94% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

ORIGINAL RESEARCH article

Front. Microbiol., 19 September 2024

Sec. Food Microbiology

Volume 15 - 2024 | https://doi.org/10.3389/fmicb.2024.1476091

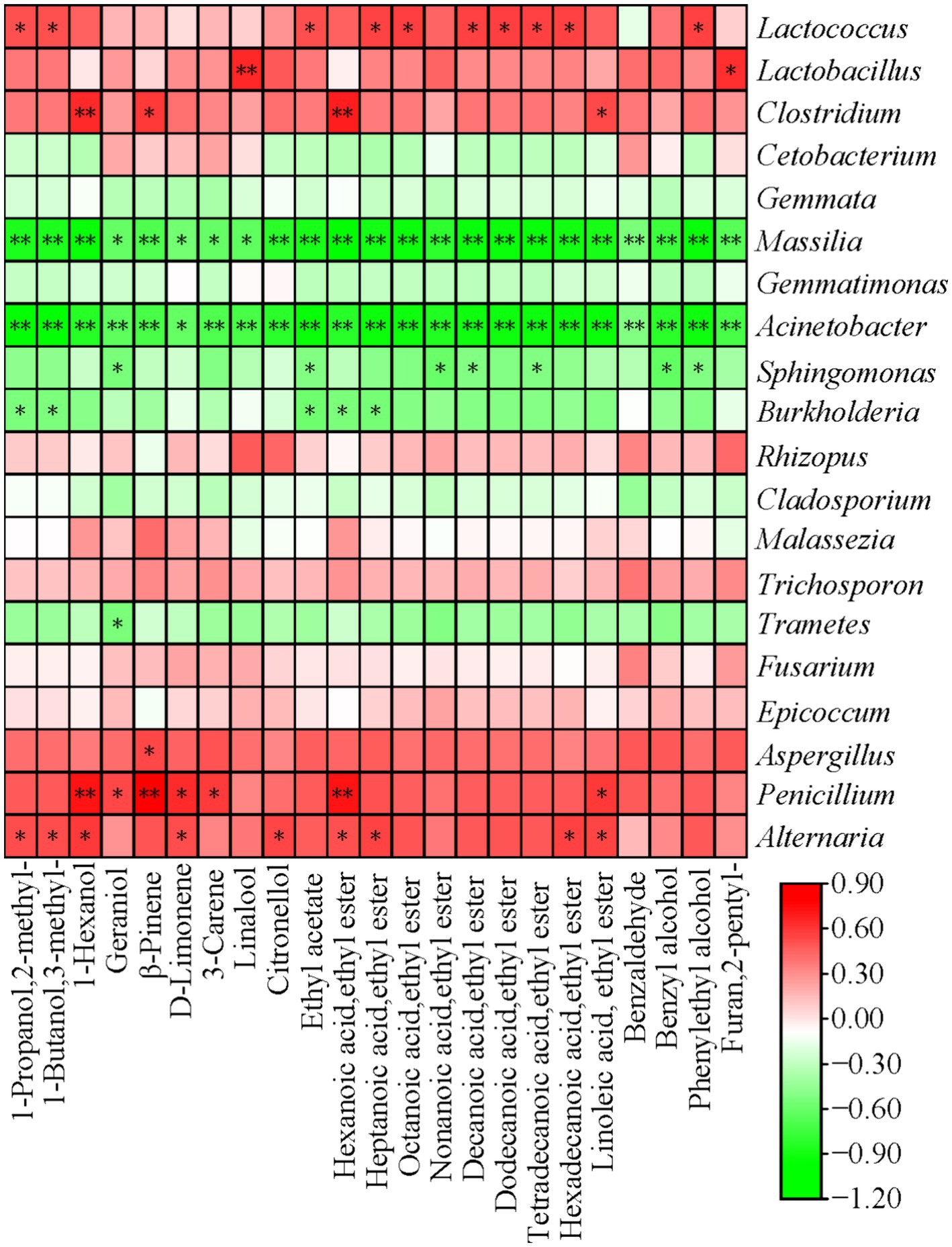

To develop a unique flavor of rice wine, coffee flowers (by-products of the coffee industry) were added because of their biologically active compounds that are conducive to health, and the fermentation parameters were optimized. In addition, the dynamic changes of microbial communities and volatile flavor compounds (VFCs) during the different fermentation stages were investigated. After the optimization of the fermentation parameters, a novel product, i.e., the coffee flower rice wine (CFRW), was obtained with a bright yellow transparent, fragrant, and harmonious aroma and mellow and refreshing taste by sensory evaluation, when 4.62% of the coffee flowers and 1.93% koji were added and fermented at 24.10°C for 3.88 days. The results showed that Lactococcus was the dominant bacteria, accounting for 87.0–95.7%, while Rhizopus and Cladosporium were the main fungi, accounting for 68.2% and 11.3% on average, respectively, in the fermentation process of the CFRW. Meanwhile, twenty-three VFCs were detected in the CFRW, which included three alcohols, six terpenes, ten esters, three aromatics, and one furan. The correlation analysis revealed that there were 16 significant positive correlations and 23 significant negative correlations between the bacterium and VFCs (|ρ| > 0.6, p < 0.05), while there were 12 significant positive correlations and one significant negative correlation between the fungi and VFCs (|ρ| > 0.6, p < 0.05). Furthermore, five VFCs, including linalool, geraniol, ethyl acetate, 1-hexanol, and 3-methyl-1-butanol, contributed vital flavors to the CFRW, and they were all significantly negatively correlated with the changes of Massilia and Acinetobacter (|ρ| > 0.6, p < 0.05). Moreover a significant positive correlation was found between the relative abundance of Lactococcus and the contents of 3-methyl-1-butanol and ethyl acetate (|ρ| > 0.6, p < 0.05). Therefore, this study provides a valuable theoretical basis for further improving the quality and production technology of CFRW.

Chinese rice wine is a traditional alcoholic beverage, with a history of more than 9,000 years, which gives it the reputation of being one of the oldest brewed wines in the world (Jiao et al., 2017; Mao et al., 2023). Undoubtedly, it has great popularity among consumers in China and East Asia due to its full aroma, low alcoholic content, unique flavor, and potential value in the medical field (Zhao et al., 2018; Chen et al., 2021; Mao et al., 2023). Numerous studies have reported that Chinese rice wine contains a wide range of chemical compounds, including carbohydrates, proteins, organic acids, vitamins, minerals, and rich bioactive substances (Jung et al., 2014; Lu et al., 2017; Hipol and Alma-in, 2018). Moreover, Chinese rice wine exhibits antioxidant properties that can remove free radicals and protect cells from oxidation, which is beneficial to the health of consumers (Que et al., 2006; Chay et al., 2020; Shen et al., 2021).

The flavor and aroma of rice wine are important indicators that are well-known for evaluating wine quality and determining consumer preference. Microorganisms produce alcohol and other metabolites during the fermentation process, wherein flavor and aroma are formed (Chen et al., 2018; Ren et al., 2019). Hence, microorganisms play a crucial role in the unique flavor formation of rice wine. Over the years, according to available document data, researchers have found that they are responsible for different contributions to the final product (Jiang et al., 2020). Furthermore, it is important to note that the raw materials used for fermented rice wine may also play an important role in its flavor and taste. Hitherto, many scholars have focused on the microbial dynamics and flavor changes in the fermentation broth of rice wine from different regions (Chen et al., 2021). Nevertheless, rice wine with a high quality and unique taste has gradually attracted the attention of researchers and has been favored by consumers as a result of the improvement in living conditions in recent years. The rice wine made with traditional raw materials can no longer fully meet the needs of current consumers. Therefore, new auxiliary foodstuffs should be applied to the traditional brewing system of rice wine to improve the commercial value and develop products with a more unique taste and flavor.

Coffee is a principal industry in Yunnan, China. However, a large number of coffee flowers fall to the ground every year and are not fully utilized, which causes abundant waste in the coffee industry (Nguyen et al., 2019). These coffee flowers can be harvested after pollination and reused in the bioenergy development and can be prepared as important ingredients in foods, beverages, and cosmetics as they contain vitamins, sugars, and rich bioactive compounds that possess potential benefits for human health because of their antioxidant, anti-fibrosis, and antiviral activities and help prevent cardiovascular diseases, cancers, and diabetes (Mlcek and Rop, 2011; Mak et al., 2013; Tseng et al., 2000; Lachenmeier et al., 2021). Recently, it has been proposed that coffee flowers can be used as a promising source in the production of beverages, bio-sugars, and functional healthy foods (Wirz et al., 2022). Interestingly, coffee flowers contain flavor compounds such as methyl jasmonate, phenylethanol, geraniol, and indole, which can emit a highly pleasant jasmine-like floral aroma (Emura et al., 1997; Stashenko et al., 2013; Shen et al., 2023). Therefore, coffee flowers can be used as raw materials to improve the flavor of food.

Hence, if coffee flower as an innovative material is added to the traditional fermentation process, we may be able to develop a new rice wine product with a unique taste and potential medical benefits, which can be of great significance to improve the additional value of coffee flowers and meet the personalized demands of consumers. However, the effects of coffee flowers on rice wine’s flavor profile and microbial community remain unclear. In this study, we will evaluate the sensory characteristics, volatile flavor compounds (VFCs), and their correlation with the microbial communities involved in the fermentation of coffee flower rice wine (CFRW) under optimal fermentation parameters, thus providing a theoretical basis for its large-scale production.

Coffee flowers were harvested and collected from Baoshan, Yunnan, China in May 2023, and glutinous rice (the starch content was 78.34%) was obtained from Shenyang Xinchang Grain Trading Co., Ltd. (Liaoning, China). Koji (rice flour fermented using Rhizopus oryzae) was purchased from Angel Yeast Co., Ltd. (Hubei, China). Reagents 3-methyl-1-butyl-1,1-d2 alcohol, n-hexyl-1,1-d2 alcohol, (±)-linalool-d3 (vinyl-d3), ethyl acetate-d3, ethyl hexanoate-d11, ethyl octanoate-d15, 2-phenylethyl acetate-d3, and ethyl octanoate-d15 were purchased from Chengdu Manst Biotechnology Co., Ltd. (Chengdu, China).

CFRW was fermented using traditional glutinous rice and coffee flowers as feedstock. The brewing test flow was performed as follows: the glutinous rice was washed to remove impurities and soaked in a diploid amount of pure water for 24 h and then drained; thereafter, the soaked glutinous rice was steamed for 45 min, followed by cooling to 30°C. According to the experimental design, a certain amount of the koji and fresh coffee flowers (cleaned with aseptic water beforehand) were added to the rice grains in different proportions; meanwhile, they were evenly mixed by stirring with hands and then put into a jar for static fermentation. It must be noted that the mixture was stacked from the edge of the jar to the center. When one-third of the fermentation raw materials remained, they were only added to the edge of the fermentation jar so that the middle was lower than the edge; after the fermentation, the liquor was pressed with a filter gauze and boiled at 65°C for 30 min to obtain the final product (Figure 1). The fermented samples were harvested every day and conserved at −80°C until required. During the different fermentation stages of 3–7 days, three parallel samples were collected each time.

The single-factor test was performed to evaluate the addition of the coffee flowers (0, 2, 4, 6, 8, and 10%), the addition of the koji (0.5, 1.0, 1.5, and 2.0%), the fermentation temperature (22, 24, 26, 28, and 30°C), and the fermentation time (3, 4, 5, 6, and 7 days) on the sensory scores of the CFRW. One factor was kept constant, and the others were changed for each single-factor test. Each group of experiments was repeated three times for a single factor. The Box–Behnken design was employed to optimize the brewing process of the CFRW further and evaluate the effects of the interactions on the quality of the CFRW based on the results of the single-factor experiments. In total, a 29-trial design was generated, and the center points per block were five in this study. The four independent variables were the addition of the coffee flowers (2, 4, and 6%), the addition of the koji (1.5, 2.0, and 2.5%), the fermentation temperature (22, 24, and 26°C), and the fermentation time (3, 4, and 5 days). Each variable corresponded to three coded levels: low (−1), middle (0), and high (+1). Then, three parallel trials were conducted to verify the reliability of the above optimal fermentation parameters of the CFRW determined by the response surface experiments.

A quantitative characterization of the sensory properties of the CFRW samples was conducted with official methods of GB/T 13662—2018. A training panel of 11 judges was organized to conduct a sensory evaluation on all indicators of the CFRW product using a sensory rating scale. The panel consisted of 11 members, including five men and six women, and they aged from 20 to 30 years old. Each member had more than 3 years of wine-tasting and sensory analysis experience. A total of four sensory descriptors were considered, and the corresponding scoring standards are shown in Figure 2. The comprehensive score of all indicators was taken as the total score. Meanwhile, the members began by evaluating the aroma profile characteristics of the CFRW samples and selecting six common quality descriptors (floral fragrance, fruity fragrance, rice fragrance, honey fragrance, nutty fragrance, and creamy fragrance) that best represented the CFRW samples. The intensities of the aroma attributes were scored on a scale ranging from 0 to 10; the higher the score, the stronger the intensity.

A microbial community analysis of the CFRW was performed under the optimal fermentation parameters. The CFRW samples with different fermentation times (0, 1, 2, 3, and 4 days) were collected and labeled as F0, F1, F2, F3, and F4, respectively. Each sample was repeated three times. Then, they were put in sterile polyethylene bags and stored at −80°C in a freezer until further analysis. The microbial DNA was extracted using the HiPure Soil DNA Kits (D3142, Guangzhou American Biotechnology Co., Ltd., Guangzhou, China) according to the protocols of the manufacturer. The final DNA quality was determined using a NanoDrop 2000 microspectrophotometer (Thermo Fisher Scientific, United States) and agarose gel electrophoresis. The primers with a barcode used for amplifying the V3–V4 region of the bacteria 16S rDNA were 341F and 806R. The primers applied to amplify the ITS2 region of the fungi gene were ITS3 and ITS4. Polymerase chain reaction (PCR) procedures were carried out by referring to previously reported methods (Liu et al., 2022; Luan et al., 2018). Amplicons were extracted from the agarose gels and purified using the AxyPrep DNA Gel Extraction Kit (Axygen Biosciences, Union City, CA, United States) according to the standard protocols. Then, the PCR product was quantified using the ABI StepOnePlus Real-Time PCR System (Life Technologies, Foster City, United States) and was pooled in equal amounts. After that, sequencing of the amplicon library was performed on the Illumina Novaseq 6,000 platform at Guangzhou Gene Denovo Co., Ltd. (Guangzhou, China). The raw reads were deposited into the National Center for Biotechnology Information (NCBI) Sequence Read Archive (SRA) database (Accession Number: PRJNA869838 for bacterial and PRJNA869566 for fungal).

The raw sequencing data were filtered and analyzed using FLASH software (v1.2.7) and QIIME software (v1.8.0). A clustering analysis of the operational taxonomic unit (OTU) was conducted using USEARCH software (v10.0). The OTU sequences of the bacterial and fungal genes were annotated using the SILVA/16S rDNA database and the UNITE database, respectively (Qian et al., 2023).

5.0 mL of the CFRW sample and 10 μL internal standards of isotope (100 μg/g 3-methyl-1-butyl-1,1-d2 alcohol, n-hexyl-1,1-d2 alcohol, (±)-linalool-d3, ethyl acetate-d3, ethyl hexanoate-d11, ethyl octanoate-d15, 2-phenylethyl acetate-d3, and ethyl octanoate-d15) were fully mixed and placed in headspace glass vials for balancing for 15 min under 60°C and 250 r/min. Then, the 0.5 mL balanced sample was collected with a 2.5 mL airtight syringe, which was then pre-heated to 80°C and placed in the headspace vials. The VFCs were extracted for 45 min at 60°C using a divinylbenzene/carboxen/polydimethylsiloxane (DVB/CAR/PDMS) fiber and desorbed at the GC injection port at 250°C for 3 min for GC–MS analysis. Each sample was repeated three times. Subsequent GC–MS analysis of the VFCs was performed according to the method reported in the literature (Yang et al., 2022). The VFCs of the CFRW were identified by matching the mass spectral databases (NIST 1.6 and Wiley 6.0), and their relative contents were calculated according to the internal standard method.

The odor activity value (OAV) of the VFCs in the CFRW was defined as the ratio of the concentration of a volatile compound to its odor detection threshold, which was found in the literature (Ferreira et al., 2002; Gomez-Miguez et al., 2007; Rahayu et al., 2017). Only compounds with an OAV > 1 can be considered contributing to the aroma of CFRW (Zhu et al., 2021).

The data of response surface methodology (RSM) were analyzed using Design-Expert 10.0.1.0 software. The data of the sensory scores and their differences among the groups were analyzed by one-way ANOVA using SPSS 22.0 software (IBM, Chicago, IL, United States). All samples were subjected to three biological replicates. The data were presented in the form of averages and standard deviations. Spearman correlation analysis was performed to assess the relationship between the dominant genera and volatile metabolites using R Project 3.6.1. The stacked bar plot of the microbial community composition was visualized in the R project ggplot2 package (version 2.2.1).

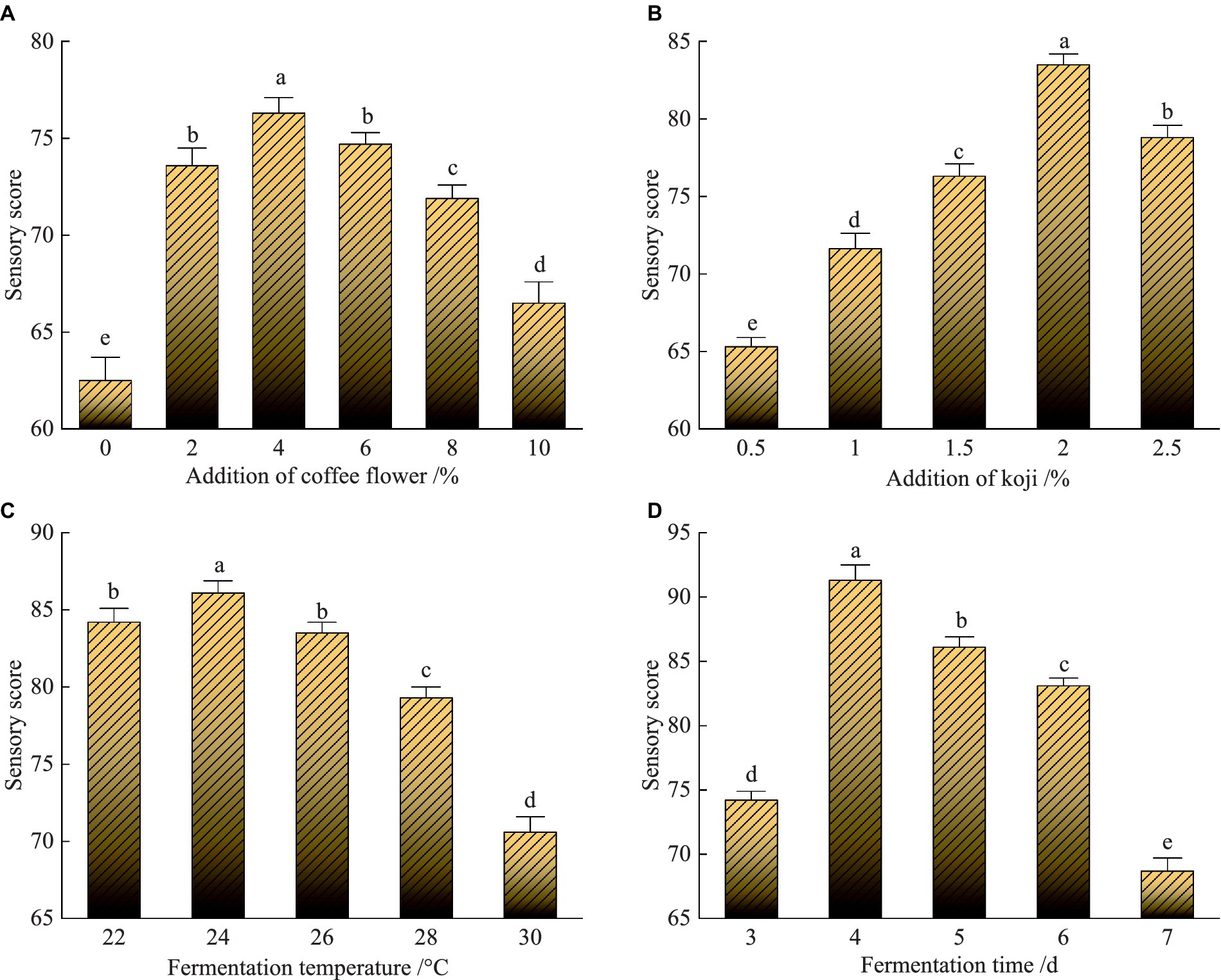

Figure 3A shows the effect of the addition of the coffee flowers on the sensory score of the CFRW. Overall, the addition of the coffee flowers had a significant effect on the sensory score of the CFRW. As more coffee flowers were added, the sensory score of the CFRW presented a trend where they first rose and then fell. It reached the highest score (76.3), and it was significantly higher than the others (p < 0.05) when 4% of the coffee flowers were added. However, sequentially appending more coffee flowers resulted in a significant decrease in the sensory score of the CFRW (p < 0.05). In particular, it got the lowest sensory score of 66.5 when 10% of the coffee flowers were added to the CFRW. Thus, 4% was regarded as the optimum addition of the coffee flowers.

Figure 3. Effect of the addition of the coffee flowers on the sensory scores of the coffee flower rice wine (CFRW) (A), effect of the addition of the koji on the sensory scores of the CFRW (B), effect of the fermentation temperature on the sensory scores of the CFRW (C), effect of the fermentation time on the sensory scores of the CFRW (D).

It can be seen that the sensory score of the CFRW continuously increased from 65.3 to 83.5, with the increase in the addition of the koji from 0.5% to 2.0% (Figure 3B). However, the sensory score dropped significantly to 78.8 when the amount of koji was 2.5%.

Overall, the sensory score of the CFRW descended with the ascending fermentation temperature from 24 to 30°C (Figure 3C). In addition, the sensory score of the CFRW brewed at 26°C was slightly lower (83.5) than that brewed at 22°C, but the difference was not significant. In the fermentation process, the excessive temperature significantly reduced the sensory score of the CFRW (p < 0.05). When the temperature was 24°C, the fermented CFRW had the highest sensory score of 86.1, which was significantly higher than the others (p < 0.05). However, when it was higher than the appropriate temperature, especially at 30°C, the CFRW was subjected to the lowest score of 70.6.

As shown in Figure 3D, the fermentation time markedly affected the sensory scores of the CFRW. It first increased and then decreased with the extension of the fermentation time. When fermented for 4 days, the sensory score of the CFRW was as high as 91.3, which was significantly higher than the others (p < 0.05). However, when the fermentation time was continued to extend, the sensory score of the CFRW decreased significantly (p < 0.05). In particular, it achieved the lowest sensory score (68.7) when it was fermented for 7 days.

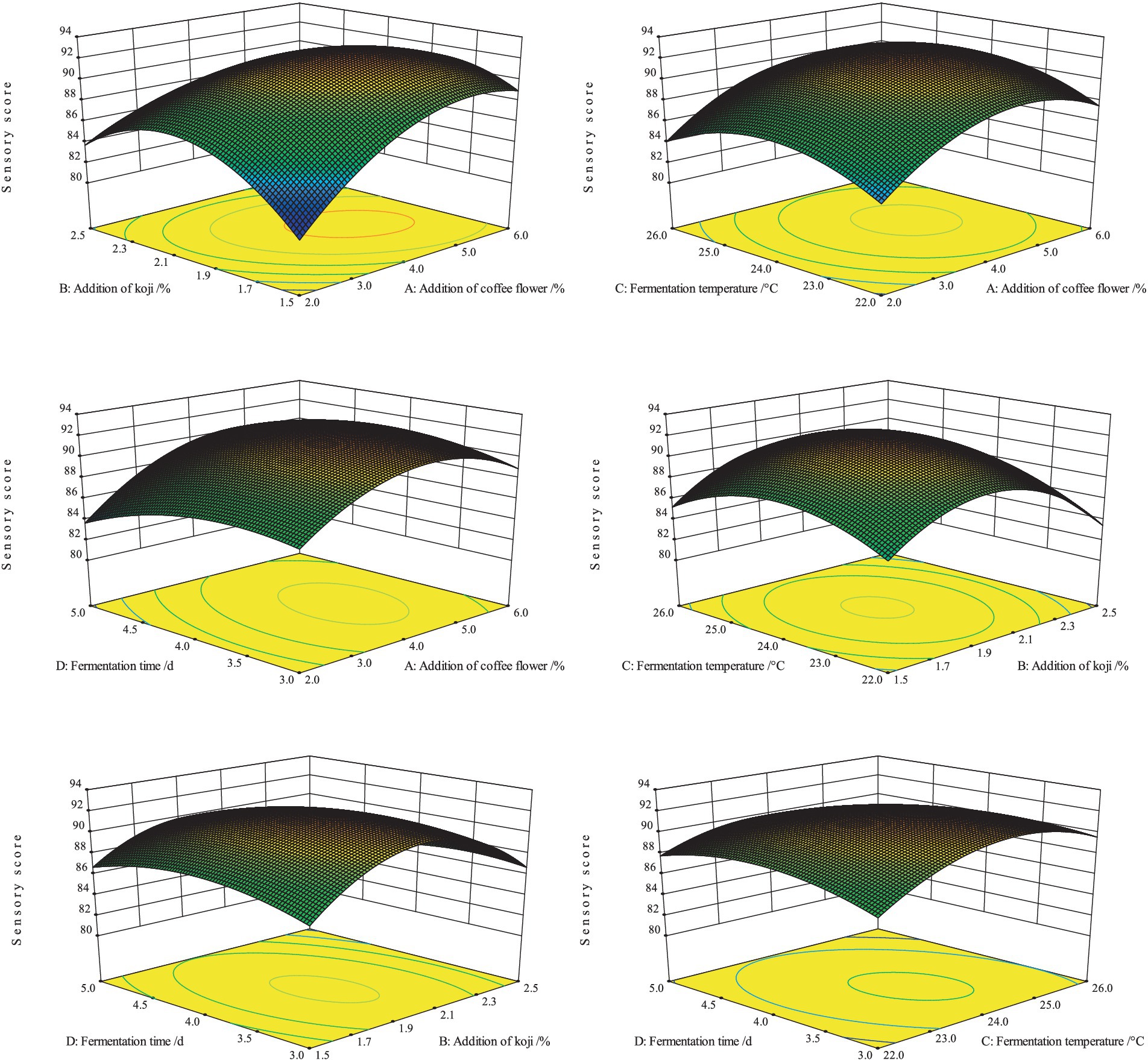

A response surface test was performed to determine the optimal fermentation parameters of the CFRW. Moreover, a sensory evaluation was conducted to evaluate the effect of different fermentation parameters on the sensory performance of the CFRW. According to the experimental design, 29 trials were conducted, and the corresponding result of the ANOVA is illustrated in Table 1. As shown in Table 1, the model was extremely significant (p < 0.01) but not significant (p > 0.05) for the lack of fit, which implied that the regression equation was well fitted. The four factors had different contributions to the response value of the CFRW. Among these factors, the addition of the coffee flowers had the most significant effect on the sensory score of the CFRW, followed by the addition of the koji and the fermentation time. In this case, the line term A and the quadric terms A2, B2, and C2 had very significant effects (p < 0.01) on the sensory score of the CFRW. However, among the interaction terms, the only significant interaction (p < 0.05) effect was found in the term AB (Table 1). As shown in Figure 4, the response surface formed by the factors A and B had the steepest slope, which verified that the interaction term AB had a significant impact on the sensory evaluation of the CFRW (p < 0.05). The final second-order quadratic regression equation of the response was evaluated as follows:

Figure 4. Response surface of the interaction effects on the sensory scores of the coffee flower rice wine.

In the above formula, Y represents the sensory score. A, B, C, and D are the independent variables of the addition of the coffee flowers (%), the addition of the koji (%), the fermentation temperature (°C), and the fermentation time (d), respectively. Based on the present study, the CFRW with the highest theoretical sensory score (92.59) may be obtained if produced under 4.62% coffee flowers and 1.93% koji fermenting at 24.1°C for 3.88 days. To verify the reliability of the response surface test results, three parallel experiments were carried out. Considering the operability of the experiment, the optimal production technology obtained by the software was appropriately adjusted to the addition of 4.6% coffee flowers and 1.9% koji, fermented at 24.1°C for 4 days. After that, the sensory evaluation was performed on the CFRW products fermented with the optimal fermentation parameters. Their average sensory score was 92.8 ± 0.7, which was stable with a deviation of <1.0% and thus proved that the result was reasonable and reliable. These samples had an orange-yellow and transparent color, rich and harmonious aroma, and mellow and refreshing taste. Overall, a unique style of coffee flower rice wine was obtained.

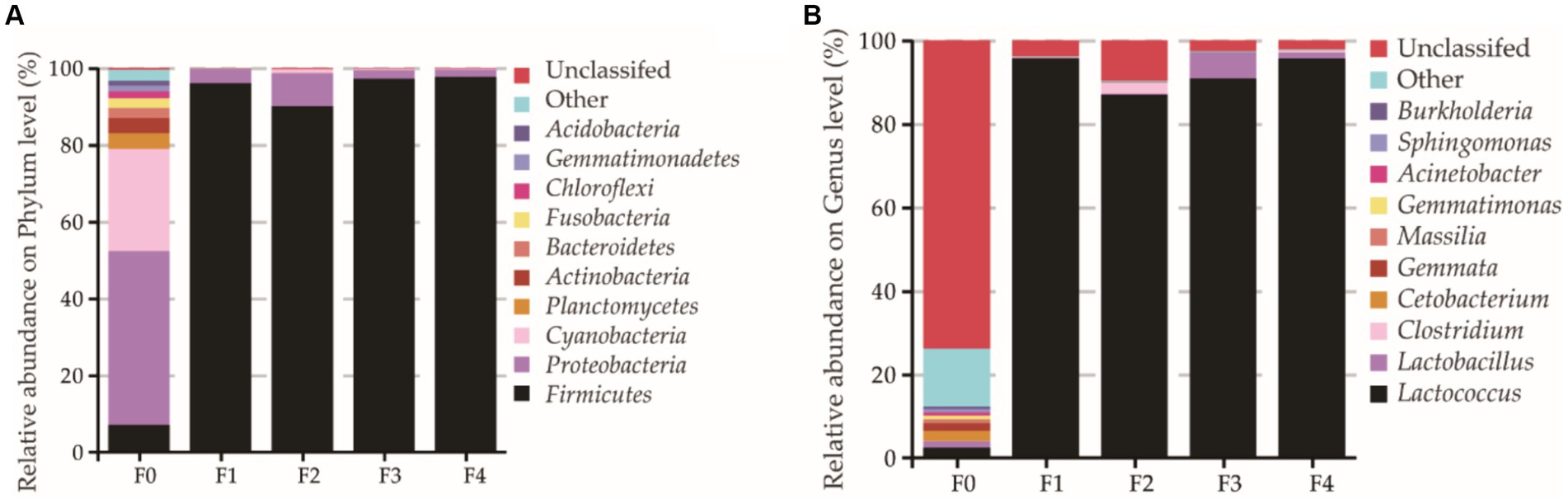

The dynamics variability in the bacterial community of the CFRW was analyzed during different fermentation stages under optimal conditions based on the RSM. A total of 551,934 sequences of the bacterial communities were acquired, which were passed through the quality control filters, and the chimera was removed. A series of alpha diversity indices were estimated to determine the intra-and inter-variability in the bacterial community among the five groups. As shown in Supplementary Figure S1, the Shannon index and Simpson index indicated that the bacterial community diversity was highest before the fermentation of the CFRW (F0), whereas it dramatically decreased after the fermentation. Among the different fermentation stages, the bacterial diversity underwent a process of increasing first and then decreasing.

The 16S rRNA gene sequences indicated that 197 bacterial genera were found in the fermentation broth, which were classified into 27 phyla and 134 families. Most bacteria of the CFRW belonged to Firmicutes during the fermentation, which accounted for 95.2% of the bacteria (Figure 5A). As shown in Figure 5B, the relative abundance of the unclassified bacterium genus appeared at its maximum (73.9%) on day 0 but then sharply decreased at the beginning of the fermentation. Interestingly, the relative abundance presented a converse trend for Lactococcus, which started increasing rapidly from the 1st day of the fermentation, reaching the highest level on the last day, which ranged from 87.0 to 95.7%. Among all groups, Lactococcus was probably the main bacterium genus, but beyond that, a small proportion of Lactobacillus (6.1%) was also detected on the 3rd day.

Figure 5. Bacterial community distribution of the different fermentation stages’ samples of the coffee flower rice wine (CFRW). Relative abundances of the most abundant bacterium at the phylum (A) and genus (B) were analyzed. F0 stands for the day 0 sample, and the remainder is deduced by analogy. Unclassified stands for unknown bacterium.

As the fermentation proceeded, the fungal diversity increased first but then decreased in the later stages of the fermentation (Supplementary Figure S2). A total of 3,468,418 effective fungal sequences were obtained from the fermentation broth of the CFRW after quality control processing. After that, they were counted and then annotated into 9 phyla, 76 families, and 102 genera. Most fungal sequences of the CFRW belonged to Mucoromycota, Ascomycota, and Basidiomycota, which accounted for 68.4, 21.8, and 8.6% of the fungal sequences, respectively (Figure 6A). Undoubtedly, Rhizopus was dominant on day 0 of the broth, which had not yet fermented (Figure 6B). However, it reduced abruptly on the 1st day of the fermentation and markedly increased and eventually tended to be stable on the 4th day. Except for Rhizopus, Cladosporium had a higher relative proportion than the other fungus genera on the first and the last 2 days of the fermentation. The relative abundance of Malassezia on the 2nd day was evidently higher than that on other days. The statistical analysis showed that there was no significant difference (p > 0.05) in the fungal community diversity among all groups, but it peaked on the 2nd day of the fermentation and then reduced with mild fluctuations.

Figure 6. Fungal community distribution of the different fermentation stages’ samples of the coffee flower rice wine (CFRW). Relative abundances of the most abundant fungus at the phylum (A) and genus (B) were analyzed. F0 stands for the day 0 sample, and the remainder is deduced by analogy. Unclassified stands for unknown fungus.

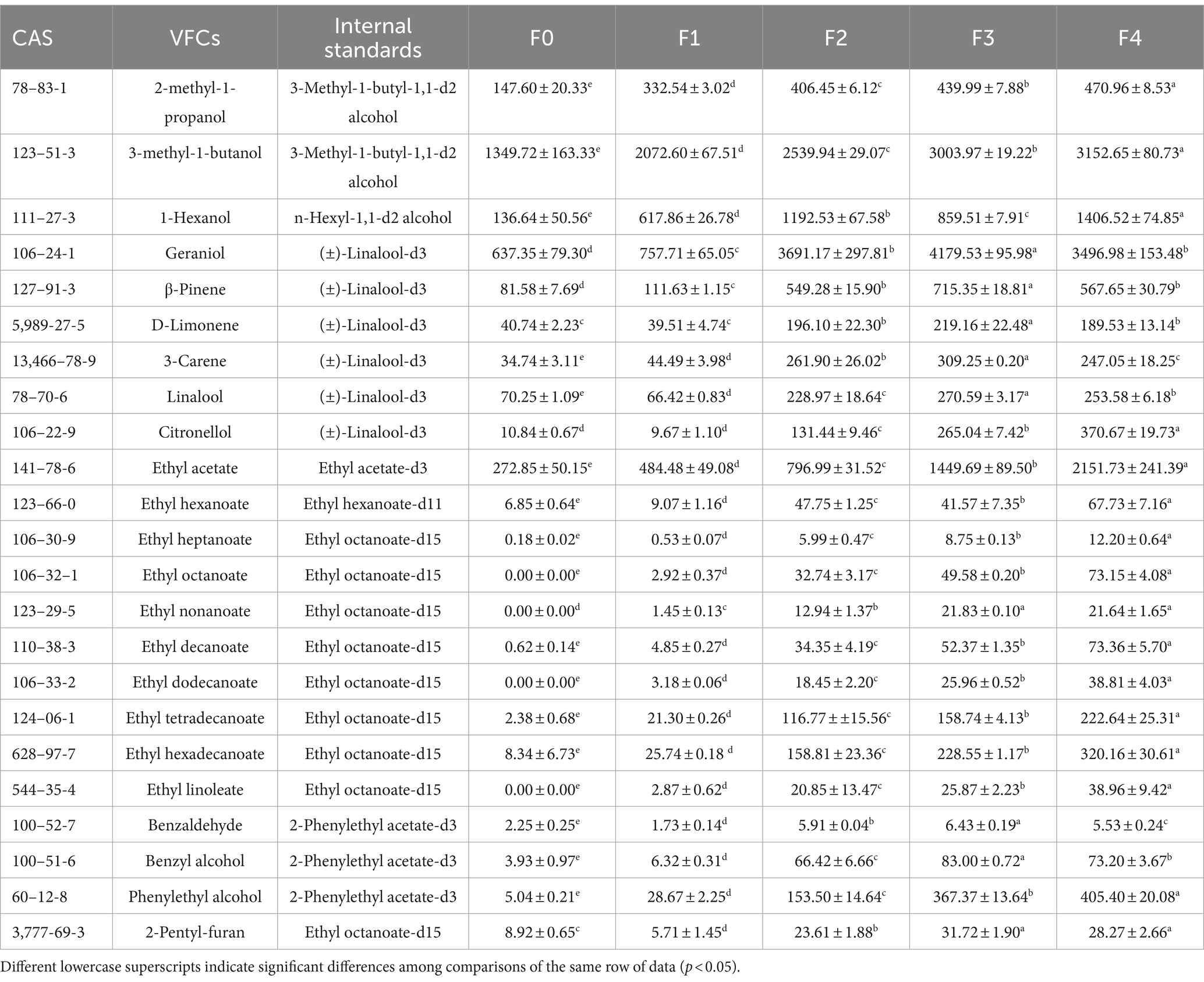

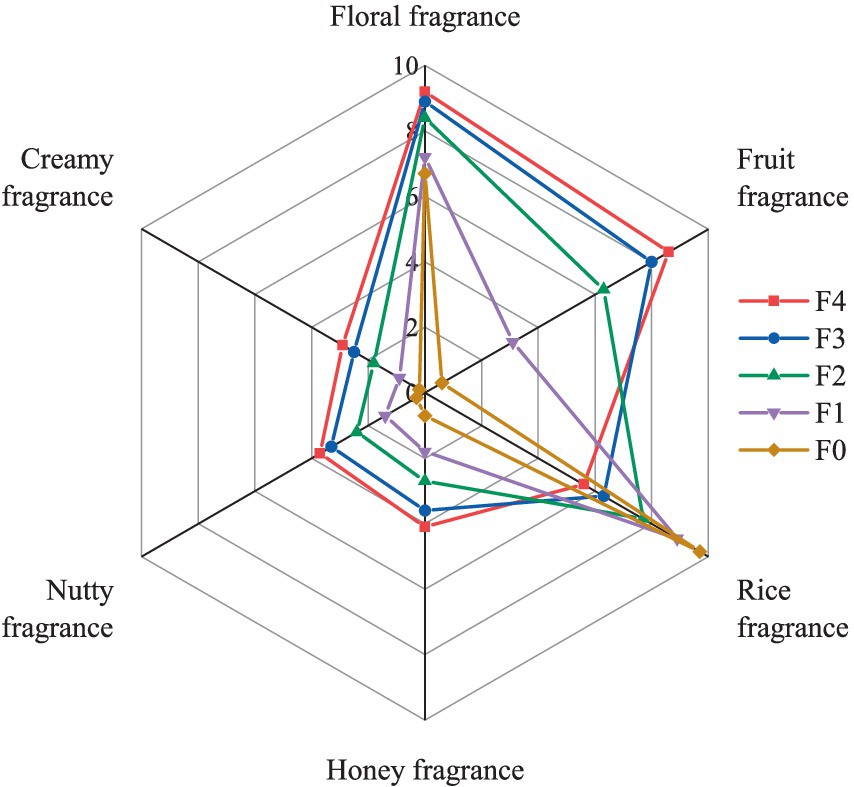

A total of 23 volatile flavor compounds (VFCs) were successfully detected and identified in the fermented samples of the CFRW, which included three alcohols, six terpenoids, ten esters, three aromatics, and one furan. The details of the result are presented in Table 2. The concentrations of almost all VFCs were significantly increased by the fermentation (p < 0.05). When it was not fermented, 3-methyl-1-butanol and geraniol were the main VFCs of the CFRW, and their concentrations were 1349.72 ± 163.33 and 637.35 ± 79.30 mg/kg, respectively, while the concentrations of most of the remaining VFCs were very low. In the brewing process of the CFRW, the concentration of 3-methyl-1-butanol significantly increased (p < 0.05), which was the predominant component (2072.60 ± 67.51 mg/kg) on the 1st day of the fermentation, followed by geraniol, 1-hexanol, ethyl acetate, and 2-methyl-1-propanol. After 2–4 days of the fermentation, the main VFCs in the CFRW were geraniol, 3-methyl-1-butanol, ethyl acetate, 1-hexanol, and β-pinene. On the 4th day, the concentrations of 3-methyl-1-butanol and 1-hexanol were significantly higher than those on other fermentation stages (p < 0.05), reaching a peak of 1406.52 ± 74.85 and 3152.65 ± 80.73 mg/kg, respectively. It is worth noting that the concentration of phenylethyl alcohol significantly increased in the later fermentation stage of the CFRW (p < 0.05) and achieved the highest level of 405.40 ± 20.08 mg/kg on the 4th day. By comparing the aroma profile characteristics related to the VFCs, it was found that the scores of the floral fragrance, fruity fragrance, honey fragrance, nutty fragrance, and creamy fragrance increased with the fermentation time of the CFRW, while the scores of the rice fragrance showed the opposite trend (Figure 7).

Table 2. Concentrations of the volatile flavor compounds in the coffee flower rice wine during the fermentation (mg/kg).

Figure 7. Aroma profile characteristics of the coffee flower rice wine during the fermentation process.

As shown in Table 3, there was a marked discrepancy in the contribution of the VFCs to the overall flavor of the rice wine fermented for different days (p < 0.05). The OAVs of most VFCs were more than 1 at the initial stage of the fermentation (F1), except for ethyl dodecanoate and ethyl linoleate. Among them, the OAV was significantly increased for the majority of the compounds compared with the unfermented samples (p < 0.05). This suggested that the 21 VFCs could contribute to the overall flavor of the CFRW only during the period of F1. Notably, ethyl octanoate was first detected in the samples of F1 compared to the unfermented samples. Moreover, this ester made a significant contribution to the flavor of the CFRW. However, the contribution of these compounds to the flavor of the CFRW varied significantly as the fermentation progressed (p < 0.05). Further analysis elucidated that five VFCs with a higher OAV were regarded as the most potentially characteristic flavor profiles of the CFRW, which included linalool, geraniol, ethyl acetate, 1-hexanol, and 3-methyl-1-butanol. They endowed the rice wine with a desirable fragrance. For example, linalool added a lemon aroma to the rice wine, while 1-hexanol had a fat fragrance. Of these, linalool was responsible for the highest contribution to the flavor of the CFRW, followed by geraniol. Although the CFRW contained a lower benzyl alcohol and 2-pentyl-furan content, both of them still contributed significantly to the flavor of the CFRW due to their lower detection thresholds, particularly in the later fermentation stage (p < 0.05).

The analysis of the correlation between the microbial community and the VFCs of the CFRW at the genus level was shown in Figure 8. It was observed that 11 microbial genera were highly correlated with the 23 VFCs of the CFRW (|ρ| > 0.6, p < 0.05). The results showed that there were 16 significant positive correlations and 23 significant negative correlations between the microbial genera and VFCs (|ρ| > 0.6, p < 0.05). Among them, Acinetobacter established extremely significant negative correlations with nearly all VFCs (|ρ| > 0.6, p < 0.01). Massilia and Sphingomonas were significantly negatively correlated with geraniol, but Penicillium showed the inverse correlation. In this study, Sphingomonas had significant negative correlations with seven VFCs (|ρ| > 0.6, p < 0.05), including geraniol, ethyl acetate, ethyl nonanoate, ethyl decanoate, ethyl tetradecanoate, benzyl alcohol, and phenylethyl alcohol. Burkholderia was significantly negatively correlated with five VFCs, 2-methyl-1-propanol, 3-methyl-1-butanol, ethyl acetate, ethyl hexanoate, and ethyl heptanoate (|ρ| > 0.6, p < 0.05). Lactococcus established significant correlations with three alcohols and seven esters, which indicated that the major microbial genera participated in the synthesis of these VFCs (|ρ| > 0.6, p < 0.05). In the fermentation process of the CFRW, Lactobacillus was significantly positively correlated to 2-pentyl-furan and linalool (|ρ| > 0.6, p < 0.05). Meanwhile, Clostridium had similar correlations with β-pinene, ethyl linoleate, 1-hexanol, and ethyl hexanoate (|ρ| > 0.6, p < 0.05).

Figure 8. Correlation analysis between the dominant genera and volatile metabolites in the CFRW. *p < 0.05 and **p < 0.01; red and green mean positive and negative correlations, respectively.

In this research, there were 12 significant positive correlations and one significant negative correlation between the fungal genera and VFCs (|ρ| > 0.6, p < 0.05). Among them, Aspergillus only had a significant positive correlation with β-pinene (|ρ| > 0.6, p < 0.05). Penicillium was significantly correlated to D-limonene, 3-carene, ethyl linoleate, 1-hexanol, β-pinene, and ethyl hexanoate (|ρ| > 0.6, p < 0.05). In this study, significant positive correlations were found between Alternaria and 2-methyl-1-propanol, 3-methyl-1-butanol, 1-hexanol, D-limonene, citronellol, ethyl hexanoate, ethyl heptanoate, ethyl hexadecanoate, and ethyl linoleate.

Aroma and flavor are the most important indicators for determining the quality of rice wine and affect consumer preference (Mao et al., 2023), which are mainly formed by the starting crude and complex microbial metabolism during the brewing process. The interactions of these flavor compounds determine the final flavor characteristics of rice wine. VFCs that are associated with the flavor of rice wine have been frequently determined and identified by researchers, such as alcohols, esters, phenols, and aldehydes (Lu et al., 2017; Huang et al., 2018; Jiang et al., 2020; Liang et al., 2020; Chen et al., 2021; Qian et al., 2023). Interestingly, variations in VFCs may lead to changes in the microbial community and vice versa (Huang et al., 2018).

Alcohols are widespread and important VFCs in wine, which can improve the mellow sensory quality and the body of wine (Fan et al., 2011). It has been reported that the optimal level of higher alcohols (below 300 mg/kg) can produce a fruity aroma and make a fuller flavor of wine; they are acceptable if the concentration is between 300 and 400 mg/kg, but strong irritation might be formed if the content exceeds 400 mg/kg (Luan et al., 2018). In this study, compared with the unfermented samples of the CFRW (F0), the content of the higher alcohols (2-methyl-1-propanol, isoamyl alcohol, and 1-hexanol) significantly increased and exceeded 400 mg/kg in the trial groups, especially in the late stage of the fermentation. Interestingly, there were three higher alcohols (linalool, citronellol, and phenylethyl alcohol) with concentrations below 400 mg/kg, except for phenylethyl alcohol fermented for 4 days. 2-Methyl-1-propanol and isoamyl alcohol are key aroma compounds that make a great contribution to the flavor of Chinese rice wine (Koay et al., 2022). Thus, isoamyl alcohol is usually considered to be one of the main higher alcohols in wine, which provides an alcoholic aroma and largely provides a spicy taste to rice wine (Yang et al., 2024). Beyond that, it may generate bitterness when its concentration is more than the appropriate level (Yu et al., 2022). Furthermore, a lower level of 1-hexanol endows rice wine with a fruity aroma and slight bitterness (Losada et al., 2012). Phenylethyl alcohol endows rice wine with a rose-honey flavor and a sweet taste, which can mask the alcohol smell, increase the intensity of the caramel-like aroma, and reduce the intensity of the fruity aroma of rice wine (Pires et al., 2014; Yu et al., 2019). Therefore, these findings indicate that the latter three higher alcohols may play an important role in neutralizing the negative effect on the CFRW flavor caused by a higher level of 2-methyl-1-propanol, isoamyl alcohol, and 1-hexanol. Integrating our understanding of the interactions of VFCs, it was concluded that perhaps these higher alcohols improved the complexity of the CFRW flavor in this study.

Interestingly, coffee flowers contain VFCs, such as phenyl ethanol and geraniol. Moreover, it was found that geraniol had an extreme OAV level in the fermented samples of the CFRW, particularly on the 3rd day. As we all know, it is one of the most widely natural spices with a mild, rose smell and a bitter taste. The result showed that geraniol detected in the CFRW was very likely derived from coffee flowers, and it contributed vital flavors to the CFRW. It has been proven that benzaldehyde with an almond fragrance is highly related to the full body of rice wine, and it can produce bitterness if the concentration is too high (Yu et al., 2020; Shen et al., 2021). In the study, the concentration of benzaldehyde was very low (< 6.43 mg/kg) and had a lower level of the OAV in all samples, so it can be considered that it could mainly impart the fullness of rice wine.

Esters are the most abundant flavor substances in rice wine, contributing a pleasant fruit and floral fragrance even at lower concentrations (Fan and Qia, 2006; Chen et al., 2013; Qian et al., 2019). In this study, a total of 10 esters were identified, wherein four esters were found to contribute the most to the flavor of the CFRW, which included ethyl acetate, ethyl hexanoate, ethyl heptanoate, and ethyl octanoate. Some studies reported that ethyl acetate could make rice wine present a fruity and brandy aroma; however, it was still considered to be bitter in terms of sensory evaluation (Koay et al., 2022). Ethyl hexanoate, which is often considered sweet, has been frequently documented in rice wine, and its aroma is similar to that of apples, bananas, strawberries, and pineapples (Peinado et al., 2006). Ethyl octanoate and 2-pentyl-furan were also reported to have a fruity aroma (Mao et al., 2023). In this study, the scores of the fruity fragrance, honey fragrance, and creamy fragrance increased as the fermentation of the CFRW progressed, according to the analysis of the aroma profile characteristics related to VFCs. Therefore, the fruit flavor of the CFRW was probably related to these four esters mentioned above and 2-pentyl-furan. In addition, among all VFCs detected in this study, ethyl hexadecanoate was the only flavor substance with a creamy fragrance. Hence, it should be considered that these esters and furan could play a promising and important role in improving the quality and flavor of CFRW in future research.

The flavor components of rice wine are affected by microbial diversity. In the study, five VFCs, linalool, geraniol, ethyl acetate, 1-hexanol, and 3-methyl-1-butanol, contributed vital flavors to the CFRW, and they were all significantly negatively correlated with the changes of Massilia and Acinetobacter with extremely low proportions (|ρ| > 0.6, p < 0.05). The major microorganisms detected in the CFRW fermented for 4 days in this study were Lactococcus, Lactobacillus, Rhizopus, and Cladosporium. According to reports, Lactococcus and Lactobacillus are of great significance to the flavor formation of rice wine because they can convert carbohydrates, proteins, and lipids of foodstuffs into aroma compounds (Yang et al., 2024). A previous study proposed that Lactobacillus may be involved in the synthesis of isoamyl alcohol (Zhang et al., 2017). However, this finding was discrepant with the results of our research. In the fermented samples, a significant positive correlation was found between the relative abundance of Lactococcus and the contents of 10 VFCs in the CFRW, such as isoamyl alcohol, ethyl acetate, ethyl octanoate, and phenyl ethanol (|ρ| > 0.6, p < 0.05). The result illustrated that the production of these aroma compound profiles was significantly influenced by Lactococcus. In the fermentation process of the CFRW, Lactobacillus was significantly positively related to 2-pentyl-furan and linalool (|ρ| > 0.6, p < 0.05). Meanwhile, Clostridium had a positive correlation with 1-hexanol and ethyl hexanoate (|ρ| > 0.6, p < 0.05). These results showed that the two microorganisms could be involved in the synthesis of VFCs with a fruit fragrance.

Previous studies have shown that Rhizopus was highly related to many flavor compounds of rice wine (Mao et al., 2023). However, there was no significant correlation between Rhizopus and the VFCs, which may have been caused by different strains. Recent research reported that Acinetobacter was conducive to the formation of a sweet taste in rice wine (Yang et al., 2024). In this study, the relative abundance of Acinetobacter in the CFRW was below 1.00% and decreased by less than 0.01% as the fermentation progressed. It implies that increasing the proportion of Acinetobacter in future research may shed light on how to balance the bitterness of CFRW with be rich in higher alcohols. It is worth noting that isoamyl alcohol had a significant negative correlation with Massilia, Acinetobacter, and Burkholderia, but a reverse trend was found for Lactococcus and Alternaria. Moreover, all the five strains mentioned above promoted the synthesis of isoamyl alcohol in the CFRW in this research. Thus, focus should be on the interactions among microorganisms to effectively reduce the production of isoamyl alcohol, thereby improving the quality of CFRW in the future.

This study explored the dynamic changes of microbial communities with the extension of the fermentation process and their impact on the VFCs of CFRW. The results showed that Lactococcus and Lactobacillus were key microbial groups, which were responsible for the flavor formation of the CFRW and thus had a great influence on the final quality of the CFRW. In addition, some microorganisms that represented lower abundance in the CFRW contributed significantly to the flavor formation of the rice wine. In this study, 5 VFCs with the highest OAVs, linalool, geraniol, ethyl acetate, 1-hexanol, and 3-methyl-1-butanol, endowed the CFRW with a pleasant aroma of fruit and fat. Therefore, they were regarded as the most potentially characteristic flavor compounds of the CFRW. Our findings can provide ideas for further developing novel products of rice wine and enhancing the quality of CFRW for promoting the additional value of coffee flowers.

The datasets presented in this study can be found in online repositories. The names of the repository/repositories and accession number(s) can be found in the article/Supplementary material.

KL: Conceptualization, Funding acquisition, Methodology, Software, Writing – original draft. RS: Methodology, Software, Writing – original draft. QW: Conceptualization, Formal analysis, Funding acquisition, Writing – review & editing. XS: Formal analysis, Resources, Writing – review & editing. BJ: Formal analysis, Investigation, Writing – review & editing. LY: Formal analysis, Investigation, Writing – review & editing. ZL: Formal analysis, Investigation, Writing – review & editing. JZ: Formal analysis, Resources, Writing – review & editing. PL: Formal analysis, Resources, Writing – review & editing.

The author(s) declare that financial support was received for the research, authorship, and/or publication of this article. This research was funded by the Introduction and Development of Talents Program of Yunnan Academy of Agricultural Sciences (No. 2024RCYP-14), Scientific Research Project of Yibin Vocational and Technical College (No. ZRZD24-12), Science and Technology Innovation Team Project of Yibin Vocational and Technical College (No. ybzy21cxtd-03), and Sichuan Province College Students Innovation Training Program Project (No. S202412966063).

Author Jia Zheng was employed by Wuliangye Yibin Co., Ltd.

The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

The Supplementary material for this article can be found online at: https://www.frontiersin.org/articles/10.3389/fmicb.2024.1476091/full#supplementary-material

Chay, C., Dizon, E. I., Hurtada, W. A., Elegado, F. B., Norng, C., and Raymundo, L. C. (2020). Total phenolic content and antioxidant activity of rice wine from waxy pigmented and non-pigmented rice varieties produced by traditional and multi-parallel fermentation. Food Res. Int. 4, 199–206. doi: 10.26656/fr.2017.4(1).036

Chen, G. M., Huang, Z. R., Wu, L., Wu, Q., Guo, W. L., Zhao, W. H., et al. (2021). Microbial diversity and flavor of Chinese rice wine (Huangjiu): an overview of current research and future prospects. Curr. Opin. Food Sci. 42, 37–50. doi: 10.1016/j.cofs.2021.02.017

Chen, S., Xu, Y., and Qian, M. C. (2013). Aroma characterization of Chinese rice wine by gas chromatography-olfactometry, chemical quantitative analysis, and aroma reconstitution. J. Agric. Food Chem. 61, 11295–11302. doi: 10.1021/jf4030536

Chen, S., Xu, Y., and Qian, M. C. (2018). Comparison of the aromatic profile of traditional and modern types of Huang Jiu (Chinese rice wine) by aroma extract dilution analysis and chemical analysis. Flavour Fragr. J. 33, 263–271. doi: 10.1002/ffj.3440

Emura, M., Nohara, I., Toyoda, T., and Kanisawa, T. (1997). The volatile constituents of the coffee flower (Coffea arabica L.). Flavour Fragr. J. 12, 9–13. doi: 10.1002/(SICI) 1099-1026(199701)12:1<9::AID-FFJ606>3.0.CO;2-P

Fan, W. L., and Qia, M. C. (2006). Characterization of aroma compounds of Chinese ‘Wuliangye’ and ‘Jiannanchun’ liquors by aroma extract dilution analysis. J. Agric. Food Chem. 54, 2695–2704. doi: 10.1021/jf052635t

Fan, W., Shen, H., and Xu, Y. (2011). Quantification of volatile compounds in Chinese soy sauce aroma type liquor by stir bar sorptive extraction and gas chromatography-mass spectrometry. J. Sci. Food Agric. 91, 1187–1198. doi: 10.1002/jsfa.4294

Ferreira, V., Ortin, N., Escudero, A., Lopez, R., and Cacho, J. F. (2002). Chemical characterization of the aroma of grenache rose wines: aroma extract dilution analysis, quantitative determination, and sensory reconstitution studies. J. Agric. Food Chem. 50, 4048–4054. doi: 10.1021/jf0115645

Gomez-Miguez, M. J., Cacho, J. F., Ferreira, V., Vicario, I. M., and Heredia, F. J. (2007). Volatile components of Zalema white wines. Food Chem. 100, 1464–1473. doi: 10.1016/j.foodchem.2005.11.045

Hipol, R. L. B., and Alma-in, A. B. (2018). Antioxidant potentials of indigenously produced Benguet tapuy (rice wine). Int. Food Res. J. 25, 1968–1976.

Huang, Z. R., Hong, J. L., Xu, J. X., Li, L., Guo, W. L., Pan, Y. Y., et al. (2018). Exploring core functional microbiota responsible for the production of volatile flavor during the traditional brewing of Wuyi Hong Qu glutinous rice wine. Food Microbiol. 76, 487–496. doi: 10.1016/j.fm.2018.07.014

Jiang, L., Su, W., Mu, Y. C., and Mu, Y. (2020). Major metabolites and microbial community of fermented black glutinous rice wine with different starters. Front. Microbiol. 11:593. doi: 10.3389/fmicb.2020.00593

Jiao, A. Q., Xu, X. M., and Jin, Z. Y. (2017). Research progress on the brewing techniques of new-type rice wine. Food Chem. 215, 508–515. doi: 10.1016/j.foodchem.2016.08.014

Jung, H., Lee, S. J., Lim, J. H., Kim, B. K., and Park, K. J. (2014). Chemical and sensory profiles of makgeolli, Korean commercial rice wine, from descriptive, chemical, and volatile compound analyses. Food Chem. 152, 624–632. doi: 10.1016/j.foodchem.2013.11.127

Koay, M. W., Fan, H. Y., and Wong, C. M. V. L. (2022). An overview of fermentation in rice winemaking. Canrea. J. Food Technol. Nutr. 5, 12–37. doi: 10.20956/canrea.v5i1.629

Lachenmeier, D. W., Rajcic de Rezende, T., and Schwarz, S. (2021). An update on sustainable valorization of coffee by-products as novel foods within the European Union. Biol. Life Sci. Forum. 6:37. doi: 10.3390/Foods2021-10969

Liang, Z. C., Lin, X. Z., He, Z. G., Su, H., Li, W. X., Ren, X. Y., et al. (2020). Amino acid and microbial community dynamics during the fermentation of Hong Qu glutinous rice wine. Food Microbiol. 90:103467. doi: 10.1016/j.fm.2020.103467

Liu, K. Y., Wang, L. Y., An, J. S., Luo, H., Wang, X. H., Ma, Y., et al. (2022). Research on the fermentation of Pu-erh tea through inoculation with aspergillus amstelodami. J. Light Ind. 37, 1–9. doi: 10.12187/2022.04.001

Losada, M. M., López, J. F., Añón, A., Andrés, J., and Revilla, E. (2012). Influence of some oenological practices on the aromatic and sensorial characteristics of white Verdejo wines. Int. J. Food Sci. Technol. 47, 1826–1834. doi: 10.1111/j.1365-2621.2012.03038.x

Lu, Y. C., Gong, Y. L., Li, Y. J., Pan, Z. J., Yao, Y., Li, N., et al. (2017). Characterization of microbial communities in Chinese rice wine collected at Yichang city and Suzhou city in China. J. Microbiol. Biotechnol. 27, 1409–1418. doi: 10.4014/jmb.1704.04029

Luan, Y., Zhang, B. Q., Duan, C. Q., and Yan, G. L. (2018). Effects of different pre-fermentation cold maceration time on aroma compounds of Saccharomyces cerevisiae co-fermentation with Hanseniaspora opuntiae or Pichia kudriavzevii. LWT 92, 177–186. doi: 10.1016/j.lwt.2018.02.004

Mak, Y. W., Chuah, L. O., Ahmad, R., and Bhat, R. (2013). Antioxidant and antibacterial activities of hibiscus (Hibiscus rosa-sinensis L.) and Cassia (Senna bicapsularis L.) flower extracts. J. King Saud Univ. Sci. 25, 275–282. doi: 10.1016/j.jksus.2012.12.003

Mao, X., Yue, S. J., Xu, D. Q., Fu, R. J., Han, J. Z., Zhou, H. M., et al. (2023). Research progress on flavor and quality of Chinese rice wine in the brewing process. ACS Omega 8, 32311–32330. doi: 10.1021/acsomega.3c04732

Mlcek, J., and Rop, O. (2011). Fresh edible flowers of ornamental plants—a new source of nutraceutical foods. Trends Food Sci. Tech. 22, 561–569. doi: 10.1016/j.tifs.2011.04.006

Nguyen, T. M. T., Cho, E. J., Song, Y., Oh, C. H., Funada, R., and Bae, H. J. (2019). Use of coffee flower as a novel resource for the production of bioactive compounds, melanoidins, and bio-sugars. Food Chem. 299:125120. doi: 10.1016/j.foodchem.2019.125120

Peinado, R. A., Mauricio, J. C., and Moreno, J. (2006). Aromatic series in sherry wines with gluconic acid subjected to different biological aging conditions by Saccharomyces cerevisiae var. capensis. Food Chem. 94, 232–239. doi: 10.1016/j.foodchem.2004.11.010

Pires, E. J., Teixeira, J. A., Branyik, T., and Vicente, A. A. (2014). Yeast: the soul of beer’s aroma-a review of flavour-active esters and higher alcohols produced by the brewing yeast. Appl. Microbiol. Biotechnol. 98, 1937–1949. doi: 10.1007/s00253-013-5470-0

Qian, Y. L., An, Y. Q., Chen, S., and Qian, M. C. (2019). Characterization of Qingke liquor aroma from Tibet. J. Agric. Food Chem. 67, 13870–13881. doi: 10.1021/acs.jafc.9b05849

Qian, M., Ruan, F. X., Zhao, W. H., Dong, H., Bai, W. D., Li, X. L., et al. (2023). The dynamics of physicochemical properties, microbial community, and flavor metabolites during the fermentation of semi-dry Hakka rice wine and traditional sweet rice wine. Food Chem. 416:135844. doi: 10.1016/j.foodchem.2023.135844

Que, F., Mao, L. C., and Pan, X. (2006). Antioxidant activities of five Chinese rice wines and the involvement of phenolic compounds. Food Res. Int. 39, 581–587. doi: 10.1016/j.foodres.2005.12.001

Rahayu, Y. Y., Yoshizaki, Y., Yamaguchi, K., Okutsu, K., Futagami, T., Tamaki, H., et al. (2017). Key volatile compounds in red koji-shochu, a Monascus-fermented product, and their formation steps during fermentation. Food Chem. 224, 398–406. doi: 10.1016/j.foodchem.2016.12.005

Ren, Q., Sun, L. P., Wu, H. J., Wang, Y. S., Wang, Z. W., Zheng, F. P., et al. (2019). The changes of microbial community and flavor compound in the fermentation process of Chinese rice wine using Fagopyrum tataricum grain as feedstock. Sci. Rep. 9:3365. doi: 10.1038/s41598-019-40337-8

Shen, X., Nie, F., Fang, H., Liu, K., Li, Z., Li, X., et al. (2023). Comparison of chemical compositions, antioxidant activities, and acetylcholinesterase inhibitory activities between coffee flowers and leaves as potential novel foods. Food Sci. Nutr. 11, 917–929. doi: 10.1002/fsn3.3126

Shen, C., Zhu, H. Y., Zhu, W. X., Zhu, Y. M., Peng, Q., Elsheery, N. I., et al. (2021). The sensory and flavor characteristics of Shaoxing Huangjiu (Chinese rice wine) were significantly influenced by micro-oxygen and electric field. Food Sci. Nutr. 9, 6006–6019. doi: 10.1002/fsn3.2531

Stashenko, E. E., Martinez, J. R., Cárdenas-Vargas, S., Saavedra-Barrera, R., and Durán, D. C. (2013). GC-MS study of compounds isolated from Coffea arabica flowers by different extraction techniques. J. Sep. Sci. 36, 2901–2914. doi: 10.1002/jssc.201300458

Tseng, T. H., Kao, T. W., Chu, C. Y., Chou, F. P., Lin, W. L., and Wang, C. J. (2000). Induction of apoptosis by Hibiscus protocatechuic acid in human leukemia cells via reduction of retinoblastoma (RB) phosphorylation and Bcl-2 expression. Biochem. Pharmacol. 60, 307–315. doi: 10.1016/S0006-2952(00)00322-1

Wirz, K., Schwarz, S., Richling, E., Walch, S. G., and Lachenmeier, D. W. (2022). Coffee flower as a promising novel food-chemical characterization and sensory evaluation. Biol. Life Sci. Forum. 18:53. doi: 10.3390/Foods2022-12967

Yang, Y. J., Ai, L. Z., Mu, Z. Y., Liu, H. D., Yan, X., Ni, L., et al. (2022). Flavor compounds with high odor activity values (OAV > 1) dominate the aroma of aged Chinese rice wine (Huangjiu) by molecular association. Food Chem. 383:132370. doi: 10.1016/j.foodchem.2022.132370

Yang, Y., Wang, H., Shuang, Q., and Xia, Y. N. (2024). Novel insights into flavor formation in whey fermented wine: a study of microbial metabolic networks. LWT 197:115911. doi: 10.1016/j.lwt.2024.115911

Yu, H., Li, Q., Xie, J., Chen, C., Lou, X., Ai, L., et al. (2022). Characterization of bitter compounds in Shaoxing Huangjiu by quantitative measurements, taste recombination, and omission experiments. J. Agric. Food Chem. 70, 12907–12915. doi: 10.1021/acs.jafc.2c02867

Yu, H., Xie, T., Xie, J., Ai, L., and Tian, H. (2019). Characterization of key aroma compounds in Chinese rice wine using gas chromatographymass spectrometry and gas chromatography-olfactometry. Food Chem. 293, 8–14. doi: 10.1016/j.foodchem.2019.03.071

Yu, H., Xie, T., Xie, J., Chen, C., Ai, L., and Tian, H. (2020). Aroma perceptual interactions of benzaldehyde, furfural, and vanillin and their effects on the descriptor intensities of Huangjiu. Food Res. Int. 129:108808. doi: 10.1016/j.foodres.2019.108808

Zhang, W. Y., Wu, Q. W., Wu, G., and Zhao, F. (2017). Effects of amino acid types and supplemental levels on the yield of Main higher alcohols in hawthorn wine. J. Light Industry 32, 1–7. doi: 10.3969/j.issn.2096-1553.2017.3.001

Zhao, P., Wang, J., Zhao, W., Ma, X. L., and Sun, H. J. (2018). Antifatigue and antiaging effects of Chinese rice wine in mice. Food Sci. Nutr. 6, 2386–2394. doi: 10.1002/fsn3.830

Zhu, J. C., Niu, Y. W., and Xiao, Z. B. (2021). Characterization of the key aroma compounds in Laoshan green teas by application of odour activity value (OAV), gas chromatography-mass spectrometry-olfactometry (GC-MS-O) and comprehensive two-dimensional gas chromatography mass spectrometry (GC× GC-qMS). Food Chem. 339:128136. doi: 10.1016/j.foodchem.2020.128136

Keywords: microbial community, volatile flavor compound, sensory evaluation, coffee flower rice wine, interaction

Citation: Liu K, Su R, Wang Q, Shen X, Jiang B, Yang L, Li Z, Zheng J and Li P (2024) Interaction and dynamic changes of microbial communities and volatile flavor compounds during the fermentation process of coffee flower rice wine. Front. Microbiol. 15:1476091. doi: 10.3389/fmicb.2024.1476091

Received: 05 August 2024; Accepted: 04 September 2024;

Published: 19 September 2024.

Edited by:

Haifeng Zhao, South China University of Technology, ChinaReviewed by:

Pengtao Zhao, Shaanxi Normal University, ChinaCopyright © 2024 Liu, Su, Wang, Shen, Jiang, Yang, Li, Zheng and Li. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Qi Wang, bXVtdTIwMjEwN0AxNjMuY29t; Jia Zheng, emhlbmdqaWFAd3VsaWFuZ3llLmNvbS5jbg==; Pingping Li, bHBwQHlhYXMub3JnLmNu

†These authors have contributed equally to this work

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.