016.01237

Li, C. C., Xiong, K. N., Su, X. L., Xu, L. X., Gao, X. Q., and Xiang, T. J. (2017). Research on the unique brewing environment of Guizhou Moutai liquor. China Brewing 36, 1–4. doi: 10.11882/j.issn.0254-5071.2017.01.001

Li, B., Zhang, C., Wang, Y. X., Wang, J., Cai, X., Yang, M., et al. (2019). Research progress on functional microbes and enzymes in Daqu of Baijiu. China Brewing 38, 7–12. doi: 10.11882/j.issn.0254-5071.2019.06.002

Liu, C. C., Feng, S. B., Wu, Q., and Huang, H. Q. (2019). Raw material regulates flavor formation via driving microbiota in Chinese liquor fermentation. Front. Microbiol. 10, 1–13. doi: 10.3389/fmicb.2019.01520

Liu, X., Guo, K. L., and Zhang, H. X. (2012). Determination of microbial diversity in Daqu, a fermentation starter culture of Maotai liquor, using nested PCR-denaturing gradient gel electrophoresis. World J. Microbiol. Biotechnol. 28, 2375–2381. doi: 10.1007/s11274-012-1045-y

Liu, H., and Sun, B. (2018). Effect of fermentation processing on the flavor of baijiu. J. Agric. Food Chem. 66, 5425–5432. doi: 10.1021/acs.jafc.8b00692

Liu, S., and Tan, H. (2011). Contaction of the soil structure in moutai town and the production of moutai liquor. Liquor Making Sci. Technol. 7, 64–67. doi: 10.13746/j.njkj.2011.07.007

Liu, Y. F., Wan, B., Yang, F., Zhang, X. L., Li, J. H., Du, G. C., et al. (2022a). Metabolomics-driven elucidation of interactions between Saccharomyces cerevisiae and Lactobacillus panis from Chinese baijiu fermentation microbiome. Fermentation 8:33. doi: 10.3390/fermentation8010033

Liu, Y. F., Wang, M. C., Yang, F., Zhang, X. L., Li, J. H., Du, G. C., et al. (2022b). A CRISPR-Cas12a-based assay for efficient quantification of Lactobacillus panis in Chinese baijiu brewing microbiome. Fermentation 8, 1–13. doi: 10.3390/fermentation8020088

Liu, J. B., Xue, D. F., Cao, J. Q., and Zhou, L. X. (2014). Application of liquid strain cultivation in the bacterial Fuqu of sesame flavor Chinese liquor. China Brewing 33, 127–129. doi: 10.11882/j.issn.0254-5071.2014.10.030

Lv, X. B., Wu, Y. C., Chen, L. Q., Liu, M. Q., Yang, F., Wang, M. M., et al. (2021). Characteristics of the bacterioplankton community and their relationships with water quality in Chishui river basin. Acta Sci. Circumst. 41, 4596–4605. doi: 10.13671/j.hjkxxb.2021.0125

Ma, S. J., Li, Y. Y., Peng, Y. K., Nie, S., Yan, S., and Zhao, X. L. (2022). An intelligent and vision-based system for baijiu brewing-sorghum discrimination. Measurement 198:111417. doi: 10.1016/j.measurement.2022.111417

Meng, X., Wu, Q., Wang, L., Wang, D., Chen, L., and Xu, Y. (2015). Improving flavor metabolism of Saccharomyces cerevisiae by mixed culture with Bacillus licheniformis for Chinese Maotai-flavor liquor making. J. Ind. Microbiol. Biotechnol. 42, 1601–1608. doi: 10.1007/s10295-015-1647-0

Niu, Y. W., Chen, X. M., Xiao, Z. B., Ma, N., and Zhu, J. C. (2017). Characterization of aroma-active compounds in three Chinese Moutai liquors by gas chromatography-olfactometry, gas chromatography-mass spectrometry and sensory evaluation. Nat. Prod. Res. 31, 938–944. doi: 10.1080/14786419.2016.1255892

Pang, X. N., Han, B. Z., Huang, X. N., Zhang, X., Hou, L. F., Cao, M., et al. (2018). Effect of the environment microbiota on the flavour of light-flavour baijiu during spontaneous fermentation. Sci. Rep. 8, 1–12. doi: 10.1038/s41598-018-21814-y

Shen, T., Liu, J., Wu, Q., and Xu, Y. (2020). Increasing 2-furfurylthiol content in Chinese sesame-flavored baijiu via inoculating the producer of precursor l-cysteine in baijiu fermentation. Food Res. Int. 138:109757. doi: 10.1016/j.foodres.2020.109757

Simon, E., Canarini, A., Martin, V., Seneca, J., Bockle, T., Reinthaler, D., et al. (2020). Microbial growth and carbon use efficiency show seasonal responses in a multifactorial climate change experiment. Commun. Biol. 3:584. doi: 10.1038/s42003-020-01317-1

Sun, W. N., Xiao, H. Z., Peng, Q., Zhang, Q. G., Li, X. X., and Han, Y. (2016). Analysis of bacterial diversity of Chinese Luzhou-flavor liquor brewed in different seasons by Illumina Miseq sequencing. Ann. Microbiol. 66, 1293–1301. doi: 10.1007/s13213-016-1223-5

Tan, X., Zhang, R. G., Meng, T. Y., Liang, H. Z., and Lv, J. (2014). Taibaiella chishuiensis sp. nov., isolated from fresh water. Int. J. Syst. Evol. Microbiol. 64, 1795–1801. doi: 10.1099/ijs.0.060269-0

Tang, J., Yang, Q., Liu, Y. C., and Chen, S. X. (2021). Research progress on flavor-producing microorganisms in baijiu. China Brewing 40, 15–20. doi: 10.11882/j.issn.0254-5071.2021.11.003

Tu, W., Cao, X., Cheng, J., Li, L., Zhang, T., Wu, Q., et al. (2022). Chinese baijiu: the perfect works of microorganisms. Front. Microbiol. 13:919044. doi: 10.3389/fmicb.2022.919044

Walker, T. W. N., Kaiser, C., Strasser, F., Herbold, C. W., Leblans, N. I. W., Woebken, D., et al. (2018). Microbial temperature sensitivity and biomass change explain soil carbon loss with warming. Nat. Clim. Chang. 8, 885–889. doi: 10.1038/s41558-018-0259-x

Wang, L. (2022). Research trends in Jiang flavor baijiu fermentation: from fermentation microecology to environmental ecology. J. Food Sci. 87, 1362–1374. doi: 10.1111/1750-3841.16092

Wang, H., Bai, S. Y., Zhao, Q., Zong, J. Q., Cai, H. P., and Wang, L. (2022a). Analysis on the uniqueness and variation of wind speed and direction in Renhuai area of Chishui river basin environmental. Ecology 4, 11–18.

Wang, X. D., Ban, S. D., Hu, B. D., Qiu, S. Y., and Zhou, H. X. (2017). Bacterial diversity of Moutai-flavour Daqu based on high-throughput sequencing method. J. Inst. Brew. 123, 138–143. doi: 10.1002/jib.391

Wang, Y. R., Cai, W. C., Wang, W. P., Shu, N., Zhang, Z. D., Hou, Q. C., et al. (2020). Analysis of microbial diversity and functional differences in different types of high-temperature Daqu. Food Sci. Nutr. 9, 1003–1016. doi: 10.1002/fsn3.2068

Wang, X., Du, H., and Xu, Y. (2017). Source tracking of prokaryotic communities in fermented grain of Chinese strong-flavor liquor. Int. J. Food Microbiol. 244, 27–35. doi: 10.1016/j.ijfoodmicro.2016.12.018

Wang, L., Hu, X. L., and Huang, Y. G. (2022b). Effects of environmental factors on diversity of bacterial communities in different fermentation rounds in Maotai town. Food Sci. 43, 150–157. doi: 10.7506/spkx1002-6630-20210305-074

Wang, L., Huang, Y. G., Hu, X. X., and Li, Y. Y. (2021). The impact of environmental factors on the environmental bacterial diversity and composition in the Jiang-flavoured baijiu production region. LWT 149:111784. doi: 10.1016/j.lwt.2021.111784

Wang, H., Huang, Y. G., and Huang, Y. L. (2021). Microbiome diversity and evolution in stacking fermentation during different rounds of Jiang-flavoured baijiu brewing. LWT 143:111119. doi: 10.1016/j.lwt.2021.111119

Wang, Z., Li, P., Luo, L., Simpson, D. J., and Gänzle, M. G. (2018). Daqu fermentation selects for heat-resistant enterobacteriaceae and bacilli. Appl. Environ. Microbiol. 84, e01483–e01418. doi: 10.1128/AEM.01483-18

Wang, Q., Liu, K. Y., Liu, L. L., Zheng, J., Chen, T., Chen, F., et al. (2021). Correlation analysis between aroma components and microbial communities in Wuliangye-flavor raw liquor based on HS-SPME/LLME-GC–MS and PLFA. Food Res. Int. 140:109995. doi: 10.1016/j.foodres.2020.109995

Wang, C. L., Shi, D. J., and Gong, G. L. (2008). Microorganisms in Daqu: a starter culture of Chinese Maotai-flavor liquor. World J. Microbiol. Biotechnol. 24, 2183–2190. doi: 10.1007/s11274-008-9728-0

Wang, L., Wang, Y. Y., Wang, H. Y., Liu, G., Yang, F., Jiang, H. G., et al. (2015a). Microbial composition of bottom pit mud in jiangxiang baijiu(liquor) pit. Liquor Making Sci. Technol. 1, 12–15. doi: 10.13746/j.njkj.2014513

Wang, L., Wang, Y. Y., Wang, D. Q., Xu, J., Yang, F., and Liu, G. (2015b). Dynamic changes in the bacterial community in Moutai liquor fermentation process characterized by deep sequencing. J. Inst. Brew. 121, 603–608. doi: 10.1002/jib.259

Wang, P., Wu, Q., Jiang, X. J., Wang, Z. Q., Tang, J. L., and Xu, Y. (2017). Bacillus licheniformis affects the microbial community and metabolic profile in the spontaneous fermentation of Daqu starter for Chinese liquor making. Int. J. Food Microbiol. 250, 59–67. doi: 10.1016/j.ijfoodmicro.2017.03.010

Wang, M. Y., Yang, J. G., Zhao, Q. S., Zhang, K. Z., and Su, C. (2018). Research progress on flavor compounds and microorganisms of Maotai flavor baijiu. J. Food Sci. 84, 6–18. doi: 10.1111/1750-3841.14409

Wang, Q., Zhang, H., and Liu, X. (2016). Microbial community composition associated with Maotai liquor fermentation. J. Food Sci. 81, M1485–M1494. doi: 10.1111/1750-3841.13319

Wu, Q., Chen, L., and Xu, Y. (2013). Yeast community associated with the solid state fermentation of traditional Chinese Maotai-flavor liquor. Int. J. Food Microbiol. 166, 323–330. doi: 10.1016/j.ijfoodmicro.2013.07.003

Wu, S. L., Du, H., and Xu, Y. (2023). Daqu microbiota adaptability to altered temperature determines the formation of characteristic compounds. Int. J. Food Microbiol. 385:109995. doi: 10.1016/j.ijfoodmicro.2022.109995

Wu, J. J., Ma, Y. K., Zhang, F. F., and Chen, F. S. (2012a). Biodiversity of yeasts, lactic acid bacteria and acetic acid bacteria in the fermentation of “Shanxi aged vinegar”, a traditional Chinese vinegar. Food Microbiol. 30, 289–297. doi: 10.1016/j.fm.2011.08.010

Wu, X. J., WU, Q., and Xu, Y. (2014). Study on an alcohol-tolerant Bacillus amyloliquefaciens cgmcc 6262. Ind. Microorganism 44:6. doi: 10.3969/j.issn.1001-6678.2014.04.002

Wu, Q., Xu, Y., and Chen, L. (2012b). Diversity of yeast species during fermentative process contributing to Chinese Maotai-flavour liquor making. Lett. Appl. Microbiol. 55, 301–307. doi: 10.1111/j.1472-765X.2012.03294.x

Xu, Y., Wang, X., Liu, X., Li, X., Zhang, C., and Li, W. (2021). Discovery and development of a novel short-chain fatty acid ester synthetic biocatalyst under aqueous phase from Monascus purpureus isolated from baijiu. Food Chem. 338:128025. doi: 10.1016/j.foodchem.2020.128025

Xu, Y., Wu, Q., and Xu, Y. (2018). Effects of main functional strains on Zygosaccharomyces bailii in Chinese Maotai-flavor liquor fermentation. Microbiol. China 45, 42–53. doi: 10.13344/j.microbiol.china.170190

Xu, Y., Zhao, J., Liu, X., Zhang, C., Zhao, Z., Li, X., et al. (2022). Flavor mystery of Chinese traditional fermented baijiu: the great contribution of ester compounds. Food Chem. 369:130920. doi: 10.1016/j.foodchem.2021.130920

Yang, F., Chen, L. Q., Liu, Y. F., Li, J. H., Wang, L., and Chen, J. (2019). Identification of microorganisms producing lactic acid during solid-state fermentation of Maotaiflavour liquor. J. Inst. Brew. 125, 171–177. doi: 10.1002/jib.537

Yang, F., Liu, Y. F., Chen, L. Q., Li, J. H., and Du, G. C. (2020a). Genome sequencing and flavor compound biosynthesis pathway analyses of bacillus licheniformis isolated from Chinese maotai-flavor liquor-brewing microbiome. Food Biotechnol. 34, 193–211. doi: 10.1080/08905436.2020.1789474

Yang, L., Xian, C., Li, P., Wang, X. Y., Song, D. D., Zhao, L., et al. (2023). The spatio-temporal diversity and succession of microbial community and its environment driving factors during stacking fermentation of Maotai-flavor baijiu. Food Res. Int. 169:112892. doi: 10.1016/j.foodres.2023.112892

Yang, F., Zhang, Q. L., Liu, Y. F., Li, J. H., and Chen, J. (2020b). Lactic acid biosynthesis pathways and important genes of Lactobacillus panis L7 isolated from the Chinese liquor brewing microbiome. Food Biosci. 36:100627. doi: 10.1016/j.fbio.2020.100627

Zha, M. S., Sun, B. G., and Wu, Y. P. (2018). Improving flavor metabolism of Saccharomyces cerevisiae by mixed culture with Wickerhamomyces anomalus for Chinese baijiu making [J]. J. Biosci. Bioeng. 126, 189–195. doi: 10.1016/j.jbiosc.2018.02.010

Zhang, Y., Li, J. T., Xu, X., Chen, H. Y., Zhu, T., Xu, J. J., et al. (2023). Temperature fluctuation promotes the thermal adaptation of soil microbial respiration. Nat. Ecol. Evol. 7, 205–213. doi: 10.1038/s41559-022-01944-3

Zhang, W., Si, G., Rao, Z., Li, J., Zhang, X., Mei, J., et al. (2019). High yield of tetramethyl pyrazine in functional Fuqu using bacillus amyloliquefaciens [J]. Food Biosci. 31:100435. doi: 10.1016/j.fbio.2019.100435

Zhang, H. X., Wang, L., Tan, Y. W., Wang, H. Y., Yang, F., Chen, L. Q., et al. (2021). Effect of Pichia on shaping the fermentation microbial community of sauce-flavor baijiu. Int. J. Food Microbiol. 336:108898. doi: 10.1016/j.ijfoodmicro.2020.108898

Zhang, C. L., Yang, L., Li, Z., Gan, G. D., and He, J. J. (2022). Microbial community and its relationship with volatile compounds in moutai-flavor baijiu stacking fermentation process. Food Sci. Technol. 47, 111–117. doi: 10.13684/j.cnki.spkj.2022.04.036

Zhao, C., Yan, X., Yang, S., and Chen, F. (2017). Screening of Bacillus strains from Luzhou-flavor liquor making for high-yield ethyl hexanoate and low-yield propanol. LWT 77, 60–66. doi: 10.1016/j.lwt.2016.11.035

Zheng, X. W., Yan, Z., Nout, M. J., Smid, E. J., Zwietering, M. H., Boekhout, T., et al. (2014). Microbiota dynamics related to environmental conditions during the fermentative production of fen-Daqu, a Chinese industrial fermentation starter. Int. J. Food Microbiol. 182-183, 57–62. doi: 10.1016/j.ijfoodmicro.2014.05.008

Zhou, J. L., Li, X. C., Li, S. J. Y., Ding, H. X., Lang, Y., Xu, P., et al. (2024). Airborne microorganisms and key environmental factors shaping their community patterns in the core production area of the Maotai-flavor baijiu. Sci. Total Environ. 912:169010. doi: 10.1016/j.scitotenv.2023.169010

Zhu, Q., Chen, L. Q., Peng, Z., Zhang, Q. L., Huang, W. Q., Yang, F., et al. (2022). Analysis of environmental driving factors on Core functional community during Daqu fermentation. Food Res. Int. 157:111286. doi: 10.1016/j.foodres.2022.111286

Zhu, M., Deng, Z., Tie, Y., Quan, S. K., Zhang, W. X., Wu, Z. Y., et al. (2024). Unveiling the synthesis of aromatic compounds in sauce-flavor Daqu from the functional microorganisms to enzymes. Food Res. Int. 190:114628. doi: 10.1016/j.foodres.2024.114628

Zhu, D. W., Wu, Z. Y., Luo, A. M., and Gao, H. (2015). Characterization and detection of toxoflavin-producing Burkholderia in rice straws and Daqu for Chinese Maotai-flavour liquor brewing. J. Inst. Brew. 121, 290–294. doi: 10.1002/jib.210

Zhuang, X. J., Wu, Q., and Xu, Y. (2017). Physiological characteristics of Zygosaccharomyces bailii and its interaction with Bacillus licheniformis in Chinese Maotai-flavor liquor making. Microbiol. China 44, 251–262. doi: 10.13344/j.microbiol.china.160174

Zhuansun, W. W., Xu, J., Li, Z. Q., Liu, H. Z., Zhao, Y., Chen, L. L., et al. (2022). Dynamic changes in the microbial community, flavour components in jiupei of a novel Maotai-Luzhou–flavoured liquor under various daqu blending modes and their correlation analysis. LWT 172:114167. doi: 10.1016/j.lwt.2022.114167

Keywords: food microbiology, Jiang-flavor-Baijiu, fermentation, microbial community, environmental ecology

Citation: Wu X, Zhao X, Wang L, Chen B, Li F, Tang Z and Wu F (2024) Unraveling the regional environmental ecology dominated baijiu fermentation microbial community succession and associated unique flavor. Front. Microbiol. 15:1487359. doi: 10.3389/fmicb.2024.1487359

Edited by:

Antonio Bevilacqua, University of Foggia, ItalyCopyright © 2024 Wu, Zhao, Wang, Chen, Li, Tang and Wu. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Xiaoli Zhao, emhhb3hpYW9saV96eGxAMTI2LmNvbQ==; Li Wang, V2FuZ2xpTW91dGFpMjAyMUAxNjMuY29t

Xiaowei Wu

Xiaowei Wu Xiaoli Zhao2*

Xiaoli Zhao2* Fengchang Wu

Fengchang Wu