- 1School of Mechanics and Electronics Engineering, Hainan University, Haikou, China

- 2College of Engineering, University of Kirkuk, Kirkuk, Iraq

- 3Mechanical Engineering Department, College of Engineering, Gulf University, Bahrain

- 4Department of Mechanical and Nuclear Engineering, University of Sharjah, Sharjah, United Arab Emirates

- 5Faculty of Mechanical and Automotive Engineering Technology, Universiti Malaysia Pahang, Pekan, Malaysia

- 6Department of Production Engineering and Metallurgy, University of Technology, Baghdad, Iraq

Alcohol-based fuels have gained more interest due to their production process and availability and environmental point of view so based alcohol-based fuel like fusel oil has been studied as an alternative fuel for compression ignition engine engines. The objective of this experimental study was to investigate the performance of a compression ignition engine based on a performance and emissions of cylinder single-cylinder diesel engine. To maintain the original fuel system of the engine, a fixed blending ratio of 20% v/v was used. The research findings indicated a decrease in nitrogen oxide (NO) emissions when using fusel oil–diesel (F20) compared to diesel. Still, higher fuel consumption was observed due to the lower energy content of fusel oil. However, F20 led to increased carbon monoxide (CO) emissions and hydrocarbons (HC) compared to diesel. The most significant reduction in NOx emissions by up to 20% occurred at an engine speed of 1,500 rpm and an engine load of 75%, possibly attributed to the higher water content in fusel oil. It is crucial to evaluate the trade-offs between these parameters carefully. Insight into these trade-offs may facilitate the optimization of fusel oil use as a prospective fuel alternative for internal combustion engines.

1 Introduction

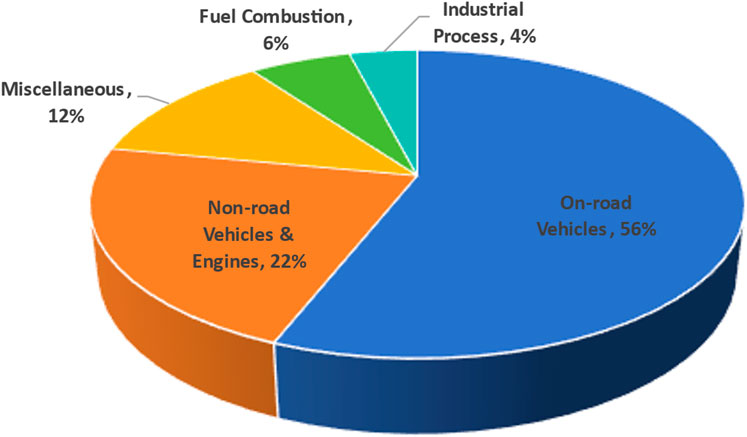

Prompt depletion of the global petroleum reserves, increased cost of the conventional petroleum fuels, and implementation of exhaust emission regulations for internal combustions (IC) engines due to environmental issues have all together created worthy demand for using other and renewable fuels in diesel engine engines (Demirbas, 2007; Karabektas and Hosoz, 2009; Asonja et al., 2013; Awad et al., 2018; Abdalla et al., 2019; Kamil et al., 2020; Abed et al., 2021; Abed et al., 2023a). Alcohol is seen not only as a replacement for traditional fuels, but also as the most investigated oxygenate for fuels globally, due to its oxygen content (Wu et al., 2020/07; Liu et al., 2019/12). Among available fuels, alcohol can be exploited as a versatile agent in the form of a blend with ordinary fuels in use already-in-use engines or biodiesel in form of addicts. (Agarwal, 2007; Bozbas, 2008; Janjić et al., 2015; Mahmudul et al., 2016; Awad et al., 2017; ABED et al., 2023). Environmental protection has been pushed to the forefront as a fundamental issue due to rising mobility, particularly in large economies. All advanced countries have implemented emission control measures to cut down on pollution from cars and trucks using internal combustion engines. Exhaust emissions from spark ignition engines and diesel engines have been lowered in a variety of ways. Some of these techniques aim to lower the levels of harmful gases by directly addressing the exhaust gases. The emissions of nitrogen oxides (NOx) from diesel engines are influenced by a range of factors, including fuel characteristics and the operational parameters of the engine (Mahmudul et al., 2016; Awad et al., 2017; Abed et al., 2023b). It is well acknowledged that NOx emissions arise as a result of elevated combustion temperatures and increased oxygen concentrations inside the cylinder. Alcohol often exhibits a lower temperature of the combustion as a result of their comparatively lower heating value and oxygen concentration. Carbon monoxide (CO) is largely produced via combustion activities. percentpercent Figure 1 shows the sources contributing to CO emissions. From the figure, it is clearly shown that the on-road vehicles are the highest contributors to CO emissions. Approx 56% of all the CO is emitted by on-road vehicles which is the largest segment, closely followed by non-road vehicles and engines constituting 22% of the total carbon monoxide. The miscellaneous contributes 12%, and fuel combustion and industrial processes account for 6% and 4% respectively. Overall, transportation and in particular vehicles on the road are the main sources of CO emissions (Dey and Dhal, 2019/12).

Figure 1. (Bacha et al., 2007). Sources of CO emission (Dey and Dhal, 2019/12).

It can be seen that the transportation sector especially on-road vehicles plays the biggest role in the CO emissions. Hence, it can be deduced from the chart that we need to deal with vehicle emissions to make the air quality better.

The idea of employing alcohol as an effective way of producing more eco-friendly diesel engines dates back more than 60 years. Also, much other research had been conducted on using alcohol like butanol, methanol, and ethanol as fuels for ICE. Regarding the experiment conducted by Ajav, et al. (Ajav et al., 1999) to measure the effect of using different percentages of ethanol-diesel mixtures on the engine performance at a constant speed, the specific fuel consumption (SFC) was increased by about 9% when comparing between mixture of diesel and pure diesel. In addition, He, et al. (He et al., 2003). conducted a study to know the effects of using ethanol-diesel emulsion fuel on a four-cylinder compression ignition (C.I) engine. was that study aimed to evaluate the impact of ethanol addition on performance parameters, including CO, Soot, and exhaust gas emissions (sulfursulfur dioxide (SO2), and nitrogen oxides (NOx)). The results indicated a significant increase of about 12.5% in NOx emissions, while CO and smoke outpouring were decreased. Additionally, the Sulphur dioxide (SO2) and inert matter also decreased.

Fusel oil is normally manufactured as a secondary product from ethyl alcohol manufacture, through the fermentation process and subsequent distillation. It is a naturally occurring source of amyl alcohols viz (Özgülsün et al., 2000; Dörmő et al., 2004; Ferreira et al., 2013). Fusel oil can be an alternative fuel to be used in an SI engine and its composition and quantity depends on several factors like source of carbon involved in manufacture of ethanol, the fermentation process, the method of preparation and the way of decomposition of fusion oil in the mixture. (Calam et al., 2014). The study of Awad (Abdalla et al., 2019) discussed the effects of fueling a 4-cylinder spark ignition engine with fusel oil as an octane booster in the gasoline fuel. The experiments took place for two different fusel oil-gasoline blend ratios and pure gasoline for different speeds and loads. and the regarded results support that fusel oil represented an efficient octane enhancer for gasoline blendstock in spark ignition engines. As a promising alternative fuel, fusel oil can serve as a feasible choice for on-demand octane enhancement applications using advanced technologies like fuel-flexible combustion cylinder systems and octane-on-demand systems, which can lower fuel consumption and emissions. More detonation control can increase the high octane number and the oxygen content, this can lead to desirable performance evolution at the high speed and rich fuel mixture with more complete combustion. Fusel oil enhanced brake power and brake thermal efficiency (BTE) with reference to the pure gasoline. Although the energy-conversion efficiency of the engine using fusel oil was comparable to that of gasoline, fusel oil caused an increase in BSFC, with a decrease of NOx. There is an increase in HC and CO2 emissions. Also Dongzhi Gao et al. (Gao et al., 2023) study addressed the technical feasibility of utilizing fusel, a production by-product of ethanol, as a clean fuel in a heavy-duty engine. The test-fuels were diesel and F20NW (20%anhydrous fusel), mostly being F20WW(20% hydrous fusel). Fusel enhanced BTE and lowered NOx and SOOT emissions, especially when EGR was optimized. Generally speaking, F20WWcould reduce more, that is fuel consumption, NOx, soot and CO2 emissions. According to the author, a 20%hydrous fusel with EGR could be implemented for diesel engines, which could help lowering the fuel consumption and emissions. Another study concludes similar findings Jia Liu et al. (Liu et al., 2023/03) found that the addition of 20 %of a by-product of ethanol fermentation known as fusel oil increased the brake thermal efficiency of diesel by 0.7%. Soot emissions were reduced by 47.5 percent, and NOx emissions reduced by 6.4%, without affecting fuel stability. The potential utilization of fusel oil as a viable alternative fuel can be recognized as a novel energy resource within the realm of diesel engines. Nevertheless, the investigation into the utilization of fusel oil in conjunction with diesel fuel has not been extensively documented in academic literature.

This research used a single-cylinder CI engine operating at four various engine loads and two speeds to investigate the effect of fusel oil–diesel F20 blends on engine exhaust emissions, fuel consumption, and temperature in comparison to pure diesel fuel.

2 Materials and methods

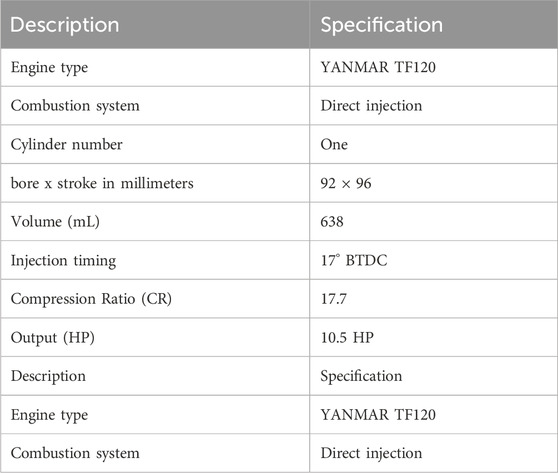

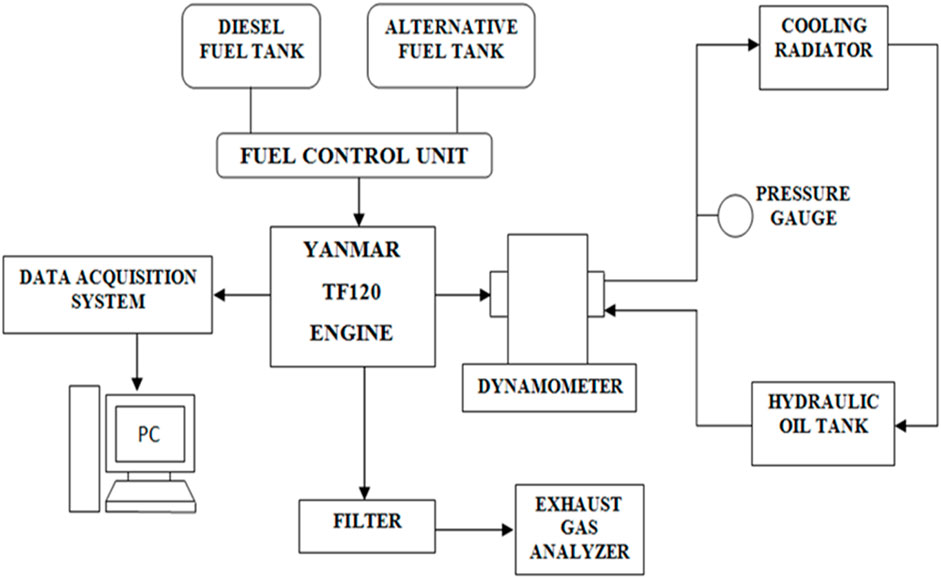

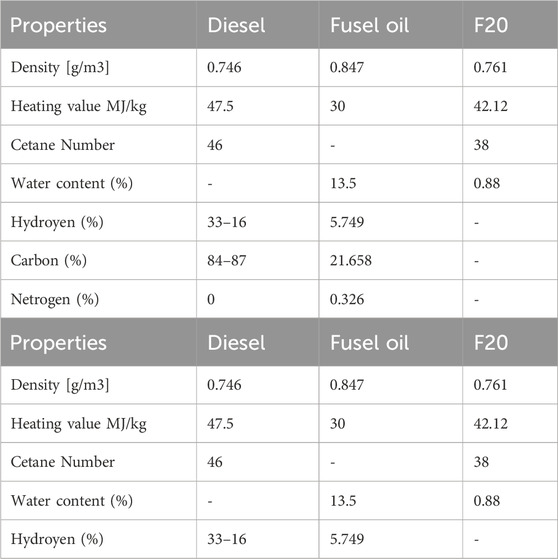

This study was carried out using a Hydrome model HGP-3A-F23 dynamometer and a single-cylinder Yanmar TF120 diesel engine with a 0.63 L and 17.7 Compression Ratio. The full specifications of the engine are listed in Table 1. Kane Automotive, a brand of exhaust gas analyzers, has also been used for exhaust gas analysis. The gas analyzer employed in this study was designed to collect engine exhaust samples and measure the levels of NOx, CO, CO2, and O2 in them. Straight through high-temperature tubing from the gas measuring point to the gas analyzer, exhaust gas was controlled. The measurement was done concurrently with engine testing and was statistically analyzed. Figure 2 depicts the engine test bed’s schematic diagram. During engine testing, TFX Engineering collected data using an in-cylinder pressure and a crank angle. Thermocouples K-type were used to measure the temperature, and data loggers were used to display the temperature readings. The temperatures that can be measured by this apparatus include ambient temperature, exhaust temperature, and intake temperature. Four engine loads (0%, 25%, 50%, and 75%) and two towing speeds (1,500 rpm and 2,100 rpm) were applied to the experimental vehicle. The test was completed using a blend of 20% vol fusel oil and 80% vol diesel (pour diesel F0 and fusel oil diesel blend F20). To gather the engine’s essential data, the test was conducted under steady-state conditions and initially with only pure diesel. In an experiment, engine emissions (CO2, CO, and NOx), exhaust temperature, and fuel consumption (FC) have all been measured.

3 Results

As previously stated, the experimental assessments were conducted on a singular-cylinder internal combustion engine using two fuels: pure diesel F0 (consisting of 100% volume diesel) and F20 (comprising 80% volume diesel and 20% volume fusel oil). The measurement of the engine’s fuel usage and exhaust temperature was conducted. The analysis focused on the engine emissions of CO, CO2, nitrogen oxides (NOx), and engine temperature. The findings are presented in the following manner:

3.1 Fuel consumptions

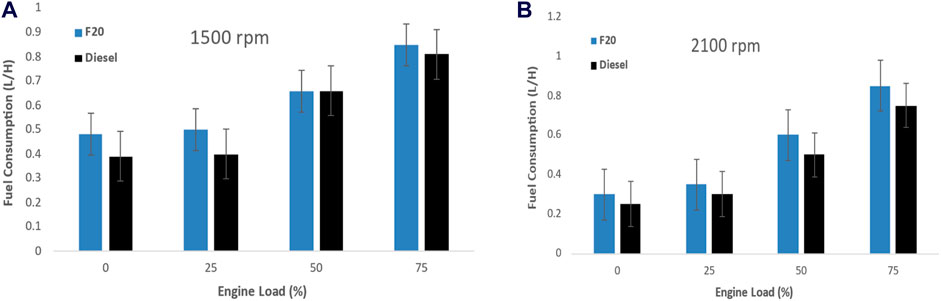

As the engine experiences higher loads and speeds, there is a corresponding increase in the energy transferred into the cylinder. The lower energy content of fusel oil in comparison to diesel (F0) resulted in a reduction in the energy content of the fuel test (F20), as seen in Table 2. Although the energy value of F20 in comparison to diesel is relatively low, it has been observed that the engine fuel consumption has slightly risen when using F0. Figure 3A, B illustrate the variations in fuel usage between F20 and F0 across various engine loads and speeds. Across all engine loads and speeds, the fuel consumption of F20 is consistently higher than that of diesel, indicating an improvement in the volumetric efficiency of F20. Alcohol-based fuels, it should be noted, have a higher latent heat of evaporation than diesel fuels. This characteristic enables the attainment of lower manifold temperatures and higher volumetric efficiency. (Bilgin et al., 2002; Yücesu et al., 2006).

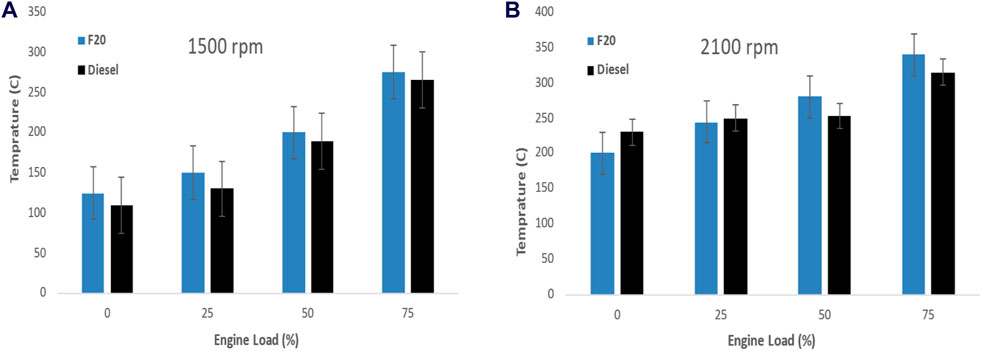

3.2 Gas exhaust temperature

Figures 4A, B depict the relationship between exhaust temperature and engine loads and speeds for the F20 and diesel F0, respectively. The temperature of diesel is somewhat greater than that of F20. Moreover, the highest recorded temperature at 1,500 was seen to be 255°C at a 75% engine load for pure diesel. Similarly, at 2,100 rpm and the same load, the temperature was 345°C. The elevated oxygen concentration present in fusel oil is expected to contribute to an increase in the in-cylinder temperature inside the combustion chamber, owing to its greater latent heat of evaporation. However, the presence of a significant amount of water in fusel oil adversely affects the combustion process, leading to a reduction in temperature.

Figure 4. Comparison of gas exhaust temperature for Diesel and F20 at (A) 1,500 rpm and (B) 2,100 rpm.

3.3 Emissions

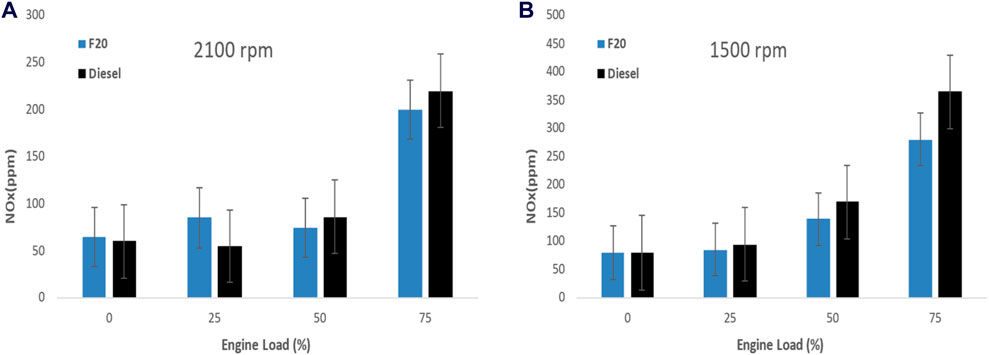

According to the engine’s operating conditions, the effect of fusel oil on emissions varies. Nitrogen oxides (NOx) are of notable relevance among the detrimental gaseous pollutants gained from a compression ignition engine. The production of NOx is significantly impacted by the temperature at which combustion happens, while other engine operating variables, such as engine speed and load, contribute to its emission. The production of thermal NOx takes place when temperatures beyond 1,500°C, and its pace experiences a significant escalation when temperatures surpass this critical point. In a comparative analysis, the use of fusel oil demonstrates a decrease in NOx emissions when compared to diesel, as seen in Figures 5A, B The decrease in combustion emissions may be ascribed to the presence of oxygen in fusel oil and alcohols, which facilitates a more thorough and environmentally friendly combustion process (Mittelbach and Remschmidt, 2004). Furthermore, NOx production is increased by a higher oxygen level in the mixture. (Solmaz and Çelikten, 2012; Yilmaz et al., 2013). As a consequence, the emission of nitrogen oxides (NOx) showed a reduction while using a fuel blend of F20 in comparison to the use of pure diesel fuel. The highest observed increase in NOx emissions occurred at an engine speed of 1,500 revolutions per minute (rpm) and an engine load of 75%.

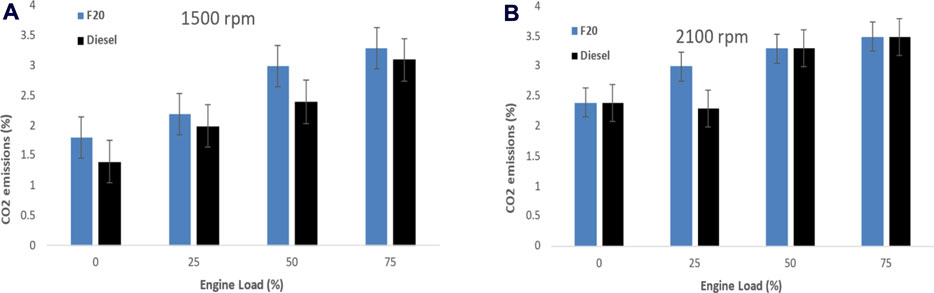

Figure 6A, B depict the carbon dioxide (CO2) emissions of F20 and pure diesel fuels across various engine loads and speeds. The findings indicate that the emission of CO2 showed an increase when exposed to F20 across all levels of engine loads and speeds. The primary factor contributing to the rise in emissions may be attributed to the elevated carbon-to-hydrogen ratio seen in fusel oil, as shown in Table 2. Additionally, the elevated oxygen concentration in fusel oil contributes to an increase in CO2 levels. The increase in CO2 levels seen while using F20 fuel at an engine speed of 2,100 rpm and a load of 75% was found to be 3% higher than when using pure diesel fuel.

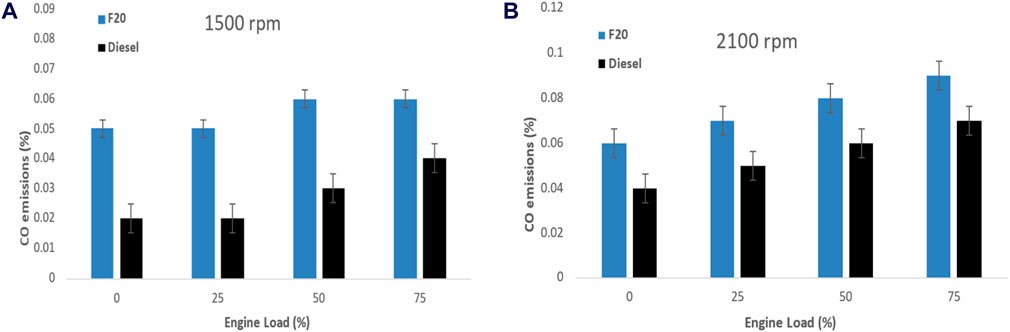

Figures 7A, B depict variations in carbon monoxide (CO) emissions under different engine loads (0%, 25%, 50%, and 75%) for two types of fuels, namely, F20 and pure diesel. The measurements were taken at two different engine speeds, specifically 1,500 and 2,100 revolutions per minute (rpm). In general, the use of alcohol-based fuelsfuels inside internal combustion engines leads to a discernible decrease in carbon monoxide (CO) emissions. The decrease in fuel consumption may be ascribed to the oxygen-rich nature and advantageous flammability attributes of alcohol-based fuels (Hsieh et al., 2002; Yüksel and Yüksel, 2004).

Nevertheless, the current investigation observed that the use of fusel oil, an alcohol-derived fuel, resulted in elevated carbon monoxide (CO) emissions, with a mean increment of 25%. The oxidation mechanism of the mixture is impacted by the temperatures inside the cylinder as the flame develops and spreads. Reduced in-cylinder temperatures have the potential to impede the achievement of full combustion, particularly in cases when the length of flame propagation is prolonged. In the context of fusel oil, the presence of water content led to a decrease in temperatures inside the combustion chamber, hence causing a significant rise in carbon monoxide (CO) emissions.

4 Conclusion

In summary, fusel oil, which is a by-product derived from the production of ethanol, is an energy source that has not been fully exploited and has promising advantages. The present research aimed to examine the utilization of diesel fuel and fuel oil-diesel blends in a single-cylinder four-stroke diesel engine with a compression ratio of 17.7. The engine was subjected to different engine loads and speeds throughout the experimental investigation.

The aforementioned data indicate that the addition of fusel oil to diesel results in an augmentation of the fuel’s oxygen content, accompanied by a reduction in its heating value. Consequently, the utilization of this blended fuel leads to heightened fuel consumption in comparison to the usage of pure diesel. Nevertheless, when subjected to certain operational circumstances, such as in F20 mixtures, the emissions of nitrogen oxides (NOx) were successfully reduced, with the most substantial decrease of 20% being seen at an engine speed of 1,500 revolutions per minute and an engine load of 75%.

In contrast, the incorporation of fusel oil resulted in a mean elevation of 30% and 10% in carbon monoxide (CO) and carbon dioxide (CO2) discharges, correspondingly, in comparison to undiluted diesel fuel. The rise in emissions may be ascribed to the reduction in in-cylinder temperatures induced by the presence of water in fusel oil, impeding the achievement of full combustion, especially during the propagation of the flame, leading to heightened levels of CO and CO2 emissions.

In general, it is worth noting that the use of fusel oil-diesel blends exhibits potential in mitigating NOx emissions. However, it is crucial to carefully evaluate the associated trade-off of elevated CO and CO2 emissions, necessitating more examination. Gaining insight into these trade-offs may facilitate the optimization of fusel oil use as a prospective fuel alternative for internal combustion engines.

Data availability statement

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

Author contributions

OA: Writing–original draft, Writing–review and editing. MK: Software, Writing–original draft. AA: Writing–original draft. OJ: Formal Analysis, Writing–original draft. OM: Funding acquisition, Writing–review and editing. MM: Validation, Writing–original draft. AA: Formal Analysis, Writing–original draft. MS: Investigation, Writing–review and editing. IY: Writing–review and editing.MH: Supervision, Writing–original draft.

Funding

The author(s) declare that financial support was received for the research, authorship, and/or publication of this article. This research was supported by Hainan University Scientific Research Start-up Fund Project KYQD (ZR)23157.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Abdalla, A. N., Awad, O. I., Tao, H., Ibrahim, T. K., Mamat, R., and Hammid, A. T. (2019). Performance and emissions of gasoline blended with fusel oil that a potential using as an octane enhancer. Energy Sources, Part A Recovery, Util. Environ. Eff. 41 (8), 931–947. doi:10.1080/15567036.2018.1521889

Abed, A. A., and Arslan, C. A. (2023). Study of the history matching and performance prediction analysis utilizing integrated material balance modeling in one Iraqi oil filed.

Abed, A. A., Arslan, C. A., and Sulaiman, I. N. (2023b). Study of the history matching and performance prediction analysis utilizing integrated material balance modeling in one Iraqi oil filed. J. Curr. Res. Eng. Sci. Technol. 9, 47–62.

Abed, A. A., Sulaiman, I. N., and Tawfeeq, Y. J. (2021). Enhancement of permeability estimation by high order polynomial regression for capillary pressure curve correlation with water saturation. Periodicals Eng. Nat. Sci. 9 (3), 788–795. doi:10.21533/pen.v9i3.2286

Abed, A. A., Suwaed, M. S., Al-Rubaye, A. H., Awad, O. I., Mohammed, M. N., Tao, H., et al. (2023a). Optimizing energy and reserve minimization in a sustainable microgrid with electric vehicle integration: dynamic and adjustable manta ray foraging algorithm. Processes 11 (10), 2848. doi:10.3390/pr11102848

Agarwal, A. K. (2007). Biofuels (alcohols and biodiesel) applications as fuels for internal combustion engines. Prog. energy Combust. Sci. 33 (3), 233–271. doi:10.1016/j.pecs.2006.08.003

Ajav, E., Singh, B., and Bhattacharya, T. (1999). Experimental study of some performance parameters of a constant speed stationary diesel engine using ethanol–diesel blends as fuel. Biomass Bioenergy 17 (4), 357–365. doi:10.1016/s0961-9534(99)00048-3

Asonja, A., Mikic, D., Stojanovic, B., Gligorić, R., Savin, L., and Tomic, M. (2013). Examination of motor oils in exploitation of agricultural tractors in process of basic treatment of plot. J. Balkan Tribol. Assoc.

Awad, O. I., Mamat, R., Ali, O. M., Othman, M. F., and Abdullah, A. (2017). Experimental study of performance and emissions of fusel oil-diesel blend in a single cylinder diesel engine. Int. J. Eng. Technol. 9 (2), 138–142. doi:10.7763/ijet.2017.v9.959

Awad, O. I., Mamat, R., Ali, O. M., Sidik, N., Yusaf, T., Kadirgama, K., et al. (2018). Alcohol and ether as alternative fuels in spark ignition engine: a review. Renew. Sustain. Energy Rev. 82, 2586–2605. doi:10.1016/j.rser.2017.09.074

Bacha, J., Freel, J., Gibbs, A., Gibbs, L., Hemighaus, G., Hoekman, K., et al. (2007). Diesel fuels technical review. San Ramon: Chevron Global Marketing.

Bilgin, A., Durgun, O., and Sahin, Z. (2002). The effects of diesel-ethanol blends on diesel engine performance. Energy sources. 24 (5), 431–440. doi:10.1080/00908310252889933

Bozbas, K. (2008). Biodiesel as an alternative motor fuel: production and policies in the European Union. Renew. Sustain. Energy Rev. 12 (2), 542–552. doi:10.1016/j.rser.2005.06.001

Calam, A., Solmaz, H., Uyumaz, A., Polat, S., Yilmaz, E., and Içingür, Y. (2014). Investigation of usability of the fusel oil in a single cylinder spark ignition engine. J. Energy Inst. 88, 258–265. doi:10.1016/j.joei.2014.09.005

Demirbas, A. (2007). Importance of biodiesel as transportation fuel. Energy policy 35 (9), 4661–4670. doi:10.1016/j.enpol.2007.04.003

Dey, S., and Dhal, G. C. (2019/12/01/2019). Materials progress in the control of CO and CO2 emission at ambient conditions: an overview. Mater. Sci. Energy Technol. 2 (3), 607–623. doi:10.1016/j.mset.2019.06.004

Dörmő, N., Bélafi-Bakó, K., Bartha, L., Ehrenstein, U., and Gubicza, L. (2004). Manufacture of an environmental-safe biolubricant from fusel oil by enzymatic esterification in solvent-free system. Biochem. Eng. J. 21 (3), 229–234. doi:10.1016/j.bej.2004.06.011

Ferreira, M. C., Meirelles, A. J., and Batista, E. A. (2013). Study of the fusel oil distillation process. Industrial Eng. Chem. Res. 52 (6), 2336–2351. doi:10.1021/ie300665z

Gao, D., Ikram, M., Geng, C., Wu, Y., Li, X., Jin, C., et al. (2023). Effects of anhydrous and hydrous fusel oil on combustion and emissions on a heavy-duty compression-ignition engine. Energies 16 (17), 6251. doi:10.3390/en16176251

He, B.-Q., Jian-Xin, W., Hao, J.-M., Yan, X.-G., and Xiao, J.-H. (2003). A study on emission characteristics of an EFI engine with ethanol blended gasoline fuels. Atmos. Environ. 37 (7), 949–957. doi:10.1016/S1352-2310(02)00973-1

Hsieh, W.-D., Chen, R.-H., Wu, T.-L., and Lin, T.-H. (2002). Engine performance and pollutant emission of an SI engine using ethanol–gasoline blended fuels. Atmos. Environ. 36 (3), 403–410. doi:10.1016/S1352-2310(01)00508-8

Janjić, N., Adamovic, Z., Nikolic, D., Asonja, A., and Stojanovic, B. (2015). Impact of diagnostics state model to the reliability of motor vehicles. J. Balkan Tribol. Assoc.

Kamil, M., Ramadan, K. M., Olabi, A. G., Al-Ali, E. I., Ma, X., and Awad, O. I. (2020). Economic, technical, and environmental viability of biodiesel blends derived from coffee waste. Renew. Energy 147, 1880–1894. doi:10.1016/j.renene.2019.09.147

Karabektas, M., and Hosoz, M. (2009). Performance and emission characteristics of a diesel engine using isobutanol–diesel fuel blends. Renew. Energy 34 (6), 1554–1559. doi:10.1016/j.renene.2008.11.003

Liu, H., Wang, X., Wu, Y., Zhang, X., Jin, C., and Zheng, Z. (2019). Effect of diesel/PODE/ethanol blends on combustion and emissions of a heavy duty diesel engine. Fuel 257, 116064. doi:10.1016/j.fuel.2019.116064

Liu, J., Dong, J., Li, X., Xu, T., Li, Z., Ampah, J. D., et al. (2023/03/01/2023). Technical analysis of blending fusel to reduce carbon emission and pollution emission of diesel engine. Fuel Process. Technol. 241, 107560. doi:10.1016/j.fuproc.2022.107560

Mahmudul, H., Hagos, F. Y., Mamat, R., Abdullah, A. A., and Awad, O. I. (2016). Experimental investigation of the impact of using alcohol-biodiesel-diesel blending fuel on combustion of single cylinder CI engine. IOP Conf. Ser. Mater. Sci. Eng. 160 1, 012038. doi:10.1088/1757-899x/160/1/012038

Mittelbach, M., and Remschmidt, C. (2004). Biodiesel: the comprehensive handbook. Martin Mittelbach.

Özgülsün, A., Karaosmanoglu, F., and Tüter, M. (2000). Esterification reaction of oleic acid with a fusel oil fraction for production of lubricating oil. J. Am. Oil Chemists' Soc. 77 (1), 105–109. doi:10.1007/s11746-000-0017-5

Solmaz, H., and Çelikten, İ. (2012). Estimation of number of vehicles and amount of pollutants generated by vehicles in turkey until 2030. Gazi Univ. J. Sci. 25 (2), 495–503.

Wu, Y., Zhang, X., Zhang, Z., Wang, X., Geng, Z., Jin, C., et al. (2020). Effects of diesel-ethanol-THF blend fuel on the performance and exhaust emissions on a heavy-duty diesel engine. Fuel 271, 117633. doi:10.1016/j.fuel.2020.117633

Yilmaz, E., Solmaz, H., Polat, S., and Altin, M. (2013). Effect of the three-phase diesel emulsion fuels on engine performance and exhaust emissions. J. Fac. Eng. Archit. Gazi Univ. 28 (1), 127–134.

Yücesu, H. S., Topgül, T., Cinar, C., and Okur, M. (2006). Effect of ethanol–gasoline blends on engine performance and exhaust emissions in different compression ratios. Appl. Therm. Eng. 26 (17), 2272–2278. doi:10.1016/j.applthermaleng.2006.03.006

Keywords: alcohol fuel, fusel oil, NOx emissions, engine emissions, diesel engine

Citation: Awad OI, Kamil M, Abed AA, Jamal O, Mohammed OK, Mohammed MN, Alobaid A, Suwaed MS, Yusri IM and Hasan MM (2024) Effect of by-product fusel oil-diesel blends fuel on emissions of single-cylinder CI engine. Front. Mech. Eng. 10:1459374. doi: 10.3389/fmech.2024.1459374

Received: 04 July 2024; Accepted: 24 July 2024;

Published: 21 August 2024.

Edited by:

Muhammad Jamshaid, Bahauddin Zakariya University, PakistanReviewed by:

Haifeng Liu, Tianjin University, ChinaAleksandar Ašonja, Business Academy University (Novi Sad), Serbia

Copyright © 2024 Awad, Kamil, Abed, Jamal, Mohammed, Mohammed, Alobaid, Suwaed, Yusri and Hasan. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Omar Ibraheem Awad, b21hcmlicjc4QGdtYWls

Omar Ibraheem Awad

Omar Ibraheem Awad Mohammed Kamil4

Mohammed Kamil4