94% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

REVIEW article

Front. Mater., 15 January 2025

Sec. Polymeric and Composite Materials

Volume 11 - 2024 | https://doi.org/10.3389/fmats.2024.1524729

This article is part of the Research TopicTackling the Multiscale Phenomena of Soft Materials for Engineering InnovationsView all 5 articles

This study is focused on applying environment-friendly materials (EFM) to construct sports facilities for sustainability. The current status and future potential of using EFM in sports facility construction are concretely discussed with a thorough literature review and analysis. First, we discuss the concept and significance of EFM, especially in terms of its advantages in reducing carbon emissions and conserving resources: e.g., Europe carries out the EU Horizon 2020 plan, which invests 3.018 billion euros for studying climate action, environment, resource efficiency, and rare materials for green manufacturing. Second, the application of EFM in venue construction, e.g., sports stadiums, is comprehensively reviewed and evaluated, including using renewable materials, energy-saving technologies, and eco-friendly architectural designs. Third, the challenges and future developing trends of applying EFM in sports facility construction are discussed by considering constructional design and material selection. We find that EFM shows great potential in constructing sports facilities, playing a key role in promoting the sustainable development of sports facilities and a low-carbon economy.

Environment-friendly materials (EFM) refer to materials posing a small or harmless impact on the environment and can promote sustainable development during their production, use, and disposal stages (Abdur et al., 2023) (Yashas Gowda et al., 2018). The purpose of the review is listed in the following several aspects: (i) Exploring the potential of EFM in constructing sports facilities0 (YUE et al., 2024), such as recreational areas, buildings, and fixed facilities used for sports competitions, training, teaching, and mass fitness activities: with the fast developing economy, environmental protection has become a global topic where EFM is essential in sports facilities. (ii) Exploring the feasibility of EFM in sports facilities: EFM exhibits unique properties such as ultraviolet resistance, corrosion resistance, and wear resistance. The feasibility of these materials in sports facilities needs to be studied in depth (Bharath et al., 2021). (iii) Promoting the concept of environmental protection: applying EFM in sports facilities can promote the concept of environmental protection, and raise public awareness of environmental protection (Kobetičová et al., 2022). (iv) Promoting the sustainable development of sports: using EFM in sports facilities can effectively promote the sustainable, green development of sports and the whole society (Zhang et al., 2019).

Currently, energy and resources are being largely consumed. There is an urgent need to develop new energy sources and reduce consumption, especially in the construction industry (Li et al., 2019; Yi et al., 2014). Some developed countries first used green materials and enacted laws to protect the environment (Rana et al., 2024) Using green materials and setting green standards then became popular worldwide (Du, 2017). In the 1960s, Paola Soleri put forward the idea of “eco-architecture”, which made green buildings come to light (Aiduang et al., 2022; Hadlahalli chandrashekar et al., 2024). Since the 1980s, the concept of green design involved in interior design. Since the 1990s, green design concepts have been emphasized by more designers (Jerry, 2014). In 1995, Leadership in Energy and Environmental Design (LEED™) was written by the U.S. Green Building Council, which proposed the LEED™ rating system to evaluate the national building design process with considerable authority and validity. U.S. architect, Jerry Yudelson, who wrote the LEED™ report published by the U.S. Green Building Council, has been a leading authoritarian in building design (Jerry, 2009). LEED™ was established and implemented by the United States Green Building Council. At present, it is considered to be the most perfect and influential evaluation standard in all kinds of building environmental protection assessment, green building assessment, and building sustainability assessment standards. LEED certification evaluation elements have 6 major evaluation indicators, each of which includes 2 to 8 evaluation subitems, with a total of 41 indicators with each dimension index score different. From high to low, they were Energy and Atmosphere (17 points), Indoor Environmental Quality (15 points), and Sustainable site evaluation (15 points) Sites (14 points), Materials and Resources (13 points), Water Efficiency (5 points), and Innovation and Design Process (5 points), with a total project score of 69 points. 26–32 points passed the certification; 33–38 points lead to a silver grade; 39–51 lead to a gold; 52–69 points lead to a platinum (Li and Liu, 2015). In Greening Existing Buildings,,Jerry Yudelson wrote about transforming existing buildings into more energy-, resource-efficient, and environment-friendly buildings and proposed a step-by-step approach to realizing the integration of green design concepts into the design of buildings, from pre-design and construction to post-operation and maintenance (Jerry, 2009; Xiong et al., 2022). In Development of a sustainable environment-friendly waste management system at large mass and sports events, Lada Rozhdestvenskaya presented the types of waste generated at the functional areas of the competition venues, examined the practice of solid waste disposal: possible utilization and collection technologies, and described the waste management options for the various phases of sports competitions (Verma et al., 2022; Rozhdestvenskaya et al., 2021). Energy-saving and environmental protection technology is constantly developing and moving forward (Thyavihalli Girijappa et al., 2019). After years of industrialization and urbanization, human beings prefer to live in a comfortable, close-to-nature living environment, which greatly improves the concept of energy-saving and EFM (O’Hegarty et al., 2021; Green Interior Design, 2012).

Applying EFM in constructing sports facilities is attracting more and more attention. However, the research and development cost of EFM is higher than that of traditional materials, especially in the early stage of research and development, which often requires a lot of manpower and material resources, and the economic benefits it brings are often difficult to reflect in the short term. Second, some EFM is still in the stage of research and development and preliminary application, and unified quality standards and technical specifications have not been established, and the overall standardization of the industry needs to be improved. Finally, although the application of EFM investment is a major trend, there is still a lack of policy support, in the future need to establish a more perfect reward and punishment mechanism and incentive measures, so that the application of EFM is implemented. To deal with the above problems, we can increase the investment in the research and development of EFM, and promote the reduction of research and development costs through the continuous promotion of technological innovation; Establish and improve the system of production and management of EFM, strengthen the cooperation between the production department of EFM and the competent department of the construction industry, build an integrated standard system from scientific research, production, building design to construction application, and improve product quality and credibility; Formulate and implement standards such as land saving, energy saving and water saving, and adopt policies such as tax relief and subsidies for the application of EFM, to comprehensively promote the application of EFM, more research will be done in the future to delve deeper into this topic.

In the Advanced Manufacturing Partnership Program (AMP2.0), the U.S. listed “sustainable manufacturing” as one of the 11 key technologies to revitalize manufacturing. The U.S. Department of Energy, the Department of Defense (Executive Office of the Presidents Council of Advisorson Scienceand Technology, 2019), the National Foundation Committee, the Department of Commerce, and other agencies jointly built the strategic framework of advanced manufacturing in the United States (Green Interior Design, 2012) Europe carries out the EU Horizon 2020 plan, in which 3.018 billion euros are used for the research of climate action, environment, resource efficiency and rare materials in the research field of social challenges closely related to green manufacturing (Horizon, 2019). The British government will promote sustainable manufacturing (Green manufacturing) defined as the next-generation of manufacturing and has developed a sustainable manufacturing roadmap for 2013–2050 (CAO et al., 2020a; United Nations Habitat, 2023; GOV.UK, 2019) Modern materials science emphasizes the needs of people on the spiritual level: the green concept begins to be applied to building space. At the same time, with the development of a variety of materials and along with new scientific technologies, the construction of engineering equipment has made outstanding contributions to the development of new building materials all over the world. (Wu, 2018; LUHAR et al., 2019).

In the 1980s, researchers began to pay attention to the protection of the environment, and more and more designers began to study how to incorporate environmental design concepts into contemporary design, and how to reduce the waste of resources and its damage to the environment in the process of the interior and exterior design (Victor, 2020). In the 1990s, researchers in many developing countries gradually applied green design concepts to architecture and interior design. For example, in The Application of New Plastic Composite Materials in Sports Facilities and Equipment in the Context of Environmental Protection, Zhu suggests that new plastic composite materials have begun to be widely used in manufacturing sports facilities and equipment, and have been verified through practice (Zhu, 2023). Compared with conventional metal and alloy materials, new plastic composite materials have the advantages of longer service life, easier processing, and lower cost. The manufacturing of these materials is mostly based on green technology and has little environmental impact (Elfaleh et al., 2023; Kumar et al., 2024a). Cui points out in The Application of Green Materials in the Construction of Sports Facilities Based on Environmental Sustainability that in the context of sustainable development of the socio-economic environment, the construction of sports facilities has begun to use green materials (Cui, 2022). These can not only reduce the consumption of resources but also reduce its harm to the ecological environment (Elfaleh et al., 2023; Cui, 2022). Therefore, in the reform and development of sports equipment, it is necessary to study green materials, focusing on their application in sports facilities, especially nanomaterials. In the Use of EFM in Sports Equipment Design, Jiang points out that the application of EFM in sports is becoming increasingly widespread, from sports equipment to sports clothing and even in constructing sports facilities0 (YUE et al., 2024). China’s national standard GB/T 50378–2019 (2024 edition) “Green Building Evaluation Standard” is implemented on Oct. 1, 2024. Further, clarifying the requirements for the pre-evaluation stage of green buildings, adding new provisions on green building design, green building instruction manual, green building performance insurance, etc., and continuing to lead the development of high-quality green buildings (Jiang, 2022). Despite the rapid development of many developing countries’ sports industry in recent years, EFM needs to be further used (Jiang, 2022; Wang et al., 2024). Studying and developing green materials require high costs, which limits the popularization of EFM. Nonetheless, in recent years, with the state’s strong support, the green industry is expanding, and technology in the sports industry is also on the rise (Cao et al., 2020).

In general, applying EFM in the design of gymnasium buildings is mainly focused on exploring the characteristics of EFM and their positive effects on the environment and the promotion of environmental protection concepts. However, we still need to develop and apply practical green materials. Much of the literature is focused on applying EFM in constructing sports facilities, analyzing the environmental friendliness, feasibility, and benefits of EFM from different perspectives and methods, and providing a good reference for their applications (Qin and Kaewunruen, 2022).

The data of this study were collected from the Web of Science Core Collection database from “January 1, 2010 to January 1, 2025”, and the language was limited to English. The SCI-EXPANDED core database was further screened. Search with the keywords “environment-friendly Materials”, “Environment Friendly Materials” or “sports facilities”. A total of 3468 foreign literature were retrieved and included in the research sample rows (except critical articles, frontispiece, etc.), as shown in Figure 1. Screening of included literature selects 9 Web of Science categories: Materials Science Multidisciplinary, Chemistry Physical, Chemistry Multidisciplinary, Green sustainable Science Technology, Physics Applied, etc., are screened according to document types, document titles, and keywords; 193 pieces of literature related to this research theme were obtained.

This study investigates the physical and chemical properties of various EFM, such as renewable energy, recycled building materials, green roofs, and water recycling systems. The goal is to understand their potential applications in sports stadiums.

This study explores the specific applications of EFM in sports stadiums, including building structures, roofs, walls, floors, underground pipes, and equipment (Vinod et al., 2021). The goal is to assess their specific application effects and sustainability.

This study analyzes the application of EFM in the operation and management of sports stadiums, including energy management, waste management, and water resource management (Elfaleh et al., 2023). The goal is to understand their potential benefits in these areas.

This research investigates the impact of social, economic, and policy factors on the application of EFM in sports stadiums. The goal is to understand how these factors can be leveraged to promote the adoption of EFM.

This research synthesizes the findings from the previous research phases to develop optimized solutions for the application of EFM in sports facility construction. The goal is to maximize the environmental and economic benefits of these materials.

This objective is to understand the potential applications of EFM in sports stadiums by studying their physical and chemical properties (Cao et al., 2020).

This objective is to evaluate the specific application effects of EFM in sports stadiums in terms of sustainability, energy conservation, and emission reduction (Qin and Kaewunruen, 2022).

This objective is to understand how social, economic, and policy factors can influence the application of EFM in sports stadiums.

This objective is to develop optimized solutions for the application of EFM in sports facility construction to maximize their environmental and economic benefits (Elfaleh et al., 2023; Reis et al., 2024).

Overall, the goal of this research is to explore the application of EFM in sports stadiums to achieve sustainability, reduce carbon emissions, and conserve energy. The research will contribute to environmental protection and sustainable development.

Studying the physical and chemical properties of various EFM and their applicability in constructing sports facilities (Reis et al., 2024).

Assessing the economic cost, feasibility, and advantages and shortcomings compared with traditional materials; combining them for the best results (Zhang H, 2020).

Using scientific methods to assess the efficacy of applying them in constructing sports venues, including sustainability, energy saving, and emission reduction, and maintenance costs.

The influence of social, economic, and policy factors on promoting and applying them in constructing sports facilities and the corresponding solutions (Adams, 2019).

The application of EFM to construct sports facilities provides a new option for constructing sports facilities.

Adopting EFM helps reduce carbon emissions, energy consumption, and environmental pollution and promotes sustainable development (Adams, 2019).

EFM can improve sports facilities’ efficiency, reliability, and safety and reduce operation and maintenance costs.

The study will help promote policy formulation to guide the broader use of EFM and support the technological development of EFM.

The current situation and development trend of the application of EFM in constructing sports facilities and evaluating the application of EFM in constructing sports facilities is understood by considering a variety of factors such as theoretical research, practical effects, socio-economics as well as policy requirements.

First, it is necessary to screen EFM and select materials that meet environmental requirements and are suitable for constructing sports facilities. These materials can be renewable resources, biodegradable materials, etc.

The screened environmental materials are subjected to performance tests, including strength, durability, waterproofness, and corrosion resistance. These tests can ensure that the selected EFM meets the sports facilities’ construction requirements.

According to the needs of different sports facilities construction, an application test is carried out on the selected EFM. For example, the use of renewable materials in paving sports venues or the use of degradable materials in manufacturing sports equipment.

When EFM is used in constructing sports facilities, their impact on the environment needs to be assessed. These can ensure that the EFM used will not harm the ecological environment (Turk and Demirhan, 2013).

In the application test of the environment-protected materials, there is a need for continuous technological innovation and promotion (Kuhn et al., 2022). The utilization process of EFM is a complex system engineering problem that fully considers resource and environment issues and reflects the characteristics of interdisciplinary research. The utilization process of EFM is shown in Figure 2. It covers a wide range, including machinery, electronics, chemical industry, etc., covering almost the entire engineering field. Green design, green use, clean production, and green recycling are the embodiment of sustainable development strategy in the field of materials science. These can promote the application of EFM in constructing sports facilities and promoting environmental protection.

In the context of environmentally sustainable development, eco-friendly material is a solution to mitigate environmental problems, primarily aiming at reducing carbon emissions, minimizing resource consumption, and protecting the environment. Eco-friendly materials have less negative impact on the environment during their life cycle (MA et al., 2014). These materials usually have the following characteristics.

The production and use of EFM produces less greenhouse gas emissions (Li, 2023). They can reduce their carbon footprint by adopting clean energy supply chains, reducing energy consumption, and using renewable energy sources.

EFM is produced to minimize excessive consumption and depletion of natural resources (FAY et al., 2007). The need for raw materials can be reduced by recycling waste, using renewable resources, or adopting efficient production techniques.

EFM tends to have a lower risk of environmental pollution and ecological damage (Ul Haq et al., 2023). They contain no or fewer hazardous substances and can effectively reduce the risk of soil, water, and atmosphere pollution.

EFM typically has a long service life and can be recycled and reused to reduce waste generation. They are designed and manufactured with recyclability and secondary use of materials (Wu, 2021; He, 2018).

In the context of environmentally sustainable development, EFM is used in various applications, covering various fields such as construction, transportation, energy, and electronics. They can be used in constructing and renovating buildings and infrastructure, manufacturing environment-friendly transportation and electronics, and promoting the development and use of renewable energy.

In conclusion, environment-friendly material in the environmentally sustainable development context is a sustainable solution that can help reduce carbon emissions, minimize resource consumption, and protect the environment. Through wide applications of these materials, a low-carbon economy can be promoted, and sustainable development goals can be realized (Chandran et al., 2024).

In the context of environmentally sustainable development, low-carbon material innovation is one of the crucial directions in developing EFM. The R&D and application of low-carbon materials aim to reduce carbon emissions during the production and use of materials (Li, 2020). The decarbonization of materials can be achieved by introducing new material preparation methods and technologies, such as carbon fiber composites and energy-efficient materials. In addition, developing and promoting sustainable resources, such as using recycled raw materials, waste, and biomass as the basis for materials, is also an essential direction for low-carbon materials innovation. Energy consumption and carbon emissions can be reduced through low-carbon materials innovation, promoting green and sustainable development in the environmentally sustainable development context.

Renewable materials are an essential part of EFM, and their utilization is one of the critical development directions in the environmentally sustainable development context. Renewable materials include renewable energy sources, and biomass materials. Utilizing renewable energy, such as solar energy, wind energy, water energy, and other materials as energy sources, leads to lower carbon emissions and environmental impacts (Yan, 2021; Călătan and Dico, 2022). In addition, developing and utilizing biomass materials, such as plant fibers and bioplastics, can reduce dependence on fossil resources and bring better environmental benefits. By promoting and applying renewable materials, the demand for non-renewable resources can be reduced, and the sustainable use of resources can be realized, contributing to sustainable development in the environmentally sustainable development context.

In the context of environmentally sustainable development, promoting a circular economy is an essential direction for developing EFM. Circular economy emphasizes combining the use of resources and recycling links to reduce the waste and emission of resources (HU, 2020; Ustaoglu et al., 2021). Specifically, the development of EFM should focus on the design and production of materials with recyclability and encourage the recycling and reuse of waste. By establishing and improving the waste recycling system and integrating waste materials into the renewable resource supply chain, the demand for raw materials can be reduced, and carbon emissions and environmental pressure can be lowered. At the same time, promoting the effective recycling of resources, such as the reuse of waste and the remanufacturing of used products, can prolong the service life of materials, improve the resource utilization rate, and achieve the goals of a circular economy and the sustainable use of resources (Zhang Z, 2020).

One of the directions for developing environmental protection materials in the context of environmental, sustainable development is the development of new functional materials. New functional materials have special functions such as high energy efficiency, self-cleaning, anti-pollution, and antibacterial, and have a wide range of application potential in environmental protection. For example, the development of materials with excellent adiabatic properties and photocatalytic degradation ability can be used for building energy-saving and indoor air purification; materials with antibacterial and microbial defense ability can be used for medical equipment and disinfection products (National Academies of Sciences Engineering, and Medicine, 2020; SUN et al., 2023). Through the research and development of new functional materials, environmental quality and quality of life can be improved, providing technical support for sustainable development in the context of environmental sustainability.

One of the focuses of developing EFM in the environmentally sustainable development context is green building materials. Green building materials focus on energy saving, environmental friendliness, and indoor air quality considerations. The development and application of green building materials involve a variety of fields, such as building envelope materials, thermal insulation materials, energy-saving materials, etc. (Kang, 2019). For example, the use of materials with high insulating and energy-saving properties to reduce the energy consumption of buildings; the use of renewable materials as the main construction materials of buildings to reduce the dependence on limited resources; and the use of environment-friendly paints, flooring materials, etc. to improve indoor air quality (Wang and Wen, 2016). The development of green building materials can help improve buildings’ energy efficiency performance and reduce carbon emissions, thus promoting sustainable building development in the environmentally sustainable development context.

Low-carbon materials are those whose manufacturing process produces lower CO2 emissions (Li et al., 2014). EFM boasts the characteristics of low carbon, energy saving, and emission reduction, and by using EFM to build sports facilities, carbon emissions can be effectively reduced and environmental pollution minimized (Chichane et al., 2023). Biodegradable materials can be decomposed by microorganisms in the natural environment without causing pollution to the environment (Jiang and Jin, 2022). In the construction of sports facilities, biodegradable materials can be used to make seating, running tracks, and other equipment to minimize the environmental impact.

Renewable resources are recovered and reused by using used items or waste (Yuan, 2010), circular economy is one of the cores of “environmentally sustainable” development, and the use of recycled and EFM in the construction of sports facilities can greatly improve the utilization of resources and reduce wastage. In the construction of sports facilities, recycled resources can be used to make basketball hoops, soccer goals, and other equipment for recycling.

EFM has good sound insulation, heat insulation, moisture, and other properties; the use of these materials can improve the comfort and use of the interior of the venue. EFM usually have a longer service life and lower maintenance costs, which reduces the operating costs of sports venues.

Green buildings minimize their impact on the environment and human health during design, construction, use, and demolition (Qaidi et al., 2022; Chatterjee et al., 2020). By applying EFM to the construction of sports facilities, we can not only meet people’s sports needs but also promote sustainable development and leave a better environment and resources for future generations. In the construction of sports facilities, the concept of green buildings can be promoted, and EFM and energy-saving technologies can be used to create more environment-friendly and sustainable venues.

The application of EFM in constructing sports facilities has a comprehensive and positive impact (Zhang and Yang, 2007; SONG et al., 2021). The application of EFM in the construction of sports facilities has a comprehensive and positive impact. Using EFM makes it possible to reduce the consumption of natural resources, reduce environmental pollution and carbon emissions, and realize sustainable development.

Designing for environmental protection is a crucial aspect in constructing sports facilities, which considers several factors such as energy efficiency, water resource management, environmental landscape, use of renewable energy, choice of materials and circular economy, intelligent and sustainable management, etc. (Jiang, 2022). To realize the goals of sustainable development and environmental protection. Through rational design, sports facilities can meet functional needs and realize the goals of energy efficiency, low carbon emission, resource conservation, and environmental protection.

Energy-saving design is a crucial aspect in the construction of sports facilities. By optimizing the orientation and layout of buildings, the use of natural light and natural ventilation is maximized, and reliance on artificial lighting and air conditioning is reduced. Highly efficient insulating and heat-insulating materials help improve the building’s thermal insulation performance and energy conservation. Apply intelligent systems to control lighting, air conditioning, heating, and other equipment operations for precise energy management (Zhao and Li, 2022; Kumar et al., 2024b).

Water is a limited resource, and it is essential to manage and utilize water resources rationally in the construction of sports facilities. Reduce water consumption by using water-saving equipment and technology, such as low-flow faucets, water-saving showers, and automatic sensor faucets (Qiaoning and Wang, 2020; Peng, 2019). Through rainwater collection systems, rainwater is used for irrigation of plants and washing facilities to minimize dependence on tap water.

Incorporate natural elements into the surroundings of sports facilities through ecological landscaping principles. Locally adapted plants are selected for greening to reduce the need for water and chemical fertilizers and to provide ecosystem restoration and habitat protection. At the same time, the landscape layout is rationally planned to incorporate natural green spaces and wildlife protection areas into the design to provide better ecological services and environmental quality.

Utilizing renewable energy is one of the most essential directions in designing sports facilities that are environment-friendly. With the help of renewable energy sources such as solar and wind power, sports facilities can be provided with clean energy (Sfameni et al., 2023; Liping, 2015). During the design process, consideration can be given to installing solar panels and wind turbines to meet the facility’s power requirements. These can reduce dependence on traditional energy sources, lower carbon emissions, and improve the facility’s sustainability (Felekoglu et al., 2014).

When designing for environmental protection, choose EFM and focus on circular economy principles. Prioritize renewable or recycled materials to reduce the consumption of limited resources. Consider the life cycle analysis of materials and select durable and easy-to-maintain materials to reduce resource waste and environmental pollution. At the same time, encourage recycling and reuse of materials to minimize waste generation during the construction process and to promote a circular economy (LIN et al., 2020; CHENG, 2020).

Designing for the environment is a crucial aspect of the construction of sports facilities (Yan, 2016). Through rational design, it is possible to reduce resource consumption, lower energy consumption, and reduce environmental impacts, thus realizing the environmental objectives of sports facilities.

In sports facilities, construction environmental protection is a crucial aspect. Through the use of EFM and the implementation of environment-friendly measures, it is possible to reduce the consumption of natural resources, reduce environmental pollution, and ensure that the construction process meets environmental protection requirements.

In the construction of sports facilities, priority is given to EFM that meet environmental standards (Fang, 2021). These materials can be certified as environment-friendly building materials or recyclable and reusable. For example, use paints and adhesives that contain fewer volatile organic compounds (VOCs) to reduce the release of harmful gases. Reduce resource consumption by choosing building materials such as recyclable steel, wood, and concrete (Yan, 2021).

Take steps to minimize waste generation during the construction of sports facilities (Wu, 2021). Accurate material measurement and construction planning can avoid excessive purchasing and waste. At the same time, construction site management should be strengthened by sorting, collecting, and recycling reusable waste materials, such as concrete, steel, and timber. These will reduce the consumption of natural resources and minimize the negative impact on the environment (Rajeshkumar et al., 2021).

Pollutant emissions need to be controlled during the construction process of building sports facilities (Chawla et al., 2022). Contractors are required to use low-polluting vehicles and mechanical equipment to reduce pollution from motor vehicle exhaust emissions. At the same time, appropriate dust control measures, such as covering the land and spraying water mist, are set up at the construction site to reduce dust pollution during construction. In addition, hazardous wastes must be handled appropriately and disposed of by the procedures stipulated in the Environmental Protection Law to prevent damage to the environment and human health.

The impact of construction noise on the surrounding environment and residents during the construction of sports facilities also needs to be emphasized (Bhuyan and Gogoi, 2020). During the construction period, noise control measures, such as setting up noise barriers, adopting low-noise equipment, and restricting the construction time, are taken to minimize the noise disturbance and impact on the surrounding residents. In addition, real-time monitoring of the noise at the construction site should be carried out to ensure that the noise level meets the relevant standards and requirements (Yljungberg, 2007).

By applying EFM and constructing environment-friendly measures in sports facilities, the consumption of natural resources can be reduced, environmental pollution can be minimized, and the ecological environment can be protected. These are beneficial to environmental protection and in line with the requirements of sustainable development (Ren, 2011; Dong et al., 2024).

In the environmentally sustainable development context, the selection of low-carbon materials is crucial. These materials have a low carbon footprint and can reduce greenhouse gas emissions during the construction and use of sports facilities (More et al., 2022). Examples include the use of bamboo and timber produced from renewable resources, as well as recyclable construction materials such as steel and concrete. Properly selecting efficient insulation materials for building facades and roofs of sports facilities can help reduce energy consumption. High-efficiency insulation materials improve the thermal performance of buildings and reduce the energy demand for air conditioning and heating equipment. These help to reduce carbon emissions and lower operating costs (Cheng et al., 2024). Choosing low-carbon materials can help reduce the carbon footprint and mitigate the effects of climate change (Chen et al., 2023).

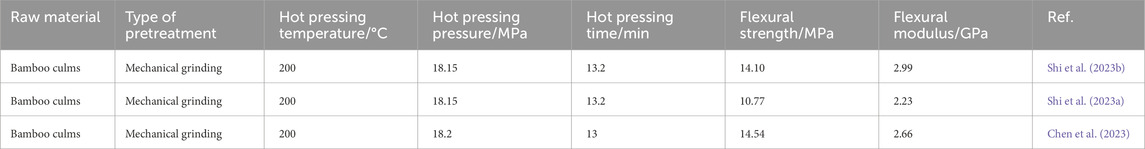

Renewable resources refer to the resources that can multiply and grow and continue to regenerate to keep up with the rate of consumption under the specific time and space conditions of nature, constantly maintaining or expanding their reserves, and can be reused by human beings. Forests, soils, grasslands, wetlands, solar energy, wind energy, water energy, animals, plants, microorganisms, and various natural biomes are all renewable resources (Zhao and Li, 2022). Renewable materials are materials that rely on such renewable resources to produce. Typically, such materials can be made or produced quickly, or replaced or supplemented by biological and other natural processes to keep pace with their use. Wood, cardboard, paper, and pulp are all widely used renewable materials. Through effective and sustainable forestry management, a continuous supply of wood can be achieved to support the normal functioning of society (Cenci et al., 2022). Preference is given to renewable materials such as bamboo and wood. These materials can be regenerated in a relatively short period and can reduce dependence on finite resources, bamboo and wood are renewable and fast-growing resources, and its planting and collection have less impact on the environment. In engineering construction, the use of bamboo and wood materials can reduce the demand for traditional wood and reduce forest mining and felling (Liu et al., 2023; Amrillah et al., 2023). Compared with traditional wood, bamboo and wood materials have lower energy consumption and greenhouse gas emissions, and at the same time, bamboo and wood materials have better strength and durability, which can meet the requirements of construction projects (More et al., 2022). The preparation process and properties of bamboo and wood are shown in Table 1. This issue could be partially addressed by making partially biodegradable composites of polymers with natural fibers (Yashas Gowda et al., 2018). Compared to traditional building materials, renewable materials have lower life cycle carbon emissions (Zhang, 2018; Shi et al., 2023a). The choice of renewable materials in the construction of sports facilities meets the requirements of sustainable development in the environmentally sustainable development context.

Table 1. Raw materials, preparation process, and the properties of plant fiber self-bonding molding environment-friendly materials.

In recycling, there are two other common concepts: biodegradable and compostable. Biodegradable means that a substance can be completely broken down into natural components by biological methods. The EU standard defines biodegradable material as within 6 months, with the help of bacteria, fungi, or other simple organisms, 90% of the original material can eventually be broken down into carbon dioxide, water, and minerals. Compostable is a higher standard than biodegradable: the efficiency of biodegradation is improved by controlling humidity, temperature, and oxidation processes, and requires that substances are ultimately broken down into completely non-toxic components. The whole process is environmentally friendly. It can be seen that compostable materials must be biodegradable, but biodegradable materials are not necessarily compostable (Qi et al., 2022; Erkmen et al., 2020).

Recyclable materials, as the name suggests, refer to materials that have recyclable value and can be recycled after recovery. Common recyclable materials in life include paper, cardboard, glass, plastic, metal, and so on. Among them, paper and cardboard take into account the dual characteristics of renewable and recyclable materials (Liu et al., 2023) (Amrillah et al., 2023). Recyclable materials play a huge role in energy conservation and environmental protection. Data show that a ton of waste paper can produce 850 kg of recycled paper, saving 3 cubic meters of wood; Discarded plastic bottles can also be recycled into yarn and used as fabric materials in furniture, automobiles, and other industries (Dušek et al., 2021). Promoting the recycling and reuse of construction waste helps to reduce the demand for raw materials and the generation of waste (Singhal, 2023). Waste concrete can be crushed and reused in the construction of road foundations, and waste steel can be recycled and reused in other construction projects. This circular economy approach helps to reduce resource consumption and environmental loads (Zhang and Liu, 2022).

In the environmentally sustainable development context, using EFM is a crucial aspect of the construction of sports facilities. The selection of low-carbon materials, renewable materials, high-efficiency insulation materials, and the promotion of reuse of construction waste can help reduce carbon emissions, resource consumption, and environmental pollution. By applying these EFM, sports facilities can positively respond to the environmentally sustainable development goal and contribute to sustainable development (Li et al., 2021).

In summary, EFM is a new model formed by the deep integration of scientific and technological innovation and the transformation and development of manufacturing, which can lead to environment-friendly manufacturing. It is an important emerging field in the new round of global industrial revolution and scientific and technological competition. First, using EFM in sports facilities are significant for environmental sustainability. With low-carbon and renewable materials, carbon emissions and resource consumption can be reduced (Gayathiri et al., 2022). Meanwhile, using highly efficient, water-saving equipment, and environment-friendly paints can reduce energy consumption and environmental pollution. Second, using EFM in sports facilities can improve the facilities’ sustainability and resource-use efficiency. Selecting materials that meet environmental standards optimizes the performance of building structures and components, improves energy-use efficiency, and reduces operating costs. Meanwhile, rationally managing water resources and controlling waste generation achieve a circular economy and maximize the use of resources (Wang et al., 2024). Third, using EFM in sports facilities not only contributes to environmental protection but also enhances user experience, social recognition, and environmental sustainability. The environment-friendly construction of sports facilities is in line with the pursuit of socially sustainable development. More importantly, a healthy, green, and comfortable environment attracts more athletes and audiences to actively participate in sports activities, thereby promoting sports development.

RL: Conceptualization, Investigation, Methodology, Writing–original draft. CZ: Conceptualization, Project administration, Supervision, Writing–original draft, Writing–review and editing.

The author(s) declare that no financial support was received for the research, authorship, and/or publication of this article.

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

The author(s) declare that no Generative AI was used in the creation of this manuscript.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Abdur, R. M., Haque, S., Athikesavan, M. M., and Kamaludeen, M. B. (2023). A review of environmental friendly green composites: production methods, current progresses, and challenges. Environmental Sci. Pollut. Res. 30 (7), 16905–16929. doi:10.1007/s11356-022-24879-5

Adams, B. (2019). Green development: environment and sustainability in a developing world. 3r ed. London: Routledge.

Aiduang, W., Chanthaluck, A., Kumla, J., Jatuwong, K., Srinuanpan, S., Waroonkun, T., et al. (2022). Amazing fungi for eco-friendly composite materials: a comprehensive review. J. Fungi 8 (8), 842. doi:10.3390/jof8080842

Amrillah, T., Prasetio, A., Supandi, A. R., Sidiq, D. H., Putra, F. S., Nugroho, M. A., et al. (2023). Environment-friendly copper-based chalcogenide thin film solar cells: status and perspectives. Mater. Horizons 10 (2), 313–339. doi:10.1039/d2mh00983h

Bharath, K. N., Madhu, P., Yashas Gowda, T. G., Verma, A., Sanjay, M. R., and Siengchin, S. (2021). Mechanical and chemical properties evaluation of sheep wool fiber–reinforced vinylester and polyester composites. Mater. Perform. Charact. 10 (1), 20200036–20200109. doi:10.1520/MPC20200036

Bhuyan, S., and Gogoi, N. (2020). Natural fibers: innovative sustainable and eco-friendly. Int. J. Curr. Microbiol. Appl. Sci. 9 (7), 1004–1011. doi:10.20546/ijcmas.2020.907.118

Călătan, G. A., and Dico, C. (2022). Environmentally friendly building materials with beneficial potential for indoor air quality. Athens J. Technol. and Eng. 9 (4), 305–319. doi:10.30958/ajte.9-4-3

Cao, H., Li, H., Zeng, D., and Ge, W. (2020). The state-of-art and future development strategies of green manufacturing. CHINA Mech. Eng. 31 (2), 135–144. doi:10.3969/j.issn.1004-132X.2020.02.002

Cenci, M. P., Scarazzato, T., Munchen, D. D., Dartora, P. C., Veit, H. M., Bernardes, A. M., et al. (2022). Eco-friendly electronics—a comprehensive review. Adv. Mater. Technol. 7 (2), 2001263. doi:10.1002/admt.202001263

Chandran, A. J., Rangappa, S. M., Suyambulingam, I., Manik, G., and Siengchin, S. (2024). Marine waste as a resource: developing bio-epoxy composites for a sustainable future. Mater. Today Sustain. 27, 100908. doi:10.1016/j.mtsust.2024.100908

Chatterjee, P., Mandal, N., Dhar, S., Chatterjee, S., and Chakraborty, S. (2020). A novel decision-making approach for light weight environment friendly material selection. Mater. Today Proc. 22, 1460–1469. doi:10.1016/j.matpr.2020.01.504

Chawla, S., Varghese, B. S., Chithra, A., Hussain, C. G., Keçili, R., and Hussain, C. M. (2022). Environmental impacts of post-consumer plastic wastes: treatment technologies towards eco-sustainability and circular economy. Chemosphere 308 (1), 135867. doi:10.1016/j.chemosphere.2022.135867

Chen, H., Shi, J. J., Zhong, T. H., Fei, B., Xu, X., Wu, J., et al. (2023). Tunable physical mechanical properties of eco-friendly and sustainable processing bamboo self-bonding composites by adjusting parenchyma cell content. ACS Sustain. Chem. and Eng. 11 (28), 10333–10343. doi:10.1021/acssuschemeng.3c01149

Cheng, P., Zhong, T., and Chen, H. (2024). Research progress of plant fiber self-bonding molding environmentally friendly materials. Acta Mater. Compos. Sin. 8 (41), 3897–3909. doi:10.13801/j.cnki.fhclxb.20240412.001

Cheng, Y.-Z. (2020). Review on process optimization and performance of carbon fiber composite sports equipment. Synthetic Mater. Aging Appl. 49 (5), 161–163+109. doi:10.16584/j.cnki.issn1671-5381.2020.05.049

Chichane, A., Boujmal, R., and El Barkany, A. (2023). Bio-composites and bio-hybrid composites reinforced with natural fibers: review. Mat. Today Proc. 72 (7), 3471–3479. doi:10.1016/j.matpr.2022.08.132

Cui, N. (2022). Embodiment of the application of green materials in the construction of sports facilities based on environmental sustainability. Environmental Eng. 40 (5), 349.

Dong, X., Song, R., Wang, P., Tang, J., Wang, Y., Shang, Y., et al. (2024). Multiscale engineered waste wood particles toward a sustainable, scalable, and high-performance structural material. Adv. Funct. Mater. 34 (9), 2308361. doi:10.1002/adfm.202308361

Du, Y. C. (2017). Application and exploration of environment-friendly materials in the built environment.

Dušek, J., Jerman, M., Podlena, M., Böhm, M., and Černý, R. (2021). Sustainable composite material based on surface-modified rape straw and environment-friendly adhesive. Constr. Build. Mater. 300, 124036. doi:10.1016/j.conbuildmat.2021.124036

Elfaleh, I., Abbassi, F., Habibi, M., Ahmad, F., Guedri, M., Nasri, M., et al. (2023). A comprehensive review of natural fibers and their composites: an eco-friendly alternative to conventional materials. Results Eng. 19, 101271. doi:10.1016/j.rineng.2023.101271

Erkmen, J., Yavuz, H. I., Kavci, E., and Sari, M. (2020). A new environmentally friendly insulating material designed from natural materials. Constr. Build. Mater. 255, 119357. doi:10.1016/j.conbuildmat.2020.119357

Executive Office of the Presidents Council of Advisorson Scienceand Technology (2019). Report to the president on capturing domestic competitive advantage in advanced manufacturing. Available at: https://www.whitehouse.gov/sites/default/files/microsites/ostp/pcast_amp_steering_committee_report_final_july_27_2012.pdf (Accessed on December 11, 2019).

Fang, G. (2021). Application of green materials in the construction of sports facilities. Mater. Prot. 54 (1), 217. doi:10.16577/j.cnki.42-1215/tb.2021.01.048

Fay, F., Linossier, I., Peron, J. J., Langlois, V., and Vallée-Rehel, K. (2007). Antifouling activity of marine paints: study of erosion. Prog. Org. Coatings 60 (3), 194–206. doi:10.1016/j.porgcoat.2007.07.027

Felekoglu, B., Tosun-Felekoglu, K., Ranade, R., Zhang, Q., and Li, V. C. (2014). Influence of matrix flowability, fiber mixing procedure, and curing conditions on the mechanical performance of HTPP-ECC. Compos. Part B Eng. 60, 359–370. doi:10.1016/j.compositesb.2013.12.076

Gayathiri, E., Prakash, P., Karmegam, N., Varjani, S., Awasthi, M. K., and Ravindran, B. (2022). Biosurfactants: potential and eco-friendly material for sustainable agriculture and environmental safety—a review. Agronomy 12 (3), 662. doi:10.3390/agronomy12030662

GOV.UK (2019). TheFutureofManufacturing:a new era of opportunity and challenge for the UKPro-ject report. Available at: https://www.gov.uk/government/uploads/system/uploads/attachment_data/file/255922/13-809-future-manufacturing-project-report.pdf. (Accessed on December 11, 2019).

Hadlahalli chandrashekar, P., Nagarajachari, U., Thyavihalli Girijappa, Y. G., Byrapura Chandregowda, H., and Kalappa, P. (2024). Synergistic effects of sisal/glass fiber hybridization and eggshell powder filler on the performance of eco-friendly polymer composites. Polym. Compos. doi:10.1002/pc.29041

He, P. (2018). Application of new materials in sports equipment. Shanxi Chem. Ind. 176 (4), 143–152.

Horizon (2019). The EU framework programme for research and innovation. Available at: https://ec.europa.eu/programmes/hori-zon2020/en/h2020sections (Accessed on December 11, 2019).

Hu, W. (2020). Application and research of graphene technology in sports materials. Adhesion 43 (7), 59–61+65.

Jiang, J. (2022). Application of environment protection materials in sports equipment design. Adhesion 49 (4), 55–59.

Jiang, Bo, and Jin, Y. (2022). Research progress of lignin functional materials based on its structural properties. Acta Mater. Compos. Sin. 39 (7), 3059–3083. doi:10.13801/j.cnki.fhclxb.20220321.001

Kang, J.-L. (2019). Exploring the application of environment-friendly materials in sports. Adhesion 40 (8), 40–42.

Kobetičová, K., Böhm, M., Jerman, M., Dušek, J., and Černý, R. (2022). Ecotoxicity and biodegradation of sustainable environment-friendly bone-glue-based adhesive suitable for insulation materials. Polymers 14 (11), 2209. doi:10.3390/polym14112209

Kuhn, R., Bryant, I. M., Jensch, R., and Böllmann, J. (2022). Applications of environmental nanotechnologies in remediation, wastewater treatment, drinking water treatment, and agriculture. Appl. Nano 3 (1), 54–90. doi:10.3390/applnano3010005

Kumar, M., Kumar, R., and Kumar, R. (2024b). Material extrusion-based additive manufacturing of sandwiched acrylonitrile butadiene styrene/glass fibers composites: machine learning approach to model tensile stress. Polym. Compos. 45, 15100–15112. doi:10.1002/pc.28823

Kumar, M., and Singh, J. (2024a). “Focus on carbon fiber reinforced composites manufacturing and properties,” in Composite materials processing using microwave heating technology. Editors M. K. Singh, G. Arora, S. Zafar, S. M. Rangappa, and S. Siengchin (Singapore: Springer Nature Singapore), 221–241. doi:10.1007/978-981-97-2772-8_11

Li, H.-M. (2023). Research on the application of green materials in home design. Foshan Ceram. 33 (2), 129–131.

Li, Y. (2020). Research on the application and performance of new fiber materials in sports equipment. Mater. Prot. 53 (10), 179–180. doi:10.16577/j.cnki.42-1215/tb.2020.10.048

Li, J., Cai, J. H., Fang, Z. C., He, Q. Z., and Hu, L. J. (2014). The research of the functional of anion fabric. Mat. Rep. 28 (1), 295–296, 306.

Li, L. Z., Cai, Z. W., Yu, K. Q., Zhang, Y., and Ding, Y. (2019). Performance-based design of all-grade strain hardening cementitious composites with compressive strengths from 40 MPa to 120 MPa. Cem. Concr. Compos. 97, 202–217. doi:10.1016/j.cemconcomp.2019.01.001

Li, X., Li, J., Wang, J., Yuan, J., Jiang, F., Yu, X., et al. (2021). Recent applications and developments of Polyurethane materials in pavement engineering. Constr. Build. Mater. 304, 124639. doi:10.1016/j.conbuildmat.2021.124639

Li, W., and Liu, Y. (2015). The revelation of LEED toward Chinese green building evaluation criteria. Railw. Stand. Des. 59 (8), 169–174. doi:10.13238/j.issn.1004-2954.2015.08.036

Liang, L. (2015). Impact of the use of advanced materials in sports equipment on the development of competitive sports. J. Hubei Inst. Sci. Technol. 35 (7), 158–160. doi:10.3969/j.issn.1006-5342.2015.07.054

Lin, J. X., Song, Y., Xie, Z. H., Guo, Y. C., Yuan, B., Zeng, J. J., et al. (2020). Static and dynamic mechanical behavior of engineered cementitious composites with PP and PVA fibers. J. Build. Eng. 29, 101097. doi:10.1016/j.jobe.2019.101097

Liu, X., Ni, R., Tian, Y., Yao, H., Xu, Q., and Xuan, Y. (2023). Environment-friendly efficient thermal energy storage paradigm based on sugarcane-derived eco-ceramics phase change composites: from material to device. Renew. Energy 217, 119155. doi:10.1016/j.renene.2023.119155

Luhar, S., Chaudhary, S., and Luhar, I. (2019). Development of rubberized geopolymer concrete: strength and durability studies. Constr. Build. Mater. 204, 740–753. doi:10.1016/j.conbuildmat.2019.01.185

Ma, J., Ma, C., Yang, Y., Xu, W., and Zhang, G. (2014). Biodegradable polyurethane carrying antifoulants for inhibition of marine biofouling. Industrial and Eng. Chem. Res. 53 (32), 12753–12759. doi:10.1021/ie502147t

More, P. R., Jambrak, A. R., and Arya, S. S. (2022). Green, environment-friendly and sustainable techniques for extraction of food bioactive compounds and waste valorization. Trends Food Sci. and Technol. 128, 296–315. doi:10.1016/j.tifs.2022.08.016

National Academies of Sciences Engineering, and Medicine (2019). Frontiers of materials research: Adecadal survey. Washington, DC: The Nat. Acade. Pre. doi:10.17226/25244

O’Hegarty, R., Kinnane, O., Newell, J., and West, R. (2021). High performance, low carbon concrete for building cladding applications. J. Build. Eng. 43, 102566. doi:10.1016/j.jobe.2021.102566

Qaidi, S., Najm, H. M., Abed, S. M., Özkılıç, Y. O., Al Dughaishi, H., Alosta, M., et al. (2022). Concrete containing waste glass as an environmentally friendly aggregate: a review on fresh and mechanical characteristics. Mater. 15 (18), 6222. doi:10.3390/ma15186222

Qi, C., Wang, S., Zhu, X., Zhang, T., Gou, Y., Xie, Z., et al. (2022). Environmental-friendly low-cost direct regeneration of cathode material from spent LiFePO4. J. Alloys Compd. 924, 166612. doi:10.1016/j.jallcom.2022.166612

Qiaoning, Z., and Wang, L. (2020). Research on the application of energy-saving and environmental protection materials in modern stadium building decoration. Chem. Biol. Environ. Prot. 44 (11), 34–38.

Qin, X., and Kaewunruen, S. (2022). Environment-friendly recycled steel fibre reinforced concrete. Constr. Build. Mater. 327, 126967. doi:10.1016/j.conbuildmat.2022.126967

Rajeshkumar, G., Seshadri, S. A., Devnani, G. L., Sanjay, M., Siengchin, S., Prakash Maran, J., et al. (2021). Environment friendly, renewable and sustainable poly lactic acid (PLA) based natural fiber reinforced composites–A comprehensive review. J. Clean. Prod. 310, 127483. doi:10.1016/j.jclepro.2021.127483

Rana, M., Kumar, M., and Kumar, R. (2024). Fused deposition modelling approach in recycled polypropylene/aluminum powder composites for sustainable development. Appl. Sci. Eng. Prog. 17 (4), 7501. doi:10.14416/j.asep.2024.07.009

Reis, J., Levandoski, W., Krogel, M., Ferrazzo, S., Pasquali, G., and Korf, E. (2024). Technological characterization and environment-friendly possibilities to reuse water treatment sludge in building materials. J. Environmental Sci. Health, Part A 59, 241–250. doi:10.1080/10934529.2024.2367353

Ren, Z. (2011). Introduction to the application of environment-friendly building materials in residential construction. Build. Mater. Technol. Appl.

Rozhdestvenskaya, L., Cherednichenko, L., Malchugova, K., and Korotenko, V. (2021). Development of a sustainable environment-friendly waste management system at large mass and sports events (2023 WJC in Novosibirsk). E3S Web Conf. 296, 02010. doi:10.1051/e3sconf/202129602010

Sfameni, S., Rando, G., and Plutino, M. R. (2023). Sustainable secondary-raw materials, natural substances and eco-friendly nanomaterial-based approaches for improved surface performances: an overview of what they are and how they work. Int. J. Mol. Sci. 24 (6), 5472. doi:10.3390/ijms24065472

Shi, J. J., Xu, X., Zhong, T. H., Zhang, W., Yuan, S., Feng, X., et al. (2023b). Fabrication and applica-tion of eco-friendly bamboo self-bonded composites for furniture. ACS Sustain. Chem. and Eng. 11 (20), 7833–7843. doi:10.1021/acssuschemeng.3c00721

Shi, J. J., Zhong, T. H., Xu, X., Wu, J., Zou, Y., Fei, B., et al. (2023a). Eco-friendly and special shaped bamboo binderless fiberboards fabricated by self-bonding technology: effect of bamboo fibers with different sizes. Industrial Crops Prod. 194, 116300. doi:10.1016/j.indcrop.2023.116300

Singhal, S. (2023). Biochar as a cost-effective and eco-friendly substitute for binder in concrete: a review. Eur. J. Environmental Civ. Eng. 27 (2), 984–1009. doi:10.1080/19648189.2022.2068658

Song, R., Hou, Y., He, Z., Xia, J., Zhu, Y., and Wu, H. (2021). Research progress of interfacial mechanical behavior and design of nanocellulose-based sequentially architected materials. J. Univ. Sci. Technol. China 51 (10), 766–786.

Sun, W., Yang, F., Hou, M., He, D., Wu, H., Liu, Q., et al. (2023). Microplastic pollution and degradation in environment. China Plast. 37 (11), 117–126. doi:10.19491/j.issn.1001-9278.2023.11.013

Thyavihalli Girijappa, Y. G., Mavinkere Rangappa, S., Parameswaranpillai, J., and Siengchin, S. (2019). Natural fibers as sustainable and renewable resource for development of eco-friendly composites: a comprehensive review. Front. Mater. 2019 Sept 6, 226. doi:10.3389/fmats.2019.00226

Turk, K., and Demirhan, S. (2013). The mechanical properties of engineered cementitious composites containing limestone powder replaced by microsilica sand. Can. J. Civ. Eng. 40 (2), 151–157. doi:10.1139/cjce-2012-0281

Ul Haq, M. Z., Sood, H., Kumar, R., Sharma, V., Kumar, A., Srinivas, T., et al. (2023). Eco-friendly building material innovation: geopolymer bricks from repurposed plastic waste. E3S Web Conf. 430, 01201. doi:10.1051/e3sconf/202343001201

United Nations Habitat (2023). The strategic plan 2020-2023. Available at: https://unhabitat.org/the-strategic-plan-2020-2023. (Accessed on December 17, 2022).

Jerry, Y. (2014). Integrated design of green buildings. Harbin: Harbin Industrial University Press, 6.

Ustaoglu, A., Yaras, A., Sutcu, M., and Gencel, O. (2021). Investigation of the residential building having novel environment-friendly construction materials with enhanced energy performance in diverse climate regions: cost-efficient, low-energy and low-carbon emission. J. Build. Eng. 43, 102617. doi:10.1016/j.jobe.2021.102617

Verma, C., Chhajed, M., Singh, S., and Maji, P. K. (2022). Cellulose nanocrystals for environment-friendly self-assembled stimuli doped multisensing photonics. ACS Appl. Polym. Mater. 4 (6), 4047–4068. doi:10.1021/acsapm.2c00061

Vinod, A., Gowda, T. Y., Vijay, R., Sanjay, M. R., Gupta, M. K., Jamil, M., et al. (2021). Novel Muntingia Calabura bark fiber reinforced green-epoxy composite: a sustainable and green material for cleaner production. J. Clean. Prod. 294, 126337. doi:10.1016/j.jclepro.2021.126337

Wang, G., and Wen, H. (2016). Green packaging[M]. 2nd edition. Harbin: Northeast Forestry University Press.

Wang, J., Liu, Y. R., and Feng, D. Y. (2024). Comparison and enlightenment of energy indicators of green eco-district assessment criteria from the goal of carbon neutrality in China, the United States, and the United Kingdom. J. Hum. Settlements West China 39 (3), 116–122. doi:10.13791/j.cnki.hsfwest.20240317

Wang, Q., Li, G., Jiang, B., Meng, C., Xie, L., Guo, Z., et al. (2024). An Introduction of GB/T 50378-2019 (2024 Version) Assessment standard for green building. Build. Sci. 40 (10), 149–152+178. doi:10.13614/j.cnki.11-1962/tu.2024.10.17

Wu, B. (2018). Research on the application of green environmental protection materials in tea packaging design.

Wu, X. (2021). Application of green materials in environmental art design. Mater. Prot. 54 (4), 10040.

Xiong, S., Tang, R., Gong, D., Deng, Y., Zheng, J., Li, L., et al. (2022). Environmentally-friendly carbon nanomaterials for photocatalytic hydrogen production. Chin. J. Catal. 43 (7), 1719–1748. doi:10.1016/s1872-2067(21)63994-3

Yan, Y.-J. (2021). Research on the application of green environmental protection materials in sports. Synthetic Mater. Aging Appl. 50 (4), 161–163. doi:10.16584/j.cnki.issn1671-5381.2021.04.051

Yan, Y. (2016). The research status and structural analysis of Coolplus fiber. Synthetic Mater. Aging Appl. 45 (2), 77–82. doi:10.16584/j.cnki.issn1671-5381.2016.02.018

Yashas Gowda, T. G., Sanjay, M. R., Subrahmanya Bhat, K., Madhu, P., Senthamaraikannan, P., and Yogesha, B. (2018). Polymer matrix-natural fiber composites: an overview. Cogent Eng. 5 (1), 1446667. doi:10.1080/23311916.2018.1446667

Yi, Z. (2014). On the research of application of environment-friendly materials in architectural design

Yljungberg, L. (2007). Materials selection and design for development of sustainable products. Mater. Des. 28 (2), 466–479. doi:10.1016/j.matdes.2005.09.006

Yuan, H. (2010). Application of environment-friendly building materials in sustainable residential construction. Henan Sci. Technol. (12X), 56.

Yue, X., Yang, H. B., Han, Z. M., Lu, Y., Yin, C., Zhao, X., et al. (2024). Tough and moldable sustainable cellulose-based structural materials via multiscale interface engineering. Adv. Mater. 36 (7), 2306451. doi:10.1002/adma.202306451

Zhang, H. (2018). Introduction to the characteristics and application development trend of environment-friendly building energy-saving materials. Const. Mater. Decor. (3), 60–61.

Zhang, Y., and Liu, Y. (2022). Application of energy saving and environmental protection material in landscape construction of urban landscape wetland system. Int. J. Nanotechnol. 19 (12), 1105–1116. doi:10.1504/ijnt.2022.129756

Zhang, Y., and Yang, Z. (2007). Eco-efficiency of urban material metabolism: a case study in Shenzhen, China. Acta Ecol. Sin. 27 (8), 3124–3131. doi:10.1016/s1872-2032(07)60067-5

Zhang, Z. (2020). Development and application of green building materials. Inf. Rec. Mater. 21 (1), 14–16. doi:10.16009/j.cnki.cn13-1295/tq.2020.01.006

Zhang, Z. G., Yuvaraj, A., DI, J., and Qian, S. (2019). Matrix design of light weight, high strength, high ductility ECC. Constr. Build. Mater. 210, 188–197. doi:10.1016/j.conbuildmat.2019.03.159

Zhang, H. (2020). Application of unsaturated polyester resin in composites in development. Chem. Eng. Equip. (12), 250–254.

Zhao, J., and Li, S. (2022). Life cycle cost assessment and multi-criteria decision analysis of environment-friendly building insulation materials-A review. Energy Build. 254, 111582. doi:10.1016/j.enbuild.2021.111582

Keywords: environment-friendly materials, sport facilities, material selection, sustainability, environmental protection

Citation: Li R and Zhai C (2025) Constructing sports facilities using environment-friendly materials. Front. Mater. 11:1524729. doi: 10.3389/fmats.2024.1524729

Received: 08 November 2024; Accepted: 24 December 2024;

Published: 15 January 2025.

Edited by:

Vinod Ayyappan, King Mongkut’s University of Technology North Bangkok, ThailandReviewed by:

Yashas Gowda T. G., Malnad College of Engineering, IndiaCopyright © 2025 Li and Zhai. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Chenxi Zhai, Y2hlbnhpemhhaUBvdXRsb29rLmNvbQ==

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.