94% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

REVIEW article

Front. Membr. Sci. Technol., 14 May 2024

Sec. Membrane Modules and Processes

Volume 3 - 2024 | https://doi.org/10.3389/frmst.2024.1389239

This article is part of the Research TopicReviews in Membrane Modules and ProcessesView all 5 articles

Wastewater, referred to as sewage, has been a byproduct of human settlement since ancient times. An increase in human activities leads to more wastewater effluents, resulting in higher concentrations of organic compounds, which are harmful to all forms of living organisms and drinking water purposes. Traditional methods cannot satisfy this issue for higher concentrations. The advanced membrane process is an alternative to this conventional method for removing organic compounds and various effluents due to its high permeate quality and less toxicity. Moreover, the modification of polymeric membranes by increasing its content led to a higher flux thereby enhancing the fouling property for effective wastewater treatment. The processes, UF, RO, NF, and FO, ion exchange, MD, and pervaporation, were developed for more robust methods to improve the quality of the environment and lead to higher salt rejection. This review provides an overview of the fabrications, methods and modifications of substrates utilized in different processes with varying modules to achieve a higher flux rate, lowering the fouling. We discuss the materials used for various membrane modules in ceramic membranes under different operating circumstances and the methods to enhance the performance of membrane fouling. This review also aims to track the ongoing research works to broaden different process combinations for further research purposes, showcasing better antifouling performance and maximizing water quality in the future.

Despite the ongoing efforts of governments and corporations to pivot to greener modes of functioning, industrial activity and unchecked urbanization continue to pose a significant threat to the environment. Among other things, this is reflected in the state of freshwater resources at regional and the global levels.

Since water is indispensable for human survival, economic expansion, and population growth drive freshwater demand. Human appropriation of critical freshwater resources is predicted to draw near fifty percent of the Earth’s total capacity by 2050, and less than one-tenth of preindustrial freshwater wetlands will remain intact (Albert et al., 2020). Finally, the effects of human activity on complex, sensitive ecosystems cannot be neglected. Besides compromising the quality of an already limited resource, the discharge of improperly treated wastewater (which accounts for 80% of all wastewater, 28% of this being industrial) into water bodies endangers several species. Freshwater biodiversity is already steeply declining in all continents at a rate that exceeds those observed in terrestrial habitats (Albert et al., 2020). Thus, the related concerns of freshwater management, water scarcity and security, and biodiversity constitute a wicked problem, solutions to which must necessarily incorporate an environmental consciousness.

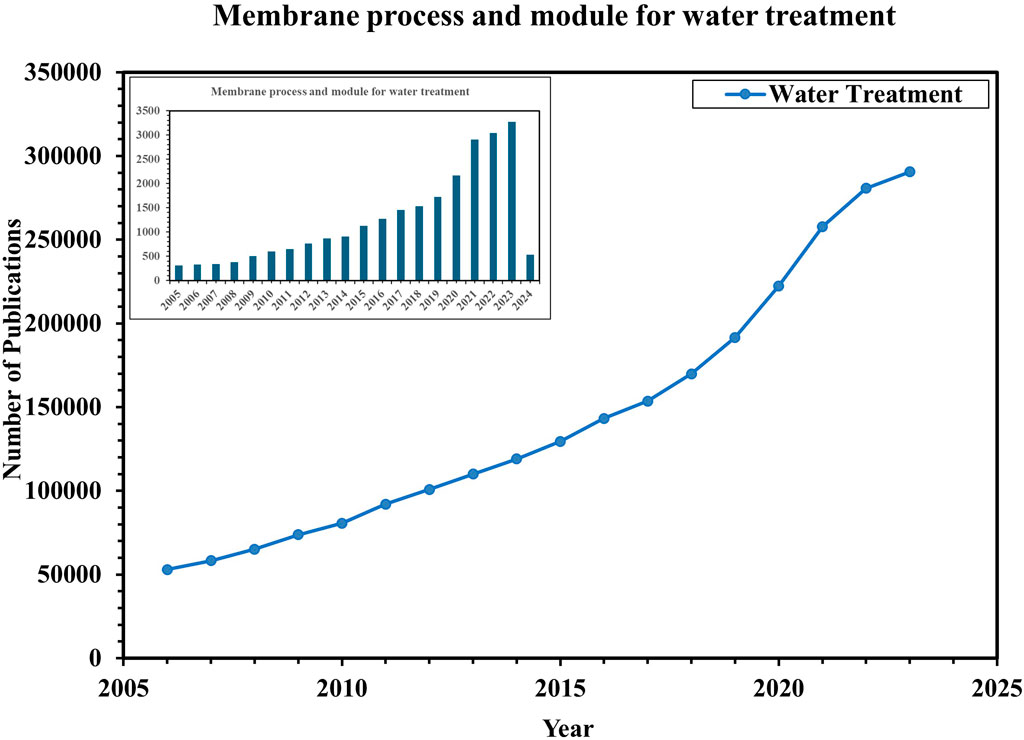

The present review article seeks to summarize recent developments in the fields of membrane separation and modular separation systems for water purification. High concentrations of heavy metals, organic compounds, and non-biodegradable synthetic chemicals in industrial effluents are highly objectionable because they may render the stream reactive, inflammable, toxic, or carcinogenic (Ahmed et al., 2021). The actual contents of industrial wastewater streams depend upon the type of industry, and they must be treated accordingly. Given the increasingly stringent requirements from companies to comply with environmental and safety regulations, a recent study estimated that a typical chemical park would spend around 28.6% of its park’s tax revenue on wastewater treatment (Lyu et al., 2020). Thus, industries face a tradeoff between responsible wastewater management and maintaining profitable economic activity. Moreover, a judicious business leader must be able to anticipate future legal strictures and act proactively to meet them without incurring exorbitant costs. All this incentivizes the search for efficient and rigorous purification techniques that can be retrofitted to existing structures. Below Figure 1 shows the trend of various papers published between 1969–2024.

Figure 1. The graph illustrates the number of new research papers published each year from 1969 to 2024 and a bar graph correspondingly showing membrane process and modules from 2005 to 2024 for water treatment.

Whereas industrial wastewater is classified as a high-strength waste stream, municipal wastewater, though low-strength (i.e., having low organic strength and high particulate organic matter content), is the most abundant type of wastewater (Sikosana et al., 2019). Thus, there is a great interest in developing technologies capable of robustly handling a city’s enormous waste output. Municipal wastewater treatment aims to mitigate water contamination and shortages in urban areas by purifying and reclaiming wastewater. More ambitious designs may also seek to extract and recover resources (water, energy (as biogas), and chemicals) from these wastewater streams (Kehrein et al., 2020). Modern separation techniques immediately lend themselves to such applications.

Membrane technology is an umbrella term for different non-traditional techniques and membrane processes. A membrane is a barrier between two phases that selectively restricts the interphase transport of various components through a size exclusion mechanism (Vasilachi et al., 2021). They may be classified according to their morphology, geometry, material, preparation methods, driving forces and mechanisms, etc. As a separation technique, membranes can be used to treat wastewater for several reasons. Besides being highly selective, compact, scalable, cost-effective, and energy-efficient, membranes are accessible, eco-friendly, and potentially eliminate chemical usage, thus “bridging the economic and sustainability gap” (Baker and Richard, 5 89. 2020). Further, their properties can be tuned to meet particular needs by designing and altering their structure; this is often facile.

For practical applications, membranes must be configured into modules to guarantee high packing density, control over concentration polarization (CP) and fouling, and lower costs (Vasilachi et al., 2021). The primary goal of modules is to deliver a huge surface area within a unit volume. They also allow for a highly dynamic and adaptive approach to separation, as in the case of hybrid membranes.

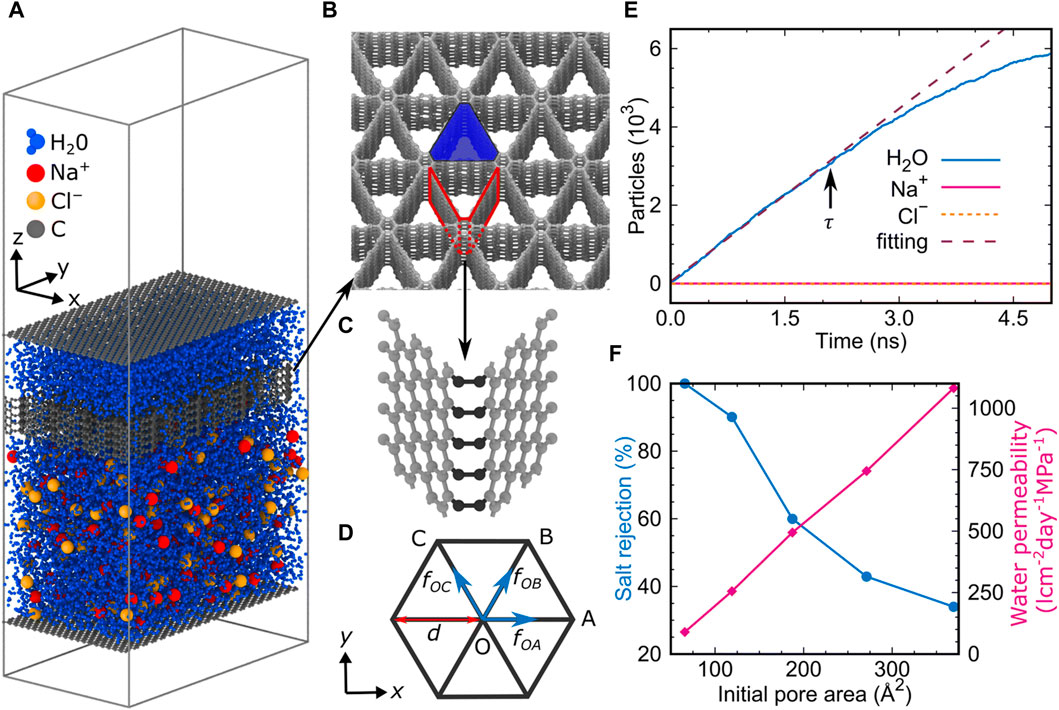

The main types of modules are plate and frame, spiral wound, hollow fiber, and tubular modules. While plate and frame modules have the most rudimentary configuration, hollow fiber membranes, though more challenging to manufacture, provide maximum packing density (Baker and Richard, 5 89. 2020). Tubular modules are ideal for treating strong streams as they show exceptional thermal and chemical resilience. Spiral wound and tubular modules have the lowest environmental impact (Lyu et al., 2015). Table 1 compares the structure and properties of the different types of modules (Kucera and Kucera, 2015).

Table 1. Structures and properties of membrane modules. (Reproduced with permission from Kucera and Kucera, 2015).

As far as wastewater treatment is concerned, different membranes can be used to remove contaminants from wastewater streams based on their size and to recover valuable resources through processes as diverse as membrane bio- and biofilm reactors, filtration, osmosis, membrane distillation (MD), etc. (Kehrein et al., 2020). Highly customized membranes can be designed to test and implement the removal of non-regular and exceptional contaminants.

Hybrid membranes are highly customized membranes composed of organic and inorganic components. Traditionally, a polymeric matrix is used to scatter inorganic particles called adsorbers. The material in question is commonly called a mixed matrix membrane (MMM). This design provides an opportunity to combine the excellent gas separation performance of inorganic materials with the ease of processing of polymers (Liguori and Wilcox, 2018).

Finally, desalination presents a promising large-scale solution to the alarming problem of water scarcity by facilitating the removal of salts from the untapped resources of seawater and brackish water to repurpose it for human consumption. Furthermore, desalination not only addresses water constraints but also improves environmental effects. Treating high salinity streams enterprises release can reduce pollution discharge into aquatic environments and protect ecosystems.

However, this process’s specific energy consumption (SEC) must be reduced and optimized further before they can be practicable. With advances in membrane manufacturing, it is already possible for a reverse osmosis desalination system to operate near the thermodynamic energy limit; hybrid configurations may further help in realizing energy efficiency (Nassrullah et al., 2020). A different application of desalination would be treating high-salinity streams emitted from industries, which disrupt aquatic habitats if released untreated. Membrane fouling, caused by undesirable depositions, poses a substantial challenge for the membrane process, resulting in decreased filtering efficiency and increased operating costs (Zhang et al., 2022). It describes various strategies involved, such as bio-synthesis, suprwetting surfaces, and antimicrobial approaches for water purification.

The present article will discuss the state-of-the-art membrane technologies as well as modules, viz. ultrafiltration (UF), reverse osmosis (RO), forward osmosis (FO), and nanofiltration (NF), ion-exchange, MD, pervaporation in the context of their applications in water purification (Flow-chart described in Figure 2). Also, the recent developments in hybrid systems of membrane operations, which pave the path to highly efficient wastewater treatment, are discussed.

Recent efforts to surmount the challenge of membrane fouling are also discussed.

UF is the purification of specific small molecules through a semipermeable membrane of pore size ranging from 0.001 to 0.1 μm. It is a pre-treatment for NF that retains suspended particles; the primary effluents are biopolymers such as proteins and polysaccharides. The study of permeability and selectivity was done to improve the ability of UF membranes to remove biopolymers (Awad et al., 2021). Kanani et al., 2010 worked on the silicon membranes with uniform slit-shaped pores to show that permeability and selectivity of the protein BSA (Bovine Serum Albumin) are inversely related and also showed that uniform slit-shaped pores can have high performance compared to the membranes that have cylindrical-shaped pores. This study shows us that the lodging of organic particles present in the water causes a reduction in the performance of the membrane. This phenomenon is known as the fouling of membranes. Several types of fouling, including colloidal, organic, and biological, are observed.

Organic fouling, which is caused by the biopolymers present in the water, like proteins, polysaccharides, lipids, collagen, etc., not only blocks the passage of the membrane by blocking the pores of the membrane but also interacts with each other, showing fouling is enhanced when the interaction is present between the foulants.

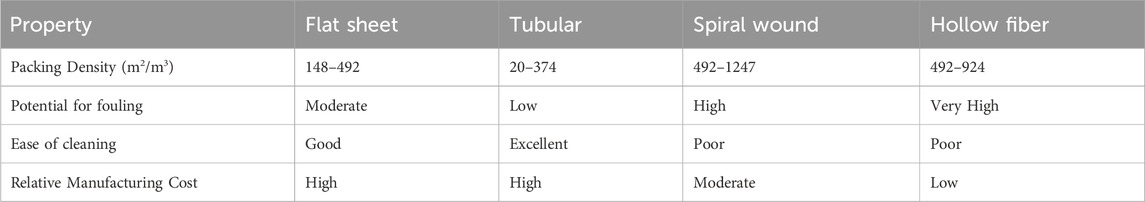

Cai et al., 2013 worked on the micro granular adsorptive filtration (μGAF) tests using heated aluminum oxide particles (HAOPs) and powdered activated carbon (PAC), revealing that fouling on the membrane is primarily caused by soluble NOM. Lee et al., 2008 evaluated the effects of different operating modes on NOM fouling and observed that medium-to low-molecular-weight of the organic molecules initiate fouling. The pre-treatment of water feed was discovered to remove dissolved organics while leaving colloidal components unaffected selectively. In addition, Wan et al., 2021, relieved the membrane fouling caused by different natural organic materials (NOM) by pre-treating UV/chlorine. After a comparative investigation, their findings were enhanced further, resulting in intermediate pore blockage following UV/Cl pre-treatment. By phase inversion technique, Abdollahi et al., 2021 further fabricated Mg-Al LDH nanoparticles with PVDF mixed matrix membranes (MMMs) to enhance their antifouling properties. Their study investigated the effects of optimizing membrane performance, and the results indicated that an increase in the content of Mg-Al LDH nanoparticles to an optimized value of 0.5 wt% led to improvements in the antifouling properties of the fabricated MMMs. Figure 3 illustrates the synthesis, SEM image, and experimental and model work overview (Ye et al., 2021). Also, they performed simulations of the optimized membrane closely aligning with the experimental findings, with a deviation of 0.2%. Later, Chen et al., 2023 conquered the challenges of selectivity and antifouling in UF membranes to purify biological molecules by fabricating spongy poly (ether sulfone) (PES) UF membranes self-cross-linked with N-hydroxyethyl acrylamide (HEAA) via the phase inversion process. These membranes demonstrated exceptional antifouling properties and prevented the accumulation of contaminants on the surface, effectively purifying biological molecules with high selectivity.

Figure 3. Illustrations of Mg-Al LDH nanoparticle Incorporated in PVDF membranes for flux recovery: Both experimental and model techniques. (A) Ni Mg-Al LDH NPs formation (Reproduced with permission from Ye, T et al., 2021), (B) SEM image of Mg-Al LDH (Reproduced with permission from Abdollahi et al., 2021), (C) process overview (Reproduced with permission from Abdollahi et al., 2021).

Colloidal foulants are prevalent in water that is suspended in the water and deposits on the surface of the membrane or in the corners of the feed spacer, restricting the flow of liquids through the membrane. Colloidal foulants like silicon dioxide (SiO2), titanium dioxide (TiO2), and aluminum were investigated by Zhu et al., 2020 in organic solvents using a polyacrylonitrile (PAN) UF membrane at five transmembranes which show that aqueous solvent foulants show different trends compared to the organic solvents. The conclusion suggested that Gibbs’s free energy and zeta potential obtained from the experiment were not in accordance with the present DLVO and XDLVO models. Fouling is known as biological fouling due to biological organisms like algae, bacteria, worms, barnacles, etc. Simple mechanical methods can be used to remove larger foulants, but foulants like bacteria and algae, which are microscopic in nature, lodge inside the pores and grow inside the membrane. To alleviate this fouling, integrated MIEX/UF membranes were introduced by Shi et al., 2021. This integration showed that fouling due to synthesized bacterial solutions had a less fouling effect on the membrane than on individual membranes. The introduction of PVDF/ZnO membranes in water treatment has tremendously decreased biofouling because of the anti-bacterial nature of ZnO. Kamaludin et al., 2022 modified an excellent BSA rate of 93.4% with a flux recovery rate of 70.9% with a ZnO/PVDF hollow fiber membrane.

Many studies investigated mitigating the UF fouling membrane by tuning the NOM contents and exhibiting high selectivity; only a few papers have been reported on innovative fouling control mechanisms. Nevertheless, it is still essential to ensure their performance and integrity for a long period of time for water purification purposes in the current research.

In every industry, “RO” is essential in eliminating waste from the water exposed. The studies on osmosis and RO research came into light in the 18th century. Various membranes have been used for multiple specific processes, whose material ranges from cellulose acetate from the 18th century to the latest nanocomposite in mixed matrix membranes (Yu, n.d., 2003).

RO as a process has seen enormous improvements and faced various difficulties, which have been overcome by introducing various membranes and modifying the membrane’s preparation method. One of the familiar and main problems with RO membranes is fouling and the energy required to overcome the membrane resistance in fouled membranes for water treatment. Several factors affect RO membranes, like hydrodynamic conditions, the inlet properties of the water, and membrane surface characteristics (Tawalbeh et al., 2023). Along with the other foulants discussed in the UF membrane, inorganic foulants like calcium carbonate, magnesium carbonate, and other ions are prevalent in desert areas like Rajasthan, which Agnihotri et al., 2020 investigated. The research found the presence of the rhombohedral structure of CaCO3 on the surface of the polyamide membrane by SEM-EDS analysis of the reject, stating Ca, Fe, Mn, Al, Na, and Mg as the main foulants in that region. Also, acceleration of the fouling was observed due to the presence of inorganic metal ions like Fe and Mn. A recent study shows that the treatment of inorganically fouled RO membranes can be regenerated by introducing carboxylic acids like citric acid in the research conducted by Melliti et al., 2023. This specific research studied the membranes filled with gypsum and Fe2+ ions and the effect of citric acid on these membranes. Post-treatment of the membrane with citric acid shows a decrease in fouling. Inhibition of fouling was observed when the pH of the solution was maintained.

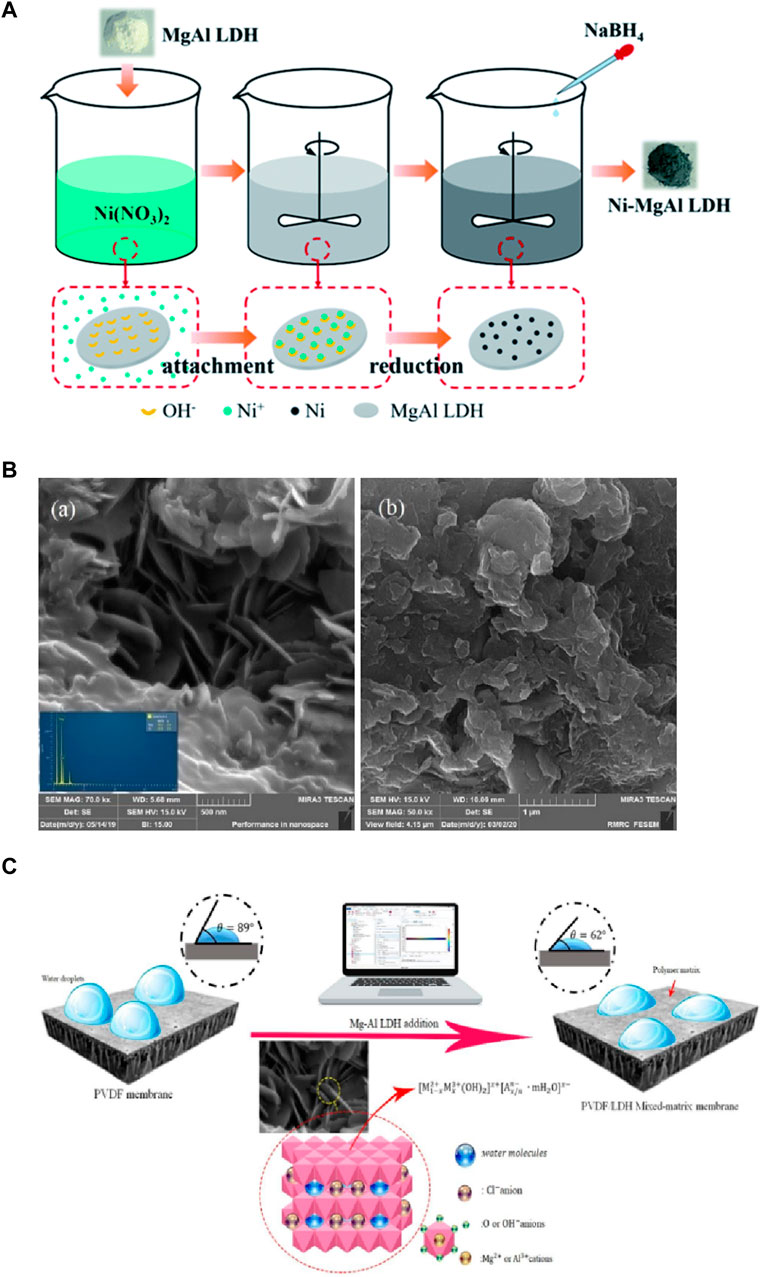

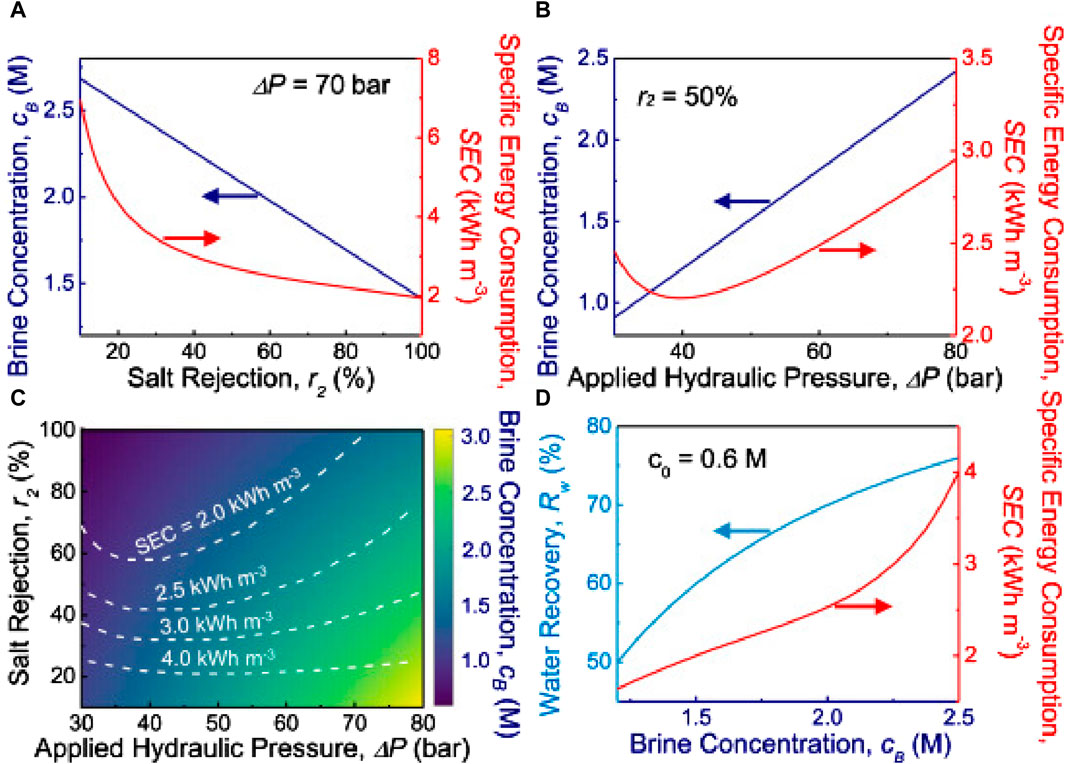

Recent research on increasing water permeance and salt rejection led to the selection of different types of materials for the preparation of ROM. Semi-aromatic polyamide ROM has gained popularity among researchers for its good retention rate (>98.28%) and high flux (65.38 L/m2.h) (Zhu et al., 2023). IP of CPTC and MDP gave semi-aromatic polyamide membranes that have a uniform modular structure, low roughness, good hydrophilicity, and high charge. Compared to traditional TMC membranes, semi-aromatic polyamide membranes are preferred for household and industrial brackish water treatment. Ho et al., 2023 introduced the graphene foam membrane as an idea using molecular dynamics and simulation showing variable pore size in an RO membrane, which is controlled by the strain applied to the membrane. The Figure 4 below shows the simulation model for preparing tunable graphene foam membranes. Zhao et al., 2010 researched fouling conditions at two recovery levels for commercial applications. This study highlighted the necessity for optimized secondary RO operations to mitigate fouling effectively. Tu et al., 2011 utilized BW 30 membrane and simulated four district membrane fouling conditions; among them, humic acid enhanced boron rejection compared to all, thereby optimizing membrane performance in water treatment applications. Later, Li et al., 2022b fabricated fluorinated seawater reverse osmosis (SWRO) for improved boron removal while maintaining high water selectivity. The resulting fluorinated membranes achieved boron rejection ranging from 86.71% to 87.71%. This study forecasts improvements to boron removal capacity and overall desalination performance. In addition, they also developed TFC SWRO membranes by incorporating a highly porous microstructure support membrane (HPμS) characterized by a narrow and highly porous surface, demonstrating high water permeability and selectivity and exhibiting high salt (NaCl, 99%) rejection rates. Despite its high salt rejection rates, conventional RO processes are hindered by the requirement of high hydraulic operating pressure. To overcome these limitations, Wang et al., 2020 introduced a low-salt rejection RO process designed to operate at moderate hydraulic pressure (<70 bar), hence achieving hypersaline brine salinities (234 g L−1 NaCl), facilitating the concentration of high saline feed streams. By enhancing the zero/minimal liquid discharge applications, this novel method offers promising solutions to address the water scarcity challenges. Figure 5 illustrates how the membrane’s salt rejection and water recovery depend on hydraulic pressure and brine concentration. Furthermore, ZIF-8 nanoparticles are inserted in a polypropylene hybrid membrane due to its low cost and high mechanical strength, with limitations such as low surface porosity and strong hydrophobicity. Li et al., 2020 proposed a novel method to overcome the limitations of polypropylene (PP), including its low surface porosity and strong hydrophobicity, by incorporating ZIF-8 nanoparticles. This method, known as position-induced nanoporous surface (PINS), boosts the membrane’s performance by employing its low cost and high mechanical strength. The resulting high performance of ZIF-8 hybrid RO exhibited optimal rejection rates of NaCl (−99%) and water flux up to 50 kg m−2 hr−1 under an operating pressure of 1.55 MPa demonstrating significant improvements in desalination performance.

Figure 4. (A) Simulation model. (B) Perspective view of a portion of the graphene foam membrane. (C) Structure near a junction. (D) Definitions for the continuum model. (E) Number of water molecules, Na+ ions, and Cl− ions passing through the unstrained graphene foam membrane with an initial pore area of 66 Å2. τ is the time when half of the water molecules have reached the permeate zone. (F) Salt rejection and water permeability of the unstrained graphene foam membrane (Reproduced with permission from Ho, Duc Tam et al., 2023).

Figure 5. 2-stage LSRRO with varied operating conditions. (A) Final brine concentration (cB, dark blue left vertical axis) and specific energy consumption (SEC, red right vertical axis) for concentrating 0.6 M saline feed as a function of salt rejection in the second stage (r2) in a 2-stage LSRRO. The operating applied hydraulic pressure (ΔP) is 70 bar. (B) cB (dark blue left vertical axis) and SEC (red right vertical axis) for concentrating 0.6 M saline feed as a function of ΔP in 2-stage LSRRO. In the calculation, r2 is assumed to be 50%. (C) cB as a function of r2 and ΔP for concentrating 0.6 M saline feed. The white dashed curves denote the SEC values. (D) water recovery (Rw) and SEC as a function of cB for concentrating 0.6 M saline feed in 2-stage LSRRO. The SEC in panel (D) is obtained after system optimization. In all calculations, a temperature of 25°C is used (Reproduced with permission from Wang, Z et al., 2020).

Cutting-edge techniques include adding carboxylic acids like citric acid have been effective in reducing fouling, and improved water permeance and salt rejection are provided by semi-aromatic polyamide and graphene foam membranes, two types of membrane materials. Position-induced nanoporous surface (PINS) is one technology that shows promise for getting beyond current obstacles and opening the door to more effective and long-lasting RO processes in a range of applications.

NF has significant advantages over RO and UF since it incorporates nanoparticles into polymers, allowing for the selective removal of ions and organic molecules. NF is a novel and promising technique that has the potential to be widely used to remove supplementary chemicals, colors, heavy metals, suspended particles, raw materials, oil, and grease from industrial effluents and drinking water. Paul and Steven, 2016 developed a critical definition of NF membrane based on multiple features: 1) pore diameters <2 nm; 2) significant monovalent ion permeance; 3) significantly higher divalent ion rejection than monovalent ion rejection; and 4) molecular weight cut-off (MWCO) for neutral species in the 150–2000 Da range. Most NF membranes sold commercially have tight NF, or a negatively charged surface, and a modest MWCO below 500 Da. Tight NFs have shown tiny pores and electrostatic solid repulsion, leading to high fouling and high-concentration polarization. Loose NF (LNF) membranes have recently become a hot topic, showing higher selectivity and lower operating pressure. The future scope for LNF is still open to exploration, which has limitations in the fabrication and regeneration of the membrane (Guo et al., 2021).

Recent developments in the dye separation process include introducing new fabrication methods for NF membranes. Setiawan et al., 2023 introduced a new solvent, sulfolane, instead of a toxic one that showed a lower critical polymer concentration (CPC) to produce a macrovoid-free membrane structure. HPEI of MW = 800 g/mol as a crosslinker increased the rigidity while retaining the pore structure. The separation factor (dye/salt) was up to 69.32, even for 268 g/mol lower-weight dyes. The trend of turning towards bamboo was observed in the work of Li et al., 2023. Bamboo cellulose-based NF was fabricated with cross-linking sodium alginate and carboxymethyl cellulose. The prepared CL-NF-BCM had an average pore size of 1.1 nm, 48% rejection of a 500 ppm NaCl solution, and a membrane flux of 17 L.m2h−1 under 0.5 MPa operating pressure.

Fouling of NF membranes by silica, linear, and cyclic siloxanes was observed, along with mineral scaling and organic fouling, which led to the irreversibility of fouling. This integrated fouling situation led to a rapid decline in NF productivity and showed the current need for serious novel antiscalants for fouling issues (Abada et al., 2023; Guo et al., 2020 have demonstrated in their work that fouling due to interactive organic molecules (polysaccharides, proteins, and fulvic acid) was more significant than individual organic molecules. Mixed matrix membrane embedded with 1.0 wt% amine-functionalized boron nitride (AFBN) showed the highest Reactive Blue 19 rejection (99.7%), the lowest contact angle (51.7°), the highest degree of fouling (FRR of 90.4%), and the highest dye solution permeability (48 L m−2. h−1.bar−1) (Vatanpour et al., 2020).

Fouling of NF membranes has become unavoidable to some extent, so the cleaning process in industries has become popular. Recent research on urea/HCl cleaning of membranes has shown specific cleaning of NF270, resulting in a lesser impact on trace organic compounds (TrOCs) than NaOH/HCl cleaning. This method also slightly increases the pore size slightly and the hydrophilicity of the membrane, marginally affecting zeta potential and membrane crosslinking (Zhou et al., 2023).

Cleaning of NF membranes by osmotic cleaning (dissolution, scouring, and backwashing) with 17% NaCl solution at 0.69 m/s cross-flow velocity and 25°C shows 100% recovery of flux in 10 min. When this was compared with acidic and alkaline cleaning, the possible reaction of acidic and basic groups with membranes could be avoided (Guan et al., 2023).

In addition to removing organic compounds, López et al., 2022 also utilized NF270 to increase the concentration of phosphate in wastewater, achieving a remarkable salt rejection (>99%). This approach facilitated the recovery of phosphate for reuse in the fertilizer industry, thereby reducing the dependency on external phosphate resources and promoting the concept of phosphate circularity.

Based on the observed trends of the exploration of nano-filtration show that there is a search for newer and possible fabrication and cleaning methods of the membrane. As the size of the particle separated here is getting smaller, the complexity and fouling possibility increases, which makes the recent research more pointed towards simple methods rather than complex chemical cleaning. Thermal stability, higher flux, lesser chemical damage, and easy maintenance are the main topics around which membrane enhancement occurs.

As the process of RO is highly energy-consuming and the membranes are costly, the investigation of FO has been gaining attention in recent years. Research on forward osmosis, or FO, dates back to the late 1950s, but because of developments in membrane technology, it has accelerated recently. A significant shift occurred in the early 2000s when FO became recognized as a competitive alternative for treating water, leading to pilot projects and commercialization initiatives (Kahrizi, Mohammad, 2022; Bao et al., 2019 developed a TFC-FO membrane with advancements in antifouling properties and enhanced selectivity for ammonia for domestic wastewater treatment applications. Later, MingQiu, Fu et al., 2021 modified FO membranes using hydrogel/MOF to improve the transport properties while enhancing the fouling resistance. Aghilesh et al., 2021 developed Response Surface Methodology (RSM), Artificial Neural Network (ANN), and Adaptive Neuro-Fuzzy Inference System (ANFIS) models to optimize the FO membrane process for textile wastewater treatments. These research shows that the wide range of applicable options for FO membranes also the selective removal technologie implemented to remove essential nutrients present in the wastewater.

Sun et al., 2021 further fabricated a novel-thin film nanocomposite membrane incorporated with Ti3C2Tx MXene, in addition to carbon nanotubes (M/C-TFNi), to improve the recovery of wastewater and water from wastewater. This research provided new insights to develop advances in the FO process to enhance the rejection of ammonia and nitrogen for environmental applications. Almoalimi and Liu, 2022 further improved cleaning efficiency by emphasizing the necessity of preserving municipal water. Results showed that the suspended solids could be more easily removed than the inorganic constituents, especially Ca2+. Minier-Matar et al., 2022 later developed a pivot scale to compare the FO modules: cellulose triacetate (CTA) and TFC. Results indicate that the TFC model (9.9L/m2.h, 5% fouling) exhibited less fouling and higher flux than CTA (1.7 L/m2.h, 13% fouling).

Removing essential nutrients from urine has become less challenging after introducing various feasible methods of separation using FO membrane processes.

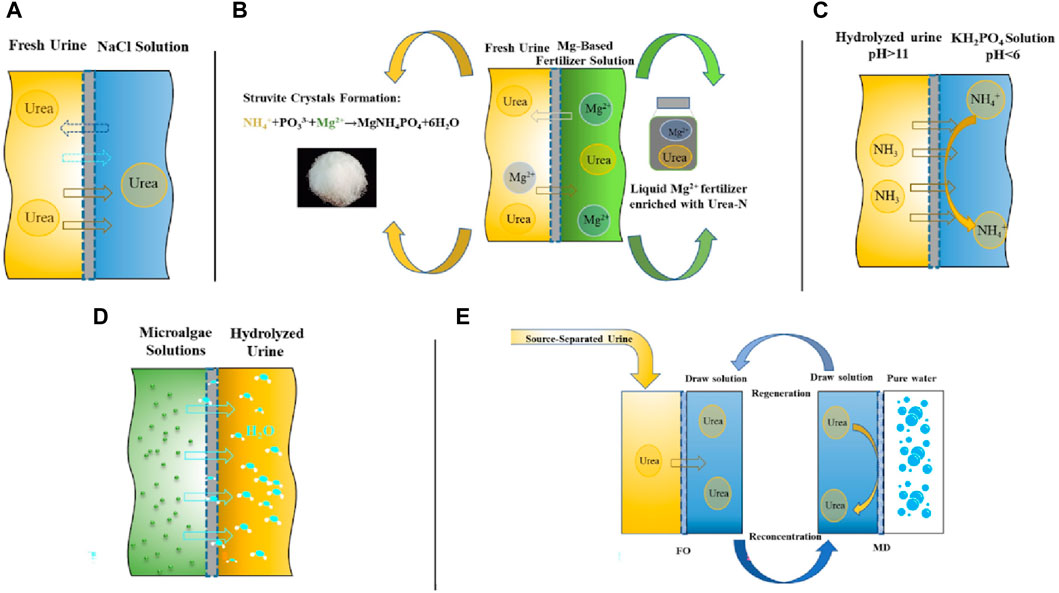

Líu et al., 2023 showed four different possible ways of recovering urea from urine using a FO membrane, among which the Fertilizer drawn Forward Osmosis (FDFO) mechanism gave >50% urea recovery and >93% other ionic recovery due to the Mg2+ gradient present across the membrane. The below Figure 6 shows the novel mechanisms performed for urea recovery from urine using FO membranes. An experiment on ammonia-based wastewater from fertilizer production used the salinity difference between concentrated seawater and dilute ammonia waste to generate electricity up to 2.687 W/m2 in a reverse electrodialysis system. A subsequent FDFO used the effluent from the RED of 36.6 m.S/cm conductivity as a draw system and increased the feed system conductivity by 1 mS/cm at the outlet (Elmakki et al., 2023).

Figure 6. Conceptual illustrations of FO-based membrane processes for urine: (A) FO alone (B) FDFO recover urea from fresh urine (FU); (C) FDFO selective recover ammonia from hydrolyzed urine, (D) Dewatering microalgae by FO, HU as draw solution, (E) Urine treatment by FO-MD hybrid process (Reproduced with permission from Líu, Hao et al., 2023).

Ion exchange resins are used in ion exchange water treatment systems to remove impurities and dissolved ions from water. This enhances the quality of water for residential and commercial uses. These systems have particular significance for boiler feedwater, as hardness ions might provide challenges. Unwanted ions are swapped out for more suitable ones during ion exchange. The extended use of an anion exchange membrane as a water electrolyzer has also been investigated in recent years. Roggi et al., 2023 functionalized commercial SBS with the 2,2,6,6-tetramethylpiperidin-N-oxyl stable radical (TEMPO) and added VBC and styrene monomers into the grafted SBS. The purified graft copolymer containing 5 mol% of VBC and 16 mol% of styrene was named g-VBC-5-co-Sty-16. The formed grafted membrane was observed to have improved mechanical strength, water uptake, hydrogen permeability, and electrochemical properties compared to the commercially available AEM for water electrolyzers.

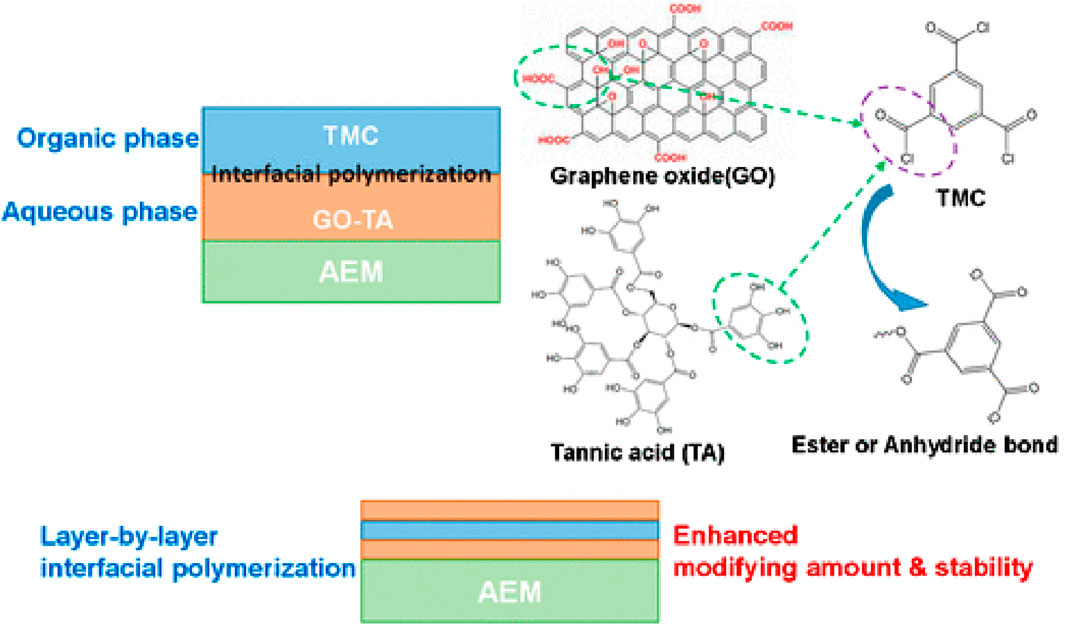

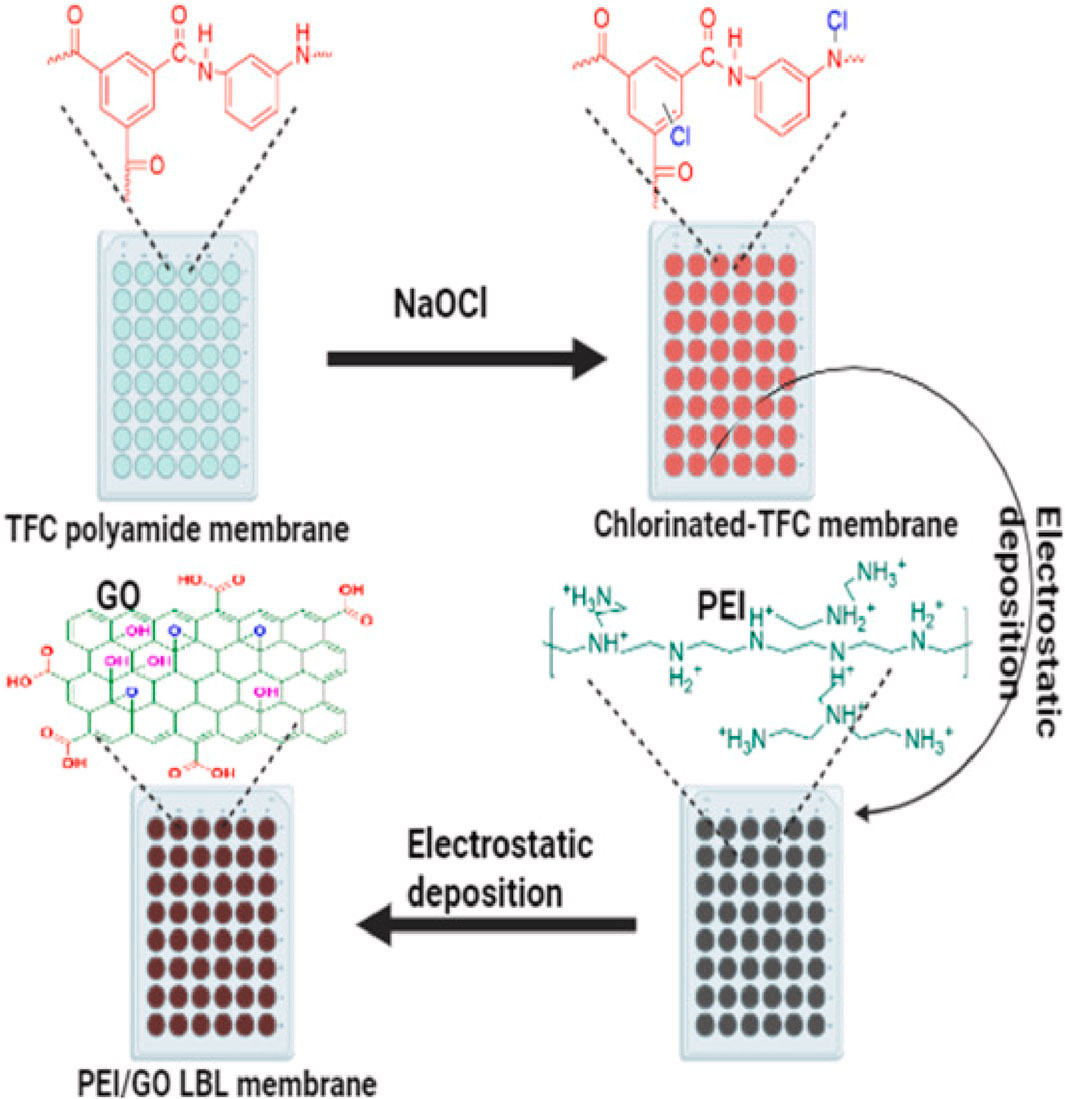

Like every other membrane, unwanted ion formation and organic precipitation cause fouling in the membrane, leading to antifouling mechanisms. Li et al., 2023 adapted a novel method of Graphene Oxide (GO)—polymer structure was created on the surface of AEM by alternatingly contacting it with GO and tannic acid (TA) aqueous as the water phase and an n-hexane solution of trimethyl chloride (TMC) as the organic phase. According to the results, the aqueous phase was the final layer-by-layer interfacial polymerization treatment that was most suited for improving the membrane surface’s hydrophilicity and negative charge density. This method enhanced the anti-organic fouling capability of the membrane. Below, Figure 7 depicts a schematic diagram of layer-by-layer polymerization.

Figure 7. Schematic representation of layer by layer interfacial polymerization of alternate GO/TA with TMC (Reproduced with permission from Líu, Hao et al., 2023).

Anion exchange membranes (AEMs) using poly (vinyl alcohol) (PVA) as the substrate and bipyridine-containing crosslinkers, or PVA-Bpy-CHO-X, were created by researchers Junbin Liao, Huimin Ruan, and Wang et al., 2023. Notable characteristics of the optimized membrane, PVA-Bpy-CHO-0.40, were a swelling ratio of 11.3%, surface area resistance of 3.21 Ω·cm2, and an increased hydrophilicity shown by a water contact angle of 76.4°. In addition, it demonstrated a high NaCl removal ratio of 85.16% ± 0.9% in 210 min, which was higher than the performance of a commercial AEM-Type-II, which was 84.46% ± 0.8%. Crucially, PVA-Bpy-CHO-0.40 demonstrated a longer transition time of 750 min in antifouling experiments employing electrodialysis, compared to 620 min for AEM-Type-II, highlighting its more excellent resistance to fouling. These results point to PVA-Bpy-CHO-0.40’s potential as a viable option for membrane applications, especially in desalination.

Membrane distillation (MD) is a new water treatment technique in which a vapor pressure gradient propels vapor over a hydrophobic membrane. Its ability to extract salts, oil, heavy metals, and organic molecules from water has drawn notice. MD is more appealing than other established techniques like reverse osmosis or thermal distillation because of its benefits, including gentle working conditions (low temperature, atmospheric pressure) and 100% theoretical salt rejection (Parani and Oluwafemi, 2021).

A recent study conducted by Lebron et al., 2023 suggests treating wastewater from gold mining by combining ion exchange (IX) with direct contact membrane distillation (DCMD). 5.49 L/m2.h flow, >99.7% ions rejection, and 33.9% permeate recovery were recorded by DCMD. Strong affinities of Amberlyst A26 for H2SO4 and Amberlite IRC747/Dowex M4195 for metal ions were found by batch equilibrium. The breakthrough sequence in fixed-bed testing was similar, with quicker breakpoints at higher feed velocities. With 4.1% carryover, the amberlyst A26 elution produced 7497.4 mg/L H2SO4; in contrast, Dowex M4195 demonstrated good selectivity for recovering metal ions. Thus, this study concludes that combining DCMD and ion exchange offers a promising treatment for gold mining wastewater.

A study by Guillén-Burrieza et al., 2023 shows how flat sheet membrane distillation (MD) can recover ammonia from wastewater treatment plants. Robust operation under ideal conditions, including low pH (8.7), low specific thermal energy consumption (13.6 kWhth per kg NH3), and low temperature (38°C), is achieved. The MD process effectively recovers 90% of the water-bound ammonia as an ammonium sulfate solution. It has a volume reduction factor and excellent quality, making it appropriate for fertilizer use.

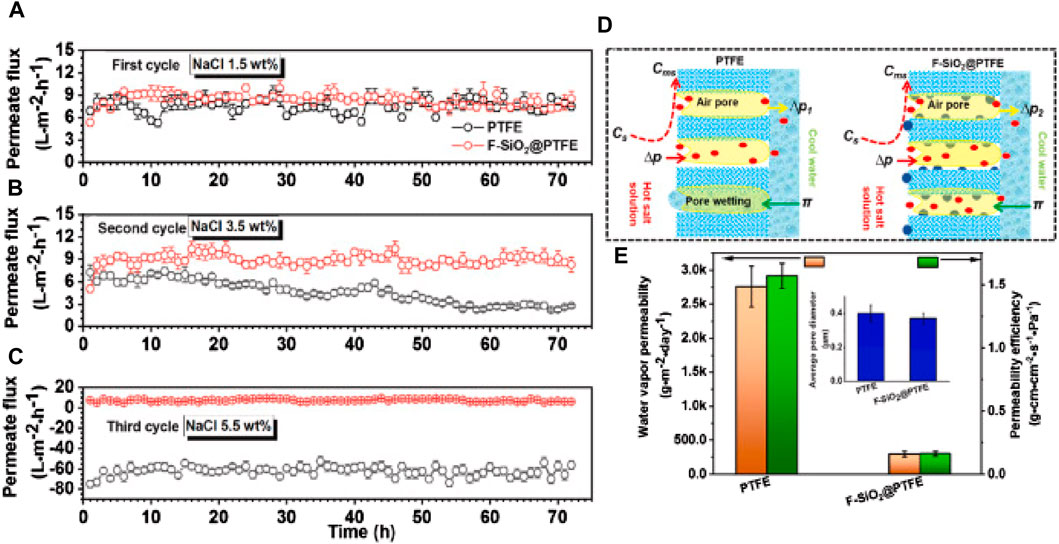

A superhydrophobic polytetrafluoroethylene (PTFE) membrane was created through surface silanization and fluorination, displaying a water contact angle of 158° ± 5° and significantly improved antiwetting and antifouling characteristics. The below Figure 8 illustrates the membrane efficiency of PTFE with different feed concentrations and water permeability (Alyami and Mahmood, 2024). Comparing the characterized membrane to the clean commercial membrane, characterization procedures revealed a slightly reduced pore size (0.37 μm) and higher penetration pressure (0.38 MPa). At about 1 mJ/m2, or one-third of the energy of the original membrane, the tailored membrane showed shallow surface energy. The membrane distillation (MD) separation findings showed that MD may be used to treat waste liquids stable and long-lasting, even when treating difficult landfill leachate (Xiong et al., 2023).

Figure 8. (A) Membrane distillation performance of the pristine PTFE and F–SiO2@PTFE membranes using different feed solutions: (A) 1.5 wt%, (B) 3.5 wt% and (C) 5.5 wt% NaCl solutions. (D) Schematic illustration of pore wetting during membrane distillation with the pristine PTFE and F–SiO2@PTFE membranes. (E) The water vapor permeabilities of the pristine PTFE and F–SiO2@PTFE membranes (the inset shows the average pore diameters of the pristine PTFE and F–SiO2@PTFE membranes) (Reproduced with permission from Xiong, Z et al., 2023).

One efficient membrane-based separation method that allows solutes to pass through membranes made of dense materials is pervaporation. The type and composition of the membrane material are important aspects that determine the membrane’s performance, primarily because mass transfer is based on the interaction between the membrane and the chemical (Purkait et al., 2020b). Wastewater may be treated with Pervaporation to remove dangerous volatile organic compounds (VOCs), including toluene and benzene. It doesn’t require harsh chemicals and is inexpensive and straightforward to use (Rasheed et al., 2023). The membranes implemented in these water treatments are highly exposed to organic fouling the membrane to degrade and lessen the efficiency of the process.

Russo et al. (2021) developed highly hydrophilic and antifouling membranes from PES plastic. The addition of a Poly Vinyl Pyrrolidone (PVP) layer using the UV-polymerisation method in Rhodiasolv Polarclean solvent shows more excellent hydrophilicity, higher pure water permeability, and improved foulant rejection. Also, compared to the non-UV-treated commercial PES membranes, it showed a higher recovery of 97.45%, while the anti-fouling test used 100 mg/L of humic acid (HA). Alyami and Mahmood, 2024b, at an initial Na + ion concentration of 45,000 mg/L, graphene oxide (GO) functionalized with chitosan and synthesized using a modified Hummers’ process shows improved adsorption capacity for sodium ions, increasing from 680.2 to 740.5 mg/g. Figure 9 illustrates the schematic representation assembly of the PEI/GO layer-by-layer membrane for pervaporation. The PEI (polyethyleneimine)/GO (Graphene Oxide) Layer by Layer membrane’s effectiveness in desalination is demonstrated by its ability to achieve a water flow of 8.9 kg/m2h with >99.9% salt rejection for a variety of salts.

Figure 9. Schematic representation assembly of PEI/GO layer by layer membrane for pervaporation (Reproduced with permission from Alyami, A., & Mahmood et al., 2024).

One of the first modules created was the flat sheet module. The membrane, feed spacers, and product spacers are all bedded into a steel frame to form its composition. These spacers create channels for feed and product flow and stop the membranes from adhering to one another. It is important to remember that this module is only used in specific situations, such as treating wastewater that include significant amounts of suspended particles, such as landfill leachate, and is not typically used. Sano et al., 2020 researched fouling in a membrane reactor using four different polymeric materials and adjusting structural vulnerability (SV). After 16 days of monitoring, the PVDF membrane attained the highest transmembrane pressure (TMP), about 30kPa, resulting in a flux increase from 0.3 to 0.65 m3/m2.d. This came up because of aeration’s shearing stress, which caused the surface layer to split from the support layer, with SV playing an important role in determining fouling properties for wastewater treatments. Kharraz et al., 2015 fabricated a two-layer composite flat sheet PVDF membrane (10%w/w) for flux stabilization, the first one to control the pore size and the second for enhancement of hydrophobicity, achieved a permeate flux reduction of 10.7% after 103 h of operation. Later, Schumann et al., 2020 utilized a Gravity-driven module (GDM) of five vertically aligned flat sheet membranes of 0.45 m2 surface area and two characteristics of GAC, namely, Epibon A (Ep) and Hydraffin CC (Hy), to further activate the PVDF membrane. After long-run (9 months) experimental run, flux was stabilized with a level of 5 L/m2.h and 3.3 L/m2.h for PVDF/Ep and PVDF/Hy membranes, respectively, after 40 days. In 2021, Poly (vinylidene fluoride-hexafluoropropylene) P(VDF-HFP) flat sheet membranes of various morphology, pore size, and contact angles were created utilizing a non-toxic solvent, Tamisolve®. Saïdi et al., 2021 investigated the effects of additives (polyvinylpyrrolidone (PVP) and polyethylene glycol (PEG)) and increasing the PVDF content from 15% to 18% using MD and membrane crystallization (MCr) techniques, achieving a salt rejection of around 99% after combining both techniques. Removal efficiency (RE) of methane from water varied with tuning gas and liquid flow rates (3.5–40.5 Lh−1 and 0.05–15.00 L h−1, respectively) of dense (polydimethylsiloxane, PDMS) and microporous (PP, PVDF) polymer membranes. Jiménez-Robles et al., 2022 improved the methane recovery by increasing the PVDF hydrophobicity.

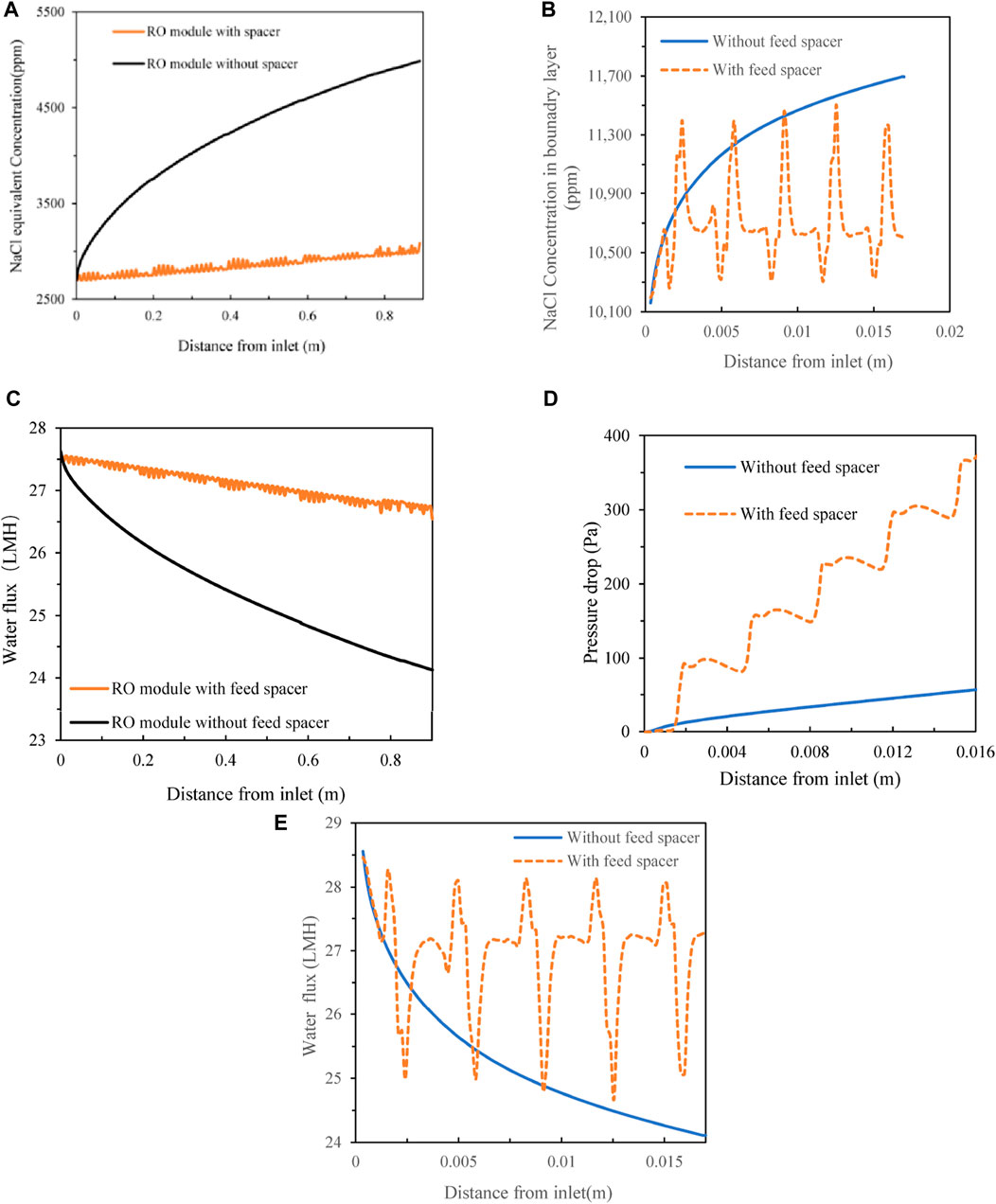

The spiral module is the most widely applied in RO and NF operations because of the high packing density, which further provides the membrane surface area (Ezugbe and Sudesh, 2020). At a tangent to the membrane, the water to be treated enters the spiral wound module. Permeate passes through the permeate spacers in this manner, flowing perpendicular to the membrane surface before gathering in the central collecting tube (Kucera, 2019). Easy replacement made spiral wound modules to be applied in large-scale industries (Baker, Richard W, 2004). Lin et al., 2021 highlighted insights on hydrodynamics, biofouling, and novel spacer design phases in the field of feed spacer technology. Also, provided future research directions exploring the role of hydrodynamics in fouling control and developing spacer designs SWM modules in the application of drinking water production. Based on this, Bristow et al., 2021 constructed a Magnetic Resonance measurement (MRM) protocol for early-detection and quantification of fouling in the membrane module, allowing for high 2D velocity cross-sectional images proving clean membrane (198 士 62, 455 士 117) having a high relaxation time T2, eff on both permeate and feed spacer value than fouled membranes (188 士 57, 349 士 126) impacting on the flow patterns within the central permeate tube. Later, Goon et al., 2021 proposed a low-operating cost cleaning method on the existing RO SWM, achieving flux recovery of 83% of the initial value and promoting the optimized membrane performance, validating both flat-sheet membranes and SWM for industrial application. Wei et al., 2021 developed a 3D model for the simulation of concentration polarization which shows modules with feed spacer had less flux loss of 1.1 LMH and increased concentration polarisation of the concentrate up to 84.67% under the same feed conditions. Figure 10 shows the difference between various properties along the feed inlet with and without feed spacers.

Figure 10. (A) Salt concentration profiles in the boundary layer of the crossflow flat sheet module in the absence and presence of the feed spacer. (B) Salt concentration distribution of the spiral wound RO module along the feed direction in the absence and presence of the feed spacer (C) Flux distributions of the spiral wound RO module along the feed direction in the absence and presence of the feed spacer. (D) Pressure loss along the crossflow flat sheet module in the absence and presence of the feed spacer. (E) Permeate flux of the crossflow flat sheet module in the absence and presence of the feed spacer (Reproduced with permission from Wei et al., 2021).

Yu et al., 2022 developed different node designs for improvements in spacer designs, namely, Arch-hole (two-elliptical cylinders) and Arch (solid) nodes. Results showed that the Arch-hole design node minimized the energy cost by 69% and reduced fouling with higher flux-value calculated via Computational Fluid Dynamics (CFD) simulation. Guan et al., 2023 further developed a dumbbell-shaped filament model utilizing CFD simulations to investigate the hydrodynamics effects of non-uniform feed spacer on energy loss and mass transfer rates in spiral wound RO modules, recommending a Reynold Number (Re) value of 200 for the optimized feed spacer configuration and improved energy loss. In addition, Yang et al., 2023 used the Response Surface Methodology (RSM) and Multi-Objective Genetic Algorithm (MOGA) to optimize space parameters with respect to membrane performance and energy consumption. Simulation in CFD revealed a 57.9% increase in average minimum wall shear at the membrane surface with reduced fouling potential. Kürzl et al., 2023 worked on increasing the stability of the SWM module by implementing a glue connection in the membrane inlet, which showed increased volume throughput of>100% and also increased the filtration and cleanability performance by 26% and 28% with pulsed flow (on/off bypass) around the membrane. Ji et al., 2024 demonstrated that implementing angular vibrations at a frequency of 15 Hz on the SWM module effectively controlled algal fouling by up to 28.5%, with a lower energy loss of 76.1 mW than the traditional increasing flow rate method. The improvements performed and observation have shown various possibilities that can be implemented and requirement of innovation to improve the flux characteristics of the membranes.

A tubular membrane module for UF uses a normal PVC pipe tubular shell with molded PVC end fittings that are bonded to the pipe with epoxy resin glue. Between the end fittings, a membrane tube within the shell is anchored by a comparable adhesive in corresponding sockets within the end fittings. To prevent fluid from entering the tube under pressure while it is being used, each socket includes a blind end that accepts the end section of the membrane tube. (Sillanpaa, Mika, Ali Khadir, and Khum Gurung, 2023) (Langerak et al., 227,063, 1993).

Федосов et al., 2020 studied the pressure loss during the UF of liquid media in a tubular membrane module, which showed that the conventional pressure loss equation gave an error of 40%–60% compared to the experimental data. Their team developed a model using Laplace transformations considering the physicochemical properties of the liquid and the process parameters, which showed promising results with 0.1% error. The proposed equation was

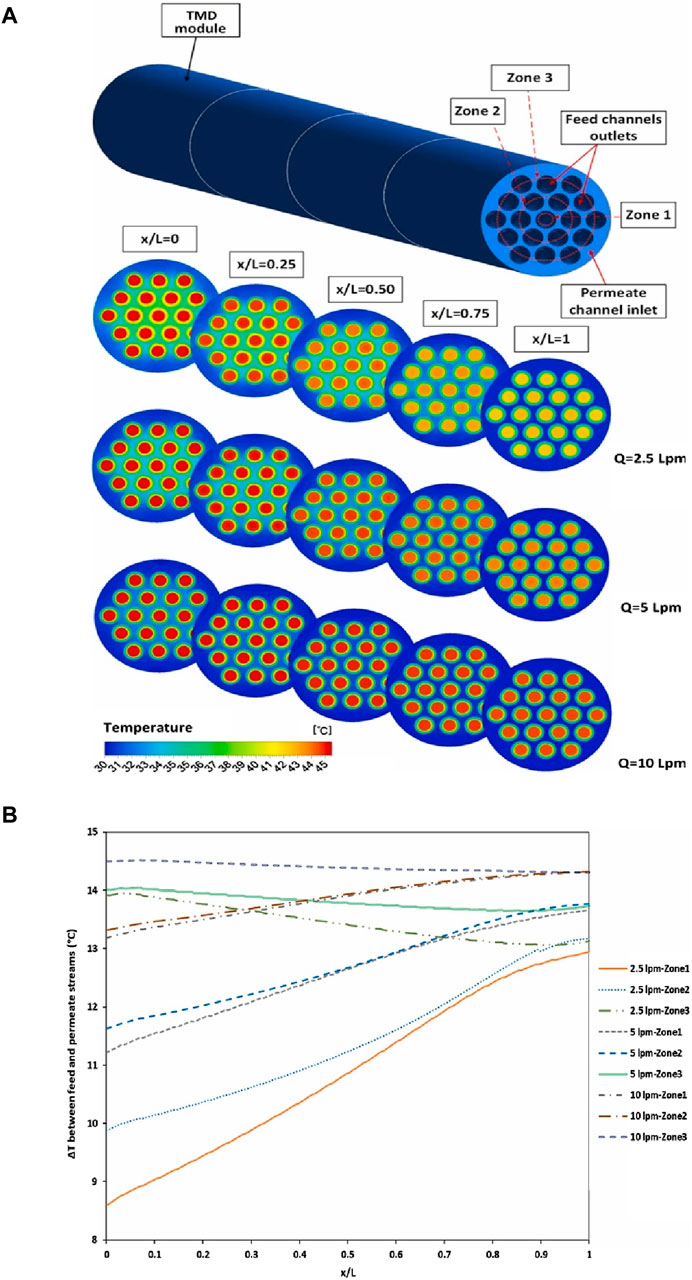

Cleaning of tubular PVDF membrane modules with 0.1 M NaOH, 0.3 M NaCl, and 0.6 M HCl showed severe damage to the membrane and caused accelerated ageing in less than 7 months. Also, compared to NaOH and NaOCl, HCl had a relatively moderate impact on the membrane framework. Further, FTIR of the washed membrane showed the formation of a new carbon-carbon double bond. TGA showed the membrane degradation happened 20 deg Celsius earlier than an untreated membrane (Menon et al., 2021; Alanezi et al., 2021 conducted a hydrophobic tubular MD module of pore size 0.2 μm. The study focused on Knudsen diffusion shows higher permeation flux than experimental and molecular diffusion with an increase in temperature. Additionally, the permeation flux was compared by varying the water flow rates from 60 to 120 L/h, which increased permeation flux by a factor ranging from 07.−1.1. Further, Shafieian et al., 2022 enhanced the performance of water productivity and highlighted the reduced water flow rate sensitivity to heat transfer coefficients below 1250 Ws/m3.degC. This finding enlightened him to develop a 3-D CFD model to optimize the heat transfer coefficient in thermal-driven tubular MD modules to achieve higher water productivity. However, this research work is limited to enhancing water productivity and could have determined other membrane fouling parameters to improve the overall system’s efficiency. Chevarin et al., 2023 prepared a CFD-guided 3D-patterned tubular ceramic membrane surface by stereolithography, an additive manufacturing process that showed an effective increase (0.1–4.6 m2.s−3) in the turbulent dissipation rate of the fluid, which decreased the membrane fouling and also the natural increase in pressure difference (0.006–0.092 bar.m−1) observed. The below Figure 11 shows the temperature distribution along the tubular module. The crossflow microfiltration tests with P. aeruginosa corroborate CFD predictions. Various models developed and simulated show the possible ways to implement the virtual models into lively products to improve the quality of the membrane processes.

Figure 11. (A) Temperature distributions at different distance ratios of the MD module. (B) Temperature difference between feed and permeate streams along the membrane module at various locations (Reproduced with permission from Shafieian et al., 2022).

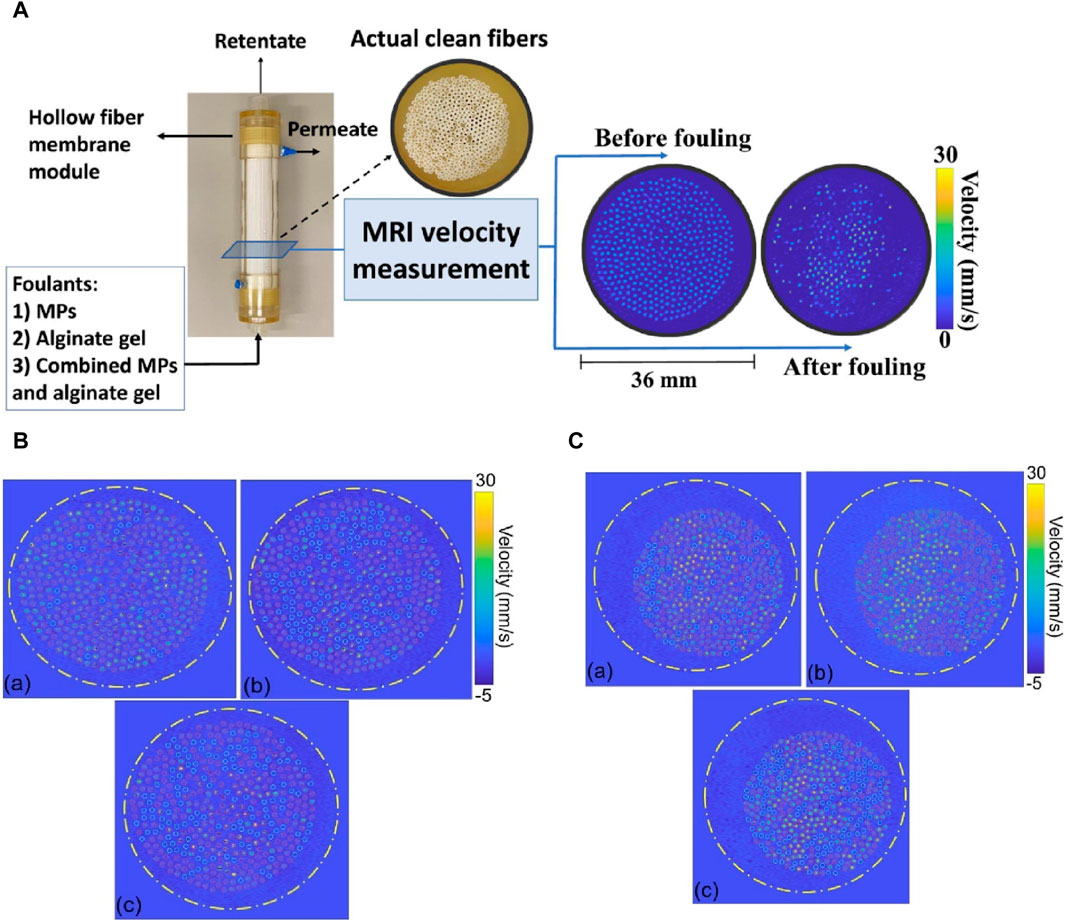

A porous, nonselective support layer of around 200 µm and an active layer with a thickness greater than 40 nm make up hollow fibers. The membrane itself is found in this active layer, but it requires assistance to endure the hydrostatic pressure (Drioli and Nakagaki, 1986). Depending on their intended usage, hollow fiber modules can be either bore-side (inside) or shell-side (outside) feed types. The shell-side feed type is ideal for high-pressure applications (up to 70 bar), whereas the bore-side feed type is preferred for low to medium-pressure applications. This module type’s capacity to include enormous membrane regions within a single module is one of its most noticeable advantages (Baker, 2012). MRI technology made it easy to study the velocity profile of the fluid inside the hollow fiber membrane module. Also, the microplastics fouling was studied using MRI which was efficient compared to traditional pressure drop. Ghasemi et al., 2023 found using MRI technology that fouling due to alginate microplastics is less compared to the alginate foulants. Figure 12 below shows the velocity of water in a fouled hollow fiber membrane with MRI technology.

Figure 12. (A) MRI technology to identify the amount of fouling in hollow fiber module membranes. (B) Fiber detection superimposed on velocity images acquired (A) 30 min, (B) 14 h and (C) 24 h after injection of 1 mL of alginate solution and 100 ppm of MP to the DI water stream being fed to the module. The system operates in recirculation mode. (C) Velocity images and identified fibers) Velocity injecting 1 mL alginate gel into (A) DI water, (B) a 10 ppm MPs solution and (C) a 100 ppm MPs solution (Reproduced with permission from Bristow et al., 2023).

MD is high thermal energy-consuming process used in water desalination. The use of hollow fiber membrane modules is a common practice in this industry. So, to improve the thermal efficiency of the MD process instead of the traditional single-pass system, a multi-pass system was implemented by Tsai et al., 2023, which showed a 1.5% higher pressure drop and 35% less thermal energy drop. This method comes with the disadvantage of decreased flux up to 92% less than the traditional method. The hollow fiber module membrane is an explorable domain with various opportunities to exploit. It provides a higher surface area to flow through the hollow space between them and promotes higher separations.

Asif et al., 2021 reviewed several modules’ performance and operation conditions for membrane fouling. They mainly emphasized the growing interest in ceramic membrane technology for wastewater treatment, which is motivated by its benefits, such as chemical stability, low fouling rates, and long life. They outperform standard membranes, demonstrating high flux and pollution removal efficiency. Ceramic membranes, such as microfiltration (MF), UF, and NF, are characterized by pore size and employed in environmental and biotechnological applications. It emphasizes that future studies will focus on ceramic membrane technology and understanding and evaluating the economic sustainability of fouling management measures.

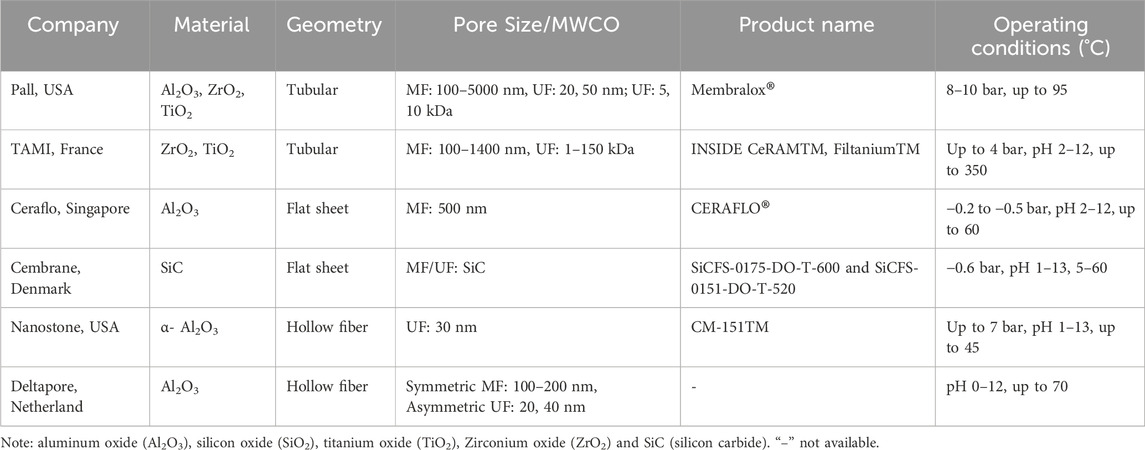

Table 2 clearly describes the evaluation of various module operating circumstances under different temperature and pressure settings. These criteria are product-specific, and performance varies depending on manufacturing processes and materials. It also highlights ceramic membrane providers who provide customized alternatives for various modules based on our specific requirements, ensuring flexibility and optimizing performance in multiple sectors.

Table 2. Features of the selected commercially available MF and UF ceramic membranes for water and wastewater treatment (Reproduced with permission from Asif et al., 2021).

The methods to mitigate four different modules of varying processes and methods are discussed below:

The innovative flat sheet submerged NF membrane module functions at a reduced water flow, which reduces fouling. This method involved stabilizing the RO-treated water before NF treatment, maintaining a constant flux (3 L/m2h), limiting TMP increase to ≤0.072 kPa/d, avoiding aeration in the membrane reservoir, replacing feed solution every 6 days, and physically cleaning the membrane surface with a polyurethane sponge to achieve TOC removal (>80%), resulting in high-quality rejected water (Ngo et al., 2021).

Yang et al., 2023 created an automated spacer design utilizing a genetic algorithm. This work used ANSYS 2021 R1 Workbench software to develop the geometric structure of the NF membrane channel and column spacer, as well as parameter setting and post-processing. Response surface methodology (RSM) and CFD post were used to define objective metrics for evaluating the performance of the NF membrane, which included shear wall force, permeate flow, and feed channel pressure drop. This study aims to improve filtration performance by optimizing factors such as flux (8% reduction in flux attenuation) and shear rate (57.9% increase in shear wall rate). More research into machine learning algorithms and other multi-scale modeling for spiral-wound modules is needed to boost efficiency.

Armbruster et al., 2018 evaluated the effects of several turbulence promoters on fouling reduction in membrane filtration, employing a ceramic membrane with a nominal cutoff of 100 kDa. Experiments used an aqueous humic acid solution to imitate natural water conditions. This ceramic membrane has a single-channel tubular construction with certain dimensions, and the experiments were conducted in a cross-flow mode with a constant feed-flow rate. Pressure step techniques caused fouling, whereas static mixers increased steady-state flux levels. Later, in 2019, they used CFD simulations to select the optimal static mixers using two approaches: 1) shortening the total length of twisted shapes and 2) regularly spaced short twisted tape elements; the results showed that for higher silica concentrations of 0.24 and 0.6 g/L, the TMP remained constant over fluxes of 150 mm twisted tape length. Lower concentrations (about 0.03 g/L) resulted in a substantially smaller pressure decrease than full-length tape, lowering flow (Armbruster et al., 2018).

Tran et al., 2020 proposed using an osmotic membrane bioreactor (OMBR) system with activated sludge to stabilize TOC removal at approximately 90%. They used a peristaltic pump to recycle the draw solution (DS) at a concentration of 35 ± 1 g/L. This study used a two-step sequential chemical cleaning procedure that included an alkaline solution (0.1% NaOH +0.1% Sodium dodecyl sulfate) followed by an acidic solution to efficiently reduce fouling in the hollow-fiber module, which had an initial water flow of 6.3 LMH. Later, the antifouling hollow-fiber membrane was fabricated for efficient removal and concentration of the contaminants (Reactive Black-5 dye (RB-5), depositing a nanoporous PVA membrane onto a UF polysulfone hollow fiber substrate was spun using a double orifice spinneret, and a PVA membrane layer was uniformly using an automatic dip coating unit (Kumar et al., 2023).

The features of some of the methods are discussed to enhance the process of antifouling strategies, as shown below in Table 3. More research is required on the Tubular module membrane for a structured mechanism of the process. To further enhance the ongoing work, complex models like multi-scale modeling need to be developed to further study fouling issues.

The role of membrane processes and different membrane modules has been playing a vital role in various water treatment systems. The application of multiple materials and process types is crucial to remove specific contaminants in water. Industrially, a combination of these membrane processes is applied to remove unnecessary particles in the water or retrieve specific chemicals in the water. As the significant challenges have always been around the fouling and scaling of the membrane, various methods have been adapted to overcome these problems. Finding new materials to make a membrane that has hydrophilic behavior has been a recent trend toward higher efficiency. This trend towards finding new and better material is getting driven towards implementing nano-composite-based MMMs, which will incorporate unique characteristics and surface texture to the membrane, adding to the retaining ability of the membrane. The incorporation of various nanocomposites into quantum dots is the current trend in increasing the efficiency of the membranes. Instead, there is quite an opening in using integrated membrane processes where more than membrane processes can be wound together to make the water treatment a better technique. Photocatalysts contribute significantly to photocatalytic activity by decomposing different organic pollutants and making them useful in wastewater treatment in the presence of antimicrobial bacteria. It also provides a cost-effective and sustainable solution by combining with membrane filtration technologies, which successfully remove many pollutants and give rise to clean water.

Various modules in usage are operated in their original state in industries without any specific modification. Module research is an open space where one can increase the possibilities of new innovations and techniques. The technology of AI-integrated tunable membrane and module systems is one area researchers focus on to obtain high-energy efficient membrane processes for water treatment. Membrane modules that have the ability to self-heal or get minor damage from treatment and cleaning are being observed for better application. The need for intelligent membranes is always the case in industries to obtain better results. Up to now, limited studies have been observed in tubular, hollow fiber, and spiral modules, which are crucial modules for future implementations. Newer antifouling methods should be idealized for better membrane processes and modules.

Membrane technologies have been present in water treatment for several decades. The review revolved around the current research trends in various membrane processes and techniques. First, the review paper generalized the properties of membranes about the inverse relation between selectivity and permeability, which leads to the fouling conditions of a membrane. This lowers productivity and calls for cleaning, which might harm membranes. Recent developments include pretreating water to lessen fouling and altering membranes (e.g., by adding nanoparticles). Recent research are focusing on developing self-cleaning membranes, creative anti-fouling mechanisms, and enhanced cleaning methods. The ultimate objective is to create long-lasting, low-maintenance membranes for environmentally friendly water filtration. Forward osmosis (FO) is gaining popularity because it requires less energy than reverse osmosis. Novel materials and techniques for ion exchange membranes are being researched to improve their fouling resistance and overall performance. Table 4 represents the summary of features of all the membrane processes. The potential of membrane distillation (MD) to eliminate impurities at low pressures and temperatures is encouraging.

Module fabrication and development has been an important domain in membrane technology. Fouling issues with flat sheet, spiral wound, tubular, and hollow fiber water treatment membrane modules is now mitigated by implementing enhanced operating circumstances and new manufacturing procedures. Topics such as spacer design, turbulence promoters, and cleaning procedures play an important role in mitigating fouling. These materials with improved antifouling qualities, integrated treatment methods, and AI-powered systems for optimal performance will be the main focuses of future developments in membrane modules. Promising avenues for further research include self-healing membranes and the many types of modules now in use, such as spiral, hollow fiber, and tubular (Characteristics of Polymeric membrane processes and modules utilized are shown in Table 5. All things considered, developing more effective and long-lasting wastewater treatment systems requires better membrane module design and anti-fouling techniques.

ST: Writing–original draft, Writing–review and editing. SD: Writing–original draft, Writing–review and editing. GA: Writing–original draft, Writing–review and editing.

The author(s) declare that no financial support was received for the research, authorship, and/or publication of this article.

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Abada, B., Joag, S., Alspach, B., Bustamante, Á., and Chellam, S. (2023). Inorganic and organic silicon fouling of nanofiltration membranes during pilot-scale direct potable reuse. ACS ES&T Eng. 3 (9), 1413–1423. doi:10.1021/acsestengg.3c00172

Abdollahi, E., Heidari, A., Mohammadi, T., Asadi, A., and Tofighy, M. A. (2021). Application of Mg-Al LDH nanoparticles to enhance flux, hydrophilicity and antifouling properties of PVDF ultrafiltration membrane: experimental and modeling studies. Sep. Purif. Technol. 257 (February 1), 117931. doi:10.1016/j.seppur.2020.117931

Aghilesh, K., Mungray, A. A., Agarwal, S., Ali, J. S., and Garg, M. C. (2021). Performance optimisation of forward-osmosis membrane system using machine learning for the treatment of textile industry wastewater. J. Clean. Prod. 289, 125690. doi:10.1016/j.jclepro.2020.125690

Agnihotri, B., Sharma, A., and Gupta, A. B. (2020). Characterization and analysis of inorganic foulants in RO membranes for groundwater treatment. Desalination 491 (October 1), 114567. doi:10.1016/j.desal.2020.114567

Ahmed, J., Thakur, A., and Goyal, A. (2021). in Biological treatment of industrial wastewater. Editor M. P. Shah (The Royal Society of Chemistry), 1–14. doi:10.1039/9781839165399-00001

Alanezi, A. A., Bassyouni, M., Abdel-Hamid, S. M. S., Ahmed, H. S., Abdel-Aziz, M. H., Zoromba, M. S., et al. (2021). Theoretical investigation of vapor transport mechanism using tubular membrane distillation module. Membranes 11 (8), 560. doi:10.3390/membranes11080560

Albert, J., Destouni, G., Magurran, A., Oberdorff, T., Reis, R., Winemiller, K., et al. (2020). Scientists’ warning to humanity on the freshwater biodiversity crisis. Ambio 50, 85–94. doi:10.1007/s13280-020-01318-8

Almoalimi, K. T., and Liu, Y. (2022). Fouling and cleaning of thin film composite forward osmosis membrane treating municipal wastewater for resource recovery. Chemosphere 288, 132507. doi:10.1016/j.chemosphere.2021.132507

Alyami, A., and Mahmood, A. (2024). Synthesis, characterization and application of chitosan functionalized and functional graphene oxide membranes for desalination of water by pervaporation. Environ. Res. 251, 118589. doi:10.1016/j.envres.2024.118589

Alyami, A., and Mahmood, A. (2024b) Synthesis, characterization and application of chitosan functionalized and functional graphene oxide membranes for desalination of water by pervaporation.

Armbruster, S., Cheong, O., Lölsberg, J., Popović, S., Yüce, S., and Weßling, M. (2018). Fouling mitigation in tubular membranes by 3D-printed turbulence promoters. J. Membr. Sci. 554, 156–163. doi:10.1016/j.memsci.2018.02.015

Armbruster, S., Stockmeier, F., Junker, M. A., Schiller-Becerra, M., Yüce, S., and Weßling, M. (2020). Short and spaced twisted tapes to mitigate fouling in tubular membranes. J. Membr. Sci. 595, 117426. doi:10.1016/j.memsci.2019.117426

Asif, M. B., and Zhang, Z. (2021). Ceramic membrane technology for water and wastewater treatment: a critical review of performance, full-scale applications, membrane fouling and prospects. Chem. Eng. J. 418, 129481. doi:10.1016/j.cej.2021.129481

Awad, E. S., Сабирова, Т. М., Tretyakova, N. А., Alsalhy, Q. F., Figoli, A., and Salih, I. K. (2021). A mini-review of enhancing ultrafiltration membranes (UF) for wastewater treatment: performance and stability. ChemEngineering 5 (3), 34. doi:10.3390/chemengineering5030034

Baker, R. W., and Richard, W. (2020). Membrane technology and applications. Membranes 10. ISBN 978-0-470-74372-0 Obotey Ezugbe, Elorm, and Sudesh Rathilal. “Membrane Technologies in Wastewater Treatment: A Review. doi:10.3390/membranes10050089

Bao, X., Wu, Q., Shi, W., Wang, W., Yu, H., Zhu, Z., et al. (2019). Polyamidoamine dendrimer grafted forward osmosis membrane with superior ammonia selectivity and robust antifouling capacity for domestic wastewater concentration. Water Res. 153, 1–10. doi:10.1016/j.watres.2018.12.067

Bristow, N. W., Vogt, S. J., Bucs, S., Vrouwenvelder, J. S., Johns, M. L., and Fridjonsson, E. O. (2021). Novel magnetic resonance measurements of fouling in operating spiral wound reverse osmosis membrane modules. Water Res. 196 (May 1), 117006. doi:10.1016/j.watres.2021.117006

Cai, Z., Wee, C., and Benjamin, M. M. (2013). Fouling mechanisms in low-pressure membrane filtration in the presence of an adsorbent cake layer. J. Membr. Sci. 433 (April 1), 32–38. doi:10.1016/j.memsci.2013.01.007

Chen, T., Zhu, H., Chen, X., Zheng, S., Liang, F., Yang, F., et al. (2023). Full-coverage spongy HEAA/PES composite ultrafiltration membrane with high selectivity and antifouling performances. ACS Appl. Polym. Mater. 5 (4), 2727–2738. doi:10.1021/acsapm.3c00004

Chevarin, C., Wang, X., Bouyer, D., Tarabara, V. V., Chartier, T., and Ayral, A. (2023). CFD-Guided patterning of tubular ceramic membrane surface by stereolithography: optimizing morphology at the mesoscale for improved hydrodynamic control of membrane fouling. J. Membr. Sci. 672 (April 1), 121435. doi:10.1016/j.memsci.2023.121435

Drioli, E., and Nakagaki, M. (1986) Membranes and membrane processes. Springer eBooks. doi:10.1007/978-1-4899-2019-5

Elmakki, T., Zavahir, S., Gulied, M., Qiblawey, H., Hammadi, B., Khraisheh, M., et al. (2023). Potential application of hybrid reverse electrodialysis (RED)-forward osmosis (FO) system to fertilizer-producing industrial plant for efficient water reuse. Desalination 550 (March 1), 116374. doi:10.1016/j.desal.2023.116374

Ezugbe, E. O., and Sudesh, R. (2020). Membrane technologies in wastewater treatment: a review. Membranes 10 (5), 89. doi:10.3390/membranes10050089

Fu, W., Chen, J., Li, C., Jiang, L., Qiu, M., Li, X., et al. (2021). Enhanced flux and fouling resistance forward osmosis membrane based on a hydrogel/MOF hybrid selective layer. J. Colloid Interface Sci. 585, 158–166. doi:10.1016/j.jcis.2020.11.092

Ghasemi, S., Yan, B., Zargar, M., Ling, N. N. A., Fridjonsson, E. O., and Johns, M. L. (2023). Impact of microplastics on organic fouling of hollow fiber membranes. Chem. Eng. J. 467 (July 1), 143320. doi:10.1016/j.cej.2023.143320

Ghasemi, S., Yan, B., Zargar, M., Ling, N. N. A., Fridjonsson, E. O., and Johns, M. L. (2023). Impact of microplastics on organic fouling of hollow fiber membranes of microplastics on organic fouling of hollow fiber membranes. Chem. Eng. J. 467, 143320. doi:10.1016/j.cej.2023.143320

Goon, G. S. S., Labban, O., Foo, Zi H., Zhao, X., and Lienhard, J. H. (2021). Deformation-induced cleaning of organically fouled membranes: fundamentals and techno-economic assessment for spiral-wound membranes. J. Membr. Sci. 626 (May 1), 119169. doi:10.1016/j.memsci.2021.119169

Goon, G. S. S., Labban, O., Foo, Z. H., Zhao, X., and Lienhard, J. H. (2021). Deformation-induced cleaning of organically fouled membranes: fundamentals and techno-economic assessment for spiral-wound membranes. J. Membr. Sci. 626, 119169. doi:10.1016/j.memsci.2021.119169

Guan, D., Hu, Z., Xie, P., Sun, Z., Zhang, Z., Shan, Y., et al. (2023). Osmotic cleaning to control inorganic fouling of nanofiltration membrane for seawater desalination. J. Environ. Chem. Eng. 11 (5), 110551. doi:10.1016/j.jece.2023.110551

Guan, H., Lin, P., Yu, S., Hu, X., Li, X., and Zhu, Z. (2023). Hydrodynamic effects of non-uniform feed spacer structures on energy loss and mass transfer in spiral wound module. J. Membr. Sci. 673 (May 1), 121479. doi:10.1016/j.memsci.2023.121479

Guillén-Burrieza, E., Moritz, E., Hobisch, M., and Muster-Slawitsch, B. (2023). Recovery of ammonia from centrate water in urban waste water treatment plants via direct contact membrane distillation: process performance in long-term pilot-scale operation from centrate water in urban waste water treatment plants via direct contact membrane distillation: Process performance in long-term pilot-scale operation. J. Membr. Sci., 667, 121161. doi:10.1016/j.memsci.2022.121161

Guo, S., Wan, Y., Chen, X., and Luo, J. (2021). Loose nanofiltration membrane custom-tailored for resource recovery. Chem. Eng. J. 409 (April 1), 127376. doi:10.1016/j.cej.2020.127376

Guo, Yu, Li, T.Yu, Xiao, K., Wang, X. M., and Xie, Y. F. (2020). Key foulants and their interactive effect in organic fouling of nanofiltration membranes. J. Membr. Sci. 610 (1), 118252. doi:10.1016/j.memsci.2020.118252

Ho, D. T., Nguyen, T. P. N., Jangir, A., and Schwingenschlögl, U. (2023). Graphene foam membranes with tunable pore size for next-generation reverse osmosis water desalination. Nanoscale Horizons 8 (8), 1082–1089. doi:10.1039/d2nh00475e

Huang, J. J., Chen, S., Liao, Y., Chen, Y., You, X., and Wang, R. (2021). Performance, fouling and cleaning of a thin film composite hollow fiber membrane during fertiliser-drawn forward osmosis process for micro-polluted water. Environ. Sci. 7, 1279–1291. doi:10.1039/d0ew00996b

Ji, Yi, Sun, Y., Li, H., Fu, Q., and Zhang, Y. (2024). Angular vibrations for fouling control during ultrafiltration of microalgae in a spiral wound module. J. Membr. Sci. 692 (February 1), 122283. doi:10.1016/j.memsci.2023.122283

Jiménez-Robles, R., Gabaldón, C., Badía, J., Izquierdo, M., and Martínez-Soria, V. (2022). Recovery of dissolved methane through a flat sheet module with PDMS, PP, and PVDF membranes. Sep. Purif. Technol. 282, 120057. doi:10.1016/j.seppur.2021.120057

Kahrizi, M., Gonzales, R. R., Kong, L., Matsuyama, H., Lu, P., Lin, J., et al. (2022). Significant roles of substrate properties in forward osmosis membrane performance: a review. Desalination 528 (April 1), 115615. doi:10.1016/j.desal.2022.115615

Kamaludin, R., Abdul Majid, L., Othman, M. H. D., Mansur, S., Kadir, S. H. S. A., Wong, K. Y., et al. (2022). Polyvinylidene difluoride (PVDF) hollow fiber membrane incorporated with antibacterial and anti-fouling by zinc oxide for water and wastewater treatment. Membranes 12 (2), 110. doi:10.3390/membranes12020110

Kanani, D. M., Fissell, W. H., Roy, S., Dubnisheva, A., Fleischman, A. J., and Zydney, A. L. (2010). Permeability–selectivity analysis for ultrafiltration: effect of pore geometry. J. Membr. Sci. 349 (1–2), 405–410. doi:10.1016/j.memsci.2009.12.003

Kehrein, P., Loosdrecht, M., Osseweijer, P., Dewulf, Jo, Garfí, A., and Posada, J. (2020). A critical review of resource recovery from municipal wastewater treatment plants – market supply potentials, technologies and bottlenecks. Environ. Sci. Water Res. Technol. 6, 877–910. doi:10.1039/C9EW00905A

Kharraz, J. A., Bilad, M. R., and Arafat, H. A. (2015). Flux stabilization in membrane distillation desalination of seawater and brine using corrugated PVDF membranes. J. Membr. Sci. 495, 404–414. doi:10.1016/j.memsci.2015.08.039

Kucera, J. (2015) “Reverse osmosis: industrial processes and applications,”. Hoboken, NJ, USA: John Wiley & Sons.

Kumar, P., Thummar, U. G., Nandha, N. H., and Singh, P. S. (2023). Sustainable treatment of saline dye wastewater and resource recovery with flux-recoverable hollow fiber of antifouling ‘water channel. Desalination 549, 116308. doi:10.1016/j.desal.2022.116308

Kürzl, C., Hartinger, M., Ong, P., Schopf, R., Schiffer, S., and Ulrich, K. (2023). Increasing performance of spiral-wound modules (SWMs) by improving stability against axial pressure drop and utilising pulsed flow. Membranes 13 (9), 791. doi:10.3390/membranes13090791

Lebron, Y. a. R., Moreira, V. R., De Souza Santos, L. V., and Amaral, M. C. S. (2023). Membrane distillation and ion exchange combined process for mining wastewater treatment, water reuse, and byproducts recovery distillation and ion exchange combined process for mining wastewater treatment, water reuse, and byproducts recovery. Chem. Eng. J., 466, 143181. doi:10.1016/j.cej.2023.143181

Lee, E. K., Chen, V., and Fane, A. G. (2008). Natural organic matter (NOM) fouling in low-pressure membrane filtration — effect of membranes and operation modes. Desalination 218 (1–3), 257–270. doi:10.1016/j.desal.2007.02.021

Li, C., Zhao, Y., Lai, G. S., and Wang, R. (2022b). Fabrication of fluorinated polyamide seawater reverse osmosis membrane with enhanced boron removal. J. Membr. Sci. 662, 121009. doi:10.1016/j.memsci.2022.121009

Li, P., Zhang, M., Zhai, Z., Niu, Q. J., Li, P., Hou, Y., et al. (2020). Precise assembly of a zeolite imidazolate framework on polypropylene support for the fabrication of thin film nanocomposite reverse osmosis membrane. J. Membr. Sci. 612, 118412. doi:10.1016/j.memsci.2020.118412

Li, S., Zheng, Z., Xia, S., Hu, J., Chen, L., Huang, L., et al. (2023). Fabrication of bamboo cellulose-based nanofiltration membrane for water purification by cross-linking sodium alginate and carboxymethyl cellulose and its dynamics simulation. Chem. Eng. J. 473 (1), 145403. doi:10.1016/j.cej.2023.145403

Li, Y., Cao, R., Shi, S., and Cao, H. (2023). GO–Polymer modified anion exchange membranes for antifouling antifouling. ACS Appl. Nano Mater., 6(19), 18255–18262. doi:10.1021/acsanm.3c03524

Liguori, S., and Wilcox, J. (2018) Design considerations for postcombustion CO2 capture with membranes. Elsevier eBooks, 385–413. doi:10.1016/b978-0-12-813645-4.00014-3

Lin, W., Zhang, Y., Li, D., Wang, X., and Huang, X. (2021). Roles and performance enhancement of feed spacer in spiral wound membrane modules for water treatment: a 20-year review on research evolvement. Water Res. 198 (June 1), 117146. doi:10.1016/j.watres.2021.117146

Líu, H., Wang, C., Sohn, W., Wang, Q., Shon, Ho K., and Sun, P. (2023). Source-separated urine treatment based on forward osmosis technology: performance, applications and future prospects. Desalination 565 (November 1), 116872. doi:10.1016/j.desal.2023.116872

López, J., Reig, M., Licon, E., Valderrama, C., Gibert, O., and Cortina, J. L. (2022). Evaluating the integration of nanofiltration membranes in advanced water reclamation schemes using synthetic solutions: from phosphorous removal to phosphorous circularity integration of nanofiltration membranes in advanced water reclamation schemes using synthetic solutions: from phosphorous removal to phosphorous circularity. Sep. Purif. Technol., 290, 120914. doi:10.1016/j.seppur.2022.120914

Lyu, Y., Ye, H., Zhao, Z., Tian, J., and Chen, L. (2015). “Exploring the cost of wastewater treatment in a chemical industrial Park: model development and application,” in Reverse osmosis: industrial processes and applications. Editor J. Kucera (Hoboken, NJ, USA: John Wiley & Sons).

Lyu, Y., Ye, H., Zhao, Z., Tian, J., and Chen, L. (2020). Exploring the cost of wastewater treatment in a chemical industrial Park: model development and application. Resour. Conservation Recycl. 155, 104663. doi:10.1016/j.resconrec.2019.104663

Melliti, E., Van Der Bruggen, B., and Elfil, H. (2023). Chemical inhibition of combined gypsum and iron oxides membrane fouling during reverse osmosis desalination process: prevention and regeneration of membranes. Desalination 551 (April 1), 116414. doi:10.1016/j.desal.2023.116414

Menon, S., Bansode, K., Nandi, S., and Kalyanraman, V. (2021). Impact of cleaning agents on properties of tubular polyvinylidene fluoride (PVDF) membrane. Mater. Today Proc. 47, 1466–1471. doi:10.1016/j.matpr.2021.03.722

Minier-Matar, J., Al-Maas, M., Hussain, A., Nasser, M. S., and Adham, S. (2022). Pilot-scale evaluation of forward osmosis membranes for volume reduction of industrial wastewater. Desalination 531, 115689. doi:10.1016/j.desal.2022.115689

Nassrullah, H., Anis, S. F., Hashaikeh, R., and Hilal, N. (2020). Energy for desalination: a state-of-the-art review. Desalination 491, 114569. ISSN 0011-9164. doi:10.1016/j.desal.2020.114569

Neto, G. L. O., De Oliveira, N. G. N., Delgado, J. M., Nascimento, L. P. C., Gomez, R. S., Cabral, A. S., et al. (2020). A new design of tubular ceramic membrane module for oily water treatment: multiphase flow behavior and performance evaluation. Membranes 10 (12), 403. doi:10.3390/membranes10120403

Ngo, M. T. T., Ueyama, T., Makabe, R., Bui, X., Nghiem, L. D., Nga, T. T. V., et al. (2021). Fouling behavior and performance of a submerged flat-sheet nanofiltration membrane system for direct treatment of secondary wastewater effluent. J. Water Process Eng. 41, 101991. doi:10.1016/j.jwpe.2021.101991

Parani, S., and Oluwafemi, O. S. (2021). Membrane distillation: recent configurations, membrane surface engineering, and applications. Membranes 11, 934. doi:10.3390/membranes11120934