94% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

ORIGINAL RESEARCH article

Front. Mater., 13 March 2024

Sec. Structural Materials

Volume 11 - 2024 | https://doi.org/10.3389/fmats.2024.1346754

This article is part of the Research TopicAsphalt Pavement Performance under Complex Service ConditionsView all 10 articles

Oxidative aging of asphalt binders seriously affects the durability of asphalt pavements and causes early damage. Hence, appropriate indices that could track the extent of asphalt binder aging are of great importance to the material selection, design, and maintenance of asphalt pavement. This paper aims to select the applicable rheological and chemical indices to characterize oxidative aging degrees of polymer-modified asphalt binders. Styrene–butadiene–styrene (SBS)-modified asphalt and two kinds of SBS/crumb rubber compound-modified asphalt were subjected to a rolling thin-film oven (RTFO) test and 20 h, 40 h, and 60 h pressure aging vessel (PAV) tests. Various rheological experiments at different temperature ranges were applied to obtain rheological indices, including complex shear modulus (|G*|), G–R parameter, and J′ (derivative of creep compliance). A range of chemical indices were determined by Fourier transform infrared spectroscopy (FTIR). The results indicate that the carbonyl index is strongly correlated with PAV aging time. |G*| at 52°C and J′ values at −18°C are the two most promising rheological indices to track the oxidative aging of asphalt binders and relate well to the chemical changes induced by PAV aging. In addition, the G–R parameter is problematic in some instances when used as the rheological index because its accuracy depends on the precise fitting of master curves.

Polymer modifiers are widely used in China to improve the anti-aging performance of asphalt binders and to extend the service life of asphalt pavement. Nevertheless, polymer-modified asphalt binders face an inevitable oxidative aging problem that causes asphalt materials to harden and reduce their cohesion capacity (Qin et al., 2014; Rahmani et al., 2018; Cai et al., 2024). Furthermore, due to asphalt hardening, asphalt mixtures may develop cracks and other deteriorations. The development of cracks leads to a decrease in the service performance of asphalt pavement, increasing the need for maintenance and repair (Yao et al., 2023; Yao et al., 2023). Therefore, it is of vital importance to identify appropriate indices that can effectively characterize the aging degrees of polymer-modified asphalt binders and contribute to the design, construction, and maintenance of asphalt pavement.

In general, rheological parameters and chemical functional groups are the two main categories used to trace and quantify the oxidative aging of asphalt binders. Researchers have proposed many rheological indices, including rutting parameter (|G*|/sinδ), fatigue parameter (|G*|∙sinδ), Glover–Rowe (G–R) parameter, and so on, because they are well correlated to the physical or mechanical properties of asphalt binders and are easily obtained by a dynamic shear rheometer (DSR) test (Hao et al., 2017; Zhang et al., 2018; Zhang et al., 2023). The main drawback when these rheological indices are used to characterize the aging behavior of asphalt binders is that they only reflect the changes in the materials' physical parameters or paving performance and can hardly indicate any alteration in material components. However, the chemical indices can directly indicate the oxygen uptake during asphalt binders’ oxidative aging process using a Fourier transform infrared spectroscopy (FTIR) technique. It is generally recognized that the formation and accumulation of sulfoxide and carbonyl are two major chemical reactions in the aging process of asphalt binders (Peterson, 2009). The index of the carbonyl function group was proved to effectively determine the long-term aging behavior of asphalt binders because the formation rate of the carbonyl group remained stable throughout the aging process (Huh and Robertson, 1996). In addition, polymer degradation is a significant part of the polymer-modified asphalt binders aging process (Xu et al., 2021; Zhou et al., 2023), and thus, the relative proportion of polystyrene (PS) and polybutadiene (PB) can be reasonable indices to trace the oxidative aging of polymer-modified asphalt binders.

Although numerous indices have been proposed in the past decades, a comprehensive investigation focusing on the rheological and chemical indices and their relationships to oxidative degrees is currently missing. In addition, because most existing studies conducted the standard aging processes, including the rolling thin-film oven (RTFO) test and the pressure aging vessel (PAV) test, there is still a lack of studies on evaluation indices that consider the long-term laboratory aging effects. Hence, this paper aims to investigate various rheological and chemical indices to characterize the long-term oxidative aging of polymer-modified asphalt binders. SBS-modified asphalt and two kinds of SBS/crumb rubber (SR1 and SR2)-modified asphalt were used to extend PAV aging to simulate long-term aging. All the asphalt binders at each aging condition were subjected to a DSR test, a bending beam rheometer (BBR) test, and an FTIR test to obtain the rheological and chemical indices at different temperature ranges. Furthermore, the relationships between aging indices and PAV aging time and the interrelationship of different indices were also discussed. A technical flowchart of this paper is shown in Figure 1.

The details of three polymer-modified asphalt binders and the long-term aging time are shown in Table 1. All these asphalt binders were obtained from Jiangsu Baoli Asphalt Co., Ltd. All the asphalt binders were subjected to a PAV (AASHTO R28) test to assess the rheological and chemical changes in terms of long-term oxidative aging, and the testing time was prolonged compared to standard aging time. In this procedure, 50 g of the residue from the RTFO (AASHTO T240) test was further conditioned in the PAV at 100°C and 2.1 MPa pressurized air for the corresponding testing time.

The temperature sweep and frequency sweep tests were conducted using HAAKE MARS 40 model DSR. For the former test, the applied strain and frequency were 1% and 1.59 Hz, respectively. The test temperatures were 52°C, 58°C, 64°C, 70°C, and 76°C to find an appropriate index that could characterize the asphalt binders’ aging degrees at a relatively higher temperature. For the frequency sweep test, a 1% strain amplitude was used to ensure the obtained rheological parameters of all asphalt binders were in their linear viscoelastic range. The test angular frequencies were set to be between 0.1 and 100 rad/s, and the same sample of each asphalt binder was tested under six temperatures (15°C, 25°C, 35°C, 45°C, 60°C, and 70°C).

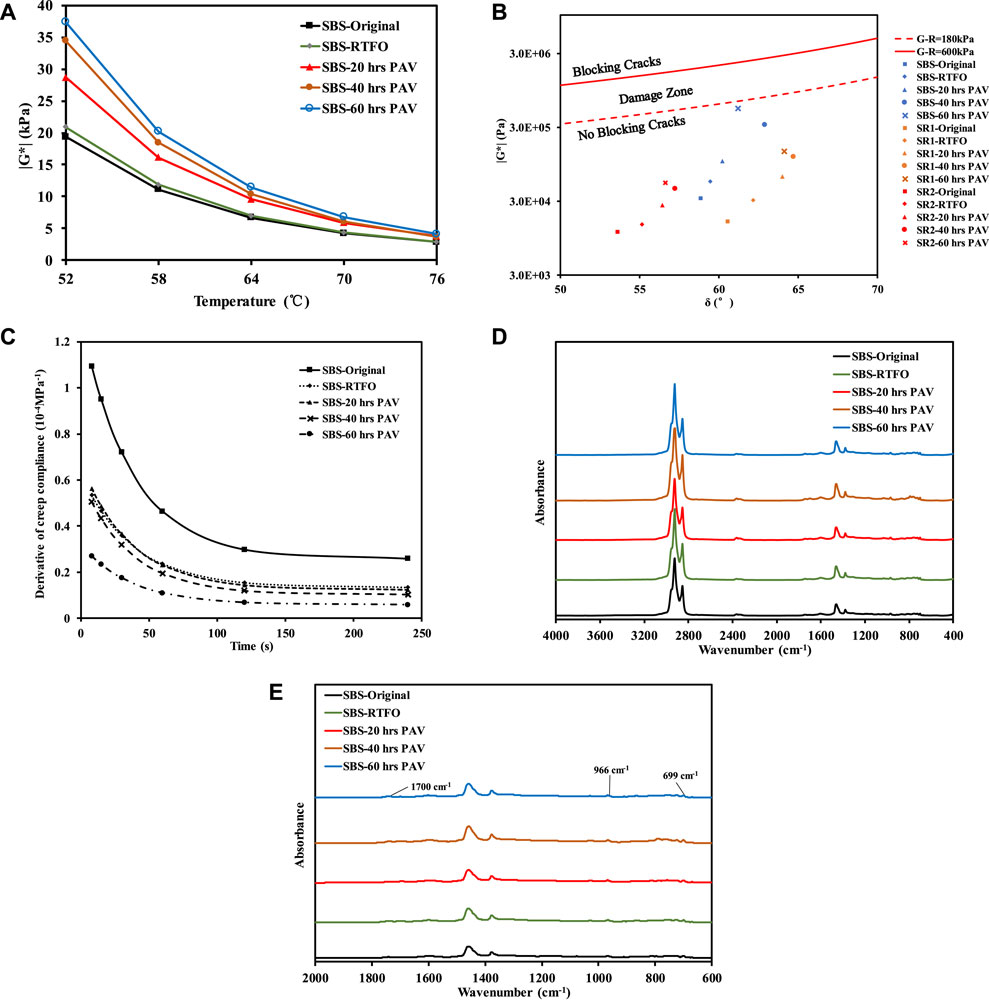

The complex shear modulus (|G*|) can be measured directly by an oscillation test and can well track changes in a binder’s physical properties induced by oxidative aging (Sun et al., 2024). Therefore, it was selected as one of the rheological indices. In addition, it is an important indicator in the Superpave performance grading specification. Figure 2A shows the variation in SBS asphalt binders |G*| with the temperature increase at different aging conditions.

FIGURE 2. (A) |G*| of the SBS-modified asphalt binder; (B) G–R parameter; (C) J′ of the SBS-modified asphalt binder at −18°C; (D) FTIR spectra of the SBS-modified asphalt binder; (E) chemical indices in the fingerprint region.

The G–R parameter was also used as a rheological index in this paper. It was proposed to quantify the age-related cracking resistance of asphalt binders at the intermediate temperature range (Glover et al., 2002; Rowe, 2011) and could be obtained from the black space diagram. In addition, based on Kandhal's (1997) ductility thresholds, the G–R parameters at values 180 kPa and 600 kPa are deemed to identify the onset of cracking and significant cracking, respectively (Rowe, 2011). The following equation details the calculation formula of the G–R parameter.

where

However, testing at 0.005 rad/s is impossible, and thus, the

The Christensen–Anderson–Marasteanu (CAM) model, which is widely used, was taken to construct master curves for complex shear moduli, as represented in the following equation (Yusoff et al., 2011).

where

Due to the addition of a relatively high content of polymer modifier, the phase angle master curves of the modified asphalt binders showed the characteristic of a plateau zone, and the CAM model could not fit very well. As a consequence, a modified double-logistic (DL) model was used to construct the phase angle master curves and was found to have a good fit with the observed data (Asgharzadeh et al., 2013). The shift factors for the construction of complex shear modulus master curves were then used to build phase angle master curves. This modified DL model is detailed in the following equation.

where

A BBR (Cannon Instrument Company) test was conducted on these three asphalt binders after each aging condition at four different temperatures (−12°C, −18°C, −24°C, and −30°C) according to AASHTO T313 to analyze their low-temperature rheological characteristics. Two parameters, creep stiffness (S) and creep rate (m-value), could be obtained from this test. The former parameter S represented the resistance to constant loading of the binder, and the latter parameter m measured the rate change of asphalt stiffness as the loads were applied (Wang et al., 2012). The S and m values of the tested binders at any time (t) were calculated by the following equations. In addition, two replicate beams of each asphalt binder were tested, and the average values are reported.

where

Although

In this paper, an FTIR spectrometer (Bruker, Germany) was used to quantify the functional groups of asphalt binders before and after aging in the wavenumber range of 4,000–400 cm−1. Spectra were recorded using 32 scans at a resolution of 4 cm−1. For reliability, a minimum of six replicates were tested for each asphalt binder. Changes in carbonyl, polystyrene, and polybutadiene functions were recorded at wavenumbers 1,700 cm−1, 699 cm−1, and 966 cm−1. An existing study (6) indicates that the number of sulfoxide functional groups determines the degree of an asphalt binder’s short-term aging, while the formation rate of the carbonyl is stable throughout the aging process. Therefore, this paper did not choose sulfoxide functional groups as the chemical index. Figures 2D, E indicate examples of the FTIR spectra and chemical indices. Chemical indices ICA and IPB/IPS were used in this study. They are calculated as shown in the following equations:

where

Linear regression is one of the most well-known modeling techniques and is a preferred technique for learning predictive models (Shen and Wang, 2024). In this technique, as the aging time is a continuous independent variable, the performance after aging (the dependent variable) can be continuous or discrete, and the property of the regression line is linear. Linear regression is very sensitive to outliers and can better identify them (Shen and Wang, 2023). Linear regression would also be convenient for practical engineering operations, predicting the performance of long-term aging asphalt.

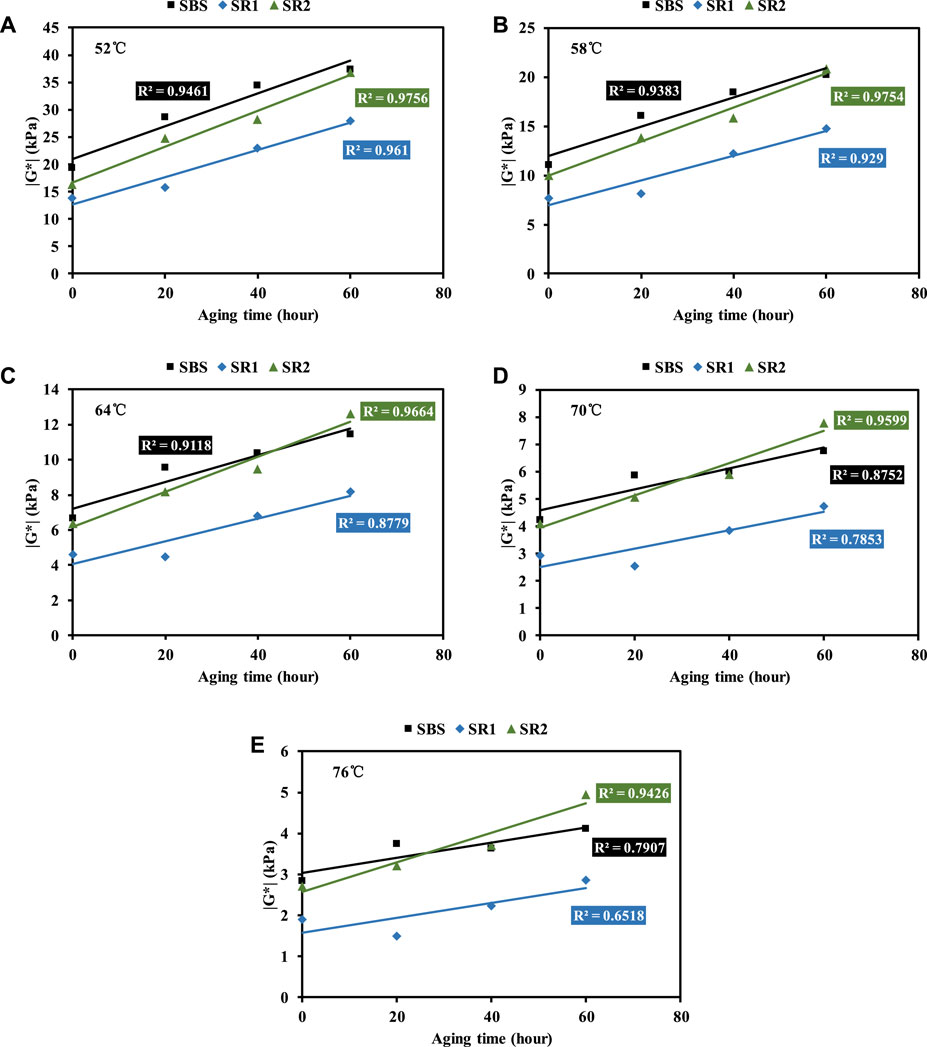

Figure 3 shows the correlations between |G*| and aging time at different temperatures. As can be seen, SBS- and SR1-modified asphalt binders’ |G*| show a good linear correlation with aging time; however, this relationship for the SR2-modified asphalt binder is relatively poor, especially at high temperatures. Thus, this paper chose the |G*| values at 52°C for the next exploration, expecting they have a good relationship with other indices. In addition, the rate of oxidation is temperature-dependent; the slopes of regression curves decline as temperature increases. This means an appropriate rheological index that is directly related to a binder’s physical property should not be tested at a relatively high temperature because the binder’s viscous characteristic will strongly affect the accuracy of experimental results. In terms of the effect of modifications, it can be seen that the |G*| values of asphalt binders decrease at 52°C with the addition of crumb rubber. For SR1- and SR2-modified asphalt binders with the same crumb rubber content, the rise of the SBS modification content can significantly increase |G*| values at all test temperatures.

FIGURE 3. Changing curves of |G*| versus aging time: (A) 52°C, (B) 58°C, (C) 64°C, (D) 70°C, and (E) 76°C.

As can be seen from Figure 4, all asphalt binders should have no cracking-related issues. In addition, it is obvious that the SBS asphalt binder’s G–R value rate of change is much larger than that of the other two asphalt binders. It indicates that adding crumb rubber effectively enhances the asphalt binder’s cracking resistance and anti-aging performance at an intermediate temperature range. Generally speaking, asphalt binder modulus and phase angle values increase with the increase of aging time in shear mode tests. This is because asphalt binders become stiffer and tend to behave more elastically. According to Figure 2B, however, the phase angle values of these three asphalt binders increase at 0.005 rad/s (which corresponds to approximately −3.099 Hz reduced frequency) before the aging time reaches 40 h, while the values decline between 40 h PAV aging and 60 h PAV aging. The same result, which is triggered by a combination of factors, was found by many researchers (Isacsson and Lu, 1999; Airey, 2003; Hao et al., 2017; Subhy et al., 2018; Zhang et al., 2018). With the increase in aging time, phase angle values increase at a low-frequency range and decrease at a high-frequency range. In addition, this changing trend is more obvious when the polymer modification content is more than 3% (Isacsson and Lu, 1999). In other words, this phenomenon is highly related to the testing frequency and modification dosage. Because the calculated frequency of the G–R parameter is 0.005 rad/s, which is relatively low, it can be predicted to appear. The decrease in phase angle values when the aging time reaches 40 h may result from the fact that most polymer has been degraded, and the asphalt phase begins to play a major role (Airey, 2003).

Figure 5 shows the correlation between J′ and aging time. It can be seen that this rheological index is not well-correlated with aging duration, especially when the test temperature is −30°C. Thus, the J′ values tested at −18°C were selected as the rheological index at a low-temperature range because of their relatively higher correlation. Another reason is that −18°C in the BBR test corresponds to −28°C in Superpave performance grading, which is an extreme service temperature for asphalt binders. We can see that all the J′ changing rates for the three asphalt binders induced by oxidative aging are not very different, while their initial J′ values are important for creep behaviors affected by oxidative aging at low-temperature conditions. Therefore, the addition of crumb rubber may not slow the asphalt binder’s aging rate but could enhance cracking resistance at low temperatures, which leads to relatively better low-temperature performance when asphalt binders are subjected to long-term aging.

Numerous studies showed that asphalt binders exhibit an initial fast reaction period, followed by a relatively slower reaction period that has an approximately constant rate of oxidative aging (Petersen, 1998; Jin et al., 2011; Petersen and Glaser, 2011). In this paper, the chemical indices were evaluated within the constant rate period because all the asphalt binders were subjected to long-term oxidative aging.

Figure 6 compares two chemical indices with respect to aging time. The formation rate of carbonyl in the SBS-modified asphalt binder is the highest, although its initial ICA is relatively low. In addition, ICA and IPB/PS show a similar rank for base asphalt aging and polymer modifier degradation processes. It also can be seen that the IPB/PS values of SR1 and SR2 are higher than those of SBS, which may be because the added crumb rubber contains a certain amount of polystyrene and polybutadiene. However, the current study (Yan et al., 2018) shows that the chemical index IPB/PS is independent of the polymer modifier’s concentration fluctuation and can effectively represent the extent of aging of the polymer-modified asphalt binder. The authors consider that all the rheological indices directly relate to asphalt binder’s physical and mechanical properties, and the modifier degradation does not contribute much to oxidation products (Nivitha et al., 2016), while the volatilization of light components and the formation of macromolecules in base asphalt are the main causes of asphalt hardening. Hence, ICA was selected as a promising chemical index and used in the following analysis with the rheological indices.

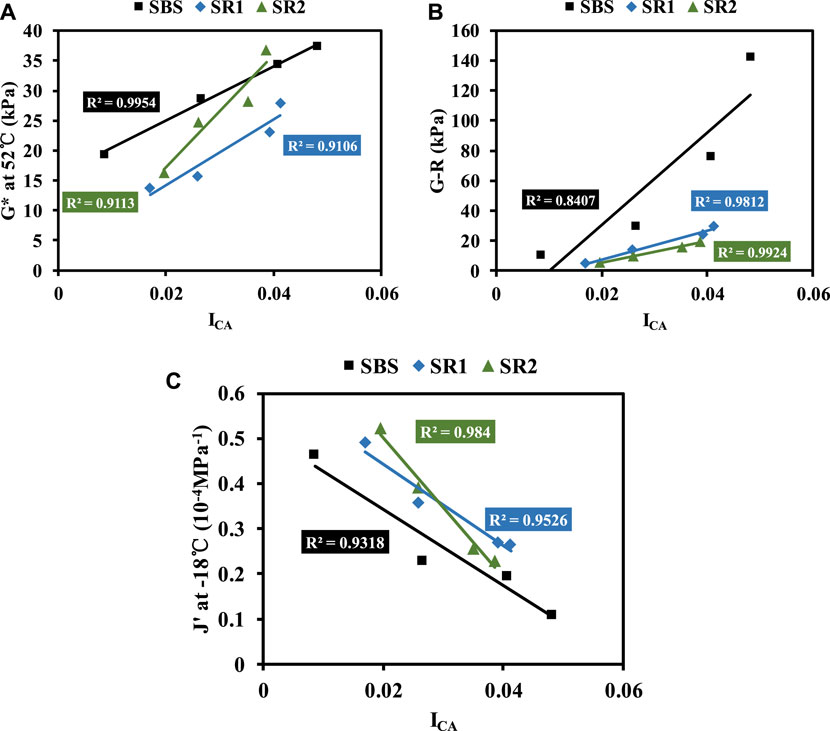

Figure 7 indicates the relationships between rheological indices, including high-, intermediate-, and low-temperature parameters, and the chemical index. As we can see, the correlation of the SBS asphalt binder’s G–R parameter with the ICA is not as good as the other rheological indices. This problem is related to the construction errors of |G*| and phase angle master curves. The G–R parameter accuracy depends on the precise fitting of master curves. In addition, the changing rates of different indices between the latter aging condition and the former aging condition are detailed in Table 2 to evaluate the aging sensitivities of different indices. Based on the comprehensive analysis of all indices, the anti-aging property of SBS-modified asphalt is relatively poor, and the SR2-modified asphalt exhibits good aging resistance performance. It can be concluded that the G–R parameter is the most sensitive index to aging effects. However, it is not reliable enough because of its relatively poor correlation with the chemical index. In addition, its calculation involves the phase angle, and the variation in the phase angle due to aging is quite complex. Therefore, based on the analysis of correlations between the different indices and their sensitivities to aging, |G*| values at 52°C and J′ values at −18°C are suggested as the rheological indices, and ICA is an effective chemical index to characterize long-term oxidative aging.

FIGURE 7. Correlations between rheological and chemical indices: (A) |G*| versus ICA; (B) G–R versus ICA; (C) J′ versus ICA.

In this study, various rheological and chemical indices were evaluated to track the long-term oxidative aging of polymer-modified asphalt binders. The main conclusions that can be drawn from the experimental and analytical results of this study are as follows:

(1) |G*| at 52°C and J′ values at −18°C are the two most promising rheological indices to track the degree of oxidative aging. The test temperature should not exceed 52°C when using |G*| as the rheological index to track the long-term oxidative aging of polymer-modified asphalt binders because the asphalt binder’s viscous characteristic will strongly affect the accuracy of experimental results.

(2) The volatilization of light components and the formation of macromolecules in base asphalt are the main causes of asphalt hardening. The carbonyl index ICA is suggested as an effective chemical index for characterizing long-term oxidative aging.

(3) Although the G–R parameter is the most sensitive index to aging effects, it is problematic in some instances when used as the rheological index because its reliability depends on the precise fitting of master curves.

The original contributions presented in the study are included in the article/supplementary material; further inquiries can be directed to the corresponding authors.

SC: conceptualization, investigation, and writing–original draft. SZ: conceptualization, data curation, and writing–review and editing. GX: conceptualization, investigation, methodology, writing–original draft, and writing–review and editing. XC: funding acquisition, supervision, and writing–review and editing. LY: funding acquisition, supervision, and writing–review and editing. QX: funding acquisition, investigation, and writing–review and editing.

The author(s) declare financial support was received for the research, authorship, and/or publication of this article. This work was supported by the National Key Research and Development Program of China under grant 2022YFB2602604.

Authors LY and QX were employed by Jiangsu Zhonghong Environmental Protection Technology Co., Ltd.

The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations or those of the publisher, the editors, and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Airey, G. D. (2003). Rheological properties of styrene butadiene styrene polymer modified road bitumens. Fuel 82 (14), 1709–1719. doi:10.1016/S0016-2361(03)00146-7

Asgharzadeh, S. M., Tabatabaee, N., Naderi, K., and Partl, M. (2013). An empirical model for modified bituminous binder master curves. Mater. Struct. 46 (9), 1459–1471. doi:10.1617/s11527-012-9988-x

Cai, X., Ashish, P. K., Leng, Z., Tan, Z. F., and Wang, H. N. (2024). Effects of residual water on mechanical properties of cold mix based semi-flexible pavement composite towards a sustainable paving material. J. Clean. Prod. 434, 139857. doi:10.1016/j.jclepro.2023.139857

Glover, C. J., Davison, R. R., Domke, C. H., Ruan, Y., Juristyarini, P., and Knorr, D. B. (2002). Development of a new method for assessing asphalt binder performance durability. U.S. Department of Transportation. Washington, DC, USA,

Hao, G., Huang, W., Yuan, J., Tang, N., and Xiao, F. (2017). Effect of aging on chemical and rheological properties of SBS modified asphalt with different compositions. Constr. Build. Mater. 156, 902–910. doi:10.1016/j.conbuildmat.2017.06.146

Huh, J., and Robertson, R. E. (1996). Modeling of oxidative aging behavior of asphalts from short-term, high-temperature data as a step toward prediction of pavement aging. Transp. Res. Rec. J. Transp. Res. Board 1535 (1), 91–97. doi:10.1177/0361198196153500112

Isacsson, U., and Lu, X. (1999). Laboratory investigation of polymer modified bitumens. J. Assoc. Asphalt Paving Technol. 68, 35–63.

Jin, X., Han, R., Cui, Y., and Glover, C. J. (2011). Fast-rate-constant-rate oxidation kinetics model for asphalt binders. Industrial Eng. Chem. Res. 50, 13373–13379. doi:10.1021/ie201275q

Kandhal, P. S. (1997). Low-Temperature Ductility in Relation to Pavement Performance. Low temperature properties of bituminous materials and compacted bituminous paving mixtures. Am. Soc. Test. Mater. 18, 95–106. doi:10.1520/STP27096S

Liu, S., Cao, W., Shang, S., Qi, H., and Fang, J. (2010). Analysis and application of relationships between low-temperature rheological performance parameters of asphalt binders. Constr. Build. Mater. 24, 471–478. doi:10.1016/j.conbuildmat.2009.10.015

Nivitha, M. R., Prasad, E., and Krishnan, J. M. (2016). Ageing in modified bitumen using FTIR spectroscopy. Int. J. Pavement Eng. 17 (7), 565–577. doi:10.1080/10298436.2015.1007230

Petersen, J. C. (1998). A dual, sequential mechanism for the oxidation of petroleum asphalts. Petroleum Sci. Technol. 16, 1023–1059. doi:10.1080/10916469808949823

Petersen, J. C., and Glaser, R. (2011). Asphalt oxidation mechanisms and the role of oxidation products on age hardening revisited. Road Mater. Pavement Des. 12 (4), 795–819. doi:10.1080/14680629.2011.9713895

Peterson, J. C. (2009). A review of the fundamentals of asphalt oxidation: chemical, physicochemical, physical property, and durability relationships. Transp. Res. Circular 18. doi:10.17226/23002

Qin, Q., Schabron, J. F., Boysen, R. B., and Farrar, M. J. (2014). Field aging effect on chemistry and rheology of asphalt binders and rheological predictions for field aging. Fuel 121 (2), 86–94. doi:10.1016/j.fuel.2013.12.040

Rahmani, H., Shirmohammadi, H., and Hamedi, G. H. (2018). Effect of asphalt binder aging on thermodynamic parameters and its relationship with moisture sensitivity of asphalt mixes. J. Mater. Civ. Eng. 30 (11), 4018278. doi:10.1061/(ASCE)MT.1943-5533.0002453

Rowe, G. M. (2011). Evaluation of the relationship between asphalt binder properties and non-load related cracking (with discussion). J. Assoc. Asphalt Paving Technol. 80, 649–663.

Shen, K. R., and Wang, H. (2023). Impact of dynamic loading on pavement deflection measurements from traffic speed deflectometer. Measurement 217, 113086. doi:10.1016/j.measurement.2023.113086

Shen, K. R., and Wang, H. (2024). Prediction of critical strains of flexible pavement from traffic speed deflectometer measurements. Constr. Build. Mater. 411, 134770. doi:10.1016/j.conbuildmat.2023.134770

Subhy, A., Pires, G. M., Presti, D. L., and Airey, G. (2018). The effects of laboratory ageing on rheological and fracture characteristics of different rubberised bitumens. Constr. Build. Mater. 180, 188–198. doi:10.1016/j.conbuildmat.2018.05.273

Sun, G., Ma, T., Hu, M., Sun, X., Cao, Z., and Zhao, R. (2024). An evaluation proposal for the fatigue and healing performances of high-viscosity polymer-modified bitumen based on continuous multiple linear amplitude sweep. Constr. Build. Mater. 411, 134632. doi:10.1016/j.conbuildmat.2023.134632

Wang, H., Dang, Z., You, Z., Hao, P., and Huang, X. (2012). Analysis of the low-temperature rheological properties of rubberized warm mix asphalt binders. J. Test. Eval. 40 (7), 0147–1131. doi:10.1520/JTE20120147

Xu, G., Yu, Y. H., Yang, J. Y., Wang, T. L., Kong, P. P., and Chen, X. H. (2021). Rheological and aging properties of composite modified bitumen by styrene-butadiene-styrene and desulfurized crumb rubber. Polymers 13 (18), 3037. doi:10.3390/polym13183037

Yan, C., Huang, W., Xiao, F., Wang, L., and Li, Y. (2018). Proposing a new infrared index quantifying the aging extent of SBS-modified asphalt. Road Mater. Pavement Des. 19 (6), 1406–1421. doi:10.1080/14680629.2017.1318082

Yao, H., Liu, Y. H., Lv, H. T., Ju, H. Y., You, Z. P., and Hou, Y. (2023). Encoder–decoder with pyramid region attention for pixel-level pavement crack recognition. Computer-Aided Civ. Infrastructure Eng. 15. doi:10.1111/mice.13128

Yao, H., Wang, Y. R., Ma, P. R., Li, X., and You, Z. P. (2023). A literature review: asphalt pavement repair technologies and materials. Proc. Institution Civ. Eng. -Engineering Sustain. 0, 1–15. doi:10.1680/jensu.22.10000

Yusoff, N., Shaw, M. T., and Airey, G. D. (2011). Modelling the linear viscoelastic rheological properties of bituminous binders. Constr. Build. Mater. 25 (5), 2171–2189. doi:10.1016/j.conbuildmat.2010.11.086

Zhang, H., Chen, Z., Xu, G., and Shi, C. (2018). Evaluation of aging behaviors of asphalt binders through different rheological indices. Fuel 221, 78–88. doi:10.1016/j.fuel.2018.02.087

Zhang, T. J., Wang, D. L., and Lu, Y. (2023). RheologyNet: a physics-informed neural network solution to evaluate the thixotropic properties of cementitious materials. Cem. Concr. Res. 168, 107157. doi:10.1016/j.cemconres.2023.107157

Zhou, Y. X., Xu, G., Wang, H. Z., Chen, X. H., Fan, Y. L., Yang, J., et al. (2023). “Investigation of the rheological properties of devulcanized rubber-modified asphalt with different rubber devulcanization degrees and rubber contents,” in Road materials and pavement design (Taylor & Francis). London, UK, doi:10.1080/14680629.2023.2287714

Keywords: SBS/rubber composite-modified asphalt binder, long-term oxidative aging, rheological properties, FTIR, G–R parameter

Citation: Chen S, Zhuo S, Xu G, Chen X, Yu L and Xu Q (2024) Rheological and chemical indices to characterize long-term oxidative aging of SBS/rubber composite-modified asphalt binders. Front. Mater. 11:1346754. doi: 10.3389/fmats.2024.1346754

Received: 29 November 2023; Accepted: 30 January 2024;

Published: 13 March 2024.

Edited by:

Linglin Li, Hefei University of Technology, ChinaReviewed by:

Hui Li, Hebei University of Technology, ChinaCopyright © 2024 Chen, Zhuo, Xu, Chen, Yu and Xu. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Gang Xu, MTAxMzAwMzQ5QHNldS5lZHUuY24=; Xianhua Chen, Y2hlbnhoQHNldS5lZHUuY24=

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.