- 1Department of Mechanical Engineering, Saveetha School of Engineering, SIMATS, Chennai, India

- 2Department of Mechanical Engineering, Lendi Institute of Engineering and Technology, Vizianagaram, India

- 3Department of Mechanical Engineering, College of Engineering And Technology, Mattu University, Metu, Ethiopia

- 4Department of Computer Science, UiT The Arctic University of Norway, Tromso, Norway

- 5Department of Mechanical Engineering, Velammal Institute of Technology, Chennai, India

- 6Department of Mechanical Engineering, Graphic Era Deemed to be University, Clement Town, Dehradun, India

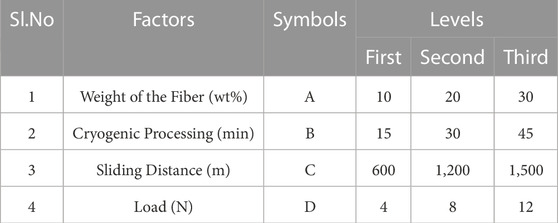

Composite materials are increasingly replacing synthetic fiber combinations in various applications. However, certain extreme environments on Earth and in space require structures to operate under low temperatures, specifically cryogenic conditions, which can significantly affect material reactions. Therefore, the main focus of this study is to develop and evaluate hybridized biocomposites, specifically assessing their tensile, bending, and impact strengths in a controlled liquid nitrogen environment (77 K). Utilizing the Taguchi optimization method, the statistical analysis of wearing characteristics was carried out utilizing cryogenic treatment hours, load, sliding distance, and weight percentage of abaca and sisal fibers. When 20 percent abaca and sisal were mixed, tensile performance increased from 28.96 to 36.58 MPa. Likewise, the same mixture increased bending strength from 59.63 to 75.68 MPa, and impact strength improved from 59.36 to 71.25 J/m. The cryogenic treatment of composite materials for 15–30 min improved the mechanical characteristics of the materials by enhancing the binding between reinforcements and substrate. The Taguchi 27 test outcomes showed a decreased friction coefficient of 7.79 × 105 mm3/Nm in the 10th trial with 30 min of cold working, 10% hybrid fibers, 600 m slide distance, and a 4 N load combination. Frictional coefficient data indicated the lowest rate during the third experiment with 15 min of cryogenic treatment, 10% hybrid fibers, 1,500 m slide length, and a 12 N load combination. The microstructural analysis of the fractured specimen was evaluated by scanning electron microscopy. Finally, such composite materials are employed in liquid propellant tanks, satellites, spaceships, rocket constructions, aeroplane components at cruising altitudes, and other applications.

1 Introduction

In industrial design, selecting suitable materials is crucial to developing and producing a sustainable product. The materials investigate their mechanical and physical qualities to improve the product and increase customer happiness. One of these materials that offers simplicity in processing, increased productivity, and lower costs is polymer composite material. The qualities of the composites, which are custom-made materials with exceptional quality, may be changed by adjusting the reinforcing and matrix phases (Velmurugan et al., 2023a; Velmurugan and Natrayan, 2023). Natural fibers offer multiple benefits over artificial fibers because of their abundance, accessibility, and affordability. Organic fibers are used instead of synthetic fibers to render the materials lighter. Natural fibers have a density between 1.2 and 1.6 g/cm3, which is considerably less than glass fiber’s 2.4 g/cm3 density and allows for the creation of lightweight composites (Al-Oqla et al., 2021). As a result, natural fiber-based composites are increasingly in demand for commercial applications across various industrial industries. Therefore, the creation of lightweight composites makes substantial use of natural fibers such as hemp, jute, sisal, banana, coir, and kenaf. Natural fiber-based composites have been used in furniture, building, packing, shipping pallets, and interior car linings (roof, rear wall, and side panel lining) (Alshammari et al., 2019; Hohe et al., 2021). Natural fibers are derived from various plants and animals, including feathers and hair from chickens. Since the structure of the polymer is hydrophobic, its inclusion of cellulose, a substance that is hydrophilic by nature, alters the chemical bonds among the fibers. One method for enhancing the interactions between natural fibers and the polymeric substrate is the chemical treatment of the fibers. The interfacial contact between the matrix and the fibers is improved because it decreases the OH functional groups on the fiber surface and improves surface roughness. To create environmentally friendly materials, research on natural fibers is necessary (Balakrishnan et al., 2016; Chun and Husseinsyah, 2016; Saba et al., 2016).

Using fiber-reinforced composites as construction components in the freezing range of temperatures is a potential one. In order to use the super conduction impact for a variety of purposes, cold temperatures are necessary. They are also necessary for the effective storage of numerous scientific gases, like liquid hydrogen, to overcome the issue of its low energy density about the amount of room needed at surrounding temperatures and pressures (Velmurugan and Babu, 2020). Fiber-reinforced polymers (FRP) are the apparent material option in the freezing region owing to the intrinsic fragility of the majority of metals at low temperatures, the desire to save as much weight as feasible, and their superior dynamic load-bearing capacity and durability against fatigue (Velmurugan et al., 2023b). Over the last few decades, the growth of freezing uses for fiber-reinforced polymers has been primarily driven by spaceship technology in pressure vessel technology. In order to further advance the creation of sustainable fuel finances, these operations are now supplemented by the requirement for practical storage containers for liquefied or frozen gases such as hydrogen (Ganesan et al., 2021). Safe and dependable fuel tanks are necessary for spaceship systems for future launchers and other uses. The containers must tolerate temperatures as low as 20 K to store oxygen and hydrogen in liquid form. The pertinent loading circumstances include static and cyclic loading, particularly in light of the potential advancement of disposable launching devices (Velmurugan et al., 2022).

Natural fibers are employed in various ways, including short, continuous, and randomly oriented. Due to their exceptional stability and conformability for cutting-edge structural applications, woven fabric mats have recently attracted the most attention and are thought to be the most appealing. Compared to short and randomly oriented reinforcements, several studies have shown that composites with woven fabric reinforcement made of natural fibers have improved functional qualities (Lakshmaiya et al., 2022a). The hybridization of fibers to create hybrid composites is an additional technique for improving performance. In this instance, the qualities of the hybrid composites are primarily influenced by several variables, including the characteristics of the individual fibers utilized, their compatibility with the matrix, and their surface properties. The advantage of hybridization is that it allows one fiber’s strength to balance out another’s weakness, resulting in balanced performance and sustainability of the composite (Sandin and Peters, 2018). Combining two woven textiles with the polymer matrix could be preferable when considering a material’s performance. Researchers have examined the combined effects of using various natural fibers as reinforcement to create composites of hybridized natural fibers. Feng et al. (Feng et al., 2020) investigated how hybridization affected the mechanical characteristics of PALF/Kevlar composites. They claimed that the hybridization of PALF and Kevlar fibers increased the mechanical strength compared to composites made of separate fibers. Similar to this, according to another publication, the mechanical characteristics of the composites were enhanced by the hybridization of Kevlar with pineapple leaf fiber (Jeyaguru et al., 2022). Researchers have looked at how hybridization affects the creep characteristics of composites made of hemp and sisal. According to their findings, sisal inclusion increases the composite’s creep qualities by up to 22%. Sekar et al. (Sanjeevi et al., 2021) investigated the impact of the moisture absorption properties of phenol formaldehyde composites reinforced with Araca fine and Calotropis gigantea. Their research showed that the hybrid composites had the most minor water absorption characteristics.

The current investigation concentrates on the mechanical behavior of hybridized, adaptable natural fabrics such as sisal and abaca. Sisal fiber is a rugged natural fiber produced from the leaves of a shrub called Agave sisalana. It's widespread in India, Brazil, Central Africa, and Southeast Asia. It has excellent toughness and is also one of the most widely farmed tough fabrics, making it widely accessible. According to estimates, sisal fiber is 40%–51% cellulose, 8%–10% lignin, 0.8%–1.2% ash, and 23%–25% hemicellulose (Kim and Netravali, 2010; Dvhg and RPSDUDWLYH, 2014; Veerasimman et al., 2021). Sisal fiber contains a considerable amount of cellulose. The incompatibility between resin and fibers created it. As a result, chemical methods are used to increase the interaction of the fiber with the polymer matrices (Pereira et al., 2020). Abaca fiber has emerged as a competitor in the creation of bio-composites among the natural fabrics that are currently available. The fiber is derived from the abaca tree (Musa textiles), popularly known as Manila hemp, which is native to Asia and belongs to the family Leguminosae. It mimics the banana plant in morphology, with 12–30 stalks from the main base system, giving it a shrubby or small look and a fake trunk. Every stem may develop to be 4–8 m long and is manually peeled, taxied, or coarsely powdered to create abaca fiber. The resulting fiber is typically 1.6–3.4 m long, maybe purple, white, red, or brown. Abaca fibers are among the most rigid natural fabrics on the market (Ramnath et al., 2014; Iucolano et al., 2015). It is now used in newspaper, wood, cordage, rope, fabrics, linen, fiber arts, insulation, furniture, and domestic building goods. Because of its high mechanical toughness, endurance, elasticity, buoyancy, and continuous fiber lengths, it has enormous potential as a sustainable source of fiber for various industry sectors. Peters’ study was the first to recognize the possibilities of employing abaca fibers as reinforcing fillers in polymers. He reinforced thermoplastic polymers with unprocessed, shorter abaca fiber and established the relevance of fiber load and fiber fibers in improving tension and impact strength in such efforts. On the other hand, Shibata and colleagues employed abaca fibers with a thermoset (Ozawa et al., 2002; Liu et al., 2014). They created compostable materials by melting and injecting shorter abaca fibers with poly (3-hydroxybutyrate)-co-3-hydroxyvarelate. That one was discovered to be equivalent to glass fiber-reinforced composites at 20% fiber content. Fiber pre-treatment using propyl hydrazine hydrate and quinoline (benzoylation) enhanced bending strength by enhancing interface adhesion properties with polyamide but did not enhance elastic strength (Abraham et al., 2021).

Depending on that great accessibility and the customized qualities of individual strands, biocomposites were created by mixing such two fibers, and their machining properties have been examined. The results showed that hybrid composites performed better than single-fiber composites. Furthermore, a thorough understanding of their tribological properties is required to use these hybrid composites for precision machining, clutching, bearing fencing, and other applications. Yucheng Liu (Liu et al., 2014) investigated the tribological properties of abaca fiber-integrated epoxy composites by altering factors such as weight, sliding distance, and velocity. The findings demonstrated that adding abaca fiber to epoxy polymers lowered friction and wear. On the other hand, especially in comparison of the engineering properties of sisal and eggshell-based composite material, it was discovered that now the tribological performance of composite materials with 4 wt% sisal fiber was significant compared to composite materials with 4 wt% grapefruit fibers, indicating that sisal fiber is a valuable replacement substance for manufacturing interfacial thermoplastics (Sumesh et al., 2020).

Because fiber-reinforced polymeric materials are the dominant ingredient in many industries, robust characterization and understanding of their performance in environmental settings have occurred. Furthermore, extremes inside and outside the upper orbit necessitate constructions operating at frigid (liquid nitrogen) temperatures, where the molecule’s behavior may change dramatically. Liquid-fueled armored vehicles (typically fiber glass to overcome different compressions), space stations, and space probes, as well as start-up vehicular constructions; ply-height lightweight materials; electromagnetic shielding for liquid nitrogen superconductors and gadgets; and frozen exploratory constructions are examples of implementations (Lakshmaiya et al., 2022a). Fiber-polymer composites showed deformations and destruction when exposed to mechanical loads at extremely low temperatures (i.e., under −150°C). Regardless of this limitation, the area of polymeric materials remained extensive. To a significant extent, the type and shape of the materials’ ingredients determine a composite’s reaction to external mechanical and chemical stresses (Sápi and Butler, 2020). At cold temperatures, these materials may exhibit coagulating fractures and exfoliated patches caused by mismatch stresses at the contact region caused by discrepancies in the thermal expansion coefficients. Furthermore, matrix resins are fragile at low temperatures unless changed by a modifying chemical. Efficiency of fiber at cold temperatures has not been thoroughly studied or well defined. Without a complete and accurate examination and analysis of composites’ components (fiber, matrix resins, and dispersed phase), the actual capacity of such materials for thermal applications might not be realized (Velmurugan et al., 2022).

The literature review found that the wear characteristics of readily accessible abaca and sisal hybrid fiber composites must be investigated further to be suitable for a broad range of engineering materials. As a result, the current investigation will fabricate and test the tribological performance of Abaca/Sisal hybridized frictional materials at low temperatures. Additionally, now a day, most researchers are searching for lightweight materials to replace synthetic materials in low-earth orbit environments like propellant tanks. In order to meet the mentioned requirement and the extent of the author’s knowledge, this is the first investigation to report on the worn surfaces of Abaca/Sisal hybrid composites in a liquid nitrogen atmosphere. In addition, Taguchi’s optimization method was used to construct the tests, and the findings have been analyzed accordingly using ANOVA. Furthermore, SEM and mechanical testing were performed to back up the current research.

2 Materials and methods

2.1 Materials

The abaca (density of 1.5 g/cm3, 200 g per Square Meter [GSM]) and sisal (1.33 g/cm3, 200 g per Square Meter [GSM]) fibers were extracted from natural fiber blowers in Salam, India. Blower machines are used for separating fibers from the plant source. The matrices were made of epoxy resin (LY566) with a viscosity of 1800–12500 MPa, density of 1.13–1.16 g/cm3 and curing agent (HY951) with a viscosity of 600–800 MPa and a density of 0.945 g/cm3 bought through Rithu Chemicals in Bangalore, India. Both fibers were thoroughly cleaned with fresh water and dried in the sun for 48 h.

2.2 Chemical pre-treatment

Natural fiber has a strong hydrophilic group that lowers adherence when using the hydrophobic matrix, but NaOH processing aids in overcoming this disadvantage. All the fibers were washed with distilled water before soaking in NaOH solution for 240 min. Motorized churning was performed every 30 min. The fibers were cleansed again with distilled water to eliminate the surplus detergent. These fibers were then exposed to direct sunlight for 3 days before being cooked in a microwave for 200 min at 70°C to eliminate the water content.

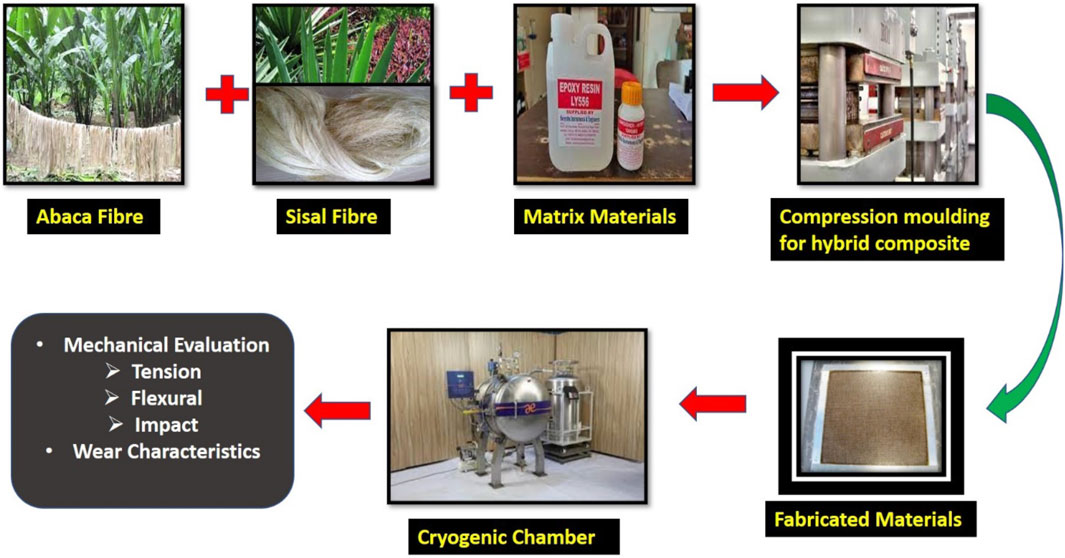

2.3 Composite preparations

In this instance, compression molding was employed to create the composite laminates used in this work. The first step is to separate the sun-exposed sisal and abaca fibers. Different formulations combining abaca, sisal fiber, and epoxy resin were created. The contemporary sculpture used a 300 × 300 × 3 mm mold. Epoxies offer higher corrosion resistance than other polymeric matrices and are more heat- and water-resistant. A polythene layer was put over the bottom jaw to prevent resin deposition throughout the squeezing operation. After the epoxy resin had been placed, natural fiber blended with epoxy resin was added to the mold. The well-mixed mixtures were compacted using a 150-tonne hydraulic compression machine, and then resin was added on top. The pressure was gradually raised to release trapped air to ensure equal resin dispersion throughout the compounds. The laminate needed to be continuously cured under pressure for over 18 h. For other composite laminates, it was the same. The weight percentages of the laminate, sisal fiber, epoxy resin combination, and abaca fiber are displayed in Table 1. After the compressed laminate was retrieved from the compression molding machine, burs were chopped with a saw, and rough edges were cleaned with emery sheets. Compression molding is widely used in most thermoset and thermoplastic polymer composites. It is extensively used in the high-volume manufacture of composite products, including structural and automotive parts. Figure 1 shows the graphical representations of the composite fabrication process.

2.4 Characterization of developed composites

2.4.1 Mechanical testing

The composites’ mechanical characterization was carried out following ASTM standards and guidelines. Utilizing the circular band saw, representative samples from different parts of the manufactured composite laminate were cut. Samples were then prepared following the ASTM D 256, D 790, and D 638 standards for tension, bending, and Charpy impact testing. The Kalpak Computerized Universal Testing Machine, version KIC-2-XXX-C having a maximum load capacity of 30 kN, was used for the tensile and bending tests. The experiments were conducted at an ambient temperature (25°C), 50 percent relative humidity, and a crosshead speed of 1 mm per minute. Three specimens were examined for every sample, and the mean results were given. The Archimedes method was employed to determine the density of the composites (ca) to use for an electronic weight gain during pregnancy of MP-5002 with the ASTM D 792 specification, as well as the theoretical density, which was calculated using the Eq. 1

where ρct denotes the theoretical density of aggregates in g/cm3, Wf and Wm are the weight percentages of fibers and matrix, respectively, and r and m are the densities of fibers and matrix in g/cm3. The proportion of vacancies in the manufactured materials was determined using Eq. 2.

2.4.2 Wear characteristics

Using the standard rotating device model (ASTM G 133-05), the wear behavior of the material was assessed. Additionally, a chrome steel rod with a diameter of 1 cm was employed as a ball sample, demonstrating interest in planar samples with dimensions of 0.4 × 0.3 cm3. The steel rod and composite samples are cleaned with a reasonably fluid lab glass cleaner, alcohol, and formaldehyde before the experiment. After that, cotton buds were used to wash the samples. The experiment employed a 600, 1,200, and 1,500 m slide with a force of 4, 8, and 12 N, reaching 50 mm every cycle.

WL is the weight loss after repeating the experiment in g, which correlates to organic fiber-reinforced densities in g/cm3, L is the active force in N, and SD is the slide length in m.

3 Result and discussion

3.1 Mechanical properties

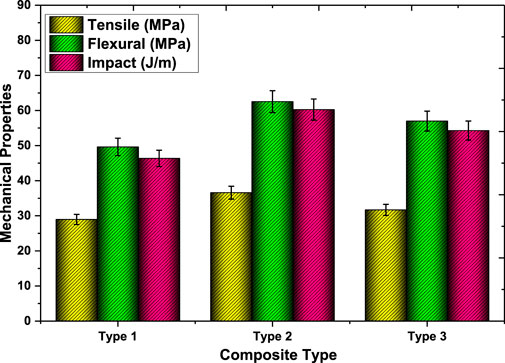

The mechanical test results are shown in Figure 2. Tensile performance improved from 28.96 to 36.58 MPa when 20 wt% abaca and sisal were combined. Likewise, the same mixture increased bending strength from 49.63 to 62.52 MPa, and impact strength improved from 46.36 to 60.25 J/m. Since low-fiber configurations improved mechanical characteristics by minimizing the distance among the interfaces, the hybrid material combinations improved mechanical qualities by up to 20%. On the other hand, increased fiber additions (30 wt%) resulted in unequal fiber dispersion in the polymer composite matrices, lowering the mechanical properties of the composites (Naveen et al., 2019). Similarly, after fiber insertion, aggregate toughness and density improved significantly. Moreover, it was discovered that the predicted and real densities do not correspond because of the presence of holes, and this increased with the rise in fiber loading because of air trapping during the manufacturing process.

Figure 3 depicts how well the density of mixtures steadily rises as the weight fraction of fiber-reinforced material increases. This happens because abaca and sisal fibers have a greater density than matrix material. The densities of the polymer matrices in natural fiber/epoxy blends improved with increasing strength and influence after drying. Its morphology is widely known to have particle characteristics and holes of 10 nm. Increased form force while drying would minimize hole scale and size (Milosevic et al., 2022).

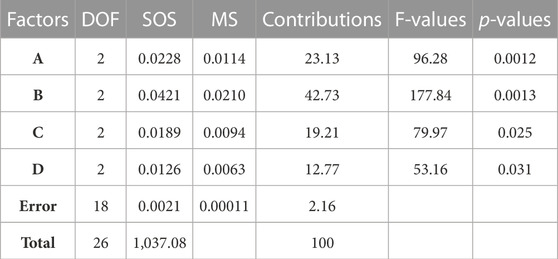

3.2 Effect of cryogenic treatment

Figure 4 shows the mechanical properties of Hybrid Composites under Cryogenic Treatment for 15, 30, and 45 min. During 15–30 min of cryogenic treatment, most combinations are visible, exhibiting their remarkable mechanical performance. The mechanical properties such as tensile increased from 36.58 to 39.1 MPa, bending strength increased from 62.52 to 68.36 MPa, and impact strength increased from 62.52 J/m to 68.69 J/m over the 30 min in liquid nitrogen. It probably concerns the liquid nitrogen strain when lightweight materials come into touch with compression. The shifting matrix and reinforcement contracting produce such latent stresses at relatively low temperatures. Compression and tension strains inside the lattice occur from the fiber’s lower thermal process than the polymer matrix (Sápi and Butler, 2020).

FIGURE 4. Mechanical Properties of Hybrid Composites under Cryogenic Treatment (A) 15 min; (B) 30 min; (C) 45 min.

These compressional interfacial pressures keep the fiber and polymer in interaction and enhance adherence, resulting in better outcomes. The parts become stronger at cold temperatures due to prepared specimens’ freezing and general corrosion. The increase in rigidity leads to a reduction in specimen flexibility, resulting in a lesser displacement. Due to the expanding and shrinking stresses at the border, the delamination resilience of sisal and abaca hybrid composites is enhanced following cryogenic treatments. The material properties of hybrids degrade whenever specimens are treated for longer than 30 min. Because of the increased amount of filament imbalance, extended cryogenic preconditioning times might result in higher thermal stress. Delamination is more detrimental to the sisal and abaca hybrid-polyester frameworks because of the poorer contact. It might be due to its highly significant decrease in drying epoxy resins. Poorly connected materials include significant interface delamination zones that amplify several risk factors that lead to hybrid breakdown (Ong et al., 2018).

3.3 Effect of wear rate through Taguchi optimization

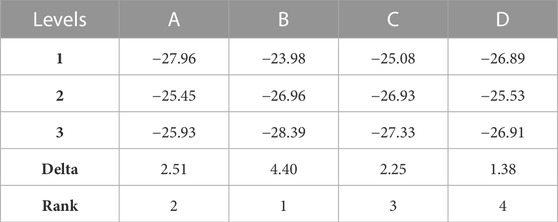

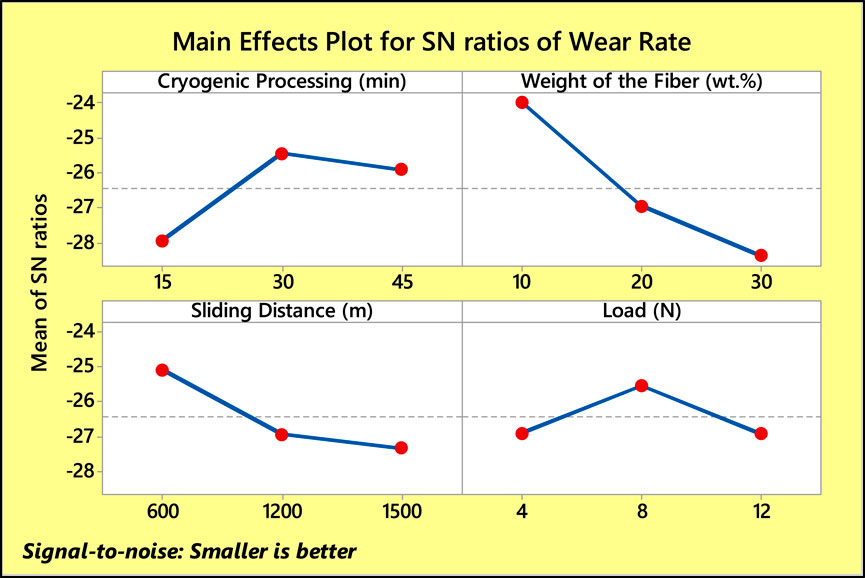

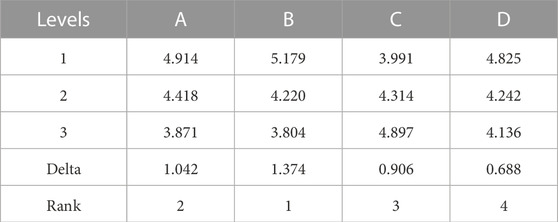

The hybridized organic fiber-based composites are treated with the Taguchi process to minimize wear. The study used the following controlled variables: fiber weight percentage, load exerted, sliding distance, and cryogenic treatment period. Wear and tear are used as measures for measuring performance. Table 2 displays the response tables of signals-to-noise (SN) proportions for both wearing rates and frictional coefficients across 27 trials. Liquid nitrogen processing (SN ratio) of 15, 30, and 45 min enhances the hardness of the materials, lowering the wear rate. However, regardless of cryogenic treatment, increasing the weight percentage of hybrid fibers enhanced the wear rate of blends. This could be related to the low adhesion strength among the hybrid composites and the matrices and interfacial deflections in the polymeric materials (Chandrasekar et al., 2021). Moreover, sliding distances ranging from 400 to 1,500 m significantly influence the polymers’ wear rate. The wearing rate decreased as the load increased from 4 to 8 N, owing to the optimal pressure on samples; however, the wearing rate rose at a 12 N load, perhaps because of the excessive pressure applied just to materials (Ponnusamy et al., 2022). Furthermore, under greater loads, a tight bonding strength arises between the samples and the surface of the shotgun slug; such molecular pressures are significantly stronger than either substance and thus dissolving the connection results in an effective wear rate in the weaker material. In general, wear loss happens owing either to abrasion or adhesive wear; throughout this research, adhesion-abrasive wear was observed among the steel ball and the hybrid sample, resulting in a localized binding involving goods receipt on both surfaces. Figure 5 explains the main effect plot of the wear rate of the hybrid composites (Sinha et al., 2020).

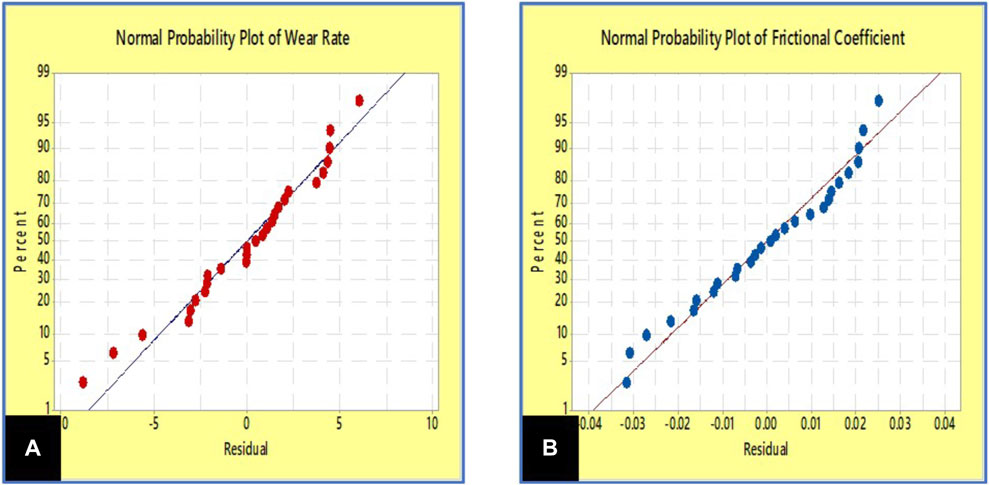

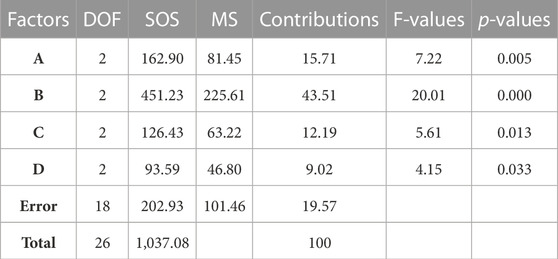

Delta scores have been derived by subtracting the short-range value from the maximum given range and representing the ranking of every component throughout this research. It must have been discovered that hybrid fibers significantly influenced the wear rate of the first compounds. A sizeable number of fiber insertions forms a barrier that safeguards the epoxy surface against degradation (Thiagamani et al., 2019; Senthilkumar et al., 2021). Adding more fibers causes a high wear rate due to fiber pulling out of the resin. The second most important component was cryogenic processing. The low-temperature treatment enhances resistance to abrasion by lowering the porosity of the composite and causing permanent deformation. Sliding distance and pressure are ranked third and fourth, respectively (Lakshmaiya et al., 2022b). The normal probability curve for wearing virtually created a perfect line, indicating that this logistic regression effectively predicted the outcome and was strongly associated with real wearing reactions (Figure 6A). The wearing ANOVA table demonstrated the impact of cryogenic processing and fiber reinforcement on wear properties. All variables demonstrated importance with p values of 0.005 and 0.001, which are lower than 0.05. On the other hand, slide distance and load have little effect on compound wear. It is indicated in Table 3.

3.4 Effect of frictional coefficient through taguchi optimization

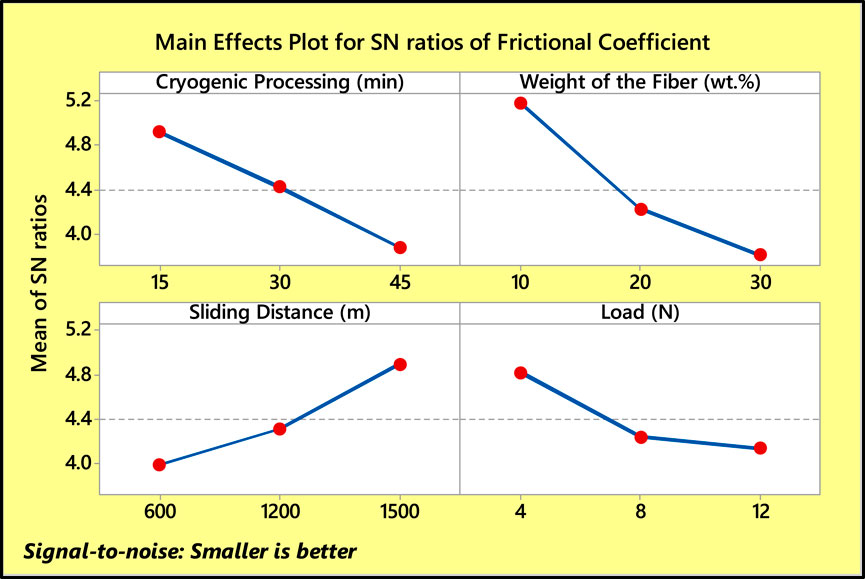

The frictional coefficient dropped as the weight percentage of supplements increased, which might be attributable to the uniform film’s distribution on the counter surface. Moreover, the inclusion of reinforcements increased the toughness of the materials, resulting in a decreased friction factor. The slide length influenced the friction factor values; the friction factor increased as the sliding distance increased. A comparable pattern of outcomes has been reported elsewhere in the literature (Xin et al., 2007). Figure 7 displays the main effect plots of frictional factors of the hybrid composites.

The force applied substantially impacts that material’s friction factor. The friction factor decreased as the load was applied in the current study, which could be attributed to the formation of thermal loading at the surface whenever the test was conducted under dry turning conditions (Senthil Muthu Kumar et al., 2021). Such temperature variations reduce the connection between the supplements and the matrices, resulting in smoother film transmission and a reduced frictional force. On the other hand, the more excellent friction factor at 4 N stress was caused by the interconnecting of abrasive particles, which required additional substance from the hybrids (Natrayan et al., 2022). Tables 4, 5 explain the response and ANOVA values of the frictional coefficient.

Delta data were collated to determine the rankings of each element influencing the frictional force of the mixtures. The concentration of reinforcements significantly impacted the materials’ friction factor, while the load applied, followed by sliding, had the least. The probability plot for the friction factor nearly created a smooth, customarily distributed line (Figure 6B), demonstrating that this linear technique effectively forecasts outcomes and strongly connects with accurate drag force response. The relevance of reinforcing was demonstrated by an ANOVA table of the friction factor with a significance level of less than 0.05. The relevance of the remaining two operational factors, including loading and sliding distance, isn't demonstrated.

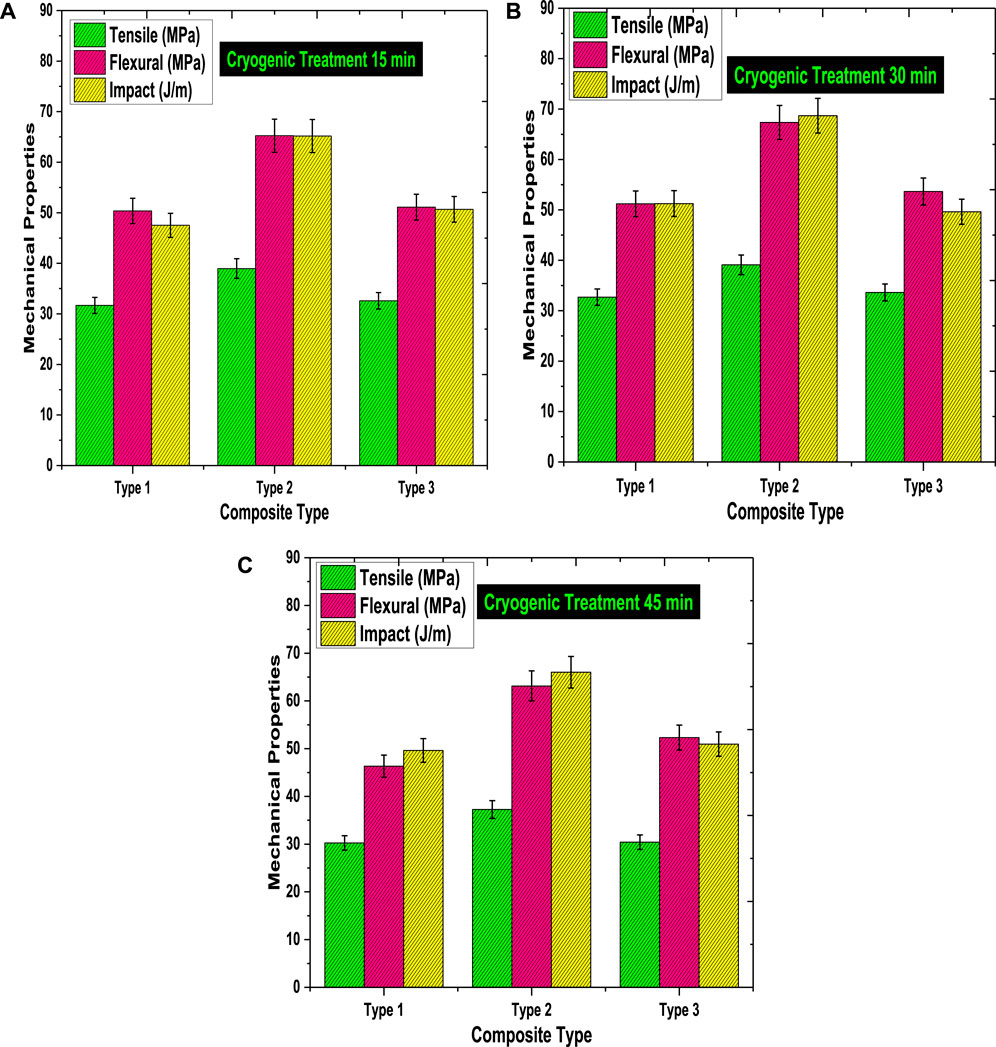

3.5 Microstructural analysis

Figure 8A depicts the microstructure of worn-out polymers treated with a 15-min cryogenic treatment and 10% cellulosic fibers. It was discovered that using fewer hybrid fibers and undergoing cryogenic processing for shorter periods minimized surface delamination in hybrids. The low-temperature treatment generated a strong connection with the matrix, reducing wear during movement. On the other hand, Figure 8B displays exterior deflections like holes and debonding in hybrids after 15 min of cryogenic treatment with 30% cellulosic fibers. The inclusion of extra hybrid fibers might be the cause of such superficial delamination in the combination. The 30 wt% fiber inclusion reduced binding in the composite, leading to a high friction coefficient, as the wear data proved. At a load of 12 N, Figure 8C depicts the abnormalities caused by the evaluated surfaces of a material with a 45-min cold working and 30% natural fibers. Due to the higher temperatures at the contact area resulting from the high load, flaws like matrix cracks, voids, groove development, and surface roughness were identified in the SEM images. The identical specimen, however, showed minute fissures and tribulated sight at 4 N Load. A lower burden and better treatment might cause this behavior. Furthermore, the low load formed a low-pressure region with inert particle surfaces, which minimized wear.

FIGURE 8. Microstructural Images of break out specimen under cryogenic conditions (A) 15 min; (B) 30 min; (C) 45 min.

As illustrated in Figures 8A–C, the primary forms of failure that may be noticed in the worn surfaces following the wear examination are wear grooves, fractures, and matrix cracks. The micro-cutting and micro-plowing activity of the abrasive imperfections of the abrasive material results in wear grooves and cracks on the worn substrates. The figurines have two different sorts of cracks: one in the resin region and the other in the fiber yarn area. This shows that there is poor wetting between the fiber and epoxy resin, which degrades the characteristics of the reinforcement laminate. Comparing hybrid composites with 15 and 30 min of cryogenic treatment, it can be seen that the worn surface of hybrid composites with −196°C cryogenic treatment (Figure 8C) has deeper grooves. Longer cryogenic treatment is thought to have an impact on worn surface fractures. While contrasted with different ailments, the deteriorated surfaces of the blended material after 30 min of cryogenic processing show deeper grooves, suggesting that this thermal treatment temperature may be the best for abaca/sisal fiber-based hybrid material to improve the wear characteristics. Because composite hybrids with 30 min of treatment have shorter grooves than in other circumstances, this suggests that they have more robust surface mechanical properties and are thus more resistant to micro-cutting and micro-plow actions throughout wear processes.

Additionally, the SEM inspection does not significantly harm the worn surfaces. The natural fiber started to deteriorate after 45 min of cryogenic treatment at −196°C, as more extensive and noticeable splits became apparent. This shows that cryogenic processing may improve abaca/sisal fiber-based hybrid composites’ wear characteristics.

4 Conclusion

The primary goal of this study would have been to create hybrid epoxy composites from abaca and sisal fibers and explore the influence of reinforcement on the tribological and mechanical characteristics of biocomposites in cryogenic settings. Three distinct fiber mixes (10, 20, and 30 wt%) were examined for the investigation. The accompanying findings have been drawn based on the findings of the experiments.

• Mechanical testing found that adding 10% abaca and sisal fibers enhanced mechanical properties from 26.19 to 33.48 MPa, bending stiffness from 67.79 to 73.07 MPa, and fracture toughness from 55.31 to 64.88 J/m. The cryogenic treatment of composite materials for 15–30 min improved the mechanical characteristics of the materials by enhancing the binding between reinforcements and substrate.

• The Taguchi 27 test outcomes showed a decreased friction coefficient of 7.79 × 105 mm3/Nm in the 10th trial with 30 min of cold working, 10% hybrid fibers, 600 m slide distance, and a 4 N load combination. Frictional coefficients data indicated the lowest rate during the third experiment with 15 min of cryogenic treatment, 10% hybrid fibers, 1,500 m slide length, and a 12 N load combination.

• The Taguchi optimization demonstrated that materials with a 15-min cryogenic treatment and 10% hybridized fiber content exhibit reduced wear and frictional coefficients. SEM data revealed that cryogenic processing time increased, as did load conditions and reinforcements, resulting in more significant interfacial delamination in materials.

However, extremes inside and above the Earth’s atmosphere call for buildings to function at low temperatures (cryogenic), wherein the material’s reaction might alter substantially. The created composites can endure −196°C for up to 30 min. Consequently, the composite plate is best suited to create liquid propellant tanks.

Data availability statement

The original contributions presented in the study are included in the article/Supplementary material, further inquiries can be directed to the corresponding author.

Author contributions

NL and RS conceived the research idea. PP, SD, and NL provided the materials for the research and prepared the samples. RS carried out further laboratory experiments on the prepared samples to obtain the required data. SK, PPP and SD did the data analyses. NL and PP wrote the first draft of the manuscript. SK and PPP contributed to the scientific discussion of the manuscript.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Abraham, R., Philip, K. D., Chacko, S., and Koshy, P. (2021). Worn surface morphological characterization of NaOH - treated chopped abaca fiber reinforced epoxy composites. J. Bio- Tribo-Corrosion 7, 1–8. doi:10.1007/s40735-020-00467-3

Al-Oqla, F. M., Alaaeddin, M. H., and El-Shekeil, Y. A. (2021). Thermal stability and performance trends of sustainable lignocellulosic olive/low density polyethylene biocomposites for better environmental green materials. Eng. Solid Mech. 9, 439–448. doi:10.5267/J.ESM.2021.5.002

Alshammari, B. A., Alotaibi, M. D., Alothman, O. Y., Sanjay, M. R., Kian, L. K., Almutairi, Z., et al. (2019). A new study on characterization and properties of natural fibers obtained from olive tree (olea europaea L) residues. J. Polym. Environ. 27, 2334–2340. doi:10.1007/s10924-019-01526-8

Balakrishnan, P., John, M. J., Pothen, L., Sreekala, M. S., and Thomas, S. (2016). Natural fibre and polymer matrix composites and their applications in aerospace engineering. Brazil: Elsevier Ltd. doi:10.1016/b978-0-08-100037-3.00012-2

Chandrasekar, M., Senthilkumar, K., Kumar, T. S. M., Siva, I., Venkatanarayanan, P. S., Phuthotham, M., et al. (2021). “Effect of adding sisal fiber on the sliding wear behavior of the coconut sheath fiber-reinforced composite,” in Tribology of polymer composites (China: Elsevier), 115–125.

Chun, K. S., and Husseinsyah, S. (2016). Agrowaste-based composites from cocoa pod husk and polypropylene: Effect of filler content and chemical treatment. J. Thermoplast. Compos. Mater. 29, 1332–1351. doi:10.1177/0892705714563125

Dvhg, P. H. U., and Rpsdudwlyh, Q. (2014). 0HFKDQLFDO 3URSHUWLHV ri %. DQDQD DQG 5, 2263–2272. doi:10.1016/j.mspro.2014.07.444

Feng, N. L., Malingam, S. D., Subramaniam, K., Selamat, M. Z., and Juan, W. X. (2020). The investigation of the tensile and quasi-static indentation properties of pineapple leaf/kevlar fibre reinforced hybrid composites. Def. S T Tech. Bull. 13, 1–13.

Ganesan, V., Shanmugam, V., Kaliyamoorthy, B., Sanjeevi, S., Shanmugam, S. K., Alagumalai, V., et al. (2021). Optimisation of mechanical properties in saw-dust/woven-jute fibre/polyester structural composites under liquid nitrogen environment using response surface methodology. Polymers 13, 2471. doi:10.3390/polym13152471

Hohe, J., Neubrand, A., Fliegener, S., Beckmann, C., Schober, M., Weiss, K. P., et al. (2021). Performance of fiber reinforced materials under cryogenic conditions—a review. Compos. Part A Appl. Sci. Manuf. 141, 106226. doi:10.1016/j.compositesa.2020.106226

Iucolano, F., Caputo, D., Leboffe, F., and Liguori, B. (2015). Mechanical behavior of plaster reinforced with abaca fibers. Constr. Build. Mater. 99, 184–191. doi:10.1016/j.conbuildmat.2015.09.020

Jeyaguru, S., Thiagamani, S. M. K., Pulikkalparambil, H., Siengchin, S., Subramaniam, J., Rangappa, S. M., et al. (2022). Mechanical, acoustic and vibration performance of intra-ply Kevlar/PALF epoxy hybrid composites: Effects of different weaving patterns. Polym. Compos. 43, 3902–3914. doi:10.1002/pc.26665

Kim, J. T., and Netravali, A. N. (2010). Mercerization of sisal fibers: Effect of tension on mechanical properties of sisal fiber and fiber-reinforced composites. Compos. Part A 41, 1245–1252. doi:10.1016/j.compositesa.2010.05.007

Lakshmaiya, N., Ganesan, V., Paramasivam, P., and Dhanasekaran, S. (2022b). Influence of biosynthesized nanoparticles addition and fibre content on the mechanical and moisture absorption behaviour of natural fibre composite. Appl. Sci. Switz. 1, 12. doi:10.3390/app122413030

Lakshmaiya, N., Kaliappan, S., Patil, P. P., Ganesan, V., Dhanraj, J. A., Sirisamphanwong, C., et al. (2022a). Influence of oil palm nano filler on interlaminar shear and dynamic mechanical properties of flax/epoxy-based hybrid nanocomposites under cryogenic condition. Coatings 12, 1675. doi:10.3390/coatings12111675

Liu, K., Yang, Z., and Takagi, H. (2014). Anisotropic thermal conductivity of unidirectional natural abaca fiber composites as a function of lumen and cell wall structure. Compos. Struct. 108, 987–991. doi:10.1016/j.compstruct.2013.10.036

Milosevic, M., Dzunic, D., Valasek, P., Mitrovic, S., and Ruggiero, A. (2022). Effect of fiber orientation on the tribological performance of abaca-reinforced epoxy composite under dry contact conditions. J. Compos. Sci. 6, 204–217. doi:10.3390/jcs6070204

Natrayan, L., Kumar, P. V. A., Baskara Sethupathy, S., Sekar, S., Patil, P. P., Velmurugan, G., et al. (2022). Water retention behaviour and fracture toughness of coir/pineapple leaf fibre with addition of Al2O3Hybrid composites under ambient conditions. Adsorpt. Sci. Technol. 2022, 1–9. doi:10.1155/2022/7209761

Naveen, J., Jawaid, M., Amuthakkannan, P., and Chandrasekar, M. (2019). 21 - mechanical and physical properties of sisal and hybrid sisal fiber-reinforced polymer composites. Brazil: Elsevier Ltd. doi:10.1016/B978-0-08-102292-4.00021-7

Ong, M. I. S., Kim, D., and Kim, H. (2018). Polymer-coated FBG sensor for simultaneous temperature and strain monitoring in composite materials under cryogenic conditions. Appl. Opt. 57, 492–497. doi:10.1364/AO.57.000492

Ozawa, K., Yosomiya, R., and Takeishi, H. Biodegradable polyester composites reinforced with short abaca fiber, (2002) 129–138. doi:10.1002/app.10665

Pereira, A. L., Banea, M. D., Neto, J. S. S., and Cavalcanti, D. K. K. (2020). Mechanical and thermal characterization of natural intralaminar hybrid composites based on sisal. Polymers 12, 866. doi:10.3390/POLYM12040866

Ponnusamy, M., Natrayan, L., Kaliappan, S., Velmurugan, G., and Thanappan, S. (2022). Effectiveness of nanosilica on enhancing the mechanical and microstructure properties of kenaf/carbon fiber-reinforced epoxy-based nanocomposites. Adsorpt. Sci. Technol. 2022, 1–10. doi:10.1155/2022/4268314

Ramnath, B. V., Manickavasagam, V. M., Elanchezhian, C., Krishna, C. V., Karthik, S., and Saravanan, K. (2014). Determination of mechanical properties of intra-layer abaca – jute – glass fiber reinforced composite. J. MATERIALS&DESIGN 60, 643–652. doi:10.1016/j.matdes.2014.03.061

Saba, N., Jawaid, M., Alothman, O. Y., and Paridah, M. T. (2016). A review on dynamic mechanical properties of natural fibre reinforced polymer composites. Constr. Build. Mater. 106, 149–159. doi:10.1016/j.conbuildmat.2015.12.075

Sandin, G., and Peters, G. M. (2018). Environmental impact of textile reuse and recycling–A review. J. Clean. Prod. 184, 353–365. doi:10.1016/j.jclepro.2018.02.266

Sanjeevi, S., Shanmugam, V., Kumar, S., Ganesan, V., Sas, G., Johnson, D. J., et al. (2021). Effects of water absorption on the mechanical properties of hybrid natural fibre/phenol formaldehyde composites. Sci. Rep. 11, 13385. doi:10.1038/s41598-021-92457-9

Sápi, Z., and Butler, R. (2020). Properties of cryogenic and low temperature composite materials – a review. Cryogenics 111, 103190. doi:10.1016/j.cryogenics.2020.103190

Senthil Muthu Kumar, T., Senthilkumar, K., Chandrasekar, M., Karthikeyan, S., Ayrilmis, N., Rajini, N., et al. (2021). Mechanical, thermal, tribological, and dielectric properties of biobased composites. Biobased Compos. Process. Charact. Prop. Appl., 53–73. doi:10.1002/9781119641803.ch5

Senthilkumar, K., Siengchin, S., Kumar, T. S. M., Karthikeyan, S., Chandrasekar, M., Yorseng, K., et al. (2021). “Tribological characterization of cellulose fiber-reinforced polymer composites,” in Tribology of polymer composites (China: Elsevier), 95–113. doi:10.1016/B978-0-12-819767-7.00005-0

Sinha, A. K., Kumar, H., and Somnath, N. (2020). Experimental determination, modelling and prediction of sliding wear of hybrid polymer composites using RSM and fuzzy logic. Arabian J. Sci. Eng. 46, 2071–2082. doi:10.1007/s13369-020-04997-3

Sumesh, K. R., Kavimani, V., Rajeshkumar, G., Ravikumar, P., and Indran, S. (2020). An investigation into the mechanical and wear characteristics of hybrid composites: Influence of different types and content of biodegradable reinforcements. J. Nat. Fibers 00, 2823–2835. doi:10.1080/15440478.2020.1821297

Thiagamani, S. M. K., Krishnasamy, S., Muthukumar, C., Tengsuthiwat, J., Nagarajan, R., Siengchin, S., et al. (2019). Investigation into mechanical, absorption and swelling behaviour of hemp/sisal fibre reinforced bioepoxy hybrid composites: Effects of stacking sequences. Int. J. Biol. Macromol. 140, 637–646. doi:10.1016/j.ijbiomac.2019.08.166

Veerasimman, A., Shanmugam, V., Johnson, D. J., Subbiah, A., and Koilpichai, J. (2021). Thermal properties of natural fiber sisal based hybrid composites – a brief review thermal properties of natural fiber sisal based hybrid composites – a brief review. J. Nat. Fibers 00, 1–11. doi:10.1080/15440478.2020.1870619

Velmurugan, G., Babu, K., Nagaraj, M., and Kumar, A. J. P. (2023a). Investigations of flame retardancy, mechanical and thermal properties of woven hemp/PP hybrid composite for insulating material reinforced with synthetic silicon and zinc oxides. Silicon. doi:10.1007/s12633-023-02408-4

Velmurugan, G., and Babu, K. (2020). Statistical analysis of mechanical properties of wood dust filled Jute fiber based hybrid composites under cryogenic atmosphere using Grey-Taguchi method. Mater. Res. Express 7, 065310. doi:10.1088/2053-1591/ab9ce9

Velmurugan, G., Natrayan, L., Rao, Y. S., Gaur, P., Sekar, S., Chebolu, R., et al. Influence of epoxy/nanosilica on mechanical performance of hemp/kevlar fiber reinforced hybrid composite with an ultrasonic frequency, Adsorpt. Sci. Technol. 2022, 1–11. doi:10.1155/2022/7233255

Velmurugan, G., and Natrayan, L. (2023). Experimental investigations of moisture diffusion and mechanical properties of interply rearrangement of glass/Kevlar-based hybrid composites under cryogenic environment. J. Mater. Res. Technol. 23, 4513–4526. doi:10.1016/j.jmrt.2023.02.089

Velmurugan, G., Siva Shankar, V., Kaliappan, S., Socrates, S., Sekar, S., Patil, P. P., et al. (2022). Effect of aluminium tetrahydrate nanofiller addition on the mechanical and thermal behaviour of Luffa fibre-based polyester composites under cryogenic environment, J. Nanomater. 2022, 1–10. doi:10.1155/2022/5970534

Velmurugan, G., Siva Shankar, V., Kalil Rahiman, M., Elil Raja, D, Nagaraj, M., and Nagalakshmi, T.J. (2023b). Experimental investigation of high filler loading of SiO2 on the mechanical and dynamic mechanical analysis of natural PALF fibre-based hybrid composite. Silicon. doi:10.1007/s12633-023-02464-w

Keywords: statistical analysis, abaca, sisal, mechanical properties, wear, cryogenic treatment

Citation: L N, Surakasi R, Paramasivam P, Dhanasekaran S, S. K and Patil PP (2023) Statistical experiment analysis of wear and mechanical behaviour of abaca/sisal fiber-based hybrid composites under liquid nitrogen environment. Front. Mater. 10:1218047. doi: 10.3389/fmats.2023.1218047

Received: 06 May 2023; Accepted: 12 July 2023;

Published: 04 August 2023.

Edited by:

Sanjay M. R., King Mongkut’s University of Technology North Bangkok, ThailandReviewed by:

Inderdeep Singh, Indian Institute of Technology Roorkee, IndiaMadhu Puttegowda, Malnad College of Engineering, India

Senthil Muthu Kumar Thiagamani, Kalasalingam University, India

Copyright © 2023 L, Surakasi, Paramasivam, Dhanasekaran, Kaliappan and Patil. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Seshathiri Dhanasekaran, U2VzaGF0aGlyaS5kaGFuYXNla2FyYW5AdWl0Lm5v

Natrayan L

Natrayan L Raviteja Surakasi2

Raviteja Surakasi2 Seshathiri Dhanasekaran

Seshathiri Dhanasekaran Kaliappan S.

Kaliappan S.