- 1State Key Laboratory for Geomechanics and Deep Underground Engineering, School of Mechanics and Civil Engineering, School of Materials and Physics, China University of Mining and Technology, Xuzhou, China

- 2State Key Laboratory of Mechanics and Control of Mechanical Structures, Nanjing University of Aeronautics and Astronautics, Nanjing, China

- 3State Key Laboratory of Solid Lubrication, Lanzhou Institute of Chemical Physics, Chinese Academy of Sciences, Lanzhou, China

Due to the unique properties, two-dimensional materials and van der Waals heterostructures play an important part in microelectronics, condensed matter physics, stretchable electronics and quantum sciences. But probing properties of two-dimensional materials and van der Waals heterostructures is hard as a result of their nanoscale structures, which hinders their development and applications. Therefore, the progress of contact probing measurement in recent years including mechanical properties, interfacial properties, tribological properties, as well as electrical properties are summarized in this paper. It is found that useful properties such as Young’s modulus, adhesive energy, friction coefficient and so on can be well estimated from contact probing methods. We believe that the contact probing methods will be more advanced to promote the blooming applications of two-dimensional materials and van der Waals heterostructures.

1 Introduction

Compared with bulk materials, two-dimensional (2D) materials (Bhimanapati et al., 2015; Cheng et al., 2019; Su et al., 2021) are of typical membrane structure with thickness of only a few angstrom. Since graphene was first discovered by Novoselov et al. (2004), new members of 2D material family, e.g., h-BN (Golberg et al., 2010), transition metal dichalcogenides (TMDs) (Chhowalla et al., 2013), black phosphorous and MXenes (Tran et al., 2014; Lu et al., 2015; Bu et al., 2020; Ihsanullah, 2020) have been fabricated and developed. Due to the versatile electrical, chemical, thermal, optical and mechanical properties (Kang et al., 2016; Lee and Park, 2017; Wu et al., 2018a; Jiang et al., 2019; Du et al., 2020; Zhao and Qin, 2021), the 2D material family has drawn great attentions of scientists and engineers and become the research hotspot in scientific studies of various fields. More recently, by assembling 2D materials via van der Waals (vdW) interactions, vdW heterostructures (Jariwala et al., 2017; Liao et al., 2019b; Geng et al., 2019; Liu et al., 2020; Onodera et al., 2020) are proposed and fabricated, which provide a platform of combining distinct two-dimensional materials and designing novel devices of special mechanical, electrical and magnetic properties. For example, the graphene/TMDs heterostructure exhibits totally different mechanical and electronic properties compared with single graphene and TMDs. In order to enhance our knowledge and accelerate applications of 2D materials and vdW heterostructures, it is crucial to measure and characterize their mechanical, interfacial, tribological, and electrical properties properly through suitable strategies (Das Sarma et al., 2011; Britnell et al., 2013; Hong et al., 2014; Deng et al., 2016).

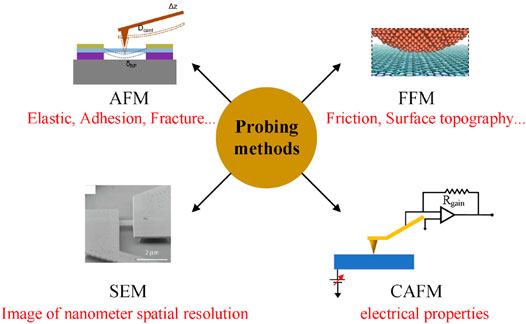

In past decades, many efforts have been done on contact probing methods of two-dimensional materials and vdW heterostructures. With the development of scientific instruments, e.g., atomic force microscopy (AFM), friction force microscopy (FFM), scanning electron microscopy (SEM), as shown in Figure 1, contact probing measurement has become key methods in characterizing properties of 2D materials and vdW heterostructures. Specifically, by using AFM, the indentation load-displacement relationships of 2D materials and the corresponding substrates can be measured, and thus the mechanical properties can be measured with the help of analytical models. What is more, combined with AFM, the blister test can be used to measure interfacial adhesive energy. Derived from AFM, FFM exploits the AFM tip to make in-plane scratch on 2D materials and vdW heterostructures, and makes use of the topographic map and friction curve to explore the interfacial and tribological properties. Different from AFM and FFM, SEM is not used independently but as an auxiliary means to measure 2D materials. For instance, obtained results will be more accurate by combining the probe of AFM and the assisted image of SEM.

FIGURE 1. Some probing methods of 2D materials and vdW heterostructures and their application scenarios. AFM can be used to test the elastic properties, interface properties and fracture properties of 2D materials. FFM can be used to measure the friction of 2D materials and draw the surface topography. SEM can provide nanoscale high-resolution images. CAFM can be used to measure the electrical properties of 2D materials. Inserted figures are reproduced with permission (Huang et al., 2011; Ye et al., 2012; Tao et al., 2015).

So far, many works have reported and summarized the contact probing methods for bulk materials (VanLandingham, 2003; Cheng and Cheng, 2004; Chen, 2012). Meanwhile, increasing scientific literatures and works are developing on probing methods for 2D materials and vdW heterostructures. However, due to high precision requirement and the difficulty of sample preparation, it is impossible for scientific researchers and engineers to have a comprehensive understanding of the new progresses in contact probing methods for 2D materials and vdW heterostructures, which hinders their development and applications. What is more, contact probing measurement of properties of 2D materials and vdW heterostructures is hard as a result of their nanoscale structures, which is different from the characterization of bulk materials. Therefore, it is key to introduce and summarize representative works of contact probing properties of 2D materials and vdW heterostructures, which are of importance in microelectronics, condensed matter physics, stretchable electronics and quantum sciences.

In this mini review, we focus on recent progress of contact probing measurement of 2D materials and vdW heterostructures. The working mechanism of contact probing method and the measurement of mechanical properties of 2D materials and vdW heterostructures are introduced first. Then, the measurement of interfacial properties is discussed in Section 3. Section 4 introduces the measurement of tribological behavior of 2D materials. In Section 5, the contact probing measurement of electrical properties of 2D materials and vdW heterostructures are given. Finally, conclusion and perspectives of contact probing methods are presented. The results of the paper should be helpful for the blooming scientific researches and applications of 2D materials and vdW heterostructures.

2 The Measurement of Mechanical Properties

To obtain mechanical properties of bulk materials such as Young’s modulus, shear modulus, Poisson’s ratio, strength, fracture toughness, hardness, etc., traditional measurement methods include the tensile test, the compressive test, impact test as well fatigue test and so on. However, due to the difficult manipulation and other restricted conditions of 2D materials and vdW heterostructures, these traditional methods cannot function very well. Thus, contact probing methods are thus be designed and employed to measure mechanical properties of 2D materials and vdW heterostructures with the help of the force feedback from direct contact and optical measurement.

2.1 Nanoindentation Model

The mechanical properties of 2D materials can obtained by indentation. During the loading process, the indentation load-displacement relationship is recorded. According to existing research, the applied force F and the probing depth d have the following relationship (Cao and Gao, 2019),

Where

Though the working mechanism of contact probing measurement is simple, while accurate measurement of mechanical properties of 2D materials and vdW heterostructures highly depends on the setup of contact probing experiment and the choice of theoretical models. In existing theoretical models, the effect of the tip is treated as a point load except cases that the ratio of sample size to tip radius is not large enough.

2.2 Clamped Beam Model

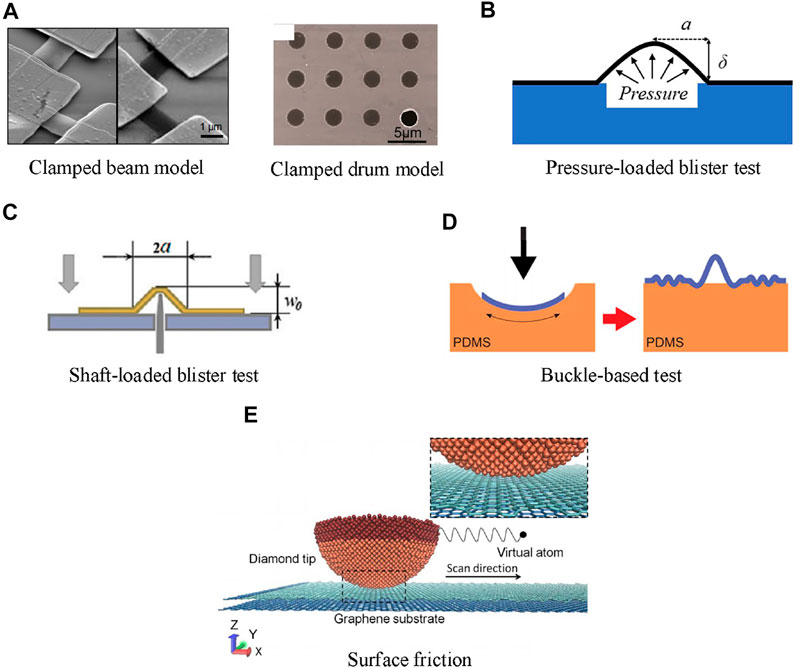

As shown in Figure 2A, the clamped beam is a typical experimental setup in contact probing experiments. For the clamped beam model, the parameters in Eq. 1 should be

FIGURE 2. (A) Two different models of nanoindentation: clamped beam model and clamped drum model. Reproduced with permission (Lin et al., 2013; Tao et al., 2015). (B) Sketch of pressure-loaded blister test. When the pressure in the micro cavity is greater than the external pressure, the 2D materials will be delaminated. blister test: pressure-loaded blister test and shaft-load blister test.

Until now, Frank et al. (2007) used this model to measure effective spring constants of stacks of graphene sheets, which agrees well with the value of dimension analysis. With the clamped beam model, the elastic properties of thin clay tactoids were studied by Kunz et al. (2009). Recently, Tao et al. (2015) conducted the contact probing experiment of a clamped black phosphorous beam. What is more, Yang et al. (2017b) studied the brittle fracture of 2D MoSe2, whose average fracture strength was 4.8 ± 2.9 Gpa.

2.3 Clamped Drum Model

Compared with the clamped beam model, it is easier to fabricate clamped drums in experiment. For the clamped drum model, the parameters in Eq. 1 should be

The elastic properties of monolayer graphene and suspended MoS2 were measured by using this model (Castellanos-Gomez et al., 2012).

Lee et al. (2008) measured the elastic properties and intrinsic strength of monolayer graphene, whose breaking strength was 42 N m−1, and Young’s modulus was 1.0 Tpa. Lin et al. (2013) studied the mechanical properties of graphene grown by chemical vapor deposition (CVD), and found that it is important to determine the zero-displacement point of the force-displacement curve precisely. The elastic properties of suspended MoS2 sheet was studied by Castellanos-Gomez et al. (2012), and the Young’s modulus for ultrathin MoS2 flakes was 0.33 ± 0.07 Tpa. Bertolazzi et al. (2011) studied stretching and breaking of ultrathin MoS2. In addition, Hatter et al. (2020) measured elastic properties of MXene reinforced epoxy composites with this model.

It is worth noting that the clamped drum model rather than the clamped beam model are used in existing nanoindentation molecular dynamics (MD) simulation. Zhao et al. (2013) obtained the temperature-dependent mechanical properties of monolayer MoS2. Tan et al. (2013) studied the size effect of indenter on probing results. Mechanical properties and thickness-determined fracture of h-BN were studied by Liu et al. (2021). In addition, Mallick and Elder (2018) measured the mechanical properties of graphene/h-BN heterostructures.

A final note about nanoindentation test is that, whether it is clamped beam model or clamped drum model, there will be slippage in the process of indentation. The slippage will cause errors in the experiment (Dai and Lu, 2021). However, different clamping methods may lead to different results. For example, in the work of Tao et al. (2015), the end of black phosphorus beam was sandwiched between Au and SiO2. In the work of Lee et al. (2008), 2D materials are laid on a pre-fabricated cavity substrate via vdW interaction. These two different clamping methods may lead to different results.

3 The Characterization of Interfacial Properties

Interfacial properties, such as adhesive energy, are key parameters in various applications of 2D materials, especially, 2D materials are usually fixed on or transferred to certain substrates. In addition, the stability of vdW heterostructures also depends on its interfacial properties. In order to assemble 2D materials and obtain stable vdW heterostructures, various contact probing methods (Jin, 2008; Zhao et al., 2010; Koenig et al., 2011; Bunch and Dunn, 2012; Na et al., 2012; Lou et al., 2020) have been developed and analyzed.

3.1 The Blister Test

As shown in Figure 2B, the pressure-loaded blister test is generally performed by generating a pressure difference between inside and outside of the sealed microcavity. AFM can be used to measure the geometry of blister, including maximum deflection

Different from the pressure-loaded blister test, the shaft-loaded blister (SLBT) test is another traditional measuring method of adhesive energy (Na et al., 2012). For the shaft-loaded blister test, a substrate with a pre-existing hole should be fabricated first, and then a film is deposited on or adhered to it. During the test, an external load is applied on the shaft to delaminate the upper film through the pre-fabricated hole, as shown in Figure 2C. We can get the adhesive energy

where the

By using the shaft-load blister test, the adhesive energies of Pt/Al2O3, Cu/Al2O3, and Cu/Cr/Al2O3 interfaces were quantitatively evaluated (Berdova et al., 2013). In addition, Lii-Rosales et al. (2020) measured the adhesive energy between Fe and graphene or graphite. With the help of MD simulation, Lou et al. (2020) measured the adhesive energy of graphene/MoS2 heterostructures.

3.2 The Buckle-Based Test

The blister test can be used to measure the adhesive energy between 2D materials and rigid substrates, but for the adhesive energy between 2D materials and elastic substrate, the buckle-based test is more suitable (Yang et al., 2017a). Note that the buckle-based test can be used not only for cases with elastic substrates but also for cases with rigid substrates.

For the buckle-based test, an elastic substrate is first covered with 2D materials, and then the film-substrate system is pressed by finger indentation. When the pressure is released, wrinkles or buckle delamination occurs as shown in Figure 2D. According to linear elastic fracture mechanics, a simple formula can be used to calculate the adhesive energy (Vella et al., 2009),

where

The adhesive energy between MoS2 and polydimethylsiloxane (PDMS) was measured by the buckle-based test, which was

4 Evaluation of Tribological Properties

Reducing the wear of mechanical components is an important topic in the field of engineering. In recent years, it has been found that 2D materials are of lowest friction coefficient, and can be used as lubricants to reduce mechanical wear. Thus, the measurement of tribological behavior of 2D materials, such as surface friction and interlayer friction, is becoming main task of contact probing methods.

Due to its unique properties, the tribological behavior of 2D materials cannot be measured by traditional methods. As an important development of AFM, FFM is designed and employed to measure the frictional behavior of various 2D materials. During the FFM test, the tip of AFM cantilever moves at a fixed frequency on the material surface, and friction diagram, friction forces are measured. The surface of FFM sample should be flat enough, or else the tip may be damaged during the fast scratching. Note that the measurement of FFM is independent of the material of the tip, the moving speed, and the force exerted by the tip (Zhang et al., 2019). Li et al. (2016) studied the surface friction of graphene, MoS2, h-BN and NbSe2 by FFM. It is found that the friction force decreased when the film number of layers increases due to the wrinkles under the compression of the tip. Fang et al. (2017) studied of the influence of tip shape on tribological behavior, and it is found that the friction is not sensitive to the film thickness under planar tip. With the contact probing method, Filleter et al. (2009) analyzed the friction behavior of monolayer and bilayer graphene films grown on SiC substrate. Quereda et al. (2014) experimentally studied the surface roughness and the lateral friction of single-layer MoS2 deposited on SiO2, mica, and h-BN.

For multilayer 2D materials such as vdW heterostructures, it is more important to study the corresponding interlayer friction properties (Filleter et al., 2009; Fang et al., 2017; Mak et al., 2019). Kobayashi et al. (2017) reported the preparation of WS2/h-BN vdW heterostructures via CVD, and manipulated the motion of atomic layers with a tip. In recent years, with the development of MD and density functional theory (DFT), atomic simulations have been developed to study interlayer friction of 2D materials. So far, Xu et al. (2011) have studied the interlayer friction of layered graphene by MD method. It is found that the interlayer friction of two or three layers of graphene was almost zero, and the interlayer friction of graphene increases with the increase of the number of layers. As shown in Figure 2E. Ye et al. (2012) studied the role of wrinkle height in friction variation with number of graphene layers. Han et al. (2019) investigate the friction and wear properties of Ti2AlN/TiAl composite, and found that the introduction of Ti2AlN results in anti-friction and wear reduction. By using DFT calculation, Wang et al. (2012) showed that chemical modification had a significant effect on the interlayer friction of 2D materials. Sun et al. (2017) reported the frictional behavior of graphene and MoS2 under high loads. Liang et al. (2008) investigated the atomic-scale energetic barriers during the sliding at MoS2/MoO3 interface. Cahangirov et al. (2012) determined the frictional merit figures of layered honeycomb nanostructures. By combining experiment and DFT, Yadav et al. (2021) studied the tribological behavior and interfacial interactions of metal-oxide/2D-material contacts.

5 The Measurement of Electrical Properties

In order to measure the electrical properties of 2D materials, some scanning probe microscopy technologies including conductive atomic force microscopy (CAFM), piezoresponse force microscopy (PFM), Kelvin probe force microscopy (KPFM) and Scanning tunneling microscopy (STM) have been developed. For conventional 2D materials, it is difficult to obtain their electrical properties by traditional methods due to the scale. CAFM provides a convenient and high-precision measurement equipment. For ferroelectrics, PFM is more suitable. PFM enables non-destructive visualization and control of ferroelectric nanodomains, as well as direct measurements of the local physical characteristics of ferroelectrics. KPFM is a scanning probe technique that is capable of measuring the local distribution of contact potential difference (CPD), which is a measure of the electrical surface potential or work function of the sample. STM can be used to study the electronic structure and electrical transport characteristics of samples (Hla, 2005).

By using contact probing methods, quantum transport in graphene/h-bN heterostructure superlattices (Zhao et al., 2017; Wu et al., 2018b), resonant tunneling in graphene/h-BN heterostructure (Mishchenko et al., 2014), etc. have been studied. The conductivity of MoS2/graphene heterostructures is found to be directly related to the rotation angle (Liao et al., 2018). For graphene on silica substrate and bilayer graphene, the relationship between the rotation angle and the conductivity was uncovered (Wu et al., 2018c; Zhang et al., 2020). The contact quality improvement strategy between monolayer MoS2 and graphite was given by Liao et al. (2019a). Zeng et al. (2021) reported an advanced PFM technology for measuring piezoelectric strain on nanoscale. Moores et al. (2010) studied KPFM in application to biomolecular films. A micro-four-point probe in STM for in situ electrical transport measurement was developed by Ge et al. (2015).

Besides the contact probing methods, there are some approaches widely used for property characterization of 2D materials and vdW heterostructures. For example, microelectromechanical system (MEMS) offers a number of merits for nanomechanical testing including controlled actuation, high-resolution force/displacement measurements (Luo et al., 2017). Raman spectroscopy is an important tool to study carbon nanotubes, graphene and other graphitic materials (Malekpour and Balandin, 2018). Due to high precision requirement and the difficulty of sample preparation, it is highly recommend to combine these tools to explore mechanical, interfacial, tribological, and electrical properties of 2D materials and vdW heterostructure through suitable strategies.

6 Conclusion and Perspectives

In this mini review, we summarize some recent progress of contact probing methods of 2D materials and vdW heterostructures, including the measurement of mechanical properties, the measurement of interfacial properties, the measurement of tribological properties, as well as electrical properties. For the measurement of mechanical properties, the working mechanism of contact probing methods, the commonly used theoretical models are mainly discussed. For the measurement of interfacial properties, the blister test and buckle-based method are summarized. Generally, the blister test are suitable for measuring the adhesion energy between 2D materials and rigid substrates, while the buckle-based method can also measure the adhesion energy between 2D materials and elastic substrates. For measurement of frictional behavior, the progress of surface and interlayer friction of 2D materials are introduced. What is more, the appearance of CAFM provides a convenient and high-precision equipment to measure electrical properties.

From this mini review, it is found that the contact probing methods greatly improve the property measurement of 2D materials and vdW heterostructures. Although the contact probing methods have been well developed, it is not enough to characterize or measure properties of 2D materials and vdW heterostructures like bulk materials. For example, further development of in situ measurement for nano materials should be done to capture the evolution properties. Moreover, strain engineering of 2D materials requires more accurate manipulation of AFM and other scientific instruments. Besides existing experimental studies and numerical simulations, more useful theoretical models which take the size effect and surface effect into consideration should be proposed. We believe that the contact probing methods will be more advanced to promote the blooming applications of 2D materials and vdW heterostructures.

Author Contributions

JZ is responsible for conceptualization, and writing of the original draft; PC is in charge of conceptualization, project administration and investigation; JP takes charge methodology and revision; YZ contributes to the revision version of the work. All the authors have reviewed and edited the manuscript.

Funding

This study is supported by National Key Research and Development Program of China (No. 2020YFA0711800), NSFC (No. 11972363), Key research and development program of Xuzhou (No. KC20174), the opening project of State Key Laboratory of Solid Lubrication (Lanzhou Institute of Chemical Physics) (No. LSL-20012001), the Research Fund of State Key Laboratory of Mechanics and Control of Mechanical Structures (Nanjing University of Aeronautics and astronautics) (Grant No. MCMS-E-0221G01), the Fundamental Research Funds for the Central Universities (No. 2019XKQYMS40).

Conflict of Interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s Note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Begley, M. R., and Mackin, T. J. (2004). Spherical Indentation of Freestanding Circular Thin Films in the Membrane Regime. J. Mech. Phys. Solids 52 (9), 2005–2023. doi:10.1016/j.jmps.2004.03.002

Berdova, M., Lyytinen, J., Grigoras, K., Baby, A., Kilpi, L., Ronkainen, H., et al. (2013). Characterization of Thin Film Adhesion by MEMS Shaft-Loading Blister Testing. J. Vac. Sci. Technol. A Vac. Surfaces, Films 31 (3), 031102. doi:10.1116/1.4801921

Bertolazzi, S., Brivio, J., and Kis, A. (2011). Stretching and Breaking of Ultrathin MoS2. ACS Nano 5 (12), 9703–9709. doi:10.1021/nn203879f

Bhimanapati, G. R., Lin, Z., Meunier, V., Jung, Y., Cha, J., Das, S., et al. (2015). Recent Advances in Two-Dimensional Materials beyond Graphene. ACS Nano 9 (12), 11509–11539. doi:10.1021/acsnano.5b05556

Boddeti, N. G., Koenig, S. P., Long, R., Xiao, J., Bunch, J. S., and Dunn, M. L. (2013). Mechanics of Adhered, Pressurized Graphene Blisters. J. Appl. Mech.-Trans. ASME 80 (4), 040909. doi:10.1115/1.4024255

Brennan, C. J., Nguyen, J., Yu, E. T., and Lu, N. (2015). Interface Adhesion between 2D Materials and Elastomers Measured by Buckle Delaminations. Adv. Mat. Interfaces 2 (16), 1500176. doi:10.1002/admi.201500176

Britnell, L., Ribeiro, R. M., Eckmann, A., Jalil, R., Belle, B. D., Mishchenko, A., et al. (2013). Strong Light-Matter Interactions in Heterostructures of Atomically Thin Films. Science 340 (6138), 1311–1314. doi:10.1126/science.1235547

Bu, F., Zagho, M. M., Ibrahim, Y., Ma, B., Elzatahry, A., and Zhao, D. (2020). Porous MXenes: Synthesis, Structures, and Applications. Nano Today 30, 100803. doi:10.1016/j.nantod.2019.100803

Bunch, J. S., and Dunn, M. L. (2012). Adhesion Mechanics of Graphene Membranes. Solid State Commun. 152 (15), 1359–1364. doi:10.1016/j.ssc.2012.04.029

Bunch, J. S., Verbridge, S. S., Alden, J. S., van der Zande, A. M., Parpia, J. M., Craighead, H. G., et al. (2008). Impermeable Atomic Membranes from Graphene Sheets. Nano Lett. 8 (8), 2458–2462. doi:10.1021/nl801457b

Cahangirov, S., Ataca, C., Topsakal, M., Sahin, H., and Ciraci, S. (2012). Frictional Figures of Merit for Single Layered Nanostructures. Phys. Rev. Lett. 108 (12), 126103. doi:10.1103/PhysRevLett.108.126103

Cao, G., and Gao, H. (2019). Mechanical Properties Characterization of Two-Dimensional Materials via Nanoindentation Experiments. Prog. Mater. Sci. 103, 558–595. doi:10.1016/j.pmatsci.2019.03.002

Cao, Z., Wang, P., Gao, W., Tao, L., Suk, J. W., Ruoff, R. S., et al. (2014). A Blister Test for Interfacial Adhesion of Large-Scale Transferred Graphene. Carbon 69, 390–400. doi:10.1016/j.carbon.2013.12.041

Castellanos-Gomez, A., Poot, M., Steele, G. A., van der Zant, H. S. J., Agraït, N., and Rubio-Bollinger, G. (2012). Elastic Properties of Freely Suspended MoS2Nanosheets. Adv. Mat. 24 (6), 772–775. doi:10.1002/adma.201103965

Chen, J. (2012). Indentation-based Methods to Assess Fracture Toughness for Thin Coatings. J. Phys. D. Appl. Phys. 45 (20), 203001. doi:10.1088/0022-3727/45/20/203001

Cheng, J., Wang, C., Zou, X., and Liao, L. (2019). Recent Advances in Optoelectronic Devices Based on 2D Materials and Their Heterostructures. Adv. Opt. Mater. 7 (1), 1800441. doi:10.1002/adom.201800441

Cheng, Y.-T., and Cheng, C.-M. (2004). Scaling, Dimensional Analysis, and Indentation Measurements. Mater. Sci. Eng. R Rep. 44 (4-5), 91–149. doi:10.1016/j.mser.2004.05.001

Chhowalla, M., Shin, H. S., Eda, G., Li, L.-J., Loh, K. P., and Zhang, H. (2013). The Chemistry of Two-Dimensional Layered Transition Metal Dichalcogenide Nanosheets. Nat. Chem. 5 (4), 263–275. doi:10.1038/nchem.1589

Dai, Z., and Lu, N. (2021). Poking and Bulging of Suspended Thin Sheets: Slippage, Instabilities, and Metrology. J. Mech. Phys. Solids 149, 104320. doi:10.1016/j.jmps.2021.104320

Das Sarma, S., Adam, S., Hwang, E. H., and Rossi, E. (2011). Electronic Transport in Two-Dimensional Graphene. Rev. Mod. Phys. 83 (2), 407–470. doi:10.1103/RevModPhys.83.407

Deng, D., Novoselov, K. S., Fu, Q., Zheng, N., Tian, Z., and Bao, X. (2016). Catalysis with Two-Dimensional Materials and Their Heterostructures. Nat. Nanotech 11 (3), 218–230. doi:10.1038/nnano.2015.340

Deng, S., Gao, E., Xu, Z., and Berry, V. (2017). Adhesion Energy of MoS2 Thin Films on Silicon-Based Substrates Determined via the Attributes of a Single MoS2 Wrinkle. ACS Appl. Mat. Interfaces 9 (8), 7812–7818. doi:10.1021/acsami.6b16175

Du, W., Li, C., Sun, J., Xu, H., Yu, P., Ren, A., et al. (2020). Nanolasers Based on 2D Materials. Laser & Photonics Rev. 14 (12), 2000271. doi:10.1002/lpor.202000271

Fang, L., Liu, D.-M., Guo, Y., Liao, Z.-M., Luo, J.-B., and Wen, S.-Z. (2017). Thickness Dependent Friction on Few-Layer MoS2, WS2, and WSe2. Nanotechnology 28 (24), 245703. doi:10.1088/1361-6528/aa712b

Filleter, T., McChesney, J. L., Bostwick, A., Rotenberg, E., Emtsev, K. V., Seyller, T., et al. (2009). Friction and Dissipation in Epitaxial Graphene Films. Phys. Rev. Lett. 102 (8), 086102. doi:10.1103/PhysRevLett.102.086102

Frank, I. W., Tanenbaum, D. M., Van der Zande, A. M., and McEuen, P. L. (2007). Mechanical Properties of Suspended Graphene Sheets. J. Vac. Sci. Technol. B 25 (6), 2558–2561. doi:10.1116/1.2789446

Ge, J.-F., Liu, Z.-L., Gao, C.-L., Qian, D., Liu, C., and Jia, J.-F. (2015). Development of Micro-four-point Probe in a Scanning Tunneling Microscope for In Situ Electrical Transport Measurement. Rev. Sci. Instrum. 86 (5), 053903. doi:10.1063/1.4919766

Geng, H., Yuan, D., Yang, Z., Tang, Z., Zhang, X., Yang, K., et al. (2019). Graphene van der Waals heterostructures for high-performance photodetectors. J. Mat. Chem. C 7 (36), 11056–11067. doi:10.1039/c9tc03213d

Golberg, D., Bando, Y., Huang, Y., Terao, T., Mitome, M., Tang, C., et al. (2010). Boron Nitride Nanotubes and Nanosheets. ACS Nano 4 (6), 2979–2993. doi:10.1021/nn1006495

Han, X., Liu, P., Sun, D., and Wang, Q. (2019). An Atomic-Level Understanding of the Friction and Wear Behaviors of Ti2AlN/TiAl Composite via MD Simulations. Tribol. Int. 137, 340–348. doi:10.1016/j.triboint.2019.05.021

Hatter, C. B., Shah, J., Anasori, B., and Gogotsi, Y. (2020). Micromechanical Response of Two-Dimensional Transition Metal Carbonitride (MXene) Reinforced Epoxy Composites. Compos. Part B Eng. 182, 107603. doi:10.1016/j.compositesb.2019.107603

Hla, S.-W. (2005). Scanning Tunneling Microscopy Single Atom/molecule Manipulation and its Application to Nanoscience and Technology. J. Vac. Sci. Technol. B 23 (4), 1351–1360. doi:10.1116/1.1990161

Hong, X., Kim, J., Shi, S.-F., Zhang, Y., Jin, C., Sun, Y., et al. (2014). Ultrafast Charge Transfer in Atomically Thin MoS2/WS2 Heterostructures. Nat. Nanotech 9 (9), 682–686. doi:10.1038/nnano.2014.167

Huang, M., Pascal, T. A., Kim, H., Goddard, W. A., and Greer, J. R. (2011). Electronic−Mechanical Coupling in Graphene from In Situ Nanoindentation Experiments and Multiscale Atomistic Simulations. Nano Lett. 11 (3), 1241–1246. doi:10.1021/nl104227t

Iguiñiz, N., Frisenda, R., Bratschitsch, R., and Castellanos-Gomez, A. (2019). Revisiting the Buckling Metrology Method to Determine the Young's Modulus of 2D Materials. Adv. Mat. 31 (10), 1807150. doi:10.1002/adma.201807150

Ihsanullah, I. (2020). Potential of MXenes in Water Desalination: Current Status and Perspectives. Nano-Micro Lett. 12 (1), 72. doi:10.1007/s40820-020-0411-9

Jariwala, D., Marks, T. J., and Hersam, M. C. (2017). Mixed-dimensional van der Waals heterostructures. Nat. Mater 16 (2), 170–181. doi:10.1038/nmat4703

Jiang, H., Zheng, L., Liu, Z., and Wang, X. (2019). Two‐dimensional Materials: From Mechanical Properties to Flexible Mechanical Sensors. InfoMat 2 (6), 1077–1094. doi:10.1002/inf2.12072

Jin, C. (2008). Analysis of Energy Release Rate and Bending-To-Stretching Behavior in the Shaft-Loaded Blister Test. Int. J. Solids Struct. 45 (25-26), 6485–6500. doi:10.1016/j.ijsolstr.2008.08.014

Kang, P., Wang, M. C., and Nam, S. (2016). Bioelectronics with Two-Dimensional Materials. Microelectron. Eng. 161, 18–35. doi:10.1016/j.mee.2016.04.003

Kobayashi, Y., Taniguchi, T., Watanabe, K., Maniwa, Y., and Miyata, Y. (2017). Slidable atomic layers in van der Waals heterostructures. Appl. Phys. Express 10 (4), 045201. doi:10.7567/apex.10.045201

Koenig, S. P., Boddeti, N. G., Dunn, M. L., and Bunch, J. S. (2011). Ultrastrong Adhesion of Graphene Membranes. Nat. Nanotech 6 (9), 543–546. doi:10.1038/nnano.2011.123

Komaragiri, U., Begley, M. R., and Simmonds, J. G. (2005). The Mechanical Response of Freestanding Circular Elastic Films under Point and Pressure Loads. J. Appl. Mech.-Trans. ASME 72 (2), 203–212. doi:10.1115/1.1827246

Kunz, D. A., Max, E., Weinkamer, R., Lunkenbein, T., Breu, J., and Fery, A. (2009). Deformation Measurements on Thin Clay Tactoids. Small 5 (16), 1816–1820. doi:10.1002/smll.200801710

Lee, C., Wei, X., Kysar, J. W., and Hone, J. (2008). Measurement of the Elastic Properties and Intrinsic Strength of Monolayer Graphene. Science 321 (5887), 385–388. doi:10.1126/science.1157996

Lee, W. H., and Park, Y. D. (2017). Tuning Electrical Properties of 2D Materials by Self‐Assembled Monolayers. Adv. Mat. Interfaces 5 (1), 1700316. doi:10.1002/admi.201700316

Li, S., Li, Q., Carpick, R. W., Gumbsch, P., Liu, X. Z., Ding, X., et al. (2016). The Evolving Quality of Frictional Contact with Graphene. Nature 539 (7630), 541–545. doi:10.1038/nature20135

Liang, T., Sawyer, W. G., Perry, S. S., Sinnott, S. B., and Phillpot, S. R. (2008). First-principles Determination of Static Potential Energy Surfaces for Atomic Friction inMoS2andMoO3. Phys. Rev. B 77 (10), 104105. doi:10.1103/PhysRevB.77.104105

Liao, M., Du, L., Zhang, T., Gu, L., Yao, Y., Yang, R., et al. (2019a). Pressure-mediated Contact Quality Improvement between Monolayer MoS 2 and Graphite. Chin. Phys. B 28 (1), 017301. doi:10.1088/1674-1056/28/1/017301

Liao, M., Wu, Z.-W., Du, L., Zhang, T., Wei, Z., Zhu, J., et al. (2018). Twist Angle-dependent Conductivities across MoS2/graphene Heterojunctions. Nat. Commun. 9 (1), 4068. doi:10.1038/s41467-018-06555-w

Liao, W., Huang, Y., Wang, H., and Zhang, H. (2019b). Van der Waals heterostructures for optoelectronics: Progress and prospects. Appl. Mater. Today 16, 435–455. doi:10.1016/j.apmt.2019.07.004

Lii-Rosales, A., Han, Y., Julien, S. E., Pierre-Louis, O., Jing, D., Wan, K.-T., et al. (2020). Shapes of Fe Nanocrystals Encapsulated at the Graphite Surface. New J. Phys. 22 (2), 023016. doi:10.1088/1367-2630/ab687a

Lin, Q.-Y., Jing, G., Zhou, Y.-B., Wang, Y.-F., Meng, J., Bie, Y.-Q., et al. (2013). Stretch-Induced Stiffness Enhancement of Graphene Grown by Chemical Vapor Deposition. ACS Nano 7 (2), 1171–1177. doi:10.1021/nn3053999

Liu, B., Du, J., Yu, H., Hong, M., Kang, Z., Zhang, Z., et al. (2020). The coupling effect characterization for van der Waals structures based on transition metal dichalcogenides. Nano Res. 14 (6), 1734–1751. doi:10.1007/s12274-020-3253-3

Liu, Y., Pan, Y., Yin, D., Song, S., Lin, L., Zhang, M., et al. (2021). Mechanical Properties and Thickness-Determined Fracture Mode of Hexagonal Boron Nitride Nanosheets under Nanoindentation Simulations. Comput. Mater. Sci. 186, 110047. doi:10.1016/j.commatsci.2020.110047

Lou, L., Chen, P., Wang, Z., Zhang, S., and Gao, F. (2020). Cohesive energy measurement of van der Waals heterostructures by the shaft loaded blister test. Extreme Mech. Lett. 41, 100987. doi:10.1016/j.eml.2020.100987

Lu, S. B., Miao, L. L., Guo, Z. N., Qi, X., Zhao, C. J., Zhang, H., et al. (2015). Broadband Nonlinear Optical Response in Multi-Layer Black Phosphorus: an Emerging Infrared and Mid-infrared Optical Material. Opt. Express 23 (9), 11183–11194. doi:10.1364/OE.23.011183

Luo, C., Wang, C., Wu, X., Zhang, J., and Chu, J. (2017). In Situ Transmission Electron Microscopy Characterization and Manipulation of Two-Dimensional Layered Materials beyond Graphene. Small 13 (35), 1604259. doi:10.1002/smll.201604259

Mak, K. F., Shan, J., and Ralph, D. C. (2019). Probing and Controlling Magnetic States in 2D Layered Magnetic Materials. Nat. Rev. Phys. 1 (11), 646–661. doi:10.1038/s42254-019-0110-y

Malekpour, H., and Balandin, A. A. (2018). Raman-based Technique for Measuring Thermal Conductivity of Graphene and Related Materials. J. Raman Spectrosc. 49 (1), 106–120. doi:10.1002/jrs.5230

Mallick, G., and Elder, R. M. (2018). Graphene/hexagonal Boron Nitride Heterostructures: Mechanical Properties and Fracture Behavior from Nanoindentation Simulations. Appl. Phys. Lett. 113 (12), 121902. doi:10.1063/1.5047782

Mishchenko, A., Tu, J. S., Cao, Y., Gorbachev, R. V., Wallbank, J. R., Greenaway, M. T., et al. (2014). Twist-controlled Resonant Tunnelling in Graphene/boron Nitride/graphene Heterostructures. Nat. Nanotech 9 (10), 808–813. doi:10.1038/nnano.2014.187

Moores, B., Hane, F., Eng, L., and Leonenko, Z. (2010). Kelvin Probe Force Microscopy in Application to Biomolecular Films: Frequency Modulation, Amplitude Modulation, and Lift Mode. Ultramicroscopy 110 (6), 708–711. doi:10.1016/j.ultramic.2010.02.036

Na, H., Chen, P., Wan, K.-T., Wong, S.-C., Li, Q., and Ma, Z. (2012). Measurement of Adhesion Work of Electrospun Polymer Membrane by Shaft-Loaded Blister Test. Langmuir 28 (16), 6677–6683. doi:10.1021/la300877r

Nadler, B., and Steigmann, D. J. (2006). Modeling the Indentation, Penetration and Cavitation of Elastic Membranes. J. Mech. Phys. Solids 54 (10), 2005–2029. doi:10.1016/j.jmps.2006.04.007

Novoselov, K. S., Geim, A. K., Morozov, S. V., Jiang, D., Zhang, Y., Dubonos, S. V., et al. (2004). Electric Field Effect in Atomically Thin Carbon Films. Science 306 (5696), 666–669. doi:10.1126/science.1102896

Onodera, M., Masubuchi, S., Moriya, R., and Machida, T. (2020). Assembly of van der Waals heterostructures: exfoliation, searching, and stacking of 2D materials. Jpn. J. Appl. Phys. 59 (1), 010101. doi:10.7567/1347-4065/ab5ee0

Pruessner, M. W., King, T. T., Kelly, D. P., Grover, R., Calhoun, L. C., and Ghodssi, R. (2003). Mechanical Property Measurement of InP-Based MEMS for Optical Communications. Sensors Actuators A Phys. 105 (2), 190–200. doi:10.1016/s0924-4247(03)00102-x

Quereda, J., Castellanos-Gomez, A., Agraït, N., and Rubio-Bollinger, G. (2014). Single-layer MoS2 Roughness and Sliding Friction Quenching by Interaction with Atomically Flat Substrates. Appl. Phys. Lett. 105 (5), 053111. doi:10.1063/1.4892650

Sanchez, D. A., Dai, Z., Wang, P., Cantu-Chavez, A., Brennan, C. J., Huang, R., et al. (2018). Mechanics of Spontaneously Formed Nanoblisters Trapped by Transferred 2D Crystals. Proc. Natl. Acad. Sci. U.S.A. 115 (31), 7884–7889. doi:10.1073/pnas.1801551115

Scharfenberg, S., Mansukhani, N., Chialvo, C., Weaver, R. L., and Mason, N. (2012). Observation of a Snap-Through Instability in Graphene. Appl. Phys. Lett. 100 (2), 021910. doi:10.1063/1.3676059

Scharfenberg, S., Rocklin, D. Z., Chialvo, C., Weaver, R. L., Goldbart, P. M., and Mason, N. (2011). Probing the Mechanical Properties of Graphene Using a Corrugated Elastic Substrate. Appl. Phys. Lett. 98 (9), 091908. doi:10.1063/1.3553228

Steigmann, D. J. (2005). Puncturing a Thin Elastic Sheet. Int. J. Non-Linear Mech. 40 (2-3), 255–270. doi:10.1016/j.ijnonlinmec.2004.05.009

Su, J., Liu, G., Liu, L., Chen, J., Hu, X., Li, Y., et al. (2021). Recent Advances in 2D Group VB Transition Metal Chalcogenides. Small 17 (14), 2005411. doi:10.1002/smll.202005411

Sun, J., Zhang, Y., Feng, Y., Lu, Z., Xue, Q., Du, S., et al. (2017). How Vertical Compression Triggers Lateral Interlayer Slide for Metallic Molybdenum Disulfide? Tribol. Lett. 66 (1), 21. doi:10.1007/s11249-017-0971-0

Tan, X., Wu, J., Zhang, K., Peng, X., Sun, L., and Zhong, J. (2013). Nanoindentation Models and Young's Modulus of Monolayer Graphene: A Molecular Dynamics Study. Appl. Phys. Lett. 102 (7), 071908. doi:10.1063/1.4793191

Tao, J., Shen, W., Wu, S., Liu, L., Feng, Z., Wang, C., et al. (2015). Mechanical and Electrical Anisotropy of Few-Layer Black Phosphorus. ACS Nano 9 (11), 11362–11370. doi:10.1021/acsnano.5b05151

Tran, V., Soklaski, R., Liang, Y., and Yang, L. (2014). Layer-controlled Band Gap and Anisotropic Excitons in Few-Layer Black Phosphorus. Phys. Rev. B 89 (23), 235319. doi:10.1103/PhysRevB.89.235319

VanLandingham, M. R. (2003). Review of Instrumented Indentation. J. Res. Natl. Inst. Stand. Technol. 108 (4), 249–265. doi:10.6028/jres.108.024

Vella, D., Bico, J., Boudaoud, A., Roman, B., and Reis, P. M. (2009). The Macroscopic Delamination of Thin Films from Elastic Substrates. Proc. Natl. Acad. Sci. U.S.A. 106 (27), 10901–10906. doi:10.1073/pnas.0902160106

Wan, K. T., Guo, S., and Dillard, D. A. (2003). A Theoretical and Numerical Study of a Thin Clamped Circular Film under an External Load in the Presence of a Tensile Residual Stress. THIN SOLID FILMS 425 (1-2), 150–162. doi:10.1016/S0040-6090(02)01103-3

Wang, G., Dai, Z., Wang, Y., Tan, P., Liu, L., Xu, Z., et al. (2017). Measuring Interlayer Shear Stress in Bilayer Graphene. Phys. Rev. Lett. 119 (3), 036101. doi:10.1103/PhysRevLett.119.036101

Wang, G., Dai, Z., Xiao, J., Feng, S., Weng, C., Liu, L., et al. (2019). Bending of Multilayer van der Waals Materials. Phys. Rev. Lett. 123 (11), 116101. doi:10.1103/PhysRevLett.123.116101

Wang, J., Sorescu, D. C., Jeon, S., Belianinov, A., Kalinin, S. V., Baddorf, A. P., et al. (2016a). Atomic Intercalation to Measure Adhesion of Graphene on Graphite. Nat. Commun. 7, 13263. doi:10.1038/ncomms13263

Wang, J., Zhao, X., and He, M. (2012). Is BDNF Biological Link between Depression and Type 2 Diabetes Mellitus? Med. Hypotheses 79 (2), 255–258. doi:10.1016/j.mehy.2012.05.002

Wang, P., Liechti, K. M., and Huang, R. (2016b). Snap Transitions of Pressurized Graphene Blisters. J. Vac. Sci. Technol. A 83 (7), 071002. doi:10.1115/1.4033305

Wang, W., Ma, X., Dai, Z., Zhang, S., Hou, Y., Wang, G., et al. (2022). Mechanical Behavior of Blisters Spontaneously Formed by Multilayer 2D Materials. Adv. Mater. Inter 9 (12), 2101939. doi:10.1002/admi.202101939

Wu, K., Wang, Y., Qiu, C., and Chen, J. (2018a). Thermo-optic All-Optical Devices Based on Two-Dimensional Materials. Phot. Res. 6 (10), C22. doi:10.1364/prj.6.000c22

Wu, S., Liu, B., Shen, C., Li, S., Huang, X., Lu, X., et al. (2018b). Magnetotransport Properties of Graphene Nanoribbons with Zigzag Edges. Phys. Rev. Lett. 120 (21), 216601. doi:10.1103/PhysRevLett.120.216601

Wu, X., Chuang, Y., Contino, A., Sorée, B., Brems, S., Tokei, Z., et al. (2018c). Boosting Carrier Mobility of Synthetic Few Layer Graphene on SiO2 by Interlayer Rotation and Decoupling. Adv. Mat. Interfaces 5 (14), 1800454. doi:10.1002/admi.201800454

Xu, L., Ma, T.-B., Hu, Y.-Z., and Wang, H. (2011). Vanishing Stick-Slip Friction in Few-Layer Graphenes: the Thickness Effect. Nanotechnology 22 (28), 285708. doi:10.1088/0957-4484/22/28/285708

Yadav, S., Arif, T., Wang, G., Sodhi, R. N. S., Cheng, Y. H., Filleter, T., et al. (2021). Interfacial Interactions and Tribological Behavior of Metal-Oxide/2D-Material Contacts. Tribol. Lett. 69 (3), 91. doi:10.1007/s11249-021-01464-4

Yang, L., Niu, T., Zhang, H., Xu, W., Zou, M., Xu, L., et al. (2017a). Self-assembly of Suspended Graphene Wrinkles with High Pre-tension and Elastic Property. 2D Mat. 4 (4), 041001. doi:10.1088/2053-1583/aa833c

Yang, Y., Li, X., Wen, M., Hacopian, E., Chen, W., Gong, Y., et al. (2017b). Brittle Fracture of 2D MoSe 2. Adv. Mat. 29 (2), 1604201. doi:10.1002/adma.201604201

Ye, Z., Tang, C., Dong, Y., and Martini, A. (2012). Role of Wrinkle Height in Friction Variation with Number of Graphene Layers. J. Appl. Phys. 112 (11), 116102. doi:10.1063/1.4768909

Zeng, Q., Wang, H., Xiong, Z., Huang, Q., Lu, W., Sun, K., et al. (2021). Nanoscale Ferroelectric Characterization with Heterodyne Megasonic Piezoresponse Force Microscopy. Adv. Sci. 8 (8), 2003993. doi:10.1002/advs.202003993

Zhang, S., Ma, T., Erdemir, A., and Li, Q. (2019). Tribology of Two-Dimensional Materials: From Mechanisms to Modulating Strategies. Mater. Today 26, 67–86. doi:10.1016/j.mattod.2018.12.002

Zhang, S., Song, A., Chen, L., Jiang, C., Chen, C., Gao, L., et al. (2020). Abnormal Conductivity in Low-Angle Twisted Bilayer Graphene. Sci. Adv. 6 (47), eabc555. doi:10.1126/sciadv.abc5555

Zhao, C., and Qin, C. (2021). Quasi-2D Lead Halide Perovskite Gain Materials toward Electrical Pumping Laser. Nanophotonics 10 (8), 2167–2180. doi:10.1515/nanoph-2020-0630

Zhao, J., Jiang, J.-W., and Rabczuk, T. (2013). Temperature-dependent Mechanical Properties of Single-Layer Molybdenum Disulphide: Molecular Dynamics Nanoindentation Simulations. Appl. Phys. Lett. 103 (23), 231913. doi:10.1063/1.4844935

Zhao, J., Li, N., Yu, H., Wei, Z., Liao, M., Chen, P., et al. (2017). Highly Sensitive MoS2 Humidity Sensors Array for Noncontact Sensation. Adv. Mat. 29 (34), 1702076. doi:10.1002/adma.201702076

Keywords: 2D materials, van der Waals heterostructure, contact probing, adhesive energy, friction

Citation: Zhang J, Chen P, Peng J and Zhang Y (2022) Recent Progress in Contact Probing Methods of Two-Dimensional Materials and Van Der Waals Heterostructures. Front. Mech. Eng 8:912134. doi: 10.3389/fmech.2022.912134

Received: 04 April 2022; Accepted: 26 May 2022;

Published: 14 June 2022.

Edited by:

Zhaohe Dai, University of Oxford, United KingdomReviewed by:

Yuan Hou, City University of Hong Kong, Hong Kong SAR, ChinaGuorui Wang, University of Toronto, Canada

Huilin Ye, Cadence Design Systems, United States

Copyright © 2022 Zhang, Chen, Peng and Zhang. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Peijian Chen, Y2hlbnBlaWppYW5AY3VtdC5lZHUuY24=

Jiazhen Zhang

Jiazhen Zhang Peijian Chen

Peijian Chen Juan Peng1

Juan Peng1