- 1Department of Engineering, University of Perugia, Perugia, Italy

- 2Department of Information Engineering and Mathematics, University of Siena, Siena, Italy

The precision grasping capabilities of robotic hands is a key feature which is more and more required in the manipulation of objects in several unstructured fields, as for instance industrial, medical, agriculture and food industry. For this purpose, the realization of soft robotic fingers is crucial to reproduce the human finger skills. From this point of view the fingerpad is the part which is mostly involved in the contact. Particular attention must be paid to the knowledge of the mechanical contact behavior of soft artificial fingerpads. In this paper, artificial silicone fingerpads are applied to the last phalanx of robotic fingers actuated by tendons. The mechanical interaction between the fingerpad and a flat surface is analyzed in terms of deformations, contact areas and indentations. A reliable model of fingertip deformation properties provides important information for understanding robotic hand performance, that can be useful both in the design phase and for defining control strategies. The approach is based on theoretical, experimental, and numerical methods. The results will be exploited for the design of more effective robotic fingers for precision grasping of soft or fragile objects avoiding damages.

Introduction

Manipulators are essential elements of robots which are constituted of a mechanical structure with a terminal element known as end-effector. The end-effector has the effective responsibility of interacting with the object to be manipulated (Melchiorri and Kaneko, 2008; Carbone, 2012; Pozzi et al., 2022).

Grasping is the function to pick up and hold an object. Grasping and manipulation are fundamental abilities for humans and in several applications robots are employed to replicate the operation of human hands. Research in this field is very active and aimed at conceiving new designs for manipulators and grippers to improve the manipulation capabilities. The main tasks performed by a gripper are grasping and manipulation of objects; for this reason, they are specialized structures with few sensors and characterized by simple kinematic structures. The most modern grippers are more and more similar to human hands (Bennett et al., 2015; Shintake et al., 2018; Ke et al., 2021), and their design varies from grippers with two parallel fingers, to those that replicate the anthropomorphism of the human hand with articulated fingers and palm (Achilli et al., 2020; Achilli et al., 2021; Achilli et al., 2022; Shorthose et al., 2022).

Being very significative for many operations in work and human life, human hands are the subject of a wide range of engineering and technology research topics: human hand serves as an inspiration for constructing successful robotic hands and grippers, as well as the starting point for developing upper limb prostheses and haptic technologies. Human hands are strong end-effectors that humans use to grasp and manipulate items and tools, as well as perceptive means (Clemente 1981; Balasubramanian and Santos, 2014; Controzzi et al., 2014). The grasping taxonomies reported in literature are more than 100 (Feix et al., 2014) and the action of grasping can be defined according to different characteristics as power grasping and precision grasping. In precision grasps the object is generally small, and sometimes fragile and it is grasped between the finger-pads. Precision grasping is required in the manipulation of components in the industrial, agricultural, and medical fields (Payne and Yang, 2014; Low et al., 2016; Gong et al., 2022).

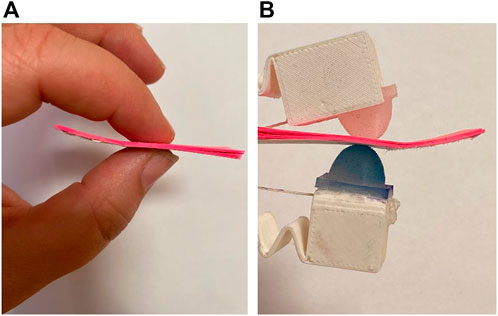

Figure 1 shows an example of both human and robotic fingers during precision grasp. As it possible to understand, the analysis of contact is an important issue to manage precision grasping with robotic fingers.

Since the contact between a hard gripper and a hard object can lead to shocks and consequent damages of the manipulated object, the compliance of grasping is a topic of great significance (Li et al., 2020). From this perspective, the use of advanced materials and soft components to make grippers is becoming an interesting practice (Salvietti et al., 2019).

3D printed materials such as PLA, ABS, TPU and silicone rubbers are becoming the most popular choice for grippers thanks to their ease of fabrication, low toxicity, and robustness (Elango and Faudzi, 2015; Malvezzi et al., 2019a; Malvezzi et al., 2019b; Dragusanu et al., 2022; Dragusanu et al., 2022b). Compliant materials are used for gripping components and pads with fingers made in PLA by 3D printing and soft components mold in silicone (Żur et al., 2019). Furthermore, in recent papers anthropomorphic grippers with partly soft components have been described (Catalano et al., 2014; Deimel and Brock, 2016) reproducing human fingertips (Pinel, 1990; Dzidek et al., 2017).

The objective of this paper is the study of contact of a silicone fingertip for robotic fingers with partly soft components. The considered artificial finger of a robotic gripper studied in (Dragusanu et al., 2022) is equipped with a silicone fingertip with the aim of performing precision grasping of objects exploiting the softness of the pad.

The attention of the paper is focused on the mechanical interaction between the fingerpad and a flat surface in terms of contact deformations, contact areas and indentations (Wu et al., 2003). The analysis is performed by exploiting both 2D and 3D techniques, considering a tribological point of view and correlating forces, displacements, and deformations of fingers. A Finite Element Model is set, and experimental results are compared with simulated and theoretical ones, obtained by applying some contact theories. The systematic contact analysis allowed to determine the relationship between contact force and deformation in soft robotic fingertips both numerically and experimentally. In particular, the correlation between applied force, indentation, and contact patch area is investigated. The results obtained from experimental measures are compared with the results from theoretical contact analysis.

This kind of research generates information that can be useful for designing and predict the contact in precision grasping of robotic hands having that kind of fingerpad. The main contribution of the paper is the identification of the contact properties of silicone fingertips to be applied to robotic underactuated grippers, in terms of contact patch and contact pressure distribution. Differently from fully actuated hands, in which joints can be precisely and independently controlled to perform complex manipulation tasks, in underactuated and soft robotic hands finger closure motion and grasp stability and robustness properties are related to the structural overall compliance, that depends both on joint stiffness, or finger structure deformation, and on contact properties (Prattichizzo et al., 2013). Notwithstanding the amount of studies on modelling, simulation and control of soft robotic grippers is increasing (Duriez and Bieze, 2017; George Thuruthel et al., 2018; Hussain et al., 2021), to the best of the author’s knowledge, fewer research is dedicated to contact properties. Contact patch extension, contact stiffness and pressure distribution have an important role in quantifying grasp robustness, stability, and stiffness (Malvezzi and Prattichizzo, 2013; Roa and Suárez, 2015).

The 2D analysis is carried out by taking ink fingerprints correlated with the applied forces, while the 3D analysis is performed by 3D deformation maps obtained by 3D optical scanners and a new experimental method inspired by (Valigi and Logozzo, 2019; Logozzo et al., 2022b; Landi et al., 2022) and using the 3D scanning technologies as in (Logozzo et al., 2018; Valigi et al., 2018; Affatato et al., 2020). The experiments were carried out using an instrumented plate and a reverse engineering method (Valigi et al., 2016; Valigi et al., 2019a; Valigi et al., 2019b). Theoretical contact models where applied and discussed (Schwarz, 2003; Adams et al., 2007; Heß and Popov, 2019). The main differences with the previously mentioned works are related to the fields of application of the methodology. Indeed, in this manuscript the methodology is used to analyze precision grasp of robotic fingers with silicone fingertips (Logozzo et al., 2022b). In addition, the applied methodology has been improved, as described in (Logozzo et al., 2022a).

The paper is structured as follows: in Section 2 the sample preparation is described together with the instruments and applied methodologies; Section 3 reports results of the experiments and numerical and theoretical analyses, discussing the comparison of results; Section 4 is dedicated to conclusions.

Materials and methods

Sample preparation

Material stiffness and gripper morphology typically define the deformation and kinematic capabilities in soft robot grippers made of one single material. The combination of soft materials with different properties in a single gripper is the solution to engineer deformation behavior required by the specific task in which the gripper is employed.

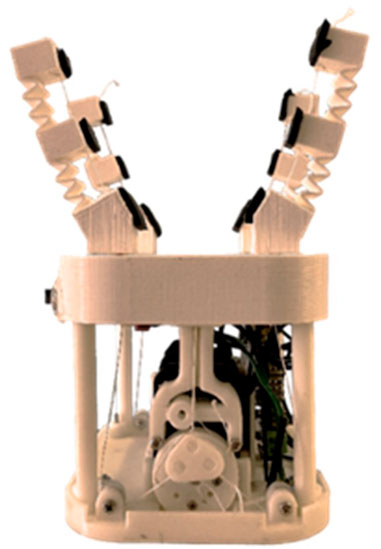

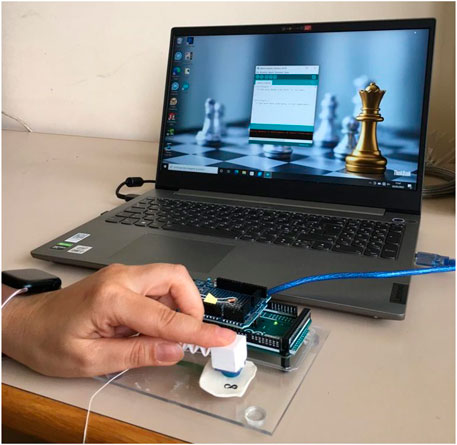

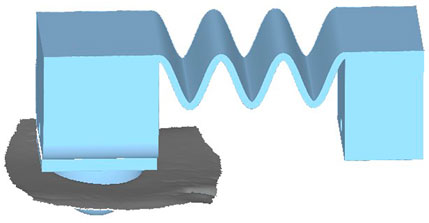

Therefore, soft grippers designers aim at systematically taking advantage of multi-material 3D printing for creating dexterous soft robotic devices. The studied finger belongs to a new type of robotic grippers named WaveJoints grippers and composed of 3D-printed fingers, actuated by tendons, in which each finger is a monolithic element composed of stiff parts (the phalanges) connected by flexible wave-shaped parts (Figure 2).

The fingers of the gripper were reproduced by 3D printing but a new element in silicone was added to simulate the human fingertip contact. The fingertip was made of EcoFlex 00–30 (Noor and Mahmud, 2015; Steck et al., 2019; Pozzi et al., 2021) and crafted using a 3D printed mould realized according to a proper design. After casting, the silicone fingerpad was mounted on the last phalanx of the WaveJoint finger (Figure 3).

The experimental contact analysis was carried out by means of both 2D and 3D techniques.

Experimental instruments and 3D contact analysis

The 3D study was based on the method used in (Logozzo et al., 2022b) with some variations, as reported in (Logozzo et al., 2022a). The applied method implies the use of 3D optical scanners and reverse engineering and inspection software but, with respect to (Logozzo et al., 2022b) in this work the indentation of the fingertip subjected to a certain force was measured by a digital force-displacement gauge. The materials and instruments used for the 3D contact analysis were:

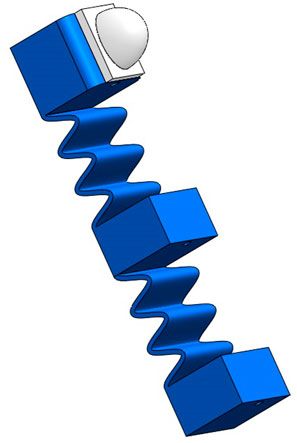

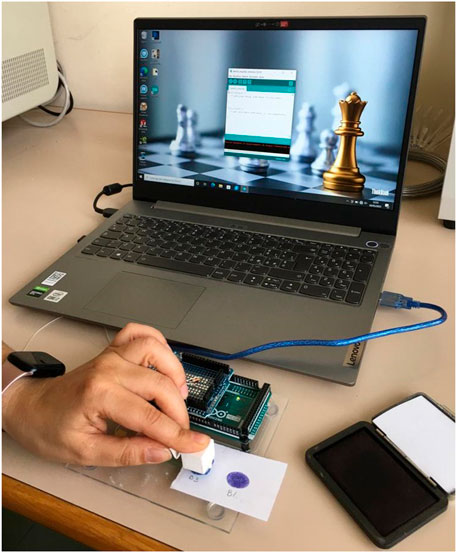

• A sensorized plate equipped with a force sensitive resistor (FSR) and controlled by Arduino

• A dough material to impress the fingerprint of the deformed fingerpad

• A digital force-displacement gauge

• A desktop 3D optical scanner

• A reverse engineering and inspection software

• A FEA software

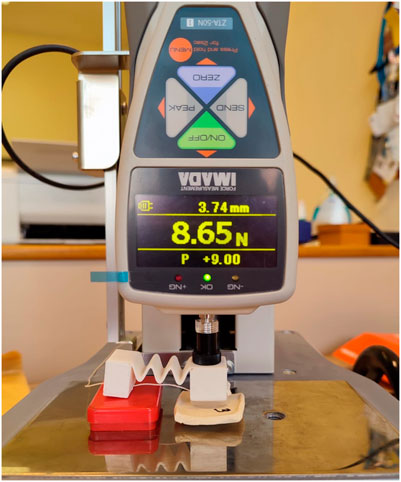

Six tests were performed with the silicone fingerpad. For each test a layer of dough material was put on the FSR on the sensorized plate and the silicone fingerpad was pressed against the plate measuring a compressive force while the deformation of the fingerpad was impressed on the dough layer (Figure 4).

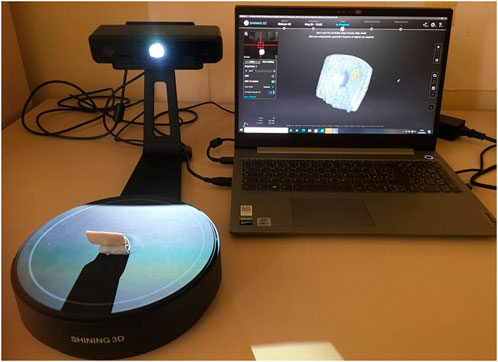

The 3D fingerprints on the dough material were left to harden to the open air. Given the values of the compressive forces measured by the FSR, the corresponding vertical displacement of the fingerpad (δ) was measured by a force-displacement gauge (ZTA 50-N, Imada, Japan), as represented in Figure 5. Then the 3D fingerprints were digitized by means of a desktop structured light 3D scanner (EinScan-SE, Shining 3D, China) with a scanning procedure comprising 12 turntable rotations and alignment based on feature recognition (Figure 6). The 3D scanning procedure was performed after calibration of the instrument. From this procedure the 3D digital models of the fingerprints impressed on the dough material were obtained in the form of triangular meshes. The 3D models of the fingerprints were imported in the mesh editing and inspection software (Geomagic, 3D Systems,US) together with the CAD model of the silicone fingertip. Then the two models were superimposed considering the indentation measured by the force-displacement gauge (Figure 7).

From this alignment the 3D indentation maps were reconstructed, which represented the deviation between the deformed and undeformed fingertip. Taking as a reference the undeformed fingertip, the indentation map displays the 3D distribution of deformations. The 3D alignment can also help to display the gross contact areas defined by the intersection curve between deformed and undeformed finger. This methodology can be applied until the indentation does not become higher than the equivalent radius of the indenter.

More insight about the 3D contact analysis proposed in this work can be found in (Logozzo et al., 2022a), where different experimental instruments are discussed with particular attention to 3D scanners and reverse engineering software. For instance, the accuracy of the 3D measurements depends on the performance parameters of the used 3D digitizers. In this paper an instrument with an accuracy grade of 0.1 mm for single frame was used. Trueness and precision of the contact area measurements depends both on the accuracy of the 3D digitizer and also on the alignment between the undeformed fingerpad model and the fingerprint model. In this work this alignment was guided by the indentations measured by the digital force-displacement gauge, but the accuracy and repeatability can also be improved using a second portable 3D scanner to digitize the fingerpad while it is imprinting on the dough material, as reported in (Logozzo et al., 2022a). In this work, this second 3D scanner was not used but the experimental contact area was also measured by using an additional method based on 2D ink fingerprints.

Numerical analysis

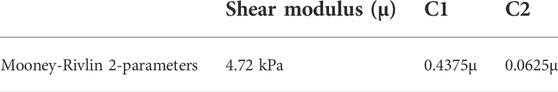

The numerical contact analysis was also performed by Finite Element Method (FEM) software. For the study, a hyperelastic material was chosen for the silicone part, considering a geometric nonlinearity (Jindrich et al., 2003; Sergachev et al., 2019). The used hyperelastic model was the 2-parameter Mooney-Rivlin one which simulates the behavior of Ecoflex 00–30 silicone (Pozzi et al., 2021). The material properties are described with the shear modulus μ and two Mooney-Rivlin constants C1 and C2, as reported in Table 1. The study applied a prescribed displacement to the fingerpad equal to the maximum displacement measured by the force-displacement gauge, as mentioned in section 2.2, with a fixed constraint on the rigid plate, to evaluate the deformation map of the component.

Experimental instruments and 2D contact analysis

The experimental 2D contact analysis was carried out using the following materials and instruments:

• A sensorized plate equipped with a force sensitive resistor (FSR) and controlled by Arduino

• Ink to create a fingerprint on a white paper

• A digital caliper

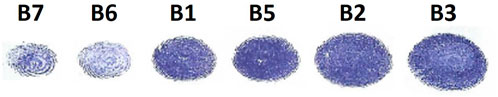

The tests were performed by wetting the silicone fingerpad with the ink and pressing it on a white paper laying on the FRS. The same compressive forces considered for the 3D tests were measured while the 2D fingerprint was impressed on the paper (Figure 8).

The obtained fingerprints had an ellipsoidal shape whose maximum and minimum semiaxes were measured by a caliper. These values were used to calculate the area of the fingerprint to be compared with the gross contact area resulting from the 3D measurements.

Theoretical contact analysis

Gross contact areas were also calculated according to the most common theoretical mechanical contact models and in particular the Hertz theory and the Johnson, Kendall and Roberts (JKR) model, considering a radius of curvature of the silicone-based finger equal to 5 mm.

The measured indentations and forces were used as inputs for the calculations of the theoretical radii of circular contact areas to be compared with the experimental ones (Schwarz, 2003; Adams et al., 2007; Dzidek et al., 2017; Heß and Popov, 2019; Sergachev et al., 2019). The Hertzian contact area was calculated based on the experimental indentation depth. The indentation was used to calculate the radius of the contact area which was in turn calculated as a circle area. Regarding the JKR model the analysis of the formation of the contact was considered, according to (Chokshi et al., 1993).

Results and discussion

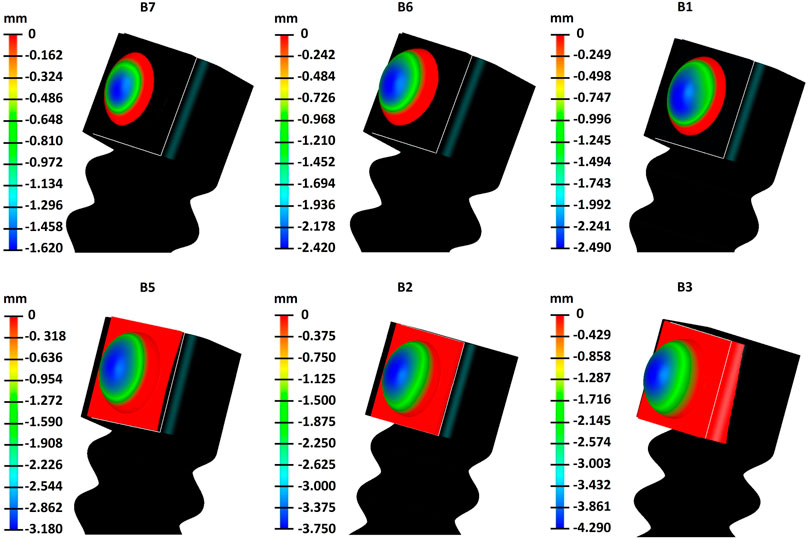

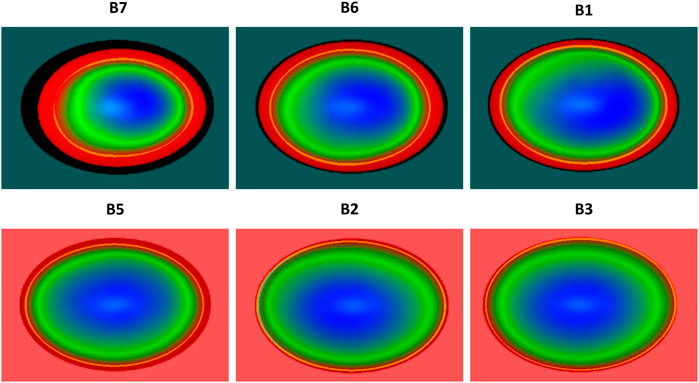

Results concerning the 3D deformation of the silicone fingerpad are given in terms of indentation maps, as represented in Figure 9. In Figure 10, the resulting gross contact areas are highlighted with an orange ellipse. Figure 11 shows the 2D fingerprints.

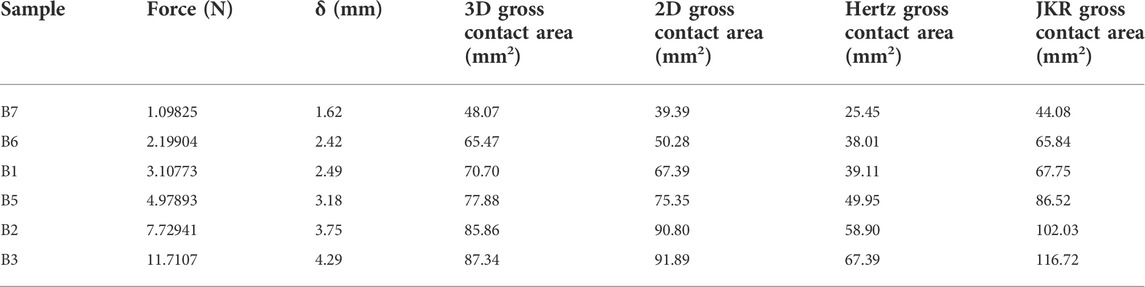

All the experimental and theoretical results are summarized in Table 2.

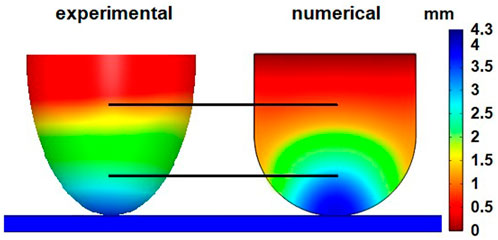

The 3D indentation map at the maximum displacement (4.29 mm) was compared to the deformation map obtained by FEM analysis. Results are displayed in Figure 12. As it can be observed, there is a slight difference between the experimental and simulated indentation maps. This difference is caused by the presence of the dough material in the experimental setup, which is necessary to take a plastic impression of the elastic deformation of the finger. Indeed, in the FEM simulation, the thickness, and the plastic deformation of the dough material, placed between the silicone fingertip and the rigid surface, are not considered.

From Table 2 one can observe that both 2D and 3D experimental results are not comparable with the theoretical results obtained by applying the Hertz theory. This evidence can be explained considering that the Hertz model does not take into account adhesion, which is not negligible in the case of soft materials as silicone (Morales-Hurtado et al., 2017; Ciavarella et al., 2019).

On the contrary, the JKR model which considers adhesion gives results which can be validated by the experimental data obtained both by 2D and 3D analyses. Results demonstrate that the JKR theory approximates 3D contact areas better than 2D ones and this can be due to the fact that the 3D experimental analysis gives better result to adhesion.

When the value of the indentation δ is close to the radius R of the indenter, the JKR model does not release reliable results, as this model is valid until δ << R. In this case, JKR overestimates the gross contact areas as demonstrated by samples B5, B2, B3.

For samples B7, B6, B1 and B5 the 2D gross contact area is lesser than the 3D one and this phenomenon can be explained considering that the 3D results also include the adhesion zone, due to the presence of the dough material.

For the samples B2 and B3, which are characterized by the deepest indentation, the presence of the dough material could have limited the lateral bulging of the silicone fingerpad, giving 3D gross contact areas lesser than the 2D ones.

The 3D contact analysis method has the capability to compute the distribution of the fingerpad 3D deformations and results allow to also display the lateral contact between a fingerpad and a soft object to be grasped.

Silicone has a hyperelastic behavior and also the dough material has an influence on the contact but considering the comparison between numerical results and the outcomes of the 3D contact analysis reported in Figure 12 one can conclude that the information about the 3D deformation distribution obtained by 3D contact analysis is reliable and gives fundamental insights to design partly soft grippers which have to grasp soft objects avoiding damages. Furthermore, the knowledge of the gross contact area can allow to better control the precision grasping operations.

Conclusion

Grasping and manipulating objects is one of the most prevalent activities in human everyday life, which is the reason why human hands and fingers have been taken as an inspiration to design several artificial grippers. This paper was focused on the contact analysis of soft fingerpads with the aim of evaluating the 3D distribution of deformations during the contact, indentations, and gross contact areas. Numerical, experimental, and theoretical analyses were performed, and results were compared and discussed.

Gross contact areas were evaluated by 3D and 2D experimental contact analyses and by theoretical contact models. 3D deformations of the fingerpad were detected by means of 3D indentation maps obtained by 3D scanning techniques and by FEM analysis.

Results demonstrated that the 3D contact analysis gave reliable information about contact deformations and areas, also considering the adhesive phenomenon typically affecting the contact of soft materials. This study put the basis for the study of contact of partly soft grippers for the design of compliant precision grasping. This work represents a first step in the characterization of soft robotic finger contact elements. As highlighted in the introductory part of the paper, the results of this study are useful in the design and control of soft robotic fingers, since contact properties are important elements in grasping and manipulation tasks. Another important field in which the results of this study could be exploited is the development of new tactile sensors (Yamaguchi and Atkeson, 2019; Gomes et al., 2020; Sun et al., 2022).

Future developments of this work will include a deeper investigation on material models including nonlinearities and anisotropy, an extension of the experimental test set with different sizes, shapes, and materials of the fingerpads.

Data availability statement

The raw data supporting the conclusion of this article will be made available by the authors, without undue reservation.

Author contributions

All authors listed have made a substantial, direct, and intellectual contribution to the work and approved it for publication.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Achilli, G. M., Logozzo, S., Valigi, M. C., and Malvezzi, M. (2021). “Preliminary study on multibody modeling and simulation of an underactuated gripper with differential transmission,” in Proceedings of the ASME Design Engineering Technical Conference, V009t009a005. doi:10.1115/DETC2021-72162

Achilli, G. M., Logozzo, S., Valigi, M. C., Salvietti, G., Prattichizzo, D., and Malvezzi, M. (2022). Underactuated soft gripper for helping humans in harmful works. Mech. Mach. Sci. 108, 264–272. doi:10.1007/978-3-030-87383-7_29

Achilli, G. M., Valigi, M. C., Salvietti, G., and Malvezzi, M. (2020). Design of soft grippers with modular actuated embedded constraints. Robotics 9 (4), 105–115. doi:10.3390/robotics9040105

Adams, M. J., Briscoe, B. J., and Johnson, S. A. (2007). Friction and lubrication of human skin. Tribol. Lett. 26 (3), 239–253. doi:10.1007/s11249-007-9206-0

Affatato, S., Valigi, M. C., and Logozzo, S. (2020). Knee wear assessment: 3D scanners used as a consolidated procedure. Materials 13 (10), 2349. doi:10.3390/ma13102349

Balasubramanian, R., and Santos, V. J. (2014). The human hand as an inspiration for robot hand development. Editors R. Balasubramanian, and V. Santos (Cham, Switzerland: Springer).

Bennett, D. A., Dalley, S. A., Truex, D., and Goldfarb, M. (2015). A multigrasp hand prosthesis for providing precision and conformal grasps. Ieee. ASME. Trans. Mechatron. 20 (4), 1697–1704. doi:10.1109/TMECH.2014.2349855

Chokshi, A., Tielens, A. G. G. M., and Hollenbach, D. (1993). Dust coagulation. Astrophys. J. 407 (2), 806–819. doi:10.1086/172562

Ciavarella, M., Joe, J., Papangelo, A., and Barber, J. R. (2019). The role of adhesion in contact mechanics. J. R. Soc. Interface 16, 20180738. doi:10.1098/rsif.2018.0738

Clemente, C. (1981). Anatomy: A regional atlas of the human body. 2nd ed. Baltimore. Munich: Urban and Achwarzengerg.

Controzzi, M., Cipriani, C., and Carrozza, M. C. (2014). Design of artificial hands: A review. Springer Tracts in Advanced Robotics., 219–246.

Dragusanu, M., Achilli, G. M., Valigi, M. C., Pratichizzo, D., Malvezzi, M., and Salvietti, G. (2022). The WaveJoints: A novel methodology to design soft-rigid grippers made by monolithic 3D printed fingers with adjustable joint stiffness". Philadelphia, PA, USA: ICRA.

Duriez, C., and Bieze, T. (2017). Soft robot modeling, simulation and control in real-time. Biosyst. Biorobotics 17, 103–109. doi:10.1007/978-3-319-46460-2_13

Dzidek, B. M., Adams, M. J., Andrews, J. W., Zhang, Z., and Johnson, S. A. (2017). Contact mechanics of the human finger pad under compressive loads. J. R. Soc. Interface 14 (127), 20160935. doi:10.1098/rsif.2016.0935

Feix, T., Bullock, I. M., and Dollar, A. M. (2014). Analysis of human grasping behavior: Correlating tasks, objects and grasps. IEEE Trans. Haptics 7 (4), 430–441. doi:10.1109/TOH.2014.2326867

George Thuruthel, T., Ansari, Y., Falotico, E., and Laschi, C. (2018). Control strategies for soft robotic manipulators: A survey. Soft Robot. 5 (2), 149–163. doi:10.1089/soro.2017.0007

Gomes, D. F., Lin, Z., and Luo, S. (2020). “GelTip: A finger-shaped optical tactile sensor for robotic manipulation,” in IEEE International Conference on Intelligent Robots and Systems, 9903–9909. doi:10.1109/IROS45743.2020.9340881

Gong, L., Wang, W., Wang, T., and Liu, C. (2022). Robotic harvesting of the occluded fruits with a precise shape and position reconstruction approach. J. Field Robot. 39 (1), 69–84. doi:10.1002/rob.22041

Heß, M., and Popov, V. L. (2019). Voltage-induced friction with application to electrovibration. Lubricants 7 (12), 102. doi:10.3390/LUBRICANTS7120102

Hussain, I., Malvezzi, M., Gan, D., Iqbal, Z., Seneviratne, L., Prattichizzo, D., et al. (2021). Compliant gripper design, prototyping, and modeling using screw theory formulation. Int. J. Rob. Res. 40 (1), 55–71. doi:10.1177/0278364920947818

Jindrich, D. L., Zhou, Y., Becker, T., and Dennerlein, J. T. (2003). Non-linear viscoelastic models predict fingertip pulp force-displacement characteristics during voluntary tapping. J. Biomechanics 36 (4), 497–503. doi:10.1016/S0021-9290(02)00438-4

Ke, A., Huang, J., and He, J. (2021). “A new anthropomorphic thumb configuration with passive finger torsion,” in IEEE International Conference on Mechatronics and Automation (ICMA)), 890–896. doi:10.1109/ICMA52036.2021.9512684

Landi, L., Logozzo, S., Morettini, G., and Valigi, M. C. (2022). Withstanding capacity of machine guards: Evaluation and validation by 3D scanners. Appl. Sci. Switz. 12 (4), 2098. doi:10.3390/app12042098

Li, B., Hauser, S., and Gerling, G. J. (2020). “Identifying 3-D spatiotemporal skin deformation cues evoked in interacting with compliant elastic surfaces,” in IEEE Haptics Symposium, HAPTICS, 2020-March, 35–40. doi:10.1109/HAPTICS45997.2020.ras.HAP20.22.5a9b38d8

Logozzo, S., Valigi, M. C., and Canella, G. (2018). Advances in optomechatronics: An automated tilt-rotational 3D scanner for high-quality reconstructions. Photonics 5 (4), 42. doi:10.3390/photonics5040042

Logozzo, S., Valigi, M. C., and Malvezzi, M. (2022a). A methodology to evaluate contact areas and indentations of human fingertips based on 3D techniques for haptic purposes. MethodsX 9, 101781. doi:10.1016/j.mex.2022.101781

Logozzo, S., Valigi, M. C., and Malvezzi, M. (2022b). Modelling the human touch: A basic study for haptic technology. Tribol. Int. 166, 107352. doi:10.1016/j.triboint.2021.107352

Low, J. H., Lee, W. W., Khin, P. M., and Kukreja, S. (2016). “A compliant modular robotic hand with fabric force sensor for multiple versatile grasping modes,” in 6th IEEE International Conference on Biomedical Robotics and Biomechatronics, 1230–1235. doi:10.1109/BIOROB.2016.7523799

Malvezzi, M., and Prattichizzo, D. (2013). “Evaluation of grasp stiffness in underactuated compliant hands,” in Proceedings - IEEE International Conference on Robotics and Automation), 2074–2079. doi:10.1109/ICRA.2013.6630855

Morales-Hurtado, M., de Vries, E. G., Peppelman, M., Zeng, X., van Erp, P. E. J., and van der Heide, E. (2017). On the role of adhesive forces in the tribo-mechanical performance of ex vivo human skin. Tribol. Int. 107, 25–32. doi:10.1016/j.triboint.2016.11.006

Noor, S. N. A. M., and Mahmud, J. (2015). “Modelling and computation of silicone rubber deformation adapting neo-hookean constitutive equation,” in Proceedings - 2015 5th International Conference on Communication Systems and Network Technologies (Gwalior: CSNT 2015), 7280134. doi:10.1109/CSNT.2015.276

Payne, C. J., and Yang, G.-Z. (2014). Hand-held medical robots. Ann. Biomed. Eng. 42 (8), 1594–1605. doi:10.1007/s10439-014-1042-4

Pozzi, M., Achilli, G. M., Valigi, M. C., and Malvezzi, M. (2022). Modeling and simulation of robotic grasping in simulink through simscape multibody. Front. Robot. AI 9, 873558. doi:10.3389/frobt.2022.873558

Pozzi, M., Gaudeni, C., Iqbal, Z., Prattichizzo, D., and Malvezzi, M. (2021). Modeling a sensorized soft layer for adding compliance to the environment in robotic manipulation. Mech. Mach. Sci. 91, 370–377. doi:10.1007/978-3-030-55807-9_42

Prattichizzo, D., Malvezzi, M., Gabiccini, M., and Bicchi, A. (2013). On motion and force controllability of precision grasps with hands actuated by soft synergies. IEEE Trans. Robot. 29 (6), 1440–1456. doi:10.1109/TRO.2013.2273849

Roa, M. A., and Suárez, R. (2015). Grasp quality measures: Review and performance. Auton. Robots 38 (1), 65–88. doi:10.1007/s10514-014-9402-3

Salvietti, G., Malvezzi, M., Iqbal, Z., and Eslami, T. (2019). “Soft hands with embodied constraints: The soft scoopgripper,” in In Proceedings of the 2019 International Conference on Robotics and Automation (New York: ICRA 2019), 2758–2764. doi:10.1109/ICRA.2019.8793563

Schwarz, U. D. (2003). A generalized analytical model for the elastic deformation of an adhesive contact between a sphere and a flat surface. J. Colloid Interface Sci. 261 (1), 99–106. doi:10.1016/S0021-9797(03)00049-3

Shintake, J., Cacucciolo, V., Floreano, D., and Shea, H. (2018). Soft robotic grippers. Adv. Mater. 30 (29), 1707035. doi:10.1002/adma.201707035

Shorthose, O., Albini, A., He, L., and Maiolino, P. (2022). Design of a 3D-printed soft robotic hand with integrated distributed tactile sensing. IEEE Robot. Autom. Lett. 7 (2), 3945–3952. doi:10.1109/LRA.2022.3149037

Steck, D., Qu, J., Kordmahale, S. B., Tscharnuter, D., Muliana, A., and Kameoka, J. (2019). Mechanical responses of Ecoflex silicone rubber: Compressible and incompressible behaviors. J. Appl. Polym. Sci. 136 (5), 47025. doi:10.1002/app.47025

Sun, H., Kuchenbecker, K. J., and Martius, G. (2022). A soft thumb-sized vision-based sensor with accurate all-round force perception. Nat. Mach. Intell. 4 (2), 135–145. doi:10.1038/s42256-021-00439-3

Valigi, M. C., Logozzo, S., and Affatato, S. (2019a). In vitro 3D wear characterization of knee joint prostheses. Mech. Mach. Sci. 73, 3855–3863. doi:10.1007/978-3-030-20131-9_382

Valigi, M. C., Logozzo, S., Butini, E., Meli, E., Marini, L., and Rindi, A. (2018). “Experimental evaluation of tramway track wear by means of 3D metrological optical scanners,” in Proceedings of the 11th International Conference on Contact Mechanics and Wear of Rail/Wheel Systems (Delft: CM2018), 1007–1012.

Valigi, M. C., Logozzo, S., Canella, G., and De Angelis, F. (2019b). Reverse engineering techniques: From 3D scanning to the CAD file in the concrete industry. Bet. und Fertigteil-Technik/Concrete Plant Precast Technol. 85 (5), 50–57.

Valigi, M. C., and Logozzo, S. (2019). Do exostoses correlate with contact disfunctions? A case study of a maxillary exostosis. Lubricants 715 (2). doi:10.3390/lubricants7020015

Valigi, M. C., Logozzo, S., and Rinchi, M. (2016). Wear resistance of blades in planetary concrete mixers. Part II: 3D validation of a new mixing blade design and efficiency evaluation. Tribol. Int. 103, 37–44. doi:10.1016/j.triboint.2016.06.040

Wu, J. Z., Dong, R. G., Smutz, W. P., and Rakheja, S. (2003). Dynamic interaction between a fingerpad and a flat surface: Experiments and analysis. Med. Eng. Phys. 25 (5), 397–406. doi:10.1016/S1350-4533(03)00035-3

Yamaguchi, A., and Atkeson, C. G. (2019). Recent progress in tactile sensing and sensors for robotic manipulation: Can we turn tactile sensing into vision?1. Adv. Robot. 33 (14), 661–673. doi:10.1080/01691864.2019.1632222

Keywords: grasping, robotic finger, manipulation, 3D scanner, robotic gripper, contact mechanics

Citation: Achilli GM, Logozzo S, Malvezzi M and Valigi MC (2022) Contact mechanics analysis of a soft robotic fingerpad. Front. Mech. Eng 8:966335. doi: 10.3389/fmech.2022.966335

Received: 10 June 2022; Accepted: 25 July 2022;

Published: 24 August 2022.

Edited by:

Markus Heß, Technical University of Berlin, GermanyReviewed by:

Lorenzo Scalera, University of Udine, ItalyShaoting Lin, Massachusetts Institute of Technology, United States

Copyright © 2022 Achilli, Logozzo, Malvezzi and Valigi. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Maria Cristina Valigi, bWFyaWFjcmlzdGluYS52YWxpZ2lAdW5pcGcuaXQ=

Gabriele Maria Achilli

Gabriele Maria Achilli Silvia Logozzo

Silvia Logozzo Monica Malvezzi

Monica Malvezzi Maria Cristina Valigi

Maria Cristina Valigi